Solar-Radiation-Dependent Anisotropic Thermal Management Device with Net Zero Energy from 4D Printing Shape Memory Polymer-Based Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Modification of Fillers

2.3. Preparation of Composite Lamina

2.4. Assembly of “Windows” Array

2.5. Characterization

3. Results and Discussion

3.1. Material Characteristics

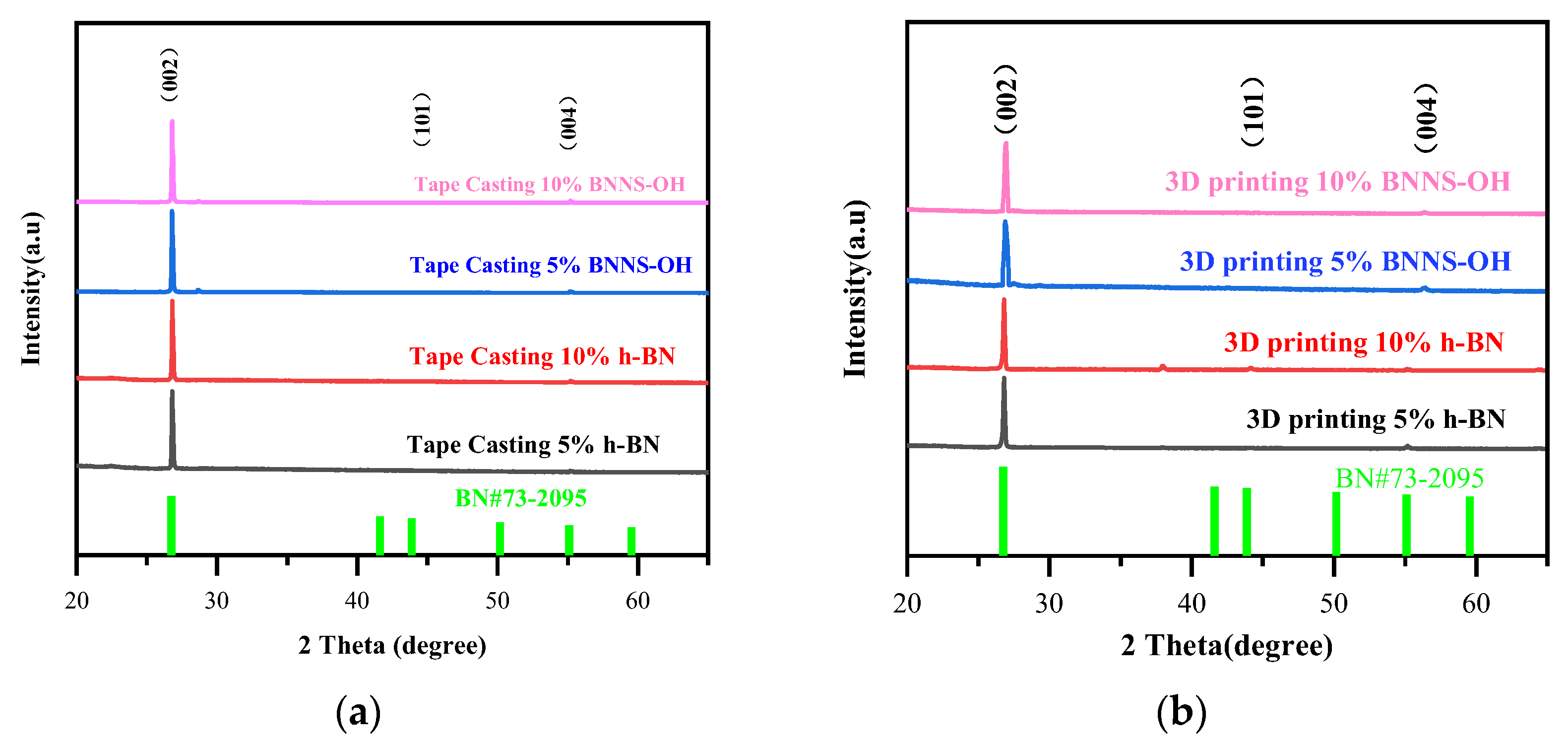

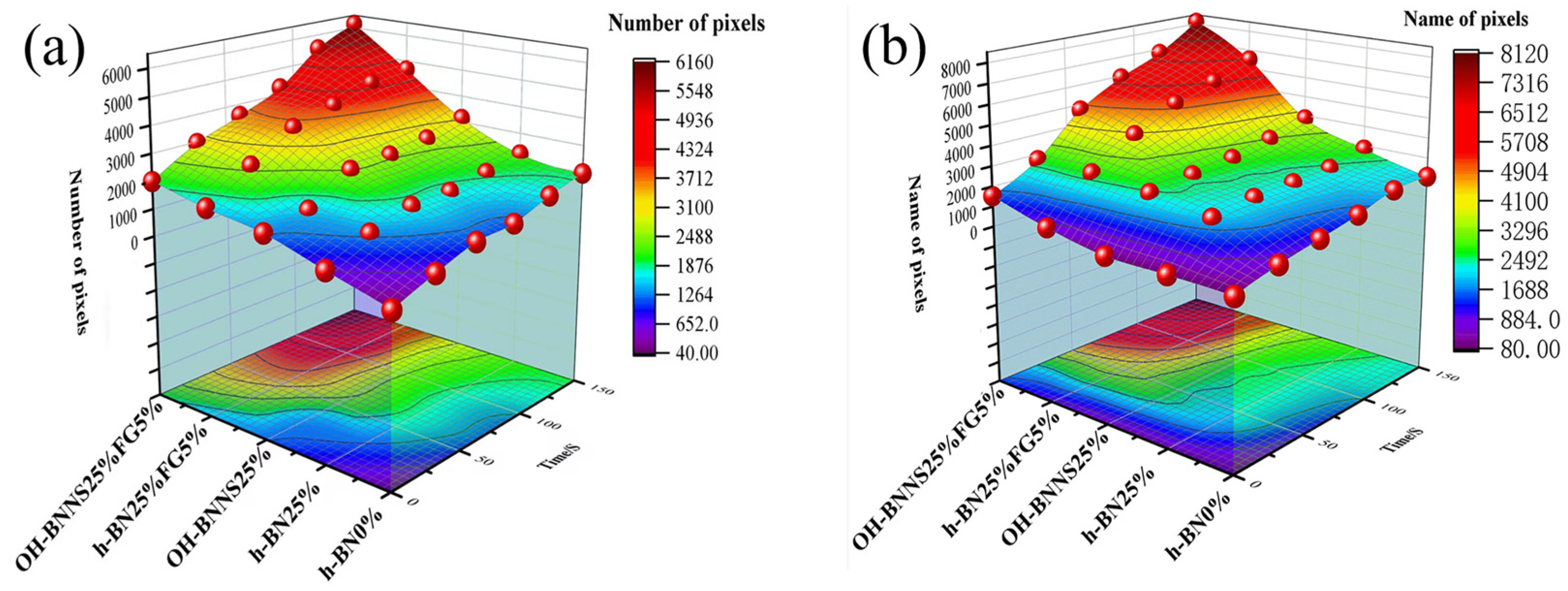

