Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Mixing Ratios

2.2. Test Specimens

2.3. Test Method

2.3.1. Axial Tensile Test

2.3.2. Axial Compression Test

2.3.3. Drop-Weight Impact Test

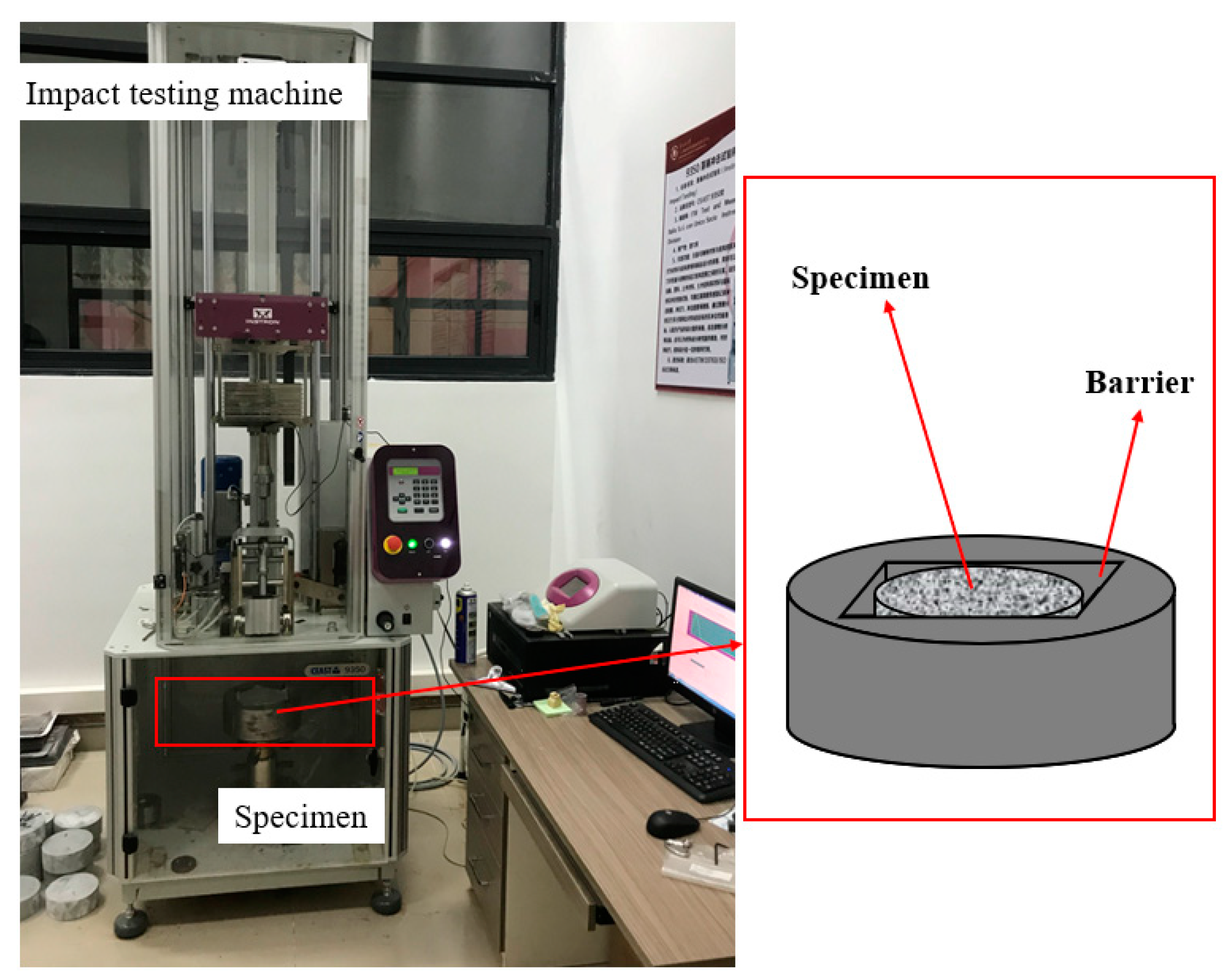

3. Experimental Results and Discussion

3.1. Failure Mode

3.1.1. Tensile Test

3.1.2. Compression Test

3.1.3. Drop-Weight Impact Test

3.2. Effect of Hybrid Fibers on Tensile Behavior

3.2.1. Axial Tensile Stress–Strain Curve

3.2.2. Effect of Hybrid Fibers on Tensile Properties

3.3. Effect of Hybrid Fibers on Compression Behavior

3.3.1. Axial Compression Stress–Strain Curve

3.3.2. Influence of Hybrid Fiber on Compression Strength and Elastic Modulus

3.3.3. Poisson’s Ratio

3.4. Effect of Hybrid Fibers on Impact Behavior

3.4.1. Effect of Hybrid Fiber Content on Impact Strength

| Groups | First Crack Blows, N1 | Failure Blows, N2 | First-Crack Impact Energy, E1/J | Failure Impact Energy, E2/J | Ductility Factor, β |

|---|---|---|---|---|---|

| PCC | 1 | 1 | 35.12 | 35.12 | 0 |

| 1.0%PVA | 5 | 12 | 175.6 | 421.44 | 1.4 |

| 1.5%PVA | 26 | 61 | 913.12 | 2142.32 | 1.35 |

| 2.0%PVA | 141 | 314 | 4951.92 | 11,027.68 | 1.23 |

| 2.5%PVA | 234 | 477 | 8218.08 | 16,752.24 | 1.04 |

| 1.0%PVA + 0.5%BF | 13 | 30 | 456.56 | 1053.6 | 1.31 |

| 1.0%PVA + 1.0%BF | 27 | 38 | 948.24 | 1334.56 | 0.41 |

| 1.0%PVA + 1.5%BF | 32 | 46 | 1123.84 | 1615.52 | 0.44 |

| 1.0%PVA + 0.5%PP | 9 | 24 | 316.08 | 842.88 | 1.67 |

| 1.0%PVA + 1.0%PP | 14 | 28 | 491.68 | 983.36 | 1.41 |

| 1.0%PVA + 1.5%PP | 17 | 35 | 597.04 | 1229.2 | 1.23 |

3.4.2. Effect of Fiber Type on Impact Strength and Ductility of Specimens

4. Conclusions

- (1)

