Assessment of Waste Glass Incorporation in Asphalt Concrete for Surface Layer Construction

Abstract

1. Introduction

2. Background

3. Materials and Methods

3.1. 50/70 Bitumen

3.2. Waste Glass

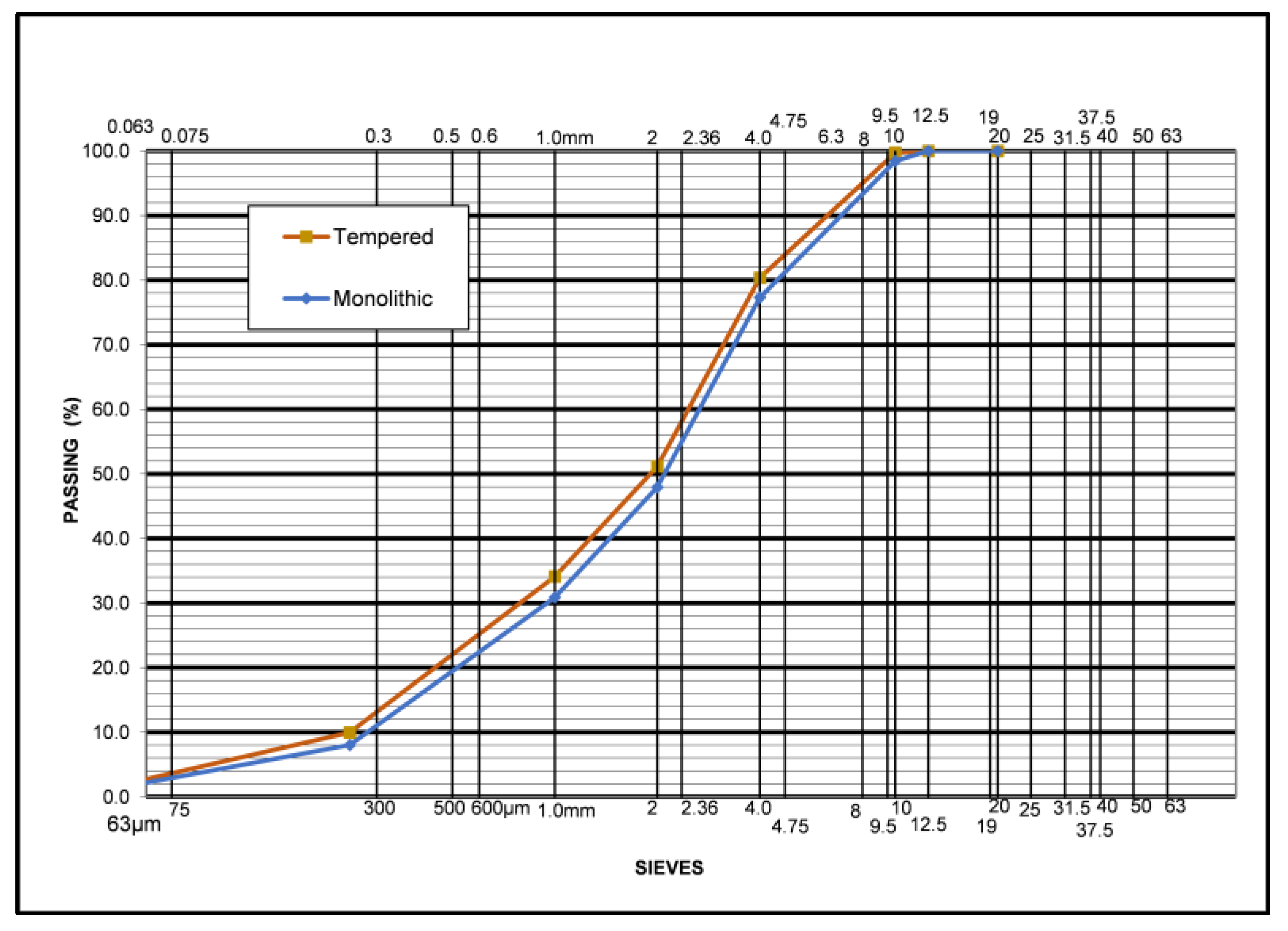

Glass Particle Size Distribution and Glass Performance under Freeze–Thaw Cycles

3.3. Aggregates

3.3.1. Aggregate Properties

3.3.2. Coarse Aggregates and Sand Particle Size Distribution

3.4. Reference Asphalt Mix-Glassphalts

3.5. Asphalt Mix Design

4. Results

4.1. Production of Test Specimens and Slabs

4.2. Void Content of Specimens Produced

4.3. Compactibility

4.4. Stiffness

4.5. Indirect Tensile Strength and Water Sensitivity

4.6. Cyclic Compression

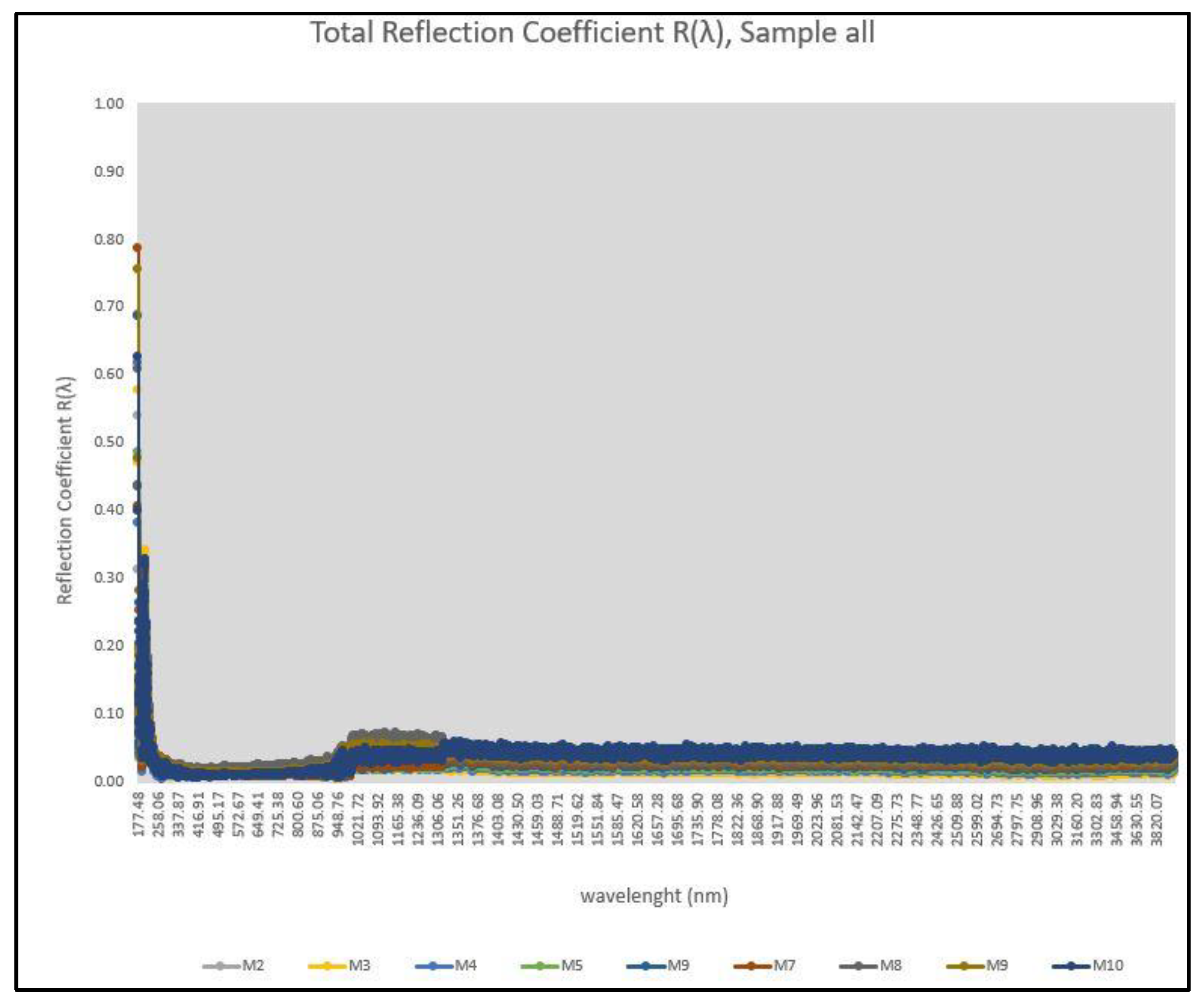

4.7. Solar Reflectance Index

5. Discussion for All Test Results

6. Conclusions

- The addition of waste glass reduced the stiffness modulus of the asphalt mix. A greater reduction was observed with the incorporation of 15% monolithic waste glass.

- The addition of waste glass reduced the resistance of the asphalt mix to permanent deformation. A greater reduction was observed with the incorporation of 15% monolithic glass.

- The ITSR of asphalt mixtures with glass was reduced compared to a conventional asphalt mixture.

