Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix

Abstract

1. Introduction

2. Brief Description of the Experimental Test

2.1. Mixture Proportion and Specimen Preparation

2.2. Testing Methods

3. Building the DEM Model of the UHPC Matrix

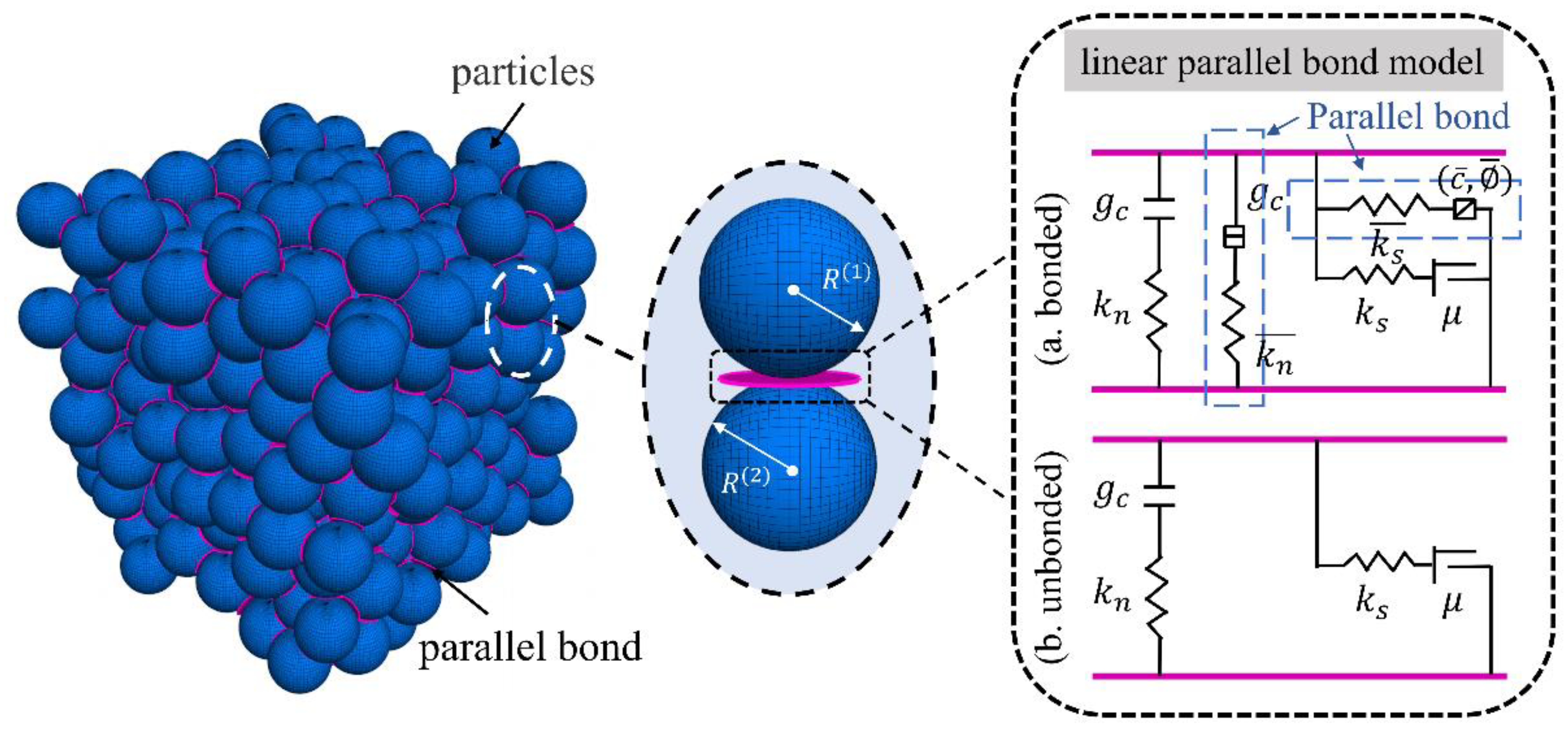

3.1. Meso-Mechanical Constitutive Model

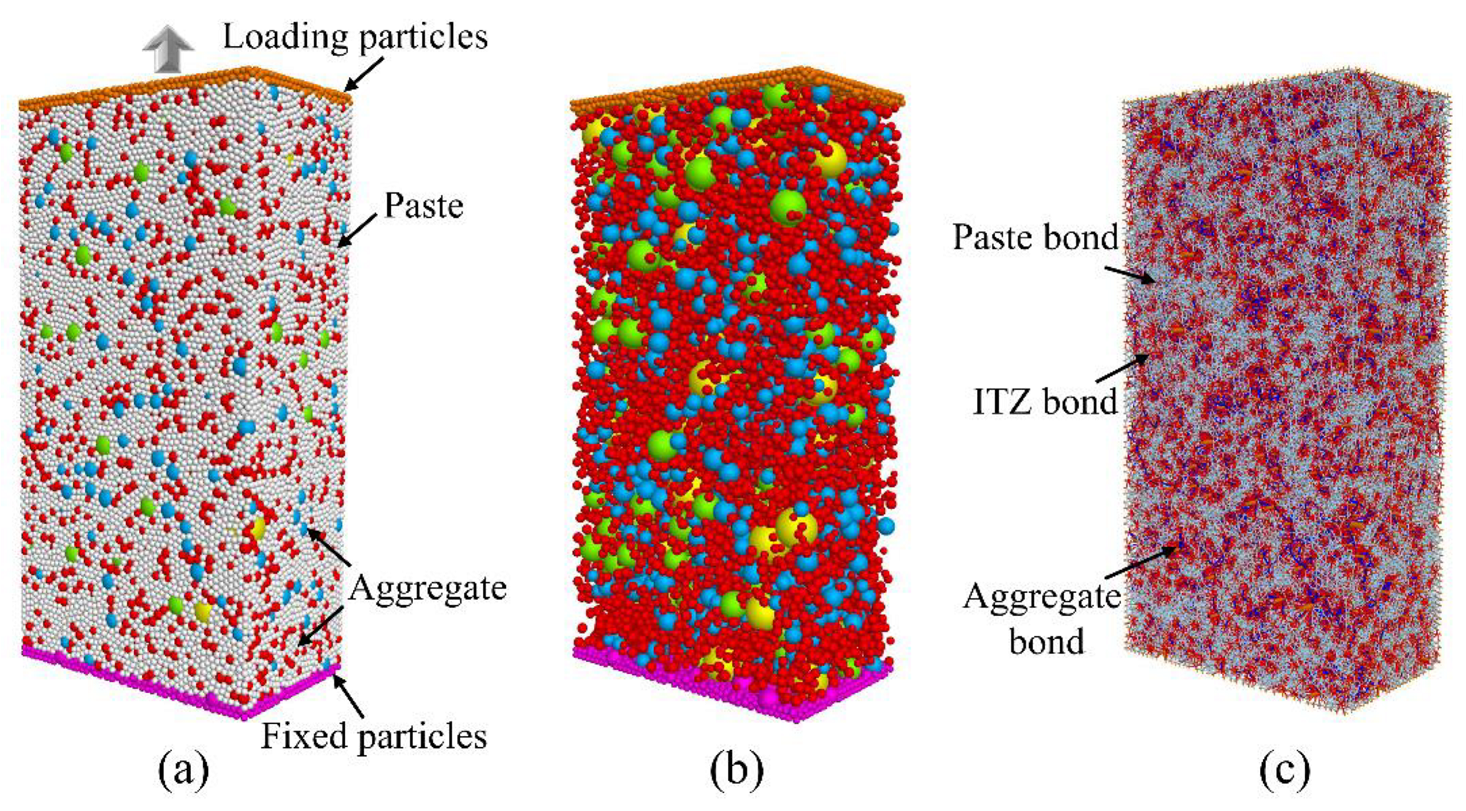

