Crack Size and Undermatching Effects on Fracture Behavior of a Welded Joint

Abstract

1. Introduction

2. Materials and Methods

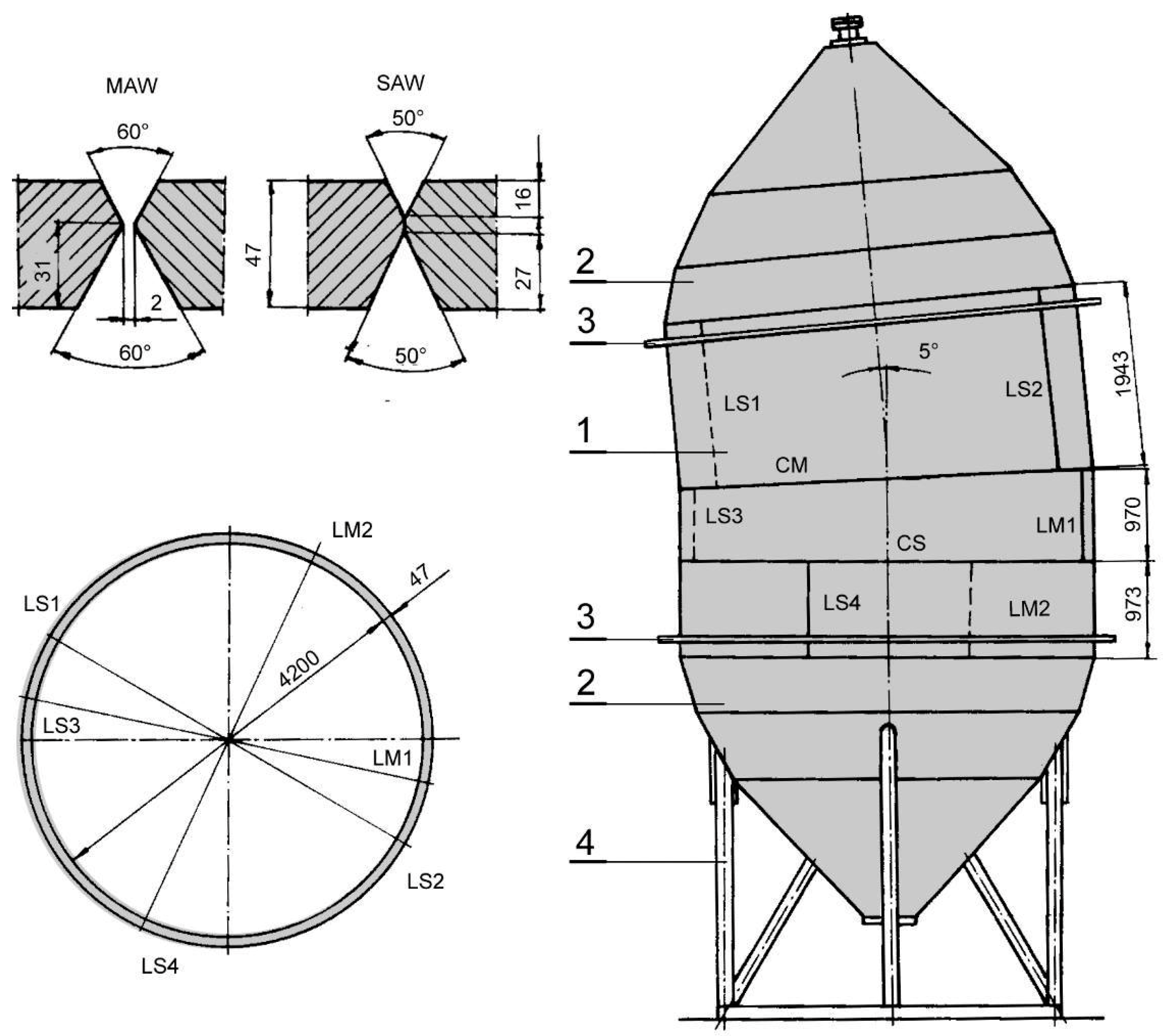

2.1. Base Metal and Welding

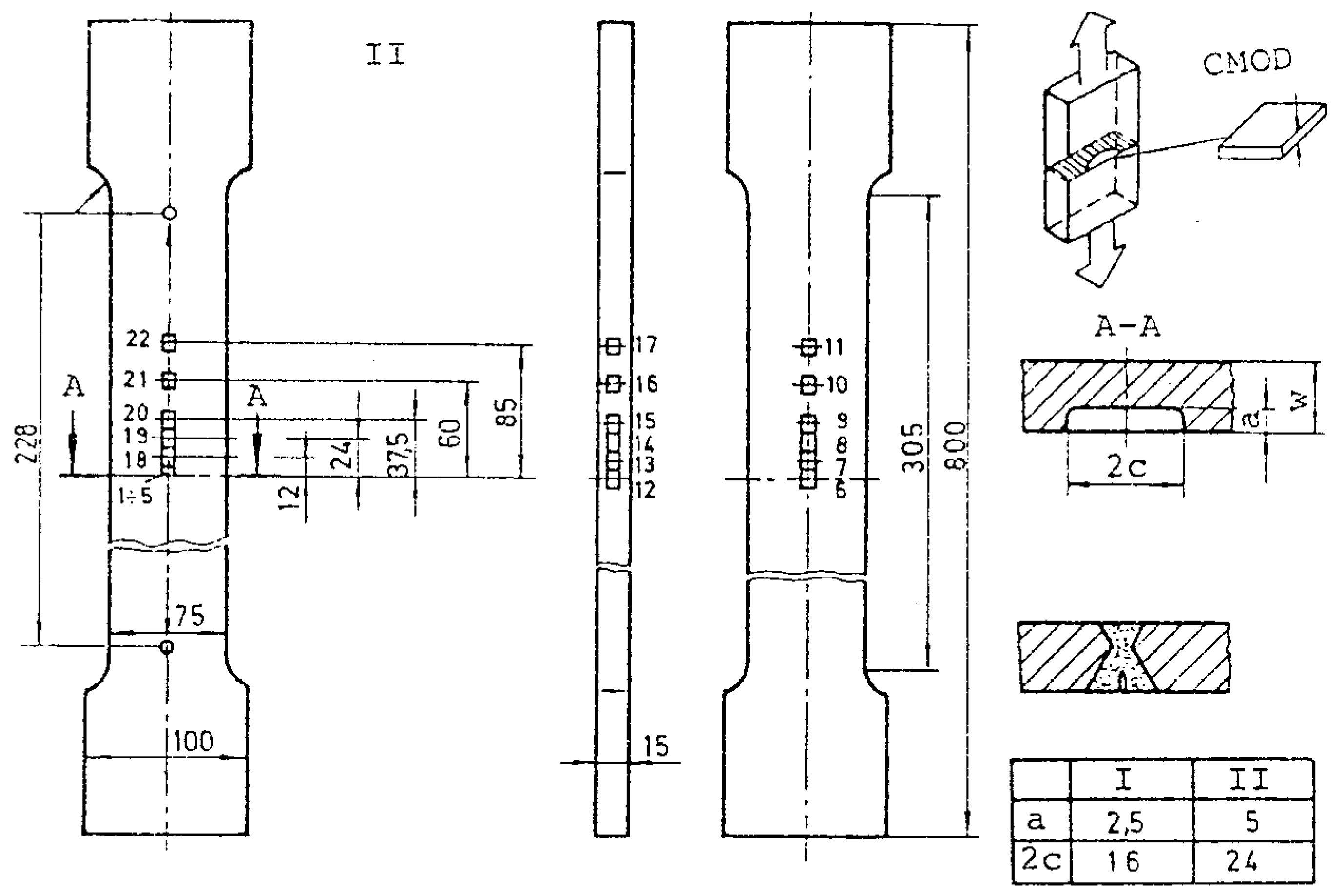

2.2. Tensile Panels

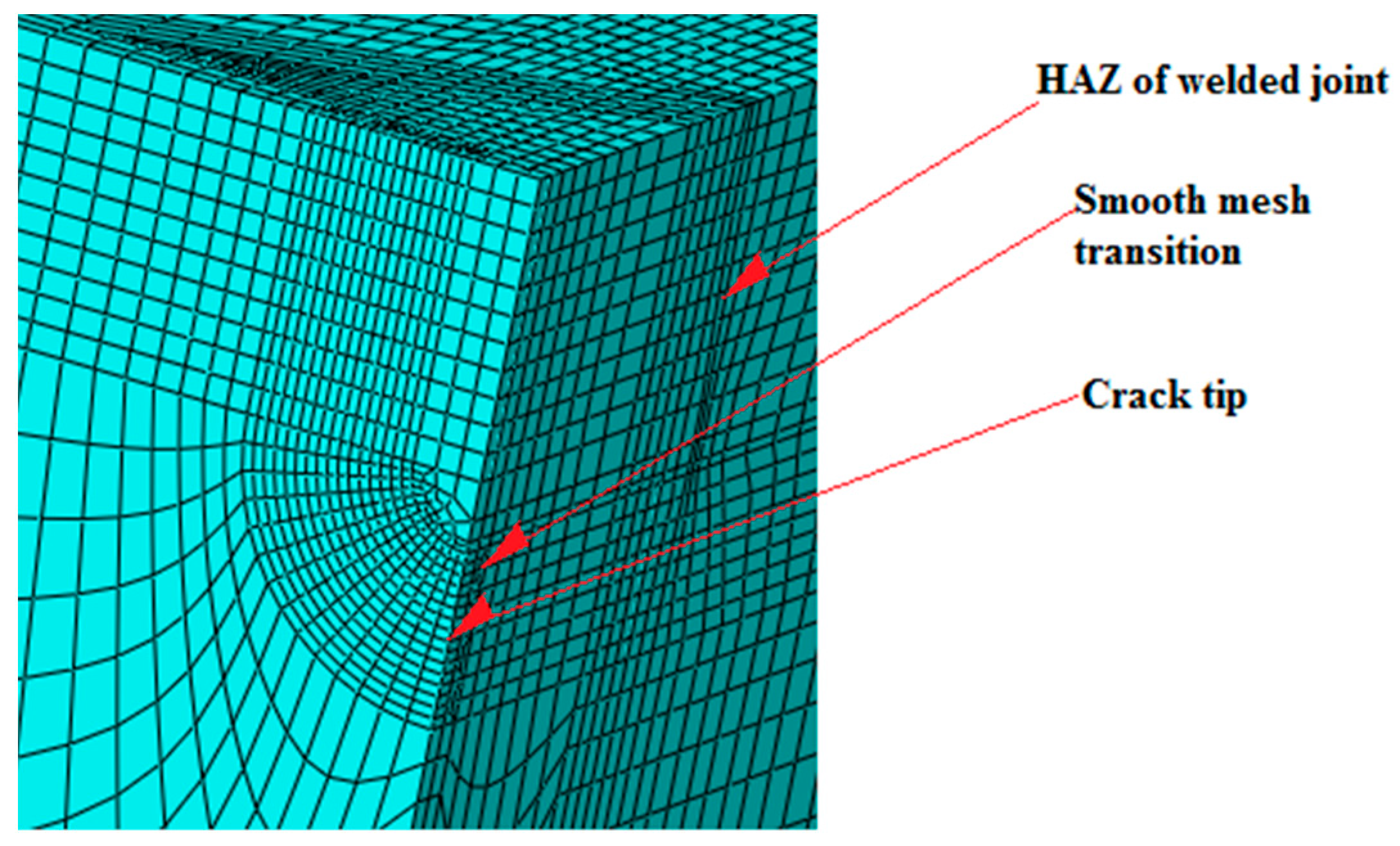

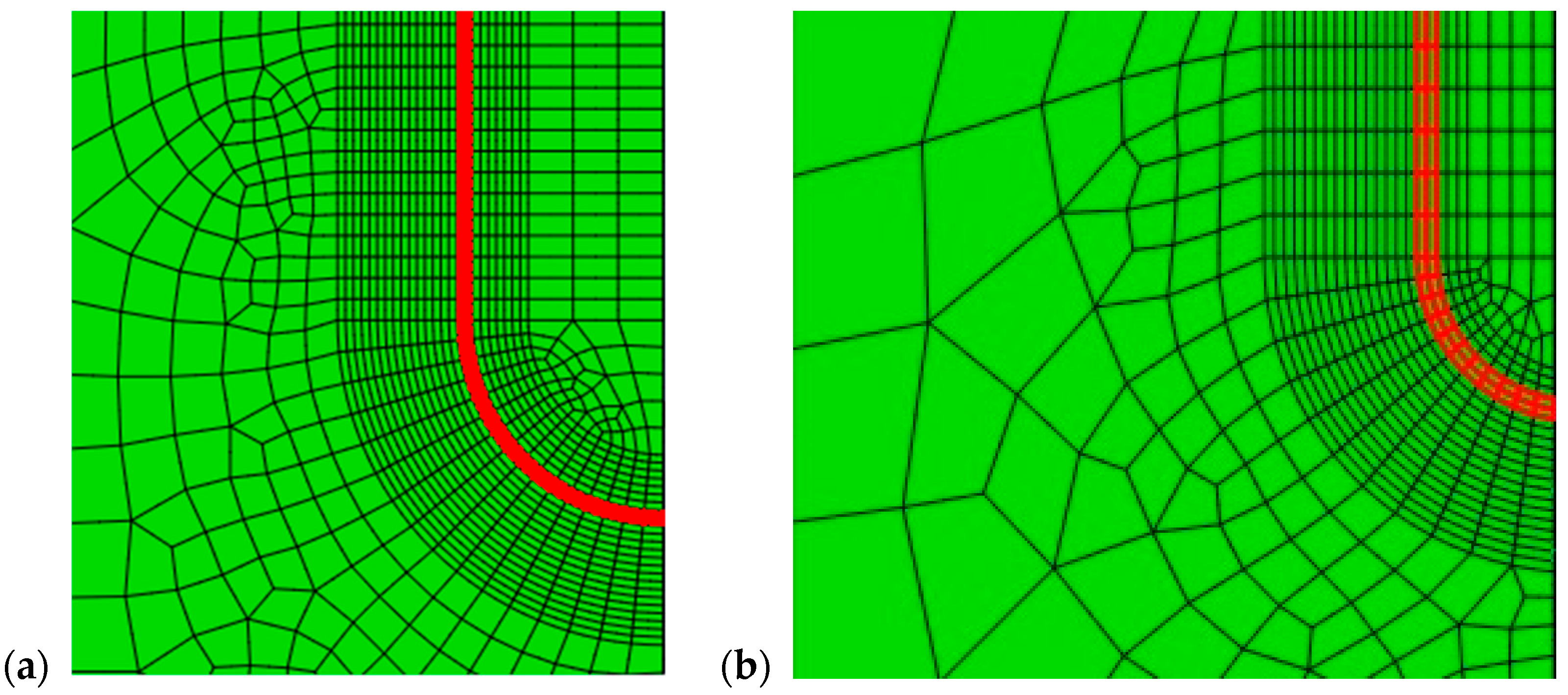

2.3. Numerical Analysis—FEM

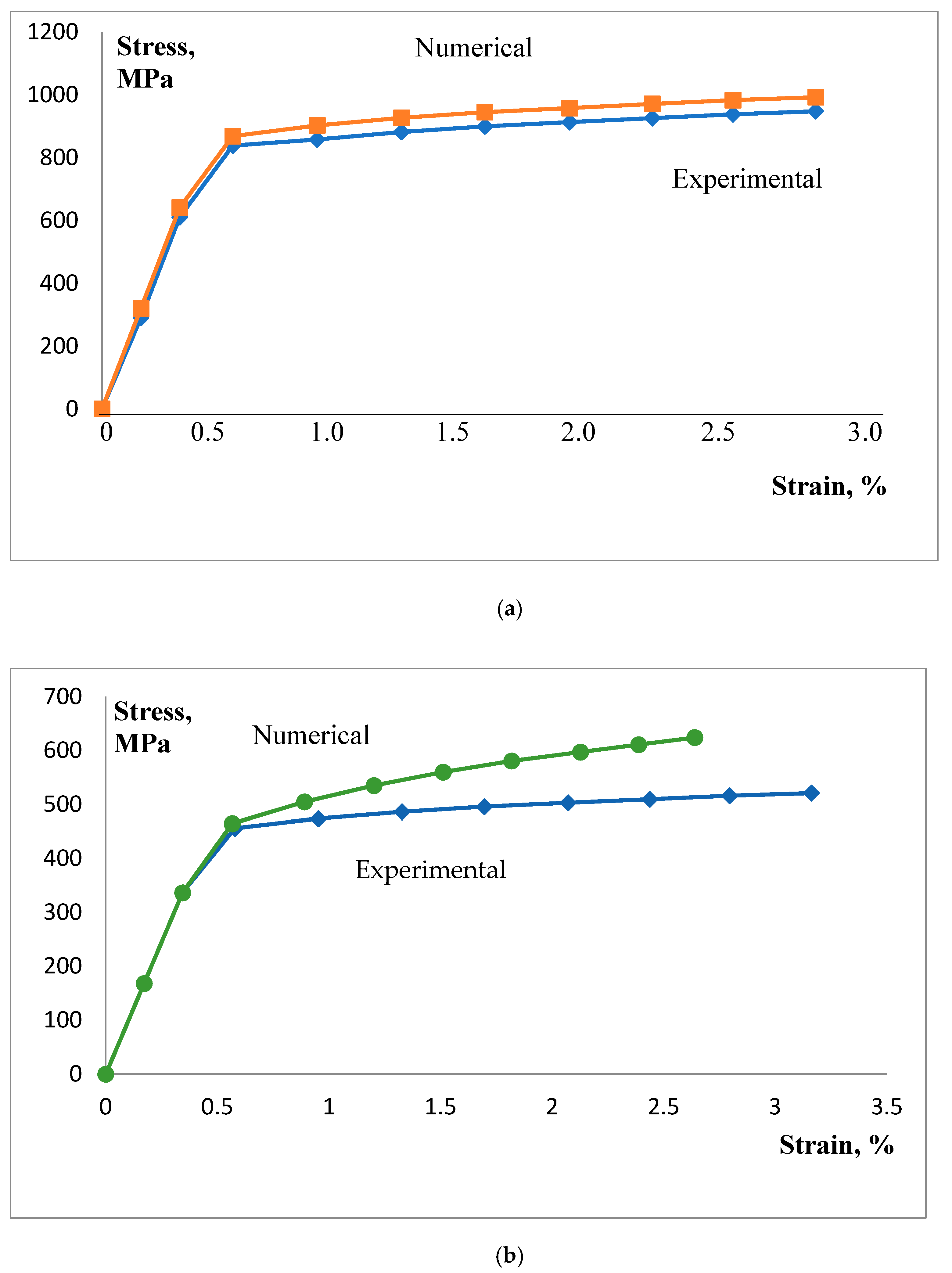

