Influence of Pretreatment Methods on Compressive Performance Improvement and Failure Mechanism Analysis of Recycled Aggregate Concrete

Abstract

1. Introduction

2. Experimental Investigation

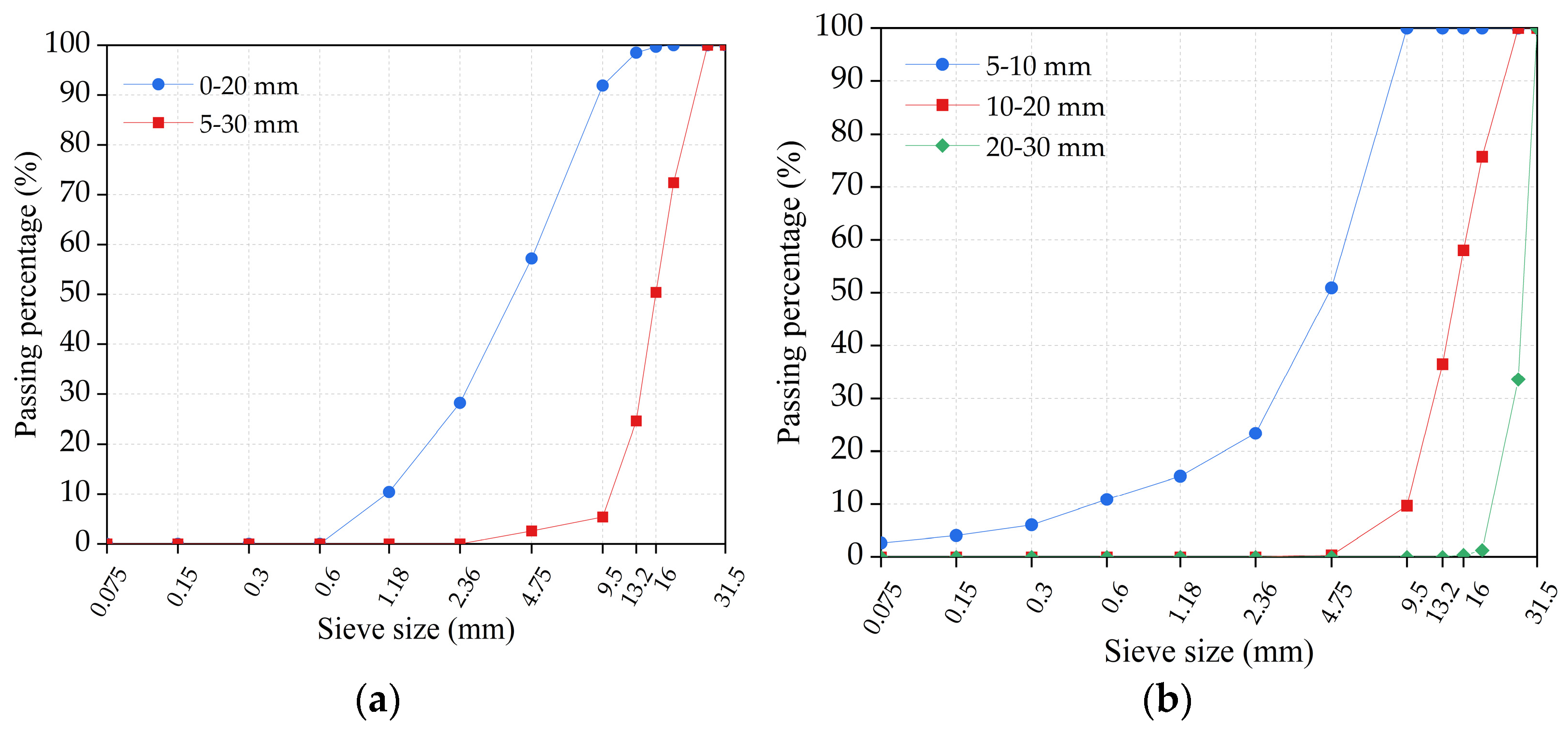

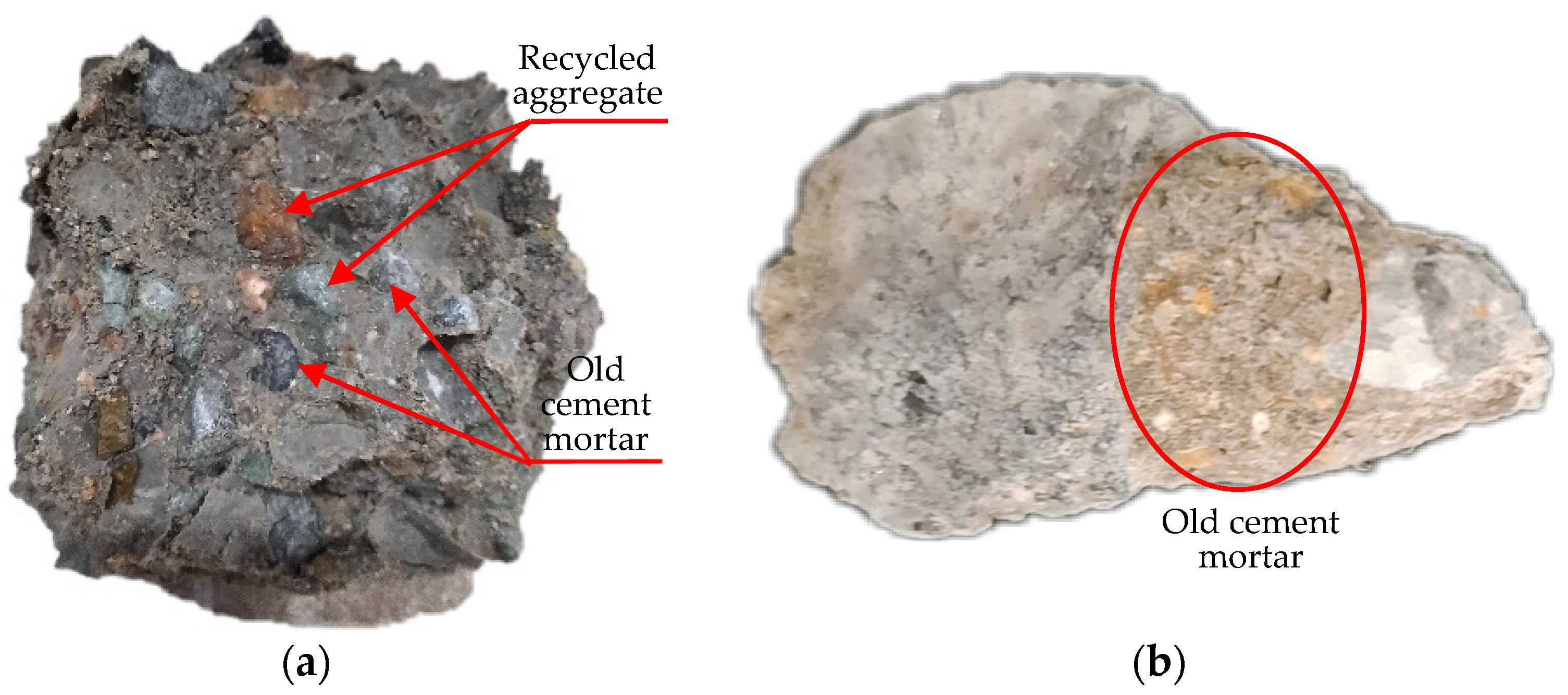

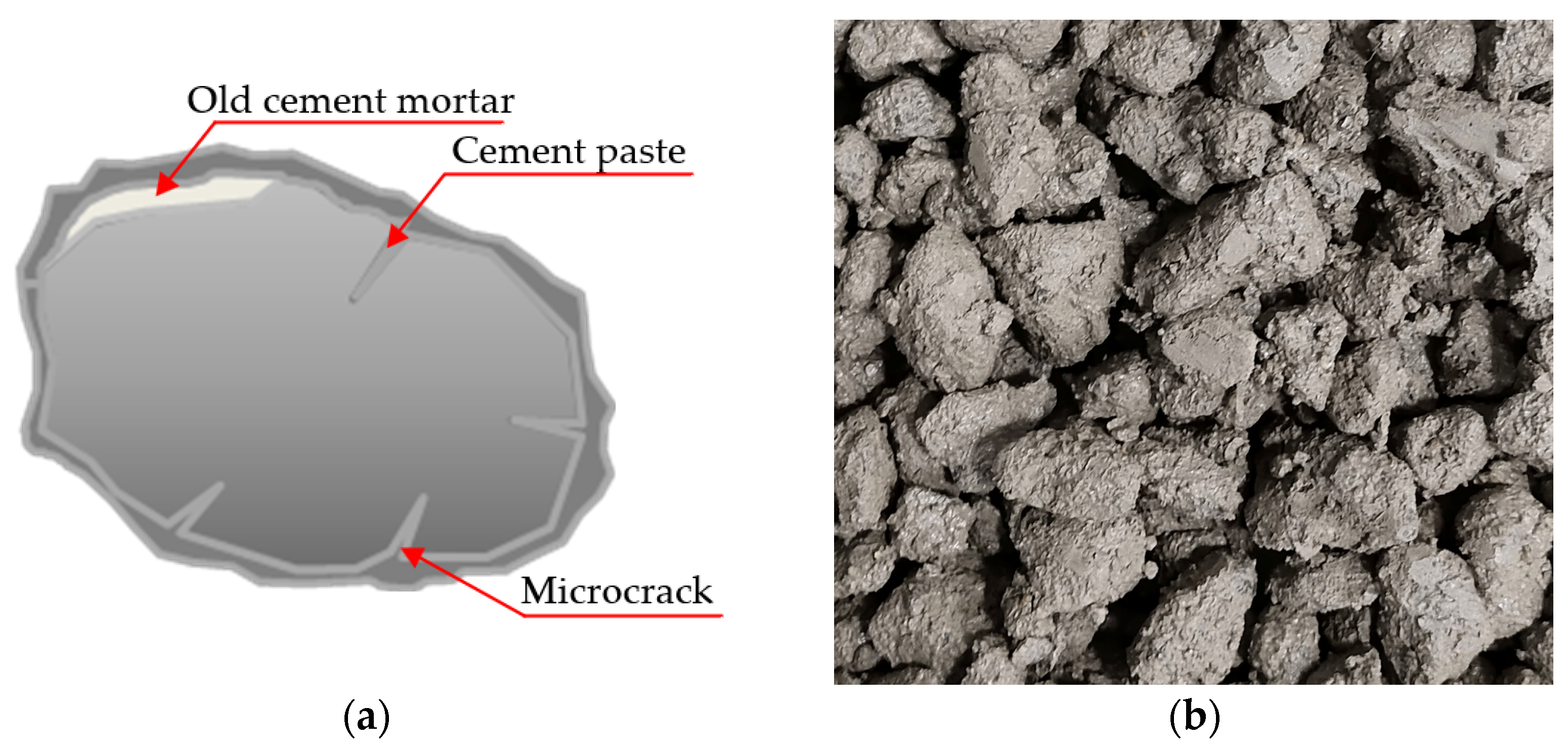

2.1. Raw Materials