- In the axial tensile test, all specimens generally exhibited strain hardening. During the crack expansion of the specimens, the PVA and BF exhibited a similar failure mode, known as pull-out failure. In contrast, PP demonstrated a fracture failure mode. In the axial compression test, the addition of fibers resulted in a ductile failure mode, which ensured the integrity of the specimens after the damage, and the PVA/PP-ECC specimens showed the most significant inhibition of crack width at the same fiber volume ratio. In the drop-weight impact test, the non-fiber-reinforced specimens showed bursting damage after damage, and the specimens were broken into many pieces, showing obvious brittle damage, while the hybrid-fiber specimens could still maintain good integrity after damage, and the cracks were radiated outward from the central impact point, and a large number of fibers could be observed in the cracks, and the specimens showed the failure mode of cracking but not scattering and breaking.

- (2)

- The tensile strength and ultimate tensile strain of PVA/BF-ECC and PVA/PP-ECC increased with the increase in fiber incorporation. The ultimate tensile strain of PCC is very low, only 0.17%. However, the specimens incorporating fibers exhibit much higher ultimate tensile strains compared to PCC, indicating that the addition of fibers can significantly enhance the material’s ultimate strain. For a given fiber combination, the ultimate tensile strain increases with the fiber content, indicating that increasing the fiber content improves the material’s ultimate tensile strain, with PVA fibers showing the most significant enhancement in the material’s ultimate tensile strain. It is worth noting that the tensile strength of PVA/BF-ECC and PVA/PP-ECC is slightly lower than that of PVA-ECC, which is due to the different mechanisms of action of different fiber materials on concrete.