- Glassphalt mixtures with 15% monolithic or tempered waste glass are not suitable for use in pavement surface layers with respect to an 80% threshold value for surface asphalt layers.

- The SRI values of all mixtures investigated herein were very low and thus it is not recommended to use the specific types of waste glass in Glassphalts in urban areas.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Agnusdei, G.P.; Gnoni, M.G.; Sgarbossa, F. Are deposit-refund systems effective in managing glass packaging? State of the art and future directions in Europe. Sci. Total Environ. 2022, 851, 158256. [Google Scholar] [CrossRef]

- Maupin, G. Final Report-Effect of Glass Concentration on Stripping of Glasphalt; Virginia Transportation Research Council: Charlottesville, VA, USA, 1998. [Google Scholar]

- Ziari, H.; Behbahani, H.; Kamboozia, N.; Ameri, M. New achievements on positive effects of nanotechnology zyco-soil on rutting resistance and stiffness modulus of glasphalt mix. Constr. Build. Mater. 2015, 101, 752–760. [Google Scholar] [CrossRef]

- Behbahani, H.; Ziari, H.; Kamboozia, N. Evaluation of the visco-elasto-plastic behavior of glasphalt mixtures through generalized and classic Burger’s models modification. Constr. Build. Mater. 2016, 118, 36–42. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C.; Thom, N.H. Mechanical Performance of Asphalt Mixtures Incorporating Slag and Glass Secondary Aggregates. In Proceedings of the 8th Conference on Asphalt Pavements for Southern Africa (CAPSA’04), Sun City, South Africa, 12–16 September 2004; Volume 12, p. 16. [Google Scholar]

- Androjić, I.; Dimter, S. Properties of hot mix asphalt with substituted waste glass. Mater. Struct. 2014, 49, 249–259. [Google Scholar] [CrossRef]

- Huang, Y.; Bird, R.N.; Heidrich, O. A review of the use of recycled solid waste materials in asphalt pavements. Resour. Conserv. Recycl. 2007, 52, 58–73. [Google Scholar] [CrossRef]

- Arabani, M.; Tahami, S.A.; Taghipoor, M. Laboratory investigation of hot mix asphalt containing waste materials. Road Mater. Pavement Des. 2016, 18, 713–729. [Google Scholar] [CrossRef]

- Arabani, M. Effect of glass cullet on the improvement of the dynamic behaviour of asphalt concrete. Constr. Build. Mater. 2011, 25, 1181–1185. [Google Scholar] [CrossRef]

- Arabani, M.; Kamboozia, N. New achievements in visco-elastoplastic constitutive model and temperature sensitivity of glasphalt. Int. J. Pavement Eng. 2013, 15, 810–830. [Google Scholar] [CrossRef]

