Design and Finite Element Analysis of Artificial Braided Meniscus Model

Abstract

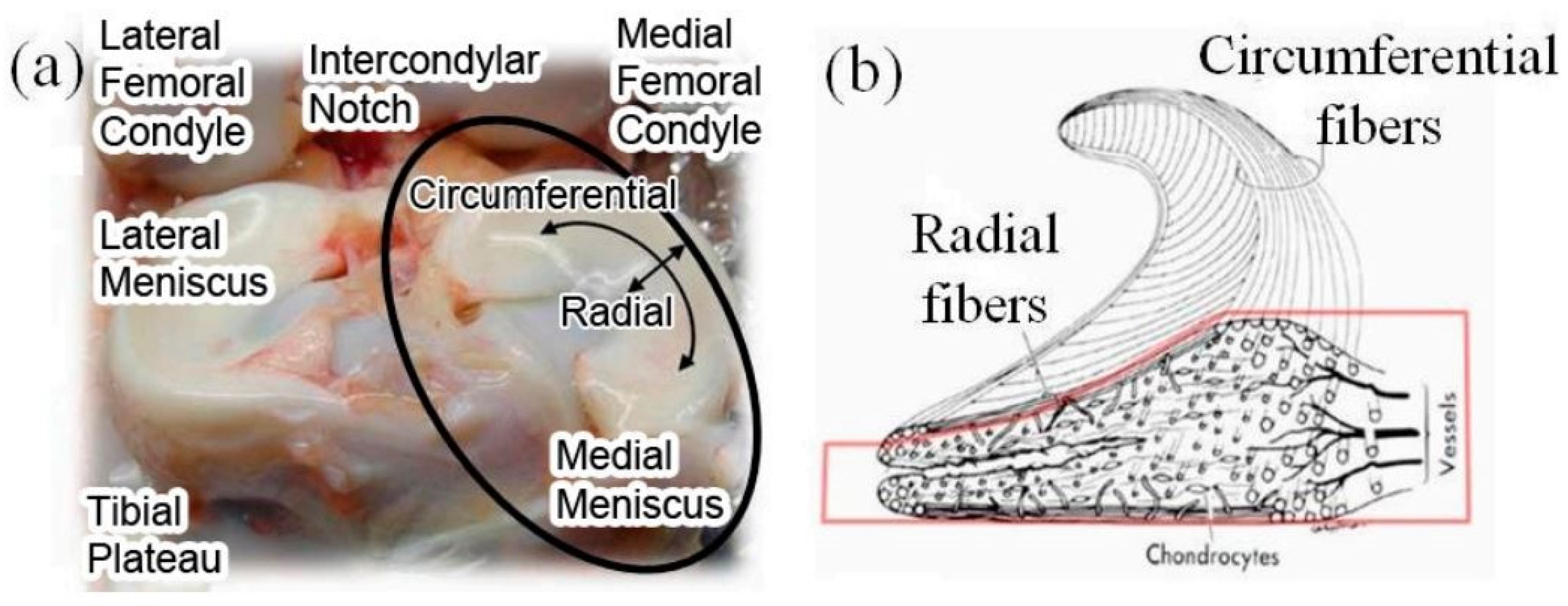

:1. Introduction

2. Design of the Meniscus’s 3D Braiding Structure and Technology

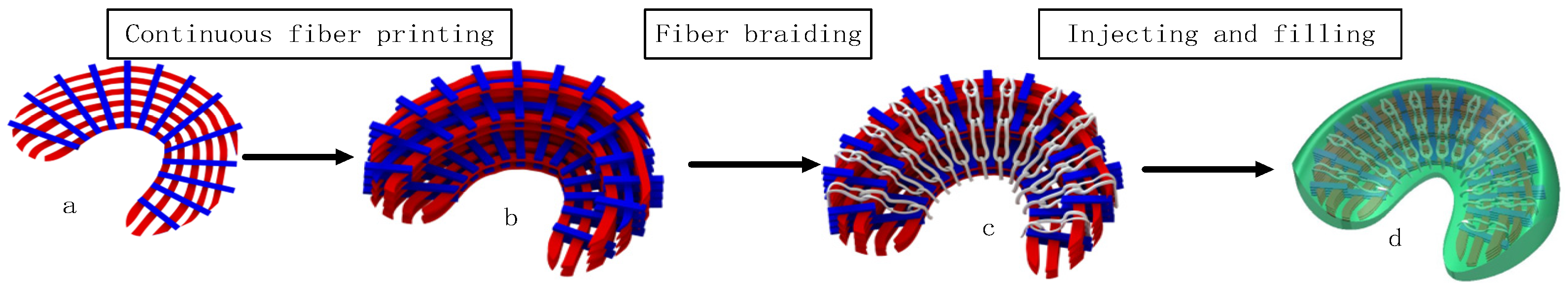