3.2. DEM-Based Model Construction and Monitoring

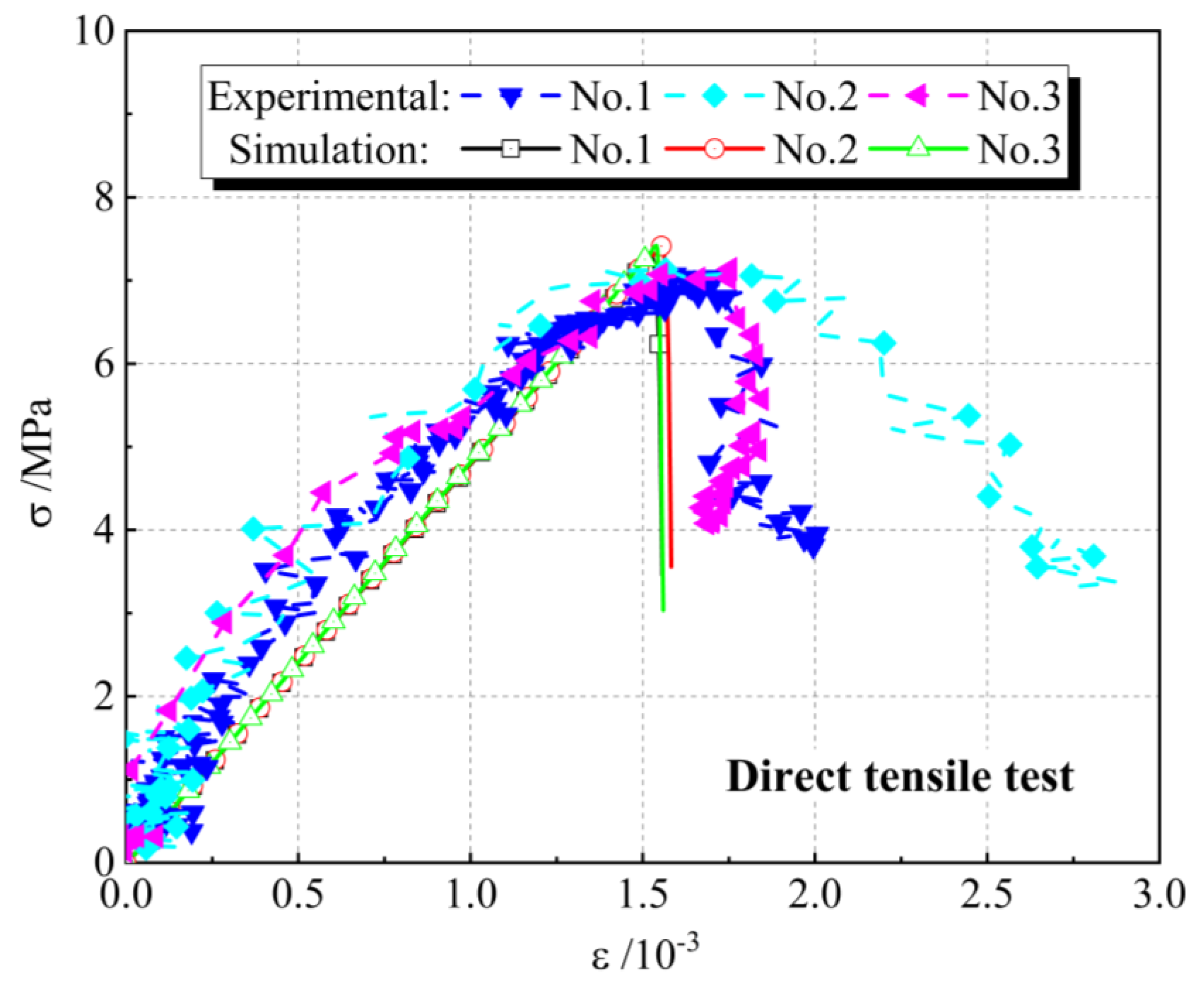

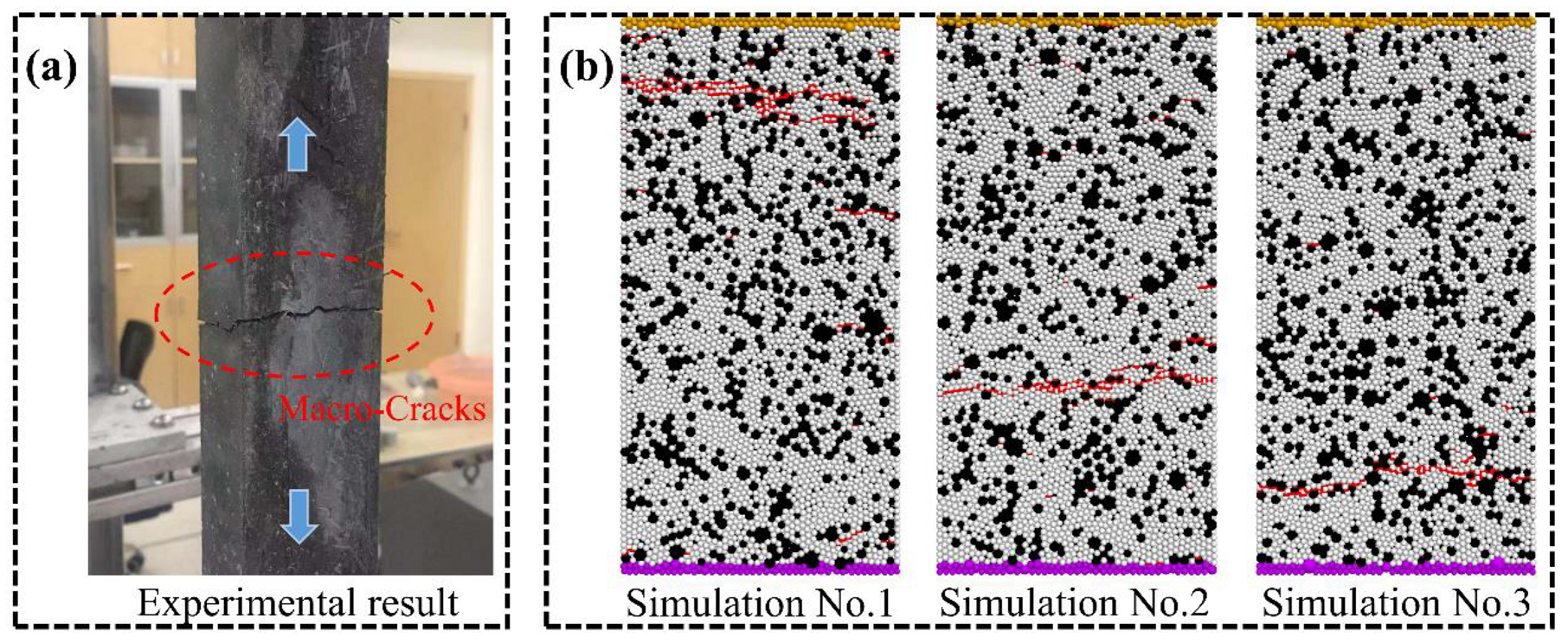

3.3. Mesoscopic Parameter Calibration and Verification

- (I)