- Arabani, M.; Mirabdolazimi, S.M.; Ferdowsi, B. Modeling the fatigue behaviors of glasphalt mixtures. Sci. Iran. 2012, 19, 341–345. [Google Scholar] [CrossRef]

- Buttlar, W.G.; Roque, R. Evaluation of Empirical and Theoretical Models to Determine Asphalt Mixture Stiffnesses at Low Temperatures (with Discussion). In Proceedings of the Asphalt Paving Technology 1996, Baltimore, MD, USA, 18–20 March 1996; Association of Asphalt Paving Technologists (AAPT): Lino Lakes, MI, USA, 1996; Volume 65. [Google Scholar]

- Flynn, L. “Glassphalt” utilization dependent on availability. Roads Bridges 1993, 31, 59–61. [Google Scholar]

- Day, D.E.; Schaffer, R. Glasphalt Paving Handbook; University of Missouri-Rolla: Rolla, MO, USA, 1989. [Google Scholar]

- Kiletico, M.J.; Hassan, M.M.; Mohammad, L.N.; Alvergue, A.J. New Approach to Recycle Glass Cullet in Asphalt Shingles to Alleviate Thermal Loads and Reduce Heat Island Effects. J. Mater. Civ. Eng. 2015, 27, 04014219. [Google Scholar] [CrossRef]

- Du, Y.; Dai, M.; Deng, H.; Deng, D.; Wei, T.; Kong, L. Laboratory investigation on thermal and road performances of asphalt mixture containing glass microsphere. Constr. Build. Mater. 2020, 264, 120710. [Google Scholar] [CrossRef]

- Yinfei, D.; Mingxin, D.; Haibin, D.; Deyi, D.; Peifeng, C.; Cong, M. Incorporating hollow glass microsphere to cool asphalt pavement: Preliminary evaluation of asphalt mastic. Constr. Build. Mater. 2020, 244, 118380. [Google Scholar] [CrossRef]

- Du, Y.; Dai, M.; Deng, H.; Deng, D.; Wei, T.; Li, W. Evaluation of thermal and anti-rutting behaviors of thermal resistance asphalt pavement with glass microsphere. Constr. Build. Mater. 2020, 263, 120609. [Google Scholar] [CrossRef]

- Al-Khateeb, G.G.; Khedaywi, T.S.; Irfaeya, M.F. Shear Properties of Waste Glass-Asphalt Mastics. Int. J. Pavement Res. Technol. 2019, 12, 307–314. [Google Scholar] [CrossRef]

- Grabowski, W.; Wilanowicz, J. The Structure of Mineral Fillers and Their Stiffening Properties in Filler-Bitumen Mastics. Mater. Struct. 2008, 41, 793–804. [Google Scholar] [CrossRef]

- Xing, B.; Fan, W.; Zhuang, C.; Qian, C.; Lv, X. Effects of the morphological characteristics of mineral powder fillers on the rheological properties of asphalt mastics at high and medium temperatures. Powder Technol. 2019, 348, 33–42. [Google Scholar] [CrossRef]

- Guo, M.; Bhasin, A.; Tan, Y. Effect of mineral fillers adsorption on rheological and chemical properties of asphalt binder. Constr. Build. Mater. 2017, 141, 152–159. [Google Scholar] [CrossRef]

- Hesami, E.; Birgisson, B.; Kringos, N. Numerical and experimental evaluation of the influence of the filler–bitumen interface in mastics. Mater. Struct. 2014, 47, 1325–1337. [Google Scholar] [CrossRef]

- Min, Z.; Zhou, L.; Wang, Q.; Zhang, Y. Performance Evaluation of Epoxy-Asphalt Mixture Blended with Glass Aggregate. J. Mater. Civ. Eng. 2019, 31, 04019083. [Google Scholar] [CrossRef]

