Analysis and Minimization of Race Tracking in the Resin-Transfer-Molding Process by Monte Carlo Simulation

Abstract

1. Introduction

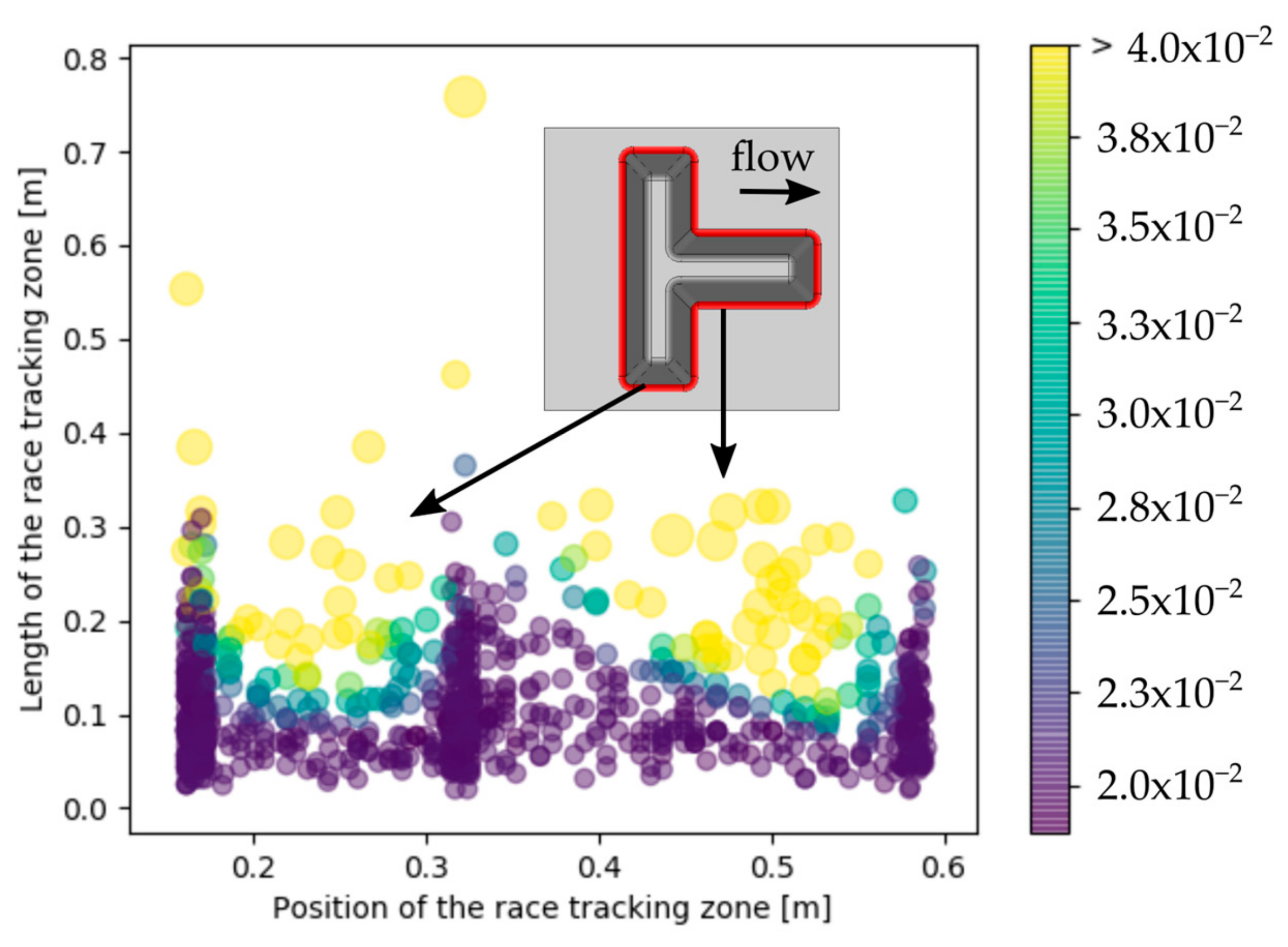