- Rough calibration: Firstly, the elastic modulus of concrete is roughly matched, and the effective modulus of particles and bonds in the numerical model is adjusted to obtain the elastic modulus that roughly matches that of the laboratory test of concrete. Then the Poisson’s ratio obtained from the simulation is roughly matched with that from the laboratory test by adjusting the stiffness ratio of particles and parallel bonds in the numerical model. Finally, the tensile strength and cohesion of parallel bonds are adjusted respectively to obtain the peak strength similar to the laboratory test;

- (II)

- Accurate calibration: The accurate calibration of the mesoscopic parameters is carried out by the “trial and error method”, and the results of the PFC simulation are matched with the results of the macroscopic mechanical parameters of concrete in laboratory tests through repeated adjustment of the meso-parameters. Finally, a set of parallel bond mesoscopic parameters that well reflect the mechanical properties of concrete are obtained, as shown in Table 4.

4. Results and Discussion

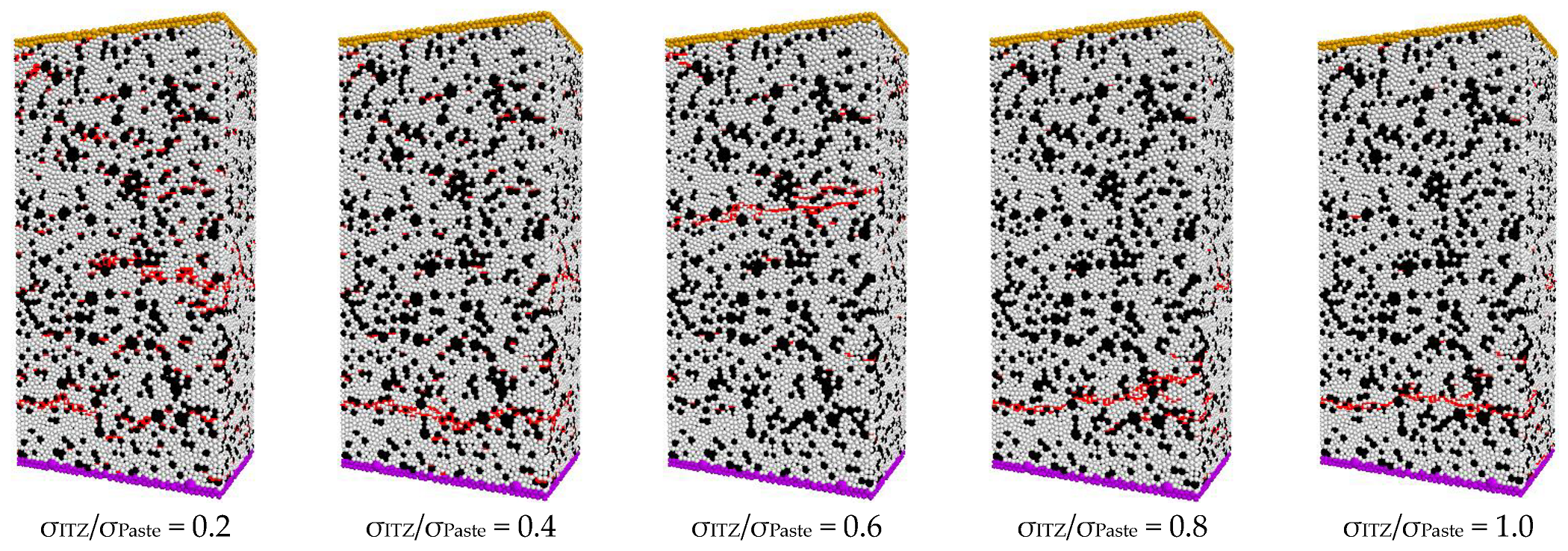

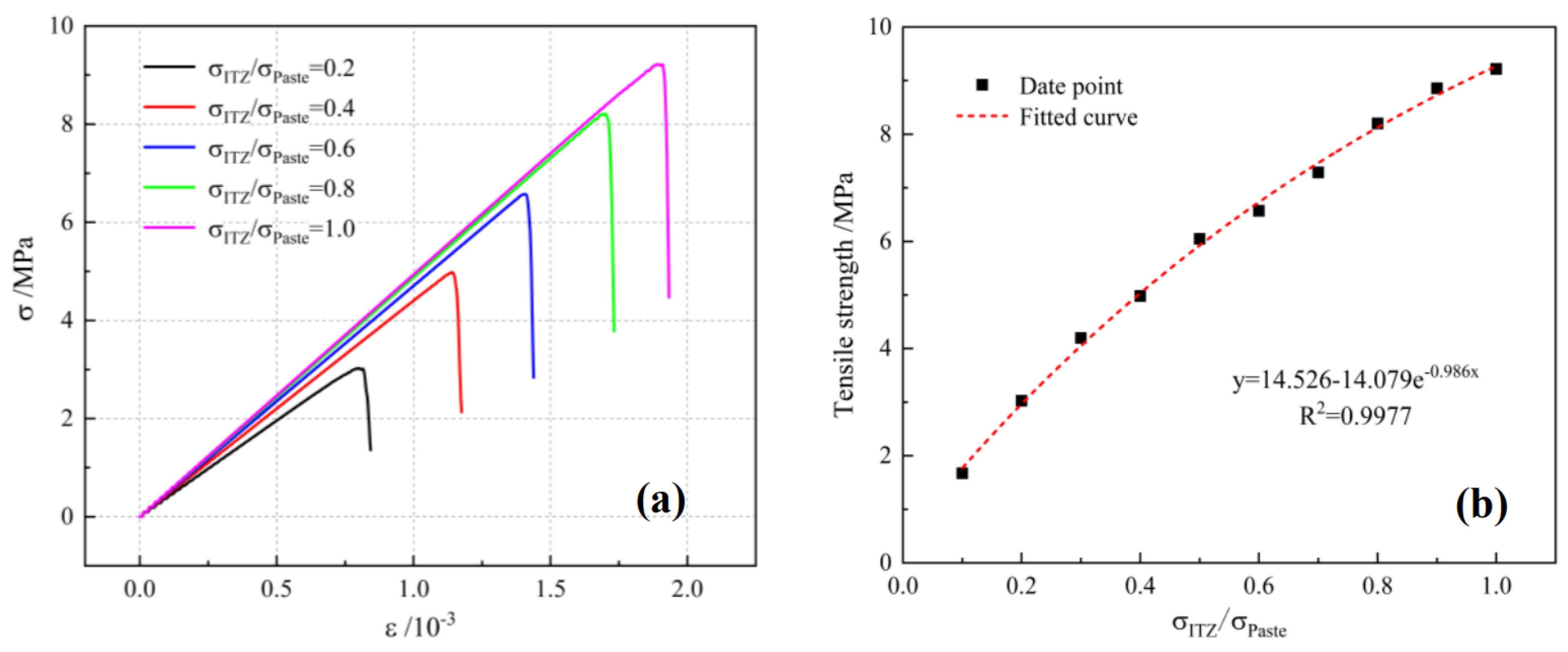

4.1. The Effect of ITZ Property on Tensile Behavior

4.2. The Effect of Binder Composition on ITZ Property and Tensile Behavior

4.3. The Effect of Chemical Activator on ITZ Property and Tensile Behavior

4.4. Discussion

5. Conclusions

- (1)

- The increase in ITZ strength will result in a decrease in the total number of microcracks. The percentage of cracks in the paste will increase as the ITZ strength increases. The tensile properties of UHPC will increase as the ITZ strength increases, but the growth rate will gradually decrease. The brittleness of UHPC will increase as the ITZ strength increases. The effect of ITZ on the tensile properties of UHPC is more significant than that of normal concrete. The tensile strength of UHPC will be increased by 48% when the ITZ property is changed from normal condition to perfect;

