Porous PZT Films: How Can We Tune Electrical Properties?

Abstract

1. Introduction

2. Materials and Methods

3. Results

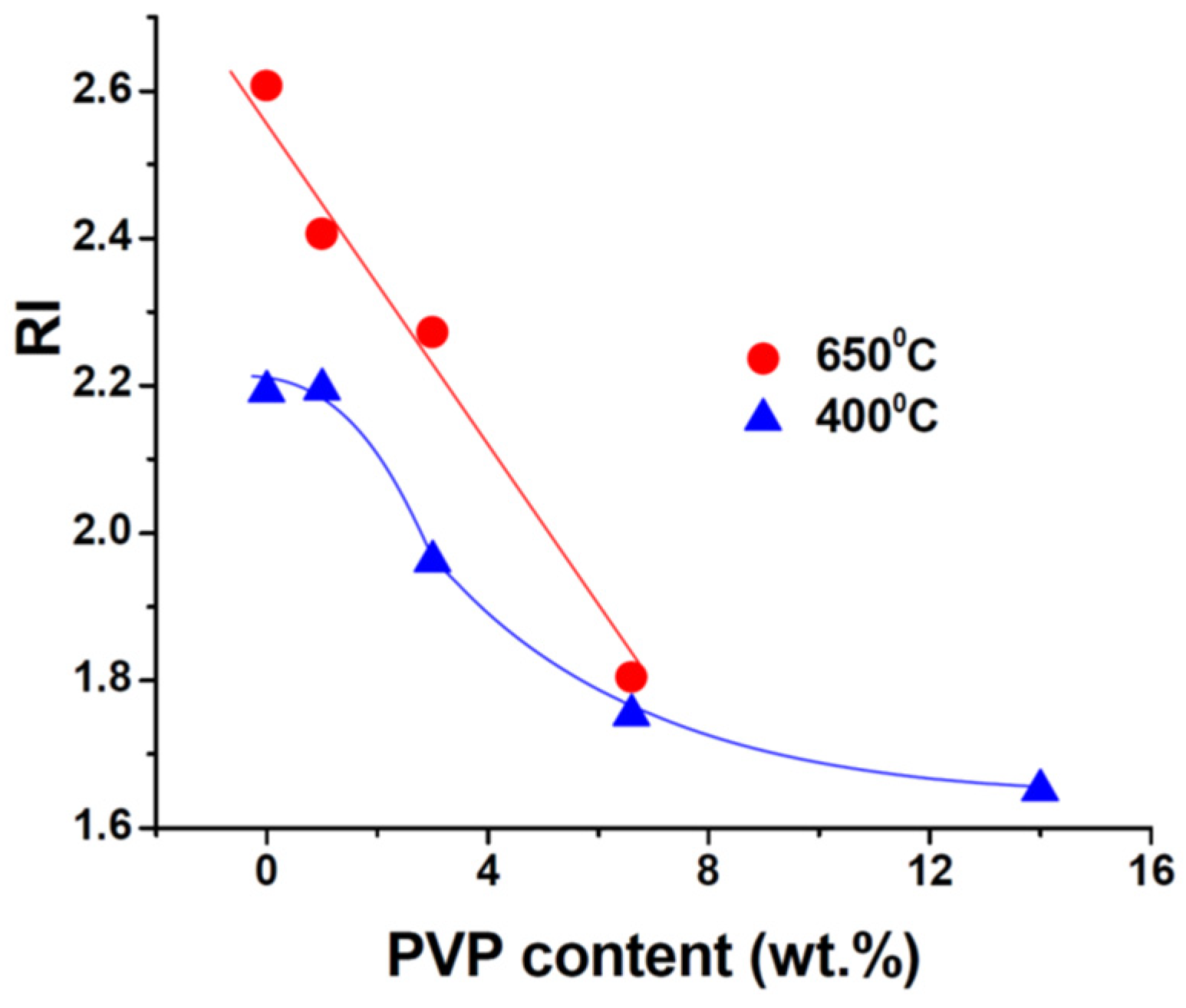

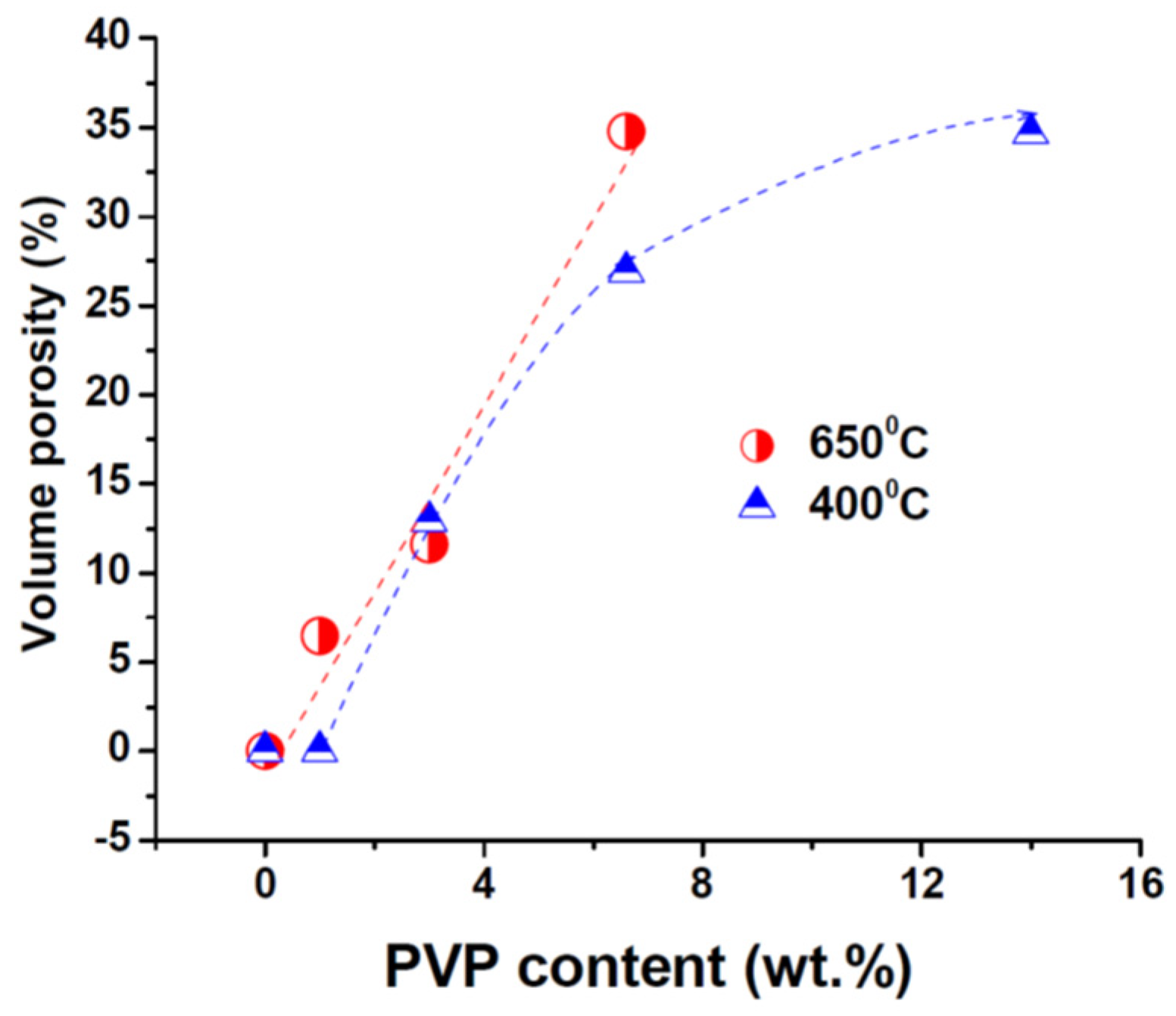

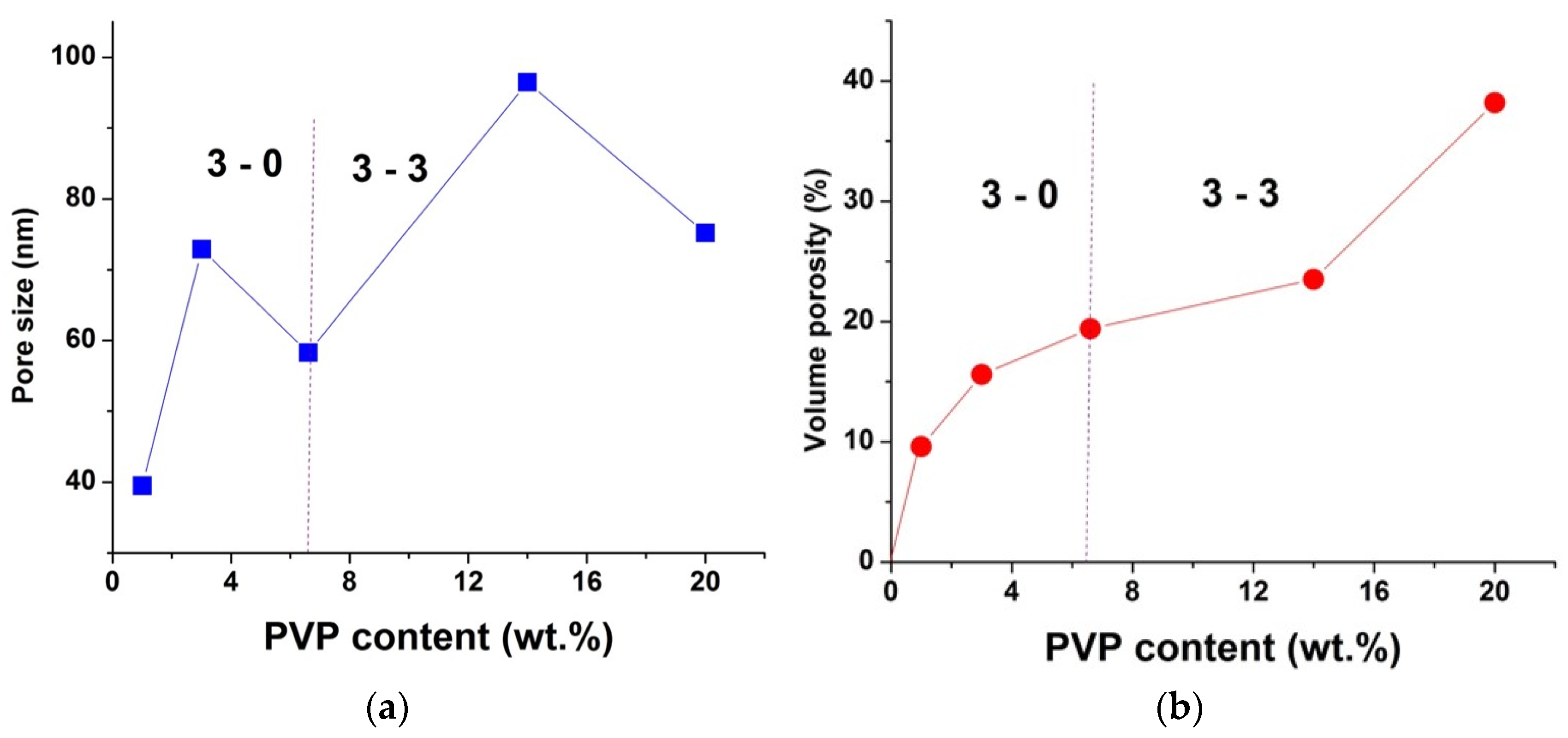