- (3)

- The effect of fiber content was more obvious than that of fiber type on the compression stress–strain curves of the specimens; with the increase in fiber content, the compression strength of the specimens decreased, but the descending section of the curve was flatter, the deformation of the specimens was larger, the residual strain was relatively larger, and the energy absorption effect and damage resistance of the specimens were better. With an increase in the volume of BF fibers and PP fibers, compared to PVA-ECC with a volume fraction of 1.0%, at high fiber content, both PVA-ECC and PVA/PP-ECC specimens show a significant decrease in strength. However, PVA/BF-ECC specimens demonstrate better stability at high fiber content without a sudden drop in compressive strength. The fiber incorporation can significantly reduce the modulus of elasticity of the specimens, where the effect of fiber incorporation is greater than the effect of fiber type.

- (4)

- With the incorporation of fibers, the damage characteristics of the matrix in the drop-weight impact test were changed, and the value of the specimen load capacity was significantly increased. In terms of fiber type, PVA has the most significant effect on the peak load capacity of the specimen, while BF fiber and PP fiber have similar effects. As the volume of BF and PP fibers increases (with the original PVA volume fraction at 1.0%), the impact strength of PVA/BF-ECC is significantly higher than that of PVA/PP-ECC. However, for a given total fiber volume ratio, the impact strength of PVA-ECC was higher than the other two.

Author Contributions

Funding

Conflicts of Interest

References

- Uratani, J.; Griffiths, S. A forward looking perspective on the cement and concrete industry: Implications of growth and development in the Global South. Energy Res. Soc. Sci. 2023, 97, 102972. [Google Scholar] [CrossRef]

- Meyer, D.M.; Combrinck, R. Utilising microCT scanning technology as a method for testing and analysing plastic shrinkage cracks in concrete. Constr. Build. Mater. 2022, 317, 125895. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. A feasibility study of strain hardening fiber reinforced fly ash-based geopolymer composites. Constr. Build. Mater. 2014, 57, 163–168. [Google Scholar] [CrossRef]

- Ohno, M.; Li, V.C. An integrated design method of Engineered Geopolymer Composite. Cem. Concr. Compos. 2018, 88, 73–85. [Google Scholar] [CrossRef]

- He, F.; Biolzi, L.; Carvelli, V. Effect of fiber hybridization on mechanical properties of concrete. Mater. Struct. 2022, 55, 73–85. [Google Scholar] [CrossRef]

- Scorza, D.; Ronchei, C.; Vantadori, S.; Zanichelli, A. Size-Effect Independence of Hybrid Fibre-Reinforced Roller-Compacted Concrete Fracture Toughness. Compos. Part C Open Access 2022, 9, 100306. [Google Scholar] [CrossRef]

- Zhuang, J.; Shen, S.; Yang, Y.; Xu, K.; Ni, P. Mechanical performance of basalt and PVA fiber reinforced hybrid-fiber engineered cementitious composite with superimposed basalt fiber content. Constr. Build. Mater. 2022, 353, 129183. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Experimental Investigation of Basalt Textile Reinforced Engineered Cementitious Composite under Apparent Hoop Tensile Loading. J. Build. Eng. 2019, 23, 270–279. [Google Scholar] [CrossRef]

- Yu, K.; Wang, Y.; Jiangtao, Y.; Xu, S. A strain-hardening cementitious composites with the tensile capacity up to 8%. Constr. Build. Mater. 2017, 137, 410–419. [Google Scholar] [CrossRef]

- Chen, G.; Zheng, D.-P.; Chen, Y.-W.; Lin, J.-X.; Lao, W.-J.; Guo, Y.-C.; Chen, Z.-B.; Lan, X.-W. Development of high performance geopolymer concrete with waste rubber and recycle steel fiber: A study on compressive behavior, carbon emissions and economical performance. Constr. Build. Mater. 2023, 393, 131988. [Google Scholar] [CrossRef]

- Peng, Y.-Q.; Zheng, D.-P.; Pan, H.-S.; Yang, J.-L.; Lin, J.-X.; Lai, H.-M.; Wu, P.-Z.; Zhu, H.-Y. Strain hardening geopolymer composites with hybrid POM and UHMWPE fibers: Analysis of static mechanical properties, economic benefits, and environmental impact. J. Build. Eng. 2023, 76, 107315. [Google Scholar] [CrossRef]

