Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance

Abstract

1. Introduction

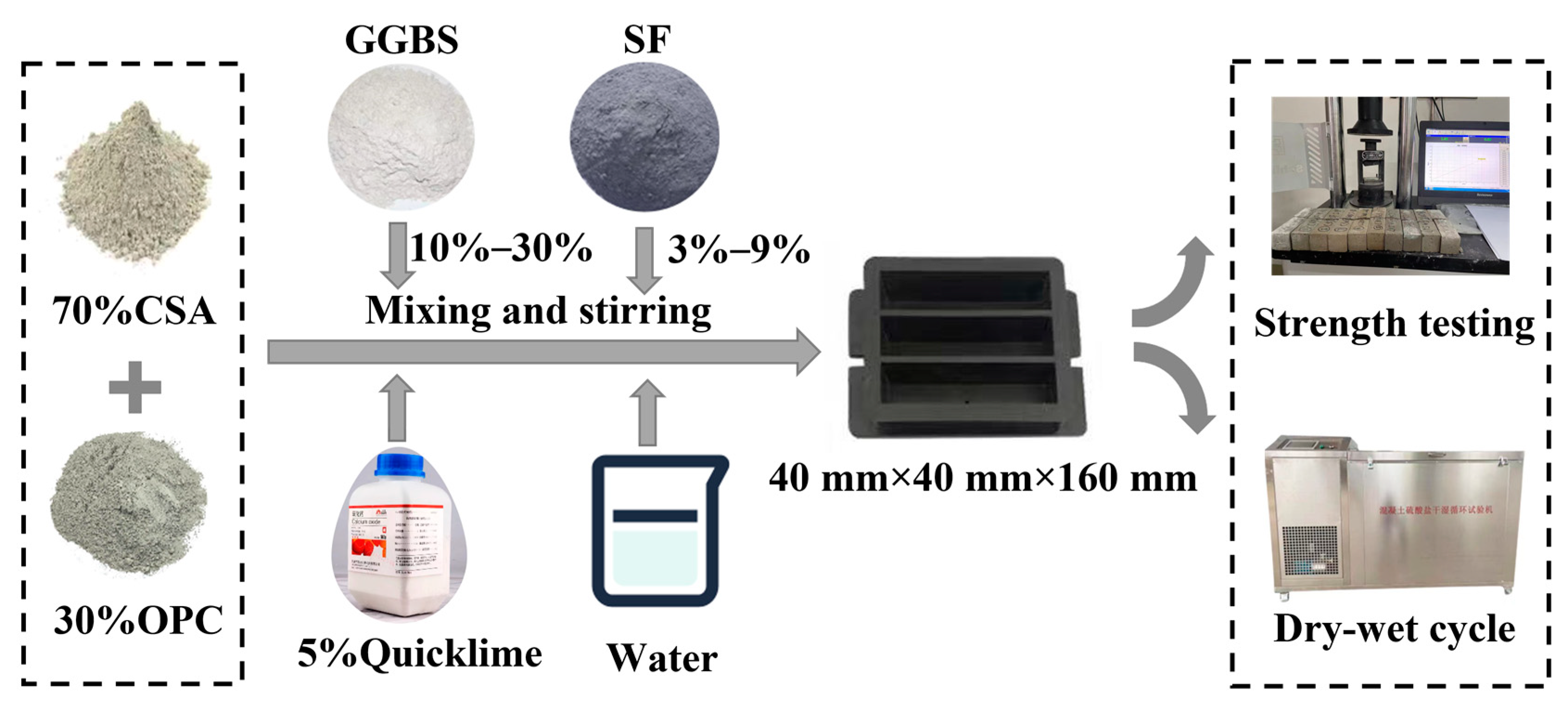

2. Materials and Methods

2.1. Raw Materials

2.2. Mixture Proportion of Composite Cement Slurry

2.3. Experimental Methods

2.3.1. Setting Time

2.3.2. Mechanical Strength

2.3.3. Sulphate Resistance Performance

2.3.4. X-ray Diffractometry (XRD)

2.3.5. Thermogravimetric Analysis (TG)

2.3.6. Scanning Electron Microscopy (SEM)

2.3.7. Mercury Intrusion Porosimetry (MIP)

3. Results

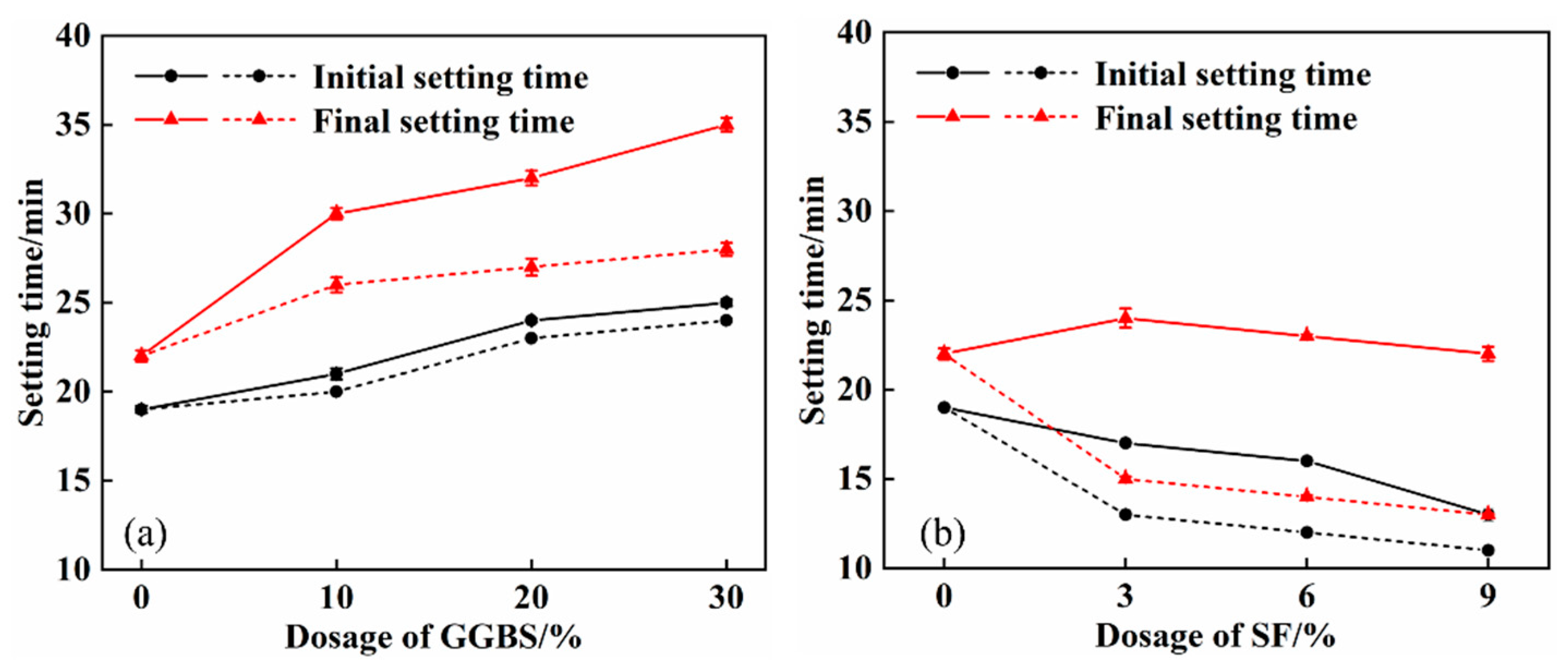

3.1. Effect of Quicklime on Setting Time of SPB and SPF Pastes

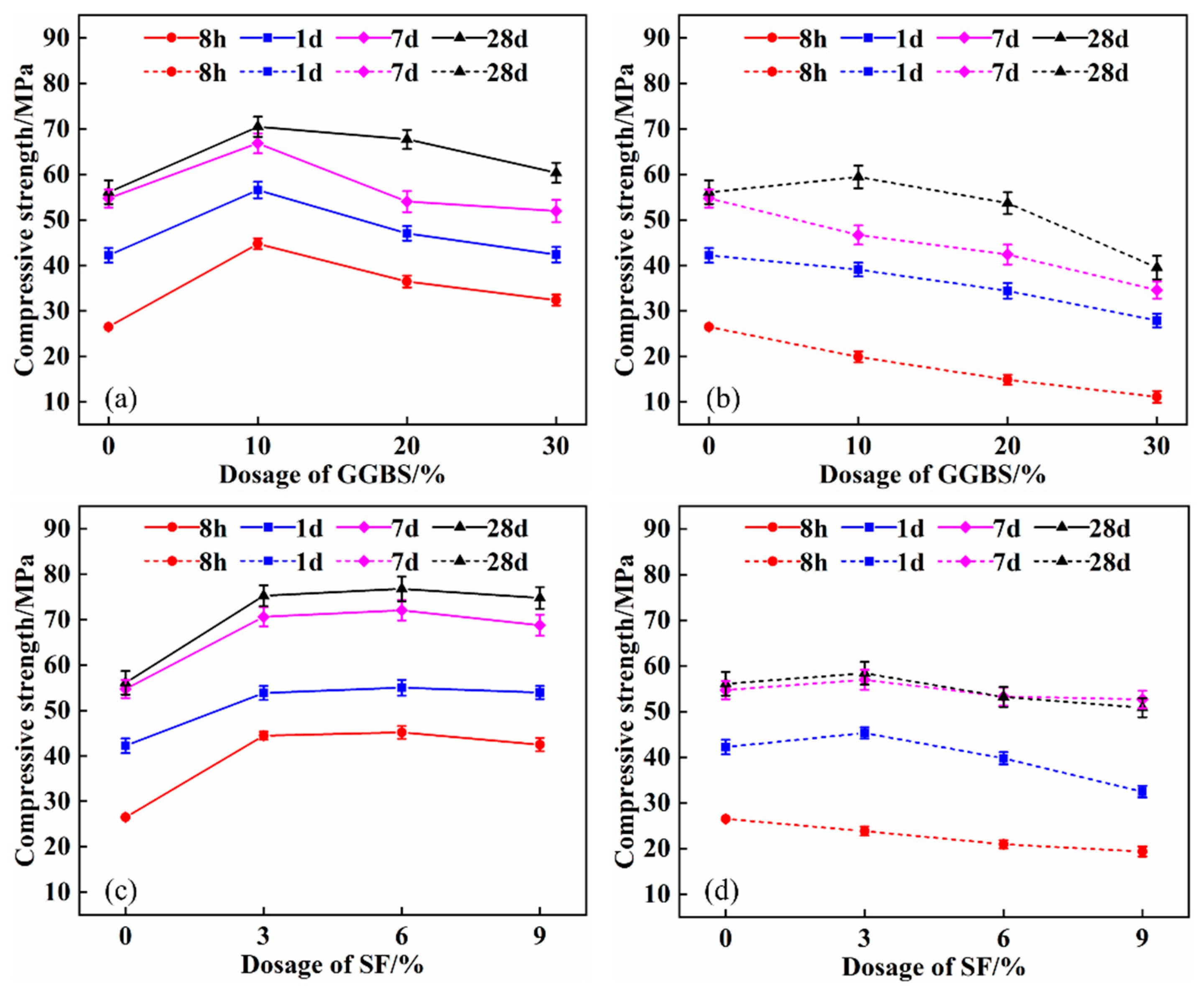

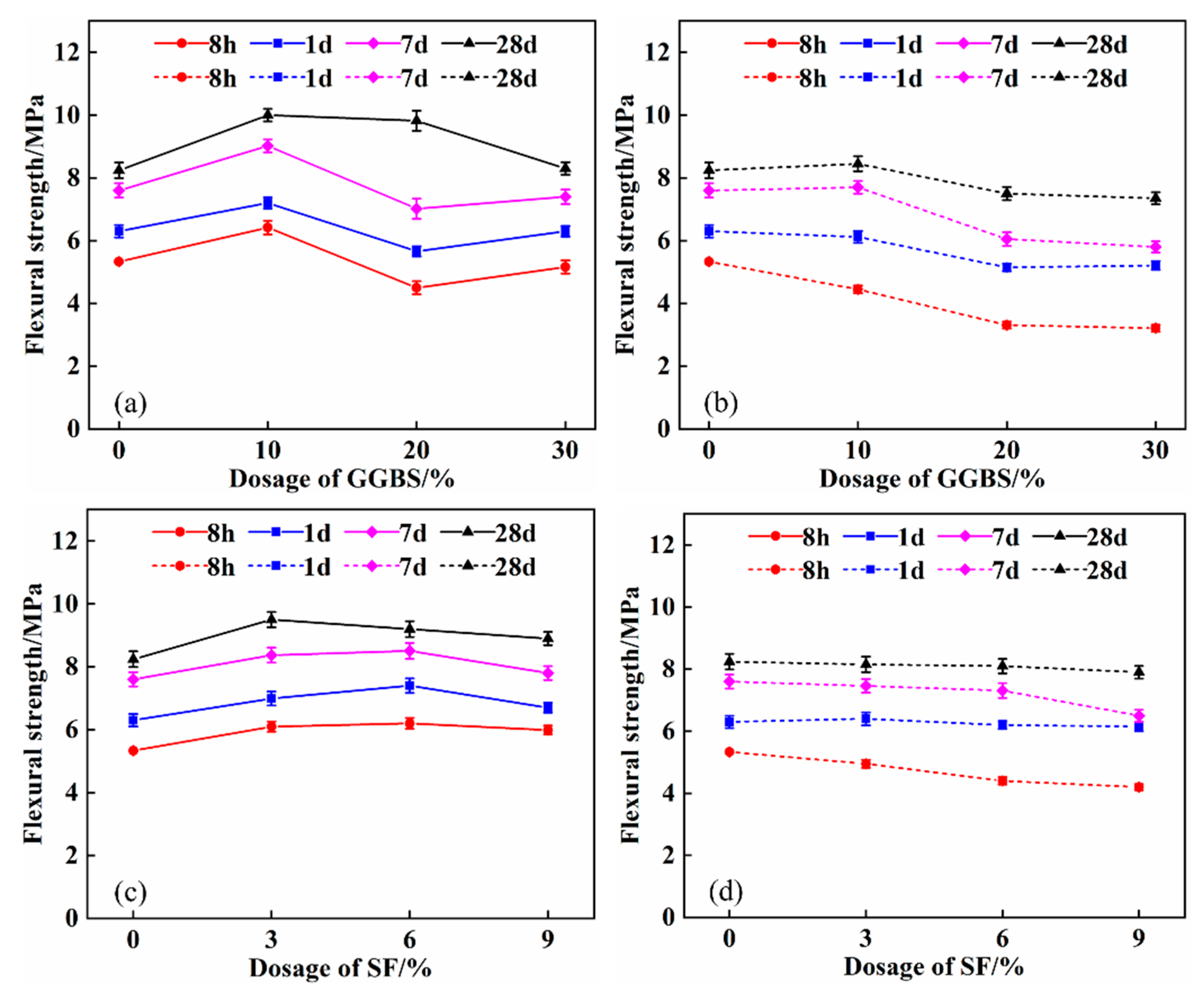

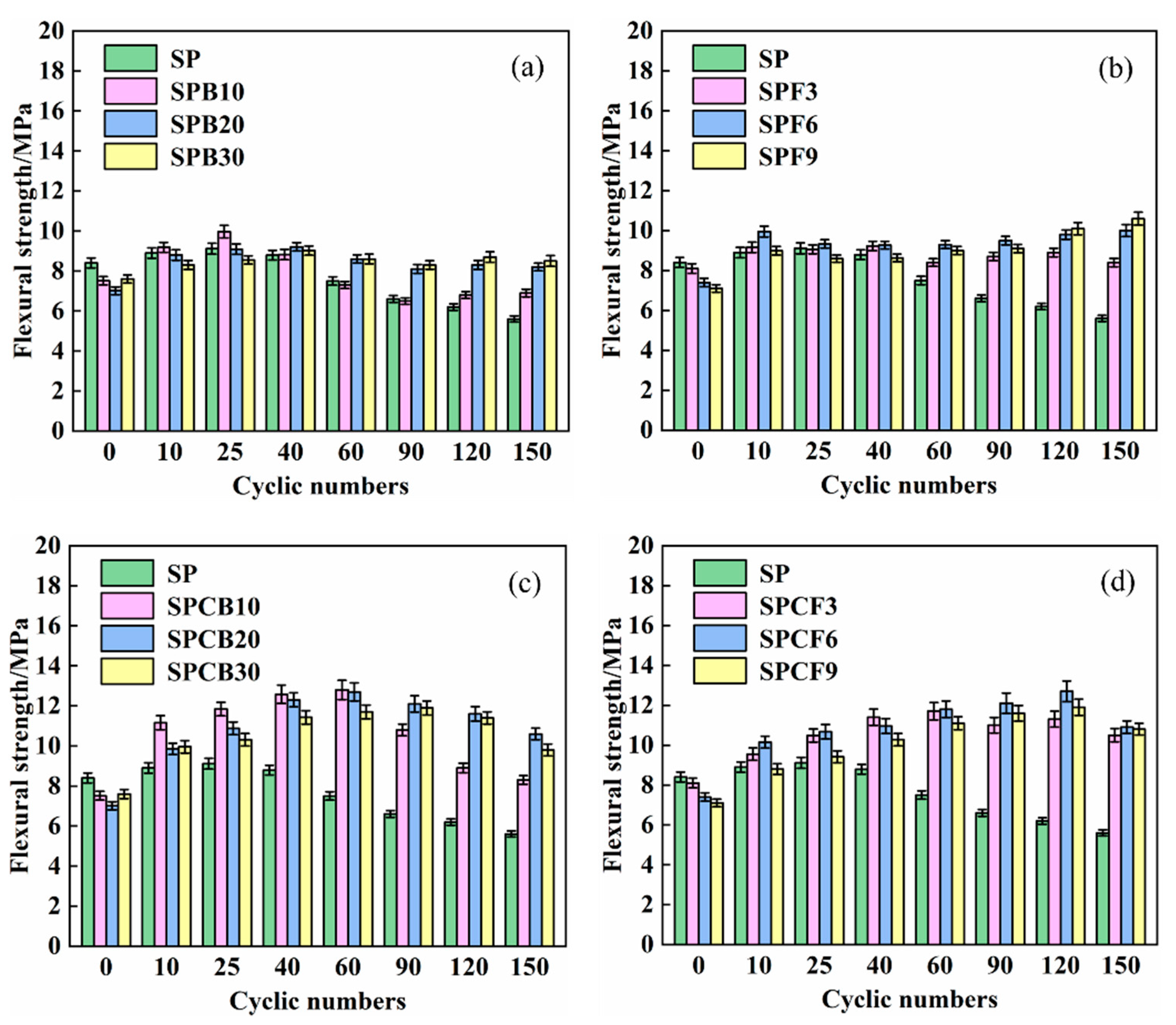

3.2. Effect of Quicklime on Mechanical Properties of SPB and SPF Repair Mortar