- Simone, A.; Mazzotta, F.; Eskandarsefat, S.; Sangiorgi, C.; Vignali, V.; Lantieri, C.; Dondi, G. Experimental application of waste glass powder filler in recycled dense-graded asphalt mixtures. Road Mater. Pavement Des. 2019, 20, 592–607. [Google Scholar] [CrossRef]

- Ghasemi, M.; Marandi, S.M. Performance improvement of a crumb rubber modified bitumen using recycled glass powder. J. Zhejiang Univ. Sci. A 2013, 14, 805–814. [Google Scholar] [CrossRef]

- Saltan, M.; Öksüz, B.; Uz, V.E. Use of glass waste as mineral filler in hot mix asphalt. Sci. Eng. Compos. Mater. 2015, 22, 271–277. [Google Scholar] [CrossRef]

- Ali, M.M.Y.; Arulrajah, A. Potential Use of Recycled Crushed Concrete-Recycled Crushed Glass Blends in Pavement Subbase Applications. In Proceedings of the GeoCongress 2012, Oakland, CA, USA, 25–29 March 2012; pp. 3662–3671. [Google Scholar]

- Chen, Z.; Poon, C.S.; Li, J.-S.; Xue, Q. Utilization of glass cullet to enhance the performance of recycled aggregate unbound sub-base. J. Clean. Prod. 2021, 288, 125083. [Google Scholar] [CrossRef]

- Saberian, M.; Li, J.; Cameron, D. Effect of Crushed Glass on Behavior of Crushed Recycled Pavement Materials Together with Crumb Rubber for Making a Clean Green Base and Subbase. J. Mater. Civ. Eng. 2019, 31, 04019108. [Google Scholar] [CrossRef]

- ΕΝ 1426; Bitumen and Bituminous Binders-Determination of Needle Penetration. CEN: Brussels, Belgium, 2015.

- ΕΝ 1427; Bitumen and Bituminous Binders-Determination of Softening Point-Ring and Ball Method. CEN: Brussels, Belgium, 2015.

- ΕΝ 13589; Bitumen and Bituminous Binders-Determination of the Tensile properties of Modified Bitumen by the Force Ductility Method. CEN: Brussels, Belgium, 2008.

- ΕΝ 13703; Bitumen and Bituminous Binders-Determination of Deformation Energy. CEN: Brussels, Belgium, 2004.

- ΕΝ 13302; Bitumen and Bituminous Binders-Determination of Dynamic Viscosity of Bituminous Binder Using a Rotating Spindle Apparatus. CEN: Brussels, Belgium, 2018.

- EN 933-02; Tests for Geometrical Properties of Aggregates—Part 2: Determination of Particle Size Distribution—Test Sieves, Nominal Size of Apertures. CEN: Brussels, Belgium, 2020.

- EN 933-03; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness index. CEN: Brussels, Belgium, 2012.

- EN 933-04; Tests for Geometrical Properties of Aggregates—Part 4: Determination of Particle Shape—Shape Index. CEN: Brussels, Belgium, 2008.

- EN 1367-01; Tests for thermal and weathering properties of aggregates. Part 1: Determination of resistance to freezing and thawing. CEN: Brussels, Belgium, 2011.

- EN 1367-06; Tests for Thermal and Weathering Properties of Aggregates—Part 6: Determination of Resistance to Freezing and Thawing in the Presence of Salt (NaCl). CEN: Brussels, Belgium, 2008.

- EN 1097-01; Tests for Mechanical and Physical Properties of Aggregates—Main Element—Part 1: Determination of the Resistance to Wear (Micro-Deval). CEN: Brussels, Belgium, 2011.

- EN 1097-06; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. CEN: Brussels, Belgium, 2022.

- EN 1097-02; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. CEN: Brussels, Belgium, 2020.

- EN 1097-8; Tests for Mechanical and Physical Properties of Aggregates—Part 8: Determination of the Polished Stone Value. CEN: Brussels, Belgium, 2020.

- EN 933-08; Tests for Geometrical Properties of Aggregates—Part 8: Assessment of Fines—Sand Equivalent Test. CEN: Brussels, Belgium, 2012.