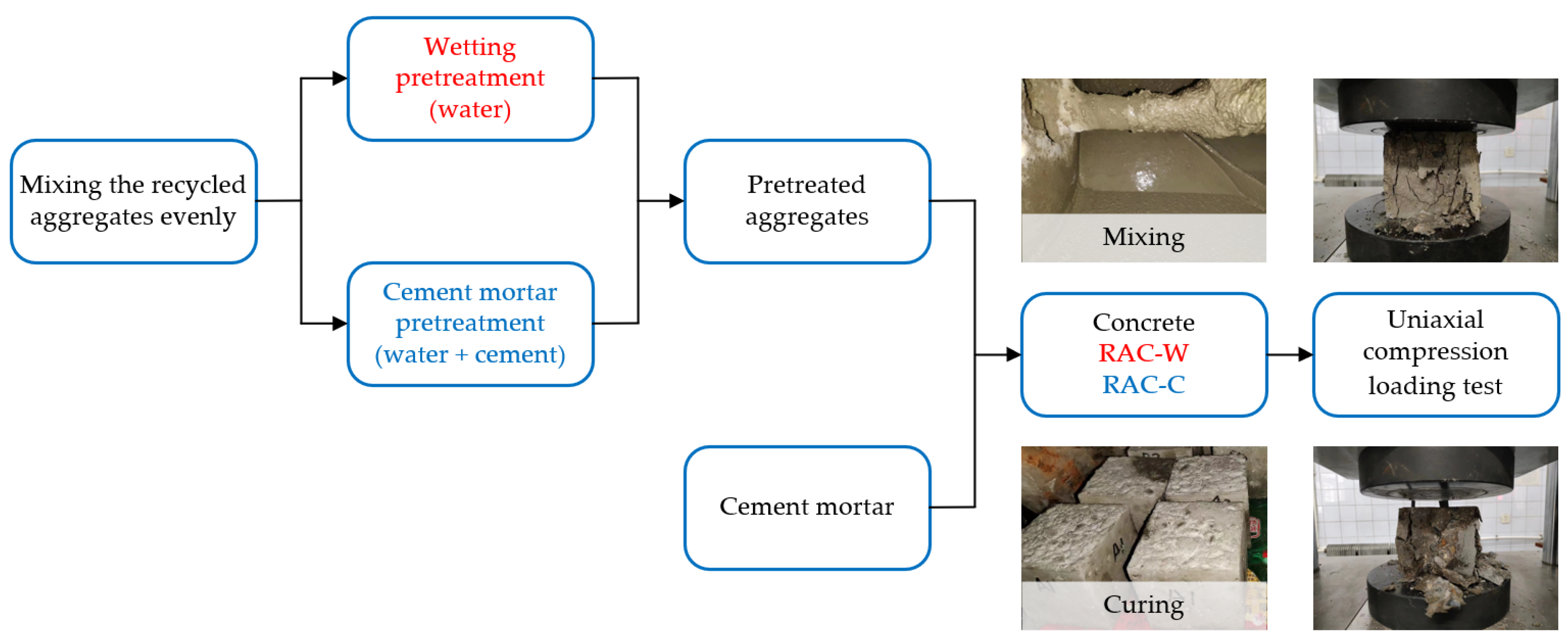

2.2. Specimen Preparation and Experimental Method

3. Results and Discussions

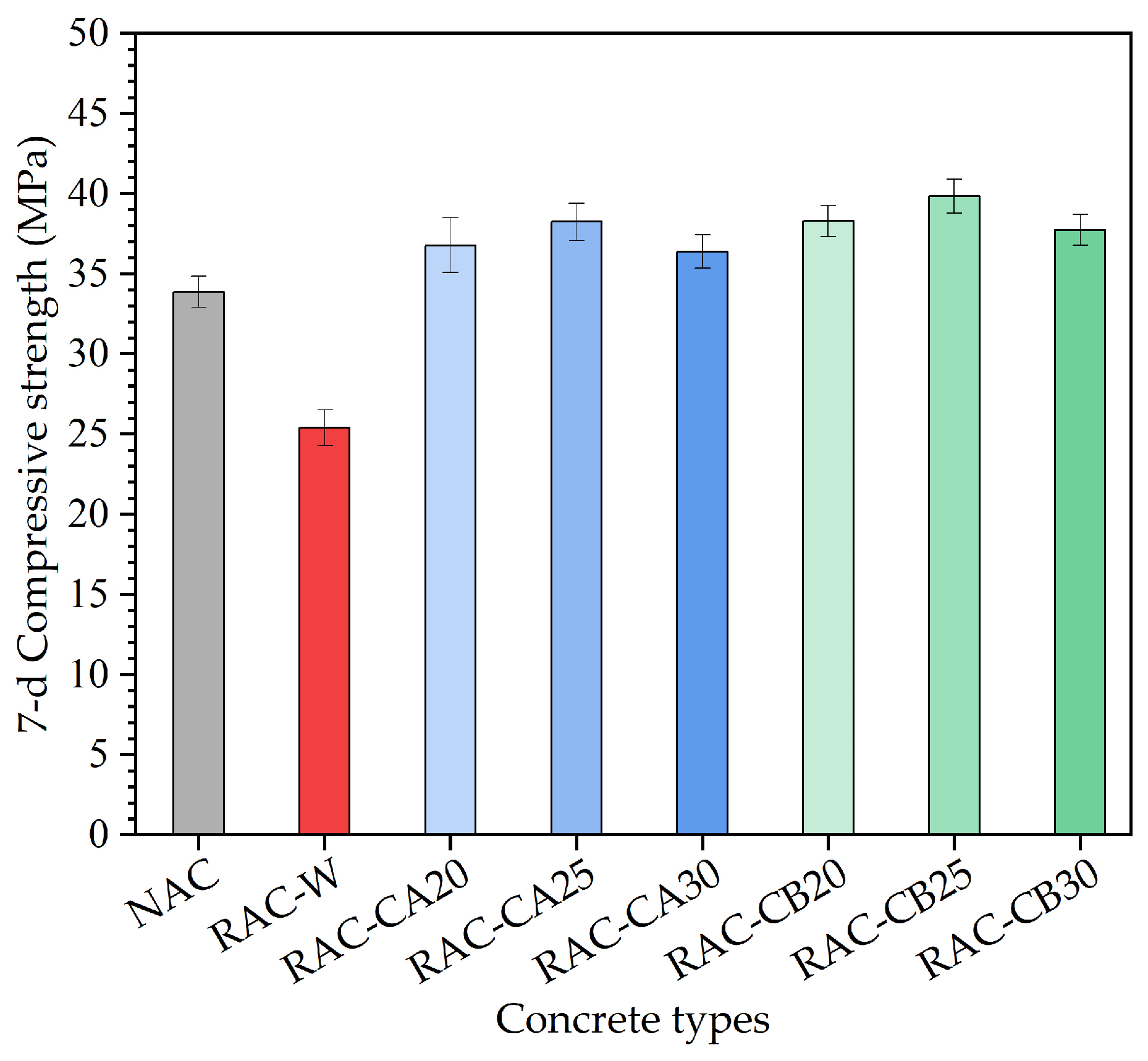

3.1. Analysis of Compressive Strength of Concrete at a 7-d Curing Age

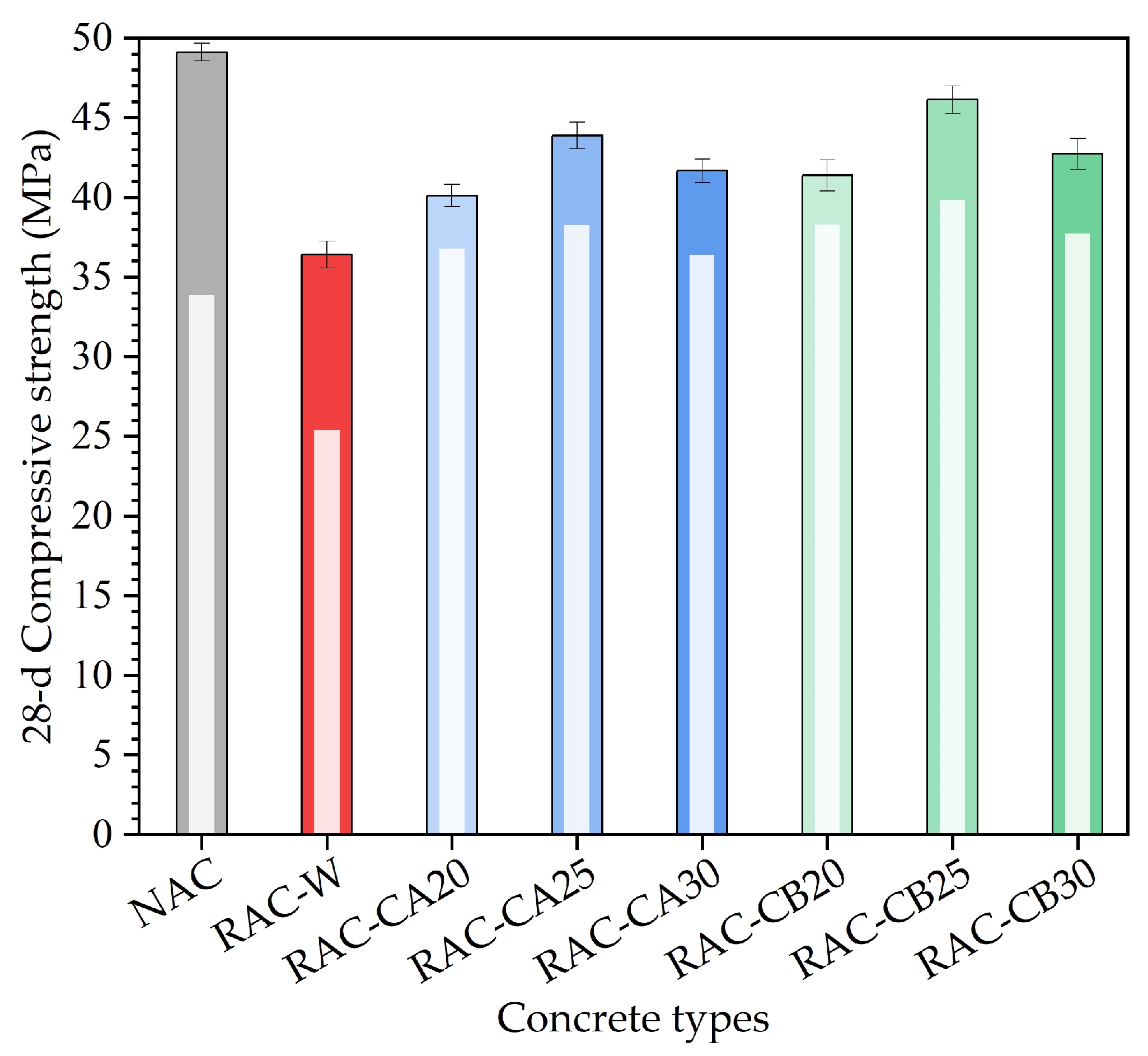

3.2. Analysis of Compressive Strength of Concrete at a 28 d Curing Age

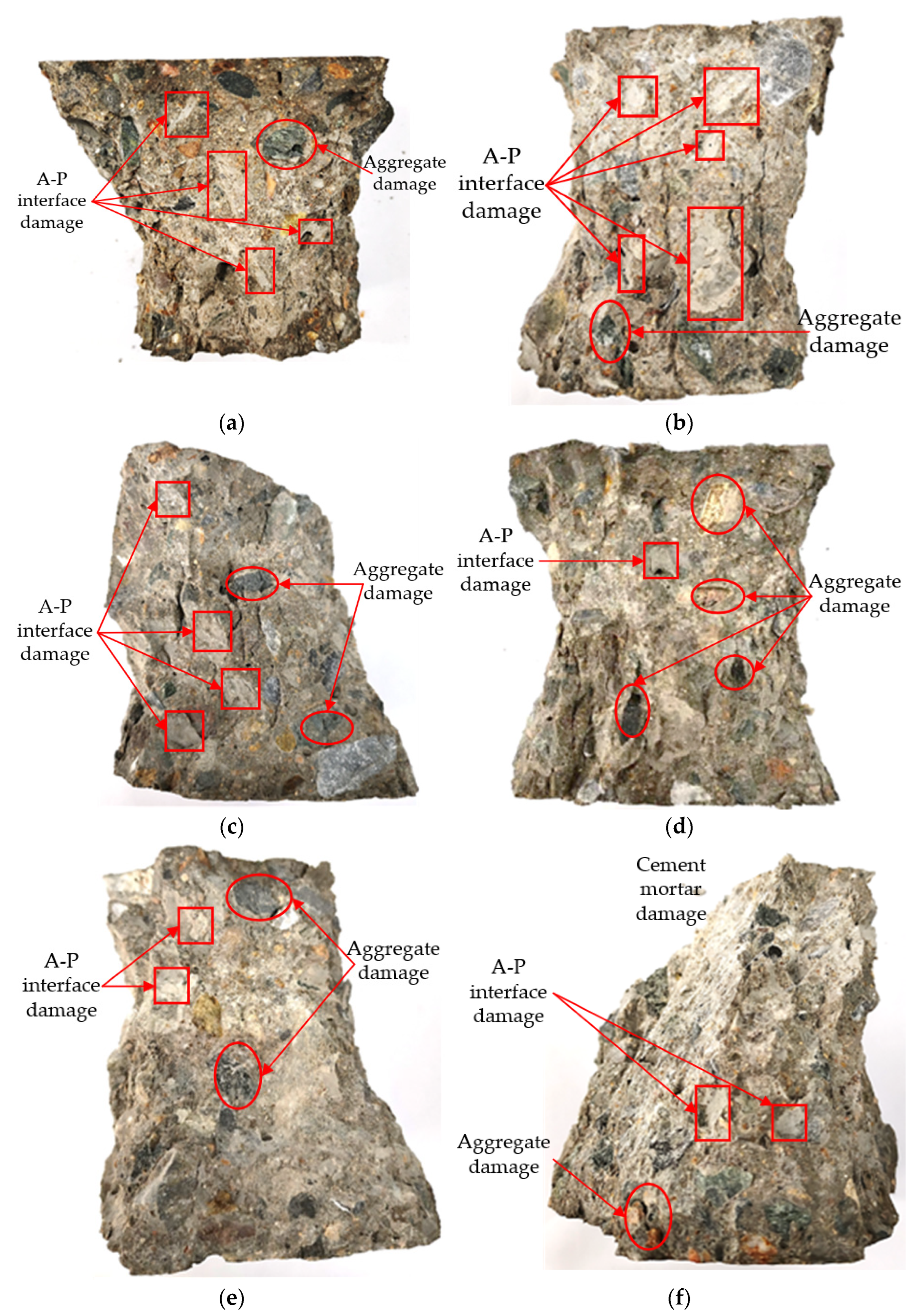

3.3. Failure Mechanism of Recycled Aggregate Concrete under the Compressive Effect

4. Conclusions

- (1)

- The compressive strength of the RAC-C group, including RAC-CA and RAC-CB, after two kinds of cement mortar pretreatment methods at a 7 d curing age is higher than that of RAC-W and NAC, and the compressive strength of the RAC-C group at a 28 d curing age is higher than RAC-W but lower than NAC. Therefore, it may be a suitable option for projects that require quick strength development.

- (2)

- At a 7 d curing age, the compressive strength of RAC-CB is about 3.8–4.2% higher than that of the RAC-CA, the compressive strength of RAC-CA is about 46.0–51.9% higher than that of RAC-W, the compressive strength of RAC-C is about 9.8–14.3% higher than that of NAC.

- (3)

- At a 28 d curing age, the compressive strength of RAC-CB is about 2.6–4.9% higher than that of the RAC-CA, the compressive strength of RAC-CA is about 44.8–57.4% higher than that of RAC-W, the compressive strength of RAC-C is about 11.4–14.5% lower than that of NAC.

- (4)