- Huang, B.-T.; Zhu, J.-X.; Weng, K.-F.; Li, V.C.; Dai, J.-G. Ultra-high-strength engineered/strain-hardening cementitious composites (ECC/SHCC): Material design and effect of fiber hybridization. Cem. Concr. Compos. 2022, 129, 104464. [Google Scholar] [CrossRef]

- Yu, K.-Q.; Zhu, W.-J.; Ding, Y.; Lu, Z.-D.; Yu, J.-T.; Xiao, J.-Z. Micro-structural and mechanical properties of ultra-high performance engineered cementitious composites (UHP-ECC) incorporation of recycled fine powder (RFP). Cem. Concr. Res. 2019, 124, 105813. [Google Scholar] [CrossRef]

- Zhou, J. Development of engineered cementitious composites with limestone powder and blast furnace slag. Mater. Struct. 2010, 43, 803–814. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Wang, Y.C.; Xu, D.L.; Li, S. Mechanical performance and hydration mechanism of geopolymer composite reinforced by resin. Mater. Sci. Eng. A 2010, 527, 6574–6580. [Google Scholar] [CrossRef]

- Akcay, B. Experimental investigation on uniaxial tensile strength of hybrid fibre concrete. Compos. Part B-Eng. 2012, 43, 766–778. [Google Scholar] [CrossRef]

- Li, V.C. Tailoring ECC for Special Attributes:A Review. Int. J. Concr. Struct. Mater. 2012, 6, 135–144. [Google Scholar] [CrossRef]

- Singh, M.; Saini, B.; Chalak, H.D. Performance and composition analysis of engineered cementitious composite (ECC)—A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar] [CrossRef]

- Liao, Q.; Su, Y.-R.; Yu, J.-T.; Yao, Q.-y.; Meng, D.; Yu, K.-Q. Experimental and theoretical investigation on compression-shear properties of high-strength engineered cementitious composites (HS-ECC). J. Build. Eng. 2023, 67, 106015. [Google Scholar] [CrossRef]

- Xu, S.-L.; Cai, X.-R. Experimental Study and Theoretical Models on Compressive Properties of Ultrahigh Toughness Cementitious Composites. J. Mater. Civ. Eng. 2010, 22, 1067–1077. [Google Scholar] [CrossRef]

- Ding, Z.; Wen, J.; Li, X.; Fu, J.; Ji, X. Mechanical behaviour of polyvinyl alcohol-engineered cementitious composites (PVA-ECC) tunnel linings subjected to vertical load. Tunn. Undergr. Space Technol. 2020, 95, 103151. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Q. Matrix Tailoring of Engineered Cementitious Composites (ECC) with non-oil-coated, low tensile strength PVA fiber. Constr. Build. Mater. 2018, 161, 420–431. [Google Scholar] [CrossRef]

- Redon, C.; Li, V.C.; Wu, C.; Hoshiro, H.; Saito, T.; Ogawa, A. Measuring and Modifying Interface Properties of PVA Fibers in ECC Matrix. J. Mater. Civ. Eng. 2001, 13, 399–406. [Google Scholar] [CrossRef]

- Lin, J.-X.; Song, Y.; Xie, Z.-H.; Guo, Y.-C.; Yuan, B.; Zeng, J.-J.; Wei, X. Static and dynamic mechanical behavior of engineered cementitious composites with PP and PVA fibers. J. Build. Eng. 2020, 29, 101097. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.K.; Leung, C.K.Y.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Jamshidi, M.; Latifi, M. Study on fiber hybridization effect of engineered cementitious composites with low- and high-modulus polymeric fibers. Constr. Build. Mater. 2016, 112, 739–746. [Google Scholar] [CrossRef]

- Pakravan, H.R.; Latifi, M.; Jamshidi, M. Ductility improvement of cementitious composites reinforced with polyvinyl alcohol-polypropylene hybrid fibers. J. Ind. Text. 2016, 45, 637–651. [Google Scholar] [CrossRef]

- Liu, J.-C.; Tan, K.H. Fire resistance of strain hardening cementitious composite with hybrid PVA and steel fibers. Constr. Build. Mater. 2017, 135, 600–611. [Google Scholar] [CrossRef]

