Numerical Simulation of Physical Fields during Spark Plasma Sintering of Boron Carbide

Abstract

1. Introduction

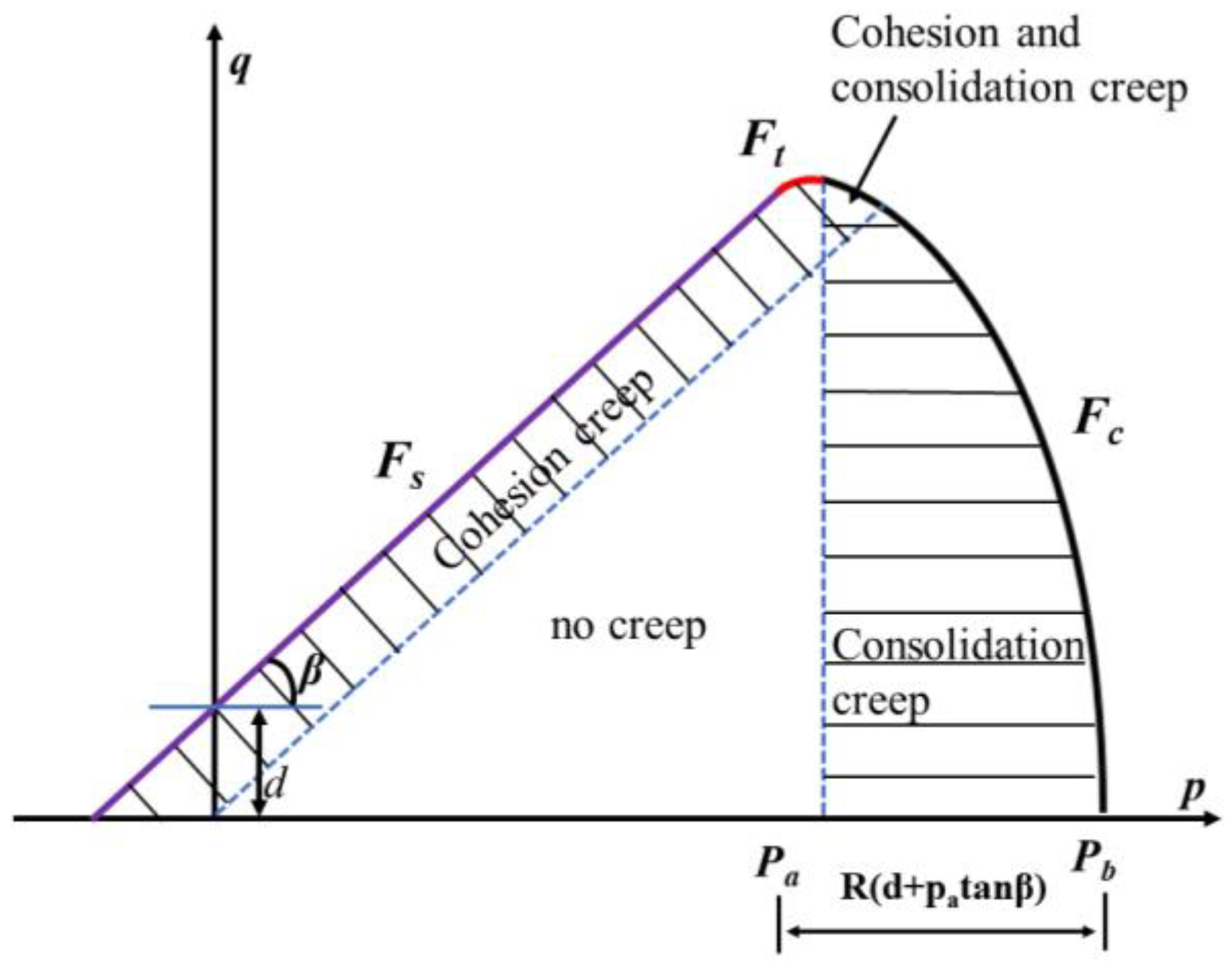

2. The Drucker-Prager Cap Model and Parameter Acquisition

2.1. The Drucker-Prager Cap Model

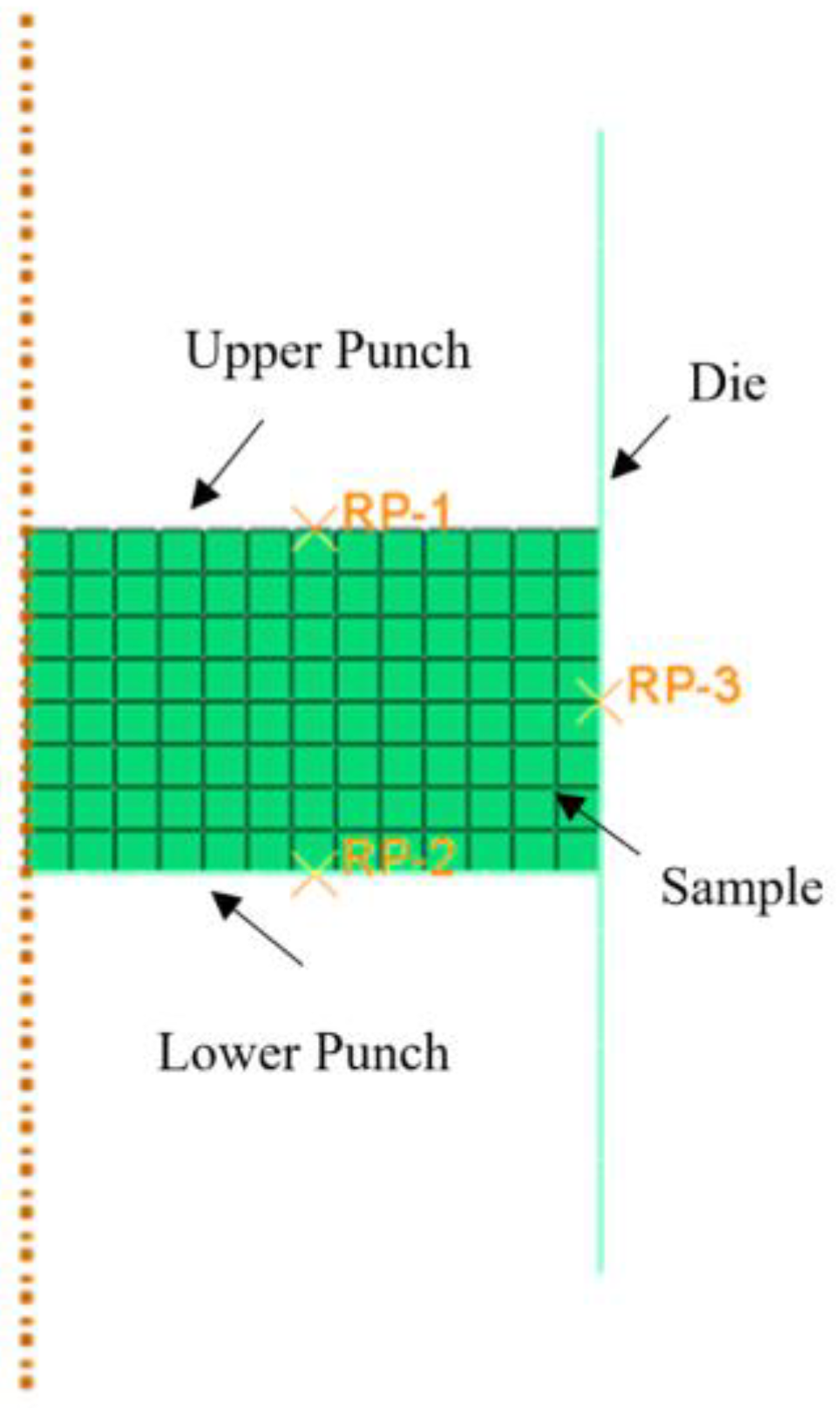

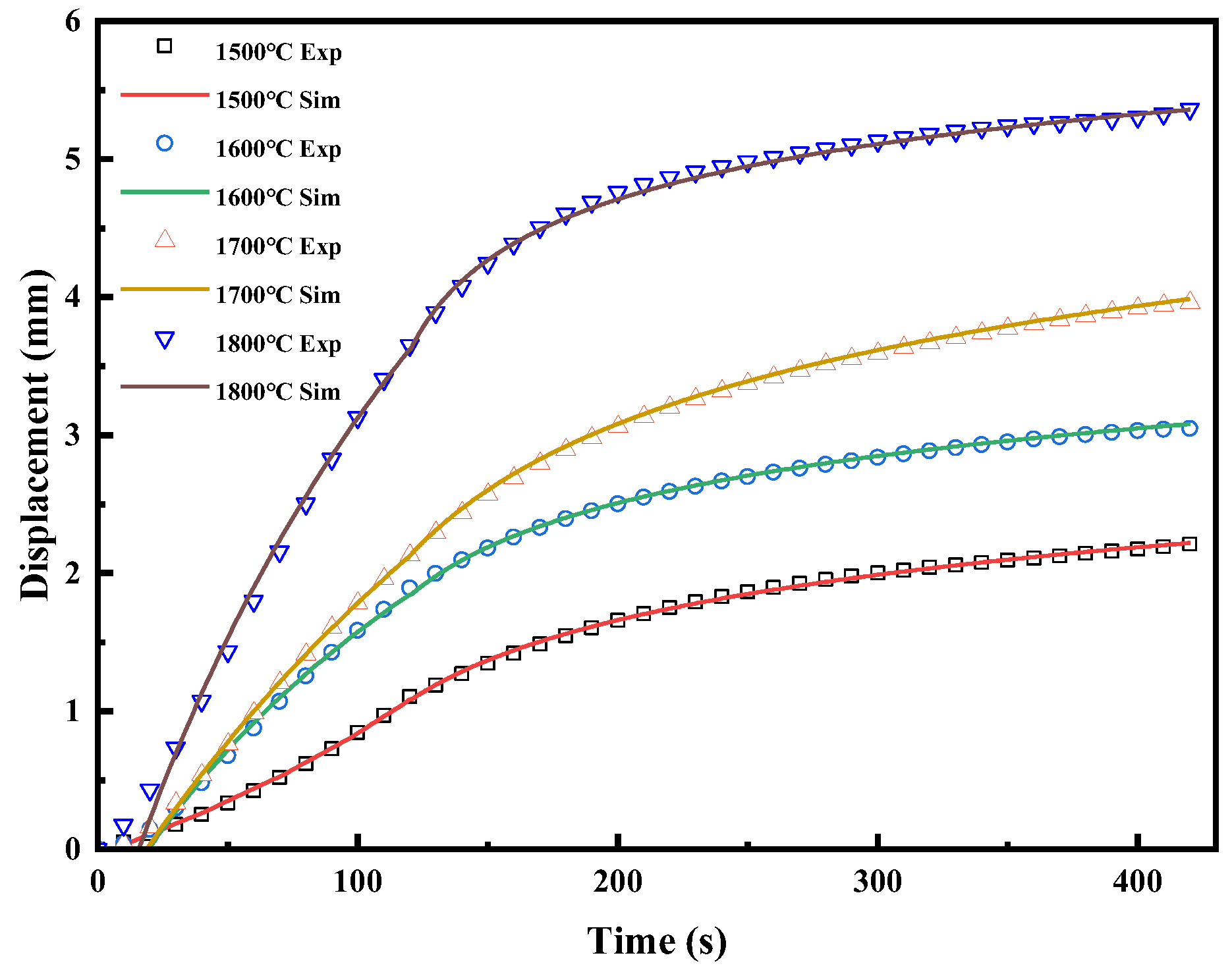

2.2. Parameter Identification of Boron Carbide Powder

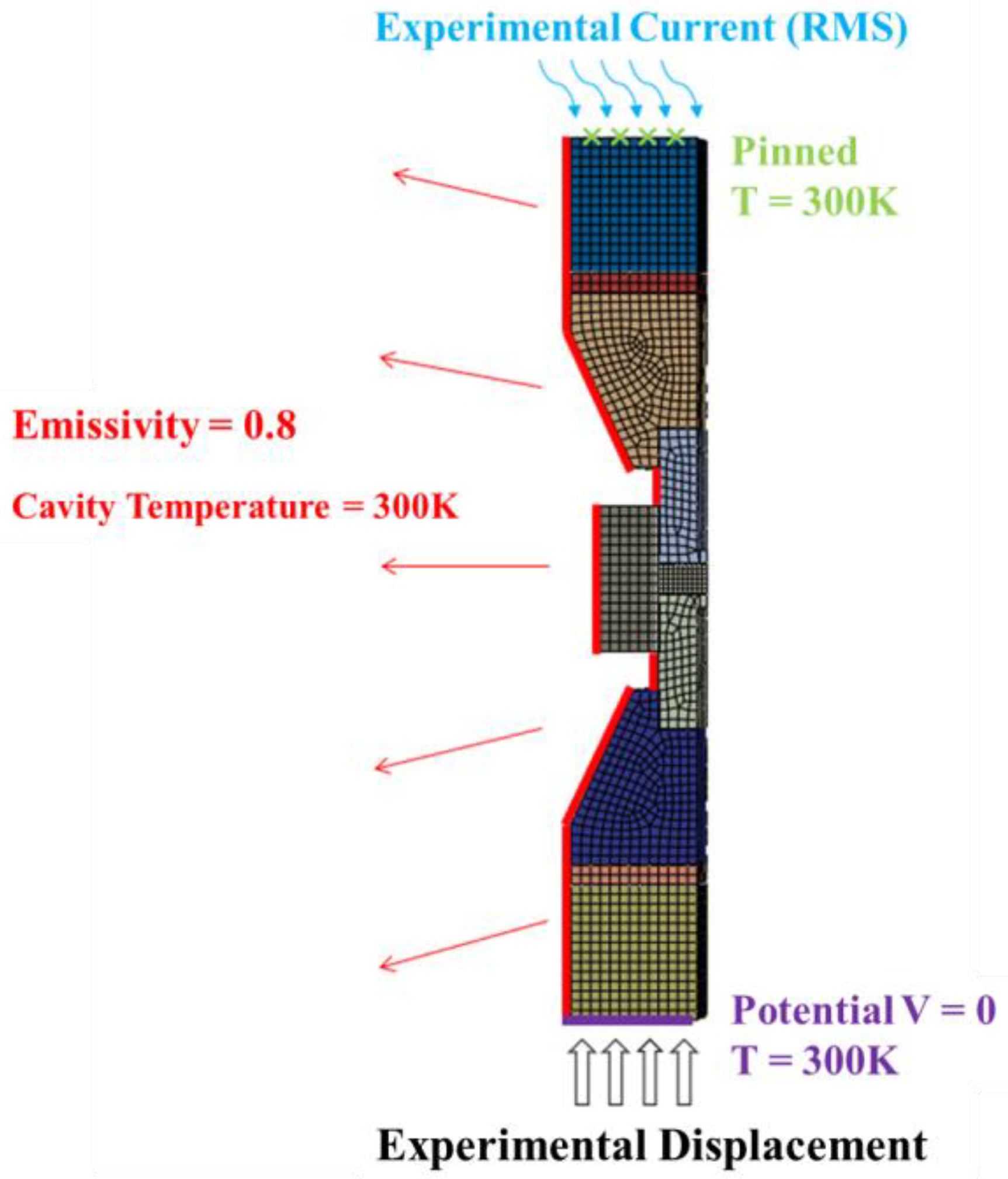

2.3. Finite Element Modeling

- A predefined temperature field of 300 K was applied to the entire system; the upper and lower surfaces of the electrodes were set to a constant temperature of 300 K.

- The potential on the lower surface of the electrode was 0, and the actual current-time curve was applied on the upper surface.

- The upper surface of the electrode was fixed, and the actual displacement-time curve was applied to the lower surface of the electrode.

- Assuming a uniform distribution of the relative density of the material before sintering, a predefined relative density field was applied to the powder with a value of 0.58.

