Microstructure and Mechanical Properties of TA2/Q235 Laser Weld Joint with Copper Interlayer

Abstract

1. Introduction

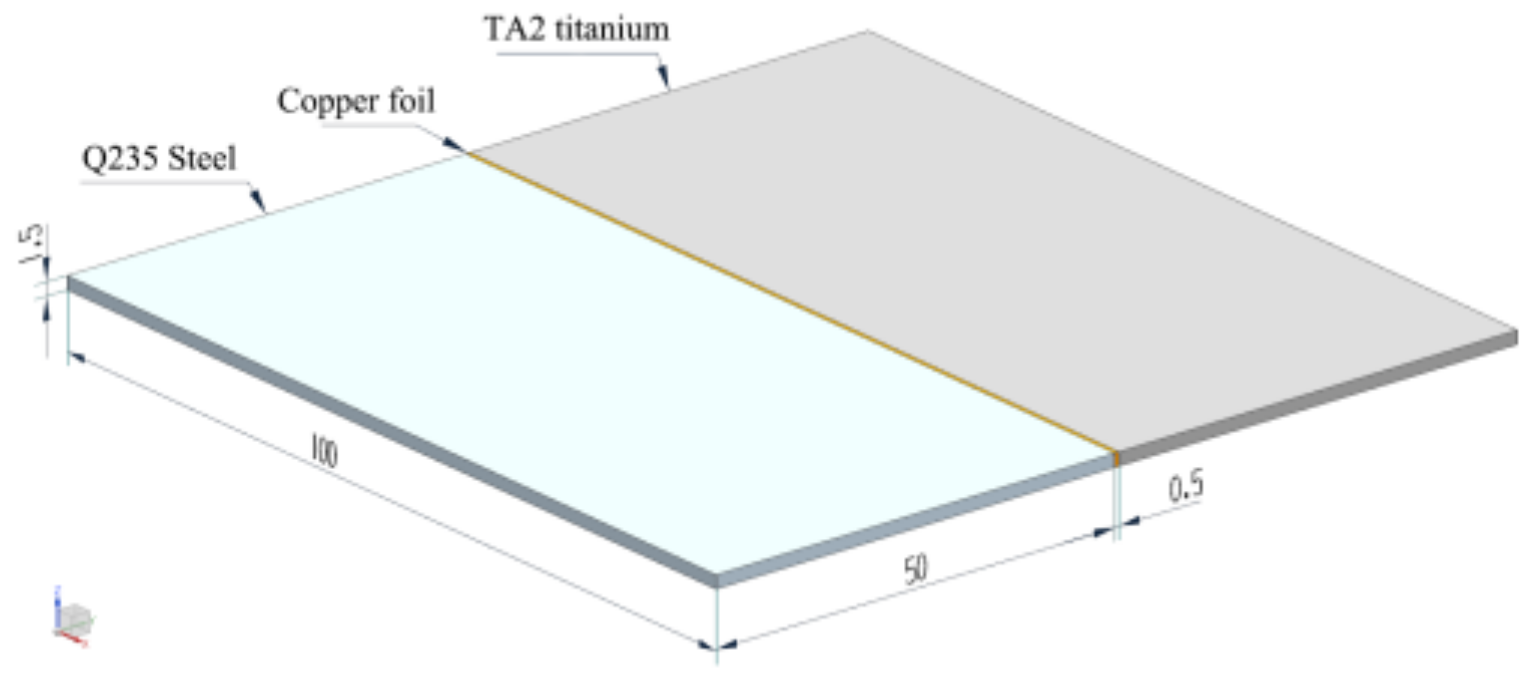

2. Materials and Methods

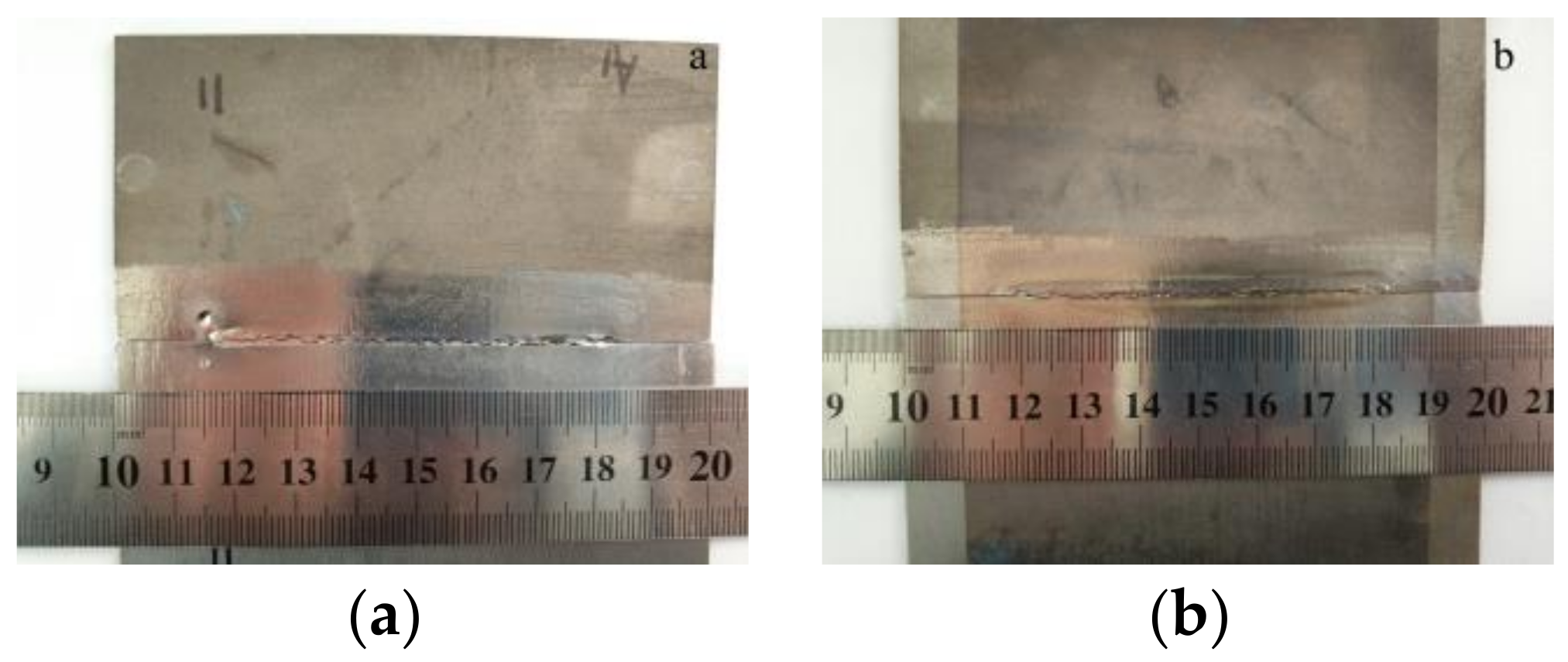

3. Preliminary Welding Experiments

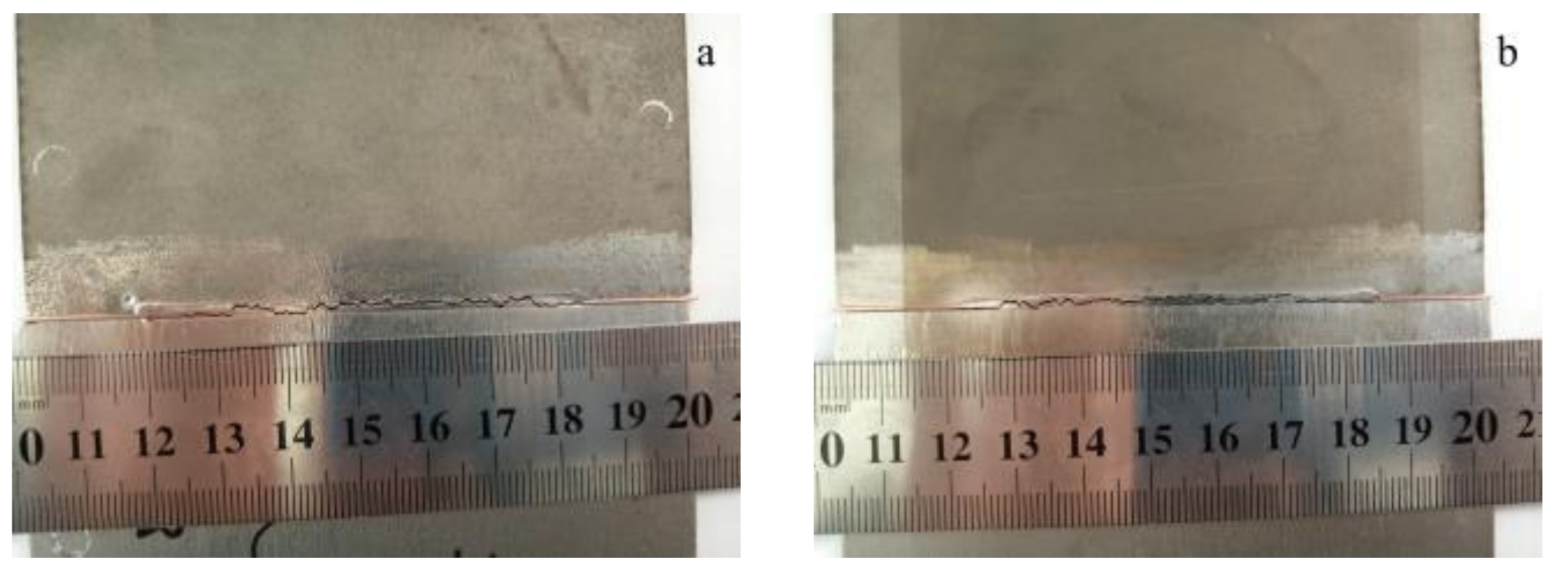

3.1. Welding Experiments without Interlayers

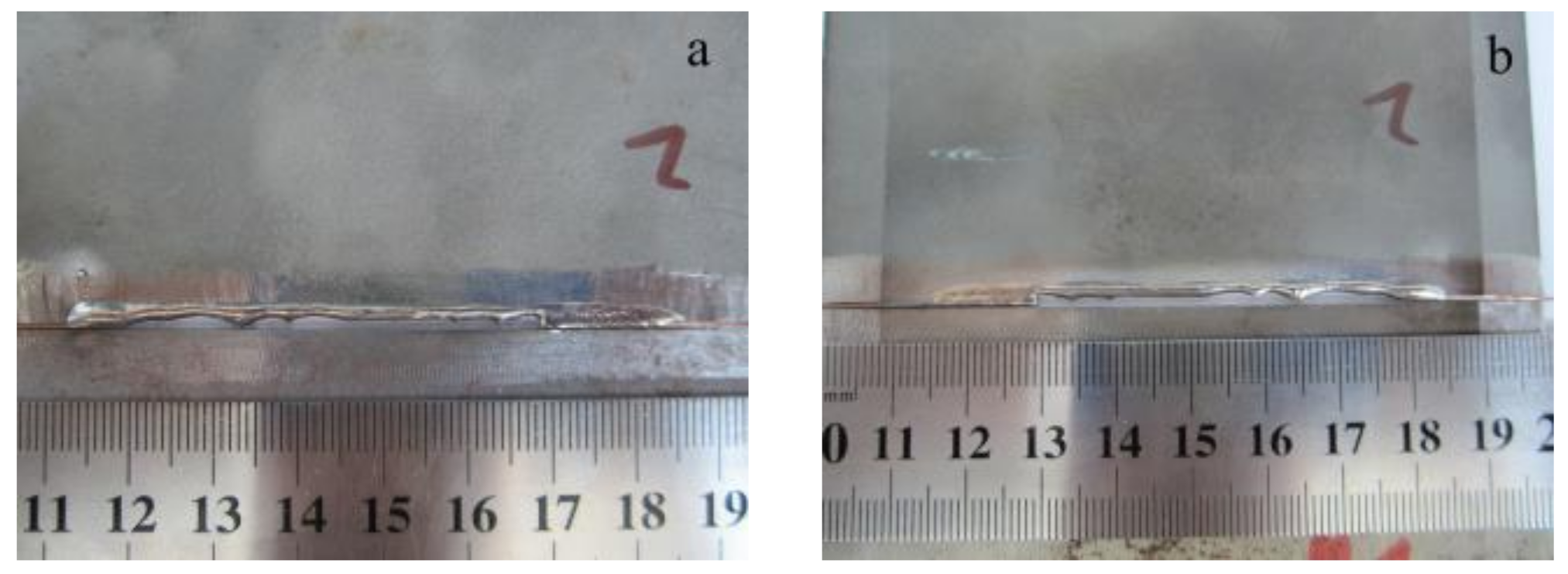

3.2. Welding Experiments with Interlayers