3.3. The Effect of Quicklime on the Mass Change Rate of SPB and SPF Repair Mortar under Sulphate Attack

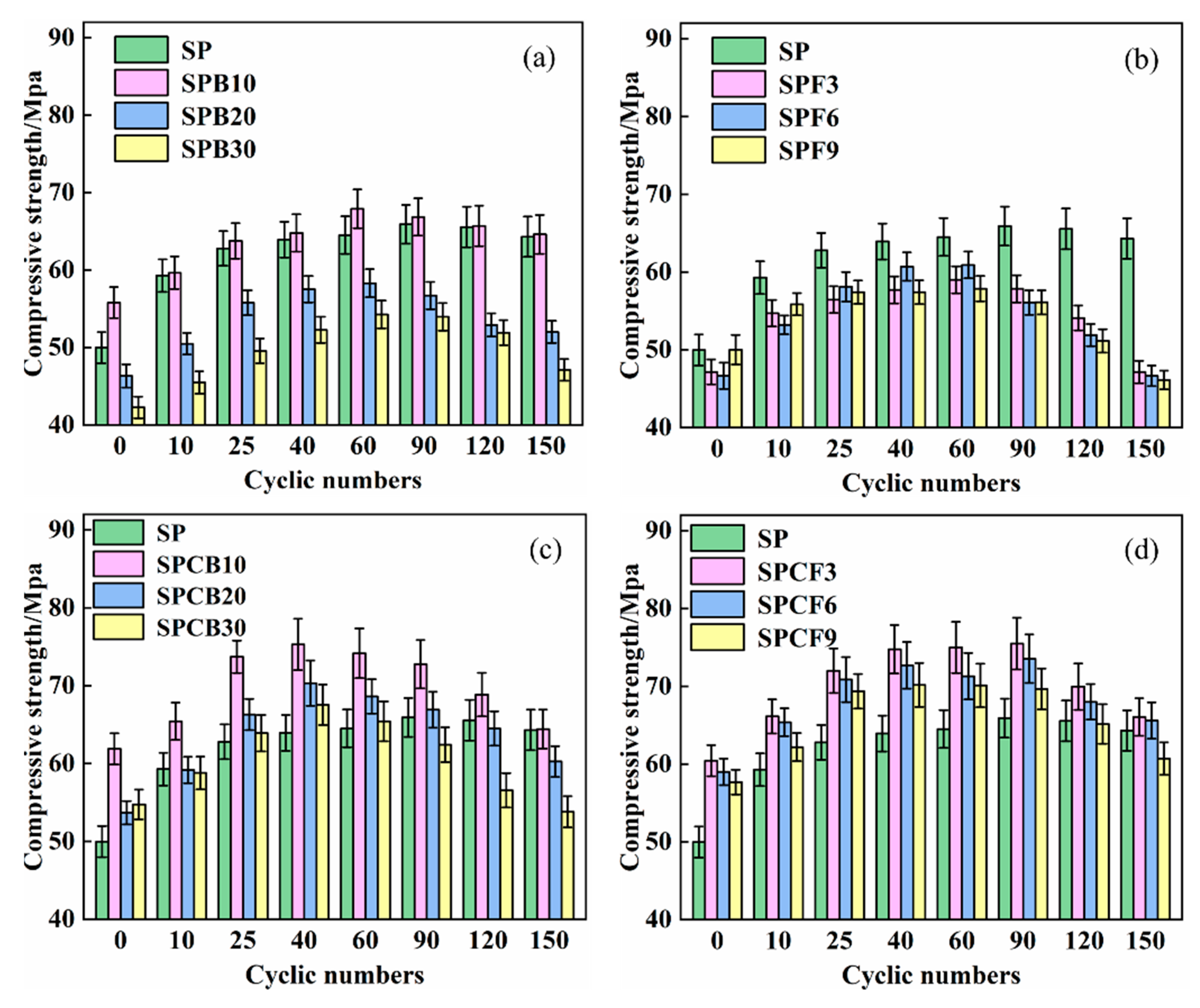

3.4. Effect of Quicklime on Mechanical Properties of SPB and SPF Repair Mortar under Sulphate Attack

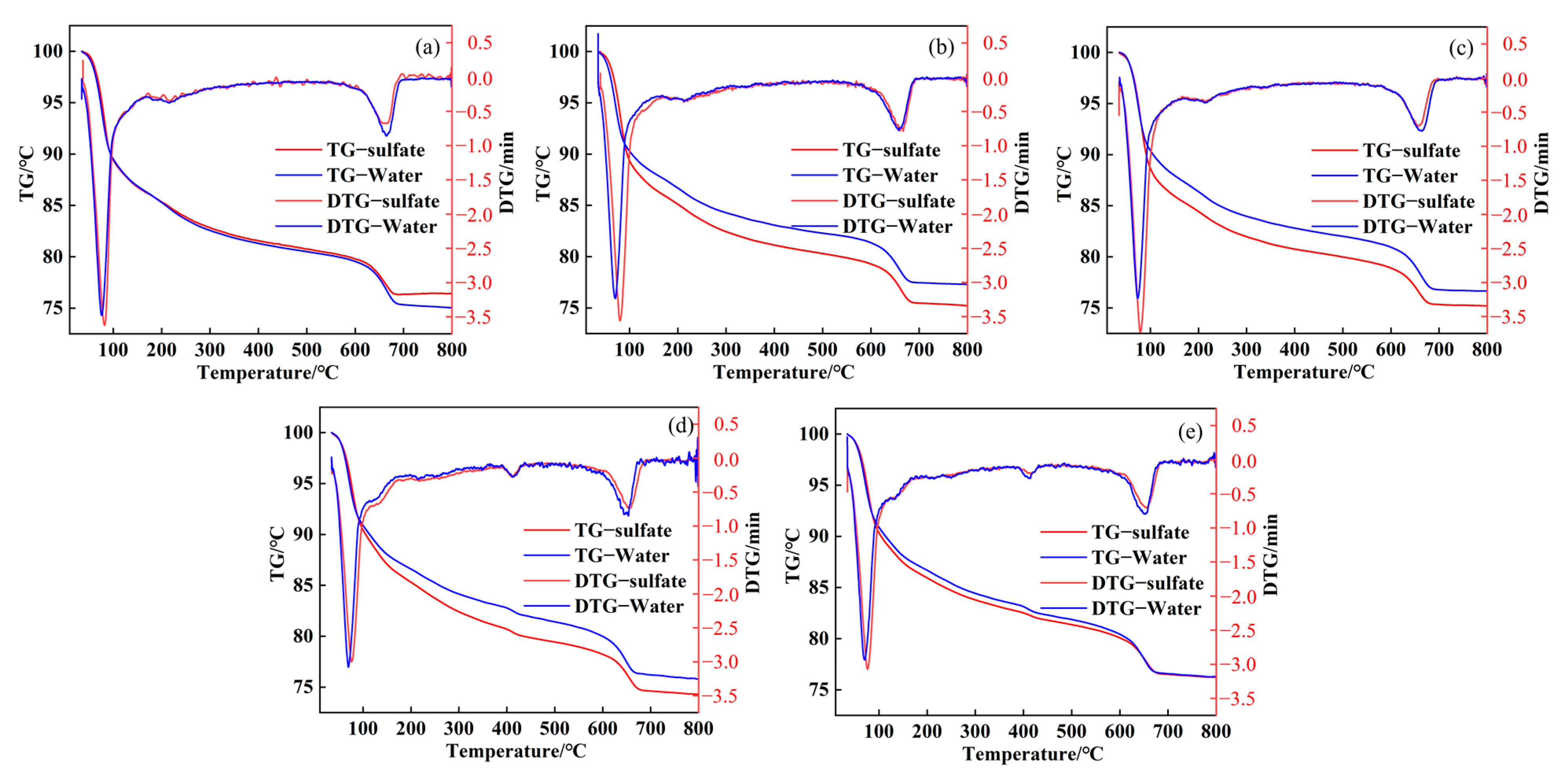

3.5. The Effect of Quicklime on the Phase and Amount of Hydration Products of SPB and SPF Pastes

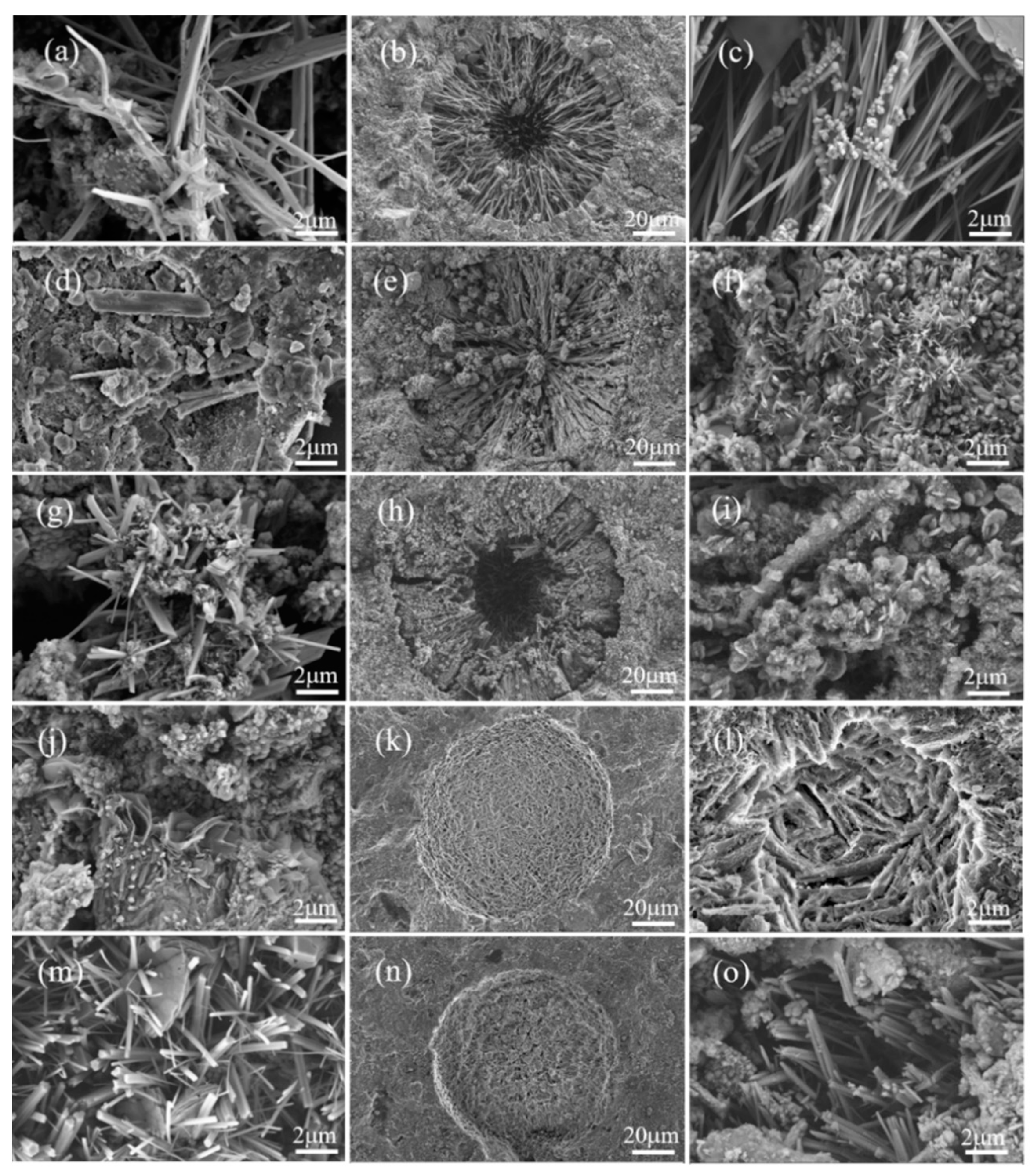

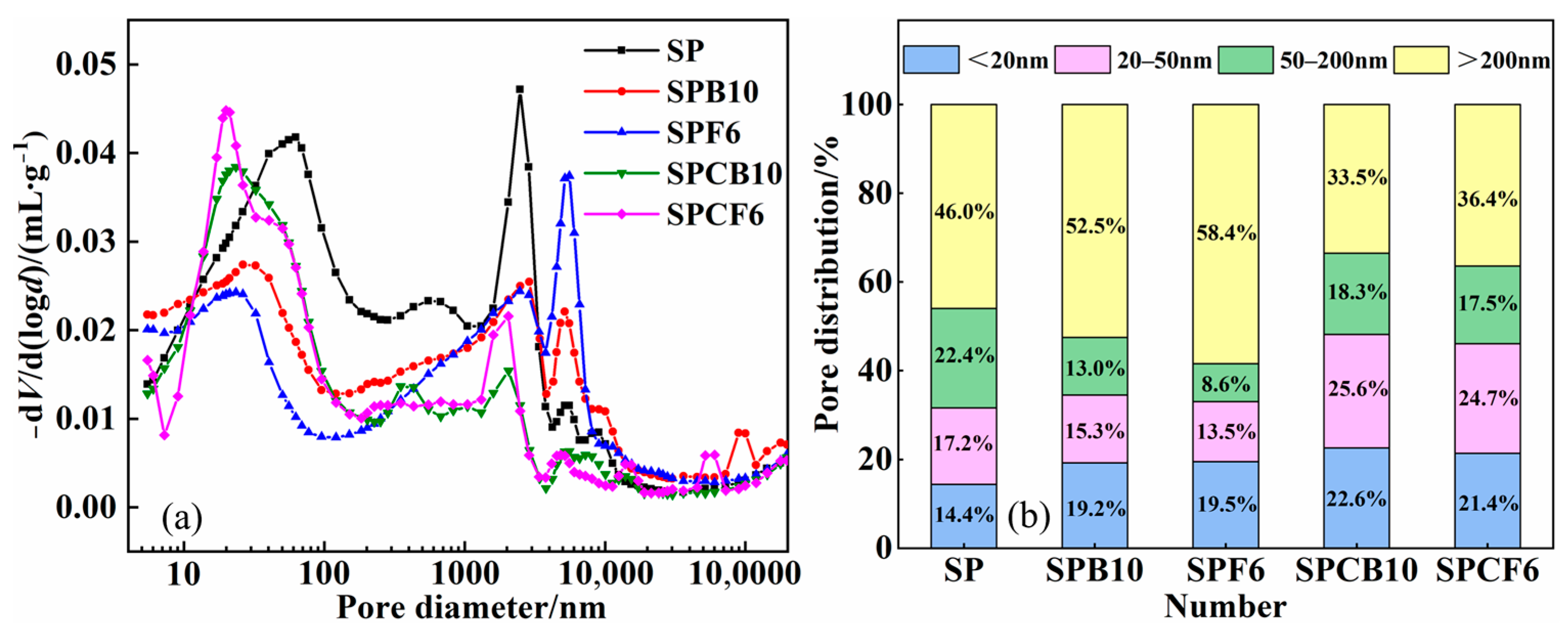

3.6. Effect of Quicklime on Microstructure and Pore Characteristics of SPB and SPF Hydration Products

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pasupathy, K.; Cheema, D.S.; Sanjayan, J. Durability performance of fly ash-based geopolymer concrete buried in saline environment for 10 years. Constr. Build. Mater. 2021, 281, 122596. [Google Scholar] [CrossRef]