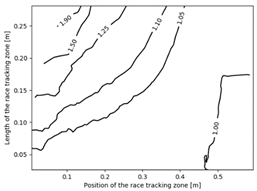

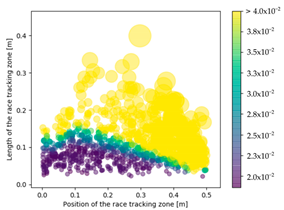

2. Methods

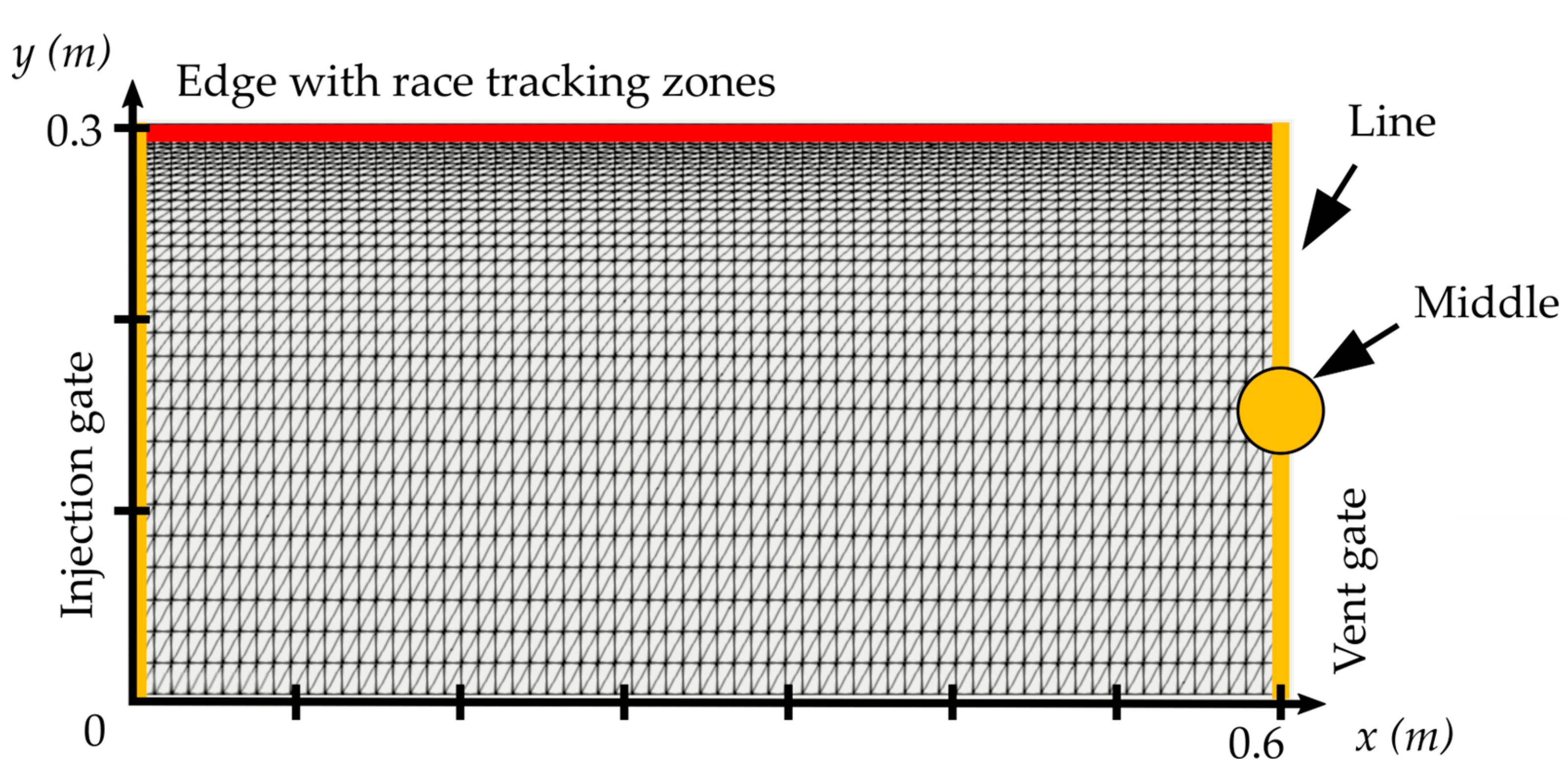

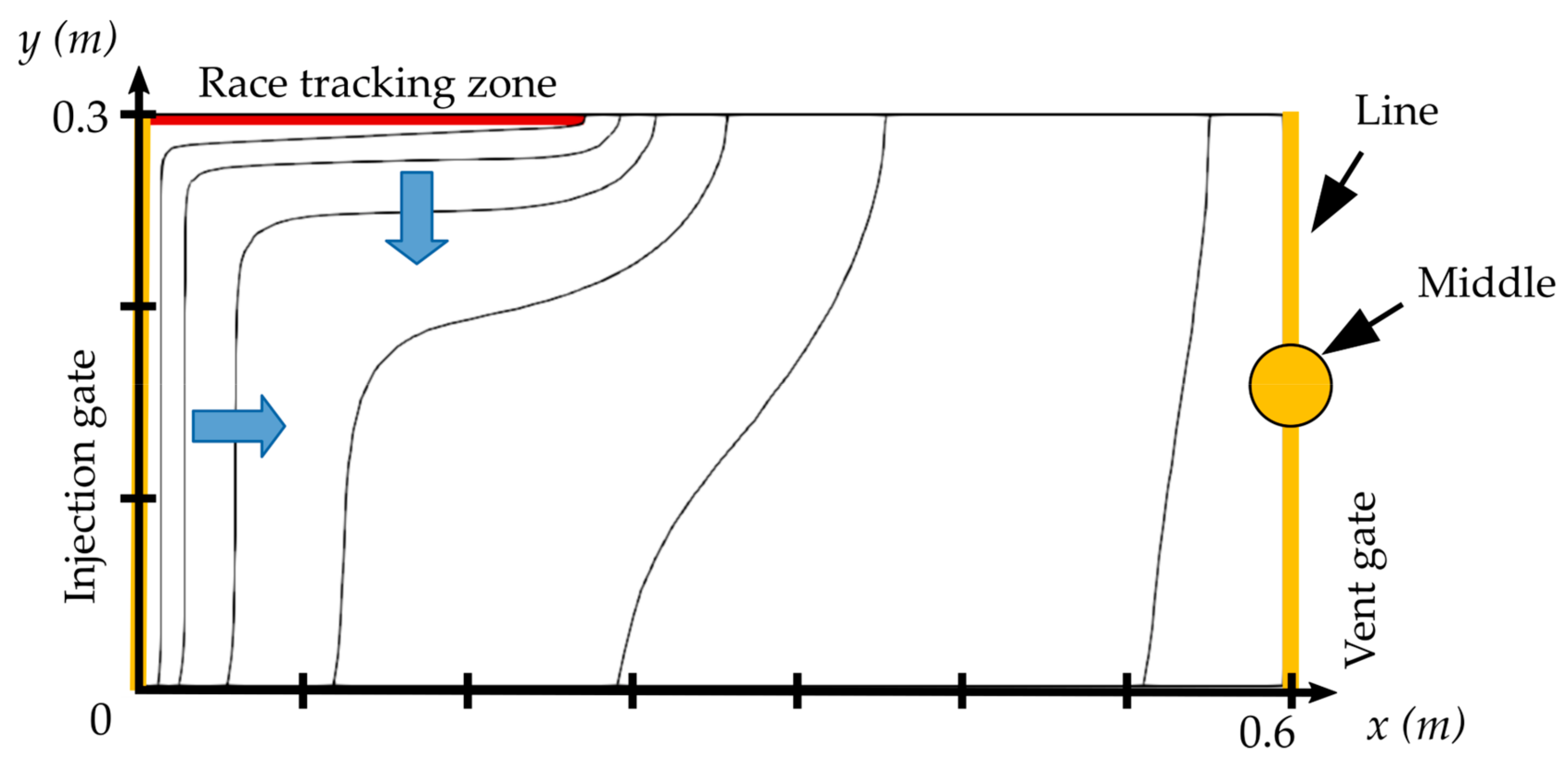

2.1. Mold Geometry

2.2. Material Properties

- Step 1: All the elements of the mesh that could be included in the race-tracking channel are sorted and registered in a list.