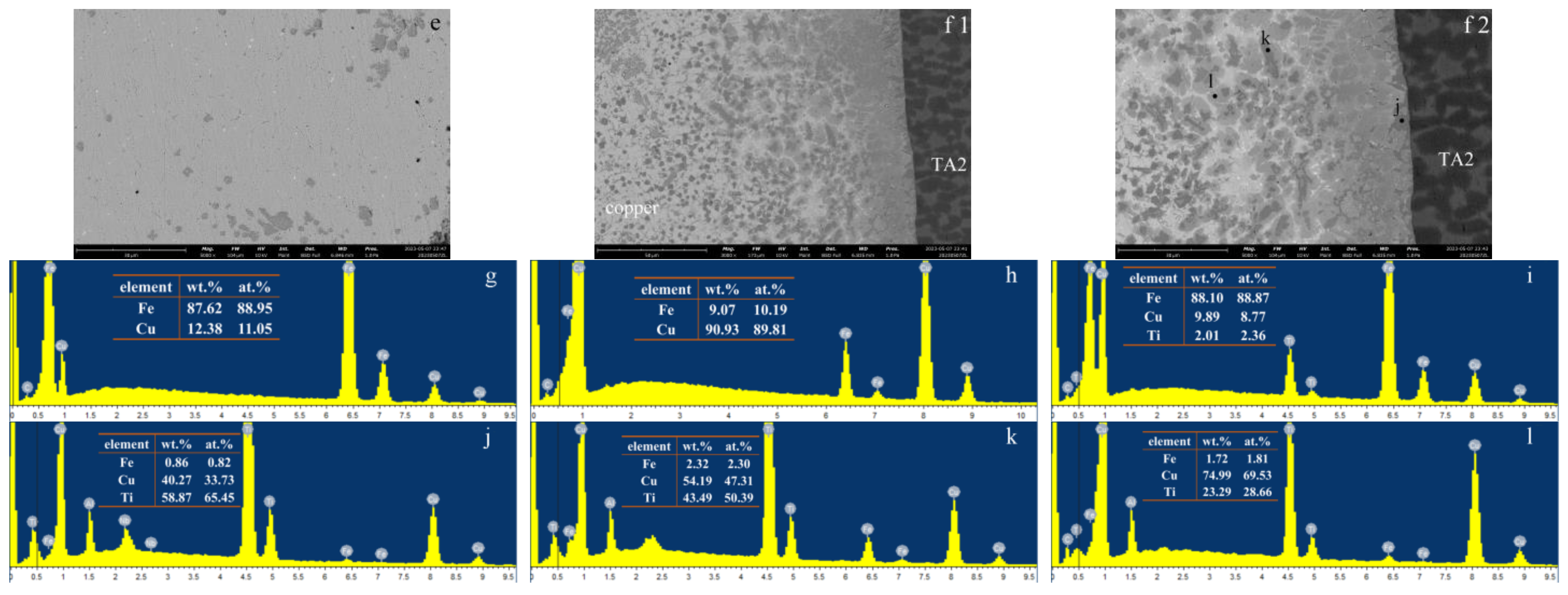

4. Welding Experiments with Interlayer and Position Offset to Q235

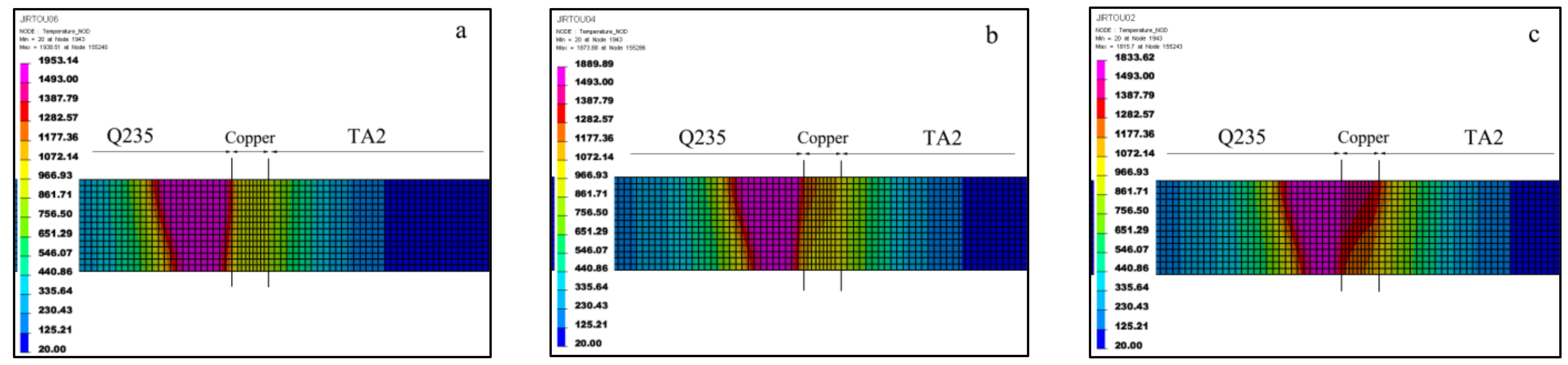

4.1. FE Simulation of Temperature Field

4.2. Macrographs of the Joint

4.3. The Microhardness Distribution of the Joint

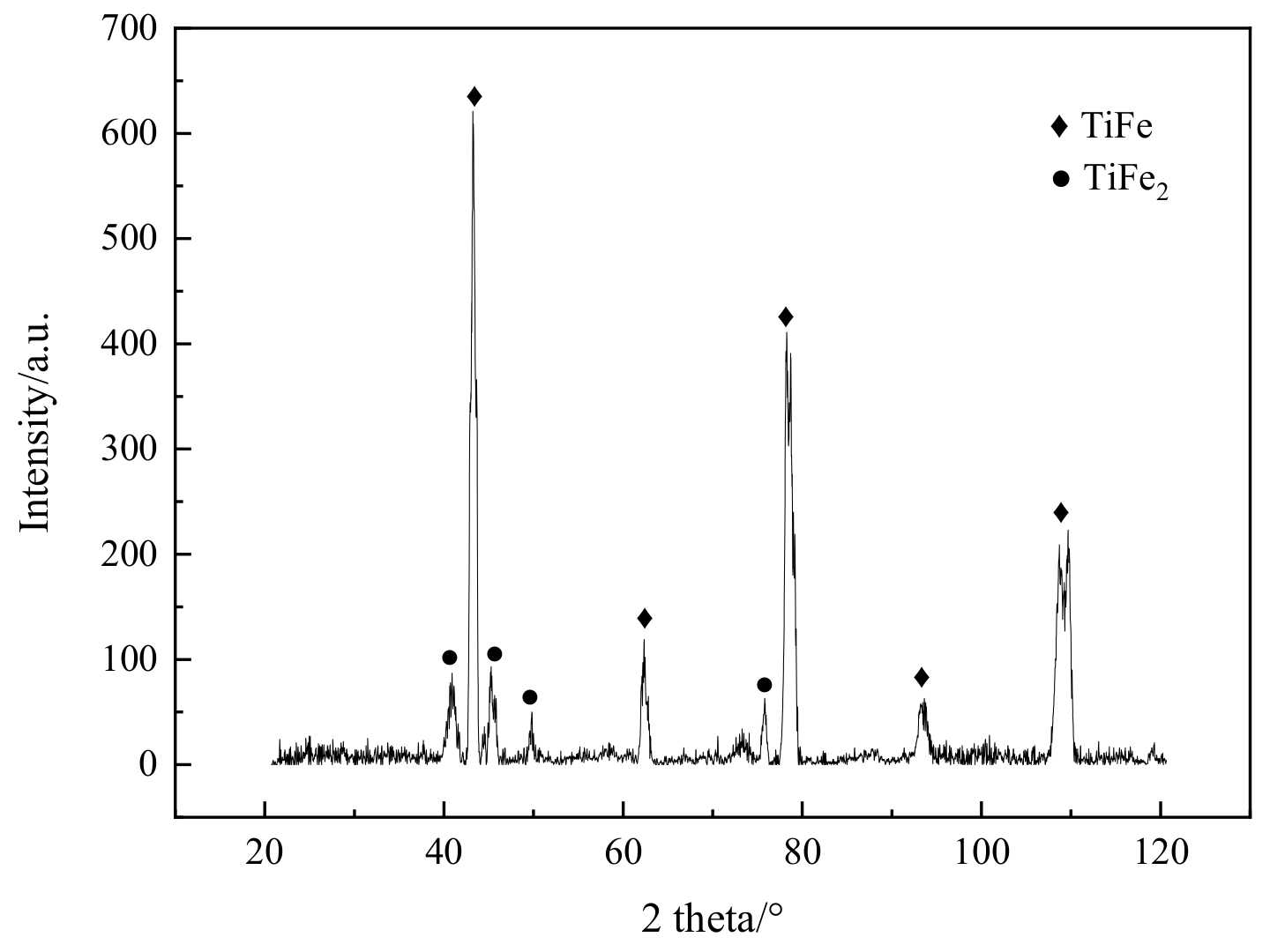

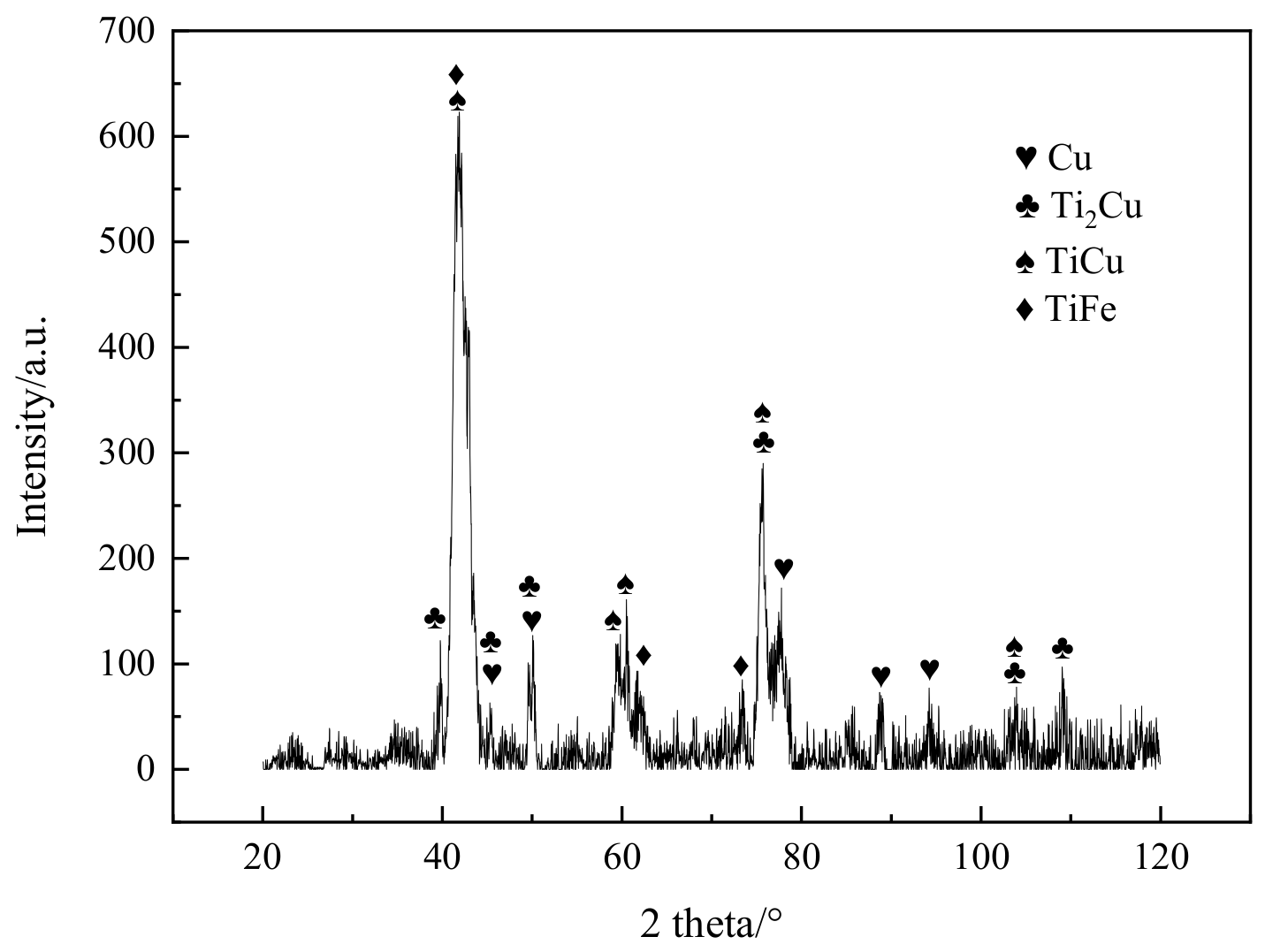

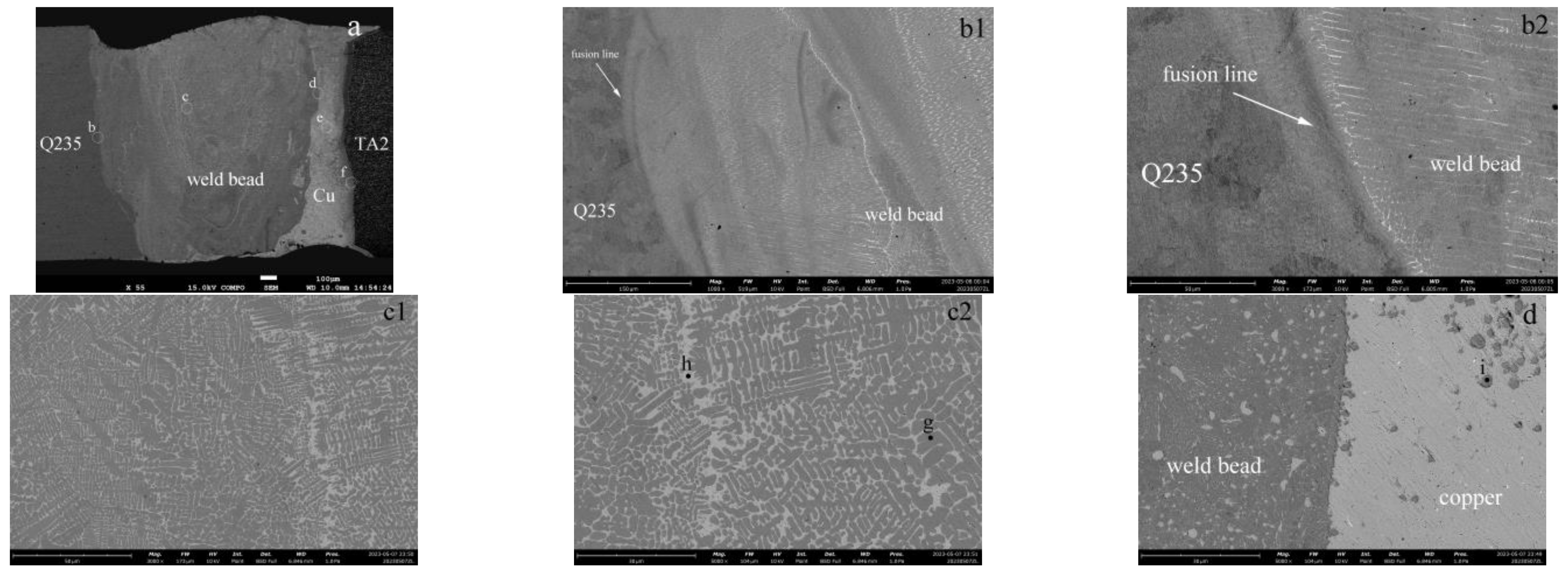

4.4. Microstructure

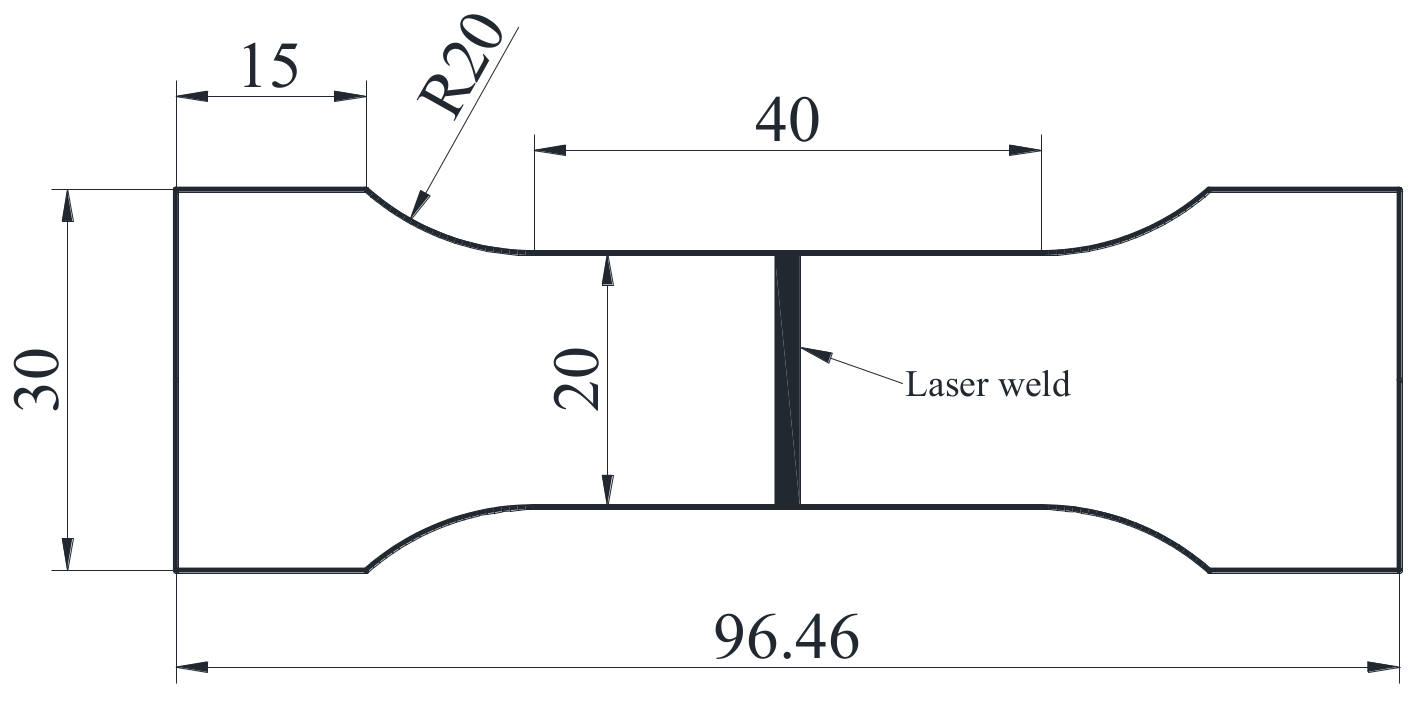