- Nadir, H.M.; Ahmed, A. The Mechanisms of Sulphate Attack in Concrete-A Review. Mod. Approaches Mater. Sci. 2022, 5, 658–670. [Google Scholar]

- Liu, F.; Zhang, T.; Luo, T.; Zhou, M.; Zhang, K.; Ma, W. Study on the Deterioration of Concrete under Dry-Wet Cycle and Sulfate Attack. Materials 2020, 13, 4095. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Guo, M.; Cui, J.; Li, J.; Xu, L. Partially-exposed cast-in-situ concrete degradation induced by internal-external sulfate and magnesium multiple coupled attack. Constr. Build. Mater. 2021, 294, 123560. [Google Scholar] [CrossRef]

- Bary, B.; Leterrier, N.; Deville, E.; Le Bescop, P. Coupled chemo-transport-mechanical modelling and numerical simulation of external sulfate attack in mortar. Cem. Concr. Compos. 2014, 49, 70–83. [Google Scholar] [CrossRef]

- Long, T.; Zhang, H.; Chen, Y.; Li, Z.; Xu, J.; Shi, X.; Wang, Q. Effect of sulphate attack on the flexural fatigue behaviour of fly ash–based geopolymer concrete. J. Strain Anal. Eng. Des. 2018, 53, 711–718. [Google Scholar] [CrossRef]

- Zhao, D.C. On design techniques for proportional ratiosof anti-corrosive concrete in multiple erosion environment. Shanxi Archit. 2021, 47, 74–76. (In Chinese) [Google Scholar]

- Hu, Z.R.; Jin, Y. Study on Mix Ratio Design of Sulphate Resistant Concrete. Sichuan Water Power 2020, 39, 39–43. (In Chinese) [Google Scholar]

- Tao, Y.; Rahul, A.V.; Mohan, M.K.; De Schutter, G.; Van Tittelboom, K. Recent progress and technical challenges in using calcium sulfoaluminate (CSA) cement. Cem. Concr. Compos. 2022, 137, 104908. [Google Scholar] [CrossRef]

