Diatomites from the Iberian Peninsula as Pozzolans

Abstract

1. Introduction

2. Materials and Methods

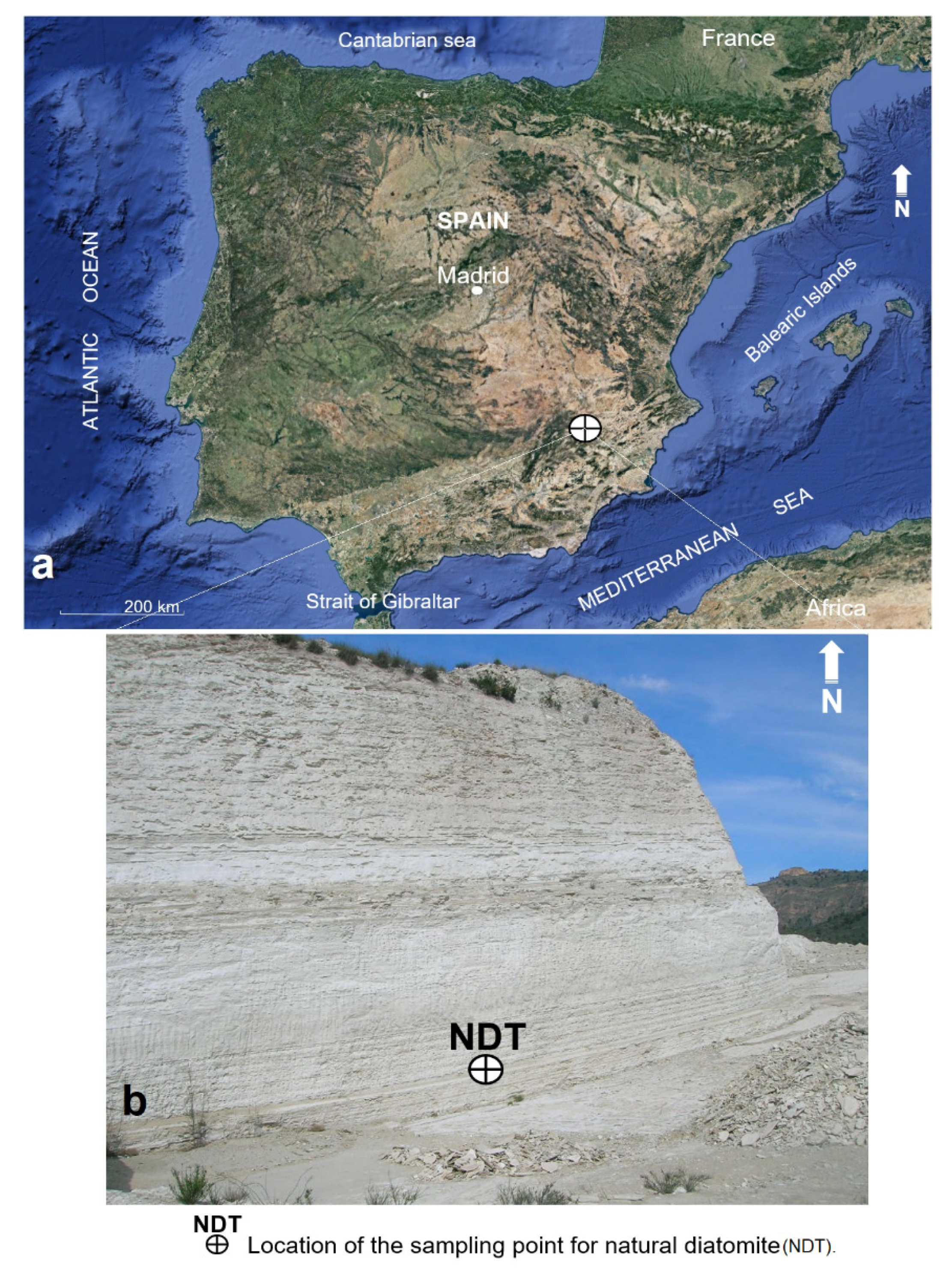

2.1. Materials

2.2. Methods

2.2.1. Morphological and Chemical Characterization Tests Using SEM and XRF

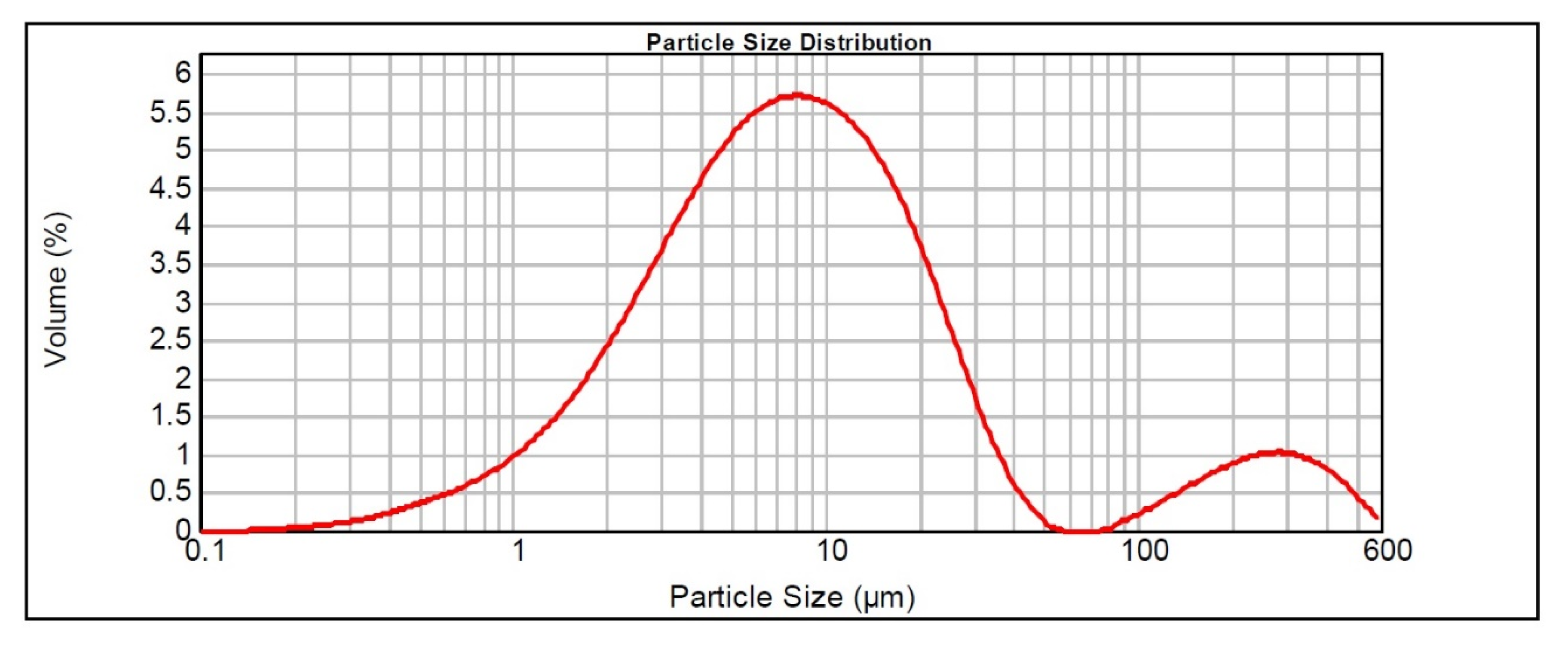

2.2.2. Physical Characterization Tests

2.2.3. Qualitative and Technological Characterization Tests

3. Results and Discussion

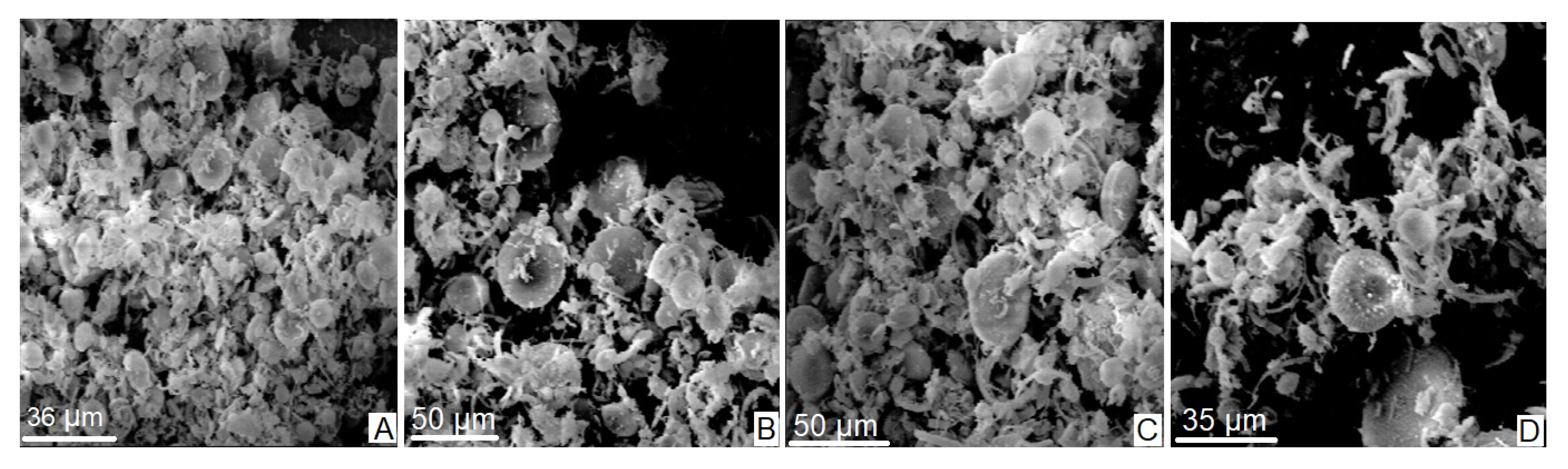