2.1. The Structure of Designed 3D Braided Meniscus

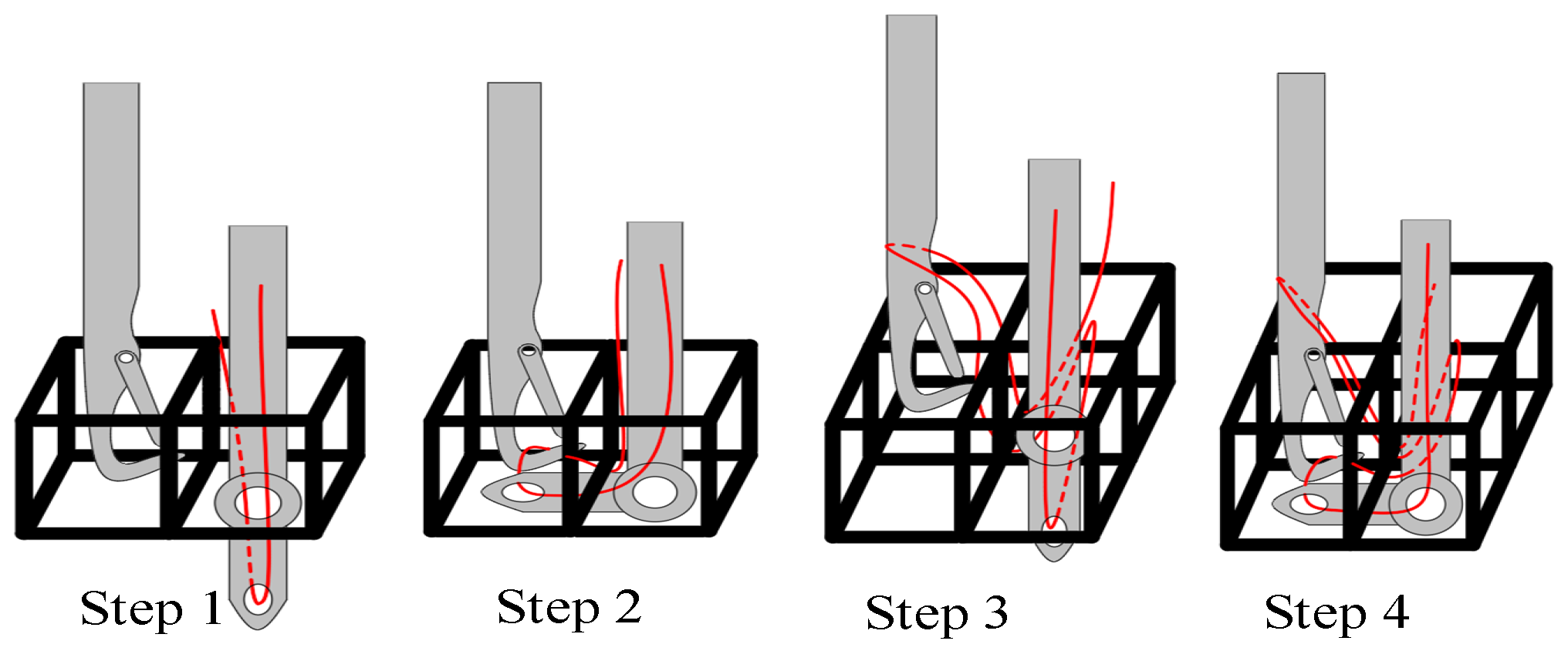

2.2. 3D Braiding Meniscus’s Technology

2.3. The Braiding Steps

3. Analytical Method

3.1. Materials

3.2. The Method of Fiber-Embedded Matrix

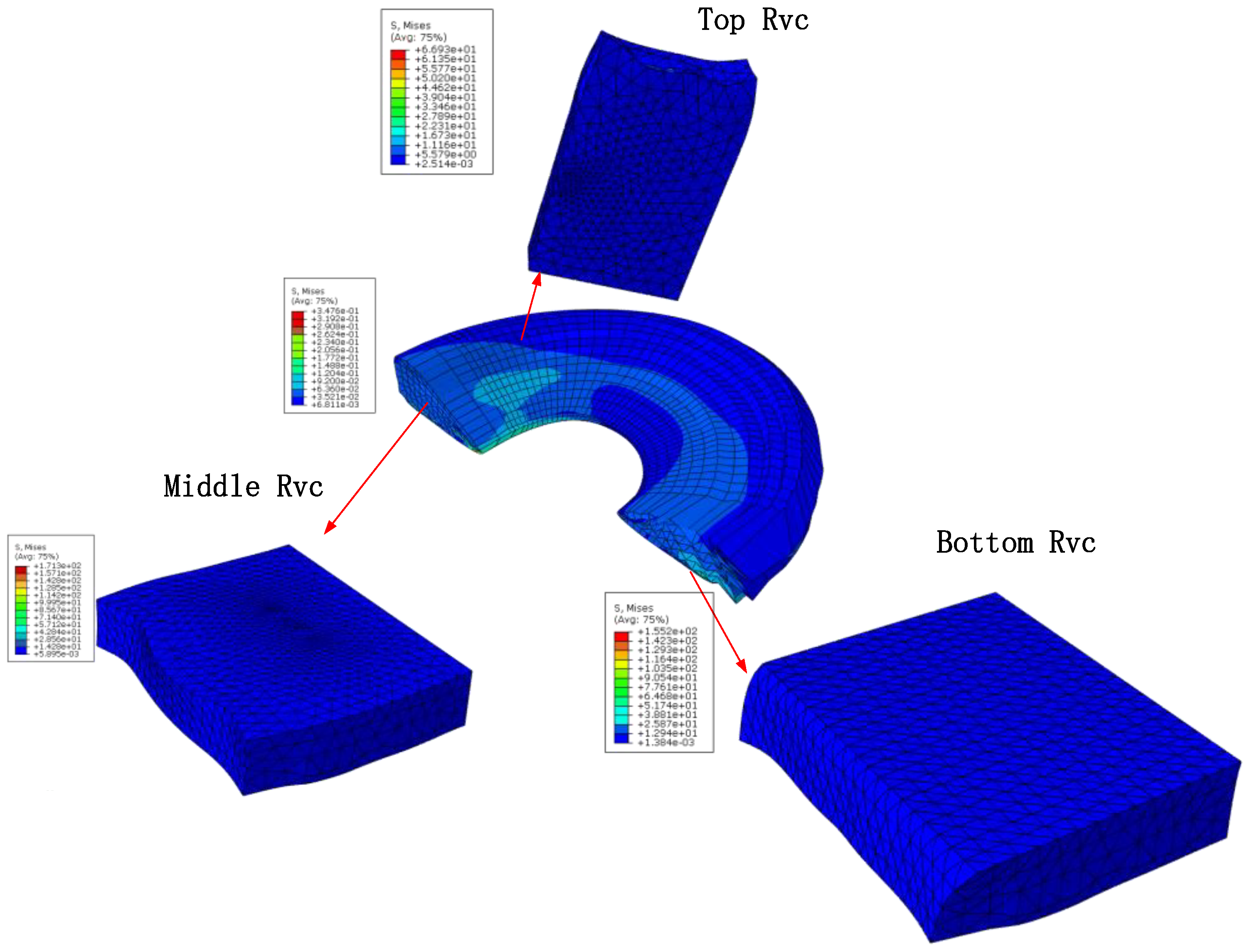

3.3. The Method of Multi-Scale Finite Element

3.4. The Comparison of Artificial and Pure Matrix Meniscus

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Andrews, S.; Shrive, N.; Ronsky, J. The shocking truth about meniscus. J. Biomech. 2011, 44, 2737–2740. [Google Scholar] [CrossRef]