- Soe, K.T.; Zhang, Y.X.; Zhang, L.C. Impact resistance of hybrid-fiber engineered cementitious composite panels. Compos. Struct. 2013, 104, 320–330. [Google Scholar] [CrossRef]

- Guo, L.; Guo, R.; Yan, Y.; Zhang, Y.; Wang, Z.; Mu, Y. Dynamic Compression Mechanical Properties of POM Fiber-Reinforced Concrete. Materials 2022, 15, 7784. [Google Scholar] [CrossRef]

- Ahmed, H.; Faraj, R.; Hilal, N.; Mohammed, A.; Sherwani, A. Use of recycled fibers in concrete composites: A systematic comprehensive review. Compos. Part B Eng. 2021, 215, 108769. [Google Scholar] [CrossRef]

- Wang, Y.; Chan, C.L.; Leong, S.H.; Zhang, M. Engineering properties of strain hardening geopolymer composites with hybrid polyvinyl alcohol and recycled steel fibres. Constr. Build. Mater. 2020, 261, 120585. [Google Scholar] [CrossRef]

- Maalej, M.; Quek, S.T.; Zhang, J. Behavior of Hybrid-Fiber Engineered Cementitious Composites Subjected to Dynamic Tensile Loading and Projectile Impact. J. Mater. Civ. Eng. 2005, 17, 143–152. [Google Scholar] [CrossRef]

- Li, V. From Micromechanics to Structural Engineering—The Design of Cementitious Composites for Civil Engineering Applications. Doboku Gakkai Ronbunshu 1992, 10, 1–12. [Google Scholar]

- Kanakubo, T. Tensile Characteristics Evaluation Method for Ductile Fiber-Reinforced Cementitious Composites. J. Adv. Concr. Technol. Copyr. 2006, 4, 3–17. [Google Scholar] [CrossRef]

- Behbahani, H.; Nematollahi, B. Steel Fiber Reinforced Concrete: A Review; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar]

- James, I.D.; Gopalaratnam, V.; Galinat, M.A. State-of-the-art report on fiber reinforced concrete. Man. Concr Pract. 2002, 21, 2–66. [Google Scholar]

- Fei, W.; Yutong, Y.; Shiping, Y. Thermal and moisture performance parameters of high toughness engineered cementitious Composite(ECC) with PVA fibers. J. Build. Eng. 2021, 43, 102905. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, Y.; Lai, M.; Gu, M.; Ho, J.C.M. Carbon fiber to improve the resistance of high strength PVA-ECC to elevated temperatures. J. Build. Eng. 2023, 71, 106475. [Google Scholar] [CrossRef]

- ASTM C 469-2002; Standard Test Method for Static Elastic Modulus and Poisson’s Ratio of Concrete in Compression. American Society for Testing and Materials: West Conshohocken, PA, USA, 2002.

- Hu, B.; Lv, H.-L.; Kundu, T. Experimental study on seismic behavior of reinforced concrete frame in primary and middle schools with different strengthening methods. Constr. Build. Mater. 2019, 217, 473–486. [Google Scholar] [CrossRef]

| Fibers | Length | Diameter | Density | Elastic Modulus | Fracture Elongation |

|---|---|---|---|---|---|

| (mm) | (μm) | (g/cm3) | (GPa) | (%) | |

| PVA | 12 | 40 | 1.3 | 40 | 6 |

| BF | 15 | 16 | 2.6 | 34 | 3.1 |

| PP | 16 | 20 | 0.91 | 4.3 | 36.4 |

| Groups | Cement | Fly Ash | Water | Silica Sand | Water Reducing Admixture | PVA | BF | PP |

|---|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | vol% | vol% | vol% | |

