Study of the TIG Welding Process of Thin-Walled Components Made of 17-4 PH Steel in the Aspect of Weld Distortion Distribution

Abstract

1. Introduction

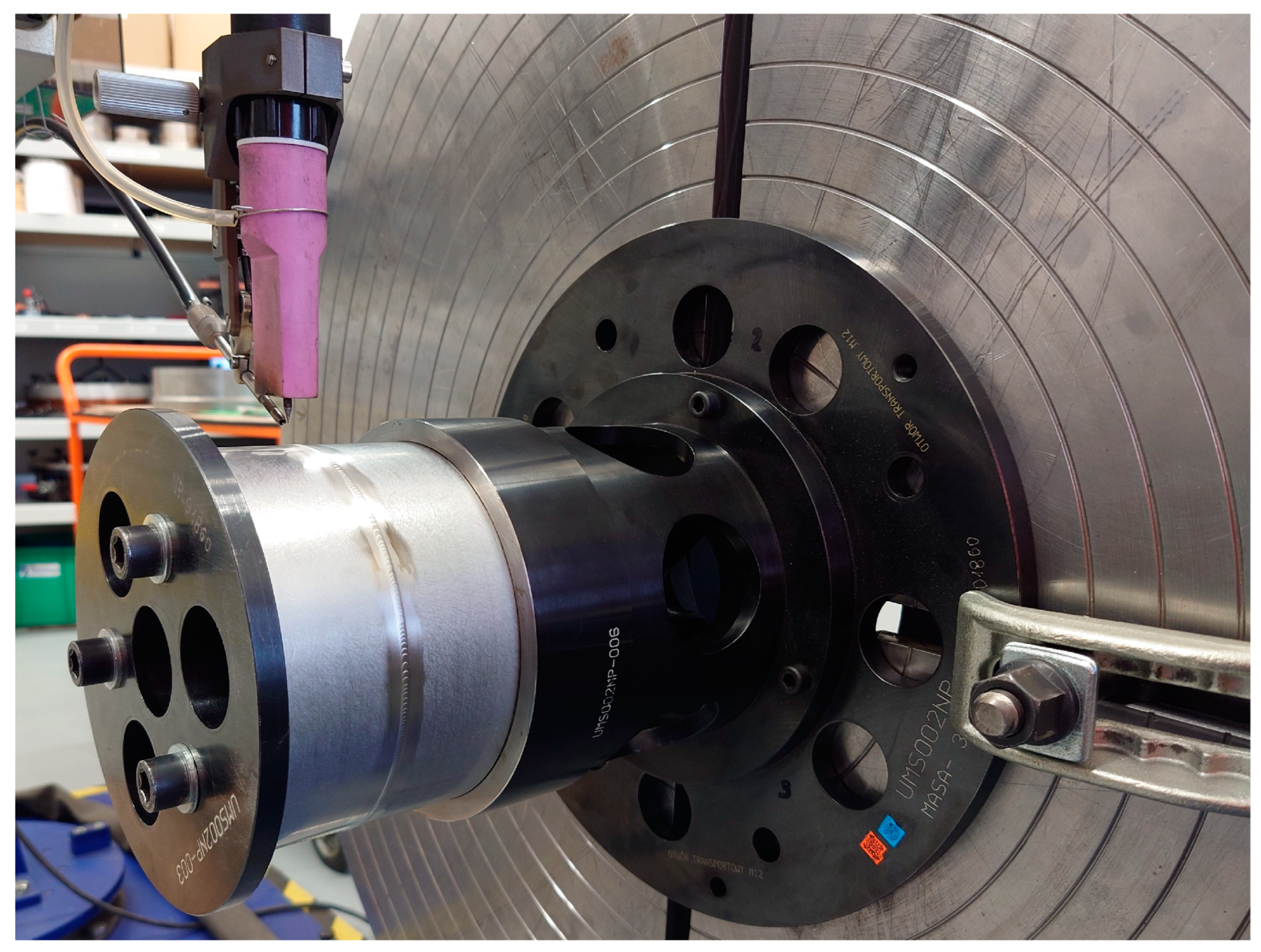

2. Materials and Methods

3. Results and Discussion

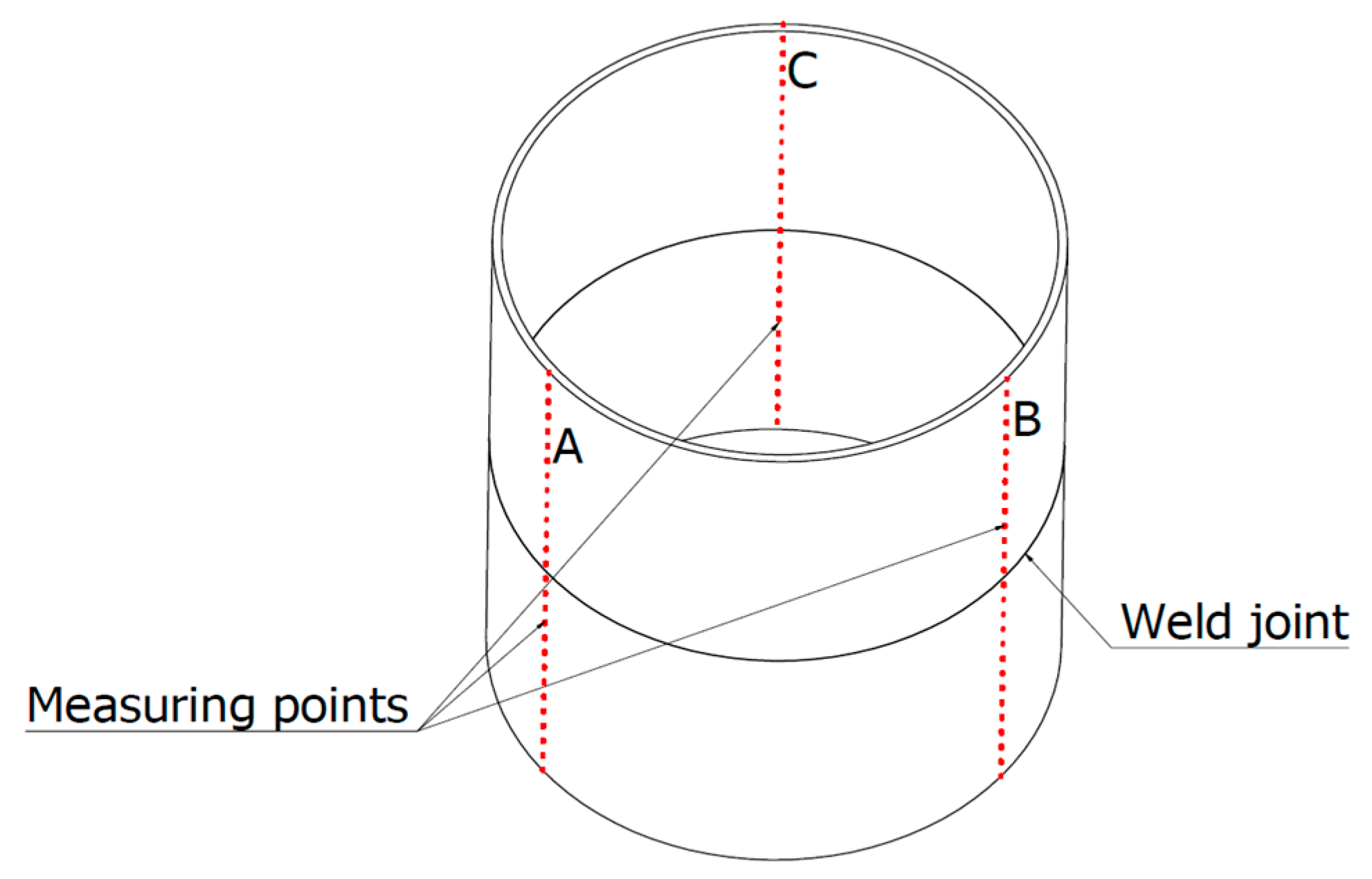

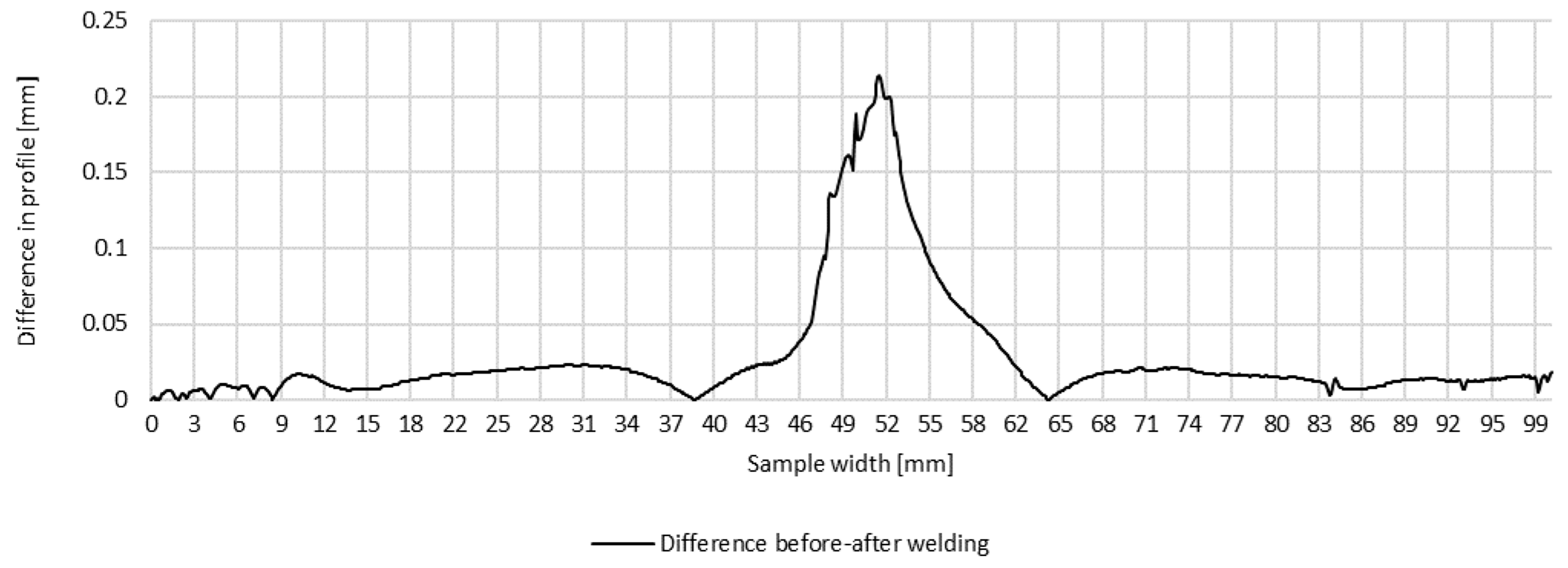

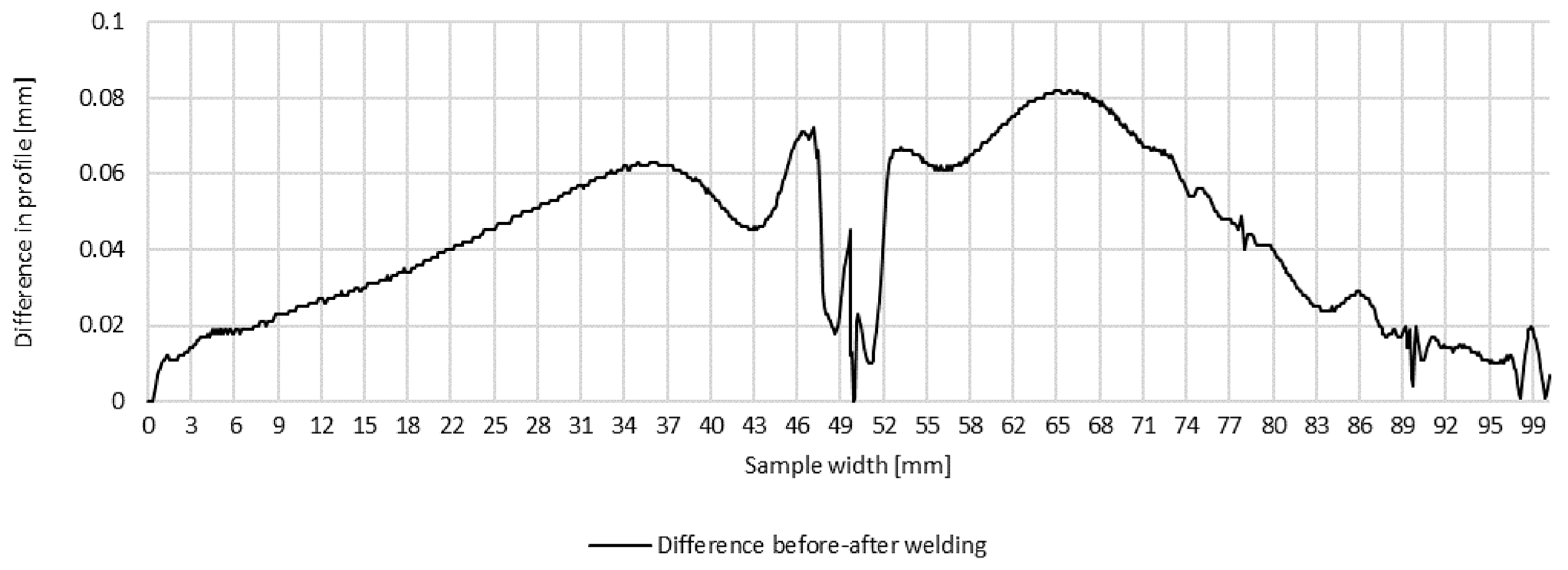

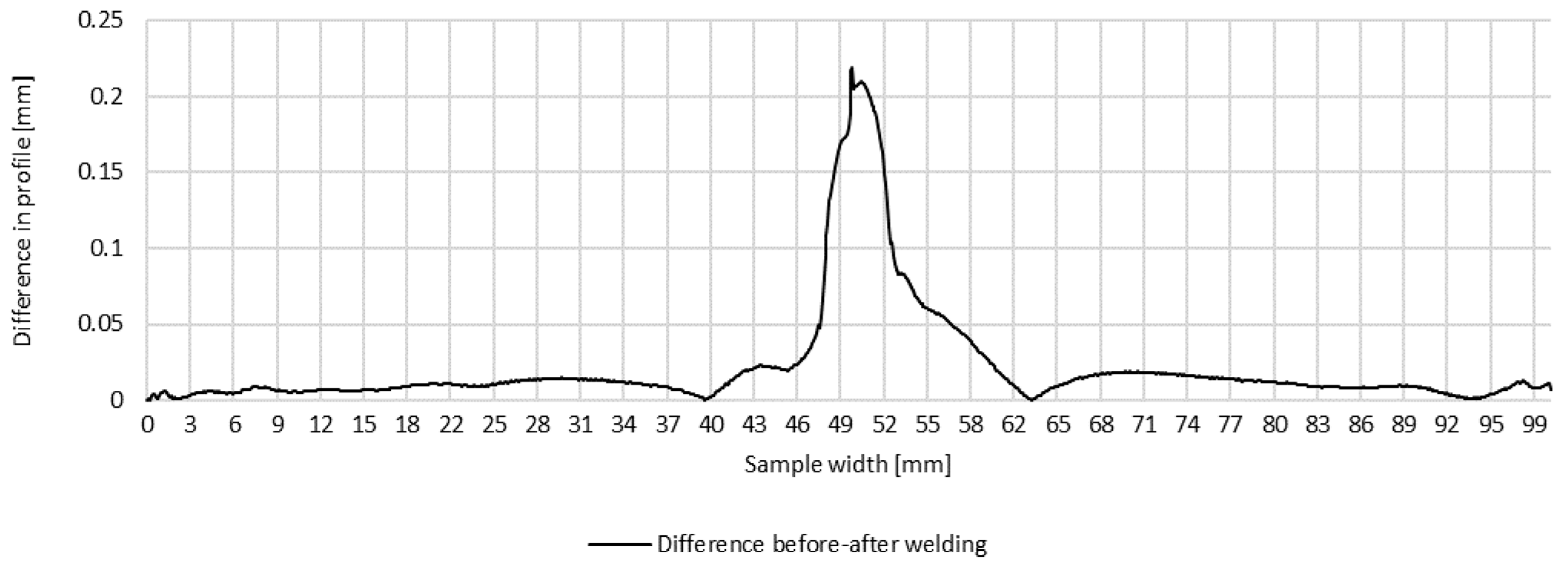

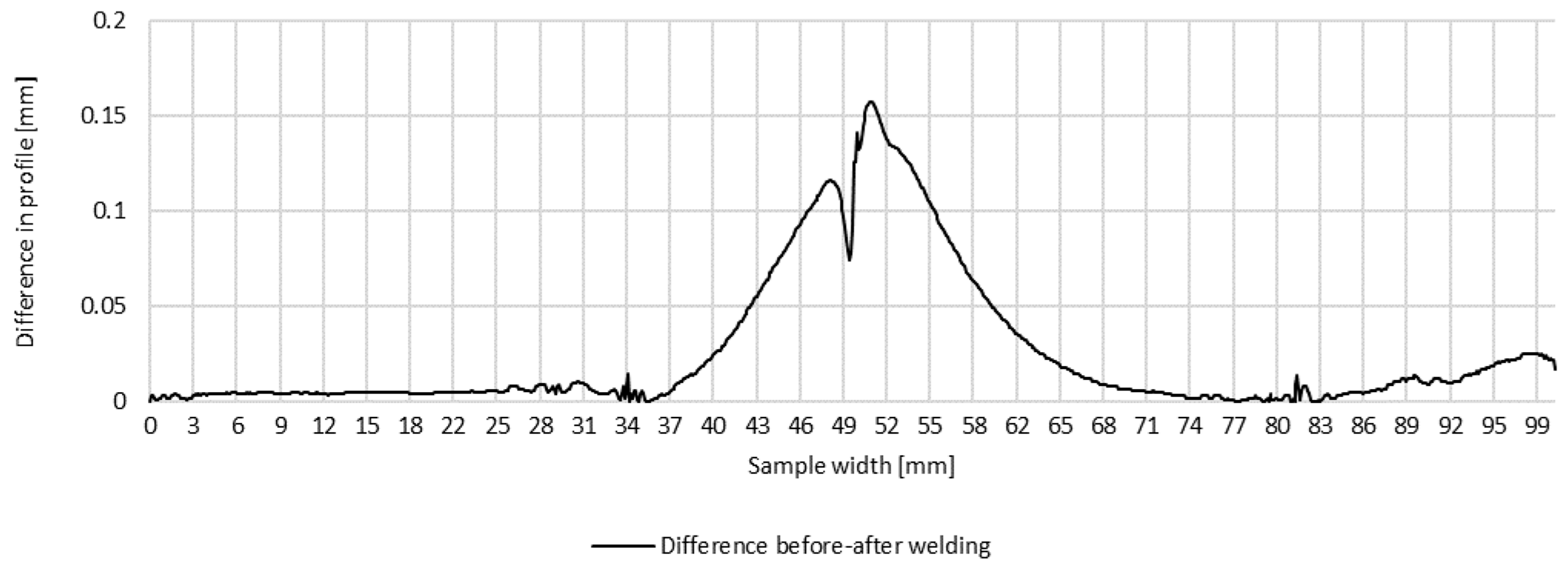

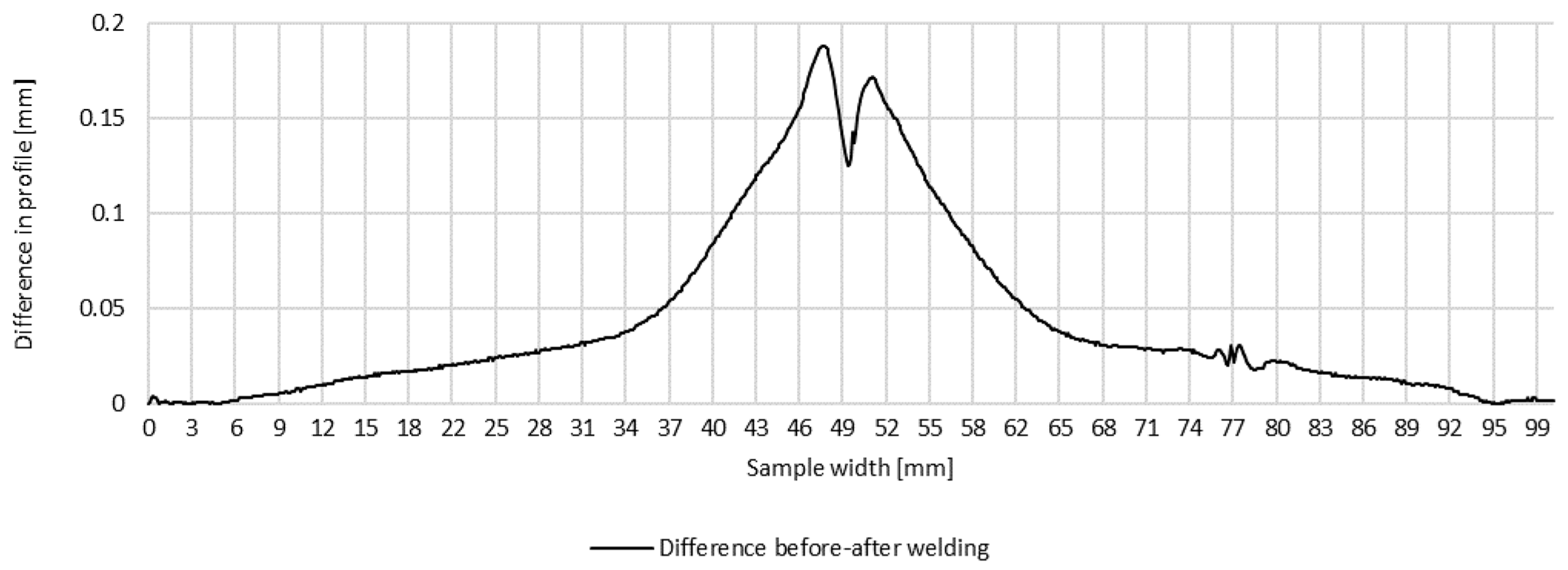

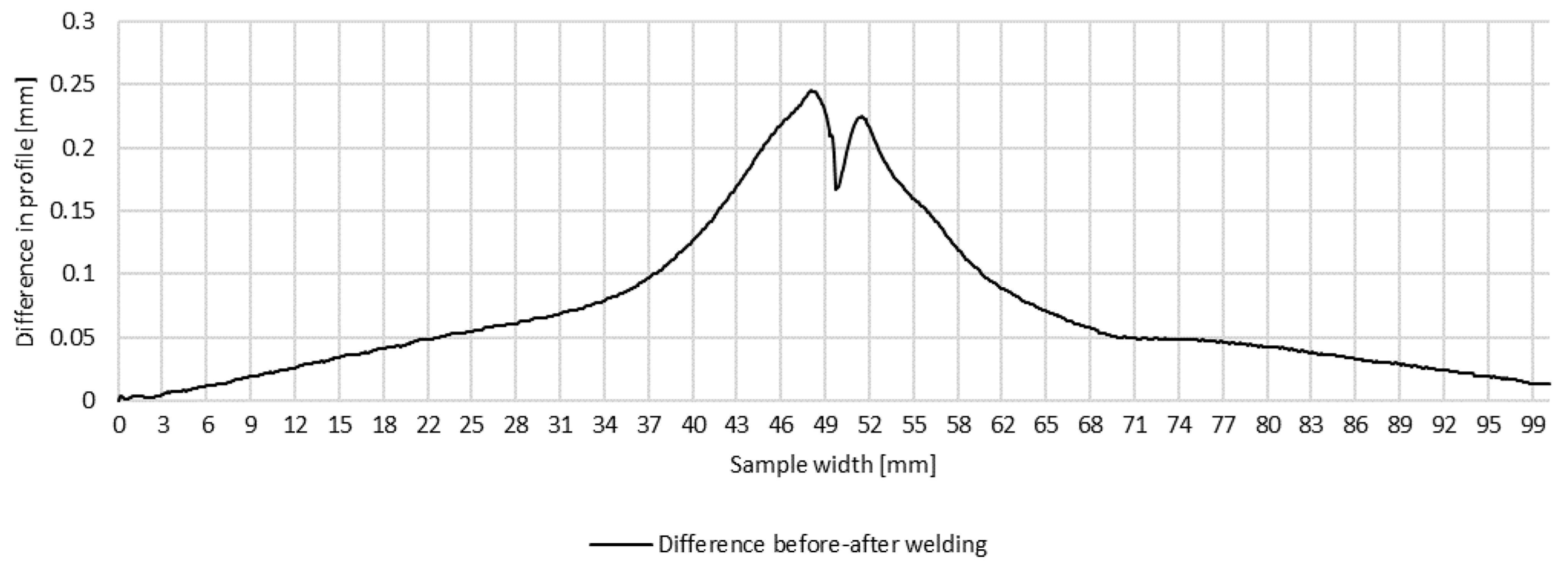

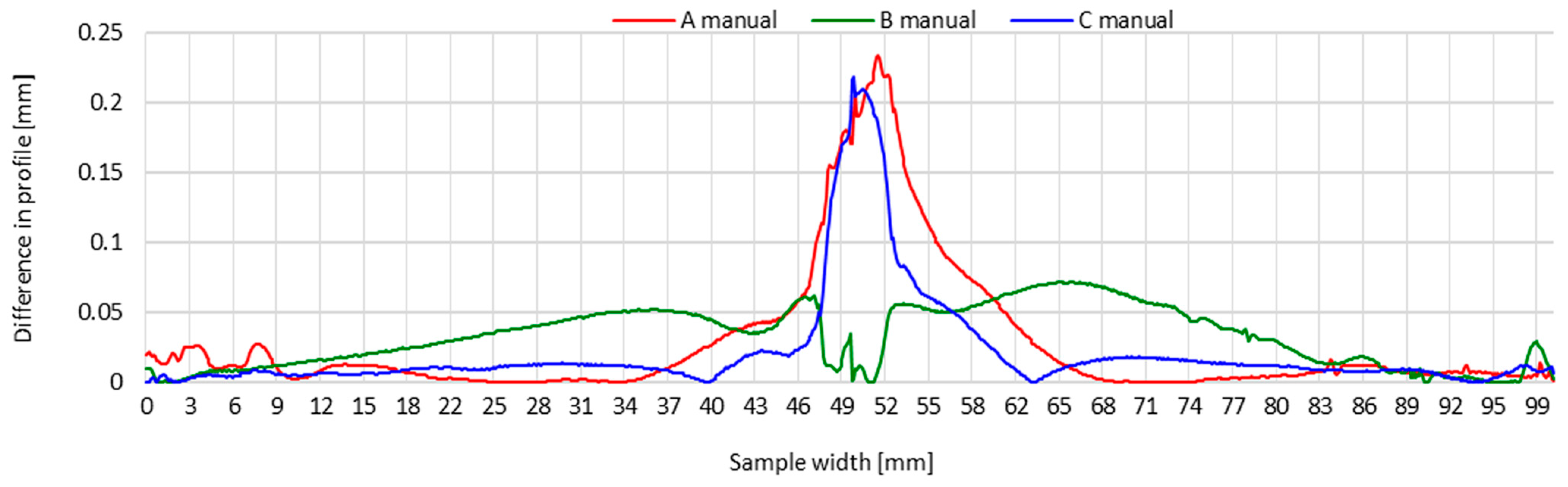

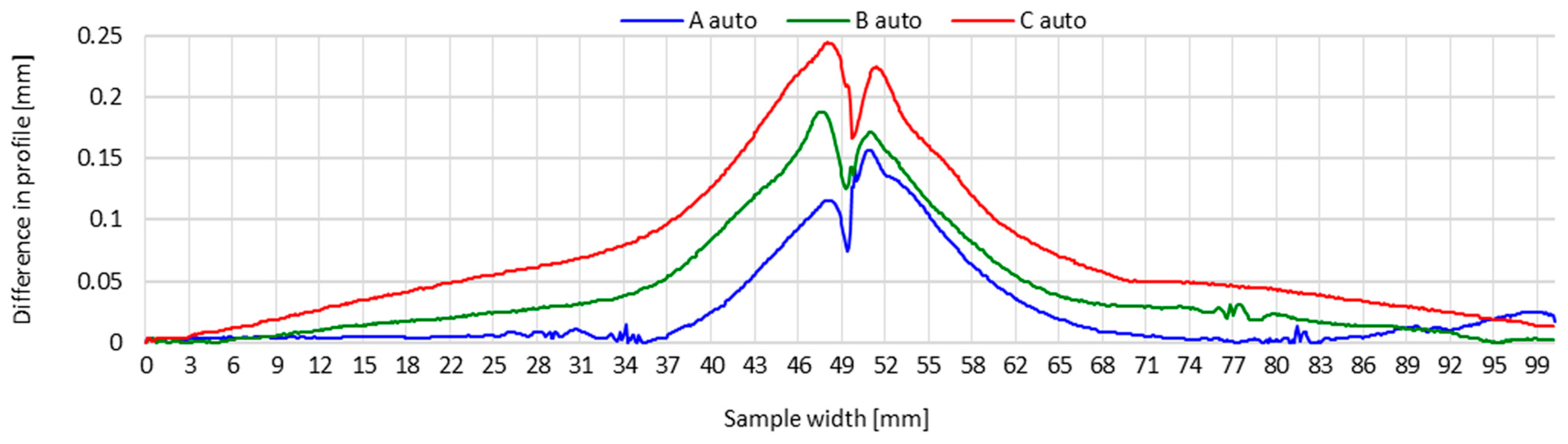

3.1. Measurements of Transverse Strain and Angular Strain

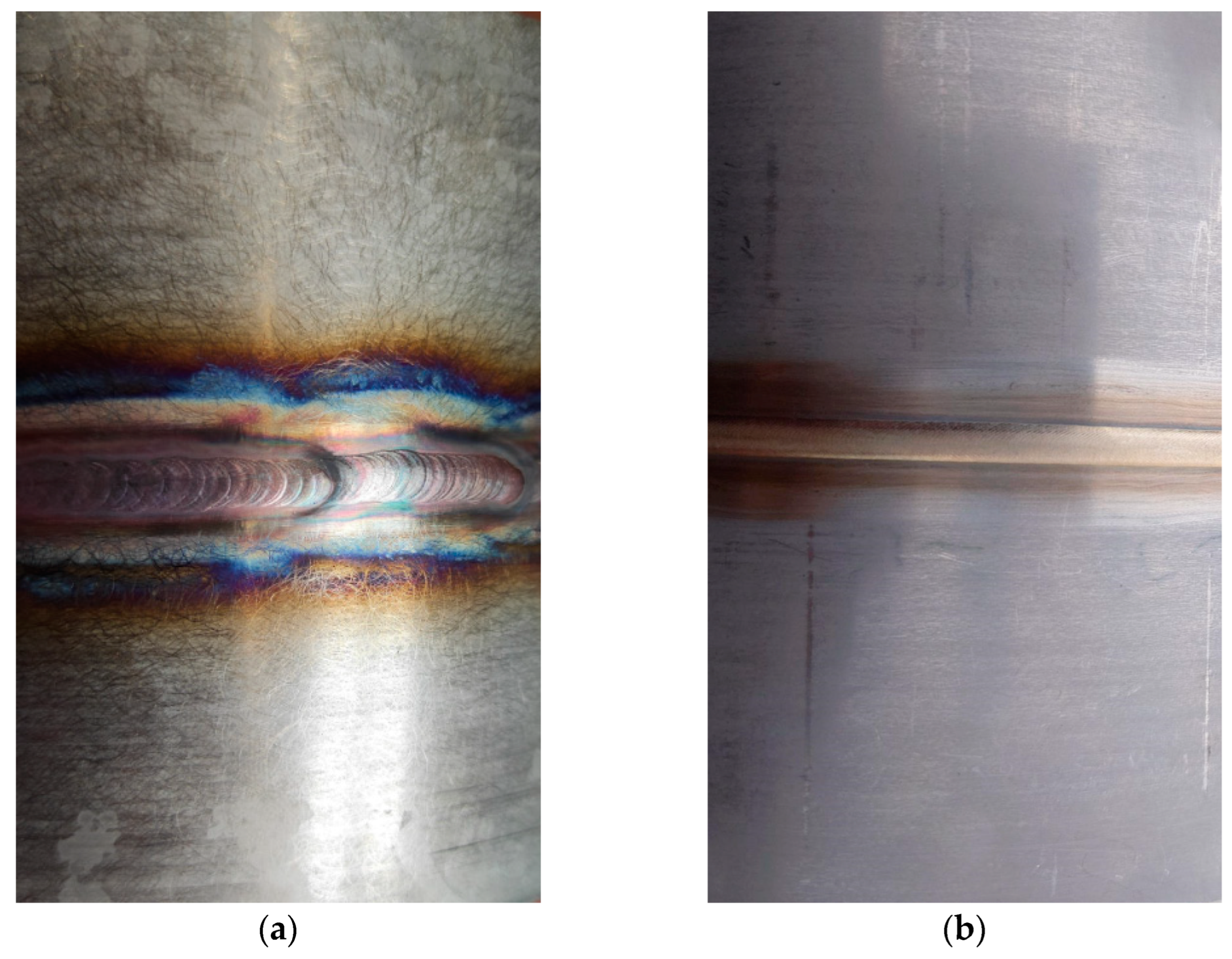

3.2. Visual Testing