- Rubman, M.H.; Noyes, F.R.; Barber-Westin, S.D. Arthroscopic repair of meniscal tears that extend into the avascular zone. A review of 198 single and complex tears. Am. J. Sport. Med. 1998, 26, 87–95. [Google Scholar] [CrossRef]

- Jin, H.A.; Yong, S.L.; Yoo, J.C.; Chang, M.J.; Park, S.J.; Pae, Y.R. Results of Arthroscopic All-Inside Repair for Lateral Meniscus Root Tear in Patients Undergoing Concomitant Anterior Cruciate Ligament Reconstruction. Arthrosc. J. Arthrosc. Relat. Surg. 2010, 26, 67–75. [Google Scholar]

- Matteo, B.D.; Perdisa, F.; Gostynska, N.; Kon, E.; Filardo, G.; Marcacci, M. Meniscal Scaffolds—Preclinical Evidence to Support their Use: A Systematic Review. Open Orthop. J. 2015, 9, 143–156. [Google Scholar] [CrossRef] [Green Version]

- Heo, J.; Koh, R.H.; Shim, W.; Kim, H.D.; Yim, H.G.; Hwang, N.S. Riboflavin-induced photo-crosslinking of collagen hydrogel and its application in meniscus tissue engineering. Drug Deliv. Transl. Res. 2016, 6, 148–158. [Google Scholar] [CrossRef]

- Bochynska, A.I.; Hannink, G.; Grijpma, D.W.; Buma, P. Tissue adhesives for meniscus tear repair: An overview of current advances and prospects for future clinical solutions. J. Mater. Sci. Mater. Med. 2016, 27, 1–18. [Google Scholar] [CrossRef] [Green Version]

- Kovacs, B.K.; Huegli, R.; Harder, D.; Cedro, L.; Hirschmann, A. MR variability of collagen meniscal implant remodelling in patients with good clinical outcome. Knee Surg. Sports Traumatol. Arthrosc. 2021, 29, 90–99. [Google Scholar] [CrossRef] [PubMed]

- Kluyskens, L.; Debieux, P.; Wong, K.L.; Krych, A.J.; Saris, D.B.F. Biomaterials for meniscus and cartilage in knee surgery: State of the art—ScienceDirect. J. ISAKOS 2022, 7, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Toanen, C.; Dhollander, A.; Bulgheroni, P.; Filardo, G.; Zaffagnini, S.; Spalding, T. Polyurethane meniscal scaffold for the treatment of partial meniscal deficiency: 5-year follow-up outcomes: A European multicentric study. Am. J. Sports Med. 2020, 48, 1347–1355. [Google Scholar] [CrossRef]

- de Caro, F.; Perdisa, F.; Dhollander, A. Meniscus scaffolds for partial meniscus defects. Clin. Sport. Med. 2020, 39, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Pereira, H.; Cengiz, I.F.; Gomes, S. Meniscal allograft transplants and new scaffolding techniques. EFORT Open Rev. 2019, 4, 279–295. [Google Scholar] [CrossRef]

- Hin, Y.-S.; Lee, H.-N.; Sim, H.-B. Polyurethane meniscal scaffolds lead to better clinical outcomes but worse articular cartilage status and greater absolute meniscal extrusion. Knee Surg. Sport. Traumatol. Arthrosc. 2018, 26, 2227–2238. [Google Scholar]

- Kobayashi, M.; Toguchi Da, J.; Oka, M. Development of an artificial meniscus using polyvinyl alcohol-hydrogel for early return to, and continuance of, athletic life in sportspersons with severe meniscus injury. II: Animal experiments. Knee 2003, 10, 47–51. [Google Scholar] [CrossRef]

- Gruchenberg, K.; Ignatius, A.; Friemert, B.; von Lübken, F.; Skaer, N.; Gellynck, K. In vivo performance of a novel silk fibroin scaffold for partial meniscal replacement in a sheep model. Knee Surg. Sport. Traumatol. Arthrosc. 2014, 23, 2218–2229. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Daniela, W.; Svenja, S.; Melanie, H.L.; Luisa, D.R.; Nick, S.; Robert, W. Biomechanical, structural and biological characterisation of a new silk fibroin scaffold for meniscal repair. J. Mech. Behav. Biomed. Mater. 2018, 86, 314–324. [Google Scholar]