3. Results

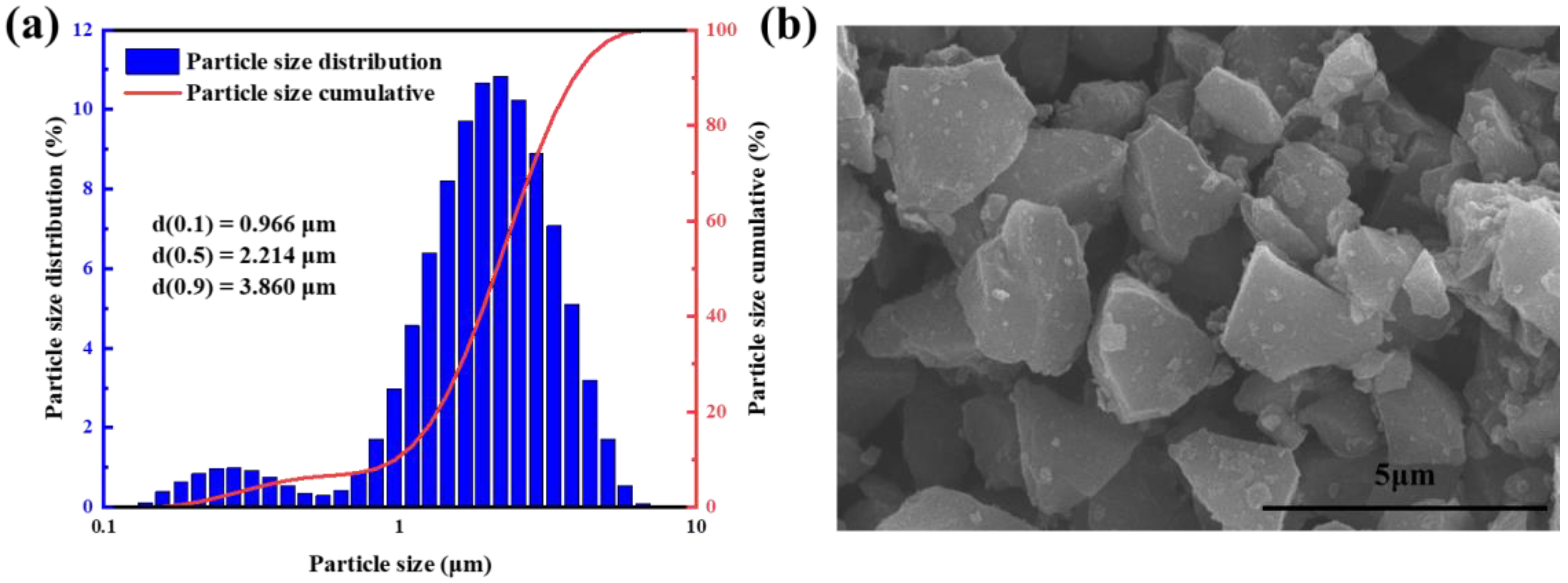

3.1. Characterization of Raw Powder

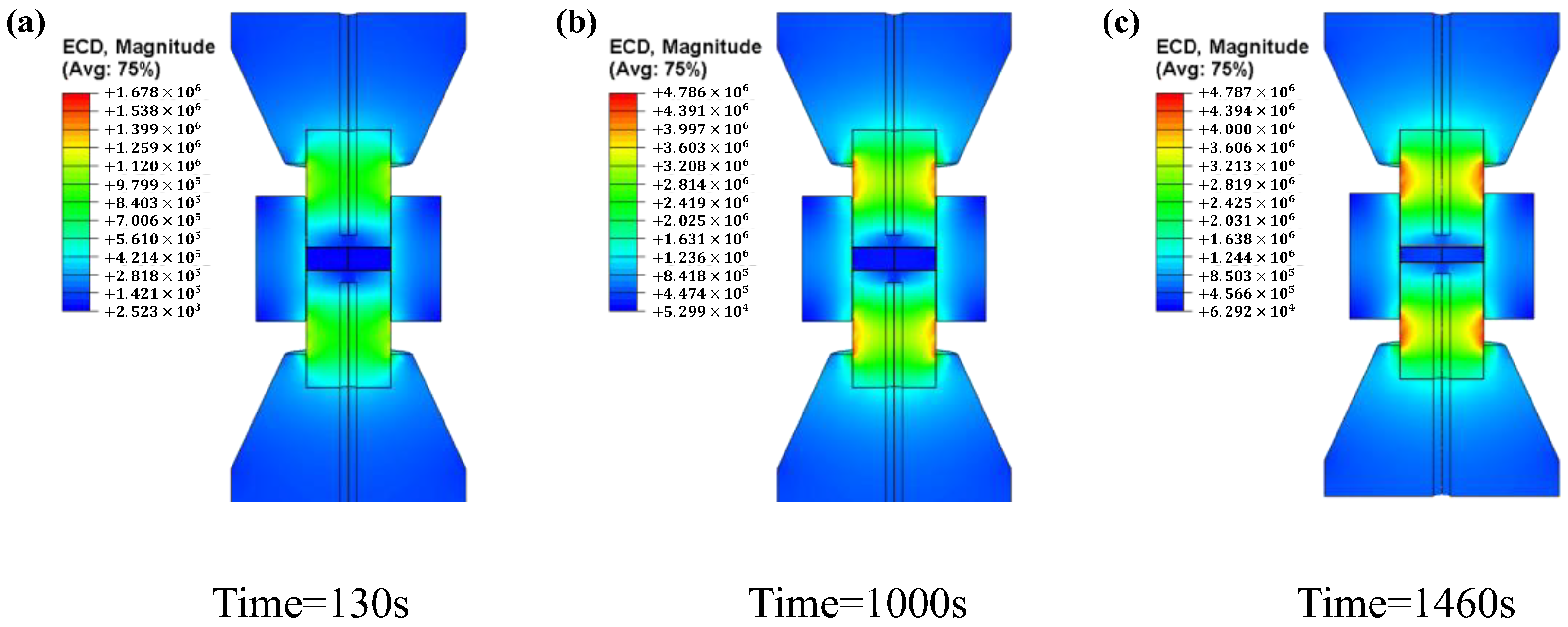

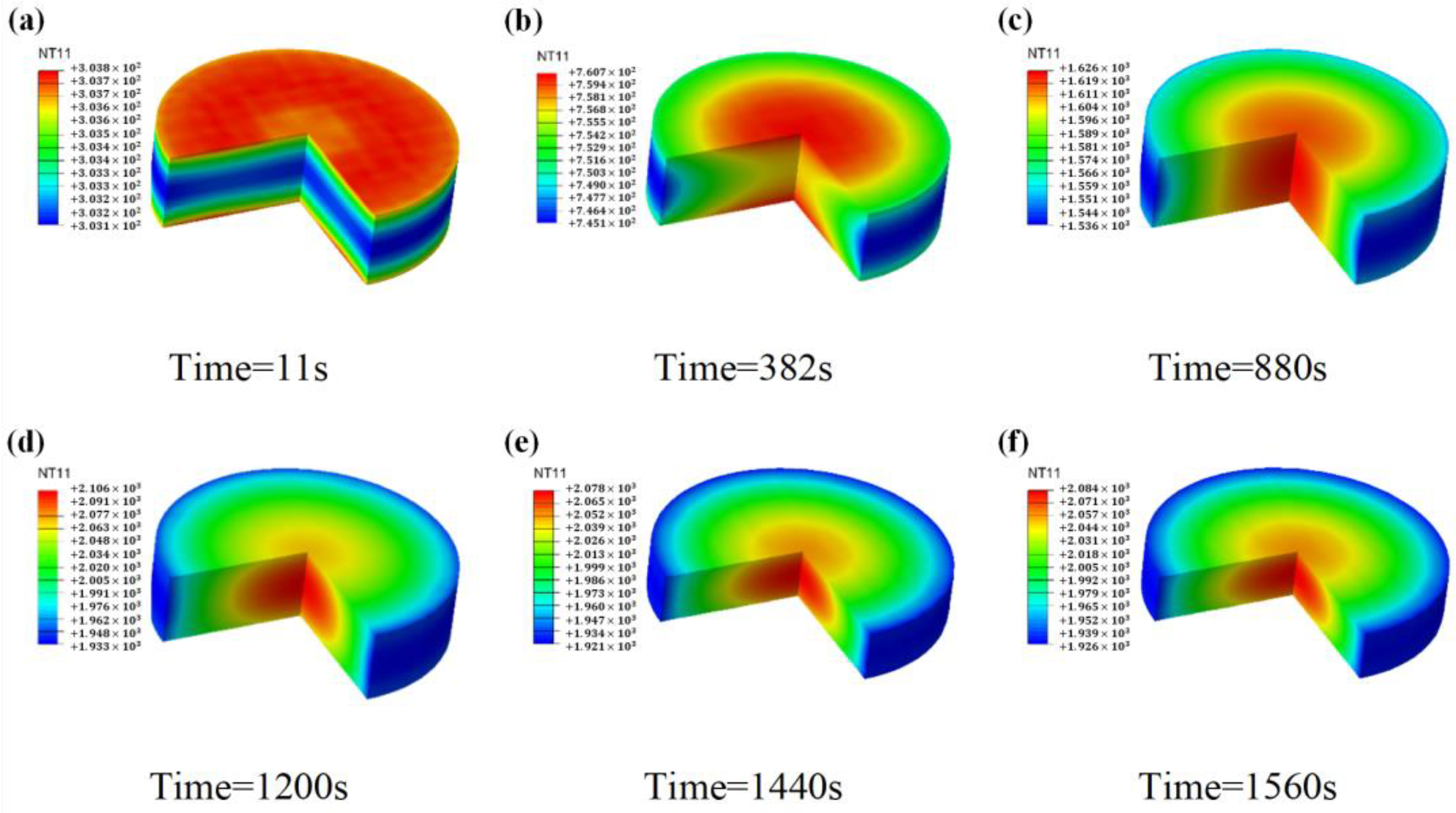