2.4. Stress–Strain Curves

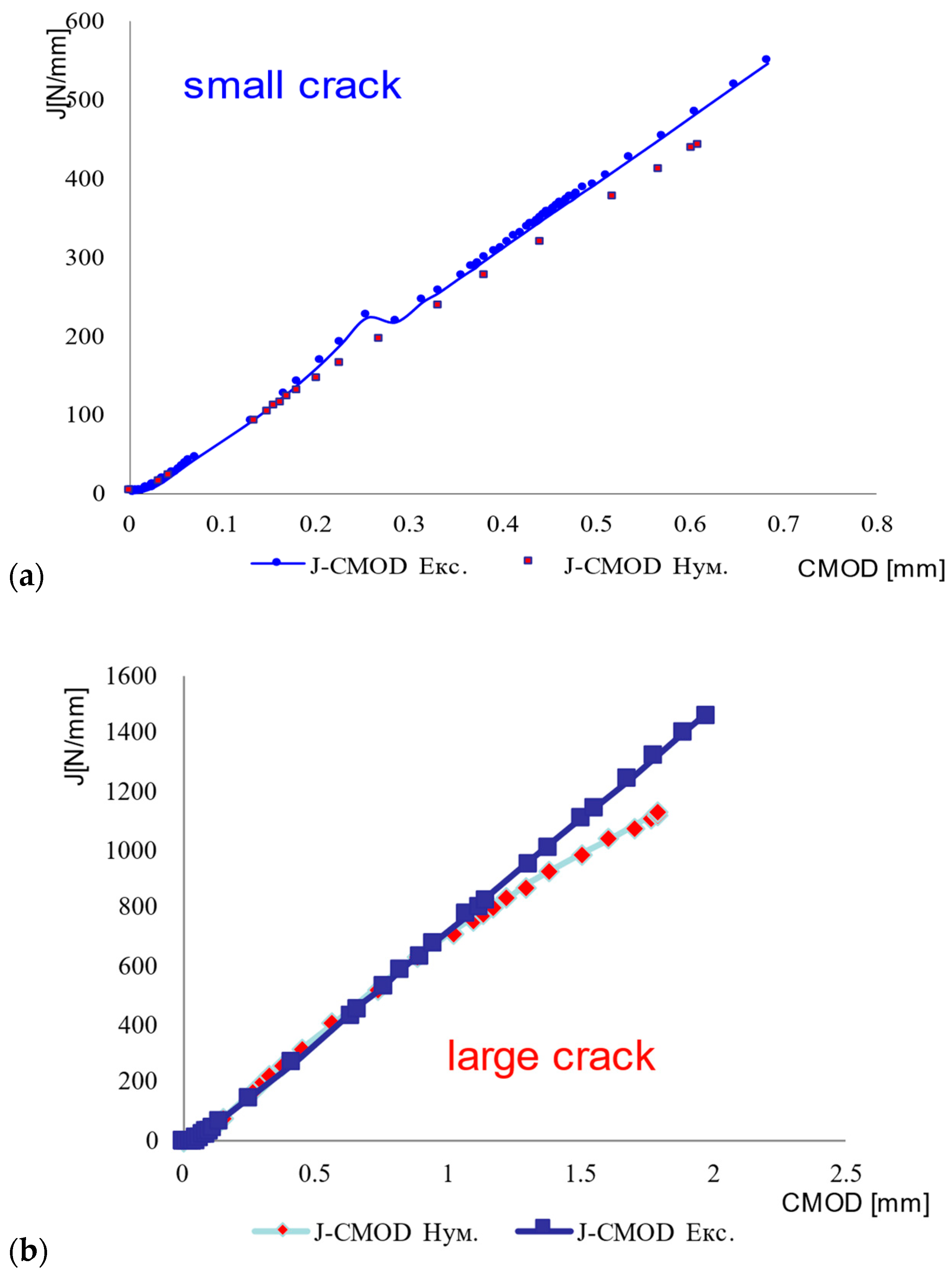

3. Numerical Results of BM and WM with SSC and LSC

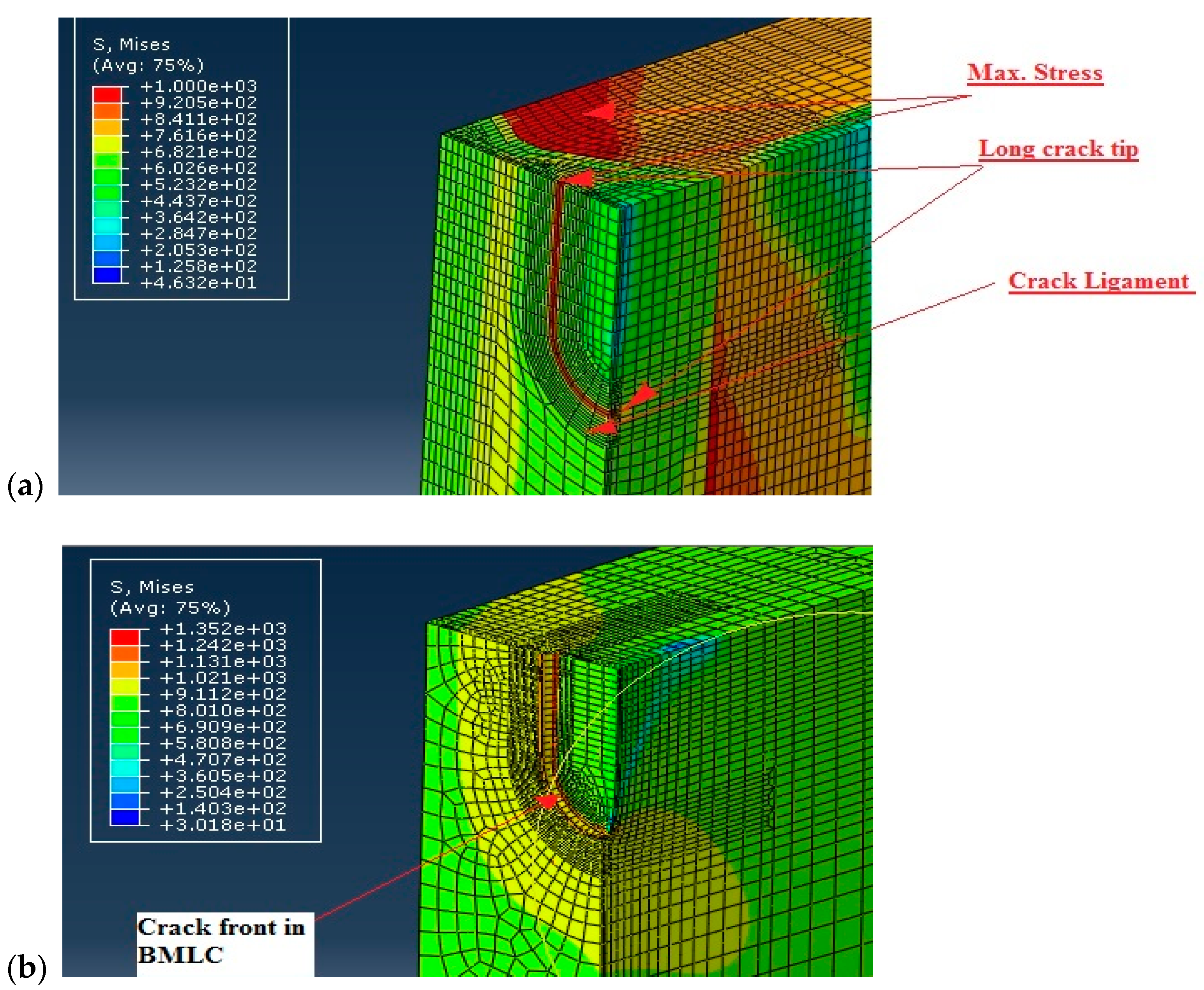

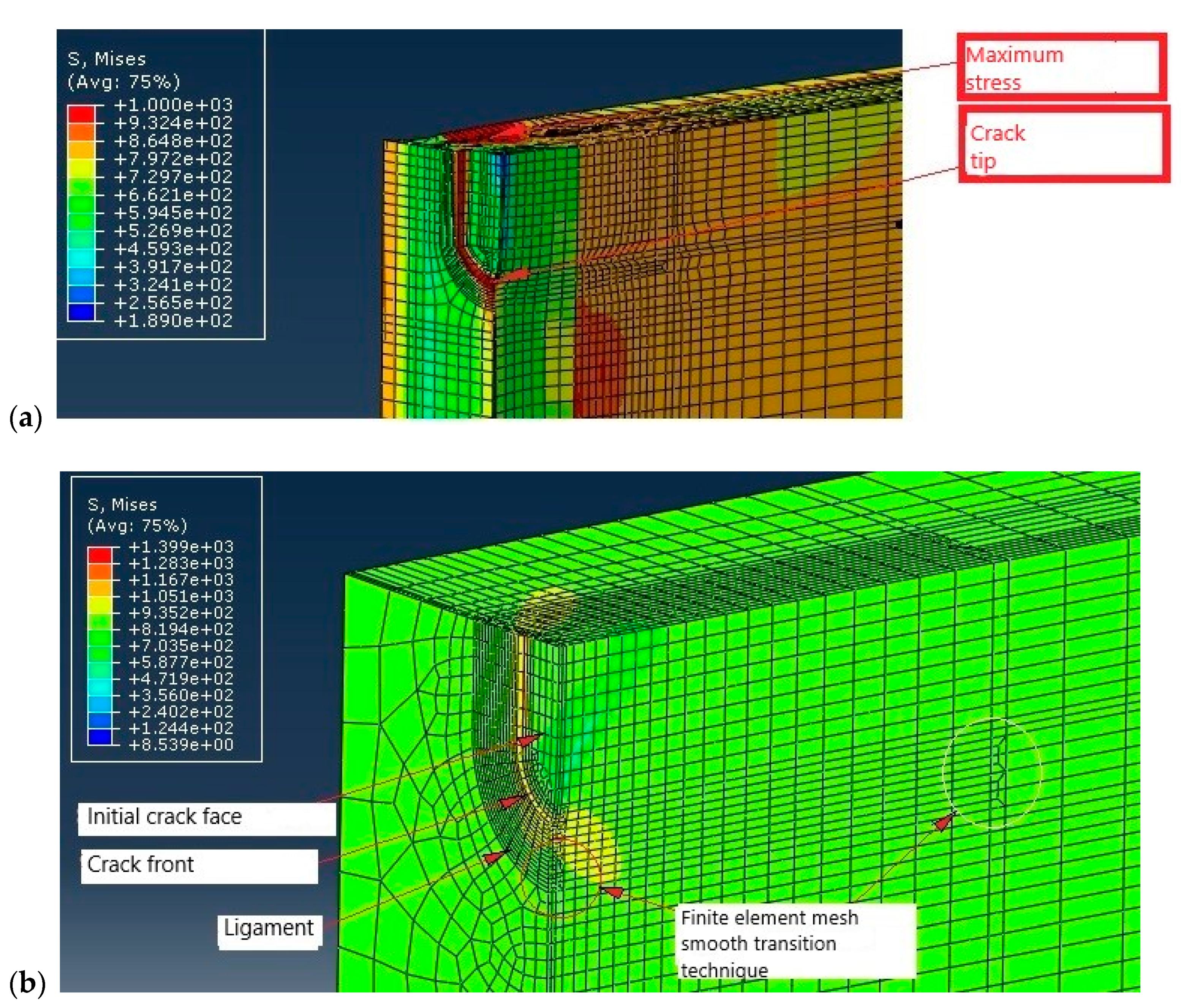

Von Mises Stress Distribution

4. Discussion

5. Conclusions

- Mismatching effects play a more significant role in fracture behavior of undermatched welded joints than crack size, since the crack tip