- Vrancken, A.C.T.; Eggermont, F.; Van Tienen, T.G.; Hannink, P.; Buma, P.; Janssen, D.; Verdonschot, N. Functional biomechanical performance of a novel anatomically shaped polycarbonate urethane total meniscus replacement. Knee Surg. Sport. Traumatol. Arthrosc. 2016, 24, 1475–1494. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Fu, Y.; Sadeghian, P. Flexural and shear characteristics of bio-based sandwich beams made of hollow and foam-filled paper honeycomb cores and flax fiber composite skins. Thin-Walled Struct. 2020, 153, 106834. [Google Scholar] [CrossRef]

- Matsuzaki, R.; Ueda, M.; Namiki, M.; Jeong, T.K.; Asahara, H.; Horiguchi, K. Three-dimensional printing of continuous-fiber composites by in-nozzle impregnation. Sci. Rep. 2016, 6, 23058. [Google Scholar] [CrossRef] [Green Version]

- Yang, C.; Tian, X.; Cao, Y.; Li, D. 3D printing for continuous fiber reinforced thermoplastic composites: Mechanism and performance. Rapid Prototyp. J. 1995, 23, 209–215. [Google Scholar] [CrossRef]

- Tian, X.; Liu, T.; Yang, C.; Wang, Q.; Li, D. Interface and performance of 3D printed continuous carbon fiber reinforced PLA composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 198–205. [Google Scholar] [CrossRef]

- Shang, J.; Tian, X.; Luo, M.; Zhu, W.; Li, D.; Qin, Y.; Shan, Z. Controllable inter-line bonding performance and fracture patterns of continuous fiber reinforced composites by sinusoidal-path 3D printing. Compos. Sci. Technol. 2020, 192, 108096. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, L.; Sun, B.; Gu, B. Transverse impact behaviors of four-step 3-D rectangular braided composites from unit-cell approach. J. Reinf. Plast. Compos. 2012, 31, 233–246. [Google Scholar] [CrossRef]

- Zhang, D.; Sun, Y.; Wang, X.; Chen, L. Prediction of macro-mechanical properties of 3D braided composites based on fiber embedded matrix method. Compos. Struct. 2015, 134, 393–408. [Google Scholar] [CrossRef]

- Chen, L.; Tao, X.M.; Choy, C.L. Mechanical analysis of 3-D braided composites by the finite multiphase element method. Compos. Sci. Technol. 1999, 59, 2383–2391. [Google Scholar] [CrossRef]

- Cox, B.N.; Carter, W.C.; Fleck, N.A. A binary model of textile composites—I. Formulation. Acta Metall. Et Mater. 1994, 42, 3463–3479. [Google Scholar] [CrossRef]

- Fox, A.J.S.; Bedi, A.; Rodeo, S.A. The Basic Science of Human KneeMenisci: Structure, Composition, and Function. Sport. Health 2012, 4, 340–351. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vrancken AC, T.; Buma, P.; van Tienen, T.G. Synthetic meniscus replacement: A review. Int. Orthop. 2013, 37, 291–299. [Google Scholar] [CrossRef] [Green Version]

- Mcdermott, I.D.; Sharifi, F.; Bull, A.; Gupte, C.M.; Thomas, R.W.; Amis, A.A. An anatomical study of meniscal allograft sizing. Knee Surg. Sport. Traumatol. Arthrosc. 2004, 12, 130–135. [Google Scholar] [CrossRef] [PubMed]

- Makris, E.A.; Hadidi, P.; Athanasiou, K.A. The knee meniscus: Structure–function, pathophysiology, current repair techniques, and prospects for regeneration. Biomaterials 2011, 32, 7411–7431. [Google Scholar] [CrossRef] [Green Version]

- Noble, J.; Hamblen, D.L. The pathology of the degenerate meniscus lesion. J. Bone Jt. Surg. Br. Vol. 1975, 57, 180. [Google Scholar] [CrossRef]