3.1. General Characterization of the Film Thickness and Microstructure

3.2. X-ray Diffraction Study

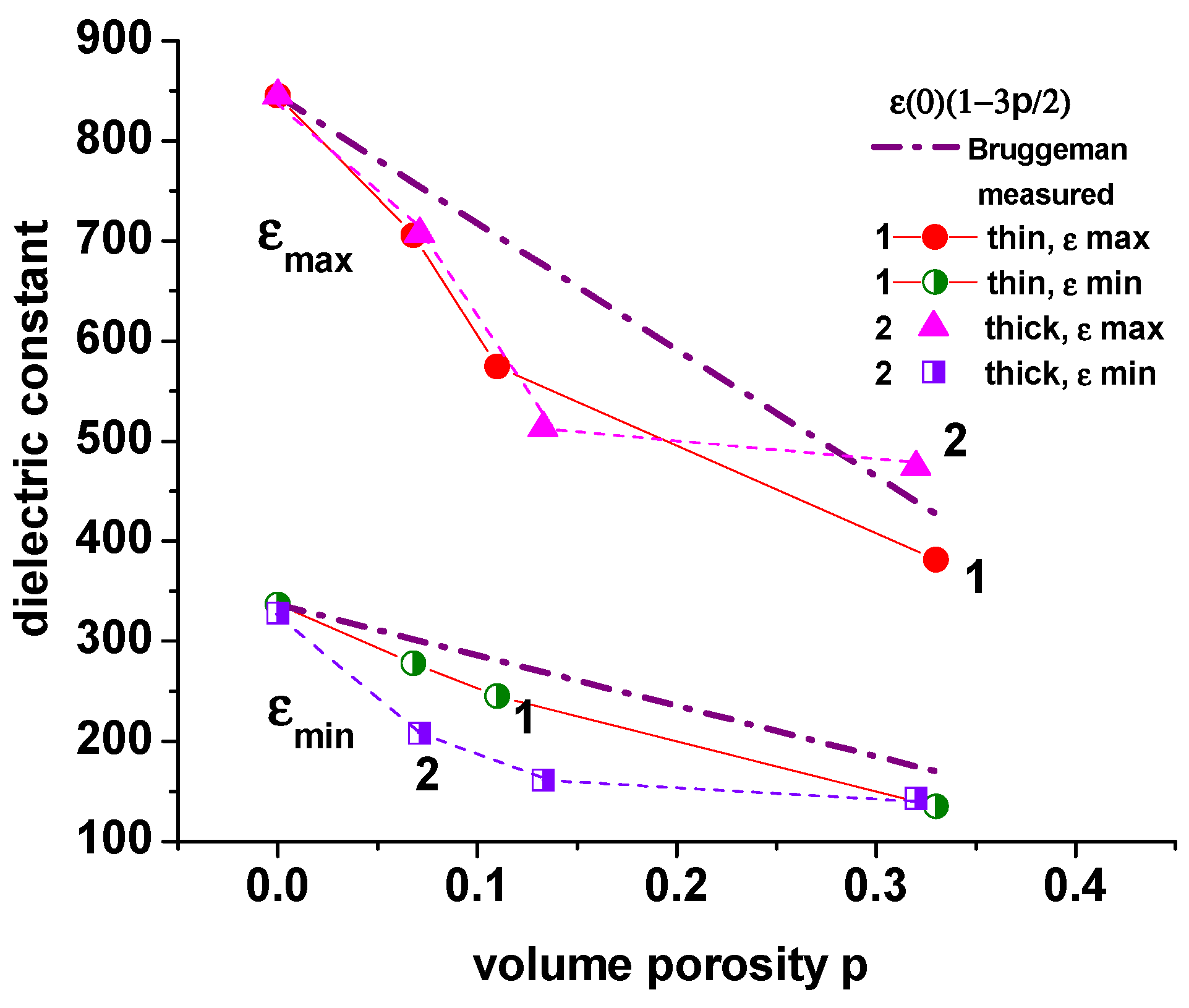

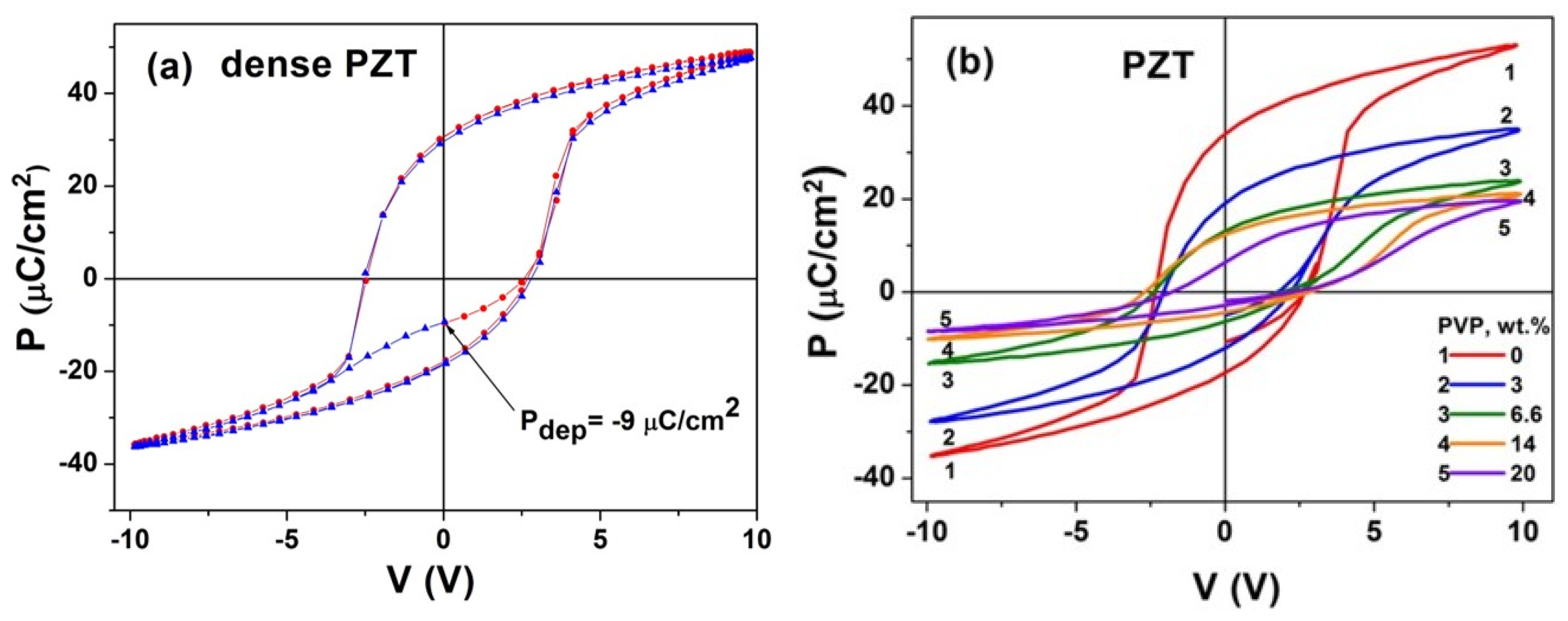

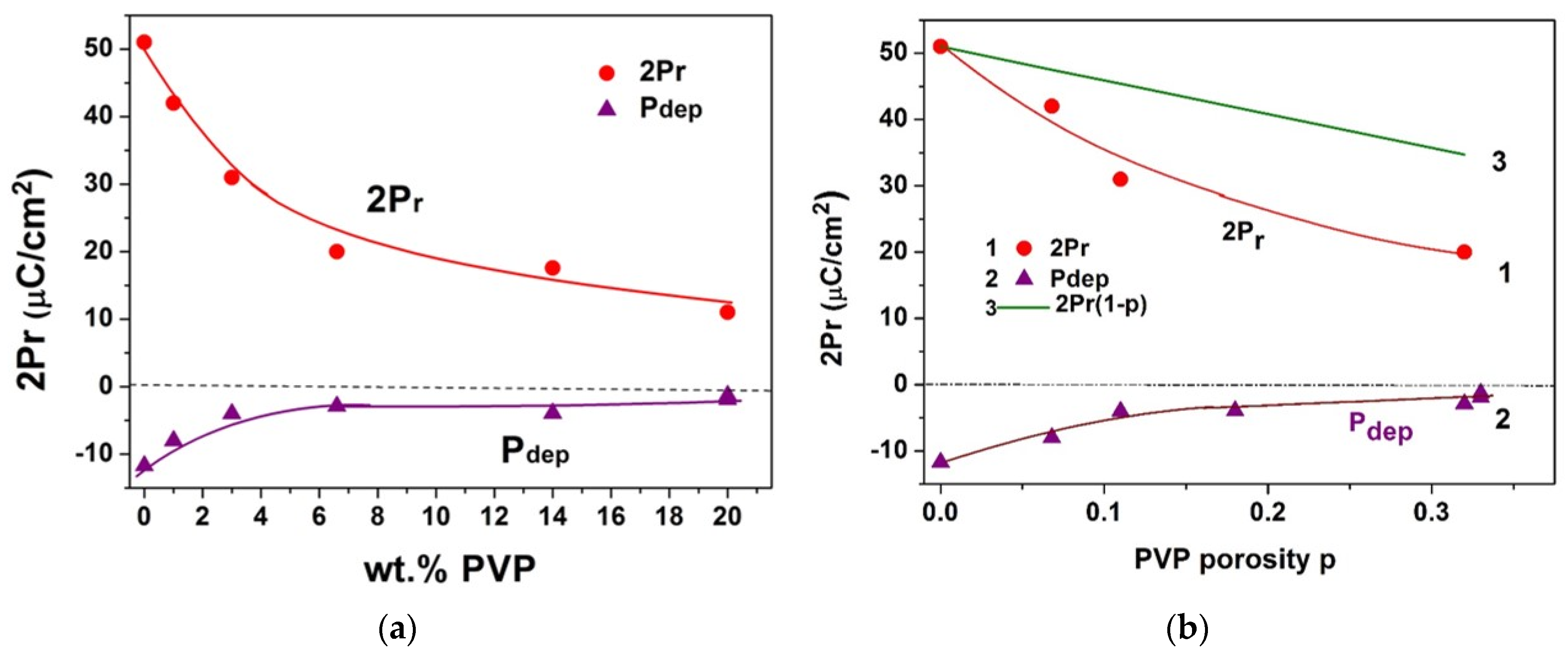

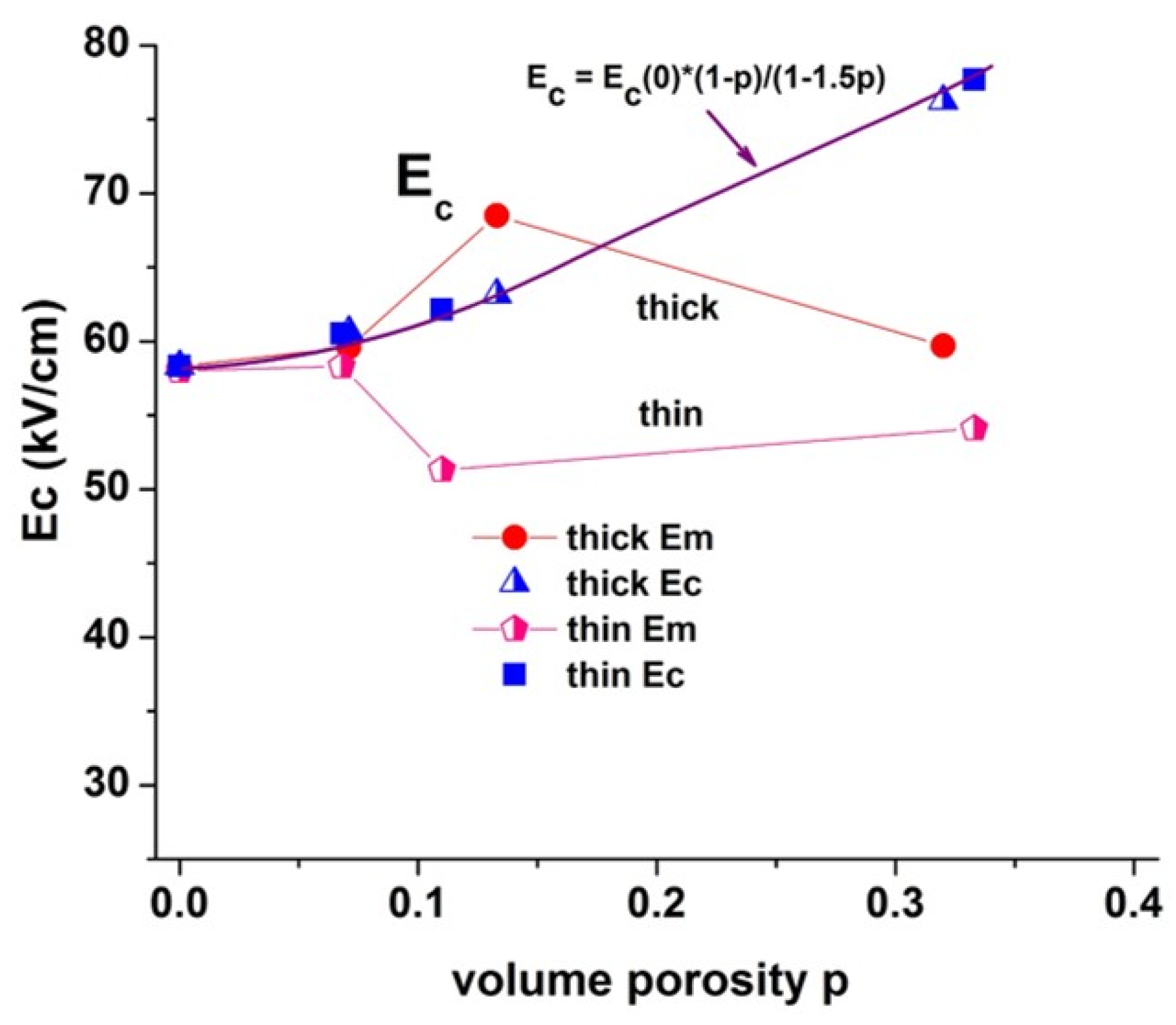

3.3. Dielectric Constant, Polarization, and Coercive Field