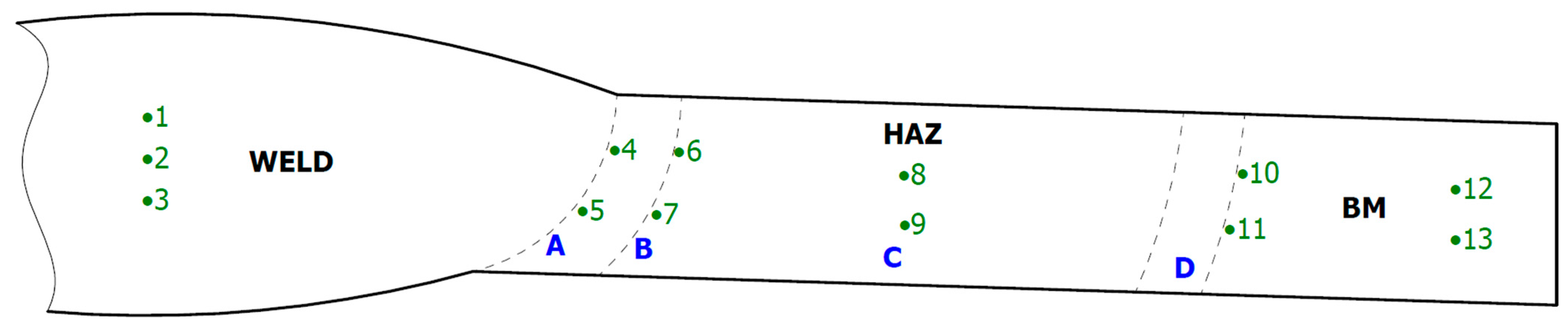

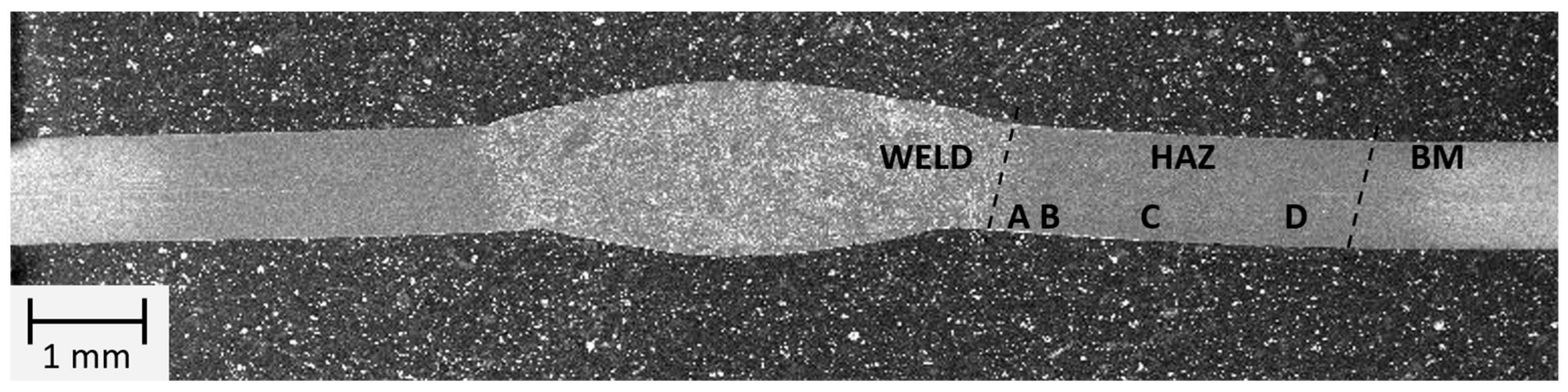

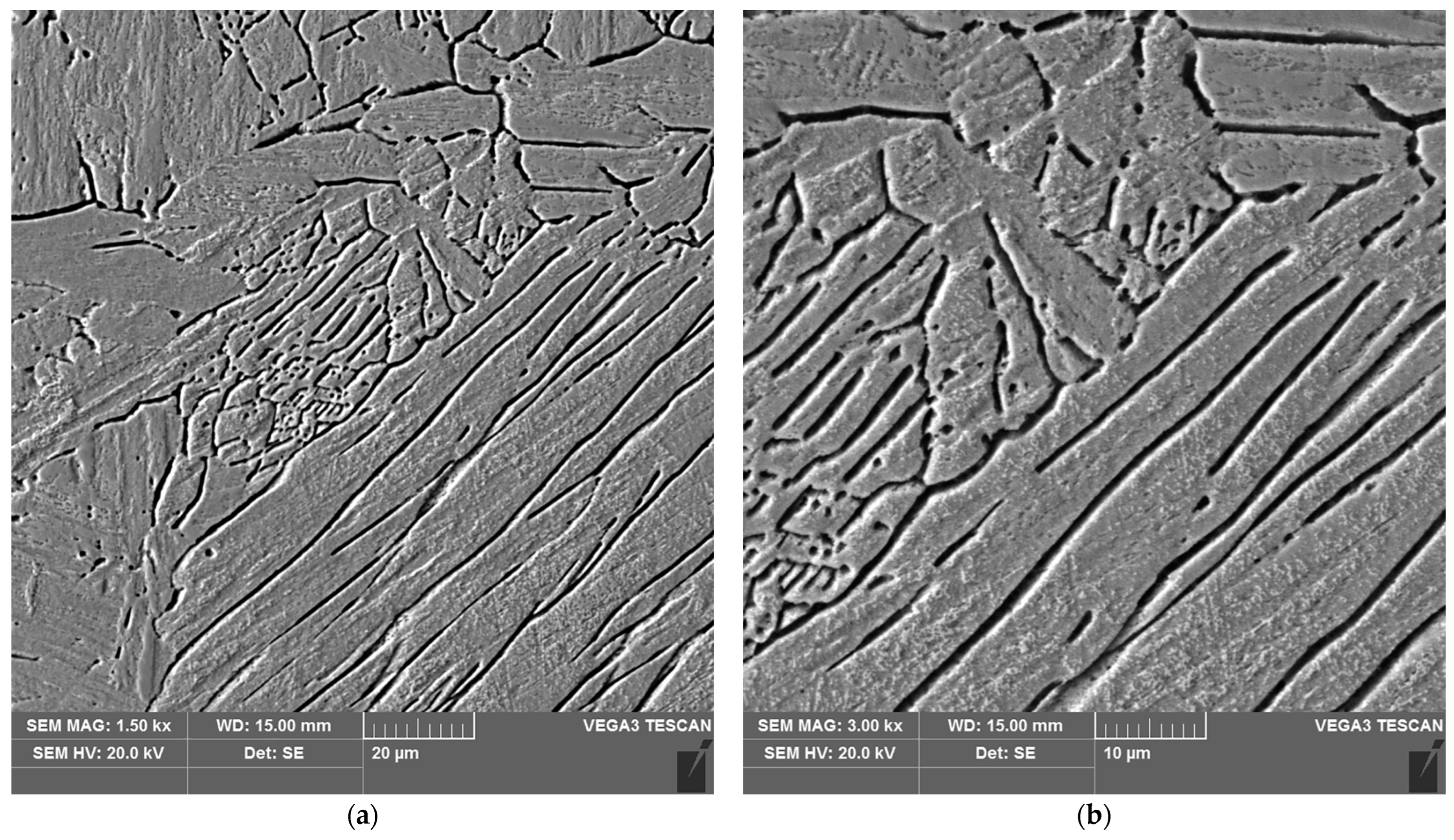

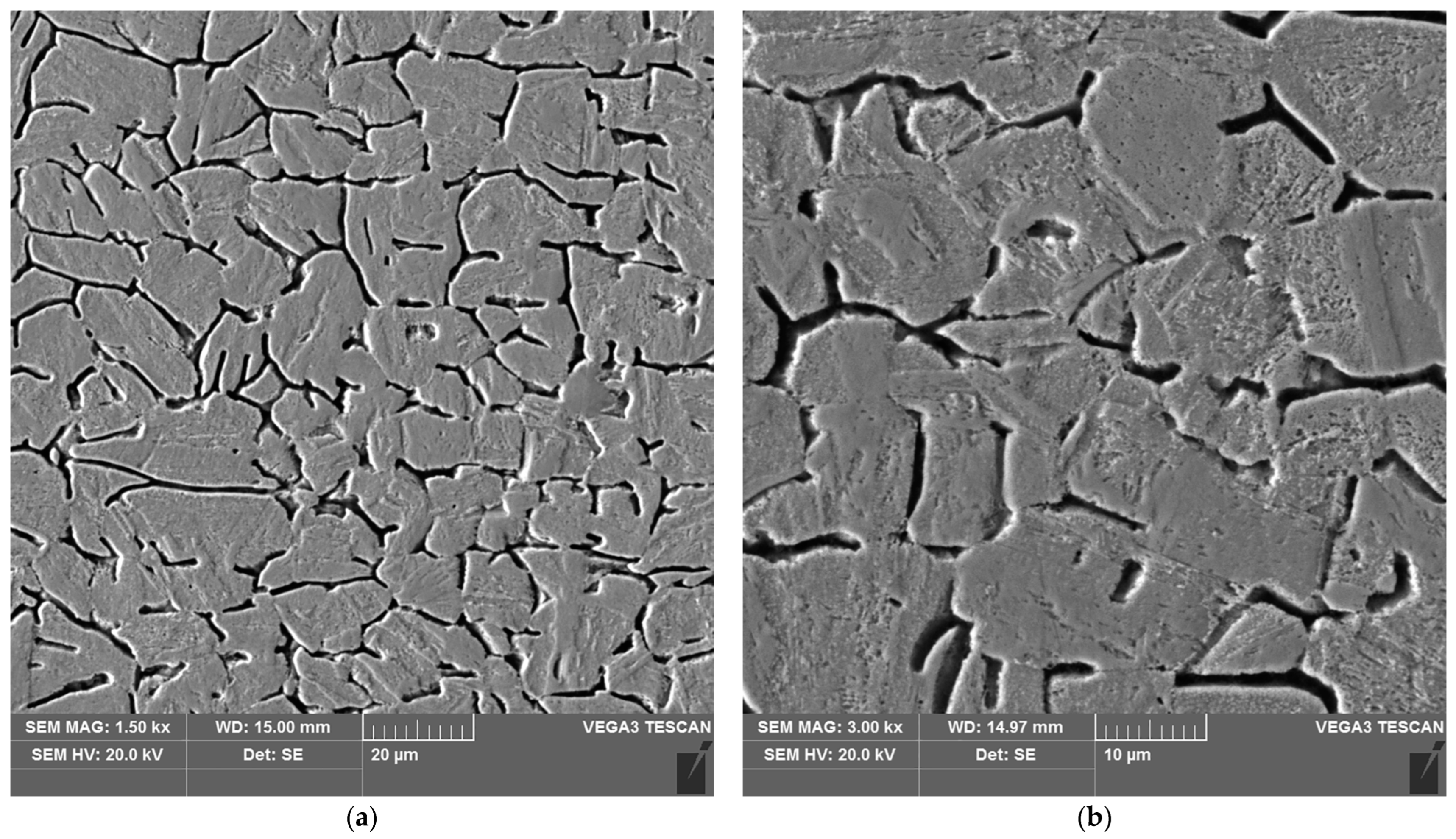

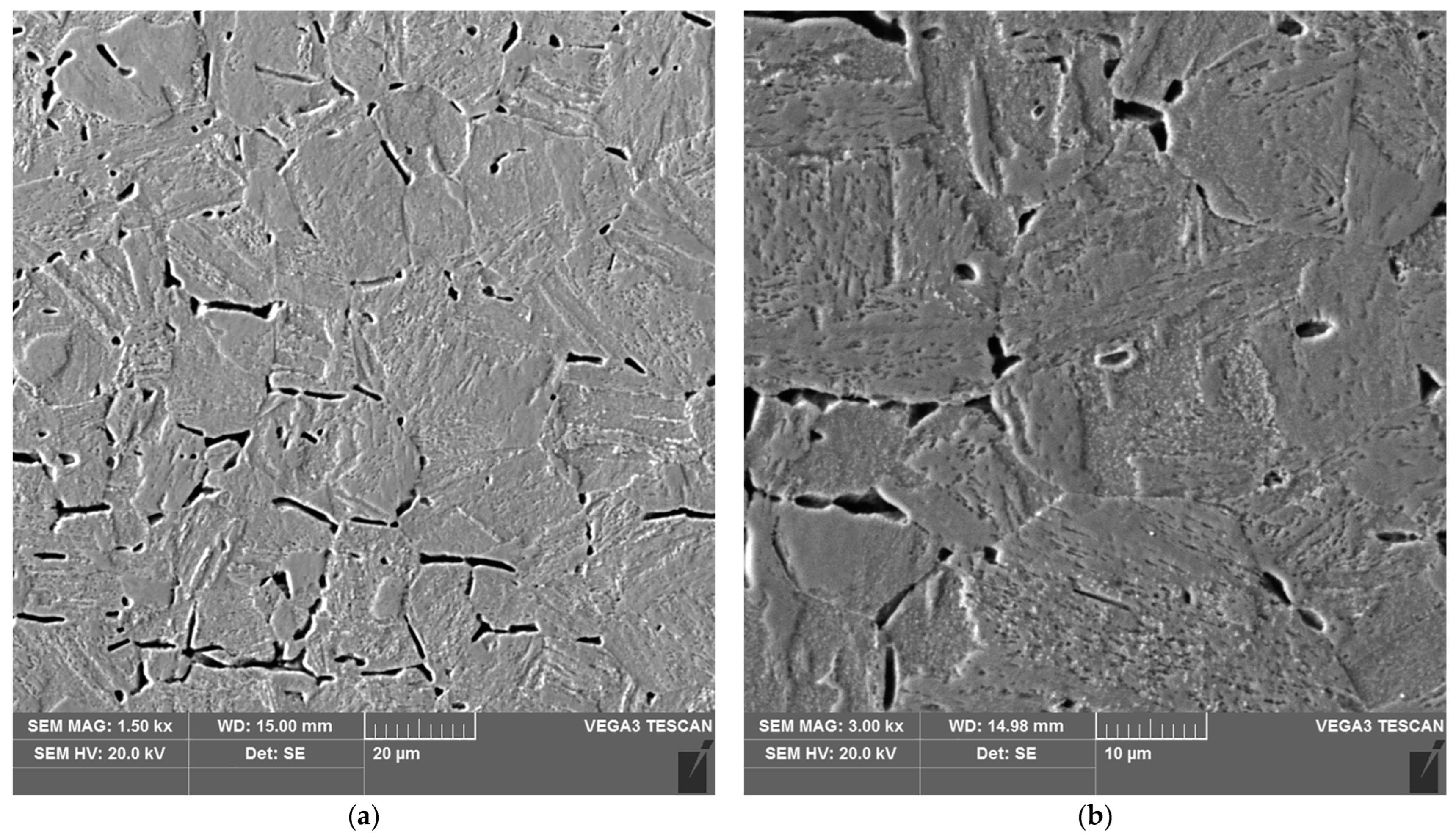

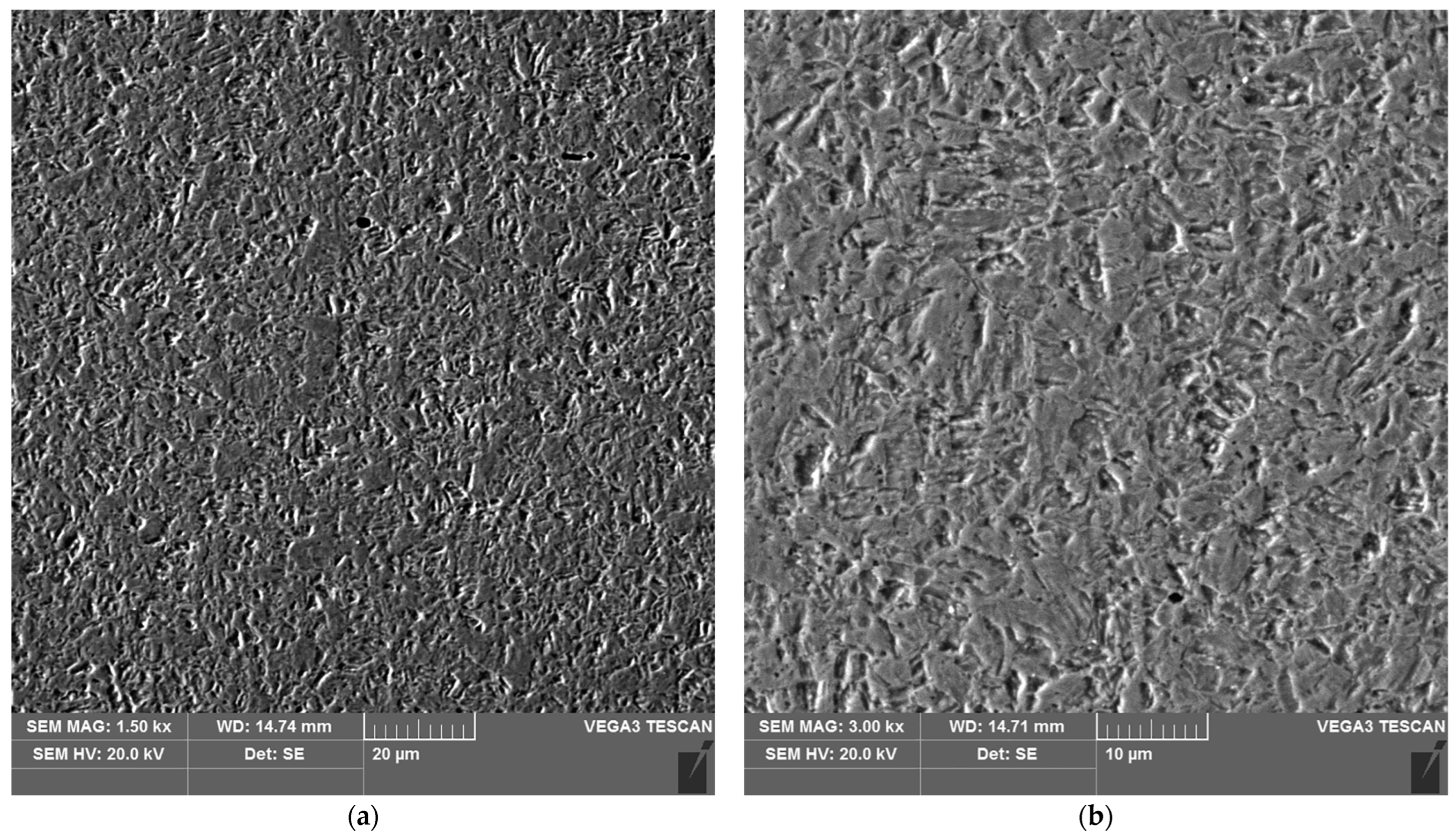

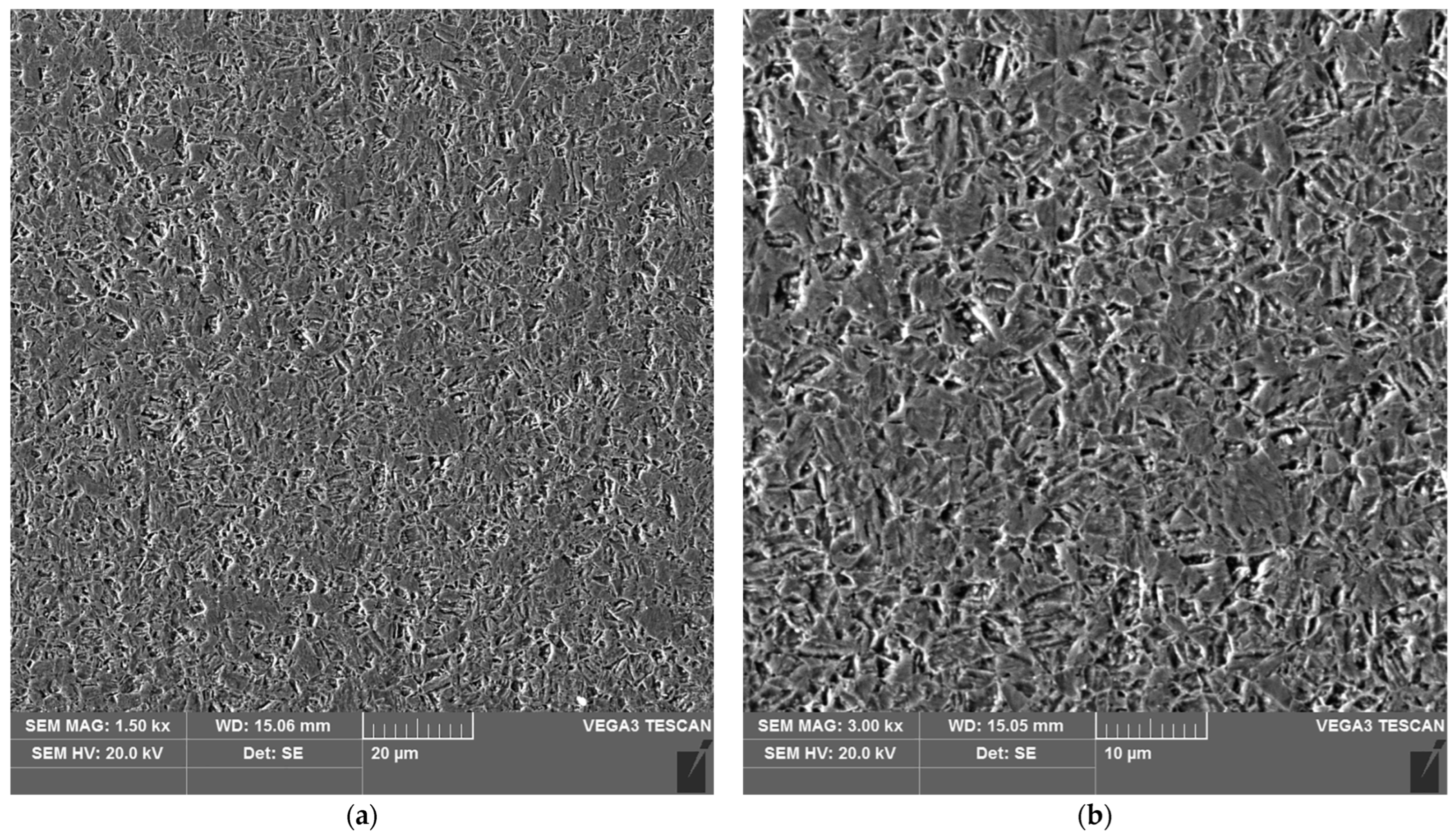

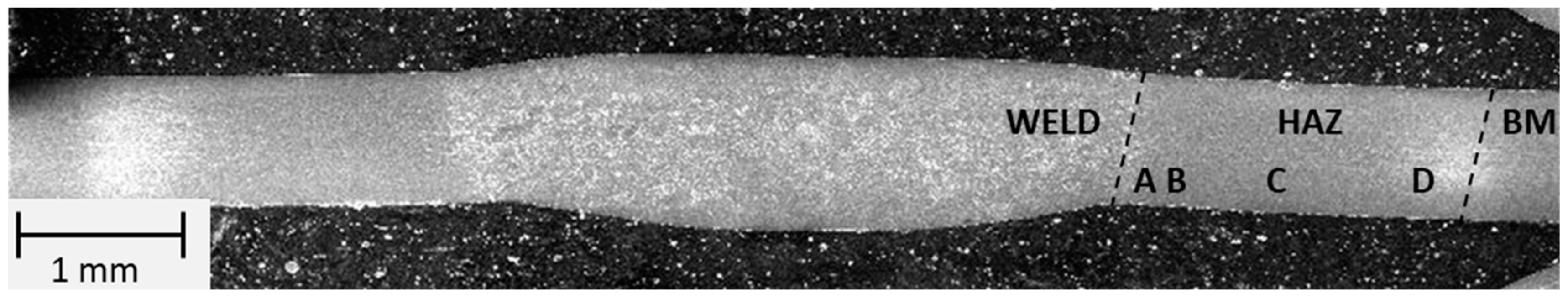

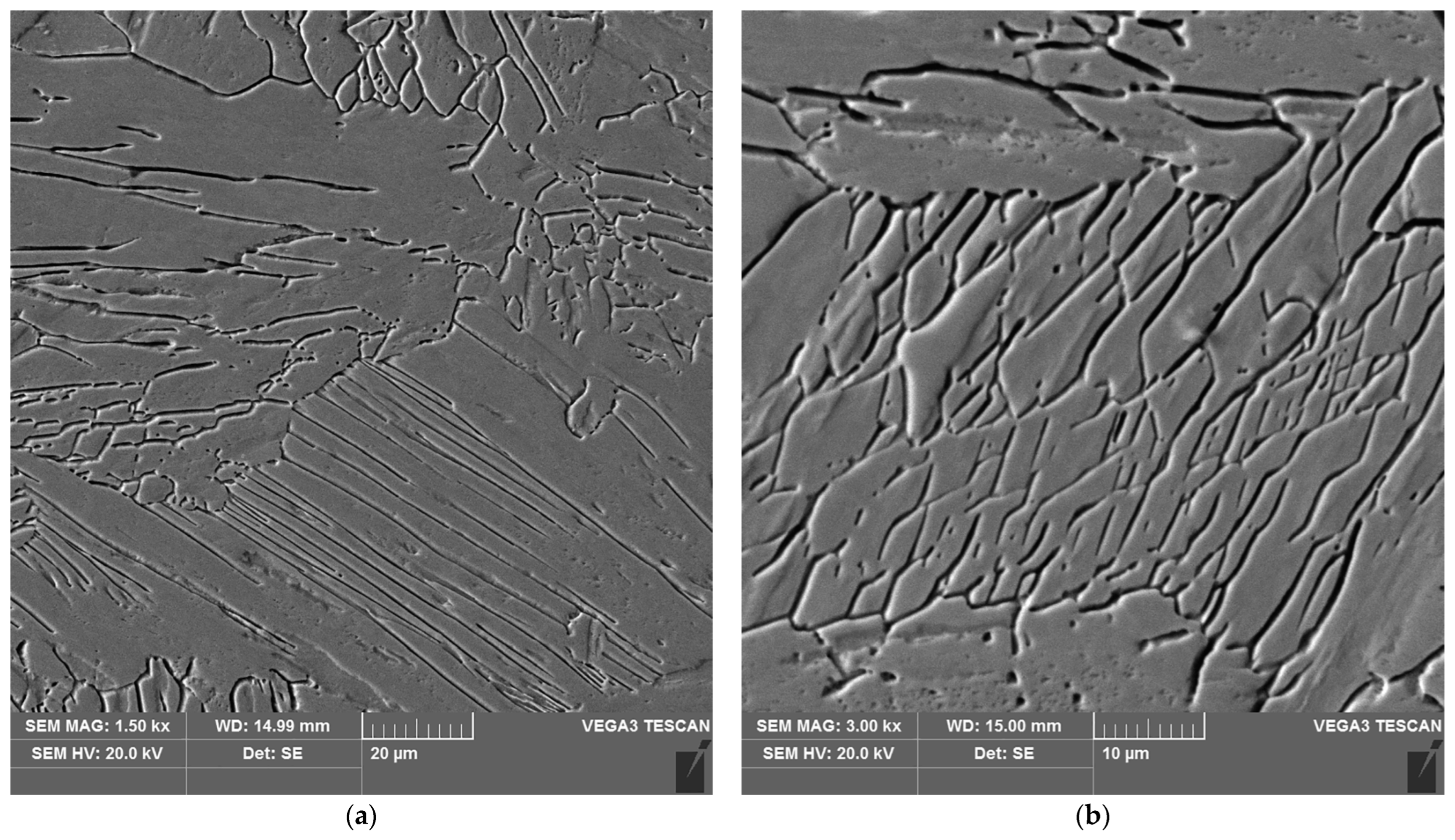

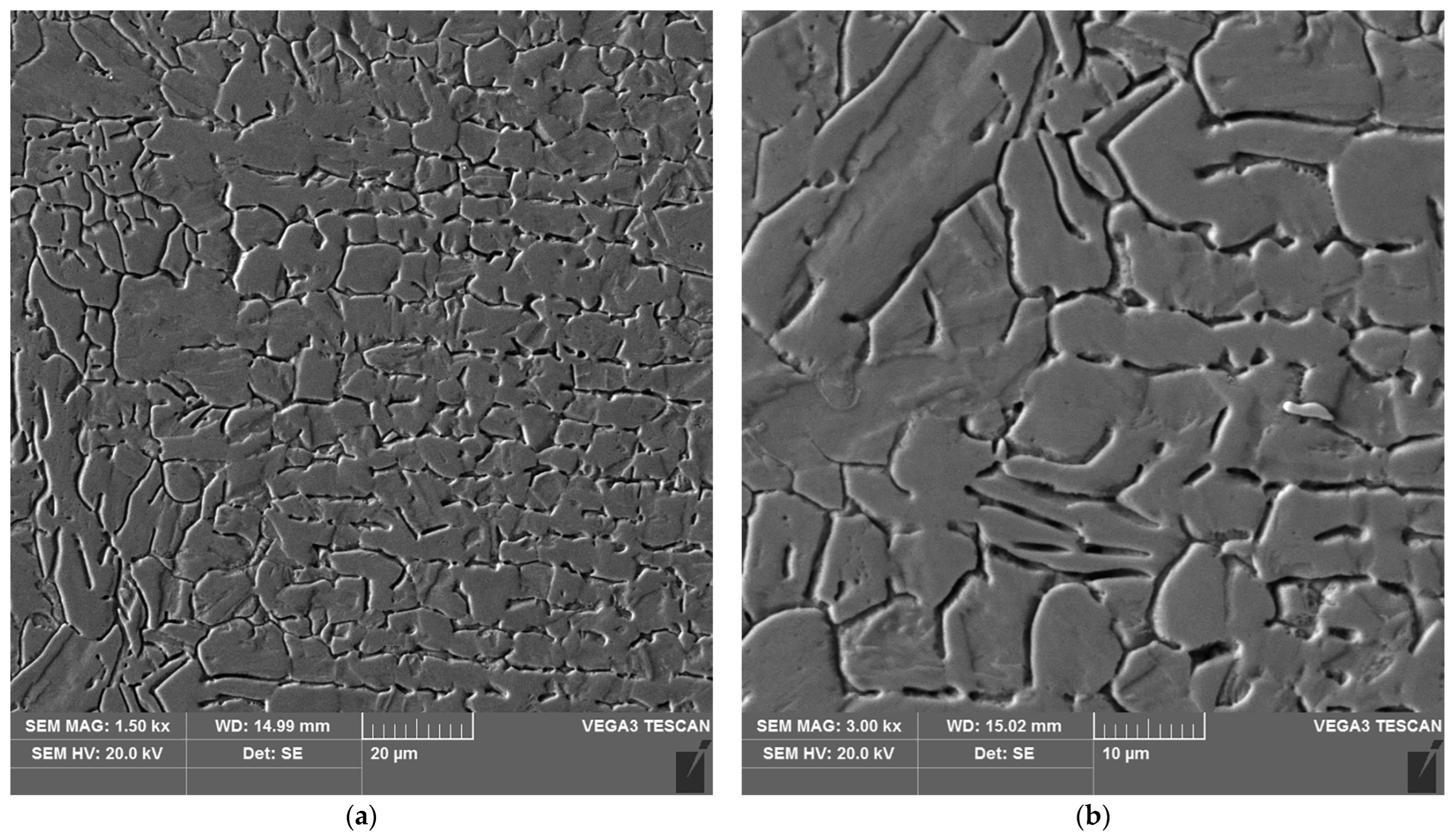

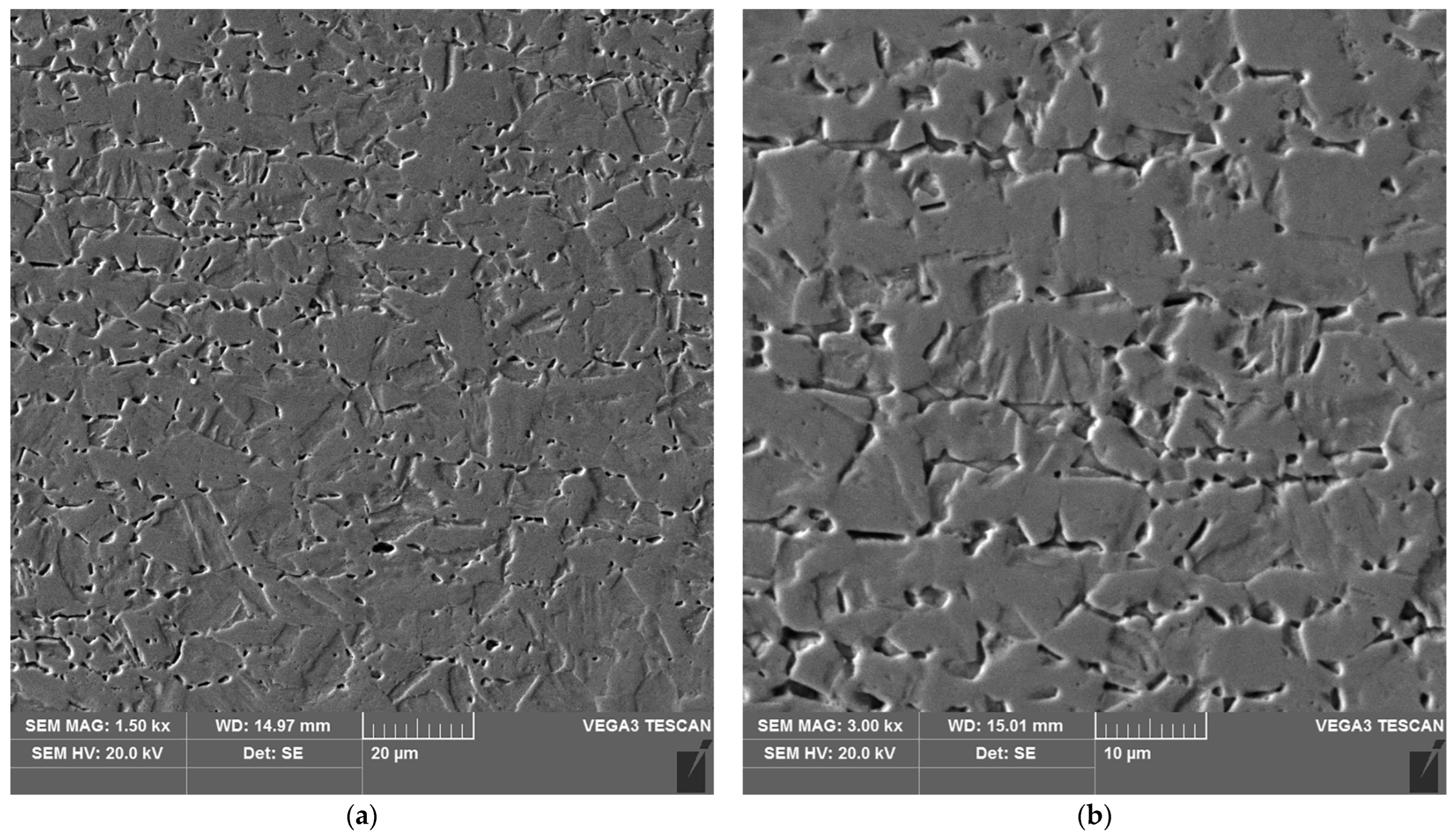

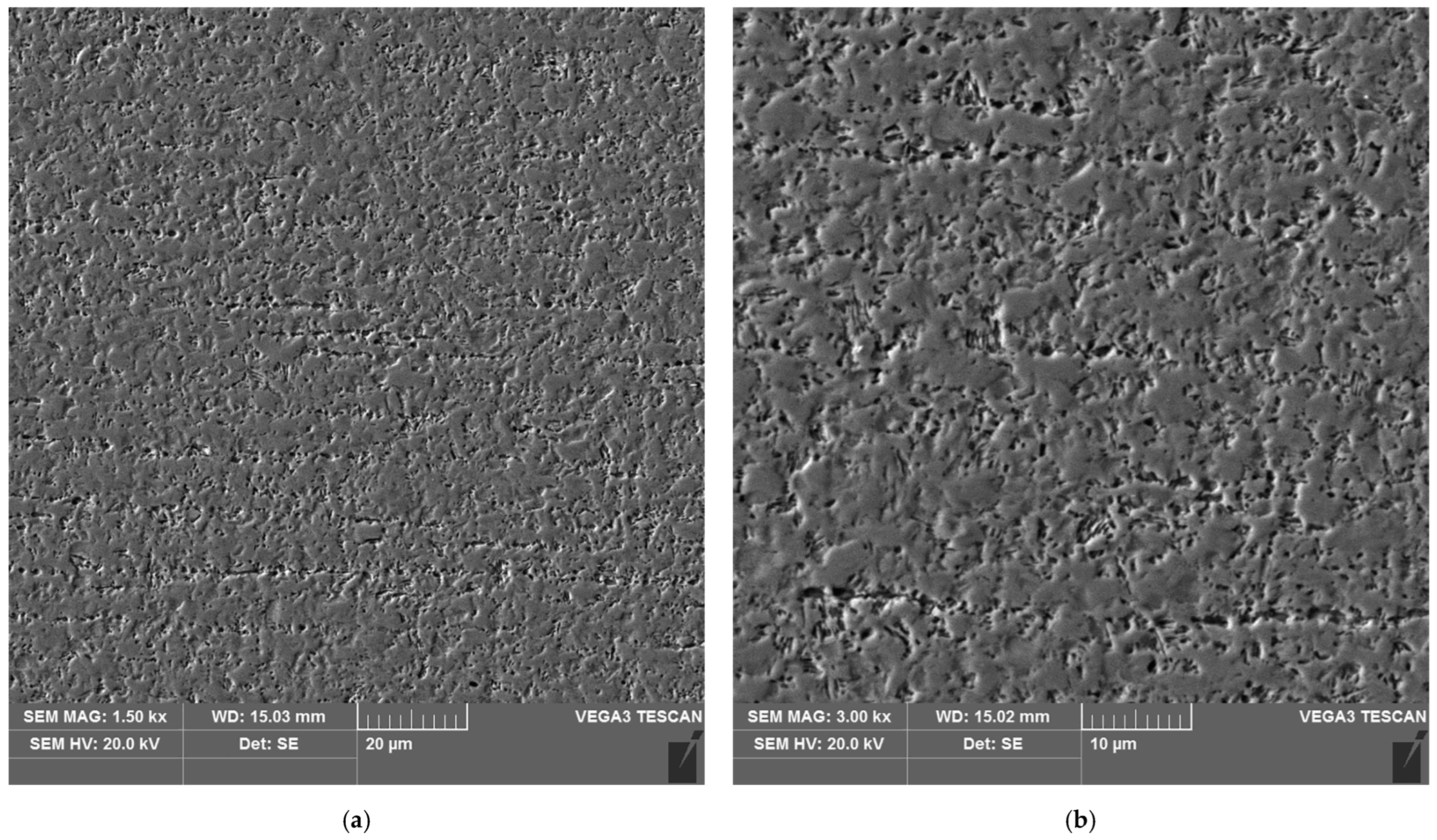

3.3. Macro- and Microstructure Testing

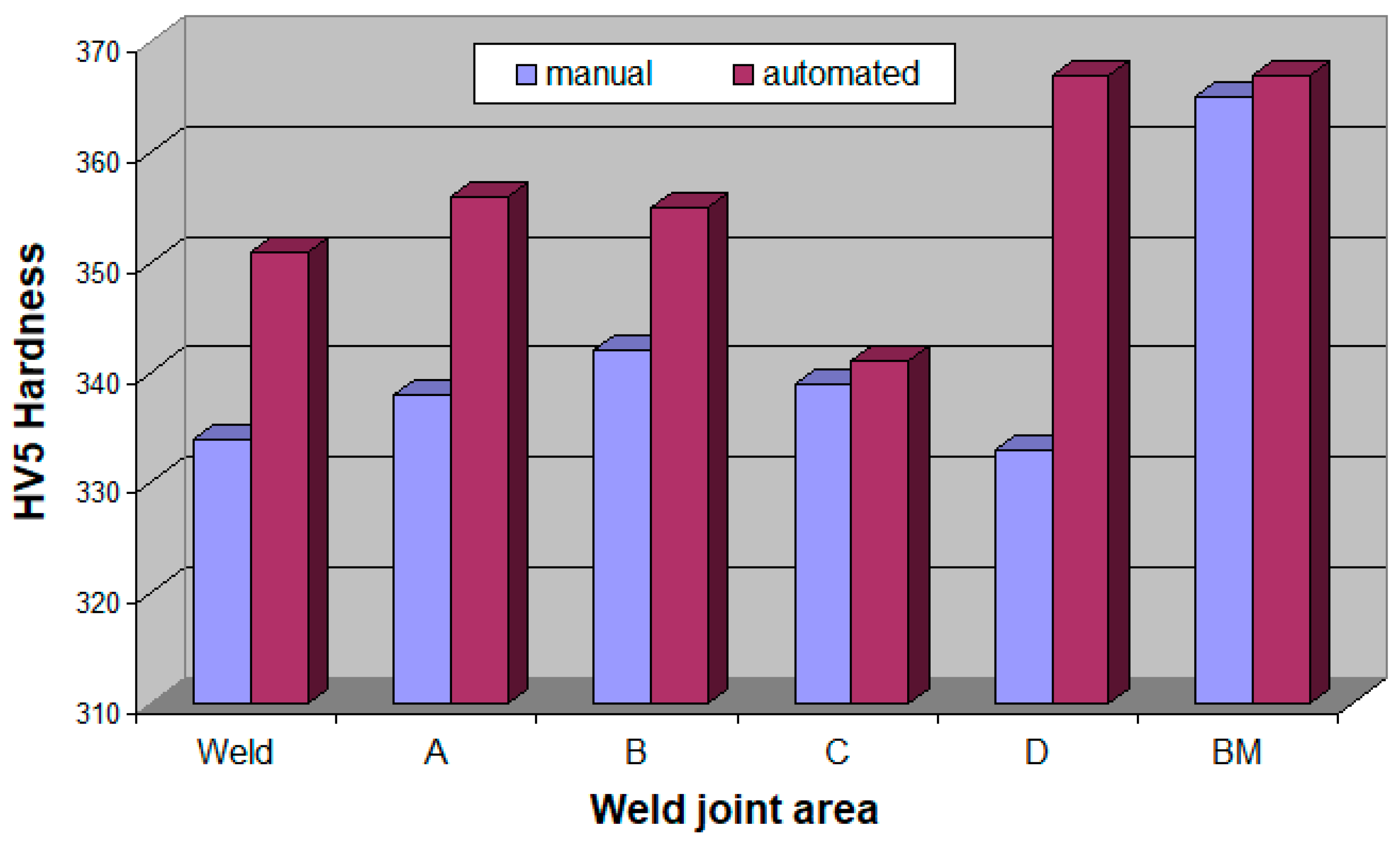

3.4. Hardness Measurements

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, H.; Zhan, M.; Zheng, Z.; Li, R.; Ma, F.; Cui, X.; Chen, S.; Lei, Y. Forming