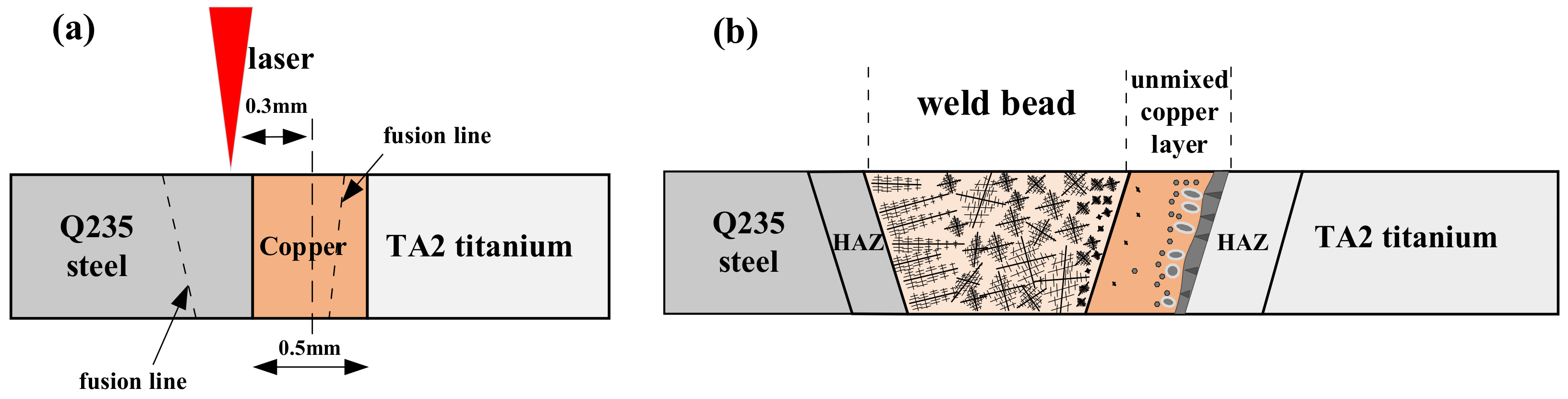

4.5. Mechanical Properties

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, H.; Chen, S.F.; Zhang, S.H. Deformation characteristics, formability and springback control of titanium alloy sheet at room temperature: A review. Materials 2022, 15, 5586. [Google Scholar] [CrossRef]

- Jian, S.C.; Wang, J.X.; Xu, D. Gradient microstructure and mechanical properties of Ti-6Al-4V titanium alloy fabricated by high-frequency induction