3.2. Textured h-BN, OH-BNNS and Graphene in Composite Lamina

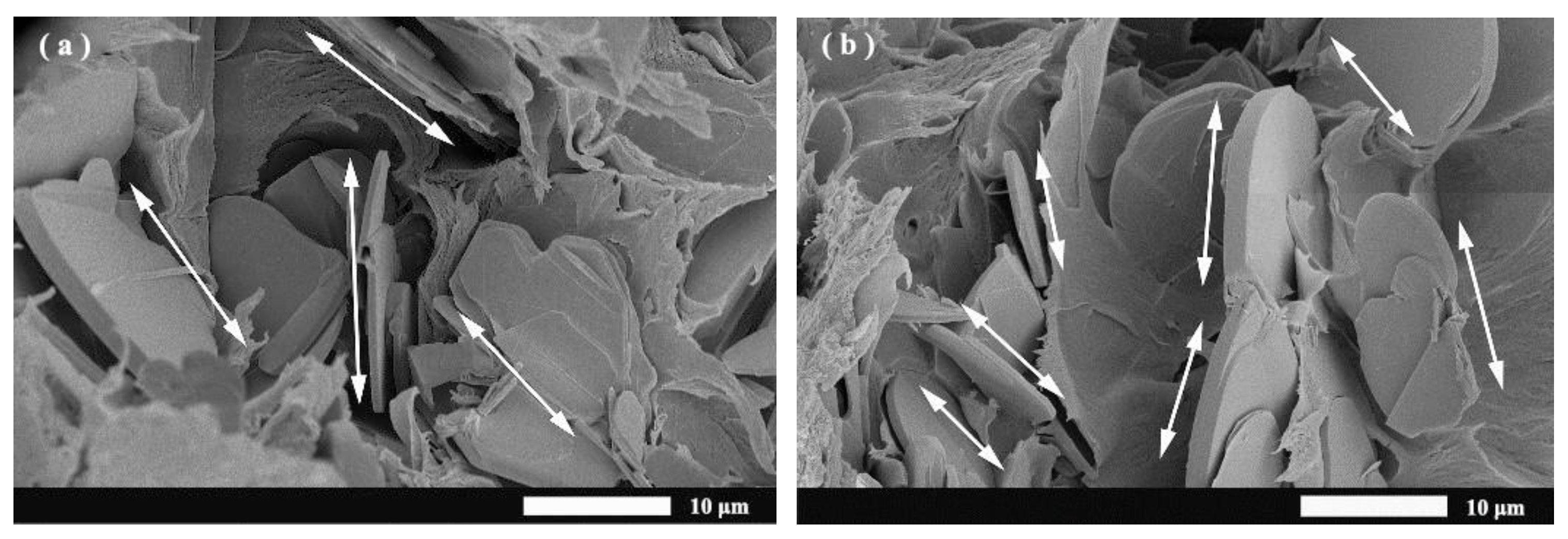

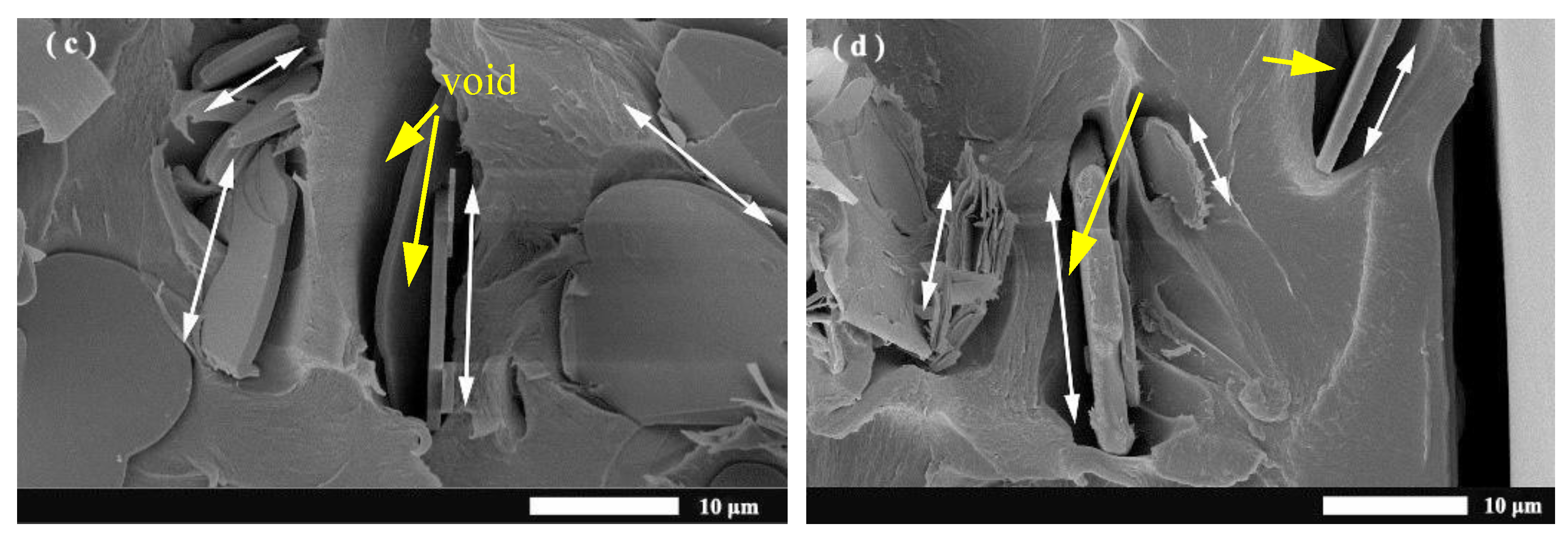

3.3. Microstructure of Samples

