The Influence of Coherent Oxide Interfaces on the Behaviors of Helium (He) Ion Irradiated ODS W

Abstract

1. Introduction

2. Experimental

2.1. Material Preparation

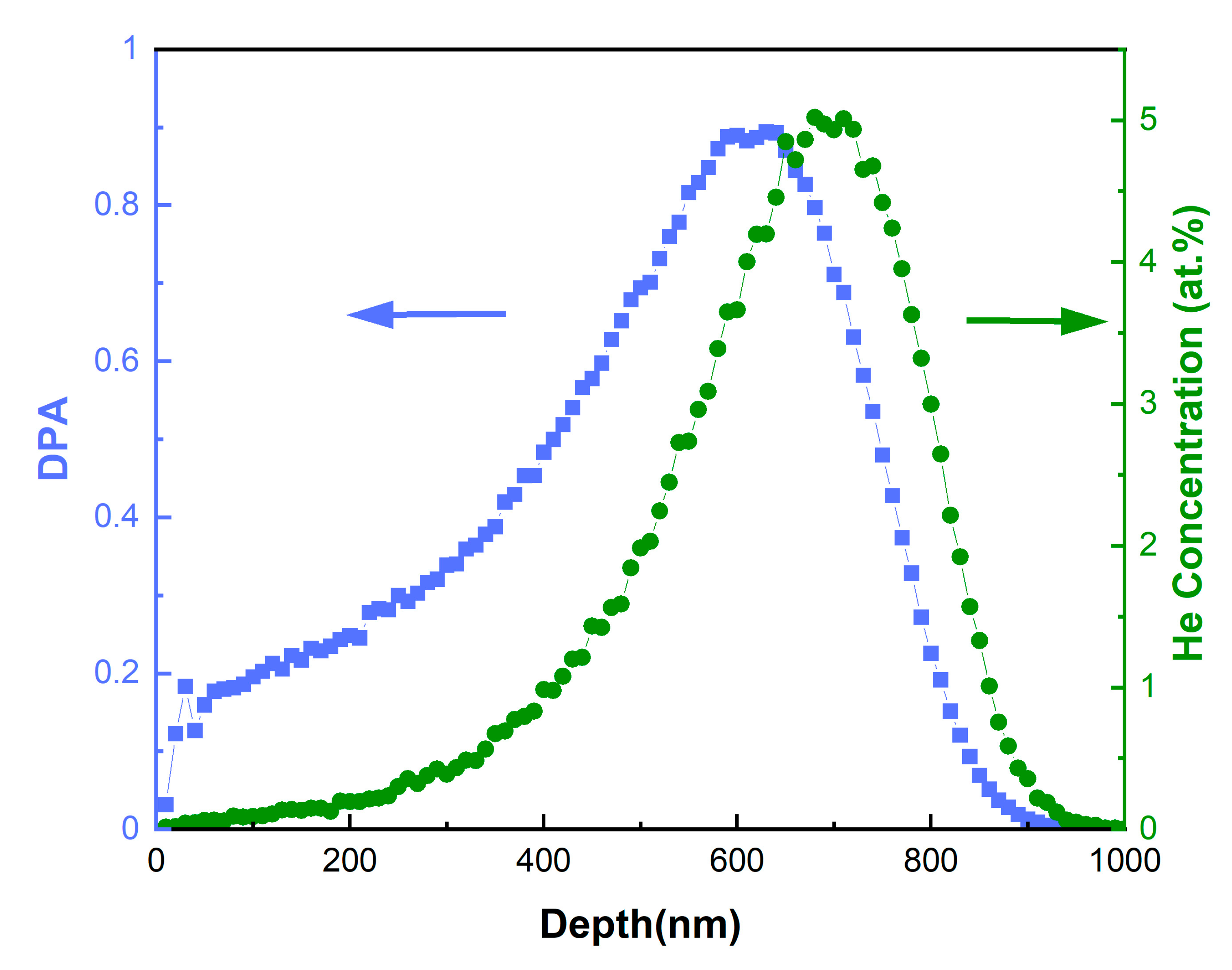

2.2. He Ion Irradiation and Characterization of Materials

3. Results and Discussion

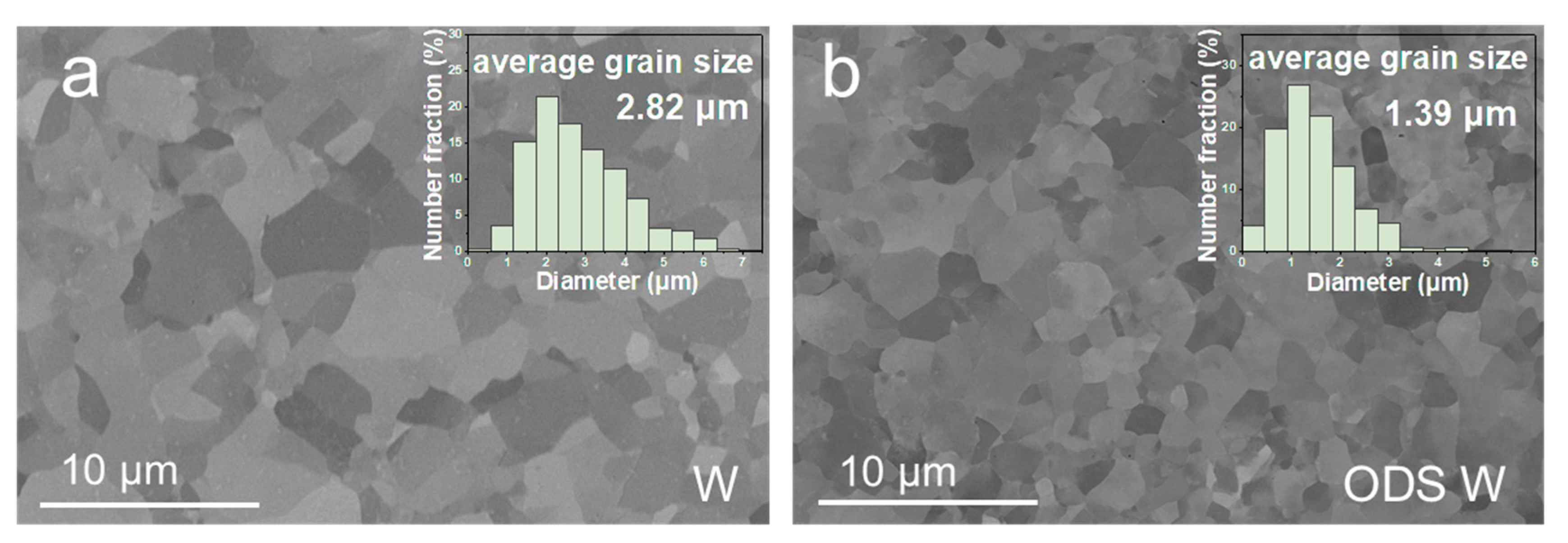

3.1. Microstructure and Coherent Oxide Nanoparticles of Pristine Alloys

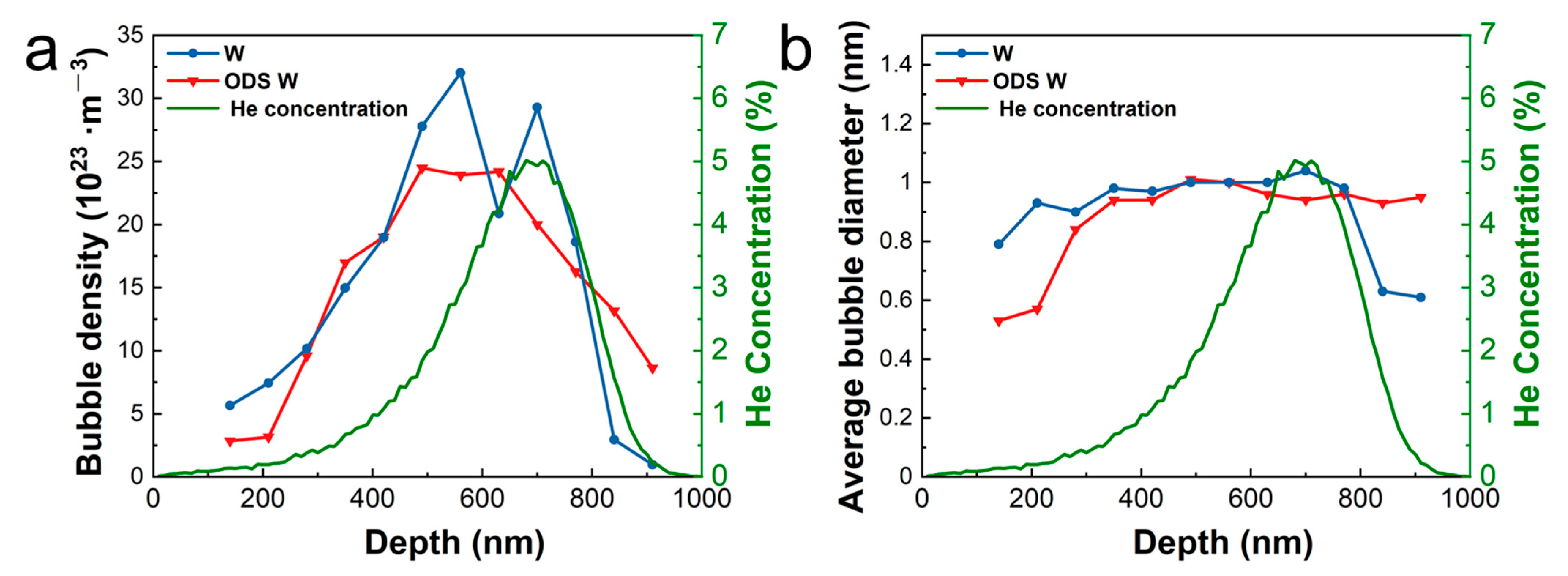

3.2. He Ion Irradiation on the Samples

4. Conclusions

- 1.

- The introduction of coherent oxide nanoparticles in ODS W has shown improved radiation resistance compared to pure W, as evidenced by a smaller radiation-induced hardening increment.

- 2.

- The presence of coherent interfaces provided by oxide particles in ODS W plays a certain role in trapping and annihilating He/V complexes, preventing their growth into stronger pinning obstacles and thus weakening He-ion-irradiation-induced hardening.