| PCC | 382 | 890 | 297 | 460 | 18 | 0 | 0 | 0 |

| 1.0%PVA | 382 | 890 | 297 | 460 | 18 | 1 | 0 | 0 |

| 1.5%PVA | 382 | 890 | 297 | 460 | 18 | 1.5 | 0 | 0 |

| 1.0%PVA + 0.5%BF | 382 | 890 | 297 | 460 | 18 | 1 | 0.5 | 0 |

| 1.0%PVA + 0.5%PP | 382 | 890 | 297 | 460 | 18 | 1 | 0 | 0.5 |

| 2.0%PVA | 382 | 890 | 297 | 460 | 18 | 2 | 0 | 0 |

| 1.0%PVA + 1.0%BF | 382 | 890 | 297 | 460 | 18 | 1 | 1 | 0 |

| 1.0%PVA + 1.0%PP | 382 | 890 | 297 | 460 | 18 | 1 | 0 | 1 |

| 2.5%PVA | 382 | 890 | 297 | 460 | 18 | 2.5 | 0 | 0 |

| 1.0%PVA + 1.5%PP | 382 | 890 | 297 | 460 | 18 | 1 | 0 | 1.5 |

| 1.0%PVA + 1.5%BF | 382 | 890 | 297 | 460 | 18 | 1 | 1.5 | 0 |

| Groups | Tensile Strength | Ultimate Tensile Strain | Average Tensile Strength | Average Ultimate Tensile Strain |

|---|---|---|---|---|

| MPa | % | MPa | % | |

| PCC | 4.25 | 0.16 | 4.34 | 0.17 |

| 4.43 | 0.2 | |||

| 4.34 | 0.16 | |||

| 1.0%PVA | 3.53 | 1.2 | 4.44 | 1.13 |

| 4.9 | 1 | |||

| 4.9 | 1.2 | |||

| 1.5%PVA | 6.65 | 1.9 | 7.54 | 1.76 |

| 8.37 | 1.94 | |||

| 7.6 | 1.45 | |||

| 1.0%PVA + 0.5%BF | 7.53 | 1.33 | 7.62 | 1.44 |

| 7.42 | 1.39 | |||

| 7.91 | 1.61 | |||

| 1.0%PVA + 0.5%PP | 3.87 | 1.43 | 4.86 | 1.38 |

| 5.22 | 1.31 | |||

| 5.5 | 1.39 | |||

| 2.0%PVA | 6.9 | 2.63 | 7.60 | 2.29 |

| 7.9 | 2 | |||

| 8.0 | 2.23 | |||

| 1.0%PVA + 1.0%BF | 5.9 | 1.31 | 5.73 | 1.35 |

| 5.5 | 1.33 | |||

| 5.78 | 1.42 | |||

| 1.0%PVA + 1.0%PP | 4.6 | 1.77 | 5.6 | 1.8 |

| 6.1 | 2 | |||

| 6.2 | 1.61 | |||

| 2.5%PVA | 5.91 | 3.4 | 6.27 | 3.33 |

| 6.8 | 2.9 | |||

| 6.09 | 3.7 | |||

| 1.0%PVA + 1.5%BF | 5.51 | 1.52 | 6.86 | 1.5 |

| 7.52 | 1.49 | |||

| 7.56 | 1.48 | |||

| 1.0%PVA + 1.5%PP | 6.5 | 1.87 | 7.0 | 1.91 |

| 6.67 | 1.9 | |||

| 7.71 | 1.93 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, W.; Wu, P.; Huang, J.; Chen, G.; Lin, J.; Guo, Y.; Chen, R. Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance. Materials 2023, 16, 5172. https://doi.org/10.3390/ma16145172

Liao W, Wu P, Huang J, Chen G, Lin J, Guo Y, Chen R. Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance. Materials. 2023; 16(14):5172. https://doi.org/10.3390/ma16145172

Chicago/Turabian StyleLiao, Weibin, Peizong Wu, Jiatao Huang, Gai Chen, Jiaxiang Lin, Yongchang Guo, and Runsheng Chen. 2023. "Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance" Materials 16, no. 14: 5172. https://doi.org/10.3390/ma16145172

APA StyleLiao, W., Wu, P., Huang, J., Chen, G., Lin, J., Guo, Y., & Chen, R. (2023). Cost-Effective Engineered Cementitious Composites with Hybrid PVA and Basalt/PP Fiber: A Study on Compressive, Tensile and Impact Performance. Materials, 16(14), 5172. https://doi.org/10.3390/ma16145172