Study on the Microstructure and Properties of Welded Joints of Laser Shock Peening on HC420LA Low-Alloy High-Tensile Steel

Abstract

1. Introduction

2. Materials and Methods

2.1. Material and Welding Process

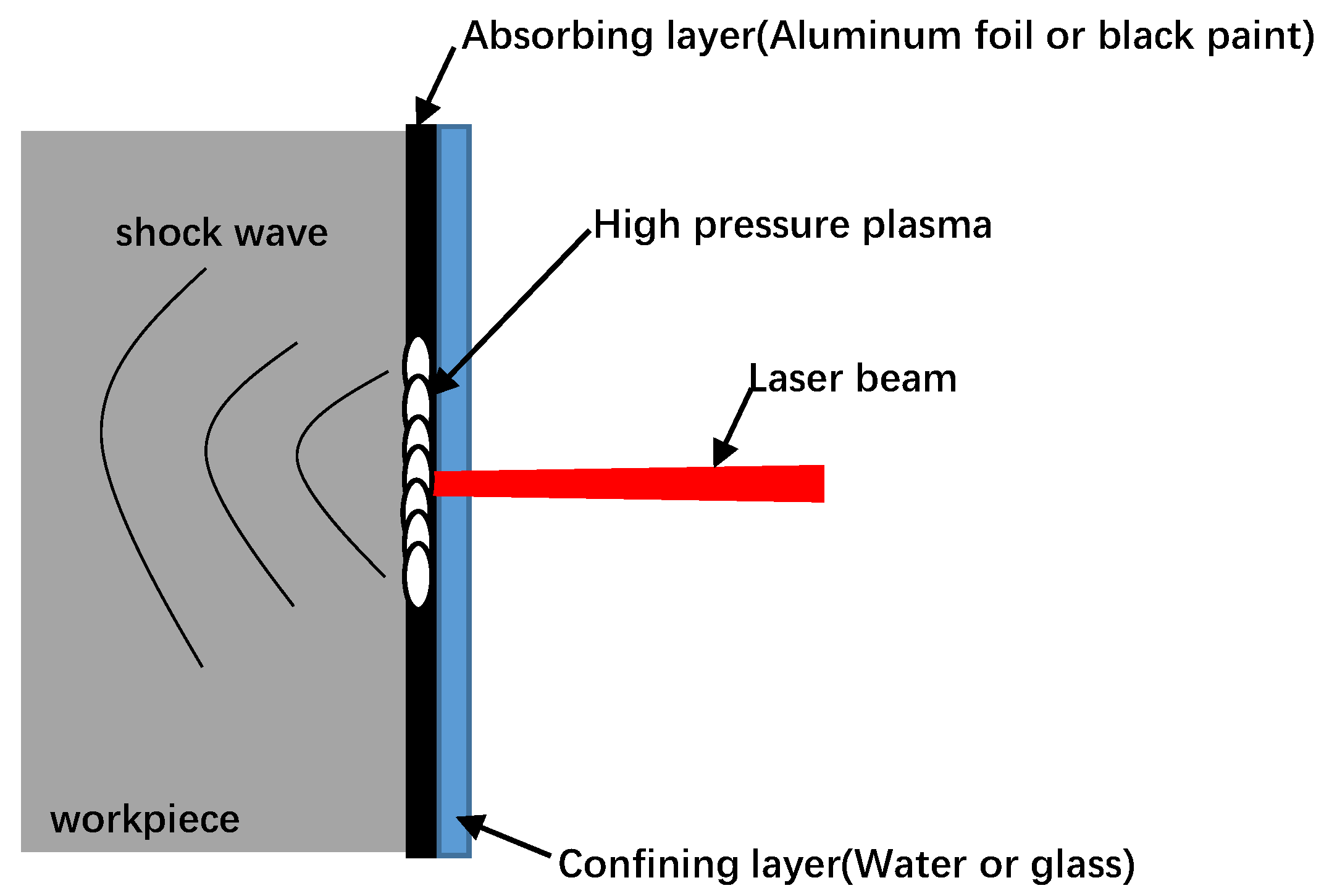

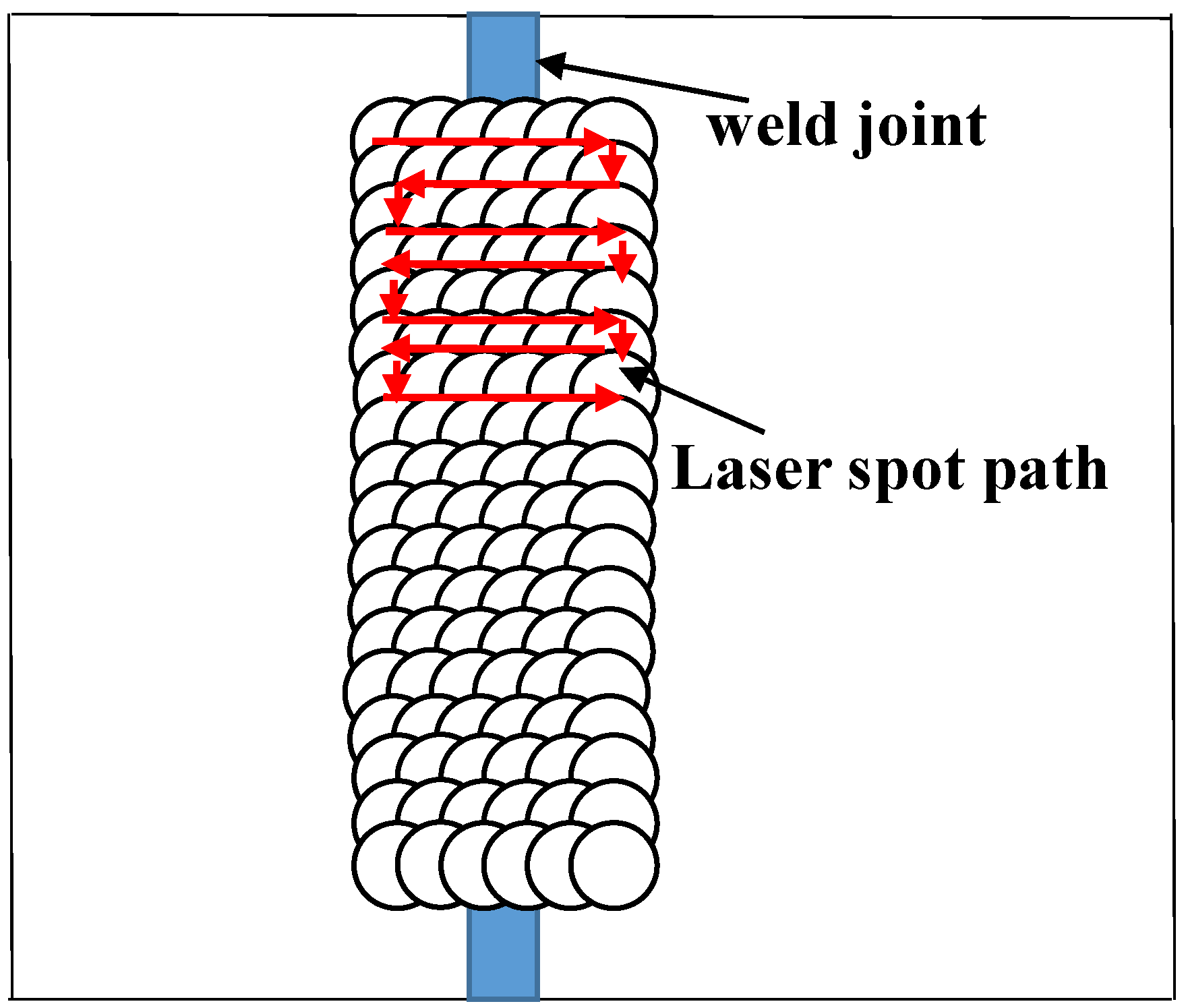

2.2. LSP Process

2.3. Characterization