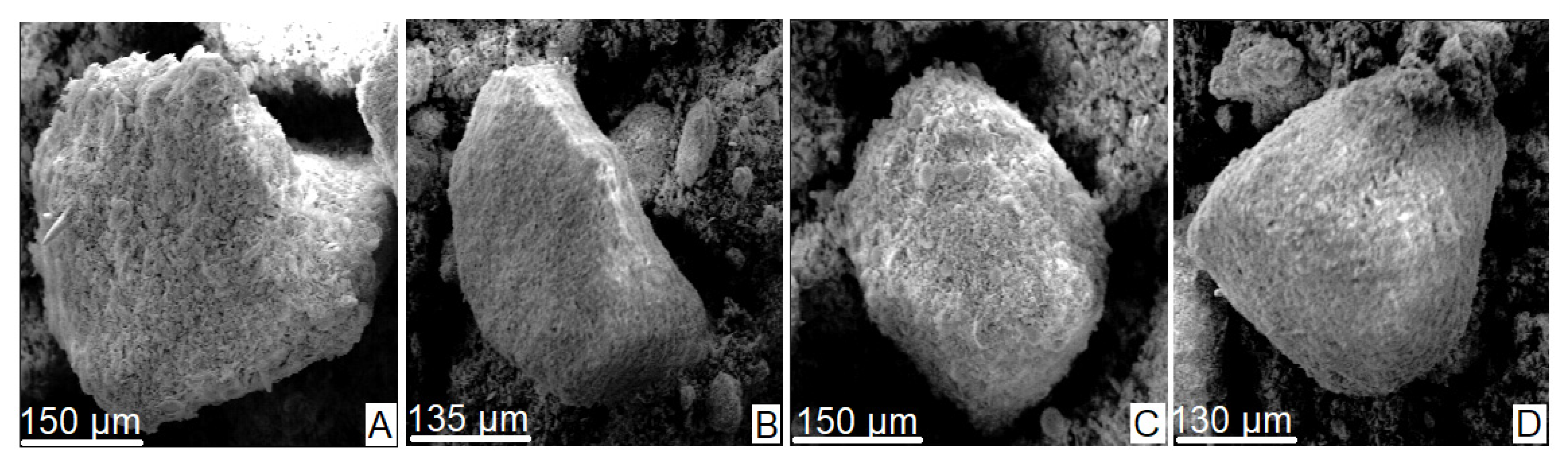

3.1. Scanning Electron Microscopy

3.2. X-ray Fluorescence

3.3. Physical Tests

3.4. Chemical Analysis of Technical Quality

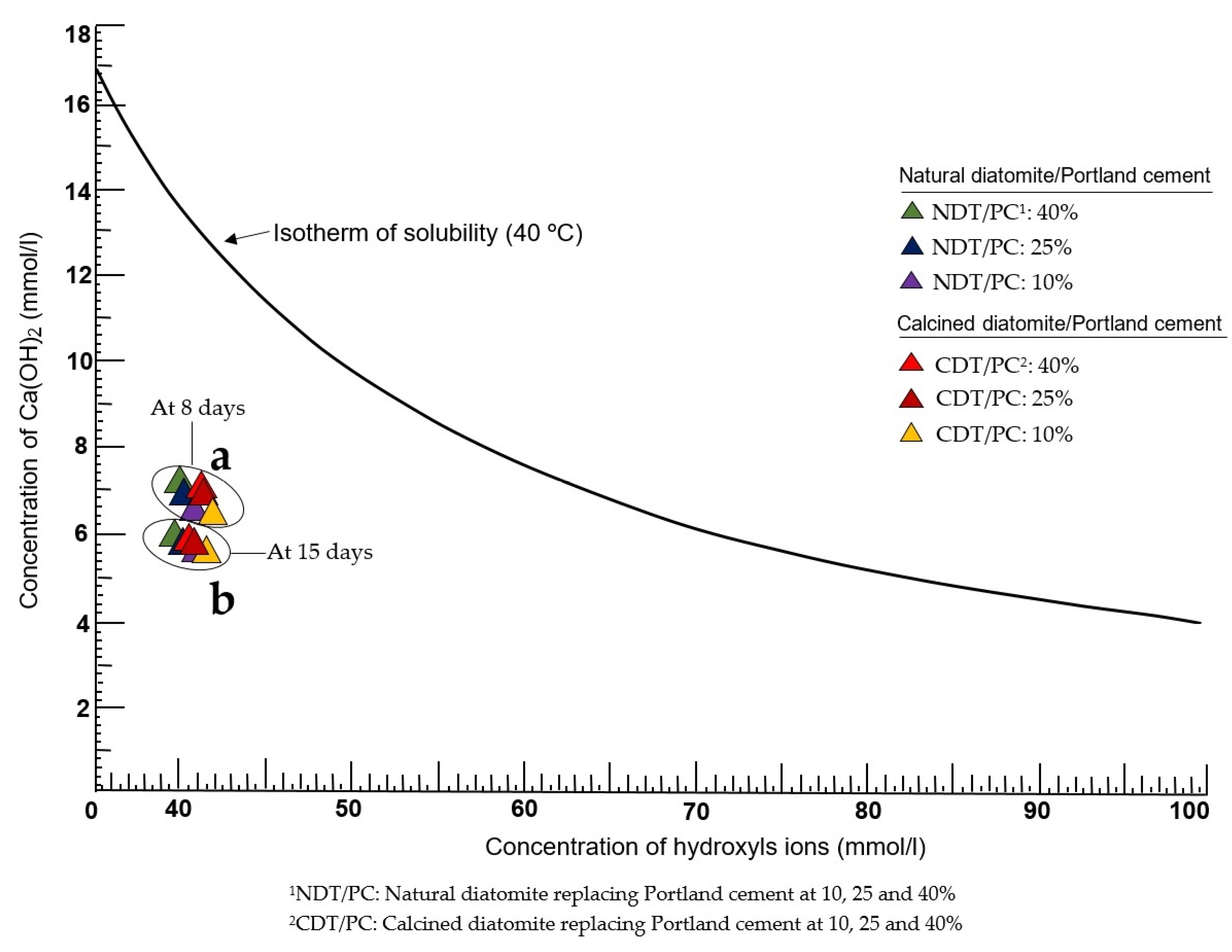

3.5. Chemical Analysis of Pozzolanicity

3.6. Mechanical Compressive Strength Tests at 7, 28, and 90 Days

| Sample | 7 Days of Curing | 28 Days of Curing | 90 Days of Curing | |||

|---|---|---|---|---|---|---|