- EN 933-09; Tests for Geometrical Properties of Aggregates—Part 9: Assessment of Fines—Methylene Blue Test. CEN: Brussels, Belgium, 2022.

- EN 12697-10; Bituminous Mixtures—Test Methods—Part 10: Compactability. CEN: Brussels, Belgium, 2017.

- EN 12697-26; Bituminous Mixtures—Test Methods—Part 26: Stiffness. CEN: Brussels, Belgium, 2018.

- EN 12697-12; Bituminous Mixtures—Test Methods—Part 12: Determination of the Water Sensitivity of Bituminous Specimens. CEN: Brussels, Belgium, 2018.

- EN 12697-23; Bituminous Mixtures—Test Methods—Part 23: Determination of the Indirect Tensile Strength of Bituminous Specimens. CEN: Brussels, Belgium, 2017.

- EN 12697-25; Bituminous Mixtures—Test Methods—Part 25: Cyclic Compression test. CEN: Brussels, Belgium, 2016.

- Sanchez-Alonso, E.; Vega-Zamanillo, A.; Castro-Fresno, D.; DelRio-Prat, M. Evaluation of compactability and mechanical properties of bituminous mixes with warm additives. Constr. Build. Mater. 2011, 25, 2304–2311. [Google Scholar] [CrossRef]

- EN 13108-20; Bituminous Mixtures—Material Specifications—Part 20: Type Testing. CEN: Brussels, Belgium, 2016.

- Galatanu, C.D.; Canale, L. Measurement of Reflectance Properties of Asphalt Using Photographical Methods. In Proceedings of the 2020 IEEE International Conference on Environment and Electrical Engineering and 2020 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Madrid, Spain, 9–12 June 2020; pp. 1–6. [Google Scholar]

- Tran, N.; Powell, B.; Marks, H.; West, R.; Kvasnak, A. Strategies for Design and Construction of High-Reflectance Asphalt Pavements. Transp. Res. Rec. J. Transp. Res. Board 2009, 2098, 124–130. [Google Scholar] [CrossRef]

- Santamouris, M. Using cool pavements as a mitigation strategy to fight urban heat island—A review of the actual developments. Renew. Sustain. Energy Rev. 2013, 26, 224–240. [Google Scholar] [CrossRef]

- ASTM E1980-11; Standard Practice for Calculating Solar Reflectance Index of Horizontal and Low-Sloped Opaque Surfaces. ASTM International: West Conshohocken, PA, USA, 2019.

| Property | Specification | Value |

|---|---|---|

| Penetration | EN1426 [31] | 61 |

| Softening point (°C) | EN1427 [32] | 50 |

| Force ductility (J/cm2) | EN 13589 [33] & EN 13703 [34] | 0.885 |

| Dynamic viscosity (150 °C, Pa·s) | EN 13302 [35] | 0.28 |

| Dynamic viscosity (100 °C, Pa·s) | EN 13302 [35] | 2.3 |

| Property | Specification | Waste Glass Type | |

|---|---|---|---|

| Monolithic | Tempered | ||

| Flakiness Index (%) | EN 933-03 [37] | 20 | 18 |

| Particle density (Mg/m3) (1) | - | 2493.7 ±0.01229% | 2485.6 ±0.0042% |

| Shape Index (%) | EN 933-04 [38] | 14 | 13 |

| Freeze–thaw performance (Mass change %) | EN 1367-01 [39] EN 1367-06 [40] | 0.2 0.0 | 0.5 0.5 |

| Micro-Deval (wet method) (MDE for 4.0–6.3 mm glass) | EN 1097-01 [41] | 69.8 | 66.0 |