fields are influenced mostly by mismatching, and to smaller a extent, by crack size.

- Crack tip fields in the case of an undermatched welded joint are favorable, since high stresses are re-distributed from the crack tip to the BM.

- Numerical results agree well with the experimental ones, with increasing differences in the case of WM due to crack growth, which was not taken into account in numerical modeling.

- Differences between numerical and experimental results in the case of WM are larger than in the case of BM, which is attributed to the modeling of stress–strain curves, being less precise in the case of WM.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Milosevic, N.; Younise, B.; Sedmak, A.; Travica, M.; Mitrovic, A. Evaluation of true stress–strain diagrams for welded joints by application of Digital Image Correlation. Eng. Fail. Anal. 2021, 128, 105609. [Google Scholar] [CrossRef]

- Milošević, N.; Sedmak, A.; Bakić, G.; Lazić, V.; Milošević, M.; Mladenović, G.; Maslarević, A. Determination of the actual stress–strain diagram for undermatching welded joint using DIC and FEM. Materials 2021, 14, 4691. [Google Scholar] [CrossRef] [PubMed]

- Milošević, N.; Sedmak, A.; Martić, I.; Prokić-Cvetković, R. Novel procedure to determine actual stress-strain curves. Struct. Integr. Life 2021, 21, 37–40. [Google Scholar]

- Čamagić, I.; Burzić, Z.; Sedmak, A.; Vasić, N.; Ćirković, B.; Algool, M.M. Influence of mechanical properties and microstructural heterogeneity of welded joint constituents on tensile properties and fracture toughness at plane strain, KIc. Struct. Integr. Life 2014, 14, 45–49. [Google Scholar]