- 3.

- ODS W exhibits a comparable size of He bubbles to pure W after He ion irradiation, indicating that the coherent interfaces have limited interaction with vacancies at the irradiation temperature of 450 °C.

- 4.

- The density of He bubbles in the peak He concentration region of ODS W is slightly lower than that in pure W, suggesting the potential of coherent oxide interfaces to suppress the formation of He bubbles.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bolt, H.; Barabash, V.; Krauss, W.; Linke, J.; Neu, R.; Suzuki, S.; Yoshida, N.; Team, A.U. Materials for the plasma-facing components of fusion reactors. J. Nucl. Mater. 2004, 329, 66–73. [Google Scholar] [CrossRef]

- Möslang, A.; Diegele, E.; Klimiankou, M.; Lässer, R.; Lindau, R.; Lucon, E.; Materna-Morris, E.; Petersen, C.; Pippan, R.; Rensman, J.; et al. Towards reduced activation structural materials data for fusion DEMO reactors. Nucl. Fusion 2005, 45, 649–655. [Google Scholar] [CrossRef]

- Hu, X.; Koyanagi, T.; Fukuda, M.; Kumar, N.K.; Snead, L.L.; Wirth, B.D.; Katoh, Y. Irradiation hardening of pure tungsten exposed to neutron irradiation. J. Nucl. Mater. 2016, 480, 235–243. [Google Scholar] [CrossRef]

- Armstrong, D.E.J.; Edmondson, P.D.; Roberts, S.G. Effects of sequential tungsten and helium ion implantation on nano-indentation hardness of tungsten. Appl. Phys. Lett. 2013, 102, 251901. [Google Scholar] [CrossRef]

- Mutoh, Y.; Ichikawa, K.; Nagata, K.; Takeuchi, M. Effect of rhenium addition on fracture toughness of tungsten at elevated temperatures. J. Mater. Sci. 1995, 30, 770–775. [Google Scholar] [CrossRef]