- (2)

- The cement content in UHPC was reduced from 80% to 35%, and the σITZ/σPaste was reduced from 0.7 to 0.32. The ITZ strength and tensile properties of eco-friendly UHPC matrix tend to decrease as the cement content decreases, while the number of microcracks tends to increase. Nanomaterials improve the tensile properties of eco-friendly UHPC by increasing the strength of ITZ and the denseness of the paste. Compared to NS, the improvement in tensile properties of NA is more significant. The chemical activator mainly improves the tensile properties of eco-friendly UHPC by improving the ITZ properties;

- (3)

- The hydration activity of the binder system has a significant influence on the ITZ strength, which increases with hydration activity. Both nanomaterials and chemical activators have the effect of promoting the hydration reaction of the binder material, which in turn leads to better ITZ performance of eco-friendly UHPC.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Larrard, F.D.; Sedran, T. Optimization of ultra-high-performance concrete by the use of a packing model. Cem. Concr. Res. 1994, 24, 997–1009. [Google Scholar] [CrossRef]

- Kim, M.K.; Kim, D.J. Electro-mechanical self-sensing response of ultra-high-performance fiber-reinforced concrete in tension. Compos. Part B Eng. 2018, 134, 254–264. [Google Scholar] [CrossRef]

- Lei, V.Y.; Nematollahi, B.; Said, A.B.M.; Gopal, B.A.; Yee, T.S. Application of ultra-high performance fiber reinforced concrete–The Malaysia perspective. Int. J. Sustain. Constr. Eng. Technol. 2012, 3, 26–44. [Google Scholar]