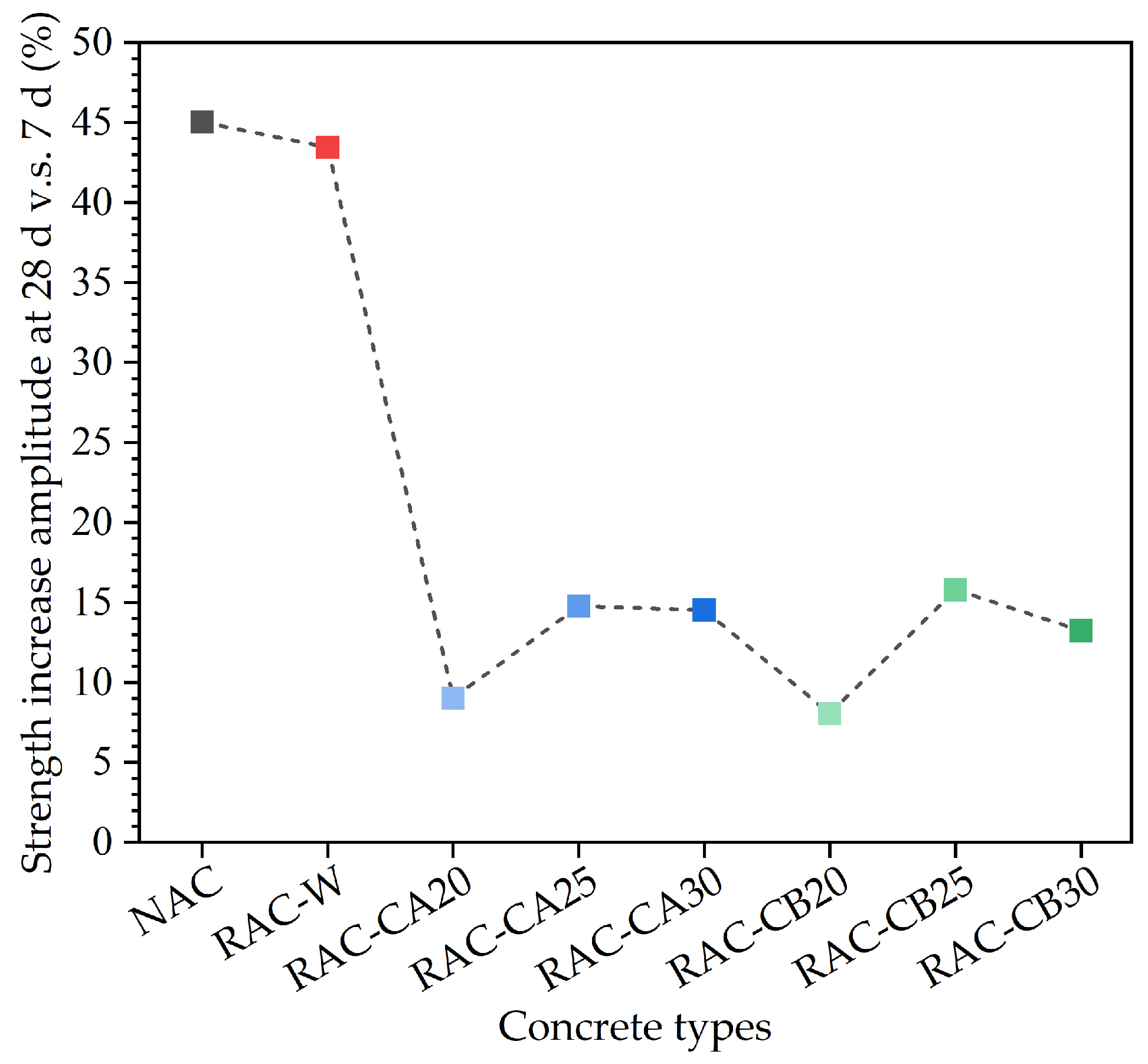

- The compressive strength of NAC and RAC-W at a 7 d curing age is about 70% of that at a 28 d curing age, and the compressive strength of RAC-C at a 7 d curing age is about 85–90% of that at a 28 d curing age. The compressive strength of RAC-C increased dramatically at the early stage, while the post-strength of the NAC and RAC-W groups increased rapidly.

- (5)

- The fracture surface of RAC-W mainly occurs in the transition zone between the recycled aggregates and old cement mortar under the pressure of the uniaxial compressive load. The main failure of RAC-C is the crushing destruction of cement mortar. With the amount of cement added beforehand changed, the proportion of aggregate damage and A-P interface damage of RAC-C also changed accordingly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kumar, G.; Gupta, R.C.; Shrivastava, S. Sustainable Zero-Slump Concrete Containing Recycled Aggregates from Construction and Demolition Waste of a 63-Year-Old Demolished Building. J. Mater. Civ. Eng. 2022, 34, 04022115. [Google Scholar] [CrossRef]

- Patra, I.; Al-Awsi, G.R.L.; Hasan, Y.M.; Almotlaq, S.S.K. Mechanical properties of concrete containing recycled aggregate from construction waste. Sustain. Energy Technol. Assess. 2022, 53, 102722. [Google Scholar] [CrossRef]

- Alani, A.A.; Lesovik, R.; Lesovik, V.; Fediuk, R.; Klyuev, S.; Amran, M.; Ali, M.; de Azevedo, A.R.G.; Vatin, N.I. Demolition Waste Potential for Completely Cement-Free Binders. Materials 2022, 15, 6018. [Google Scholar] [CrossRef] [PubMed]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Ozkilic, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2022, 14, 4388. [Google Scholar] [CrossRef]

- Karalar, M.; Özkılıç, Y.O.; Aksoylu, C.; Sabri Sabri, M.M.; Beskopylny, A.N.; Stel’makh, S.A.; Shcherban’, E.M. Flexural behavior of reinforced concrete beams using waste marble powder towards application of sustainable concrete. Front. Mater. 2022, 9, 1068791. [Google Scholar] [CrossRef]

- Zeybek, O.; Ozkilic, Y.O.; Karalar, M.; Celik, A.I.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P. Influence of Replacing Cement with Waste Glass on Mechanical Properties of Concrete. Materials 2022, 15, 7513. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ozlahc, Y.O.; Al Dughaishi, H.; Alosta, M.; Sabri, M.M.S.; Alkhatib, F.; Milad, A. Concrete Containing Waste Glass as an Environmentally Friendly Aggregate: A Review on Fresh and Mechanical Characteristics. Materials 2022, 15, 6222. [Google Scholar] [CrossRef]

- Celik, A.I.; Ozkilic, Y.O.; Zeybek, O.; Karalar, M.; Qaidi, S.; Ahmad, J.; Burduhos-Nergis, D.D.; Bejinariu, C. Mechanical Behavior of Crushed Waste Glass as Replacement of Aggregates. Materials 2022, 15, 8093. [Google Scholar] [CrossRef]