- Poehling, G.G.; Ruch, D.S.; Chabon, S.J. The landscape of meniscal injuries. Clin. Sport. Med. 1990, 9, 539–549. [Google Scholar] [CrossRef]

- Feng, Y.; Yan, X.; Guo, J.; Cheng, L.; Jiao, L.; Zhang, Y. Synthesis and characterization of poly(carbonate urethane) networks with shape-memory properties. J. Appl. Polym. Sci. 2010, 112, 473–478. [Google Scholar] [CrossRef]

- Wang, H.; Feng, Y.; An, B.; Zhang, W.; Khan, M. Fabrication of PU/PEGMA crosslinked hybrid scaffolds by in situ UV photopolymerization favoring human endothelial cells growth for vascular tissue engineering. J. Mater. Sci. Mater. Med. 2012, 23, 1499–1510. [Google Scholar] [CrossRef]

- Wang, H.; Feng, Y.; Zhao, H.; Xiao, R.; Lu, J.; Zhang, L. Electrospun hemocompatible PU/gelatin-heparin nanofibrous bilayer scaffolds as potential artificial blood vessels. Macromol. Res. 2012, 20, 347–350. [Google Scholar] [CrossRef]

- Feng, Y.; Zhao, H.; Behl, M.; Yang, D. Grafting of poly(ethylene glycol) monoacrylates on polycarbonateurethane by UV initiated polymerization for improving hemocompatibility. J. Mater. Sci. Mater. Med. 2013, 24, 61–70. [Google Scholar] [CrossRef]

- Guo, C.Y.; Ke, Y.; Liu, Y.; Zhang, M.G. Preparation and properties of polyethylene/montmorillonite nanocomposites formed via ethylene copolymerization. Polym. Int. 2009, 58, 1319–1325. [Google Scholar] [CrossRef]

- Raju, H.; Pelegri, A.A. Experimental Investigation of Transverse Mechanical Properties of High-Performance Kevlar KM2 Single Fiber. In Proceedings of the Asme International Mechanical Engineering Congress & Exposition, Tampa, FL, USA, 3–9 November 2017. [Google Scholar]

- Wagner, H.D.; Phoenix, S.L.; Schwartz, P. A Study of Statistical Variability in the Strength of Single Aramid Filaments. J. Compos. Mater. 1984, 18, 312–338. [Google Scholar] [CrossRef]

- Zhu, D.; Mobasher, B.; Erni, J.; Bansal, S.; Rajan, S.D. Strain rate and gage length effects on tensile behavior of Kevlar 49 single yarn. Compos. Part A Appl. Sci. Manuf. 2012, 43, 2021–2029. [Google Scholar] [CrossRef]

- Nilakantan, G.; Nutt, S. State of the Art in the Deterministic and Probabilistic Ballistic Impact Modeling of Soft Body Armor: Filaments to Fabrics. In Proceedings of the American Society for Composites 29th Technical Conference, Sandiego, CA, USA, 8–10 September 2014. [Google Scholar]

- Zohdi, T.I.; Steigmann, D.J. The toughening effect of microscopic filament misalignment on macroscopic ballistic fabric response. Int. J. Fract. 2002, 118, 71–76. [Google Scholar] [CrossRef]

- Wu, L.; Sun, B.; Gu, B. Numerical analyses of bending fatigue of four-step three-dimensional rectangular-braided composite materials from unit cell approach. J. Text. Inst. 2015, 106, 67–79. [Google Scholar] [CrossRef]

- Li, D.S.; Lu, Z.X.; Li, C.; Li, J.L. Microstructure and mechanical properties of three-dimensional five-directional braided composites. Int. J. Solids Struct. 2009, 46, 3422–3432. [Google Scholar] [CrossRef] [Green Version]

- Li, D.S.; Li, J.L.; Chen, L.; Lu, Z.X.; Fang, D.N. Finite Element Analysis of Mechanical Properties of 3D Four-Directional Rectangular Braided Composites Part 1: Microgeometry and 3D Finite Element Model. Appl. Compos. Mater. 2010, 17, 373–387. [Google Scholar] [CrossRef]