- Strunz, P.; Kunčická, L.; Beran, P.; Kocich, R.; Hervoches, C. Correlating microstrain and activated slip systems with mechanical properties within rotary swaged WNiCo pseudoalloy. Materials 2020, 13, 208. [Google Scholar] [CrossRef]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.T.; Hlaváč, L.M. Effect of thermomechanical processing via rotary swaging on properties and residual stress within tungsten heavy alloy. Int. J. Refract. Hard Met. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Wu, Z.; Zhang, J.; Huang, J.; Fan, Y.; Yu, X.; Zhao, Y.; Zhu, J.; Jin, C.; Wang, P.; Fu, E. Nanocrystalline W-based alloys with ultrahigh hardness and exceptional irradiation tolerance. Nucl. Fusion 2019, 59, 106050. [Google Scholar] [CrossRef]

- Wu, Z.; Zhou, X.; Liu, J.; Du, J.; Zou, S.; Huang, Y.; Yang, K.J.; Zhang, J.; Huang, J.; Fu, E. Ultrafine-grained W alloy prepared by spark plasma sintering with high thermal stability and excellent irradiation resistance. Nucl. Fusion 2020, 60, 036006. [Google Scholar] [CrossRef]

- Wu, Z.; Liang, Y.; Fu, E.; Du, J.; Wang, P.; Fan, Y.; Zhao, Y. Effect of ball milling parameters on the refinement of tungsten powder. Metals 2018, 8, 281. [Google Scholar] [CrossRef]

- Liu, R.; Wang, X.; Hao, T.; Liu, C.; Fang, Q. Characterization of ODS-tungsten microwave-sintered from sol–gel prepared nano-powders. J. Nucl. Mater. 2014, 450, 69–74. [Google Scholar] [CrossRef]

- Xie, Z.M.; Miao, S.; Liu, R.; Zeng, L.F.; Zhang, T.; Fang, Q.F.; Cai, L.H. Recrystallization and thermal shock fatigue resistance of nanoscale ZrC dispersion strengthened W alloys as plasma-facing components in fusion devices. J. Nucl. Mater. 2017, 496, 41–53. [Google Scholar] [CrossRef]

- Wurster, S.; Baluc, N.; Battabyal, M.; Crosby, T.; Du, J.; García-Rosales, C.; Hasegawa, A.; Hoffmann, A.; Kimura, A.; Kurishita, H.; et al. Recent progress in R&D on tungsten alloys for divertor structural and plasma facing materials. J. Nucl. Mater. 2013, 442, S181–S189. [Google Scholar]

- Zhang, T.; Yan, W.; Xie, Z.; Miao, S.; Yang, J.; Wang, X.; Fang, Q.; Liu, C. Recent progress of oxide/carbide dispersion strengthened W-based materials. Acta Metall. Sin. 2018, 54, 831–843. [Google Scholar]

- Ding, H.L.; Xie, Z.M.; Fang, Q.F.; Zhang, T.; Cheng, Z.J.; Zhuang, Z.; Liu, C. Determination of the DBTT of nanoscale ZrC doped W alloys through amplitude-dependent internal friction technique. Mater. Sci. Eng. A 2018, 716, 268–273. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; Demkowicz, M.J.; Misra, A.; Uberuaga, B.P. Defect-interface interactions Prog. Mater. Sci. 2015, 74, 125–210. [Google Scholar]

- Luo, L.M.; Zhao, Z.H.; Yao, G.; Wu, Y.C. Recent progress on preparation routes and performance evaluation of ODS/CDS-W alloys for plasma facing materials in fusion devices. J. Nucl. Mater. 2021, 548, 152857. [Google Scholar] [CrossRef]

- Liu, R.; Xie, Z.; Fang, Q.; Zhang, T.; Wang, X.; Hao, T.; Liu, C.; Dai, Y. Nanostructured yttria dispersion-strengthened tungsten synthesized by sol–gel method. J. Alloy. Compd. 2016, 657, 73–80. [Google Scholar] [CrossRef]