- Li, S.S.; Liu, H.; Bharath, M.S.; Zhang, S.X.; Cheng, X. Variation in the sulfate attack resistance of iron rich-phosphoaluminate cement with mineral admixtures subjected to a Na2SO4 solution. Constr. Build. Mater. 2020, 230, 116817. [Google Scholar] [CrossRef]

- Jaya, R.P.; Ibrahim, M.H.W.; Salwa, M.Z. Performance of RHA Cement Concrete under Marine Environment via Wetting and Drying Cyclic by Rapid Migration Test. Int. J. Integr. Eng. 2013, 5, 2. [Google Scholar]

- Huang, Q.; Xiong, G.; Fang, Z.; Wang, S.; Wang, C.; Sun, H.; Zhu, X. Long-term performance and microstructural characteristics of cement mortars containing nano-SiO2 exposed to sodium sulfate attack. Constr. Build. Mater. 2023, 364, 130011. [Google Scholar] [CrossRef]

- Sereewatthanawut, I.; Pansuk, W.; Pheinsusom, P.; Prasittisopin, L. Chloride-induced corrosion of a galvanized steel-embedded calcium sulfoaluminate stucco system. J. Build. Eng. 2021, 44, 103376. [Google Scholar] [CrossRef]

- Elahi, M.M.A.; Shearer, C.R.; Reza, A.N.R.; Saha, A.K.; Khan, M.N.N.; Hossain, M.M.; Sarker, P.K. Improving the sulfate attack resistance of concrete by using supplementary cementitious materials (SCMs): A review. Constr. Build. Mater. 2021, 281, 122628. [Google Scholar] [CrossRef]

- Pelletier-Chaignat, L.; Winnefeld, F.; Lothenbach, B.; Müller, C.J. Beneficial use of limestone filler with calcium sulphoaluminate cement. Constr. Build. Mater. 2012, 26, 619–627. [Google Scholar] [CrossRef]