| Compressive Strength (MPa) | RAI * Calculated (%) | Compressive Strength (MPa) | RAI Calculated (%) | Compressive Strength (MPa) | RAI Calculated (%) | |

| RMS | 42.7 | - | 51.6 | - | 57.8 | - |

| NDT-40 | 14.3 | 33.5 | 25.9 | 50.1 | 27.9 | 48.2 |

| NDT-25 | 22.8 | 53.3 | 35.8 | 69.3 | 43.5 | 75.2 |

| NDT-10 | 41.0 | 96.0 | 52.4 | 101.5 | 56.6 | 97.9 |

| CDT-40 | 17.2 | 40.2 | 28.1 | 54.4 | 33.0 | 57.0 |

| CDT-25 | 24.6 | 57.6 | 41.1 | 80.0 | 44.4 | 77.0 |

| CDT-10 | 41.4 | 97.0 | 54.0 | 104.6 | 64.2 | 111.0 |

3.7. Ultrasonic Pulse Velocity Determination

4. Conclusions

- The samples of diatomites studied, both in their natural (NDT) and calcined (CDT) states, behave similar to typical natural pozzolans; the features that potentially affect this fact are: their chemical composition, mainly the high contents of total SiO2 and reactive SiO2, porosity, absorption capacity, tendency to loss on ignition, and the active surface of diatomite particles.