- Karalar, M.; Bilir, T.; Cavuslu, M.; Ozkilic, Y.O.; Sabri, M.M.S. Use of recycled coal bottom ash in reinforced concrete beams as replacement for aggregate. Front. Mater. 2022, 9, 1064604. [Google Scholar] [CrossRef]

- Qaidi, S.; Al-Kamaki, Y.; Hakeem, I.; Dulaimi, A.F.; Özkılıç, Y.; Sabri, M.; Sergeev, V. Investigation of the physical-mechanical properties and durability of high-strength concrete with recycled PET as a partial replacement for fine aggregates. Front. Mater. 2023, 10, 1101146. [Google Scholar] [CrossRef]

- Liu, Z.H.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S.L.; Hao, Q. The Effect of Cementitious Materials on the Engineering Properties and Pore Structure of Concrete with Recycled Fine Aggregate. Materials 2023, 16, 305. [Google Scholar] [CrossRef]

- Kim, J. Influence of quality of recycled aggregates on the mechanical properties of recycled aggregate concretes: An overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Bu, C.M.; Liu, L.; Lu, X.Y.; Zhu, D.X.; Sun, Y.; Yu, L.W.; OuYang, Y.H.; Cao, X.M.; Wei, Q.K. The Durability of Recycled Fine Aggregate Concrete: A Review. Materials 2022, 15, 1110. [Google Scholar] [CrossRef]

- Sasanipour, H.; Aslani, F.; Taherinezhad, J. Chloride ion permeability improvement of recycled aggregate concrete using pretreated recycled aggregates by silica fume slurry. Constr. Build. Mater. 2021, 270, 121498. [Google Scholar] [CrossRef]

- Ouyang, K.; Shi, C.J.; Chu, H.Q.; Guo, H.; Song, B.X.; Ding, Y.H.; Guan, X.M.; Zhu, J.P.; Zhang, H.B.; Wang, Y.L.; et al. An overview on the efficiency of different pretreatment techniques for recycled concrete aggregate. J. Clean. Prod. 2020, 263, 121264. [Google Scholar] [CrossRef]

- Li, Y.; Yang, X.B.; Lou, P.; Wang, R.J.; Li, Y.L.; Si, Z. Sulfate attack resistance of recycled aggregate concrete with NaOH-solution-treated crumb rubber. Constr. Build. Mater. 2021, 287, 123044. [Google Scholar] [CrossRef]

- Al-Baghdadi, H.M. Experimental study on sulfate resistance of concrete with recycled aggregate modified with polyvinyl alcohol (PVA). Case Stud. Constr. Mater. 2021, 14, e00527. [Google Scholar] [CrossRef]

- Fayed, S.; Madenci, E.; Ozkilic, Y.O.; Mansour, W. Improving bond performance of ribbed steel bars embedded in recycled aggregate concrete using steel mesh fabric confinement. Constr. Build. Mater. 2023, 369, 130452. [Google Scholar] [CrossRef]

- Zhong, C.H.; Tian, P.; Long, Y.H.; Zhou, J.Z.; Peng, K.; Yuan, C.X. Effect of Composite Impregnation on Properties of Recycled Coarse Aggregate and Recycled Aggregate Concrete. Buildings 2022, 12, 1035. [Google Scholar] [CrossRef]

- Reddy, R.R.K.; Yaragal, S.C. A novel approach for optimizing the processing of recycled coarse aggregates. Constr. Build. Mater. 2023, 368, 130480. [Google Scholar] [CrossRef]

- Xue, H.J.; Zhu, H.Y.; Guo, M.Z.; Shao, S.W.; Zhang, S.Y.; Zhang, Y. Modeling for predicting triaxial mechanical properties of recycled aggregate concrete considering the recycled aggregate replacement. Constr. Build. Mater. 2023, 368, 130447. [Google Scholar] [CrossRef]

- Kim, Y.; Hanif, A.; Kazmi, S.M.S.; Munir, M.J.; Park, C. Properties enhancement of recycled aggregate concrete through pretreatment of coarse aggregates—Comparative assessment of assorted techniques. J. Clean. Prod. 2018, 191, 339–349. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the Improvement of Recycled Aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Tian, Y.; Guo, Y.; Guo, L.; Wang, L.; Cao, Y.; Liu, J.; Luo, Y. Study on the Effect of Pretreatment on Property of Recycled Concrete. Yellow River 2019, 41, 131–134, 143. [Google Scholar]

- Zhang, M.Q.; Liu, B.J.; Xie, Y.L.; Luo, Y.Q. Influence of Pre-wetted Recycled Fine Aggregate on Drying Shrinkage and Freeze-thaw Resistance of Concrete. Build. Sci. 2016, 32, 89–95. [Google Scholar]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of moisture conditioning of recycled aggregates on the properties of fresh and hardened concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Wengui, L.; Chu, L.; Luo, Z.Y.; Zhengyu, H. Investigation on Failure Mechanism of Nanomodified Recycled Aggregate Concrete. J. Build. Mater. 2017, 20, 685–691, 786. [Google Scholar]

- Hou, Y.-L.; Zheng, G. Mechanical Properties of Recycled Aggregate Concrete in Different Age. J. Build. Mater. 2013, 16, 683–687. [Google Scholar]

- Fernandes, B.; Carre, H.; Mindeguia, J.C.; Perlot, C.; La Borderie, C. Spalling behaviour of concrete made with recycled concrete aggregates. Constr. Build. Mater. 2022, 344, 128124. [Google Scholar] [CrossRef]

- da Franca, A.P.M.; da Costa, F.B.P. Evaluating the effect of recycled concrete aggregate and sand in pervious concrete paving blocks. Road Mater. Pavement 2023, 24, 560–577. [Google Scholar] [CrossRef]