3. Results and Discussion

3.1. Microstructure

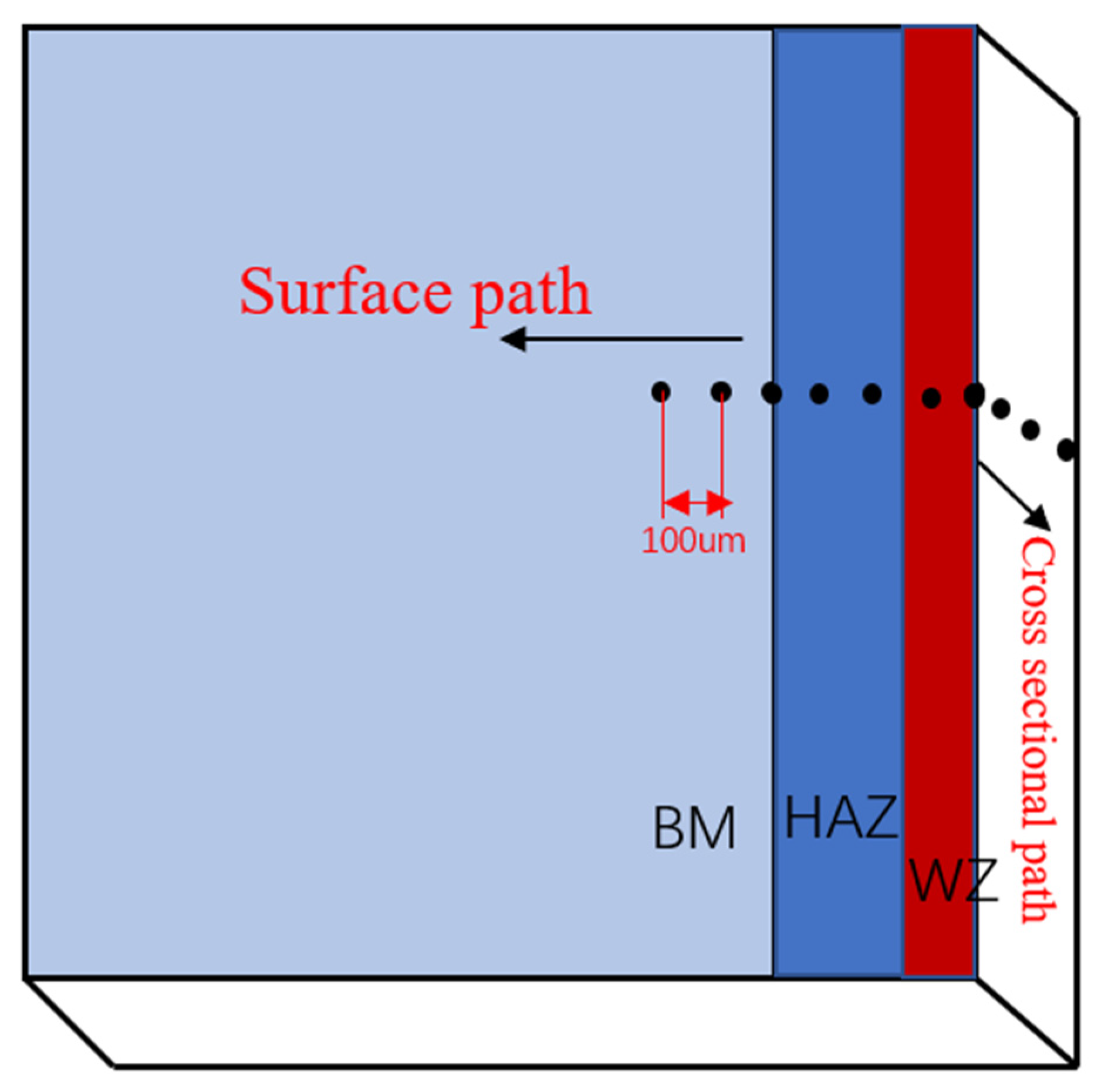

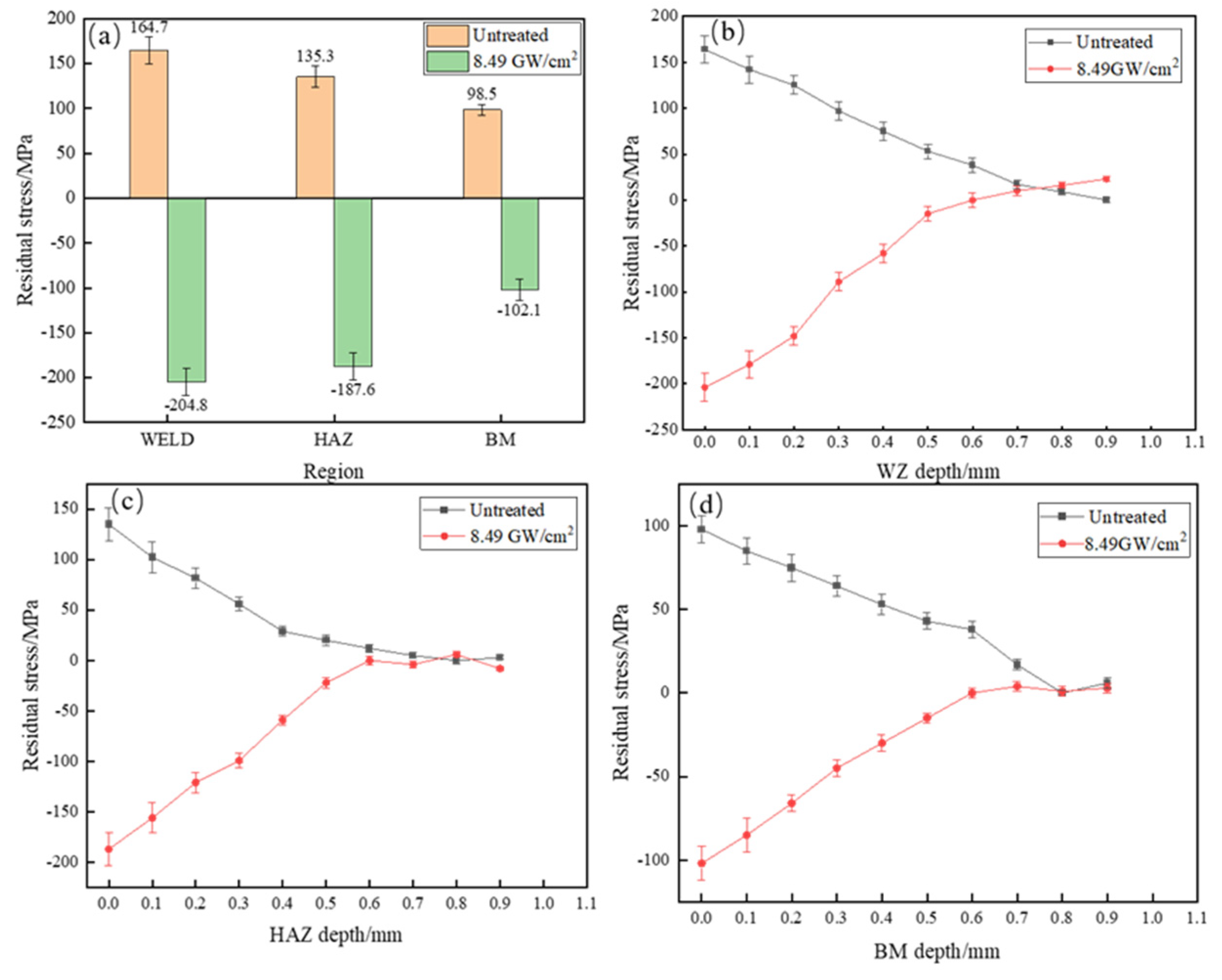

3.2. Residual Stresses