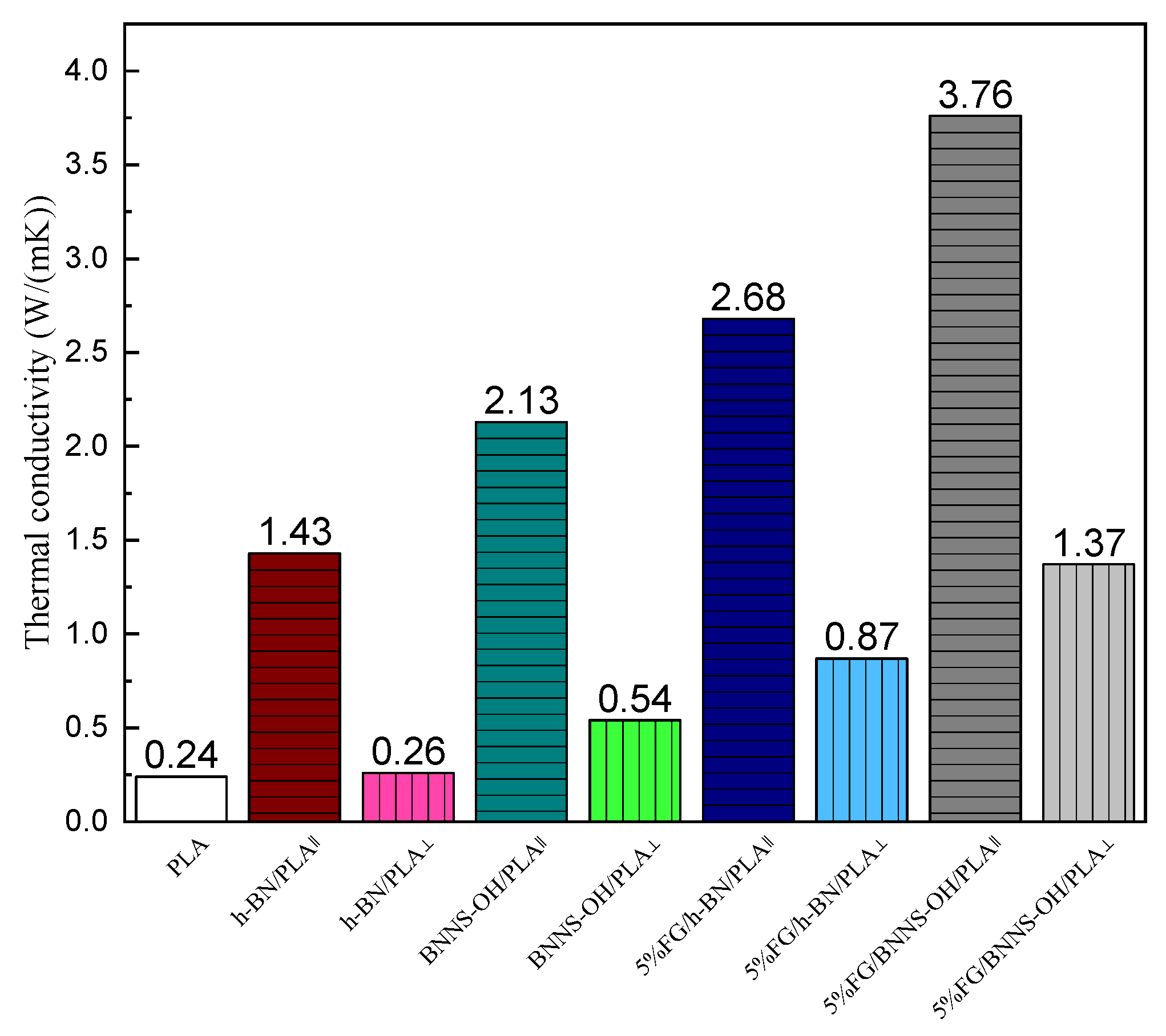

3.4. Anisotropic Thermal Conductivity

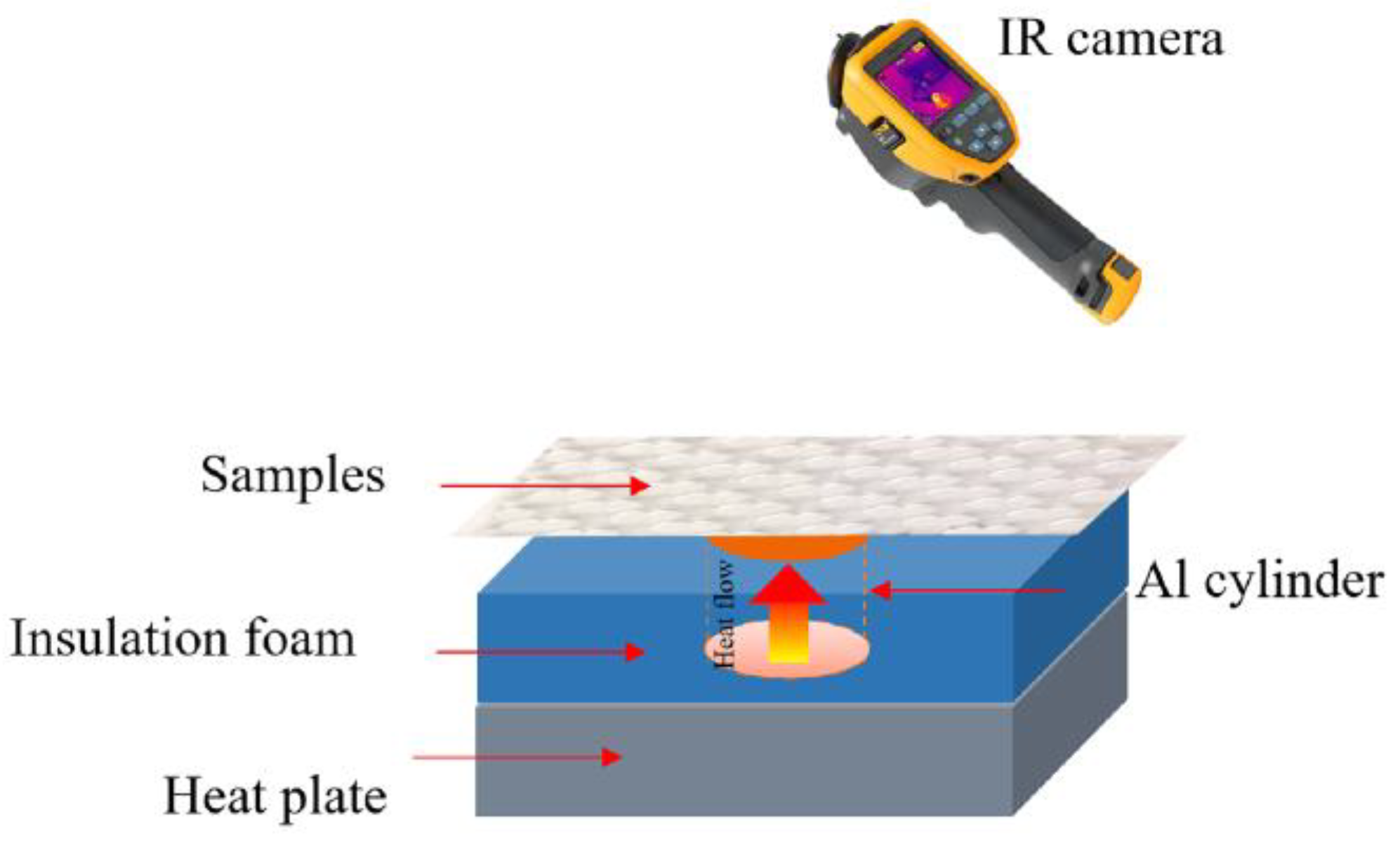

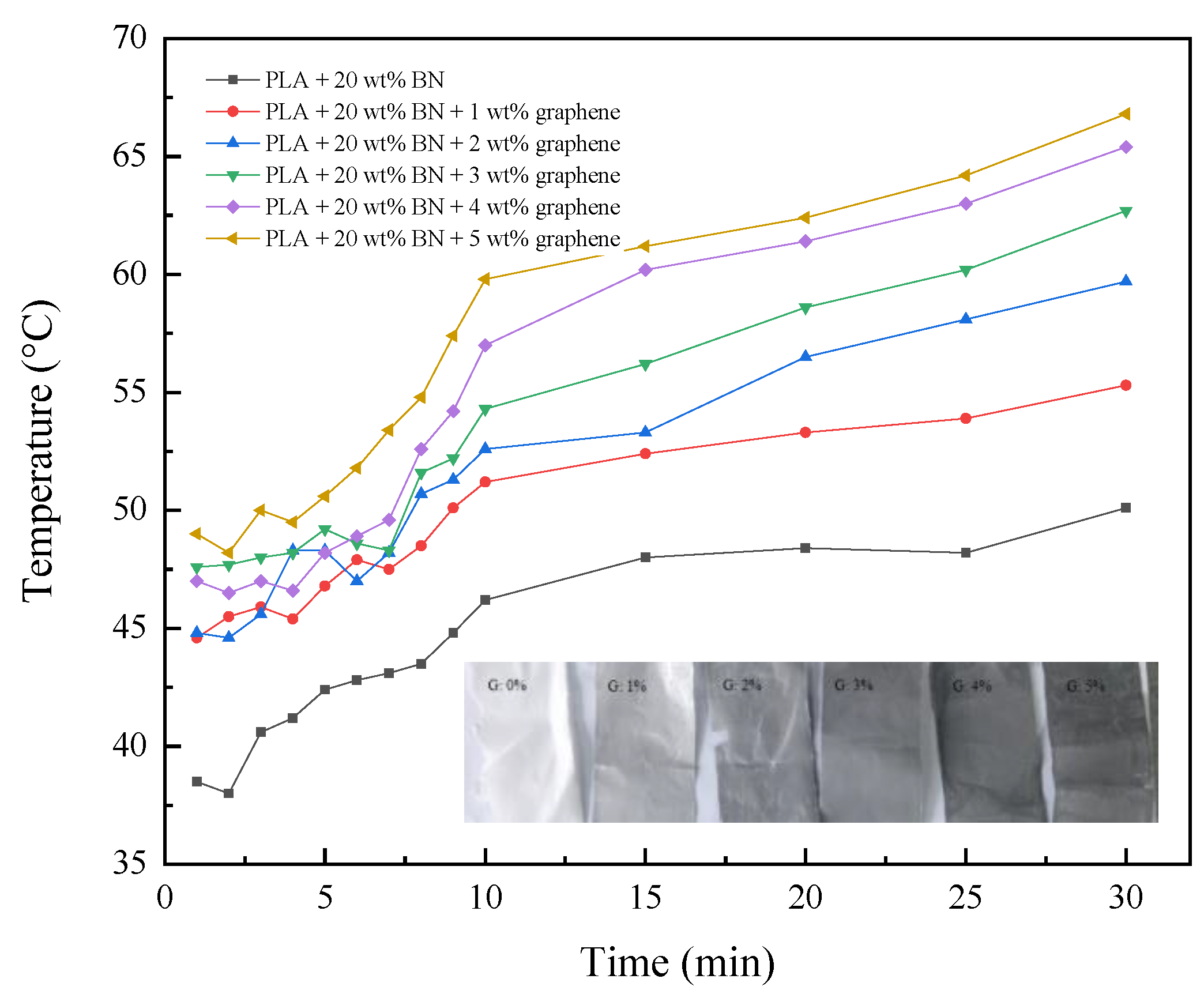

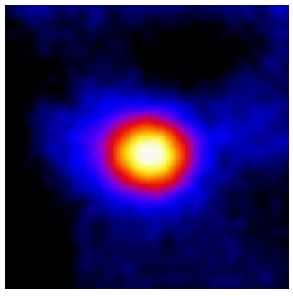

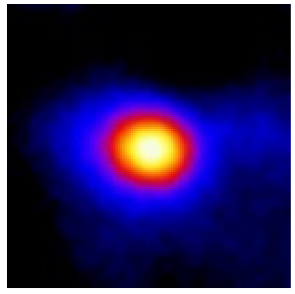