- Ghasemi, S.; Zohrevand, P.; Mirmiran, A.; Xiao, Y.; Mackie, K. A super lightweight UHPC–HSS deck panel for movable bridges. Eng. Struct. 2016, 113, 186–193. [Google Scholar] [CrossRef]

- Ferrier, E.; Labossière, P.; Neale, K.W. Modelling the bending behaviour of a new hybrid glulam beam reinforced with FRP and ultra-high-performance concrete. Appl. Math. Model. 2012, 36, 3883–3902. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Mix design and properties assessment of ultra-high performance fibre reinforced concrete (UHPFRC). Cem. Concr. Res. 2014, 56, 29–39. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Zen, X.; Xie, Y.; Shang, T. Design of binder system of eco-efficient UHPC based on physical packing and chemical effect optimization. Constr. Build. Mater. 2021, 274, 121382. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Zeng, X.; Xie, Y.; Wang, H. Green ultra-high-performance concrete with very low cement content. Constr. Build. Mater. 2021, 303, 124482. [Google Scholar] [CrossRef]

- Li, H.; Li, L.; Li, L.; Zhou, J.; Mu, R.; Xu, M. Influence of fiber orientation on the microstructures of interfacial transition zones and pull-out behavior of steel fiber in cementitious composites. Cem. Concr. Compos. 2022, 128, 104459. [Google Scholar] [CrossRef]

- Rohrmller, B.; Gumbsch, P.; Hohe, J. Calibrating a fiber-matrix interface failure model to single fiber push-out tests and numerical simulations. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106607. [Google Scholar] [CrossRef]

- Zhu, M.; Wang, Y.; Wang, C.; Chen, F.; Liu, Q. An improved analytical model for inversely determining multiple interfacial parameters from single fiber micro-Raman and fragmentation tests. Compos. Sci. Technol. 2021, 214, 108983. [Google Scholar] [CrossRef]

- Thomason, J. An overview of some scaling issues in the sample preparation and data interpretation of the microbond test for fibre-matrix interface characterisation. Polym. Test. 2022, 111, 107591. [Google Scholar] [CrossRef]

- Li, F.; Tang, H.; Wen, T.; Li, J.; Chen, Z.; Jiang, Y.; Gao, H. Pullout behavior of studs in ultra-high-performance concrete with steel fibers and novel structural fibers. Structures 2022, 44, 405–417. [Google Scholar] [CrossRef]

- Esmaeili, J.; Andalibi, K.; Gencel, O.; Maleki, F.K.; Maleki, V.A. Pull-out and bond-slip performance of steel fibers with various ends shapes embedded in polymer-modified concrete. Constr. Build. Mater. 2021, 271, 121531. [Google Scholar] [CrossRef]

- Garcia-Diaz, Y.; Torres-Ortega, R.; Tovar, C.T.; Quinones-Bolanos, E.; Saba, M. Characterization of pull-out behavior in the fiber–mortar interface with superficial treatments. Constr. Build. Mater. 2021, 303, 124474. [Google Scholar] [CrossRef]

- Oushabi, A. The pull-out behavior of chemically treated lignocellulosic fibers/polymeric matrix interface (LF/PM): A review. Compos. Part B Eng. 2019, 174, 107059. [Google Scholar] [CrossRef]

- Teklal, F.; Djebbar, A.; Allaoui, S.; Hivet, G.; Joliff, Y.; Kacimi, B. A review of analytical models to describe pull-out behavior–Fiber/matrix adhesion. Compos. Struct. 2018, 201, 791–815. [Google Scholar] [CrossRef]

- Luo, Z.; Li, W.; Wang, K.; Shah, S.P.; Sheng, D. Nano/micromechanical characterization and image analysis on the properties and heterogeneity of ITZs in geopolymer concrete. Cem. Concr. Res. 2022, 152, 106677. [Google Scholar] [CrossRef]

- Diamond, S.; Huang, J. The ITZ in concrete–a different view based on image analysis and SEM observations. Cem. Concr. Compos. 2001, 23, 179–188. [Google Scholar] [CrossRef]

- Rangaraju, P.R.; Olek, J.; Diamond, S. An investigation into the influence of inter-aggregate spacing and the extent of the ITZ on properties of Portland cement concretes. Cem. Concr. Res. 2010, 40, 1601–1608. [Google Scholar] [CrossRef]

- Vargas, P.; Restrepo-Baena, O.; Tobón, J.I. Microstructural analysis of interfacial transition zone (ITZ) and its impact on the compressive strength of lightweight concretes. Constr. Build. Mater. 2017, 137, 381–389. [Google Scholar] [CrossRef]

- Nili, M.; Ehsani, A. Investigating the effect of the cement paste and transition zone on strength development of concrete containing nanosilica and silica fume. Mater. Des. 2015, 75, 174–183. [Google Scholar] [CrossRef]