dependence on spin roller paths for thin-walled complex components from 2195 Al-Li alloy TWBs. Int. J. Adv. Manuf. Technol. 2022, 120, 3113–3122. [Google Scholar] [CrossRef]

- Zhang, C.; Li, H.; Yang, J.; Lu, H.; Su, P. Research on Model Slice and Forming Method of Thin-walled Parts. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2021; Volume 233. [Google Scholar] [CrossRef]

- Zhang, C.; Gümmer, V. High temperature heat exchangers for recuperated rotorcraft powerplants. Appl. Therm. Eng. 2019, 154, 548–561. [Google Scholar] [CrossRef]

- Abdolvand, H.; Faraji, G.; Besharati Givi, M.K.; Hashemi, R.; Riazat, M. Evaluation of the microstructure and mechanical properties of the ultrafine grained thin-walled tubes processed by severe plastic deformation. Met. Mater. Int. 2015, 21, 1068–1073. [Google Scholar] [CrossRef]

- Ma, J.; Atabaki, M.M.; Liu, W.; Pillai, R.; Kumar, B.; Vasudevan, U.; Kovacevic, R. Laser-based welding of 17-4 PH martensitic stainless steel in a tubular butt joint configuration with a built-in backing bar. Opt. Laser Technol. 2016, 82, 38–52. [Google Scholar] [CrossRef]

- Zhu, X.K.; Chao, Y.J. Effects of temperature-dependent material properties on welding simulation. Comput. Struct. 2002, 80, 967–976. [Google Scholar] [CrossRef]

- Lahtinen, T.; Vilaça, P.; Peura, P.; Mehtonen, S. MAG Welding Tests of Modern High Strength Steels with Minimum Yield Strength of 700 MPa. Appl. Sci. 2019, 9, 1031. [Google Scholar] [CrossRef]