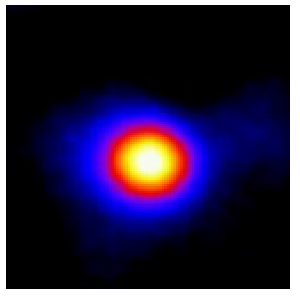

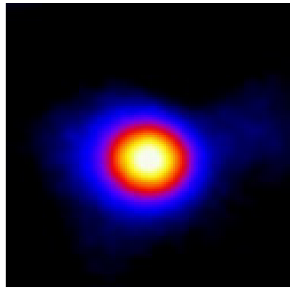

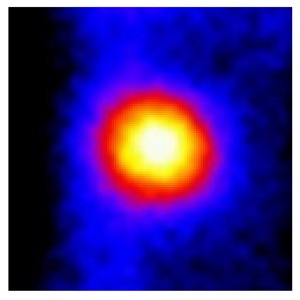

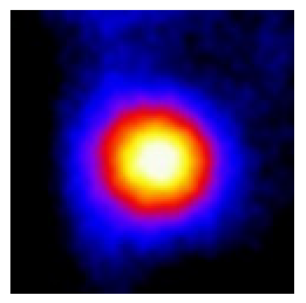

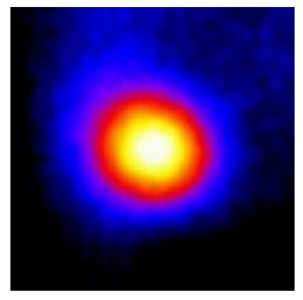