3.4. Polarization Dependences of the Transient Current

3.5. Polarization Dependences of the Short-Circuited Photocurrent

3.6. Local Current Study by c-AFM

4. Discussion

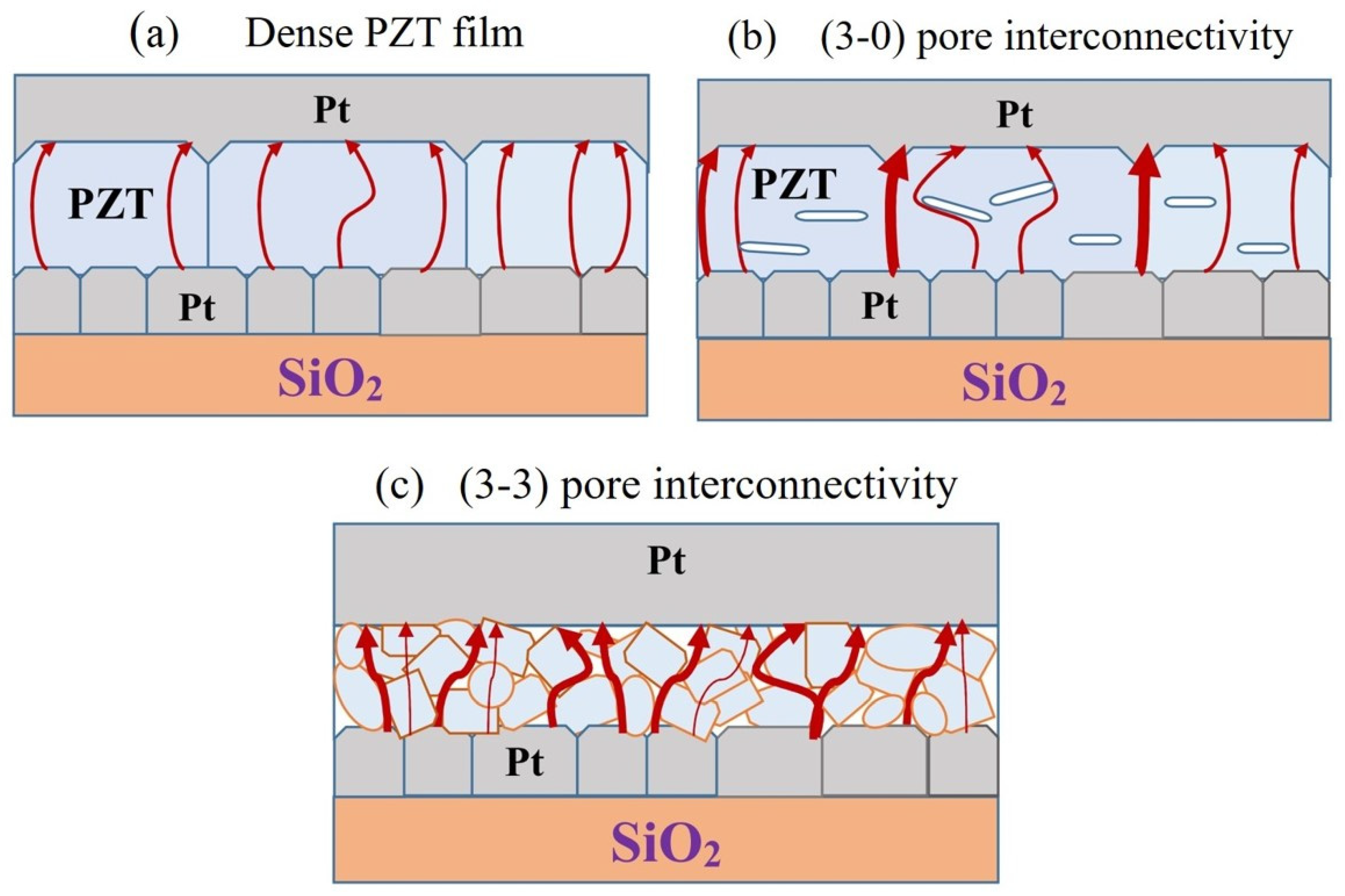

4.1. Structure—Polarization

4.2. Polarization Dependences of the Transient Current

4.3. Polarization Dependencies of Photocurrents

4.4. Local Current Study

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, J.F.; Takagi, K.; Ono, M.; Pan, W.; Watanabe, R.; Almajid, A.; Taya, M. Fabrication and evaluation of porous piezoelectric ceramics and porosity-graded piezoelectric actuators. J. Am. Ceram. Soc. 2003, 86, 1094–1098. [Google Scholar] [CrossRef]

- Shaw, C.P.; Whatmore, R.W.; Alcock, J.R. Porous, functionally gradient pyroelectric materials. J. Am. Ceram. Soc. 2007, 90, 137–142. [Google Scholar] [CrossRef]