- Shen, Y.; Chen, X.; Zhang, W.; Li, X.; Qian, J. Influence of ternesite on the properties of calcium sulfoaluminate cements blended with fly ash. Constr. Build. Mater. 2018, 193, 221–229. [Google Scholar] [CrossRef]

- Nie, S.; Wang, J.; Lan, M.; Wang, Y.; Zhang, Q. Effect of Portland Cement versus Sulphoaluminate Cement on the Properties of Blended Lime-Based Mortars Prepared by Carbide Slag. Materials 2019, 12, 1012. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Chen, L.; Sun, X.; Mao, Y. Preparation of micro-iron ore tailings by wet-grinding and its application in sulphoaluminate cement. J. Renew. Mater. 2022, 10, 1007. [Google Scholar] [CrossRef]

- Gao, J.; Yu, Z.; Song, L.; Wang, T.; Wei, S. Durability of concrete exposed to sulfate attack under flexural loading and drying–wetting cycles. Constr. Build. Mater. 2013, 39, 33–38. [Google Scholar] [CrossRef]

- Carsana, M.; Gastaldi, M.; Redaelli, E. A case study on corrosion conditions and guidelines for repair of a reinforced concrete chimney in industrial environment. Struct. Infrastruct. Eng. 2022, 19, 366–377. [Google Scholar] [CrossRef]

- Feng, P.; Liu, J.; She, W.; Hong, J. A model investigation of the mechanisms of external sulfate attack on portland cement binders. Constr. Build. Mater. 2018, 175, 629–642. [Google Scholar] [CrossRef]

- Khan, M.I.; Siddique, R. Utilization of silica fume in concrete: Review of durability properties. Resour. Conserv. Recycl. 2011, 57, 30–35. [Google Scholar] [CrossRef]

- Li, X.; Hao, J.; Zhang, Q. Effect of mineral admixtures on the properties of grouting materials made from a ternary complex system. Adv. Cem. Res. 2020, 32, 389–397. [Google Scholar] [CrossRef]

- Sun, J.; Zhang, Z.; Hou, G. Utilization of fly ash microsphere powder as a mineral admixture of cement: Effects on early hydration and microstructure at different curing temperatures. Powder Technol. 2020, 375, 262–270. [Google Scholar] [CrossRef]

- Chaunsali, P.; Mondal, P. Physico-chemical interaction between mineral admixtures and OPC–calcium sulfoaluminate (CSA) cements and its influence on early-age expansion. Cem. Concr. Res. 2016, 80, 10–20. [Google Scholar] [CrossRef]

- Ding, X.Q.; Zhao, X.Y.; Xu, X.W.; Fang, Y.F. Effect of admixtures on properties of sulphoaluminate cement-common Portland cement composite system. New Build. Mater. 2020, 47, 40–44. (In Chinese) [Google Scholar]

- Zhang, G.P.; Liu, Q.F.; Niu, M.D.; Li, G.X. Effects of Nano-SiO2, and Granulated Blast Furnace Slag Powder on Corrosion Resistance of OPC-CSA Composite Reoair Mortar to Saline Soil. Bull. Chin. Ceram. Soc. 2020, 39, 3589–3594+3608. (In Chinese) [Google Scholar]

- Atahan, H.N.; Dikme, D. Use of mineral admixtures for enhanced resistance against sulfate attack. Constr. Build. Mater. 2011, 25, 3450–3457. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Papageorgiou, A.; Papadakis, V.G.; Tsimas, S. Influence of quicklime addition on the mechanical properties and hydration degree of blended cements containing different fly ashes. Constr. Build. Mater. 2008, 22, 1191–1200. [Google Scholar] [CrossRef]

- Cai, G.H.; Zhou, Y.F.; Li, J.S.; Han, L.J.; Poon, C.S. Deep insight into mechanical behavior and microstructure mechanism of quicklime-activated ground granulated blast-furnace slag pastes. Cem. Concr. Compos. 2022, 134, 104767. [Google Scholar] [CrossRef]

- Kumar, S.S.; Maheswaran, S. Thermal, Microstructural, and Mechanical Properties of Ternary Blended Geopolymers. ACI Mater. J. 2022, 119, 103–115. [Google Scholar]

- Amin, M.; Zeyad, A.M.; Tayeh, B.A.; Agwa, I.S. Effect of ferrosilicon and silica fume on mechanical, durability, and microstructure characteristics of ultra high-performance concrete. Constr. Build. Mater. 2022, 320, 126233. [Google Scholar] [CrossRef]

- Velandia, D.F.; Lynsdale, C.J.; Provis, J.L.; Ramirez, F.; Gomez, A.C. Evaluation of activated high volume fly ash systems using Na2SO4, lime and quicklime in mortars with high loss on ignition fly ashes. Constr. Build. Mater. 2016, 128, 248–255. [Google Scholar] [CrossRef]

- Wang, Y.; Yu, J.; Wang, J.; Guan, X. Effects of aluminum sulfate and quicklime/fluorgypsum ratio on the properties of calcium sulfoaluminate (CSA) cement-based double liquid grouting materials. Materials 2019, 12, 1222. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Sulfate resistance of alkali-activated slag and Portland cement based reactive powder concrete. J. Build. Eng. 2021, 43, 103205. [Google Scholar] [CrossRef]

- Das, S.K.; Mustakim, S.M.; Adesina, A.; Mishra, J.; Alomayri, T.S.; Assaedi, H.S.; Kaze, C.R. Fresh, strength and microstructure properties of geopolymer concrete incorporating lime and silica fume as replacement of fly ash. J. Build. Eng. 2020, 32, 101780. [Google Scholar] [CrossRef]

- Antiohos, S.; Papageorgiou, A.; Tsimas, S. Activation of fly ash cementitious systems in the presence of quicklime. Part II: Nature of hydration products, porosity and microstructure development. Cem. Concr. Res. 2006, 36, 2123–2131. [Google Scholar] [CrossRef]

- Haufe, J.; Vollpracht, A. Tensile strength of concrete exposed to sulfate attack. Cem. Concr. Res. 2019, 116, 81–88. [Google Scholar] [CrossRef]

- Min, Y.; Jueshi, Q.; Ying, P. Activation of fly ash–lime systems using calcined phosphogypsum. Constr. Build. Mater. 2008, 22, 1004–1008. [Google Scholar] [CrossRef]

- Senhadji, Y.; Escadeillas, G.; Mouli, M.; Khelafi, H. Influence of natural pozzolan, silica fume and limestone fine on strength, acid resistance and microstructure of mortar. Powder Technol. 2014, 254, 314–323. [Google Scholar] [CrossRef]