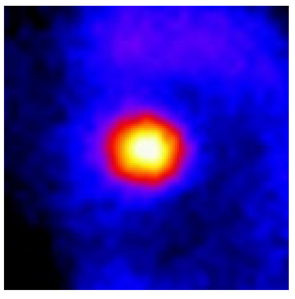

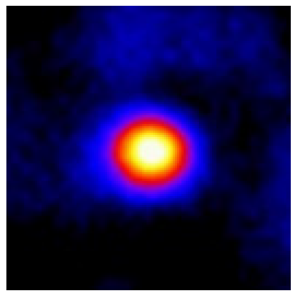

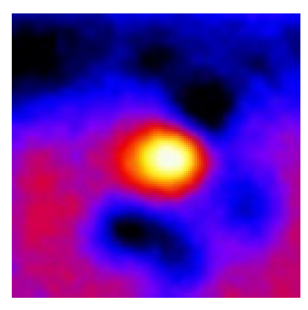

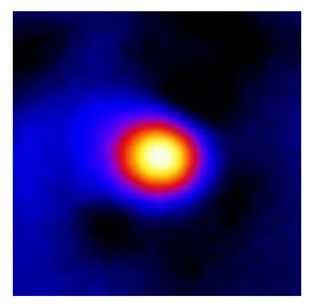

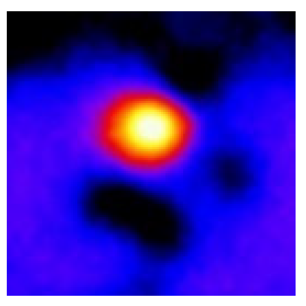