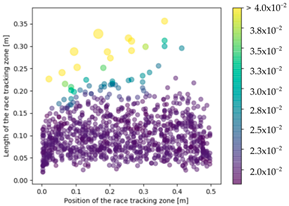

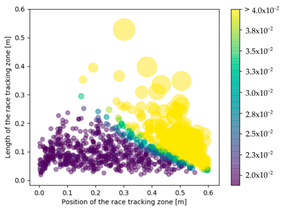

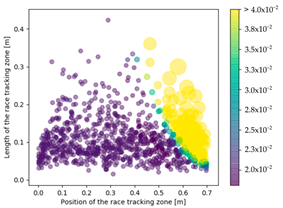

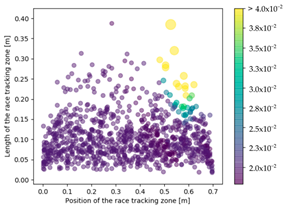

- Step 2: Two random numbers are generated. The first one, generated with a uniform distribution, defines the center of the race-tracking channel. The second one, generated with a lognormal distribution (Equation (2)), defines the length of the race-tracking channel. While there have been discussions in the literature on the proper probability distribution for permeability [3,8,18,19], there are no studies regarding race-tracking channels. The distributions chosen herein for the channel’s center and length could easily be changed based on experimental measurements.

- Step 3: For each element registered in the list in step 1, if the distance between the element and the center of the race-tracking channel is lower than half the length, then the properties (e.g., equivalent permeability) of the race-tracking channel are assigned to the element. Otherwise, the properties of the preform are assigned.

2.3. Monte Carlo Simulation Method

2.4. Post-Processing

- Overall filling fraction: The mold-filling process is considered terminated as soon as the resin has reached at least one of the vent nodes. The overall filling fraction is then estimated by computing the ratio of the mold volume filled by the resin to the total mold volume at this stage of the process.

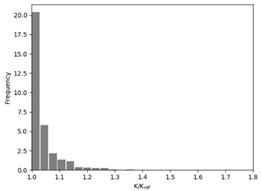

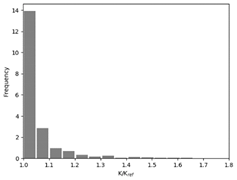

- Unsaturated permeability (): The unsaturated permeability is computed by monitoring the average flow position (in X axis) in time using the following equation for rectilinear flow:where is the average flow position along the width of the mold (i.e., averaged along the Y axis) [m], is the injection pressure [Pa], is the dynamic viscosity of the resin [Pa.s], and is the fiber volume fraction. Following the work of Gokce et al. [4] and Siddig et al. [15], the effective permeability, , obtained by the aforementioned Equation (3) is then divided by the real permeability of the preform to obtain the ratio, , which is monitored. The flow front position is computed from the fill factor, , by using the following equation, assuming and are respectively the volume and the width of the mold:

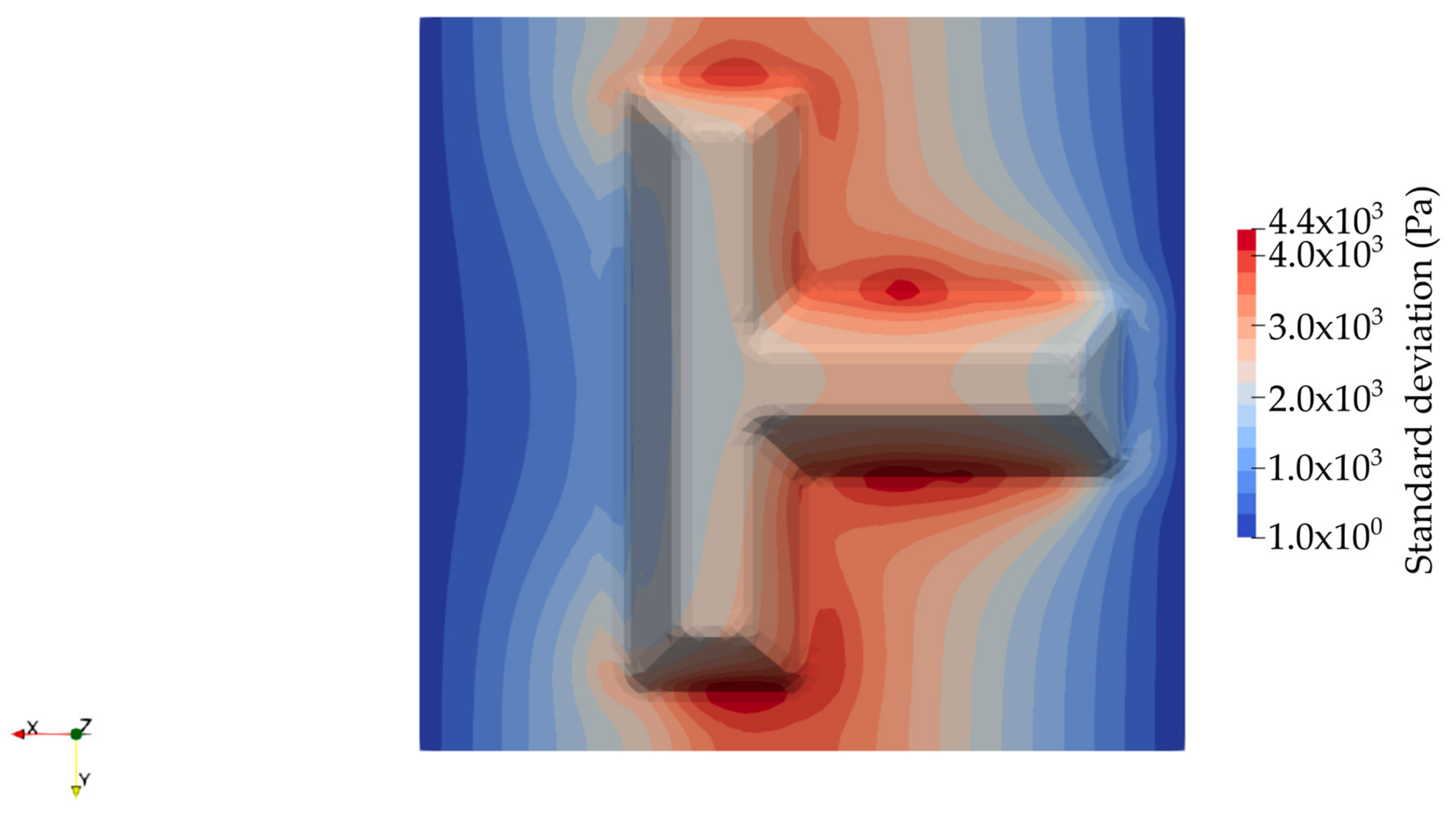

- Statistical fluctuation of flow front position and pressure field: the first two statistical moments (i.e., mean and standard deviation) are employed as indicators of statistical fluctuation. The outputs are the maps of mean and standard deviation of the flow front position and the pressure field over 1000 calculations, which are similar to the ones obtained by Zhang et al. [3].

3. Results and Discussion

3.1. Convergence Rate of the Monte Carlo Simulation Method

3.2. Effect of Race Tracking on the Permeability Measurement

3.3. Effect of Race Tracking on Dry Spots Formation

3.4. Application to a Complex Shape Mold

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Struzziero, G.; Teuwen, J.J.E.; Skordos, A.A. Numerical optimisation of thermoset composites manufacturing processes: A review. Compos. Part A 2019, 124, 105499. [Google Scholar] [CrossRef]

- Chai, B.X.; Eisenbart, B.; Nikzad, M.; Fox, B.; Blythe, A.; Blanchard, P.; Dahl, J. Simulation-based optimisation for injection configuration design of liquid composite moulding processes: A review. Compos. Part A 2021, 149, 106540. [Google Scholar] [CrossRef]

- Zhang, F.; Cosson, B.; Comas-Cardona, S.; Binetruy, C. Efficient stochastic simulation approach for RTM process with random fibrous permeability. Compos. Sci. Technol. 2011, 71, 1478–1485. [Google Scholar] [CrossRef]

- Gokce, A.; Advani, S. Combinatorial Search to Optimize Vent Locations in the Presence of Disturbances in Liquid Composite Molding Processes. Mater. Manuf. Process. 2003, 18, 261–285. [Google Scholar] [CrossRef]

- Dong, C. Model development for the formation of resin-rich zones in composites processing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 419–424. [Google Scholar] [CrossRef]

- Holmberg, J.A.; Berglund, L.A. Manufacturing and performance of RTM U-beams. Compos. Part A Appl. Sci. Manuf. 1997, 28, 513–521. [Google Scholar] [CrossRef]

- Bickerton, S.; Advani, S.G.; Mohan, R.V.; Shires, D.R. Experimental analysis and numerical modeling of flow channel effects in resin transfer molding. Polym. Compos. 2000, 21, 134–153. [Google Scholar] [CrossRef]