- Sinaie, S.; Ngo, T.D.; Nguyen, V.P. A discrete element model of concrete for cyclic loading. Comput. Struct. 2018, 196, 173–185. [Google Scholar] [CrossRef]

- Zhou, X.; Xie, Y.; Long, G.; Zeng, X.; Li, J.; Yao, L.; Jiang, W.; Pan, Z. DEM analysis of the effect of interface transition zone on dynamic splitting tensile behavior of high-strength concrete based on multi-phase model. Cem. Concr. Res. 2021, 149, 106577. [Google Scholar] [CrossRef]

- Nitka, M.; Tejchman, J. Meso-mechanical modelling of damage in concrete using discrete element method with porous ITZs of defined width around aggregates. Eng. Fract. Mech. 2020, 231, 107029. [Google Scholar] [CrossRef]

- Xue, B.; Pei, J.; Zhou, B.; Zhang, J.; Li, R.; Guo, F. Using random heterogeneous DEM model to simulate the SCB fracture behavior of asphalt concrete. Constr. Build. Mater. 2020, 236, 117580. [Google Scholar] [CrossRef]

- Ren, J.; Xu, Y.; Huang, J.; Wang, Y.; Jia, Z. Gradation optimization and strength mechanism of aggregate structure considering macroscopic and mesoscopic aggregate mechanical behaviour in porous asphalt mixture. Constr. Build. Mater. 2021, 300, 124262. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, L.; Wang, X.; Huang, D. Quantifying the effects of elongation and flatness on the shear behavior of realistic 3D rock aggregates based on DEM modeling. Adv. Powder Technol. 2021, 32, 1318–1332. [Google Scholar] [CrossRef]

- Zhou, X.; Xie, Y.; Long, G.; Li, J. Effect of surface characteristics of aggregates on the compressive damage of high-strength concrete based on 3D discrete element method. Constr. Build. Mater. 2021, 301, 124101. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, C.; Liao, L.; Wang, C. Numerical study of the effect of ITZ on the failure behaviour of concrete by using particle element modelling. Constr. Build. Mater. 2018, 170, 776–789. [Google Scholar] [CrossRef]

- Schöpfer, M.P.; Abe, S.; Childs, C.; Walsh, J.J. The impact of porosity and crack density on the elasticity, strength and friction of cohesive granular materials: Insights from DEM modelling. Int. J. Rock Mech. Min. Sci. 2009, 46, 250–261. [Google Scholar] [CrossRef]

- Shi, Y.; Long, G.; Ma, C.; Xie, Y.; He, J. Design and preparation of ultra-high-performance concrete with low environmental impact. J. Clean. Prod. 2019, 214, 633–643. [Google Scholar] [CrossRef]

- ITASCA Consulting Group I. PFC 3D User’s Guide; ITASCA Consulting Group I: Minneapolis, MN, USA, 2014. [Google Scholar]

- Liakas, S.; O’Sullivan, C.; Saroglou, C. Influence of heterogeneity on rock strength and stiffness using discrete element method and parallel bond model. J. Rock Mech. Geotech. Eng. 2017, 9, 575–584. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, L. A new contact model to improve the simulated ratio of unconfined compressive strength to tensile strength in bonded particle models. Int. J. Rock Mech. Min. Sci. 2014, 69, 111–119. [Google Scholar] [CrossRef]

- Yang, B.; Jiao, Y.; Lei, S. A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng. Comput. 2006, 23, 607–631. [Google Scholar] [CrossRef]

- Li, S.; Jensen, O.M.; Wang, Z.; Yu, Q. Influence of micromechanical property on the rate-dependent flexural strength of ultra-high-performance concrete containing coarse aggregates (UHPC-CA). Compos. Part B Eng. 2021, 227, 109394. [Google Scholar] [CrossRef]

- Stankowski, T. Numerical Simulation of Progressive Failure in Particle Composites. Ph.D. Thesis, University of Colorado Boulder, Boulder, CO, USA, 1990. [Google Scholar]

- Li, N.; Long, G.; Fu, Q.; Song, H.; Ma, C.; Ma, K.; Xie, Y.; Li, H. Dynamic mechanical characteristics of filling layer self-compacting concrete under impact loading. Arch. Civ. Mech. Eng. 2019, 19, 851–861. [Google Scholar] [CrossRef]

- Shah, V.; Scrivener, K.; Bhattacharjee, B. Changes in microstructure characteristics of cement paste on carbonation. Cem. Concr. Res. 2018, 109, 184–197. [Google Scholar] [CrossRef]

- Kawashima, S.; Hou, P.; Corr, D.J.; Shah, S.P. Modification of cement-based materials with nanoparticles. Cem. Concr. Compos. 2013, 36, 8–15. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K.H. Multi-scale investigation of microstructure, fiber pullout behavior, and mechanical properties of ultra-high-performance concrete with nano-CaCO3 particles. Cem. Concr. Compos. 2018, 86, 255–265. [Google Scholar] [CrossRef]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A review on ultra-high-performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Chan, Y.W.; Chu, S.H. Effect of silica fume on steel fiber bond characteristics in reactive powder concrete. Cem. Concr. Res. 2004, 34, 1167–1172. [Google Scholar] [CrossRef]