- Lian, Y.; Liu, X.; Feng, F.; Song, J.; Yan, B.; Wang, Y.; Wang, J.; Chen, J. Mechanical properties and thermal shock performance of W-Y2O3 composite prepared by high-energy-rate forging. Phys. Scr. 2017, T170, 014044. [Google Scholar] [CrossRef]

- Xie, Z.; Liu, R.; Miao, S.; Zhang, T.; Wang, X.; Fang, Q.; Liu, C.; Luo, G. Effect of high temperature swaging and annealing on the mechanical properties and thermal conductivity of W–Y2O3. J. Nucl. Mater. 2015, 464, 193–199. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, G.J.; Jiang, F.; Ding, X.; Sun, Y.J.; Sun, J.; Ma, E. Nanostructured high-strength molybdenum alloys with unprecedented tensile ductility. Nat. Mater. 2013, 12, 344–350. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, T.; Tan, L.; Poplawsky, J.D.; An, K.; Wang, Y.; Samolyuk, G.D.; Littrell, K.; Lupini, A.R.; Borisevich, A.; et al. Bifunctional nanoprecipitates strengthen and ductilize a medium-entropy alloy. Nature 2021, 595, 245–249. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, T.; Li, Y.; Fan, L.; Han, B.; Jiao, Z.; Chen, D.; Liu, C.; Kai, J. Superior high-temperature properties and deformation-induced planar faults in a novel L12-strengthened high-entropy alloy. Acta Mater. 2020, 188, 517–527. [Google Scholar] [CrossRef]

- Yang, T.; Zhao, Y.L.; Tong, Y.; Jiao, Z.B.; Wei, J.; Cai, J.X.; Han, X.D.; Chen, D.; Hu, A.; Kai, J.J.; et al. Multicomponent intermetallic nanoparticles and superb mechanical behaviors of complex alloys. Science 2018, 362, 933–937. [Google Scholar] [CrossRef]

- Dong, Z.; Ma, Z.; Yu, L.; Liu, Y. Achieving high strength and ductility in ODS-W alloy by employing oxide@ W core-shell nanopowder as precursor. Nat. Commun. 2021, 12, 5052. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Meth. B 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Chookajorn, T.; Murdoch, H.A.; Schuh, C.A. Design of stable nanocrystalline alloys. Science 2012, 337, 951–954. [Google Scholar] [CrossRef]

- Tan, X.; Luo, L.; Chen, H.; Zhu, X.; Zan, X.; Luo, G.; Chen, J.; Li, P.; Cheng, J.; Liu, D.; et al. Mechanical properties and microstructural change of W–Y2O3 alloy under helium irradiation. Sci. Rep. 2015, 5, 12755. [Google Scholar] [CrossRef]

- Jenkins, M.L.; Kirk, M.A. Analysis of small centres of strain: Counting and sizing small clusters. In Characterization of Radiation Damage by Transmission Electron Microscopy; Taylor & Francis Group: Boca Raton, FL, USA, 2001. [Google Scholar]

- Mujahid, M.; Martin, J.W. The effect of oxide particle coherency on Zener pinning in ODS superalloys. J. Mater. Sci. Lett. 1994, 13, 153–155. [Google Scholar] [CrossRef]

- Chen, T.; Gigax, J.G.; Price, L.; Chen, D.; Ukai, S.; Aydogan, E.; Shao, L. Temperature dependent dispersoid stability in ion-irradiated ferritic-martensitic dual-phase oxide-dispersion-strengthened alloy: Coherent interfaces vs. incoherent interfaces. Acta Mater. 2016, 116, 29–42. [Google Scholar] [CrossRef]

- Valles, G.; González, C.; Martin-Bragado, I.; Iglesias, R.; Perlado, J.M.; Rivera, A. The influence of high grain boundary density on helium retention in tungsten. J. Nucl. Mater. 2015, 457, 80–87. [Google Scholar] [CrossRef]

- Ferroni, F.; Yi, X.; Arakawa, K.; Fitzgerald, S.P.; Edmondson, P.D.; Roberts, S.G. High temperature annealing of ion irradiated tungsten. Acta Mater. 2015, 90, 380–393. [Google Scholar] [CrossRef]