- Pozzolanic reactivity visibly increases after calcination of the diatomite, which may be due to an increase in the degree of porosity of the sample and an increase in amorphous silica from total SiO2 after heating.

- The presence of NDT and CDT provides effective volume stability to mixed mortar paste and considerable durability to hardened specimens.

- The setting start and final times of the paste of mortars containing NDT and CDT tend to increase relative to the fresh mortar reference, especially when the portion of diatomite is between 25 and 40%; however, these values are drastically reduced when the proportion is 10%.

- The mechanical resistance to compression increases visibly between 7 and 90 days of curing, mainly in those specimens that contain NDT and CDT at 10 and 25%. In some cases, these increases exceed the value of the mechanical compressive strength of the reference specimen. This same trend has been determined with the calculation of the Resistant Activity Index.

- Specimens made with NDT and CDT slow down the rate of the ultrasonic pulse through the specimens, which can be a direct consequence of the high silica content and porosity of the sample, factors that produce a strong acoustic impedance. This characteristic could be a predictive factor when formulating lighter mortars and concretes with insulating properties, both thermal and acoustic.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yilmaz, B. A study on the effects of diatomite blend in natural pozzolan-blended cements. Adv. Cem. Res. 2008, 20, 13–21. [Google Scholar] [CrossRef]

- Yilmaz, B. The use of raw and calcined diatomite in cement production. Cem. Concr. Compos. 2007, 30, 202–211. [Google Scholar] [CrossRef]

- Janotka, I.; Krajči, L.; Uhlík, P.; Bačuvčík, M. Natural and calcined clayey diatomite as cement replacement materials: Microstructure and pore structure study. Int. J. Res. Eng. Technol. 2014, 3, 20–26. [Google Scholar]

- Mota, A.A.; Chagas, G. Investigation of particle characteristics and enhancing the pozzolanic activity of diatomite by grinding. Mater. Chem. Phys. 2021, 270, 124799. [Google Scholar] [CrossRef]

- Paiva, H.; Silva, A.S.; Velosa, A.; Cachim, P.; Ferreira, V.M. Microstructure and hardened state properties on pozzo-lan-containing concrete. Constr. Build. Mater. 2017, 140, 374–384. [Google Scholar] [CrossRef]

- Maina, P.; Mbarawa, M. Enhancement of lime reactivity by addition of diatomite. Fuel Process. Technol. 2011, 92, 1910–1919. [Google Scholar] [CrossRef]

- Karaman, S.; Oztoprak, B.; Sisman, C.B. Usage Possibilities of Diatomite in the Concrete Production for Agricultural Buildings. J. Basic Appl. Sci. 2015, 11, 31–38. [Google Scholar] [CrossRef]

- Gülbandılar, E.; Koçak, Y. Prediction of Splitting Tensile Strength of Concrete Containing Zeolite and Diatomite by ANN. Int. J. Econ. Environ. Geol. (IJEEG) 2016, 8, 32–40. [Google Scholar]

- Talero, R.; Trusilewicz, L.; Delgado, A.; Pedrajas, C.; Lannegrand, R.; Rahhal, V.; Mejía, R.; Delvasto, S.; Ramírez, F.A. Comparative and semi-quantitative XRD analysis of Friedel’s salt originating from pozzolan and Portland cement. Constr. Build. Mater. 2010, 25, 2370–2380. [Google Scholar] [CrossRef]

- Dedeloudis, C.; Zervaki, M.; Sideris, K.; Juenger, M.; Alderete, N.; Kamali-Bernard, S.; Villagrán, Y.; Snellings, R. Natural Pozzolans. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials. RILEM State-of-the-Art Reports; De Belie, N., Soutsos, M., Gruyaert, E., Eds.; Springer: Cham, Switzerland, 2018; Volume 25. [Google Scholar] [CrossRef]

- Gerengi, H.; Kocak, Y.; Jazdzewska, A.; Kurtay, M.; Durgun, H. Electrochemical investigations on the corrosion behaviour of reinforcing steel in diatomite- and zeolite-containing concrete exposed to sulphuric acid. Constr. Build. Mater. 2013, 49, 471–477. [Google Scholar] [CrossRef]

- Gerengi, H.; Kocak, Y.; Jazdzewska, A.; Kurtay, M. Corrosion behavior of concrete produced with diatomite and zeolite exposed to chlorides. Comput. Concr. 2017, 19, 161–169. [Google Scholar] [CrossRef]