quenching treatment. Mater. Des. 2022, 222, 111031. [Google Scholar] [CrossRef]

- Williams, J.C.; Boyer, R.R. Opportunities and issues in the application of titanium alloys for aerospace components. Metals 2020, 10, 705. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Huang, J.H. Study on titanium alloy/stainless steel welding methods. Appl. Mech. Mater. 2015, 751, 72–76. [Google Scholar] [CrossRef]

- Bi, Y.B.; Xu, Y.; Luo, Z. Material characterization and mechanical performance of laser diffusion welded joint between titanium alloy and stainless steel. Mater. Lett. 2023, 336, 133927. [Google Scholar] [CrossRef]

- Giri, S.R.; Khamari, B.K.; Moharana, B.R. Joining of titanium and stainless steel by using different welding processes: A review. Mater. Today Proc. 2022, 66, 505–508. [Google Scholar] [CrossRef]

- Chang, J.; Cao, R.; Yan, Y. The joining behavior of titanium and Q235 steel joined by cold metal transfer joining technology. Materials 2019, 12, 2413. [Google Scholar] [CrossRef]

- Pasang, T.; Pramana, S.S.; Kracum, M.; Misiolek, W.Z. Characterisation of intermetallic phases in fusion welded commercially pure titanium and stainless steel 304. Metals 2018, 8, 863. [Google Scholar] [CrossRef]

- Wu, T.; Yang, C.L. Influence of pulse TIG welding thermal cycling on the microstructure and mechanical properties of explosively weld titanium/steel joint. Vacuum 2022, 197, 110817. [Google Scholar] [CrossRef]

- Angshuman, C.; Gopinath, M.; Sagar, S. Mitigation of cracks in laser welding of titanium and stainless steel by in-situ nickel interlayer deposition. J. Mater. Process. Tech. 2022, 300, 117403. [Google Scholar]

- Gao, M.; Mei, S.W.; Wang, Z.M. Characterisation of laser welded dissimilar Ti/steel joint using Mg interlayer. Sci. Technol. Weld. Join. 2012, 17, 269–276. [Google Scholar] [CrossRef]