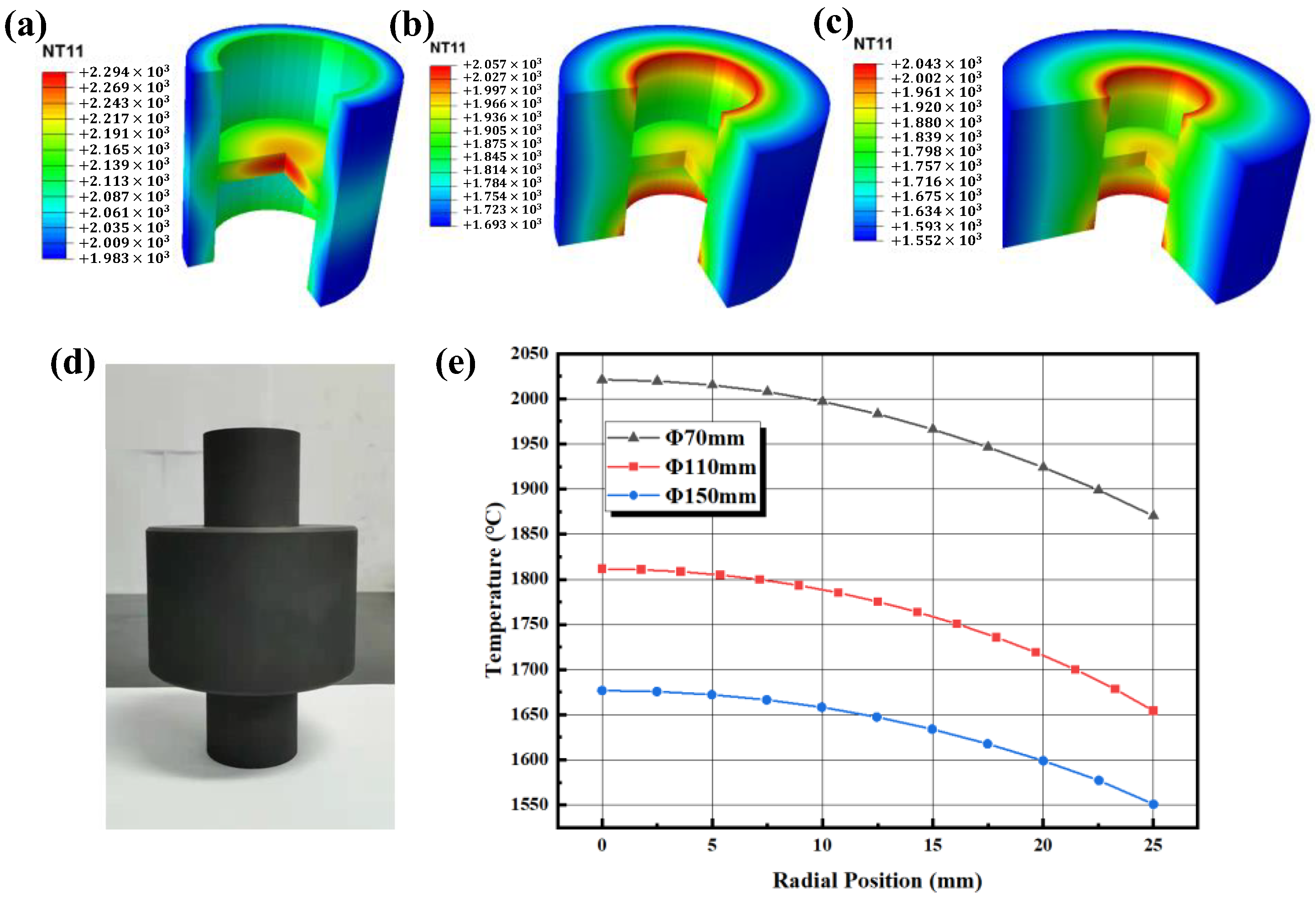

3.2. Electrical and Thermal Fields

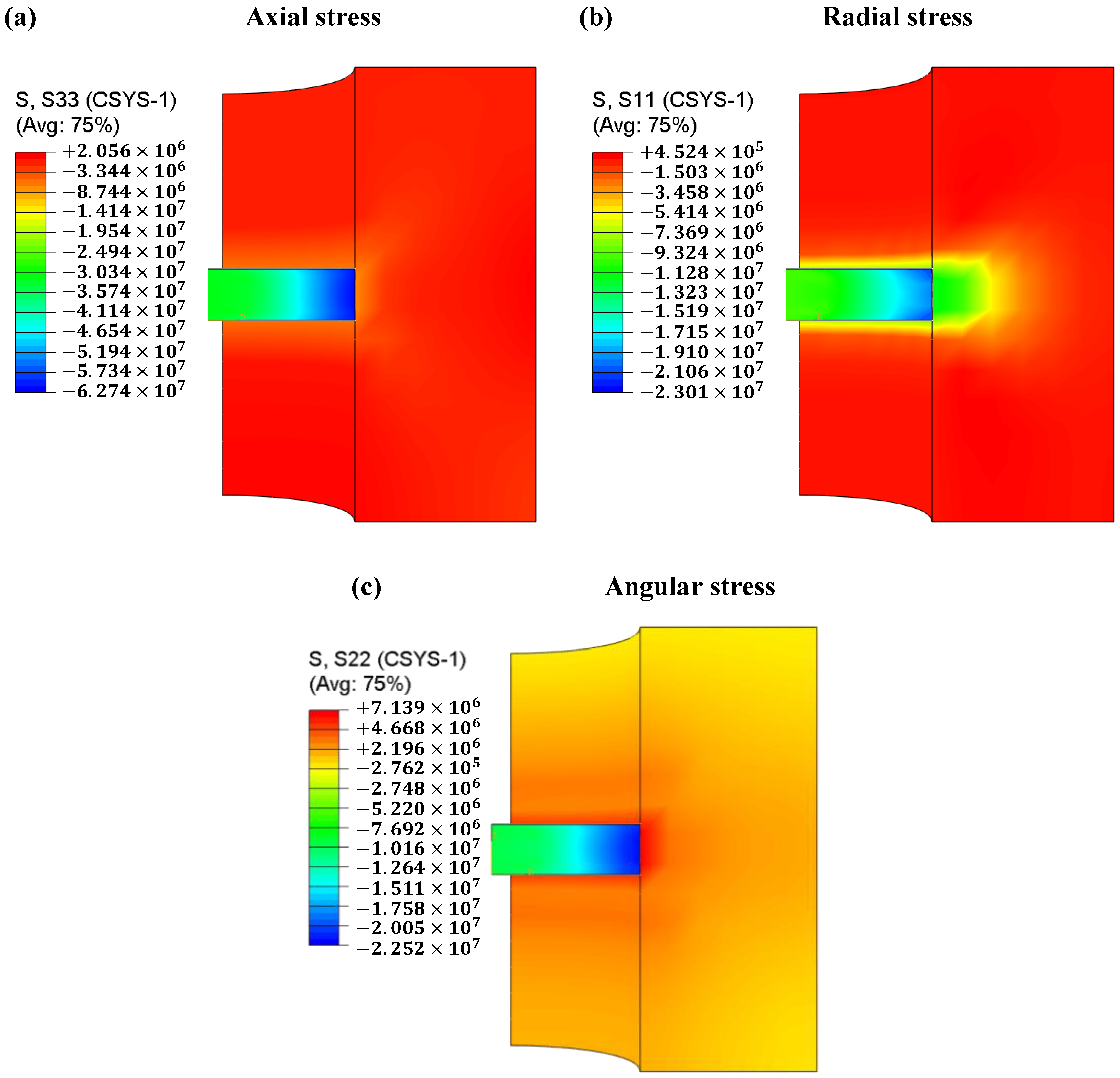

3.3. Stress Fields

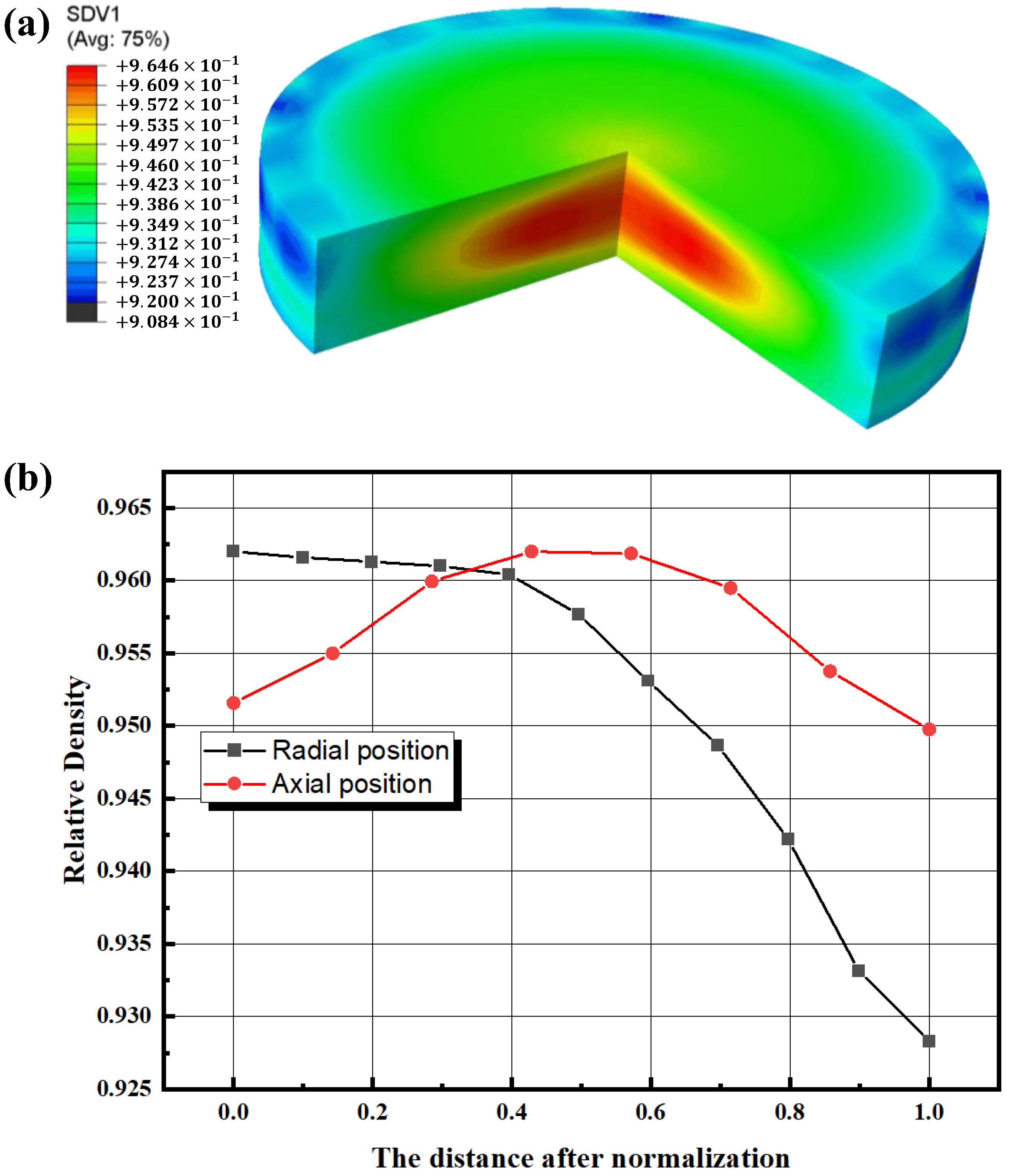

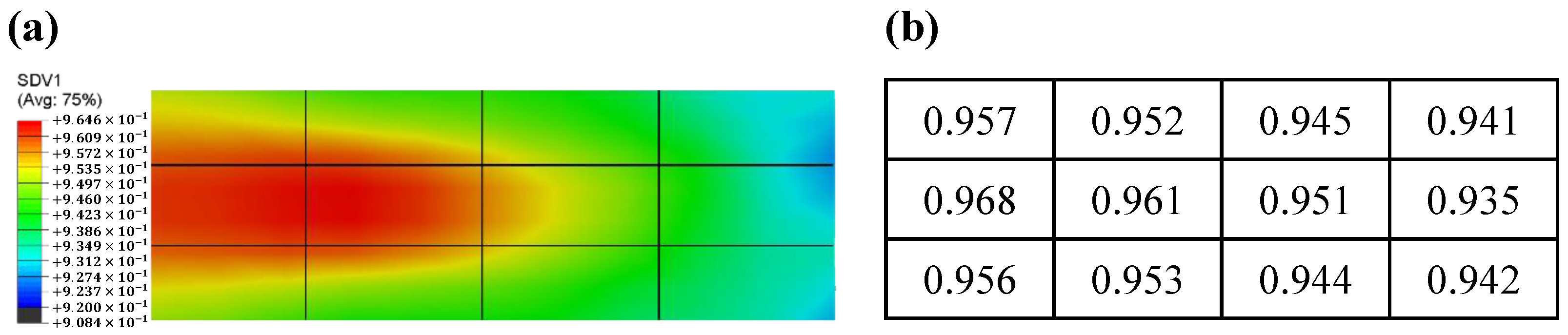

3.4. Relative Density Fields

4. Discussion

5. Conclusions and Outlook

- A radial temperature gradient of up to 155 °C was present in the sample when the thermal steady state was reached, while the axial temperature gradient was relatively limited, only up to 24 °C. The radial temperature generation could be attributed to the heat radiation loss from the die.