- Degirmenci, N.; Yilmaz, A. Use of diatomite as partial replacement for Portland cement in cement mortars. Constr. Build. Mater. 2009, 23, 284–288. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Jiang, Q.; Zhang, S. Study of natural hydraulic lime-based mortars prepared with masonry waste powder as aggregate and diatomite/fly ash as mineral admixtures. J. Clean. Prod. 2016, 119, 118–127. [Google Scholar] [CrossRef]

- Xu, S.; Wang, J.; Mac, Q.; Zhao, X.; Zhang, T. Study on the lightweight hydraulic mortars designed by the use of di-atomite as partial replacement of natural hydraulic lime and masonry waste as aggregate. Constr. Build. Mater. 2014, 73, 33–40. [Google Scholar] [CrossRef]

- Becerra-Duitama, J.A.; Rojas-Avellaneda, D. Pozzolans: A Review. Eng. Appl. Sci. Res. 2022, 49, 495–504. Available online: https://ph01.tci-thaijo.org/index.php/easr/article/view/247697 (accessed on 4 March 2023).

- Pavlíková, M.; Rovnaníková, P.; Záleská, M.; Pavlík, Z. Diatomaceous Earth—Lightweight Pozzolanic Admixtures for Repair Mortars—Complex Chemical and Physical Assessment. Materials 2022, 15, 6881. [Google Scholar] [CrossRef]

- Ince, C.; Derogar, S.; Ball, R.J.; Ekinci, A. and Yuzer, N. Long-term mechanical properties of cellulose fibre-reinforced cement mortar with diatomite. Adv. Cem. Res. 2019, 31, 343–352. [Google Scholar] [CrossRef]

- Rocha, F.; Costa, C.; Hajjaji, W.; Andrejkovičová, S.; Moutinho, S.; Cerqueira, A. Properties Improvement of Metakaolin-Zeolite-Diatomite-Red Mud Based Geopolymers. In Springer Proceedings in Earth and Environmental Sciences, Proceedings of the 14th International Congress for Applied Mineralogy, Belgorod, Russia, 23–27 September 2019; Glagolev, S., Ed.; Springer: Cham, Switzerland, 2019; pp. 381–384. [Google Scholar]

- Tounchuen, K.; Umponpanarat, P.; Buggakupta, W.; Panpa, W. Effects of Diatomite and Glass Cullet in the Waste-Based Gypsum Building Materials. Key Eng. Mater. 2013, 545, 122–128. [Google Scholar] [CrossRef]

- Lv, Z.; Jiang, A.; Liang, B. Development of eco-efficiency concrete containing diatomite and iron ore tailings: Mechanical properties and strength prediction using deep learning. Constr. Build. Mater. 2022, 327, 126930. [Google Scholar] [CrossRef]

- Yang, Y.; Shen, Z.; Wu, W.; Zhang, H.; Ren, Y.; Yang, Q. Preparation of a novel diatomite-based PCM gypsum board for temperature-humidity control of buildings. Build. Environ. 2022, 226, 109732. [Google Scholar] [CrossRef]

- Google Earth. Available online: https://earth.google.com/web/@39.28941152,-4.23079161,-2731.47524373a,1782178.3365798d,35y,0h,0t,0r (accessed on 14 March 2023).

- UNE-EN-196-6:2019; Métodos de Ensayo de Cementos. Parte 6: Determinación de la Finura. AENOR: Madrid, Spain, 2011.

- UNE-EN-80103:2013; Métodos de Ensayo de Cementos. Ensayos Físicos. Determinación de la Densidad Real. AENOR: Madrid, Spain, 2013.

- UNE-EN 1097-3:1999; Ensayos para Determinar las Propiedades Mecánicas y Físicas de los Áridos. Parte 3: Determinación de la Densidad Aparente y la Porosidad. AENOR: Madrid, Spain, 1999.

- UNE-EN 196-3:2017; Métodos de Ensayo de Cementos. Parte 3: Determinación del Tiempo de Fraguado y de la Estabilidad de Volumen. AENOR: Madrid, Spain, 2017.

- UNE-EN 196-2:2014; Métodos de Ensayo de Cementos. Parte 2: Análisis Químico de Cementos. AENOR: Madrid, Spain, 2014.

- UNE-EN 196-5:2011; Métodos de Ensayo de Cementos. Parte 5: Ensayo de Puzolanicidad para los Cementos Puzolánicos. AENOR: Madrid, Spain, 2011.

- UNE-EN 196-1:2018; Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias. AENOR: Madrid, Spain, 2018.