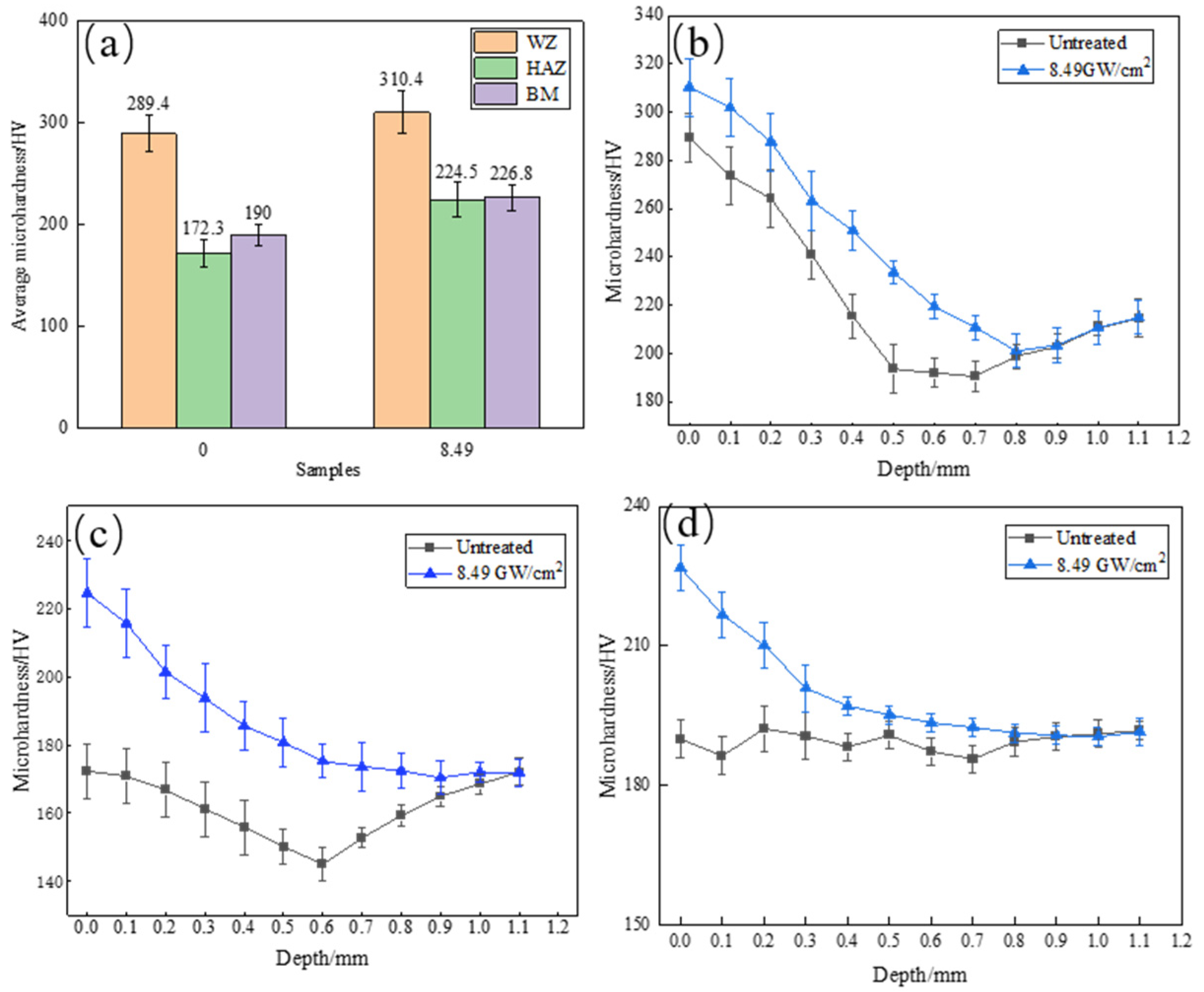

3.3. Microhardness

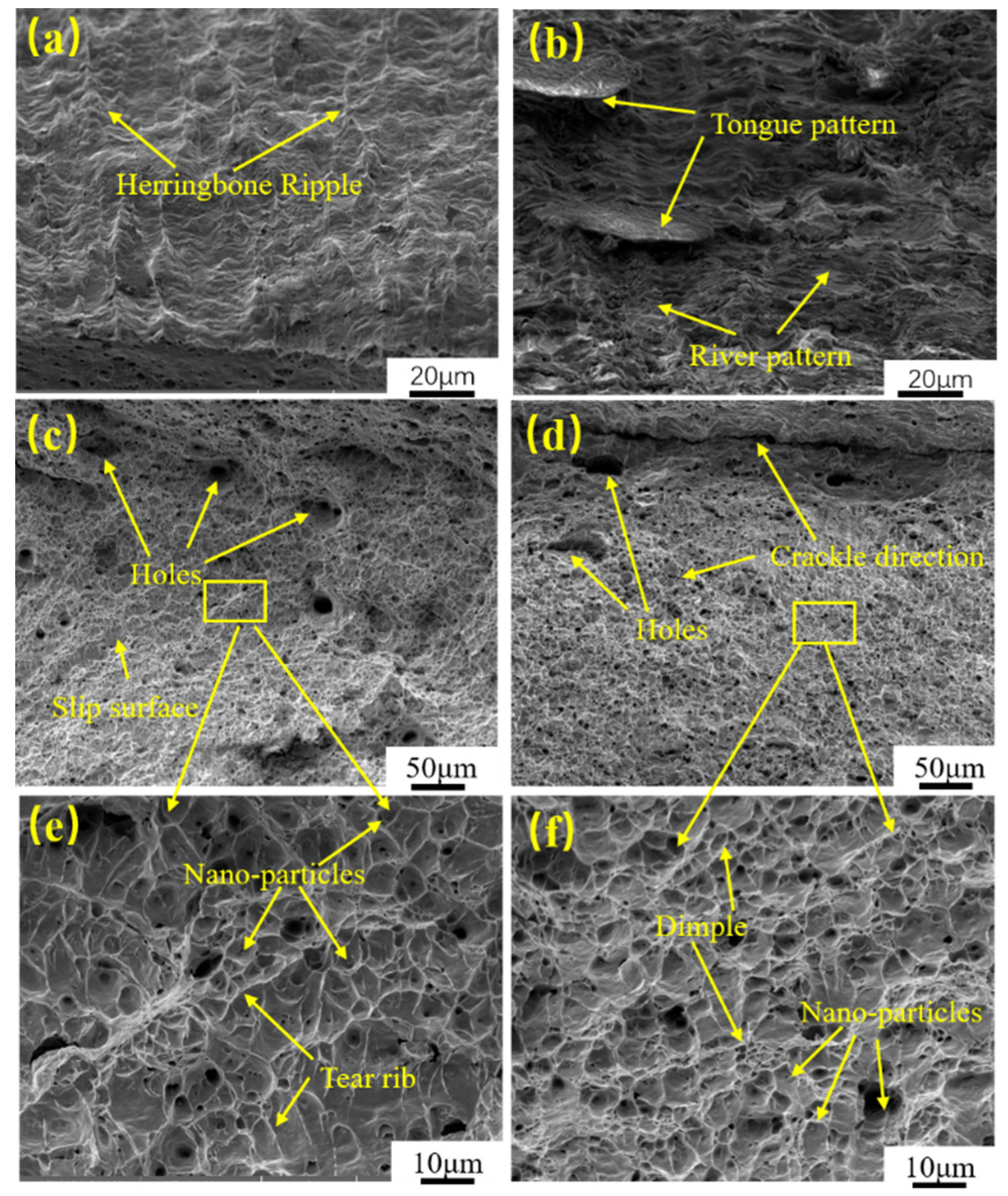

3.4. Tensile Fracture Morphology

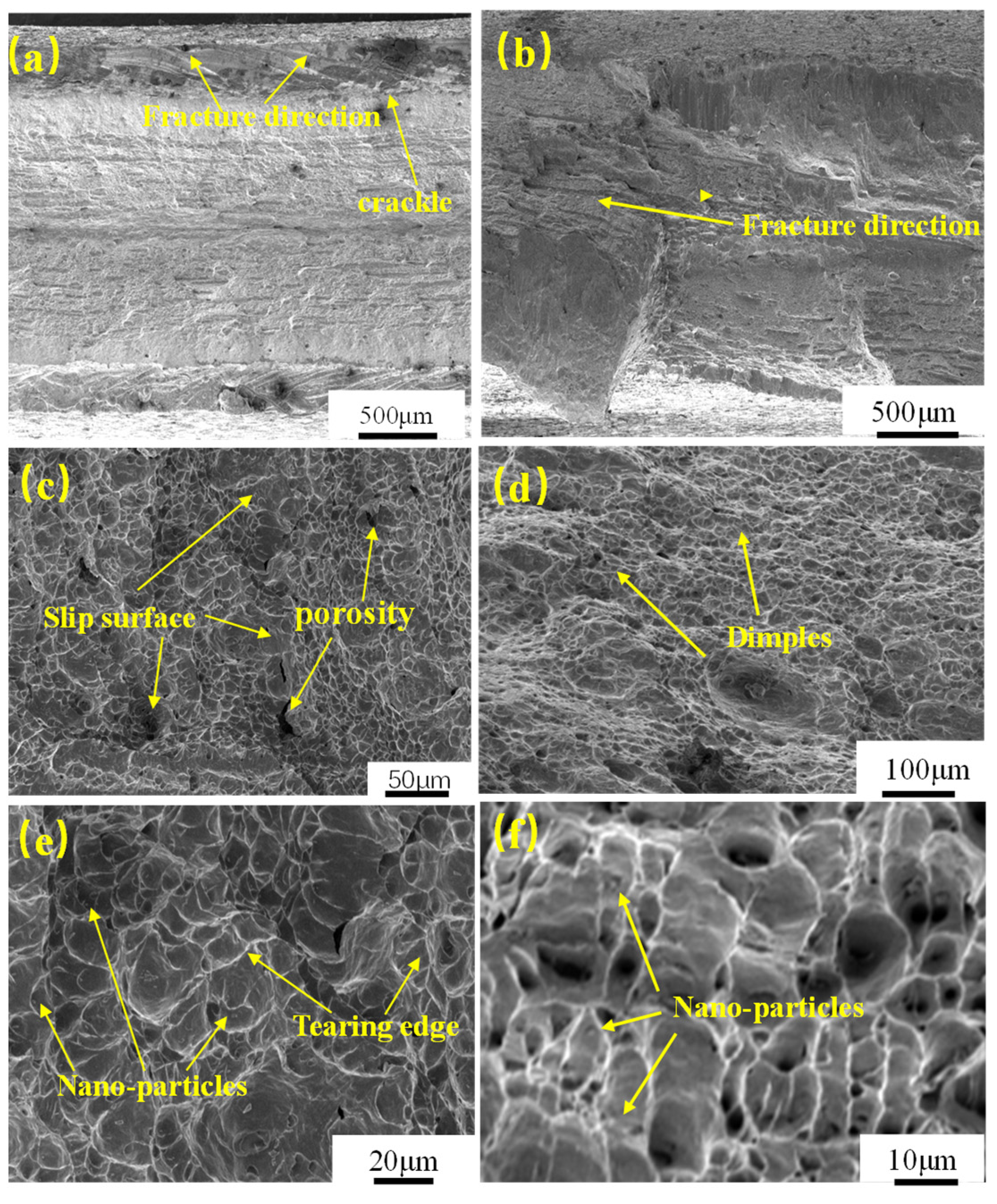

3.5. Impact Toughness

4. Conclusions

- (1)

- After laser shock peening, the ferrite microstructure of the joint weld area in the high-power shock wave extrusion becomes elongated with a mesh distribution; bainite grains have a broken distribution in which the heat-affected zone and the parent material area of grain refinement increases;