- Zhang, Y.; Bi, Y.B.; Zhou, J.P. Butt laser welding of TC4 titanium alloy and 304 stainless steel with Ag-base filler metal based on a hybrid connection mechanism. Opt. Laser Technol. 2020, 124, 105957. [Google Scholar] [CrossRef]

- Wang, T.; Zhang, B.G.; Feng, J.C. Influences of different filler metals on electron beam welding of titanium alloy to stainless steel. Trans. Nonferrous Met. Soc. China 2014, 24, 108–114. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Belyavina, N.; Pilloz, M. Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater. Sci. Eng. A 2013, 585, 114–122. [Google Scholar] [CrossRef]

- Wang, Y.R.; Fan, Y.L.; Yu, Y. Effect of isolation coatings on mechanical property of electron beam welding joint of titanium alloy to stainless-steel. Rare Metal Mater. Eng. 2018, 47, 299–304. [Google Scholar]

- Pardal, G.; Ganguly, S.; Williams, S. Dissimilar metal joining of stainless steel and titanium using copper as transition metal. Int. J. Adv. Manuf. Technol. 2016, 86, 1139–1150. [Google Scholar] [CrossRef]

- Tesař, K.; Koller, M.; Vokoun, D. Texture, elastic anisotropy and thermal stability of commercially pure titanium prepared by room temperature ECAP. Mater. Des. 2023, 226, 111678. [Google Scholar] [CrossRef]

- Shunya, S.; Gareoung, K.; Tsunehiro, T. Thermal conduction in titanium-chromium oxide natural superlattices with an ordered arrangement of nearly pristine interfaces. J. Alloys Compd. 2023, 934, 167915. [Google Scholar]

- Chen, C.; Wang, A.; Zheng, Z. A Study on drilling of CFRP/Ti stacks: Temperature field and thermal damage of the Interface region. Materials 2023, 16, 2586. [Google Scholar] [CrossRef]

- Chen, P.; Yao, X.; Zhou, Z. Finite element simulation of tensile behavior of laser welded 5083 aluminum alloy joint with different filler wires. J. Laser Appl. 2022, 34, 220–231. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, Q.; Chen, P. Finite element analysis of restraint intensities and welding residual stresses in the Ti80 T-joints. Metals 2023, 13, 125. [Google Scholar] [CrossRef]

- Kenneth, C.M. Recommended Values of Thermophysical Properties for Selected Commercial Alloys; Woodhead Publishing Limited: Abington, MA, USA, 2002. [Google Scholar]

- Chen, Y.Z.; Liu, F.; Yang, G.C. Rapid solidification of bulk undercooled hypoperitectic Fe-Cu alloy. J. Alloys Compd. 2007, 427, L1–L5. [Google Scholar] [CrossRef]

- Cao, C.D.; Sun, Z.; Bai, X.J. Metastable phase diagrams of Cu-based alloy systems with a miscibility gap in undercooled state. J. Mater. Sci. 2011, 46, 6203–6212. [Google Scholar] [CrossRef]

- Lang, R.Q.; Han, Y.Q.; Bai, X.Y. Influence of the metal flow in the keyhole molten pool on the molten pool stability in continuous variable polarity plasma arc keyhole vertical-up welding. J. Manuf. Process. 2022, 76, 195–209. [Google Scholar] [CrossRef]

| Fe | C | Mn | Cu | Si | Ti | P | S | O | |

|---|---|---|---|---|---|---|---|---|---|

| Q235 | 99.12 | 0.16 | 0.56 | 0.02 | 0.08 | - | 0.016 | 0.009 | 0.03 |

| TA2 | 0.2 | 0.07 | - | - | - | 99.84 | - | - | 0.015 |

| Cu | 0.008 | - | - | 99.96 | 0.004 | - | 0.007 | 0.009 | 0.01 |

| Yield Strength/MPa | Tensile Strength/MPa | Percentage Elongation/% | |

|---|---|---|---|

| Q235 | 249 | 384 | 31 |

| TA2 | 341 | 421 | 35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Wang, Q.; Guo, X.; Chen, P.; Wang, Y.; Wang, C.; Wang, Z.; Wang, Z. Microstructure and Mechanical Properties of TA2/Q235 Laser Weld Joint with Copper Interlayer. Materials 2023, 16, 3838. https://doi.org/10.3390/ma16103838

Zhang L, Wang Q, Guo X, Chen P, Wang Y, Wang C, Wang Z, Wang Z. Microstructure and Mechanical Properties of TA2/Q235 Laser Weld Joint with Copper Interlayer. Materials. 2023; 16(10):3838. https://doi.org/10.3390/ma16103838

Chicago/Turabian StyleZhang, Liang, Qi Wang, Xiaolei Guo, Pan Chen, Yinling Wang, Chen Wang, Zhanxue Wang, and Zongling Wang. 2023. "Microstructure and Mechanical Properties of TA2/Q235 Laser Weld Joint with Copper Interlayer" Materials 16, no. 10: 3838. https://doi.org/10.3390/ma16103838

APA StyleZhang, L., Wang, Q., Guo, X., Chen, P., Wang, Y., Wang, C., Wang, Z., & Wang, Z. (2023). Microstructure and Mechanical Properties of TA2/Q235 Laser Weld Joint with Copper Interlayer. Materials, 16(10), 3838. https://doi.org/10.3390/ma16103838