- UNE-EN ISO 16810; Ensayos no Destructivos. Ensayos por Ultrasonidos. Principios Generales. AENOR: Madrid, Spain.

- Abdellaoui, I.; Monirul, M.; Sakurai, T.; Hamzaoui, S.; Akimoto, K. Impurities removal process for high-purity silica pro-duction from diatomite. Hydrometallurgy 2018, 179, 207–214. [Google Scholar] [CrossRef]

- Jung, K.W.; Jang, D.; Ahn, K.H. A novel approach for improvement of purity and porosity in diatomite (diatomaceous earth) by applying an electric field. Int. J. Miner. Process. 2014, 131, 7–11. [Google Scholar] [CrossRef]

- Manevich, V.E.; Subbotin, R.K.; Nikiforov, E.A.; Senik, N.A.; Meshkov, A.V. Diatomite—Siliceous material for the glass industry. Glass Ceram 2012, 69, 168–172. [Google Scholar] [CrossRef]

- Aksakal, E.L.; Angin, I.; Oztas, T. Effects of diatomite on soil physical properties. CATENA 2011, 88, 1–5. [Google Scholar] [CrossRef]

- Hernández-Ávila, J.; Salinas-Rodríguez, E.; Cerecedo-Sáenz, E.; Reyes-Valderrama, M.I.; Arenas-Flores, A.; Román-Gutiérrez, A.D.; Rodríguez-Lugo, V. Diatoms and Their Capability for Heavy Metal Removal by Cationic Exchange. Metals 2017, 7, 169. [Google Scholar] [CrossRef]

- Fragoulis, D.; Stamatakis, M.G.; Chaniotakis, E.; Columbus, G. Characterization of lightweight aggregates produced with clayey diatomite rocks originating from Greece. Mater. Charact. 2004, 53, 307–316. [Google Scholar] [CrossRef]

- Costafreda Mustelier, J.L. Geología, Caracterización y Aplicaciones de las Rocas Zeolíticas del 20Complejo Volcánico de Cabo de Gata (Almería). Ph.D. Thesis, Escuela Técnica Superior de Ingenieros de Minas y Energía, Universidad Politécnica de Madrid, Madrid, Spain, 2008. [Google Scholar]

- Sarıdemir, M.; Çelikten, S.; Yıldırım, A. Mechanical and microstructural properties of calcined diatomite powder modified high strength mortars at ambient and high temperatures. Adv. Powder Technol. 2020, 31, 3004–3017. [Google Scholar] [CrossRef]

- Tironi, A.; Trezza, M.A.; Scian, A.N.; Irassar, E.F. Assessment of pozzolanic activity of different calcined clays. Cem. Concr. Compos. 2013, 37, 319–327. [Google Scholar] [CrossRef]

- Ahmad, S.; Baghabra, O.S.; Khan, S.M.S.; Maslehuddin, M. Effect of silica fume inclusion on the strength, shrinkage and durability characteristics of natural pozzolan-based cement concrete. Case Stud. Constr. Mater. 2022, 17, e01255. [Google Scholar] [CrossRef]

- Küçükyıldırım, E.; Uzal, B. Characteristics of calcined natural zeolites for use in high-performance pozzolan blended cements. Constr. Build. Mater. 2014, 73, 229–234. [Google Scholar] [CrossRef]

- Martín, D.A.; Costafreda, J.L.; Presa, L.; Crespo, E.; Parra, J.L.; Astudillo, B.; Sanjuán, M.Á. Ignimbrites Related to Neogene Volcanism in the Southeast of the Iberian Peninsula: An Experimental Study to Establish Their Pozzolanic Character. Materials 2023, 16, 1546. [Google Scholar] [CrossRef]

- Presa, L.; Costafreda, J.L.; Martín, D.A. Correlation between Uniaxial Compression Test and Ultrasonic Pulse Rate in Cement with Different Pozzolanic Additions. Appl. Sci. 2021, 11, 3747. [Google Scholar] [CrossRef]

| Sample | Proportion (Ratios) | Temperature of Calcination (°C) | (B.P.F.) 6 (cm2/g) | ||

|---|---|---|---|---|---|

| NDT 1/CDT 2:PC 3 (%) | NS 4 (g) | DW 5 (g) | |||

| NDT-40 | 40:60 | 1350 | 225 | - | 5416 |

| NDT-25 | 25:75 | - | |||

| NDT-10 | 10:90 | - | |||

| CDT-40 | 40:60 | 900 | |||

| CDT-25 | 25:75 | 900 | |||

| CDT-10 | 10:90 | 900 | |||

| Sample | Compounds in % Weight | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | SO3 | K2O | MgO | P2O5 | Na2O | Cl | LOI * | |