- Haslberger, P.; Holly, S.; Ernst, W.; Schnitzer, R. Microstructure and mechanical properties of high-strength steel welding consumables with a minimum yield strength of 1100 MPa. J. Mater. Sci. 2018, 53, 6968–6979. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, P.; Fang, H.; Ma, N. Mitigation of residual stress and deformation induced by TIG welding in thin-walled pipes through external constraint. J. Mater. Res. Technol. 2021, 15, 4636–4651. [Google Scholar] [CrossRef]

- Rubio-Ramirez, C.; Giarollo, D.F.; Mazzaferro, J.E.; Mazzaferro, C.P. Prediction of angular distortion due GMAW process of thin-sheets Hardox 450® steel by numerical model and artificial neural network. J. Manuf. Process. 2021, 68, 1202–1213. [Google Scholar] [CrossRef]

- Mróz, M.; Czech, R.; Kupiec, B.; Dec, A.; Spólnik, M.; Rąb, P. Numerical and Physical Simulation of MAG Welding of Large S235JRC+N Steel Industrial Furnace Wall Panel. Materials 2023, 16, 2779. [Google Scholar] [CrossRef]

- Solfronk, P.; Sobotka, J.; Bukovská, Š.; Bradáč, J. Experimental and Numerical Analysis of the Residual Stresses in Seamed Pipe in Dependence on Welding and Metal Forming. Materials 2023, 16, 2256. [Google Scholar] [CrossRef]

- Tien, D.N. Numerical simulation for determination of temperature field and residual stress of stainless steel butt joints with and without clamping. Vietnam. J. Sci. Technol. 2022, 60, 713–725. [Google Scholar] [CrossRef] [PubMed]

- Ramos, H.M.E.; Tavers, S.M.O.; de Castro, P.M.S.T. Numerical modelling of welded T-joint configurations using SYSWELD. Sci. Technol. Mater. 2018, 30, 6–15. [Google Scholar] [CrossRef]

- Lima, T.R.; Tavares, S.M.O.; de Castro, P.M.S.T. Residual stress field and distortions resulting from welding processes: Numerical modelling using Sysweld. Ciênc. Tecnol. Mater. 2017, 29, 56–61. [Google Scholar] [CrossRef]

- Capriccioli, A.; Frosi, P. Multipurpose ANSYS FE procedure for welding processes simulation. Fusion Eng. Des. 2009, 84, 546–553. [Google Scholar] [CrossRef]

- Unni, A.K.; Vasudevan, M. Computational fluid dynamics simulation of hybrid laser-MIG welding of 316 LN stainless steel using hybrid heat source. Int. J. Therm. Sci. 2023, 185, 108042. [Google Scholar] [CrossRef]