- Sedmak, S.; Petrovski, B.; Sedmak, A. The Resistance to Crack Growth of Different Regions of Weldment in a Real Structure. Int. J. Press. Vessel. Pip. 1992, 52, 313–335. [Google Scholar] [CrossRef]

- Petrovski, B.; Kocak, M.; Sedmak, S. Fracture behavior of undermatched weld joint with short surface crack. In Proceedings of the 10th International Conference on Offshore Mechanics and Arctic Engineering, Stavanger, Norway, 23–28 June 1991; pp. 101–107. [Google Scholar]

- Kirk, M.T.; Dodds, R.H. The influence of weld strength mismatch on crack-tip constraint in single edge notch specimens. Int. J. Fract. 1993, 63, 297–316. [Google Scholar] [CrossRef]

- Tang, W.; Shi, Y.W. Influence of strength matching and crack depth on fracture toughness of welded joints. Eng. Fract. Mech. 1995, 51, 649–659. [Google Scholar] [CrossRef]

- Younise, B.S.; Sedmak, A. Micromechanical study of ductile fracture initiation and propagation on welded tensile specimen with a surface pre-crack in weld metal. Struct. Integr. Life 2014, 14, 185–191. [Google Scholar]

- Jovanović, M.; Čamagić, I.; Sedmak, S.; Živković, P.; Sedmak, A. Crack initiation and propagation resistance of HSLA steel welded joint constituents. Struct. Integr. Life 2020, 20, 11–14. [Google Scholar]

- Busari, Y.O.; Manurung, Y.H.P. Welded high strength low alloy steel influence on fatigue crack propagation of using LEFM: A practical and thematic review. Struct. Integr. Life 2020, 20, 263–279. [Google Scholar]

- Jovanović, M.; Čamagić, I.; Sedmak, S.; Sedmak, A.; Burzić, Z. Effect of material heterogeneity and testing temperature on fatigue behaviour of Cr-Mo steel welded joints. Eng. Fail. Anal. 2022, 141, 106542. [Google Scholar] [CrossRef]

- Praunseis, Z.; Toyoda, M.; Sundararajan, T. Fracture behaviours of fracture toughness testing specimens with metallurgical heterogeneity along crack front, Steel research international. Mater. Technol. 2000, 71, 366–372. [Google Scholar] [CrossRef]

- Praunseis, Z.; Sundararajan, T.; Toyoda, M.; Ohata, M. The influence of soft root on fracture behaviors of high-strength, low-alloyed (HSLA) steel weldments. Mater. Manuf. Process. 2006, 16, 229–244. [Google Scholar] [CrossRef]

- Gubeljak, N. Fracture behaviour of specimens with surface notch tip in the heat affected zone (HAZ) of strength mis-matched welded joints. Int. J. Fract. 1999, 100, 155–167. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Wu, K.; Sui, Y.; Feng, Q.; Wang, D.; Zhang, H. Full-scale experimental investigation of the fracture behaviours of welding joints of APL X80 wide plate based on DIC technology. Eng. Fail. Anal. 2022, 131, 105832. [Google Scholar] [CrossRef]

- Aranđelović, M.; Petrović, A.; Đorđević, B.; Sedmak, S.; Sedmak, A.; Dikić, S.; Radu, R. Effects of Multiple Defects on Welded Joint Behaviour under the Uniaxial Tensile Loading: Fem and Experimental Approach. Sustainability 2023, 15, 761. [Google Scholar] [CrossRef]

- Que, Y.; Wu, Y.; Wang, G.; Jia, H.; Zhang, S.; Feng, Q.; Dai, L. Study of Tensile Deformation and Damage Law in Undermatching X80 Pipeline Steel Welded Joints. Metals 2023, 13, 226. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Simha, C.H.M.; Gerlich, A.P. Assessment of yield strength mismatch in X80 pipeline steel welds using instrumented indentation. Int. J. Press. Vessel. Pip. 2018, 168, 258–268. [Google Scholar] [CrossRef]

- Wu, X.; Shuai, J.; Xu, K.; Lv, Y.; Shan, K. Determination of local true stress-strain response of X80 and Q235 girth-welded joints based on digital image correlation and numerical simulation. Int. J. Press. Vessel. Pip. 2020, 188, 104232. [Google Scholar] [CrossRef]

- Petrovski, B. Residual Strength Evaluation of Pressure Vessel with a Surface Crack (in Serbian). Ph.D. Thesis, University of Belgrade Faculty of Technology and Metallurgy, Belgrade, Serbia, 1985. [Google Scholar]

- Sedmak, S.; Sedmak, A. Integrity of Penstock of hydroelectric power plant. Struct. Integr. Life 2005, 5, 59–70. [Google Scholar]

- Gubeljak, N.; Predan, J.; Rak, I.; Kozak, D. Integrity Assessment of HSLA Steel Welded Joint with Mis-Matched Strength. Struct. Integr. Life 2009, 9, 157–164. [Google Scholar]

- Sedmak, A.; Petrovski, B.; Gubeljak, N.; Legat, J.; Samardžić, I.; Kozak, D.; Kuzmanović, S.; Adžiev, T.; Adžiev, G.; Ćulafić, V.; et al. Weldment fracture mechanics. In Proceedings of the 3rd South-East European Welding Congress, Timişoara, Romania, 3–5 June 2015; pp. 49–60. [Google Scholar]