- Wille, K.; El-Tawil, S.; Naaman, A.E. Properties of strain hardening ultra-high performance fiber reinforced concrete (UHP-FRC) under direct tensile loading. Cem. Concr. Compos. 2014, 48, 53–66. [Google Scholar] [CrossRef]

| Raw Materials | Content/% by Weight | Ignition Loss/% | ||||||

|---|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | FexOy | CaO | MgO | SO3 | f-CaO | ||

| OPC | 22.01 | 4.41 | 3.12 | 62.48 | 2.26 | 2.59 | 0.77 | 2.02 |

| FA | 52.60 | 25.90 | 9.60 | 3.80 | 1.20 | 0.20 | -- | 4.10 |

| GGBS | 26.15 | 13.70 | 13.90 | 33.50 | 8.00 | -- | -- | 3.50 |

| SF | 92.41 | -- | 0.15 | 0.57 | 0.36 | 0.04 | -- | 2.40 |

| NS | 99.8 | -- | -- | -- | -- | -- | -- | 0 |

| NA | -- | 99.9 | -- | -- | -- | -- | -- | 0 |

| Opening Size (mm) | Coarse Sand (%) | Medium Sand (%) | Fine Sand (%) |

|---|---|---|---|

| 2.5 | 0 | 0 | 0 |

| 1.18 | 13.26 | 0 | 0 |

| 0.63 | 84.44 | 0 | 0 |

| 0.315 | 2.2 | 73.98 | 0 |

| 0.16 | 0 | 22.81 | 42.56 |

| <0.16 | 0 | 3.21 | 57.44 |

| PC-80 | PC-55 | PC-35 | PC-35-NS | PC-35-NA | PC-35-AA | |

|---|---|---|---|---|---|---|

| OPC | 856 | 577 | 364 | 359 | 359 | 362 |

| GGBS | - | 105 | 312 | 307 | 307 | 311 |

| SF | 214 | 210 | 208 | 205 | 205 | 207 |

| FA | - | 157 | 156 | 154 | 154 | 155 |

| nano | - | - | - | 15.6 (NS) | 15.6 (NA) | - |

| SS | - | - | - | - | - | 5.2 |

| Water | 182 | 178 | 177 | 177 | 177 | 177 |

| SP | 24.6 | 15.7 | 8.8 | 11.4 | 11.4 | 13.5 |

| Sand | 1177 | 1154 | 1145 | 1145 | 1145 | 1145 |

| Linear Parallel Bond Model Meso-Parameters | Parameter Types | |

|---|---|---|

| Paste | ITZ | |

| Bond effective modulus | 43 | 30 |

| Normal-to-shear stiffness ratio | 1.5 | 1.5 |

| Cohesion | 34 | 23.8 |

| Tensile strength | 10.7 | 7.5 |

| Friction angle | 30 | 30 |

| Friction coefficient | 0.5 | 0.5 |

| PC-80 | PC-55 | PC-35 | PC-35-NS | PC-35-NA | PC-35-AA | |

|---|---|---|---|---|---|---|

| Tensile strength of the matrix (Experiment) | 7.3 MPa | 4.7 MPa | 4.2 MPa | 4.7 MPa | 7.0 MPa | 6.7 MPa |

| σITZ/σPaste (Simulation) | 0.7 | 0.37 | 0.32 | 0.37 | 0.63 | 0.59 |

| PC-80 | PC-55 | PC-35 | PC-35-NS | PC-35-NA | PC-35-AA | |

|---|---|---|---|---|---|---|

| Paste porosity | 1.65% | 1.12% | 1.50% | 0.77% | 0.79% | 1.96% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, X.; Shi, Y.; Hu, Q.; Zhang, S.; Zhang, X.; Meng, L. Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix. Materials 2023, 16, 3844. https://doi.org/10.3390/ma16103844

Zhou X, Shi Y, Hu Q, Zhang S, Zhang X, Meng L. Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix. Materials. 2023; 16(10):3844. https://doi.org/10.3390/ma16103844

Chicago/Turabian StyleZhou, Xiang, Ye Shi, Qingchun Hu, Shen Zhang, Xihong Zhang, and Lingzhen Meng. 2023. "Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix" Materials 16, no. 10: 3844. https://doi.org/10.3390/ma16103844

APA StyleZhou, X., Shi, Y., Hu, Q., Zhang, S., Zhang, X., & Meng, L. (2023). Discrete Element Simulation of the Relationship between Composition, ITZ Property, and Tensile Behavior of Eco-Friendly UHPC Matrix. Materials, 16(10), 3844. https://doi.org/10.3390/ma16103844