- Satyanarayana, G.; Narayana, K.L.; Rao, B.N. Incorporation of Taguchi approach with CFD simulations on laser welding of spacer grid fuel rod assembly. Mater. Sci. Eng. B 2021, 269, 115182. [Google Scholar] [CrossRef]

- Chou, A.P.; Shi, G.; Liu, C.; Zhou, L. Residual stress and compression buckling of large welded equal-leg steel angles. J. Constr. Steel Res. 2023, 201, 107756. [Google Scholar] [CrossRef]

- Saternus, Z.; Piekarska, W.; Kubiak, M.; Domański, T.; Goszczyńska-Króliszewska, D. Numerical estimation of temperature field in a laser welded butt joint made of dissimilar materials. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 157, p. 02043. [Google Scholar] [CrossRef]

- Adewuyi, R.A.; Aweda, J.O. Modeling and simulation of welding temperature fields in cr-mo steel bar. Eur. J. Mater. Sci. Eng. 2021, 6, 3–18. [Google Scholar] [CrossRef]

- Horajski, P.; Bohdal, L.; Kukielka, L.; Patyk, R.; Kaldunski, P.; Legutko, S. Advanced Structural and Technological Method of Reducing Distortion in Thin-Walled Welded Structures. Materials 2021, 14, 504. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Li, Y.; Ma, X.; Zhang, X.; Fu, D.; Yan, Q. Study on Welding Deformation and Optimization of Fixture Scheme for Thin-Walled Flame Cylinder. Materials 2022, 15, 6418. [Google Scholar] [CrossRef]

- Stanisz, D.; Machniewicz, T.; Parzych, S.; Jeż, G.; Dvorkin, L.; Hebda, M. Microstructure and Mechanical Properties of Joints Depending on the Process Used. Materials 2022, 15, 5171. [Google Scholar] [CrossRef]

- Machniewicz, T.; Nosal, P.; Korbel, A.; Hebda, M. Effect of FSW Traverse Speed on Mechanical Properties of Copper Plate Joints. Materials 2020, 13, 1937. [Google Scholar] [CrossRef]

- Balajaddeh, M.B.; Naffakh-Moosavy, H. Pulsed Nd: YAG laser welding of 17-4 PH stainless steel: Microstructure, mechanical properties, and weldability investigation. Opt. Laser Technol. 2019, 119, 105651. [Google Scholar] [CrossRef]

- Tuz, L.; Sokołowski, Ł.; Stano, S. Effect of Post-Weld Heat Treatment on Microstructure and Hardness of Laser Beam Welded 17-4 PH Stainless Steel. Materials 2023, 16, 1334. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.M. Making aviation green. Adv. Manuf. 2013, 1, 42–49. [Google Scholar] [CrossRef]

- Federal Aviation Administration. Airplane Flying Handbook; Skyhorse Publishing Inc.: Oklahoma City, OK, USA, 2011. [Google Scholar]

- Gurrappa, I.; Yashwanth, I.V.S. Design and Development of Smart Coatings for Gas Turbines. In Gas Turbines; Intech Open: Rijeka, Croatia, 2010; pp. 65–78. [Google Scholar]

- Uliasz, M.; Ornat, A.; Burghardt, A.; Muszyńska, M.; Szybicki, D.; Kurc, K. Automatic Evaluation of the Robotic Production Process for an Aircraft Jet Engine Casing. Appl. Sci. 2022, 12, 6443. [Google Scholar] [CrossRef]

- Biao, Z.; Wenfeng, D.; Zhongde, S.; Jun, W.; Changfeng, Y.; Zhengcai, Z.; Jia, L.; Shihong, X.; Yue, D.; Xiaowei, T.; et al. Collaborative manufacturing technologies of structure shape and surface integrity for complex thin-walled components of aero-engine: Status, challenge and tendency. Chin. J. Aeronaut. 2023. [Google Scholar] [CrossRef]

- Pfennig, A.; Kranzmann, A. Corrosion and Fatigue of Heat Treated Martensitic Stainless Steel 1.4542 Used for Geothermal Applications. Matter. Int. J. Sci. Technol. 2019, 5, 138–158. [Google Scholar] [CrossRef]

- Wu, J.H.; Lin, C.K. Tensile and fatigue properties of 17-4 PH stainless steel at high temperatures. Metall. Mater. Trans. A 2002, 33, 1715–1724. [Google Scholar] [CrossRef]

- Arisoy, C.F.; Başman, G.; Şeşen, M.K. Failure of a 17-4 PH stainless steel sailboat propeller shaft. Eng. Fail. Anal. 2003, 10, 711–717. [Google Scholar] [CrossRef]

- Ziewiec, A.; Czech, J.; Tasak, E. Welded Joint Cracking in Martensitic Stainless Steel Precipitation-Sthregthened with Copper. Arch. Metall. Mater. 2012, 57, 1055–1061. [Google Scholar] [CrossRef]

- Ponnusamy, P.; Sharma, B.; Masood, S.H.; Rashid, R.R.; Rashid, R.; Palanisamy, S.; Ruan, D. A study of tensile behavior of SLM processed 17-4 PH stainless steel. Mater. Today Proc. 2021, 45, 4531–4534. [Google Scholar] [CrossRef]

- Trzepieciński, T.; Pieja, T.; Malinowski, T.; Smusz, R.; Motyka, M. Investigation of 17-4 PH steel microstructure and conditions of elevated temperature forming of turbine engine strut. J. Mater. Process. Technol. 2018, 252, 191–200. [Google Scholar] [CrossRef]

- Bhaduri, A.K.; Sujith, S.; Srinivasan, G.; Gill, T.P.S.; Mannan, S.L. Optimized postweld heat treatment procedures for 17-4 PH stainless steels. Weld. J. 1995, 74, 153. [Google Scholar]

- Hosseini Farzaneh, S.M.; Belbasi, M. Effects of Shielding Gas on the Depth, Width and Hardness of 17-4 PH Stainless Steel during TIG Welding. J. Environ. Friendly Mater. 2020, 4, 25–29. [Google Scholar]

- Prabhakar, A.S.; Agilan, M.; Venkateswaran, T.; Sivakumar, D.; Venkatakrishnan, P.G. Effect of Post Weld Heat Treatment on Mechanical Properties of 17-4-PH Stainless Steel Welds. Mater. Werkst. 2022, 53, 947. [Google Scholar] [CrossRef]

- Mousavi, S.A.; Sufizadeh, A.R. Metallurgical investigations of pulsed Nd: YAG laser welding of AISI 321 and AISI 630 stainless steels. Mater. Des. 2009, 30, 3150–3157. [Google Scholar] [CrossRef]

- Liu, W.; Ma, J.; Atabaki, M.M.; Pillai, R.; Kumar, B.; Vasudevan, U.; Sreshta, H.; Kovacevic, R. Hybrid laser-arc welding of 17-4 PH martensitic stainless steel. Lasers Manuf. Mater. Process. 2015, 2, 74–90. [Google Scholar] [CrossRef]

- Ziewiec, A.; Zielińska-Lipiec, A.; Tasak, E. Microstructure of welded joints of X5CrNiCuNb16-4 (17-4 PH) martensitic stainless steel after heat treatment. Arch. Metall. Mater. 2014, 59, 965–970. [Google Scholar] [CrossRef]

- Gholipour, A.; Shamanian, M.; Ashrafizadeh, F. Microstructure and wear behavior of stellite 6 cladding on 17-4 PH stainless steel. J. Alloys Compd. 2011, 509, 4905–4909. [Google Scholar] [CrossRef]

- Hsiao, C.N.; Chiou, C.S.; Yang, J.R. Aging reactions in a 17-4 PH stainless steel. Mater. Chem. Phys. 2002, 74, 134–142. [Google Scholar] [CrossRef]

- Tavares, S.S.M.; Da Silva, F.J.; Scandian, C.; Da Silva, G.F.; De Abreu, H.F.G. Microstructure and intergranular corrosion resistance of UNS S17400 (17-4 PH) stainless steel. Corros. Sci. 2010, 52, 3835–3839. [Google Scholar] [CrossRef]

| Chemical Compositions (%wt.) | |||||||

|---|---|---|---|---|---|---|---|

| C | Si | Mn | P | S | Cr | Mo | Ni |

| 0.052 | 0.376 | 0.511 | 0.084 | 0.0081 | 16.18 | 0.075 | 3.857 |

| Cu | Al | Co | Nb | Ti | V | W | Fe |

| 4.092 | 0.0068 | 0.048 | 0.329 | 0.0075 | 0.059 | 0.029 | 74.24 |

| Parameter | Automated | Manual |

|---|---|---|

| Amperage I (A) | 34 | 37 |

| Voltage U (V) | ~8.3 | ~8.1 |

| Welding speed v (mm/min) | 170 | 65 |

| Linear energy (kJ/cm) | 1.00 | 2.8 |

| Welding Method | Measurement Point | Angular Strain β (Degrees) |

|---|---|---|

| Manual | A | 0.02 |

| B | 0.13 | |

| C | 0.21 | |

| Automated | A | 0.04 |

| B | 0.26 | |

| C | 0.04 |

| Point | Chemical Composition [%wt.] | ||||

|---|---|---|---|---|---|

| C | Cr | Ni | Cu | Fe | |

| 1 | 2.87 | 16.69 | 4.30 | 2.76 | 73.39 |

| 2 | 2.17 | 16.64 | 4.54 | 3.10 | 73.55 |

| 3 | 1.73 | 16.83 | 4.53 | 2.94 | 73.97 |

| Welding Method | Measurement Point | Width of the Heat Affected Zone Area [μm] |

|---|---|---|

| manually | A | 120–150 |

| B | 90–105 | |

| C | 1800 | |

| D | 2000 | |

| automatically | A | 90–100 |

| B | 80–90 | |

| C | 900 | |

| D | 1100 |

| Welding Method | Hardness Measurement Point (HV5) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | |

| Manual | 330 | 336 | 366 | 338 | 338 | 344 | 340 | 338 | 340 | 330 | 336 | 366 | 364 |

| average value | 334 in weld | 338 in area A | 342 in area B | 339 in area C | 333 in area D | 365 in BM | |||||||

| Automated | 350 | 348 | 355 | 354 | 358 | 356 | 354 | 342 | 340 | 366 | 368 | 368 | 366 |

| average value | 351 in weld | 356 in area A | 355 in area B | 341 in area C | 367 in area D | 367 in BM | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mróz, M.; Kucel, B.; Rąb, P.; Olszewska, S. Study of the TIG Welding Process of Thin-Walled Components Made of 17-4 PH Steel in the Aspect of Weld Distortion Distribution. Materials 2023, 16, 4854. https://doi.org/10.3390/ma16134854

Mróz M, Kucel B, Rąb P, Olszewska S. Study of the TIG Welding Process of Thin-Walled Components Made of 17-4 PH Steel in the Aspect of Weld Distortion Distribution. Materials. 2023; 16(13):4854. https://doi.org/10.3390/ma16134854

Chicago/Turabian StyleMróz, Marek, Bartłomiej Kucel, Patryk Rąb, and Sylwia Olszewska. 2023. "Study of the TIG Welding Process of Thin-Walled Components Made of 17-4 PH Steel in the Aspect of Weld Distortion Distribution" Materials 16, no. 13: 4854. https://doi.org/10.3390/ma16134854

APA StyleMróz, M., Kucel, B., Rąb, P., & Olszewska, S. (2023). Study of the TIG Welding Process of Thin-Walled Components Made of 17-4 PH Steel in the Aspect of Weld Distortion Distribution. Materials, 16(13), 4854. https://doi.org/10.3390/ma16134854