- Nie, H.; Yu, Y.; Liu, Y.; He, H.; Wang, G.; Dong, X. Enhanced shock performance by disperse porous structure: A case study in PZT95/5 ferroelectric ceramics. J. Am. Ceram. Soc. 2017, 100, 5693–5699. [Google Scholar] [CrossRef]

- Roscow, J.; Zhang, Y.; Taylor, J.; Bowen, C.R. Porous ferroelectrics for energy harvesting applications. Eur. Phys. J. Spec. Top. 2015, 224, 2949–2966. [Google Scholar] [CrossRef]

- Mercadelli, E.; Galassi, C. How to make porous piezoelectrics? Review on processing strategies. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2020, 68, 217–218. [Google Scholar] [CrossRef] [PubMed]

- Corkovic, S.; Whatmore, R.W.; Zhang, Q. Sol-gel fabrication of PZT thick films for MEMS. Integr. Ferroelectr. 2007, 88, 93–102. [Google Scholar] [CrossRef]

- Zhow, X.; Zhow, K.; Zhang, D.; Bowen, C.; Wang, Q.; Zhong, J.; Zhang, Y. Perspective on porous piezoelectric ceramics to control internal stress. Nanoenergy Adv. 2022, 2, 269–290. [Google Scholar] [CrossRef]

- Matavz, A.; Bradesko, A.; Rojac, T.; Malic, B.; Bobnar, V. Self-assembled porous ferroelectric thin films with a greatly enhanced piezoelectric response. Appl. Mater. Today 2019, 16, 83–89. [Google Scholar] [CrossRef]

- Castro, A.; Martins, M.; Ferreira, L.P.; Godinho, M.; Vilarinho, P.M.; Ferreira, P. Maltifunctional nanopatterned porous bismuth ferrite thin films. J. Mater. Chem. C 2019, 7, 7788–7797. [Google Scholar] [CrossRef]

- Suzuki, N.; Osada, M.; Billah, M.; Alothman, Z.A.; Bando, Y.; Yamauchi, Y.; Hossain, M.S. Origin of thermaly stable ferroelectricity in a porous barium titanate thin film synthesized through block copolymer templating. APL Mater. 2017, 5, 076111. [Google Scholar] [CrossRef]

- Ferreira, P.; Castro, A.; Vilarinho, P.M.; Willinger, M.-G.; Mosa, J.; Laberty, C.; Sanchez, C. Electron Microscopy study of porous and Co Functionalized BaTiO3 thin films. Microsc. Microanal. 2012, 18, 115–116. [Google Scholar] [CrossRef]

- Gao, Q.; Huang, A.; Zhang, J.; Ji, Y.; Zhang, J.; Chen, X.; Geng, X.; Hu, Q.; Wang, M.; Xiao, Z.; et al. Artificial synapses with a sponge-like double-layer porous oxide memristor. NPG Asia Mater. 2021, 13, 3. [Google Scholar] [CrossRef]

- Gao, Q.; Huang, A.; Hu, Q.; Zhang, X.; Chi, Y.; Li, R.; Ji, Y.; Chen, X.; Zhao, R.; Wang, M.; et al. Stability and repeatability of a Karst-like hierarchical porous silicon oxide-based memristor. ACS Appl. Mater. Interfaces 2019, 11, 21734–21740. [Google Scholar] [CrossRef] [PubMed]

- Augurio, A.; Alvarez-Fernandez, A.; Panchal, V.; Pittenger, B.; Wolf, P.D.; Guldin, S.; Briscoe, J. Controlled porosity in ferroelectric BaTiO3photoanodes. ASC Appl. Mater. Interfaces 2022, 14, 13147–13157. [Google Scholar] [CrossRef]

- Kozuka, H.; Kajimura, M.; Hirano, T.; Katayama, K. Crack-free, thick ceramic coating films via non-repetitive dip-coating using polyvinylpyrrolidone as stress-relaxing agent. J. Sol-Gel Sci. Technol. 2000, 19, 205–209. [Google Scholar] [CrossRef]

- Kozuka, H.; Kajimura, M. Achievement of crack-free BaTiO3 films over 1 μm in thickness via non-repetitive dip-coating. Chem. Lett. 1999, 10, 1029–1030. [Google Scholar] [CrossRef]

- Kozuka, H.; Takenaka, S. Single-Step Deposition of Gel-Derived Lead Zirconate Titanate Films: Critical Thickness and Gel Film to Ceramic Film Conversion. J. Am. Ceram. Soc. 2002, 85, 2696–2702. [Google Scholar] [CrossRef]

- Saegusa, T.; Chujo, Y. Macromolecular engineering on the basis of the polymerization of 2-oxazolines. Makromol. Chem. Macromol. Symp. 1991, 51, 1–10. [Google Scholar] [CrossRef]

- Saegusa, T.; Chujo, Y. An Organic/Inorganic Hybrid Polymer. J. Macromol. Sci. Part A—Chem. 1990, 27, 1603–1612. Available online: https://www.tandfonline.com/doi/abs/10.1080/00222339009351504 (accessed on 3 July 2023). [CrossRef]

- Kozuka, H.; Kajimura, M. Single-Step Dip Coating of Crack-Free BaTiO3 Films > 1 μm Thick: Effect of Poly(vinylpyrrolidone) on Critical Thickness. J. Am. Ceram. Soc. 2000, 83, 1056–1062. [Google Scholar] [CrossRef]

- Komandin, G.A.; Porodinkov, O.E.; Spektor, I.E.; Volkov, A.A.; Vorotilov, K.A.; Seregin, D.S.; Sigov, A.S. The Mechanisms of Absorption of Terahertz and Infrared Radiation in PZT Films. Phys. Solid State 2018, 60, 1226–1234. [Google Scholar] [CrossRef]

- Ohya, Y.; Yahata, Y.; Ban, T. Dielectric and piezoelectric properties of dense and porous PZT films prepared by sol-gel method. J. Sol-Gel Sci. Technol. 2007, 42, 397–405. [Google Scholar] [CrossRef]

- Stancu, V.; Boerasu, I.; Lisca, M.; Pintilie, L.; Popescu, M.; Sava, F. Structural and microstructural properties of porous PZT films. J. Optoelectron. Adv. Mater. 2006, 8, 1492–1497. Available online: https://www.researchgate.net/publication/268175799 (accessed on 3 July 2023).