- Pan, R.; Liang, Z.; Zhang, C.; Wang, B. Statistical characterization of fiber permeability for composite manufacturing. Polym. Compos. 2000, 21, 996–1006. [Google Scholar] [CrossRef]

- Park, C.H.; Woo, L. Modeling void formation and unsaturated flow in liquid composite molding processes: A survey and review. J. Reinf. Plast. Compos. 2011, 30, 957–977. [Google Scholar] [CrossRef]

- Di Fratta, C.; Klunker, F.; Ermanni, P. A methodology for flow-front estimation in LCM processes based on pressure sensors. Compos. Part A Appl. Sci. Manuf. 2013, 47, 1–11. [Google Scholar] [CrossRef]

- Bickerton, S. Characterization and modeling of race-tracking in liquidcomposite molding processes. Compos. Sci. Technol. 1999, 59, 2215–2229. [Google Scholar] [CrossRef]

- Minaie, B.; Chen, Y.F. Adaptive Control of Filling Pattern in Resin Transfer Molding Process. J. Compos. Mater. 2005, 39, 1497–1513. [Google Scholar] [CrossRef]

- Lee, D.H.; Lee, W.I.; Kang, M.K. Analysis and minimization of void formation during resin transfer molding process. Compos. Sci. Technol. 2006, 66, 3281–3289. [Google Scholar] [CrossRef]

- Sas, H.S.; Šimáček, P.; Advani, S.G. A methodology to reduce variability during vacuum infusion with optimized design of distribution media. Compos. Part A Appl. Sci. Manuf. 2015, 78, 223–233. [Google Scholar] [CrossRef]

- Siddig, N.A.; Binetruy, C.; Syerko, E.; Simacek, P.; Advani, S. A new methodology for race-tracking detection and criticality in resin transfer molding process using pressure sensors. J. Compos. Mater. 2018, 52, 4087–4103. [Google Scholar] [CrossRef]

- Seyednourani, M.; Yildiz, M.; Sas, H.S. A two-stage optimization methodology for gate and vent locations and distribution media layout for liquid composite molding process. Compos. Part A 2021, 149, 106522. [Google Scholar] [CrossRef]

- Hammami, A.; Gauvin, R.; Trochu, F.; Touret, O.; Ferland, P. Analysis of the Edge Effect on Flow Patterns in Liquid Composites Molding. Appl. Compos. Mater. 1998, 5, 161–173. [Google Scholar] [CrossRef]

- Li, J.; Zhang, C.; Liang, Z.; Wang, B. Stochastic simulation based approach for statistical analysis and characterization of composites manufacturing processes. J. Manuf. Syst. 2006, 25, 108–121. [Google Scholar] [CrossRef]

- Caglar, B.; Salvatori, D.; Sozer, E.M.; Michaud, V. In-plane permeability distribution mapping of isotropic mats using flow front detection. Compos. Part A Appl. Sci. Manuf. 2018, 113, 275–286. [Google Scholar] [CrossRef]

- Kang, M. A flow-front refinement technique for the numerical simulation of the resin-transfer molding process. Compos. Sci. Technol. 1999, 59, 1663–1674. [Google Scholar] [CrossRef]

- Lawrence, J.M.; Barr, J.; Karmakar, R.; Advani, S.G. Characterization of preform permeability in the presence of race tracking. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1393–1405. [Google Scholar] [CrossRef]

- Park, C.H.; Saouab, A.; Bréard, J.; Han, W.S.; Vautrin, A.; Lee, W.I. An integrated optimisation for the weight, the structural performance and the cost of composite structures. Compos. Sci. Technol. 2009, 69, 1101–1107. [Google Scholar] [CrossRef]

- Chebil, N.; Deléglise-Lagardère, M.; Park, C.H. Efficient numerical simulation method for three dimensional resin flow in laminated preform during liquid composite molding processes. Compos. Part A Appl. Sci. Manuf. 2019, 125, 105519. [Google Scholar] [CrossRef]

- Johnson, R.J.; Pitchumani, R. Enhancement of flow in VARTM using localized induction heating. Compos. Sci. Technol. 2003, 63, 2201–2215. [Google Scholar] [CrossRef]

- Rubino, F.; Esperto, V.; Tucci, F.; Carlone, P. Flow enhancement in liquid composite molding processes by online microwave resin preheating. Polym. Eng. Sci. 2020, 60, 2377–2389. [Google Scholar] [CrossRef]