- (2)

- After laser shock peening on HC420LA, the surface and depth direction of microhardness, the welding residual tensile stress into residual compressive stress, and the residual stress value of the welded joints in each region increased by 2.24, 2.39 and 2.04 times when compared to the untreated specimens; microhardness values compared to untreated specimens increased by 7.3%, 30.3% and 19.4%. The microhardness and residual stress in the depth direction decreased due to the enhancement of the inverse bremsstrahlung effect, which affects the layer depth up to 0.6 mm;

- (3)

- After laser shock peening on HC420LA, the tensile strength and heat-affected zone of low-alloy high-strength steel welded joints with Charpy impact absorbed more work than untreated specimens by 4.7% and 37%; given the tough fracture characteristics, the impact fracture is a slip surface—with tough fracture characteristics. Tensile fractures are of the microporous aggregation-type of ductile fracture characteristics. The welded joint toughness is increased due to residual pressure, the increase in residual stress and hardening layer formation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, K.; Hou, J.; Xiang, H.; Cheng, Y. Development and application of cold-rolled low-alloy high-strength steel HC340LA. Henan Metall. 2019, 27, 12–13+24. [Google Scholar]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Xie, Z.; Shang, C.; Wang, X.; Han, G.; Misra, R. Recent progress in third-generation low alloy steels developed under M 3 microstructure control. Int. J. Miner. Metall. Mater. 2020, 27, 1–9. [Google Scholar] [CrossRef]

- Riofrío, P.G.; Capela, C.A.; Ferreira, J.A.; Ramalho, A. Interactions of the process parameters and mechanical properties of laser butt welds in thin high strength low alloy steel plates. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2020, 234, 665–680. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, K.Y.; Lu, J.Z.; Zhang, Y.K.; Dai, F.Z.; Zhong, J.W. Effects of laser shock processing with different shocked paths on mechanical properties of laser welded ANSI 304 stainless steel joint. Mater. Sci. Eng. A 2011, 528, 4652–4657. [Google Scholar] [CrossRef]

- Du, Q.B.; Zhang, Z.W.; Zhang, L.Y.; Liu, C.P. Effect of post-weld treatment on the organization and properties of Q690 steel joints. Coal Min. Mach. 2020, 41, 101–103. [Google Scholar]

- Muhammed, M.; Mustapha, M.; Ginta, T.L.; Ali, A.M.; Mustapha, F.; Hampo, C.C. Statistical review of microstructure-property correlation of stainless steel: Implication for pre-and post-weld treatment. Processes 2020, 8, 811. [Google Scholar] [CrossRef]

- Qiao, H.; Hu, X.; Zhao, J.; Wu, J.; Sun, B.; Lu, Y.; Guo, Y. Influence parameters and development applications of laser impact peening. Surf. Technol. 2019, 48, 1–9+53. [Google Scholar]

- Acharya, S.; Suwas, S.; Chatterjee, K. Review of recent developments in surface nanocrystallization of metallic biomaterials. Nanoscale 2021, 13, 2286–2301. [Google Scholar] [CrossRef]

- Lou, S.; Li, Y.; Zhou, L.; Nie, X.; He, G.; Li, Y.; He, W. Surface nanocrystallization of metallic alloys with different stacking fault energy induced by laser shock processing. Mater. Des. 2016, 104, 320–326. [Google Scholar] [CrossRef]

- Dorman, M.; Toparli, M.B.; Smyth, N.; Cini, A.; Fitzpatrick, M.E.; Irving, P.E. Effect of laser shock peening on residual stress and fatigue life of clad 2024 aluminium sheet containing scribe defects. Mater. Sci. Eng. A 2012, 548, 142–151. [Google Scholar] [CrossRef]

- Lim, H.; Kim, P.; Jeong, H.; Jeong, S. Enhancement of abrasion and corrosion resistance of duplex stainless steel by laser shock peening. J. Mater. Process. Technol. 2012, 212, 1347–1354. [Google Scholar] [CrossRef]

- Qin, Q.; Wang, Z.; Wen, R.; Yu, S.Y.; Zhang, J.N. Study and analysis of the strengthening mechanism of laser technology in metals. Therm. Process. Technol. 2021, 50, 17–21. [Google Scholar]

- Li, W.; Li, Y.H.; He, W.F.; Li, Q.P. Development and application of laser impact intensification technology. Adv. Laser Optoelectron. 2008, 12, 15–19. [Google Scholar]

- Liu, X.J.; Zhang, Y.N.; Wu, J.J.; Hu, T.Y.; Zhang, H.Y.; Wan, L.J. Research on the principle of laser impact peening technology and its application. Nonferrous Met. Process. 2019, 48, 10–15. [Google Scholar]