- According to the stress field analysis, a large axial stress gradient and a radial stress gradient existed inside the sample. The simulated relative density distribution field was compared with the experimentally measured values, and the Pearson correlation coefficient between the two distributions was 0.9699, confirming the validity of the model.

- When sintering boron carbide ceramics using the SPS device, selecting a temperature measurement point above the sample can better reflect the true temperature of the sample.

- Reducing the mold diameter can improve thermal efficiency, while not significantly affecting the thermal gradient.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Suri, A.K.; Subramanian, C.; Sonber, J.K.; Murthy, T.S.R.C. Synthesis and consolidation of boron carbide: A review. Int. Mater. Rev. 2013, 55, 4–40. [Google Scholar] [CrossRef]

- Moshtaghioun, B.M.; Cumbrera-Hernández, F.L.; Gómez-García, D.; de Bernardi-Martín, S.; Domínguez-Rodríguez, A.; Monshi, A.; Abbasi, M.H. Effect of spark plasma sintering parameters on microstructure and room-temperature hardness and toughness of fine-grained boron carbide (B4C). J. Eur. Ceram. Soc. 2013, 33, 361–369. [Google Scholar] [CrossRef]

- Vargas-Gonzalez, L.; Speyer, R.F.; Campbell, J. Flexural Strength, Fracture Toughness, and Hardness of Silicon Carbide and Boron Carbide Armor Ceramics. Int. J. Appl. Ceram. Technol. 2010, 7, 643–651. [Google Scholar] [CrossRef]

- Roumiguier, L.; Jankowiak, A.; Pradeilles, N.; Antou, G.; Maître, A. Mechanical properties of submicronic and nanometric boron carbides obtained by Spark Plasma Sintering: Influence of B/C ratio and oxygen content. Ceram. Int. 2019, 45, 9912–9918. [Google Scholar] [CrossRef]

- Kang, P.C.; Cao, Z.W.; Wu, G.H.; Zhang, J.H.; Wei, D.J.; Lin, L.T. Phase identification of Al–B 4C ceramic composites synthesized by reaction hot-press sintering. Int. J. Refract. Met. Hard Mater. 2010, 28, 297–300. [Google Scholar] [CrossRef]

- Ocak, B.C.; Goller, G. Investigation the effect of FeNiCoCrMo HEA addition on properties of B4C ceramic prepared by spark plasma sintering. J. Eur. Ceram. Soc. 2021, 41, 6290–6301. [Google Scholar] [CrossRef]

- Song, Q.; Zhang, Z.-H.; Hu, Z.-Y.; Wang, H.; Zhang, Y.-F.; Li, X.-Y.; Liu, L.-J.; Li, S.-L.; Cheng, X.-W. Mechanical properties and pre-oxidation behavior of spark plasma sintered B4C ceramics using (Ti3SiC2+ CeO2/La2O3) as sintering aid. Ceram. Int. 2020, 46, 22189–22196. [Google Scholar] [CrossRef]

- Zamora, V.; Martínez-Vázquez, F.J.; Guiberteau, F.; Ortiz, A.L. Unlubricated sliding wear of B4C composites spark-plasma sintered with Si aids and of their reference B4C monoliths. J. Eur. Ceram. Soc. 2023, 43, 814–823. [Google Scholar] [CrossRef]

- Hu, Z.-Y.; Zhang, Z.-H.; Cheng, X.-W.; Wang, F.-C.; Zhang, Y.-F.; Li, S.-L. A review of multi-physical fields induced phenomena and effects in spark plasma sintering: Fundamentals and applications. Mater. Des. 2020, 191, 108662. [Google Scholar] [CrossRef]

- Sakkaki, M.; Sadegh Moghanlou, F.; Vajdi, M.; Shahedi Asl, M.; Mohammadi, M.; Shokouhimehr, M. Numerical simulation of heat transfer during spark plasma sintering of zirconium diboride. Ceram. Int. 2020, 46, 4998–5007. [Google Scholar] [CrossRef]

- Mohammad Bagheri, S.; Vajdi, M.; Sadegh Moghanlou, F.; Sakkaki, M.; Mohammadi, M.; Shokouhimehr, M.; Shahedi Asl, M. Numerical modeling of heat transfer during spark plasma sintering of titanium carbide. Ceram. Int. 2020, 46, 7615–7624. [Google Scholar] [CrossRef]

- Fattahi, M.; Najafi Ershadi, M.; Vajdi, M.; Sadegh Moghanlou, F.; Sabahi Namini, A.; Shahedi Asl, M. On the simulation of spark plasma sintered TiB2 ultra high temperature ceramics: A numerical approach. Ceram. Int. 2020, 46, 14787–14795. [Google Scholar] [CrossRef]

- Tukmakova, A.; Novotelnova, A.; Samusevich, K.; Usenko, A.; Moskovskikh, D.; Smirnov, A.; Mirofyanchenko, E.; Takagi, T.; Miki, H.; Khovaylo, V. Simulation of Field Assisted Sintering of Silicon Germanium Alloys. Materials 2019, 12, 570. [Google Scholar] [CrossRef] [PubMed]

- Achenani, Y.; Saâdaoui, M.; Cheddadi, A.; Fantozzi, G. Finite element analysis of the temperature uncertainty during spark plasma sintering: Influence of the experimental procedure. Ceram. Int. 2017, 43, 15281–15287. [Google Scholar] [CrossRef]

- Achenani, Y.; Saâdaoui, M.; Cheddadi, A.; Bonnefont, G.; Fantozzi, G. Finite element modeling of spark plasma sintering: Application to the reduction of temperature inhomogeneities, case of alumina. Mater. Des. 2017, 116, 504–514. [Google Scholar] [CrossRef]

- Wolff, C.; Mercier, S.; Couque, H.; Molinari, A.; Bernard, F.; Naimi, F. Thermal-electrical-mechanical simulation of the nickel densification by Spark Plasma Sintering. Comparison with experiments. Mech. Mater. 2016, 100, 126–147. [Google Scholar] [CrossRef]

- Manière, C.; Pavia, A.; Durand, L.; Chevallier, G.; Afanga, K.; Estournès, C. Finite-element modeling of the electro-thermal contacts in the spark plasma sintering process. J. Eur. Ceram. Soc. 2016, 36, 741–748. [Google Scholar] [CrossRef]

- Schwertz, M.; Katz, A.; Sorrel, E.; Lemonnier, S.; Kosior, F. Coupled Electro-Thermo-Mechanical Finite Element Modeling of the Spark Plasma Sintering Technique. Metall. Mater. Trans. B 2015, 47, 1263–1273. [Google Scholar] [CrossRef]