- Harrison, R.; Greaves, G.; Hinks, J.; Donnelly, S. A study of the effect of helium concentration and displacement damage on the microstructure of helium ion irradiated tungsten. J. Nucl. Mater. 2017, 495, 492–503. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Kasada, R.; Takayama, Y.; Yabuuchi, K.; Kimura, A. A new approach to evaluate irradiation hardening of ion-irradiated ferritic alloys by nano-indentation techniques. Fusion Eng. Des. 2011, 86, 2658–2661. [Google Scholar] [CrossRef]

- Hu, X.; Xu, D.; Byun, T.S.; Wirth, B.D. Modeling of irradiation hardening of iron after low-dose and low-temperature neutron irradiation. Model. Simul. Mater. Sc. 2014, 22, 065002. [Google Scholar] [CrossRef]

- Rice, P.M.; Stoller, R.E. Correlation of nanoindentation and conventional mechanical property measurements. MRS Online Proc. Libr. (OPL) 2000, 649, Q7.11. [Google Scholar] [CrossRef]

- Zheng, R.-Y.; Jian, W.-R.; Beyerlein, I.J.; Han, W.-Z. Atomic-scale hidden point-defect complexes induce ultrahigh-irradiation hardening in tungsten. Nano Lett. 2021, 21, 5798–5804. [Google Scholar] [CrossRef]

- Ren, Q.-Y.; Li, Y.-H.; Gao, N.; Han, W.-Z.; Niu, Y.-Z.; Xie, H.-X.; Zhang, Y.; Gao, F.; Lu, G.-H.; Zhou, H.-B. Revealing the synergistic effect of invisible helium clusters in helium irradiation hardening in tungsten. Scr. Mater. 2022, 219, 114850. [Google Scholar] [CrossRef]

- Schultz, H. Vacancy migration in BCC transition metals. Scr. Metall. 1974, 8, 721–726. [Google Scholar] [CrossRef]

- Bakaev, A.; Terentyev, D.; Grigorev, P.; Posselt, M.; Zhurkin, E.E. Ab initio study of interaction of helium with edge and screw dislocations in tungsten. Nucl. Instrum. Meth. B 2017, 393, 150–154. [Google Scholar] [CrossRef]

| -pristine | -irradiated | ||||

| W | 6.47 | 11.74 | 5.27 | 1.85 | 3.42 |

| ODS W | 7.39 | 11.57 | 4.18 | 1.59 | 2.59 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Dong, Z.; Shen, S.; Wang, Y.; Wu, Z.; Hao, L.; Du, J.; Zhang, J.; Ma, Z.; Liu, Y.; et al. The Influence of Coherent Oxide Interfaces on the Behaviors of Helium (He) Ion Irradiated ODS W. Materials 2023, 16, 4613. https://doi.org/10.3390/ma16134613

Liu X, Dong Z, Shen S, Wang Y, Wu Z, Hao L, Du J, Zhang J, Ma Z, Liu Y, et al. The Influence of Coherent Oxide Interfaces on the Behaviors of Helium (He) Ion Irradiated ODS W. Materials. 2023; 16(13):4613. https://doi.org/10.3390/ma16134613

Chicago/Turabian StyleLiu, Xing, Zhi Dong, Shangkun Shen, Yufei Wang, Zefeng Wu, Liyu Hao, Jinlong Du, Jian Zhang, Zongqing Ma, Yongchang Liu, and et al. 2023. "The Influence of Coherent Oxide Interfaces on the Behaviors of Helium (He) Ion Irradiated ODS W" Materials 16, no. 13: 4613. https://doi.org/10.3390/ma16134613

APA StyleLiu, X., Dong, Z., Shen, S., Wang, Y., Wu, Z., Hao, L., Du, J., Zhang, J., Ma, Z., Liu, Y., & Fu, E. (2023). The Influence of Coherent Oxide Interfaces on the Behaviors of Helium (He) Ion Irradiated ODS W. Materials, 16(13), 4613. https://doi.org/10.3390/ma16134613