- Soares, L.L.; Amico, S.C.; Isoldi, L.A.; Souza, J.A. Modeling of the resin transfer molding process including viscosity dependence with time and temperature. Polym. Compos. 2021, 42, 2795–2807. [Google Scholar] [CrossRef]

- Park, C.H. Numerical simulation of flow processes in composites manufacturing. In Advances in Composites Manufacturing and Process Design; Elsevier: Amsterdam, The Netherlands, 2015; pp. 317–378. [Google Scholar]

- Bodaghi, M.; Park, C.H.; Krawczak, P. Reactive Processing of Acrylic-Based Thermoplastic Composites: A Mini-Review. Front. Mater. 2022, 9, 931338. [Google Scholar] [CrossRef]

| Geometry | Dimensions | Aspect Ratio | Injection Parameter | Vent Geometry | Number of Computations |

|---|---|---|---|---|---|

| Plate | 1.1 | Pa | Line | 1000 | |

| Plate | 1.1 | Pa | Middle | 1000 | |

| Plate | 2.0 | Pa | Line | 1000 | |

| Plate | 2.0 | Pa | Middle | 1000 | |

| Plate | 4.7 | Pa | Line | 1000 | |

| Plate | 4.7 | Pa | Middle | 1000 | |

| Complex shape | Pa | Line | 1000 |

| .Nb. of Computations | Pressure—Mean | Pressure—Standard Deviation | ||

|---|---|---|---|---|

| Value [Pa] | % of the Reference | Value [Pa] | % of the Reference | |

| Probe located in the middle of the race tracking zone, coordinates (0.3, 0.3) | ||||

| 10 | 104 | 0.27% | 103 | 34.48% |

| 100 | 104 | 1.23% | 103 | 3.28% |

| 400 | 104 | 1.46% | 103 | 8.96% |

| 500 | 104 | 1.25% | 103 | 3.63% |

| 700 | 104 | −0.05% | 103 | −1.43% |

| 1000 | 104 | Reference | 103 | Reference |

| Probe located in the middle of the preform, coordinates (0.3, 0.15) | ||||

| 10 | 104 | 4.66% | 103 | −0.23% |

| 100 | 104 | 1.24% | 103 | 3.07% |

| 400 | 104 | 1.47% | 103 | 8.77% |

| 500 | 104 | 1.26% | 103 | 3.42% |

| 700 | 104 | −0.04% | 103 | −1.64% |

| 1000 | 104 | Reference | 103 | Reference |

| Aspect Ratio | ||

|---|---|---|

| 1.1 |  |  |

| 2.0 |  |  |

| 4.7 |  |  |

| Aspect Ratio | Vent Line | Vent Middle |

|---|---|---|

| 1.1 |  |  |

| 2.0 |  |  |

| 4.7 |  |  |

| Parameter | Unit | Value |

|---|---|---|

| Fiber volume fraction | - | 0.4 |

| Permeability of the perform | ||

| Permeability of the edge-gaps | ||

| Permeability of the corner-gaps | ||

| Viscosity of the resin | Pa·s | 0.1 |

| Injection pressure | Pa | |

| Vent pressure | Pa | 0 |

| Average length of defects | m | 0.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Agogué, R.; Shakoor, M.; Beauchêne, P.; Park, C.H. Analysis and Minimization of Race Tracking in the Resin-Transfer-Molding Process by Monte Carlo Simulation. Materials 2023, 16, 4438. https://doi.org/10.3390/ma16124438

Agogué R, Shakoor M, Beauchêne P, Park CH. Analysis and Minimization of Race Tracking in the Resin-Transfer-Molding Process by Monte Carlo Simulation. Materials. 2023; 16(12):4438. https://doi.org/10.3390/ma16124438

Chicago/Turabian StyleAgogué, Romain, Modesar Shakoor, Pierre Beauchêne, and Chung Hae Park. 2023. "Analysis and Minimization of Race Tracking in the Resin-Transfer-Molding Process by Monte Carlo Simulation" Materials 16, no. 12: 4438. https://doi.org/10.3390/ma16124438

APA StyleAgogué, R., Shakoor, M., Beauchêne, P., & Park, C. H. (2023). Analysis and Minimization of Race Tracking in the Resin-Transfer-Molding Process by Monte Carlo Simulation. Materials, 16(12), 4438. https://doi.org/10.3390/ma16124438