- Liu, J.; Ma, K.L.; Shen, J.T.; Zhu, J.B.; Long, G.C.; Xie, Y.J.; Liu, B.J. Influence of recycled concrete aggregate enhancement methods on the change of microstructure of ITZs in recycled aggregate concrete. Constr. Build. Mater. 2023, 371, 130772. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of pumice powder and nano-clay on the strength and permeability of fiber-reinforced pervious concrete incorporating recycled concrete aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Medina, C.; Zhu, W.; Howind, T.; Sánchez de Rojas, M.I.; Frías, M. Influence of mixed recycled aggregate on the physical—Mechanical properties of recycled concrete. J. Clean. Prod. 2014, 68, 216–225. [Google Scholar] [CrossRef]

- De Maio, U.; Gaetano, D.; Greco, F.; Lonetti, P.; Pranno, A. The damage effect on the dynamic characteristics of FRP-strengthened reinforced concrete structures. Compos. Struct. 2023, 309, 116731. [Google Scholar] [CrossRef]

- Rimkus, A.; Cervenka, V.; Gribniak, V.; Cervenka, J. Uncertainty of the smeared crack model applied to RC beams. Eng. Fract. Mech. 2020, 233, 107088. [Google Scholar] [CrossRef]

- Chen, Y.W.; Pan, W.H.; Sun, X.W. Performance study of pretreated concrete with recycled aggregate. Concrete 2012, 1, 81–83. [Google Scholar]

- Shang, X.; Yang, J.; Wang, S.; Zhang, M. Fractal analysis of 2D and 3D mesocracks in recycled aggregate concrete using X-ray computed tomography images. J. Clean. Prod. 2021, 304, 127083. [Google Scholar] [CrossRef]

- Guo, Y.D.; Liu, Y.Z.; Chen, Y.; Wang, W.J.; Li, K. Effect of pre-wetting of recycled coarse aggregate on compressive strength of concrete. J. Guangxi Univ. 2017, 42, 1548–1553. [Google Scholar]

- Zhang, S.J.; Li, X.; Wang, F.J.; Li, F.; Zhou, L.A. Research on the water absorption and desorption properties of recycled brick aggregate. Concrete 2017, 185–188. [Google Scholar]

- Xiao, W.; Ding, C.P.; Xie, X.J. Experimental Investigation on Influence of Cement Content on Concrete Performance. Bull. Chin. Ceram. Soc. 2018, 37, 2083–2087. [Google Scholar]

| Immersion Time (h) | 1/6 | 1/3 | 0.5 | 1 | 2 | 3 |

|---|---|---|---|---|---|---|

| Water absorption (%) | 6.52 | 6.58 | 6.77 | 6.82 | 6.85 | 7.03 |

| Mesh Size (mm) | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 |

|---|---|---|---|---|---|---|

| Cumulative residual percentage (%) | 5.1 | 19.3 | 27.9 | 4.26 | 81.8 | 92.5 |

| Type | Superplasticizer (%) | Ingredients (kg/m3) | |||||

|---|---|---|---|---|---|---|---|

| Recycled Coarse Aggregate | Natural Coarse Aggregate | Total Cement | Total Water | Pre-Add Cement | Pre-Add Water | ||

| NAC | 0.5 | 0 | 1888.4 | 400 | 160 | 0 | 0 |

| RAC-W | 0.5 | 1191.9 | 0 | 400 | 160 | 0 | 0 |

| RAC-CA20 | 1 | 1191.9 | 0 | 400 | 160 | 80 | 32 |

| RAC-CA25 | 1 | 1191.9 | 0 | 400 | 160 | 100 | 40 |

| RAC-CA30 | 1 | 1191.9 | 0 | 400 | 160 | 120 | 48 |

| RAC-CB20 | 1 | 1191.9 | 0 | 480 | 192 | 80 | 32 |

| RAC-CB25 | 1 | 1191.9 | 0 | 500 | 200 | 100 | 40 |

| RAC-CB30 | 1 | 1191.9 | 0 | 520 | 208 | 120 | 48 |

| Type | NAC | RAC-W | RAC-CA20 | RAC-CA25 | RAC-CA30 | RAC-CB20 | RAC-CB25 | RAC-CB30 |

|---|---|---|---|---|---|---|---|---|

| Ratio (%) | 68.9 | 69.7 | 91.6 | 86.8 | 87.3 | 92.3 | 86.2 | 88.3 |

| Damage | RAC-CA20 | RAC-CB20 | RAC-CA25 | RAC-CB25 | RAC-CA30 | RAC-CB30 |

|---|---|---|---|---|---|---|

| Aggregate damage (%) | 1.01 | 1.18 | 3.32 | 3.95 | 1.36 | 1.42 |

| A-P interface damage (%) | 6.37 | 8.15 | 5.84 | 2.91 | 3.04 | 1.72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lv, D.; Huang, K.; Wang, W. Influence of Pretreatment Methods on Compressive Performance Improvement and Failure Mechanism Analysis of Recycled Aggregate Concrete. Materials 2023, 16, 3807. https://doi.org/10.3390/ma16103807

Lv D, Huang K, Wang W. Influence of Pretreatment Methods on Compressive Performance Improvement and Failure Mechanism Analysis of Recycled Aggregate Concrete. Materials. 2023; 16(10):3807. https://doi.org/10.3390/ma16103807

Chicago/Turabian StyleLv, Dongbin, Kainan Huang, and Wensheng Wang. 2023. "Influence of Pretreatment Methods on Compressive Performance Improvement and Failure Mechanism Analysis of Recycled Aggregate Concrete" Materials 16, no. 10: 3807. https://doi.org/10.3390/ma16103807

APA StyleLv, D., Huang, K., & Wang, W. (2023). Influence of Pretreatment Methods on Compressive Performance Improvement and Failure Mechanism Analysis of Recycled Aggregate Concrete. Materials, 16(10), 3807. https://doi.org/10.3390/ma16103807