- Suyal, G.; Setter, N. Enhanced performance of pyroelectric microsensors through the introduction of nanoporosity. J. Eur. Ceram. Soc. 2004, 24, 247–251. [Google Scholar] [CrossRef]

- Zhang, Q.; Corcovic, S.; Shaw, C.P.; Huang, Z.; Whatmore, R.W. Effect of porosity on the ferroelectric properties of Sol-Gel prepared Lead Zirconate Titanate thin films. Thin Solid Film. 2005, 488, 258–264. [Google Scholar] [CrossRef]

- Stancu, V.; Lisca, M.; Boerasu, I.; Pintilie, L.; Kosec, M. Effects of porosity on ferroelectric properties of Pb(Zr0.2Ti0.8)O3 films. Thin Solid Films 2007, 515, 6557–6561. [Google Scholar] [CrossRef]

- Zhang, Y.; Roscow, J.; Lewis, R.; Khanbareh, H.; Topolov, V.Y.; Xie, M.; Bowen, C.R. Understanding the effect of porosity on the polarisation-field response of ferroelectric materials. Acta Mater. 2018, 154, 100–112. [Google Scholar] [CrossRef]

- Podgorny, Y.; Vorotilov, K.; Lavrov, P.; Sigov, A. Leakage currents in porous PZT films. Ferroelectrics 2016, 503, 77–84. [Google Scholar] [CrossRef]

- Izyumskaya, N.; Alivov, Y.I.; Cho, S.J.; Morkoç, H.; Lee, H.; Kang, Y.S. Processing, structure, properties, and applications of PZT thin films. Crit. Rev. Solid State Mater. Sci. 2007, 32, 111–202. [Google Scholar] [CrossRef]

- Delimova, L.A.; Guschina, E.V.; Seregin, D.S.; Vorotilov, K.A.; Sigov, A.S. Unexpected behavior of transient current in thin PZT films caused by grain-boundary conduction. J. Appl. Phys. 2017, 121, 224104. [Google Scholar] [CrossRef]

- Krishtab, M.; Afanas’Ev, V.; Stesmans, A.; De Gendt, S. Leakage current induced by surfactant residues in self-assembly based ultralow-k dielectric materials. Appl. Phys. Lett. 2017, 111, 032908. [Google Scholar] [CrossRef]

- Kotova, N.M.; Vorotilov, K.A.; Seregin, D.S.; Sigov, A.S. Role of precursors in the formation of lead zirconate titanate thin films. Inorg. Mater. 2014, 50, 612–616. [Google Scholar] [CrossRef]

- Newnham, R.E.; Skinner, D.P.; Cross, L.E. Connectivity and Piezoelectric-Pyroelectric Composites. Mater. Res. Bull. 1978, 13, 525–536. [Google Scholar] [CrossRef]

- Atanova, A.V.; Zhigalina, O.M.; Khmelenin, D.N.; Orlov, G.A.; Seregin, D.S.; Sigov, A.S.; Vorotilov, K.A. Microstructure Analysis of Porous Lead Zirconate–Titanate Films. J. Am. Ceram. Soc. 2022, 105, 639–652. [Google Scholar] [CrossRef]

- Gidley, D.W.; Peng, H.-G.; Vallery, R.; Soles, C.L.; Lee, H.-J.; Vogt, B.D.; Lin, E.K.; Wu, W.-L.; Baklanov, M.R. Porosity of low dielectric constant materials. In Dielectric Films for Advanced Microelectronics; Baklanov, M.M., Green, K., Eds.; John Wiley and Sons, Ltd.: Hoboken, NJ, USA, 2007. [Google Scholar] [CrossRef]

- Wersin, W.; Lubits, K.; Mohaupt, J. Dielectric, Elastic and Piezoelectric Properties of porous PZT ceramics. Ferroelwectrics 1986, 68, 77–97. [Google Scholar] [CrossRef]

- Delimova, L.A.; Zaitseva, N.V.; Ratnikov, V.V.; Yuferev, V.S.; Seregin, D.S.; Vorotilov, K.A.; Sigov, A.S. Comparison of Characteristics of Thin PZT Films on Si-on-Sapphire and Si Substrates. Phys. Solid State 2021, 63, 1224–1231. [Google Scholar] [CrossRef]

- Scott J., F. Ferroelectrics go bananas. J. Phys. Condens. Matter 2008, 20, 021001. [Google Scholar] [CrossRef]

- Scott, J.F.; Gardner, J. Ferroelectrics, multiferroics and artifacts: Lozenge-shaped hysteresis and things that go bump in the night. Mater. Today 2018, 21, 553. [Google Scholar] [CrossRef]

- Jin, L.; Li, F.; Zhang, S. Decoding the fingerprint of ferroelectric loops: Comprehension of the material properties and structures. J. Am. Ceram. Soc. 2014, 97, 1. [Google Scholar] [CrossRef]

- Marutake, M. A Calculation of Physical Constants of Ceramic Barium Titanate. J. Phys. Soc. Jpn. 1956, 11, 807–814. [Google Scholar] [CrossRef]

- Nagata, K. Effects of porosity and grain size on hysteresis loops of piezoelectric ceramics (Pb-La)(Zr-Ti)O3. Electr. Eng. Jpn. 1980, 11, 1–8. [Google Scholar] [CrossRef]

- Robertson, J.; Warren, W.L.; Tuttle, B.A.; Dimos, D.; Smith, D.M. Shallow Pb3+ hole traps in lead zirconate titanate ferroelectrics. Appl. Phys. Lett. 1993, 63, 1519–1521. [Google Scholar] [CrossRef]

- Warren, W.L.; Robertson, J.; Dimos, D.B.; Tuttle, B.A.; Smyth, D.M. Transient hole traps in PZT. Ferroelectrics 1994, 153, 303–308. [Google Scholar] [CrossRef]

- Delimova, L.A.; Yuferev, V.S. Transient carrier transport and rearrangement of Schottky barrier layers under the action of a bias applied to the M/PZT/M structure. J. Appl. Phys. 2018, 124, 184102. [Google Scholar] [CrossRef]