- Li, D.S.; Lu, Z.X.; Chen, L.; Li, J.L. Microstructure Analysis and Prediction of the Elastic Properties of 3D and 5-D Tubular Braided Composites. Acta Aeronaut. Et. Astronaut. Sin. 2007, 28, 123–129. [Google Scholar]

- Sun, X.; Sun, C. Mechanical properties of three-dimensional braided composites. Compos. Struct. 2004, 65, 485–492. [Google Scholar] [CrossRef]

- Wu, L.; Gu, B. Fatigue behaviors of four-step three-dimensional braided composite material: A meso-scale approach computation. Text. Res. J. 2014, 84, 1915–1930. [Google Scholar] [CrossRef]

- Chao, Z.; Xu, X. Finite element analysis of 3D braided composites based on three unit-cells models. Compos. Struct. 2013, 98, 130–142. [Google Scholar]

- He, C.; Ge, J.; Qi, D.; Gao, J.; Chen, Y.; Liang, J.; Fang, D. A multiscale elasto-plastic damage model for the nonlinear behavior of 3D braided composites. Compos. Sci. Technol. 2019, 171, 21–33. [Google Scholar] [CrossRef]

- Yang, J.-M.; Ma, C.-L.; Chou, T.-W. Fiber Inclination Model of Three-Dimensional Textile Structural Composites. J. Compos. Mater. 1986, 20, 472–484. [Google Scholar] [CrossRef]

- Fang, G.D.; Liang, J.; Yu, W.; Bao-Lai, W. The effect of yarn distortion on the mechanical properties of 3D four-directional braided composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 343–350. [Google Scholar]

| Kevlar | Polycarbonate Polyurethane (PCU) | |

|---|---|---|

| Longitudinal modulus (GPa) | 128.7 | 0.057 |

| Transverse modulus (GPa) | 12.87 | |

| Longitudinal passion ratio | 0.3 | 0.43 |

| Longitudinal shear modulus (GPa) | 12.87 | |

| Transverse shear modulus (GPa) | 12.87 |

| (Gpa) | (Gpa) | (Gpa) | (Gpa) | (Gpa) | (Gpa) | ||

|---|---|---|---|---|---|---|---|

| Fiber bundles | 90.1 | 0.479 | 0.479 | 0.37 | 0.17 | 0.17 | 0.17 |

| Top RVC | 13.09 | 0.2 | 10.0 | 0.61 | 0.03 | 0.036 | 0.03 |

| Interior RVC | 11.44 | 2.19 | 10.76 | 0.63 | 0.03 | 0.039 | 0.03 |

| Bottom RVC | 13.6 | 0.2 | 9.09 | 0.67 | 0.03 | 0.037 | 0.03 |

| (Gpa) | (Gpa) | (Gpa) | (Gpa) | (Gpa) | (Gpa) | ||

|---|---|---|---|---|---|---|---|

| Fiber bundles | 91 | 0.417 | 0.417 | 0.31 | 0.15 | 0.15 | 0.15 |

| Top RVC | 13.23 | 0.2 | 10.12 | 0.67 | 0.03 | 0.035 | 0.03 |

| Interior | 11.44 | 2.19 | 10.76 | 0.63 | 0.03 | 0.039 | 0.03 |

| Bottom | 13.73 | 0.197 | 9.19 | 0.67 | 0.03 | 0.035 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Zhang, W.; Ding, X. Design and Finite Element Analysis of Artificial Braided Meniscus Model. Materials 2023, 16, 4775. https://doi.org/10.3390/ma16134775

Wei J, Zhang W, Ding X. Design and Finite Element Analysis of Artificial Braided Meniscus Model. Materials. 2023; 16(13):4775. https://doi.org/10.3390/ma16134775

Chicago/Turabian StyleWei, Jiakai, Wuxiang Zhang, and Xilun Ding. 2023. "Design and Finite Element Analysis of Artificial Braided Meniscus Model" Materials 16, no. 13: 4775. https://doi.org/10.3390/ma16134775

APA StyleWei, J., Zhang, W., & Ding, X. (2023). Design and Finite Element Analysis of Artificial Braided Meniscus Model. Materials, 16(13), 4775. https://doi.org/10.3390/ma16134775