| Aggregate Type | Test | Specification | Value |

|---|---|---|---|

| Coarse | Particle density | EN 1097-06 [42] | 2882 Mg/m3 |

| Water absorption | EN 1097-06 [42] | 0.80% | |

| Flakiness Index | EN 933-03 [37] | 12% | |

| Los Angeles | EN 1097-02 [43] | 20% | |

| PSV | EN 1097-08 [44] | 58% | |

| AAV | EN 1097-08 (Annex A) [44] | 5.5% | |

| Limestone sand | Particle density | EN 1097-06 [42] | 2515 Mg/m3 |

| Water absorption | EN 1097-06 [42] | 1.20% | |

| Sand equivalent | EN 933-08 [45] | 71% | |

| Methylene blue | EN 933-09 [46] | 1.7 g/kg |

| Sieve Size (mm) | AC Type 2 Gradation Limits (% Passing) |

|---|---|

| 20 | 100 |

| 12.5 | 90–100 |

| 10 | 60–90 |

| 4 | 18–48 |

| 2 | 5–30 |

| 1 | 4–24 |

| 0.25 | 3–16 |

| 0.063 | 2–8 |

| Asphalt Mix | Aggregate Fraction Content (%) | Glass Content (%) | |||

|---|---|---|---|---|---|

| Coarse | Sand | Filler | Monolithic | Tempered | |

| AC Type2-Ref. | 83 | 15 | 2 | - | - |

| AC Type2–10%-Mon. | 75 | 13 | 2 | 10 | - |

| AC Type2–15%-Mon. | 75 | 8 | 2 | 15 | - |

| AC Type2–10%-Tem. | 75 | 13 | 2 | - | 10 |

| AC Type2–15%-Tem. | 75 | 8 | 2 | - | 15 |

| Test | Specification | Total Number of Specimens/Slabs |

|---|---|---|

| Compactibility | EN12697-10 [47] | 10 specimens |

| Stiffness | EN12697-26 [48] | 30 specimens |

| ITS and ITSR | EN12697-12 [49] & EN12697-23 [50] | 30 specimens 1 |

| Cyclic Compression test | EN12697-25 [51] | 10 specimens |

| Reflectivity | - | 5 slabs |

| No. Specimen | AC-T2-Ref | AC-T2-M10 | AC-T2-M15 | AC-T2-T10 | AC-T2-T15 |

|---|---|---|---|---|---|

| Air Voids (%) | |||||

| 1 | 11.6 | 11.9 | 11.1 | 12.2 | 10.6 |

| 2 | 11.9 | 11.2 | 10.6 | 10.3 | 11.6 |

| 3 | 10.8 | 12.0 | 11.0 | 10.6 | 10.0 |

| 4 | 11.5 | 10.9 | 11.8 | 11.2 | 10.1 |

| 5 | 12.0 | 11.4 | 10.6 | 10.9 | 9.7 |

| 6 | 11.6 | 11.2 | 11.5 | 11.8 | 11.5 |

| 7 | 11.5 | 10.8 | 11.7 | 11.7 | 11.5 |

| 8 | 12.0 | 11.1 | 10.6 | 11.7 | 10.8 |

| Average | 11.6 | 11.3 | 11.1 | 11.3 | 10.7 |

| St. Deviation | 0.39 | 0.44 | 0.50 | 0.66 | 0.75 |

| Asphalt Mix | Compactibility Curve Equation | Parameter K |

|---|---|---|

| AC-T2-Ref | Vα = 21.885 − 3.7151ln(N) | 3.7151 |

| AC-T2-M10 | Vα = 27.553 − 4.6710ln(N) | 4.6710 |

| AC-T2-M15 | Vα = 35.819 − 6.0722ln(N) | 6.0722 |

| AC-T2-T10 | Vα = 26.175 − 4.4374ln(N) | 4.4374 |

| AC-T2-T15 | Vα = 28.793 − 4.8812ln(N) | 4.8812 |

| No. Specimen | AC-T2-Ref | AC-T2-M10 | AC-T2-M15 | AC-T2-T10 | AC-T2-T15 |

|---|---|---|---|---|---|

| Stiffness (MPa) | |||||

| 1 | 3255 | 2930 | 2552 | 3056 | 2826 |