- Engelke, L.; Brendel, L.; Wolf, D. Microstructure evolution during sintering: Discrete element method approach. J. Am. Ceram. Soc. 2023. [Google Scholar] [CrossRef]

- So, M.; Inoue, G.; Park, K.; Nunoshita, K.; Ishikawa, S.; Tsuge, Y. Contact model for DEM simulation of compaction and sintering of all-solid-state battery electrodes. MethodsX 2022, 9, 101857. [Google Scholar] [CrossRef]

- Matsuda, T. Development of a DEM taking account of neck increments caused by surface diffusion for sintering and application to analysis of the initial stage of sintering. Comput. Mater. Sci. 2021, 196, 110525. [Google Scholar] [CrossRef]

- Shi, H.; Giuntini, D.; van Dommelen, H.; Geers, M.G.D.; Remmers, J.J.C. Efficient modelling of ceramic sintering processes: Application to bilayers and membranes. J. Eur. Ceram. Soc. 2023, 43, 4939–4949. [Google Scholar] [CrossRef]

- Manière, C.; Harnois, C.; Marinel, S. 3D printing of porcelain and finite element simulation of sintering affected by final stage pore gas pressure. Mater. Today Commun. 2021, 26, 102063. [Google Scholar] [CrossRef]

- Kakanuru, P.; Pochiraju, K. Simulation of shrinkage during sintering of additively manufactured silica green bodies. Addit. Manuf. 2022, 56, 102908. [Google Scholar] [CrossRef]

- Wang, C.; Cheng, L.; Zhao, Z. FEM analysis of the temperature and stress distribution in spark plasma sintering: Modelling and experimental validation. Comput. Mater. Sci. 2010, 49, 351–362. [Google Scholar] [CrossRef]

- Mondalek, P.; Silva, L.; Bellet, M. A Numerical Model for Powder Densification by SPS Technique. Adv. Eng. Mater. 2011, 13, 587–593. [Google Scholar] [CrossRef]

- Ni, Y.; Liu, K.; Wang, J.; Sun, H.; Du, Y.; Liu, W. Establishment of constitutive models and numerical simulation of dry pressing and solid state sintering processes of MgTiO3 ceramic. Ceram. Int. 2021, 47, 8769–8780. [Google Scholar] [CrossRef]

- Bai, W.; Liu, W.; Wang, W.; Peng, C.; Wang, A.; He, Q.; Liu, G.; Huang, S. Drucker-Prager-Cap modelling of boron carbide powder for coupled electrical-thermal-mechanical finite element simulation of spark plasma sintering. Ceram. Int. 2021, 47, 21536–21545. [Google Scholar] [CrossRef]

- Vanmeensel, K.; Laptev, A.; Hennicke, J.; Vleugels, J.; Vanderbiest, O. Modelling of the temperature distribution during field assisted sintering. Acta Mater. 2005, 53, 4379–4388. [Google Scholar] [CrossRef]

- Wolff, C.; Mercier, S.; Couque, H.; Molinari, A. Modeling of conventional hot compaction and spark plasma sintering based on modified micromechanical models of porous materials. Mech. Mater. 2012, 49, 72–91. [Google Scholar] [CrossRef]

- Antou, G.; Mathieu, G.; Trolliard, G.; Maître, A. Spark plasma sintering of zirconium carbide and oxycarbide: Finite element modeling of current density, temperature, and stress distributions. J. Mater. Res. 2011, 24, 404–412. [Google Scholar] [CrossRef]

- Diarra, H.; Mazel, V.; Busignies, V.; Tchoreloff, P. FEM simulation of the die compaction of pharmaceutical products: Influence of visco-elastic phenomena and comparison with experiments. Int. J. Pharm. 2013, 453, 389–394. [Google Scholar] [CrossRef] [PubMed]

- Hofer, D.; Kamlah, M. Drucker–Prager–Cap creep modelling of pebble beds in fusion blankets. Fusion Eng. Des. 2005, 73, 105–117. [Google Scholar] [CrossRef]

- Han, L.H.; Elliott, J.A.; Bentham, A.C.; Mills, A.; Amidon, G.E.; Hancock, B.C. A modified Drucker-Prager Cap model for die compaction simulation of pharmaceutical powders. Int. J. Solids Struct. 2008, 45, 3088–3106. [Google Scholar] [CrossRef]

- Buljak, V.; Baivier-Romero, S.; Kallel, A. Calibration of Drucker-Prager Cap Constitutive Model for Ceramic Powder Compaction through Inverse Analysis. Materials 2021, 14, 4044. [Google Scholar] [CrossRef] [PubMed]

- Chtourou, H.; Guillot, M.; Gakwaya, A. Modeling of the metal powder compaction process using the cap model. Part I. Experimental material characterization and validation. Int. J. Solids Struct. 2002, 39, 1059–1075. [Google Scholar] [CrossRef]

- Zhou, R.; Yang, L.; Liu, Z.-w.; Liu, B.-f. Modeling the powder compaction process by an integrated simulation and inverse optimization method. Mater. Today Commun. 2020, 25, 101475. [Google Scholar] [CrossRef]

- Lewis-Beck, M.; Bryman, A.; Futing Liao, T. The SAGE Encyclopedia of Social Science Research Methods; SAGE Publications, Inc.: Thousand Oaks, CA, USA, 2004. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Liu, W.; Wang, W.; Gao, Y.; Wang, A.; He, Q.; Bai, W.; Li, R. Numerical Simulation of Physical Fields during Spark Plasma Sintering of Boron Carbide. Materials 2023, 16, 3967. https://doi.org/10.3390/ma16113967

Zhang S, Liu W, Wang W, Gao Y, Wang A, He Q, Bai W, Li R. Numerical Simulation of Physical Fields during Spark Plasma Sintering of Boron Carbide. Materials. 2023; 16(11):3967. https://doi.org/10.3390/ma16113967

Chicago/Turabian StyleZhang, Song, Wei Liu, Weimin Wang, Ying Gao, Aiyang Wang, Qianglong He, Wenhui Bai, and Runfeng Li. 2023. "Numerical Simulation of Physical Fields during Spark Plasma Sintering of Boron Carbide" Materials 16, no. 11: 3967. https://doi.org/10.3390/ma16113967

APA StyleZhang, S., Liu, W., Wang, W., Gao, Y., Wang, A., He, Q., Bai, W., & Li, R. (2023). Numerical Simulation of Physical Fields during Spark Plasma Sintering of Boron Carbide. Materials, 16(11), 3967. https://doi.org/10.3390/ma16113967