- Meyerhofer, D. Characteristics of resist films produced by spinning. J. Appl. Phys. 1978, 49, 3993–3997. [Google Scholar] [CrossRef]

- Schulthei, B.J.; Roscow, J.I.; Koruza, J. Orienting anisometric pores in ferroelectrics: Piezoelectric property engineering through local electric field distributions. Phys. Rev. Mater. 2019, 3, 084408. [Google Scholar] [CrossRef]

- Lewis, R.W.C.; Dent, A.C.E.; Stevens, R.; Bowen, C.R. Microstrutural modelling of the polarization and properties of porous ferroelectrics. Smart Mater. Struct. 2011, 20, 085002. [Google Scholar] [CrossRef]

- Batra, V.; Kotru, S. A simulation model for understanding the charge transport and recombination behavior in PLZT based ferroelectric photovoltaic devices. Ferroelectrics 2018, 532, 121–137. [Google Scholar] [CrossRef]

- Baklanov, M.R.; Zhao, L.; Besien, E.V.; Pantouvaki, M. Effect of porogen residue on electrical characteristics of ultra low-k materials. Microelectron. Eng. 2011, 88, 990–993. [Google Scholar] [CrossRef]

| PVP wt.% | Volume Porosity, % | Number of Layers | Thickness d, nm | Refractive Index | Thickness per Layer |

|---|---|---|---|---|---|

| 0 | 0 | 10 | 370 | 2.54 | 37 |

| 0 | 0 | 17 | 607 | 2.61 | 36 |

| 1 | 6.8 | 9 | 390 | 2.40 | 43 |

| 1 | 7.1 | 16 | 705 | 2.39 | 44 |

| 3 | 11.0 | 7 | 345 | 2.29 | 49 |

| 3 | 13.3 | 12 | 600 | 2.23 | 50 |

| 6.6 | 33.3 | 4 | 383 | 1.83 | 96 |

| 6.6 | 32.0 | 7 | 566 | 1.85 | 81 |

| 14 | * | 3 | 380 | * | 127 |

| 14 | * | 5 | 500 | * | 100 |

| 20 | * | 3 | 617 | * | 206 |

| PVP wt.% | XRD Texture |

|---|---|

| 0 | (111) 100% (100) 28% (200) 22% |

| 1 | (110) 100% (211) 14% |

| 3 | (110) 100% (211) 7% |

| 6.6 | (110) 100% (211) 16% |

| 14 | (110) 100% (211) 5% |

| 20 | (110) 100% |

| XRD reflexes | 100 | 110 | 111 | 200 | 211 |

| PZT powder reflex, % | 20% | 100% | 20% | 22% | 26% |

| Lattice constant, Å | 4.068 | 4.068 | 4.068 | 4.068 | 4.068 |

| PVP, wt.% | Lattice constant in PZT, Å | ||||

| 0 | 4.029 | 4.061 | 4.019 | ||

| 1 | 4.061 | 4.047 | |||

| 3 | 4.072 | 4.027 | |||

| 6.6 | 4.072 | 4.055 | |||

| 14 | 4.072 | 4.062 | |||

| 20 | 4.073 | ||||

| PVP, wt.% | I–V PEAK Is Observed When: | ||

|---|---|---|---|

| 0 | P//V, nonconductive grain boundaries (GBs) | columnar grain structure | |

| 1 | P//V, 100% nonconductive GBs | columnar grain structure; porous 3-0 connectivity | |

| 3 | |||

| 6.6 | V < 0 | there are no peaks, 100% | porous 3-3 connectivity causes a destruction of the columnar grain structure; numerous depolarizing fields induced by polarization charges at pore boundaries lead to a decrease in polarization and disappearance of current peaks |

| V > 0 | there are no peaks, 42% | ||

| 35% weak peaks at P > 0, nonconductive GBs | |||

| 23% weak peaks at P < 0, conductive GBs | |||

| 14 | V < 0 | there are no peaks, 100% | |

| V > 0 | there are no peaks, 70% | ||

| 15% weak plateau at P > 0 | |||

| 15% weak plateau at P < 0 | |||

| 20 | V < 0 | there are no peaks, 100% | |

| V > 0 | there are no peaks, 50% | ||

| 50% weak plateau at P > 0 | |||

| Polarization, P | Current Way | Grain–Boundary Conductivity | I–V Peak | Reason | |

|---|---|---|---|---|---|

| Dense film | P conserves its direction and value across the film up to electrodes | Inside the grains by the action of an averaged built-in field | Nonconductive | Pronounced I–V peaks in both bias directions | Columnar grain texture; P is high enough to induce an accumulated space charge layer at a cathode |

| Porous 3-0 | P value decreases, but conserves its direction across film | Inside the grains; a small intergrain current appears | Nonconductive | Pronounced I–V peaks with a lower current value | Columnar grain texture; porous 3-0 connectivity |

| Porous 3-3 | P value decreases; P vector loses its single direction across a film | Grain boundaries and along pores | Conductive | I–V peaks disappear due to P decreasing; growing conduction along GBs and pores | Sponge-like 3-3 pore connectivity |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delimova, L.; Seregin, D.; Orlov, G.; Zaitseva, N.; Gushchina, E.; Sigov, A.; Vorotilov, K. Porous PZT Films: How Can We Tune Electrical Properties? Materials 2023, 16, 5171. https://doi.org/10.3390/ma16145171

Delimova L, Seregin D, Orlov G, Zaitseva N, Gushchina E, Sigov A, Vorotilov K. Porous PZT Films: How Can We Tune Electrical Properties? Materials. 2023; 16(14):5171. https://doi.org/10.3390/ma16145171

Chicago/Turabian StyleDelimova, Liubov, Dmitry Seregin, Georgy Orlov, Nina Zaitseva, Ekaterina Gushchina, Alexander Sigov, and Konstantin Vorotilov. 2023. "Porous PZT Films: How Can We Tune Electrical Properties?" Materials 16, no. 14: 5171. https://doi.org/10.3390/ma16145171

APA StyleDelimova, L., Seregin, D., Orlov, G., Zaitseva, N., Gushchina, E., Sigov, A., & Vorotilov, K. (2023). Porous PZT Films: How Can We Tune Electrical Properties? Materials, 16(14), 5171. https://doi.org/10.3390/ma16145171