- Furlan, A.P.; Razakamanantsoa, A.; Ranaivomanana, H.; Amiri, O.; Levacher, D.; Deneele, D. Effect of Fly Ash on microstructural and resistance characteristics of dredged sediment stabilized with lime and cement. Constr. Build. Mater. 2021, 272, 121637. [Google Scholar] [CrossRef]

- Ganjian, E.; Pouya, H.S. Effect of magnesium and sulfate ions on durability of silica fume blended mixes exposed to the seawater tidal zone. Cem. Concr. Res. 2005, 35, 1332–1343. [Google Scholar] [CrossRef]

- Guo, Z.; Hou, P.; Xu, Z.; Gao, J.; Zhao, Y. Sulfate attack resistance of tricalcium silicate modified with nano-silica and supplementary cementitious materials. Constr. Build. Mater. 2022, 321, 126332. [Google Scholar] [CrossRef]

- Ye, H.; Chen, Z.; Huang, L. Mechanism of sulfate attack on alkali-activated slag: The role of activator composition. Cem. Concr. Res. 2019, 125, 105868. [Google Scholar] [CrossRef]

- He, W.; Li, B.; Meng, X.; Shen, Q. Compound Effects of Sodium Chloride and Gypsum on the Compressive Strength and Sulfate Resistance of Slag-Based Geopolymer Concrete. Buildings 2023, 13, 675. [Google Scholar] [CrossRef]

- Zhang, R.; Hu, R.; Bocharnikova, E.; Matichenkov, V. Co-treatment with silicon and quicklime in pig manure application as a promising option of environmnetal management. J. Environ. Manag. 2022, 309, 114684. [Google Scholar] [CrossRef]

- Sui, S.; Wu, M.; Yang, Z.; Wang, F.; Liu, Z.; Jiang, J. An investigation on the formation of Friedel’s salt in tricalcium silicate combined with metakaolin and limestone systems. Constr. Build. Mater. 2021, 284, 122855. [Google Scholar] [CrossRef]

- Adu-Amankwah, S.; Black, L.; Skocek, J.; Haha, M.B.; Zajac, M. Effect of sulfate additions on hydration and performance of ternary slag-limestone composite cements. Constr. Build. Mater. 2018, 164, 451–462. [Google Scholar] [CrossRef]

- Mun, K.J.; So, S.Y.; Soh, Y.S. The effect of slaked lime, anhydrous gypsum and limestone powder on properties of blast furnace slag cement mortar and concrete. Constr. Build. Mater. 2007, 21, 1576–1582. [Google Scholar] [CrossRef]

- Burciaga-Díaz, O. Parameters affecting the properties and microstructure of quicklime (CaO)-Activated slag cement pastes. Cem. Concr. Compos. 2019, 103, 104–111. [Google Scholar] [CrossRef]

- Koteng, D.O.; Chen, C.T. Strength development of lime–pozzolana pastes with silica fume and fly ash. Constr. Build. Mater. 2015, 84, 294–300. [Google Scholar] [CrossRef]

- Rajasekaran, G. Sulphate attack and ettringite formation in the lime and cement stabilized marine clays. Ocean. Eng. 2005, 32, 1133–1159. [Google Scholar] [CrossRef]

| Oxide | CaO | Al2O3 | SiO2 | Fe2O3 | MgO | SO3 | K2O | Na2O |

|---|---|---|---|---|---|---|---|---|

| OPC | 63.28 | 5.81 | 19.72 | 4.36 | 1.95 | 2.63 | 0.18 | 0.29 |

| CSA | 42.25 | 36.46 | 6.56 | 2.28 | 1.84 | 8.92 | 0.18 | 0.24 |

| GGBS | 34.00 | 17.70 | 34.50 | 1.03 | 6.01 | 1.64 | 0.56 | 0.34 |

| SF | 0.71 | 0.54 | 96.00 | 0.65 | 0.68 | 0.18 | 0.40 | 0.17 |

| Cement | Setting Time (min) | Flexural Strength (MPa) | Compressive Strength (MPa) | Secific Surface Area (m2/kg) | Secific Gravity (g/cm3) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Set | Final Set | 3 d | 28 d | 3 d | 28 d | |||

| OPC | 63 | 115 | 6.1 | 7.8 | 29.4 | 49.6 | 350 | 3.1 |

| CSA | 16 | 26 | 6.5 | 8.2 | 36.5 | 50.8 | 428 | 2.9 |

| Sample | CSA/g | OPC/g | GGBS/g | SF/g | Quicklime/g |

|---|---|---|---|---|---|

| SP | 490.0 | 210.0 | 0.0 | 0.0 | 0.0 |

| SPCB10 | 441.0 | 189.0 | 70.0 | 0.0 | 35.0 |

| SPCB20 | 392.0 | 168.0 | 140.0 | 0.0 | 35.0 |

| SPCB30 | 343.0 | 147.0 | 210.0 | 0.0 | 35.0 |

| SPB10 | 441.0 | 189.0 | 70.0 | 0.0 | 0.0 |

| SPB20 | 392.0 | 168.0 | 140.0 | 0.0 | 0.0 |

| SPB30 | 343.0 | 147.0 | 210.0 | 0.0 | 0.0 |

| SPCF3 | 475.3 | 203.7 | 0.0 | 21.0 | 35.0 |

| SPCF6 | 460.6 | 197.4 | 0.0 | 42.0 | 35.0 |

| SPCF9 | 445.9 | 191.1 | 0.0 | 63.0 | 35.0 |

| SPF3 | 475.3 | 203.7 | 0.0 | 21.0 | 0.0 |

| SPF6 | 460.6 | 197.4 | 0.0 | 42.0 | 0.0 |

| SPF9 | 445.9 | 191.1 | 0.0 | 63.0 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shi, C.; Yang, Y. Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance. Materials 2023, 16, 4026. https://doi.org/10.3390/ma16114026

Shi C, Yang Y. Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance. Materials. 2023; 16(11):4026. https://doi.org/10.3390/ma16114026

Chicago/Turabian StyleShi, Chen, and Ying Yang. 2023. "Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance" Materials 16, no. 11: 4026. https://doi.org/10.3390/ma16114026

APA StyleShi, C., & Yang, Y. (2023). Unveiling the Effects of Quicklime on the Properties of Sulfoaluminate Cement–Ordinary Portland Cement–Mineral Admixture Repairing Composites and Their Sulphate Resistance. Materials, 16(11), 4026. https://doi.org/10.3390/ma16114026