| 2 | 3175 | 2935 | 2598 | 2958 | 2874 |

| 3 | 3301 | 2856 | 2635 | 2965 | 2726 |

| 4 | 3259 | 2974 | 2617 | 2895 | 2715 |

| 5 | 3425 | 3000 | 2665 | 2889 | 2803 |

| 6 | 3418 | 3085 | 2567 | 2845 | 2745 |

| Average | 3306 | 2963 | 2606 | 2935 | 2782 |

| St. Deviation | 99 | 77 | 42 | 75 | 63 |

| No. Specimen | AC-T2-Ref | AC-T2-M10 | AC-T2-M15 | AC-T2-T10 | AC-T2-T15 |

|---|---|---|---|---|---|

| Indirect Tensile Strength of Dry Specimens (kPa) | |||||

| 1 | 942 | 865 | 813 | 882 | 822 |

| 2 | 935 | 884 | 804 | 873 | 837 |

| 3 | 927 | 873 | 815 | 870 | 829 |

| Average | 935 | 874 | 811 | 875 | 829 |

| St. Deviation | 7.5 | 9.5 | 5.9 | 6.2 | 7.5 |

| No. specimen | Indirect Tensile Strength of wet specimens (kPa) | ||||

| 4 | 795 | 698 | 602 | 726 | 651 |

| 5 | 815 | 705 | 598 | 735 | 643 |

| 6 | 798 | 715 | 602 | 749 | 657 |

| Average | 803 | 706 | 601 | 737 | 650 |

| St. Deviation | 10.8 | 8.5 | 2.3 | 11.6 | 7.0 |

| ITSR (%) | 85.9% | 80.8% | 74.1% | 84.2% | 78.4% |

| Asphalt Mix | Cumulative Axial Strain (%) | Creep Rate (μm/m/Loading Cycles) |

|---|---|---|

| AC-T2-Ref | 0.40 | 0.08 |

| AC-T2-M10 | 0.79 | 0.21 |

| AC-T2-M15 | 1.16 | 0.33 |

| AC-T2-T10 | 0.67 | 0.16 |

| AC-T2-T15 | 0.73 | 0.19 |

| Asphalt Mix | SRItot (%) | Standard Deviation SRtot * Solar Spectrum | Uncertainty Rtot * Solar Spectrum |

|---|---|---|---|

| AC-T2-Ref | 1.621 | 0.0026 | 0.0017 |

| AC-T2-M10 | 1.454 | 0.0037 | 0.0023 |

| AC-T2-M15 | 1.910 | 0.0024 | 0.0015 |

| AC-T2-T10 | 2.076 | 0.0024 | 0.0015 |

| AC-T2-T15 | 1.922 | 0.0024 | 0.0015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalampokis, S.; Kalama, D.; Kesikidou, F.; Stefanidou, M.; Manthos, E. Assessment of Waste Glass Incorporation in Asphalt Concrete for Surface Layer Construction. Materials 2023, 16, 4938. https://doi.org/10.3390/ma16144938

Kalampokis S, Kalama D, Kesikidou F, Stefanidou M, Manthos E. Assessment of Waste Glass Incorporation in Asphalt Concrete for Surface Layer Construction. Materials. 2023; 16(14):4938. https://doi.org/10.3390/ma16144938

Chicago/Turabian StyleKalampokis, Stavros, Danai Kalama, Fotini Kesikidou, Maria Stefanidou, and Evangelos Manthos. 2023. "Assessment of Waste Glass Incorporation in Asphalt Concrete for Surface Layer Construction" Materials 16, no. 14: 4938. https://doi.org/10.3390/ma16144938

APA StyleKalampokis, S., Kalama, D., Kesikidou, F., Stefanidou, M., & Manthos, E. (2023). Assessment of Waste Glass Incorporation in Asphalt Concrete for Surface Layer Construction. Materials, 16(14), 4938. https://doi.org/10.3390/ma16144938