- Zhang, Z.; Nian, Q.; Doumanidis, C.C.; Liao, Y. First-principles modeling of laser-matter interaction and plasma dynamics in nanosecond pulsed laser shock processing. J. Appl. Phys. 2018, 123, 054901. [Google Scholar] [CrossRef]

- Zhang, P.J.; Chen, J.Q.; Yang, X. Laser impact process of 16MnR steel and its effect on the stress corrosion performance of welded structures. Mater. Eng. 2022, 50, 145–154. [Google Scholar]

- Ramkumar, K.D.; Kumar, P.S.G.; Krishna, V.R.; Chandrasekhar, A.; Dev, S.; Abraham, W.S.; Prabhakaran, S.; Kalainathan, S.; Sridhar, R. Influence of laser peening on the tensile strength and impact toughness of dissimilar welds of Inconel 625 and UNS S32205. Mater. Sci. Eng. A 2016, 676, 88–99. [Google Scholar] [CrossRef]

- Salimianrizi, A.; Foroozmehr, E.; Badrossamay, M.; Farrokhpour, H. Effect of Laser Shock Peening on surface properties and residual stress of Al6061-T6. Opt. Lasers Eng. 2016, 77, 112–117. [Google Scholar] [CrossRef]

- Li, K.; He, X.; Li, L.; Yang, L.; Hu, J. Residual stress distribution of aluminium-lithium alloy in hybrid process of friction stir welding and laser peening. Opt. Laser Technol. 2022, 152, 108149. [Google Scholar] [CrossRef]

- Ayad, M.; Lapostolle, L.; Rondepierre, A.; Le Bras, C.; Ünaldi, S.; Donik, Č.; Klobčar, D.; Berthe, L.; Trdan, U. New methodology of dynamical material response of dissimilar FSWed Al alloy joint under high strain rate laser shock loading. Mater. Des. 2022, 222, 111080. [Google Scholar] [CrossRef]

- Mao, B.; Li, B.; Lin, D.; Liao, Y. Enhanced room temperature stretch formability of AZ31B magnesium alloy sheet by laser shock peening. Mater. Sci. Eng. A 2019, 756, 219–225. [Google Scholar] [CrossRef]

- Lu, Y.; Zhao, J.B.; Qiao, H.C.; Sun, B. Strengthening mechanism of TC17 titanium alloy warm laser shock peening. Surf. Technol. 2018, 47, 1–7. [Google Scholar]

- Berto, F. Some recent results on the fatigue strength of notched specimens made of 40CrMoV13. 9 steel at room and high temperature. Phys. Mesomech. 2015, 18, 105–126. [Google Scholar] [CrossRef]

- Wilshaw, T.R.; Pratt, P.L. On the plastic deformation of Charpy specimens prior to general yield. J. Mech. Phys. Solids 1966, 14, 7–19. [Google Scholar] [CrossRef]

- Shuang, D. Mechanical Properties of Metals; Machinery Industry Press: Beijing, China, 1999; pp. 1–169. [Google Scholar]

| C | Si | Mn | S | P | Nb | Als | Ti |

|---|---|---|---|---|---|---|---|

| 0.1 | 0.5 | 1.6 | 0.025 | 0.025 | 0.09 | 0.015 | 0.015 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Feng, A.; Pan, X.; Chen, C.; Wei, Y.; Wang, J. Study on the Microstructure and Properties of Welded Joints of Laser Shock Peening on HC420LA Low-Alloy High-Tensile Steel. Materials 2023, 16, 4238. https://doi.org/10.3390/ma16124238

Wang Y, Feng A, Pan X, Chen C, Wei Y, Wang J. Study on the Microstructure and Properties of Welded Joints of Laser Shock Peening on HC420LA Low-Alloy High-Tensile Steel. Materials. 2023; 16(12):4238. https://doi.org/10.3390/ma16124238

Chicago/Turabian StyleWang, Yu, Aixin Feng, Xiaoming Pan, Chunlun Chen, Yacheng Wei, and Jun Wang. 2023. "Study on the Microstructure and Properties of Welded Joints of Laser Shock Peening on HC420LA Low-Alloy High-Tensile Steel" Materials 16, no. 12: 4238. https://doi.org/10.3390/ma16124238

APA StyleWang, Y., Feng, A., Pan, X., Chen, C., Wei, Y., & Wang, J. (2023). Study on the Microstructure and Properties of Welded Joints of Laser Shock Peening on HC420LA Low-Alloy High-Tensile Steel. Materials, 16(12), 4238. https://doi.org/10.3390/ma16124238