| NDT | 83.8 | 1.0 | 0.5 | 5.2 | 0.06 | 0.09 | 0.13 | 0.38 | 0.06 | 0.02 | 0.02 | 8.3 |

| PC | 17.47 | 5.57 | 3.39 | 64.01 | 0.33 | 4.0 | 1.39 | 0.64 | 0.07 | 0.09 | - | 2.41 |

| Size (µm) | Retained (%) | Passing through (%) | Percentage (%) | Size (µm) | (B.P.F.) 1 (cm2/g) |

|---|---|---|---|---|---|

| 32 | 10.4 | 89.5801 | 10 | 1.876 | 5416 |

| 45 | 8.6 | 91.4355 | 50 | 7.807 | |

| 63 | 8.4 | 91.6265 | 63.2 | 11.17 | |

| 90 | 8.3 | 91.6711 | 90 | 33.525 |

| Sample | RD 1 (g/cm3) | AD 2 (g/cm3) | Porosity (%) |

|---|---|---|---|

| NDT | 1.98 | 0.173 | 0.912 |

| Sample | Volume Stability (mm) | Start and Final Setting Time | |||

|---|---|---|---|---|---|

| A 1 | C 2 | C-A | Start (min) | Final (min) | |

| RMS 3 | 0 | 0 | 0 | 170 | 230 |

| NDT-40 4 | 0.5 | 1 | 0.5 | 210 | 295 |

| NDT-25 | 0 | 0 | 0 | 195 | 265 |

| NDT-10 | 0 | 0 | 0 | 130 | 175 |

| CDT-40 5 | 0 | 0 | 0 | 205 | 265 |

| CDT-25 | 0 | 0 | 0 | 200 | 245 |

| CDT-10 | 0 | 1 | 1 | 155 | 220 |

| Compounds | NDT 1 (%) | CDT 2 (%) | Limit Allowed * (%) |

|---|---|---|---|

| Total SiO2 | 89.99 | 84.64 | - |

| Reactive SiO2 | 89.44 | 84.00 | >25 |

| Total CaO | 5.80 | 5.48 | - |

| Reactive CaO | 4.33 | 0.89 | - |

| Al2O3 | 0.92 | 0.92 | <16 |

| MgO | 0.38 | 0.39 | <5 |

| Fe2O3 | 0.42 | 0.28 | - |

| SO3 | - | - | <4 |

| Humidity | 13.90 | - | - |

| IR 3 | 1.54 | 1.92 | <3 |

| LOI 4 | 7.42 | 1.96 | - |

| Cl 5 | 0.01 | 0.01 | <0.1 |

| SiO2/(CaO + MgO) | 19.11 | 66.13 | >3.5 |

| Samples | Ultrasonic Wave Propagation Time (µs) | Value of UPV Calculated (km/s) |

|---|---|---|

| RMS | 36.33 | 4.40 |

| NDT-40 | 44.60 | 3.59 |

| NDT-25 | 40.83 | 3.92 |

| NDT-10 | 37.06 | 4.25 |

| CDT-40 | 44.13 | 3.63 |

| CDT-25 | 41.43 | 3.86 |

| CDT-10 | 37.43 | 4.27 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costafreda, J.L.; Martín, D.A.; Astudillo, B.; Presa, L.; Parra, J.L.; Sanjuán, M.A. Diatomites from the Iberian Peninsula as Pozzolans. Materials 2023, 16, 3883. https://doi.org/10.3390/ma16103883

Costafreda JL, Martín DA, Astudillo B, Presa L, Parra JL, Sanjuán MA. Diatomites from the Iberian Peninsula as Pozzolans. Materials. 2023; 16(10):3883. https://doi.org/10.3390/ma16103883

Chicago/Turabian StyleCostafreda, Jorge L., Domingo A. Martín, Beatriz Astudillo, Leticia Presa, José Luis Parra, and Miguel A. Sanjuán. 2023. "Diatomites from the Iberian Peninsula as Pozzolans" Materials 16, no. 10: 3883. https://doi.org/10.3390/ma16103883

APA StyleCostafreda, J. L., Martín, D. A., Astudillo, B., Presa, L., Parra, J. L., & Sanjuán, M. A. (2023). Diatomites from the Iberian Peninsula as Pozzolans. Materials, 16(10), 3883. https://doi.org/10.3390/ma16103883