- Sedmak, A.; Ković, M.; Kirin, S. Structural integrity—Historical context. Tech. Gaz. 2022, 29, 1770–1776. [Google Scholar] [CrossRef]

- Jeremić, L.; Petrovski, B.; Đorđević, B.; Sedmak, S. Structural integrity assessment of welded pipeline designed with reduced safety. Teh. Vjesn. 2020, 27, 1461–1466. [Google Scholar]

- Martic, I.; Sedmak, A.; Mitrovic, N.; Sedmak, S.; Vucetic, I. Effect of Over-Pressure on Pipeline Structural Integrity. Tech. Gaz. 2019, 26, 852–855. [Google Scholar]

- Sedmak, S.; Mahdi, A.; Sedmak, A.; Tatic, U.; Dzindo, E. Elastic-plastic behaviour of welded joints during loading and unloading of pressure vessels. Procedia Struct. Integr. 2016, 2, 3546–3553. [Google Scholar] [CrossRef]

- Doncheva, E.; Medjo, B.; Sedmak, A. Finite element analysis of fracture resistance parameters for stationary semi-elliptical surface cracks in high strength steel. Struct. Integr. Life 2015, 15, 131–134. [Google Scholar]

- Doncheva, E.; Medjo, B.; Adziev, G.; Sedmak, S. Elastic-plastic numerical analysis of tensile specimens with surface center-cracked asymmetric welded X-joints. In Proceedings of the 7th International Conference TEAM, Belgrade, Serbia, 23–25 May 2015; pp. 421–425. [Google Scholar]

- Petrovski, B.; Kojak, M. Fracture of Surface-Cracked Undermatched Weld Joint in High-Strength Steel. J. Offshore Mech. Arct. Eng. 1993, 115, 229–236. [Google Scholar] [CrossRef]

- Adziev, G.; Sedmak, A.; Sedmak, S.; Adziev, T.; Radakovic, Z. Crack tip fields effects on crack propagation through the heat affected zone in an overmatched welded joint. Fatigue Fract. Eng. Mater. Struct. 2023. [Google Scholar] [CrossRef]

- Rakin, M.; Medjo, B.; Gubeljak, N.; Sedmak, A. Micromechanical assessment of mismatch effects on fracture of high-strength low alloyed steel welded joints. Eng. Fract. Mech. 2013, 109, 221–235. [Google Scholar] [CrossRef]

- Sedmak, A. Computational fracture mechanics: An overview from early efforts to recent achievements. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 2438–2474. [Google Scholar] [CrossRef]

- Jovicic, R.; Sedmak, A.; Colic, K.; Milosevic, M.; Mitrovic, N. Evaluation of the local tensile properties of austenite ferrite welded joint. Chem. Listy 2011, 105, 754–757. [Google Scholar]

- Sedmak, A. The role of weldment interfaces in fracture mechanics parameters evaluation. In Proceedings of the 9th International Conference of Fracture (ICF9), Sidney, Australia, 1–5 April 1997; pp. 2345–2356. [Google Scholar]

- Adziev, G.; Sedmak, A.; Adžiev, T. Numerical analysis of tensile specimen fracture with crack in HAZ. Struct. Integr. Life 2008, 8, 107–113. [Google Scholar]

| Element | C | Si | Mn | P | S | Cu | Cr | Ni | Mo | V | B | Ceq | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SM 80P | 0.10 | 0.30 | 0.90 | 0.01 | 0.008 | 0.24 | 0.48 | 1.01 | 0.47 | 0.03 | 0.0016 | 0.5 | |

| Weld metal | MAW | 0.06 | 0.53 | 1.48 | 0.011 | 0.005 | - | 0.24 | 1.80 | 0.43 | - | - | - |

| SAW | 0.07 | 0.37 | 1.87 | 0.01 | 0.011 | - | 0.44 | 0.13 | 0.73 | - | - | - | |

| Material | Direction | Tensile Properties | ||

|---|---|---|---|---|

| Y.S. [MPa] | U.T.S. (MPa) | Elongation (%) | ||

| SM 80P | Rolling | Min. 755 | Min. 804 | Min. 24 |

| cross rolling | Min. 755 | Min. 795 | Min. 22 | |

| Weld metal | SMAW | 722 | 810 | 22 |

| SAW | 687 | 804 | 23 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sedmak, A.; Doncheva, E.; Medjo, B.; Rakin, M.; Milosevic, N.; Radu, D. Crack Size and Undermatching Effects on Fracture Behavior of a Welded Joint. Materials 2023, 16, 4858. https://doi.org/10.3390/ma16134858

Sedmak A, Doncheva E, Medjo B, Rakin M, Milosevic N, Radu D. Crack Size and Undermatching Effects on Fracture Behavior of a Welded Joint. Materials. 2023; 16(13):4858. https://doi.org/10.3390/ma16134858

Chicago/Turabian StyleSedmak, Aleksandar, Elisaveta Doncheva, Bojan Medjo, Marko Rakin, Nenad Milosevic, and Dorin Radu. 2023. "Crack Size and Undermatching Effects on Fracture Behavior of a Welded Joint" Materials 16, no. 13: 4858. https://doi.org/10.3390/ma16134858

APA StyleSedmak, A., Doncheva, E., Medjo, B., Rakin, M., Milosevic, N., & Radu, D. (2023). Crack Size and Undermatching Effects on Fracture Behavior of a Welded Joint. Materials, 16(13), 4858. https://doi.org/10.3390/ma16134858