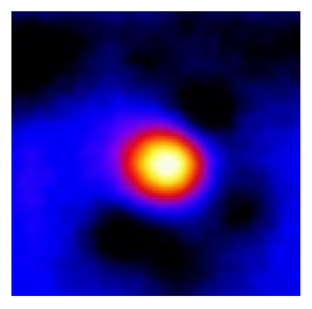

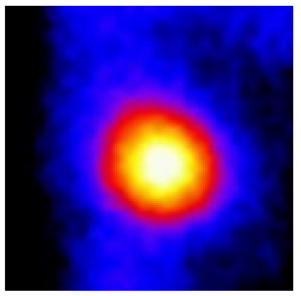

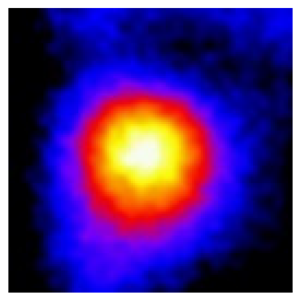

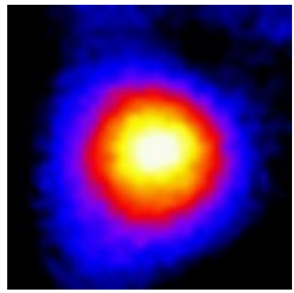

3.5. Photothermal Behavior

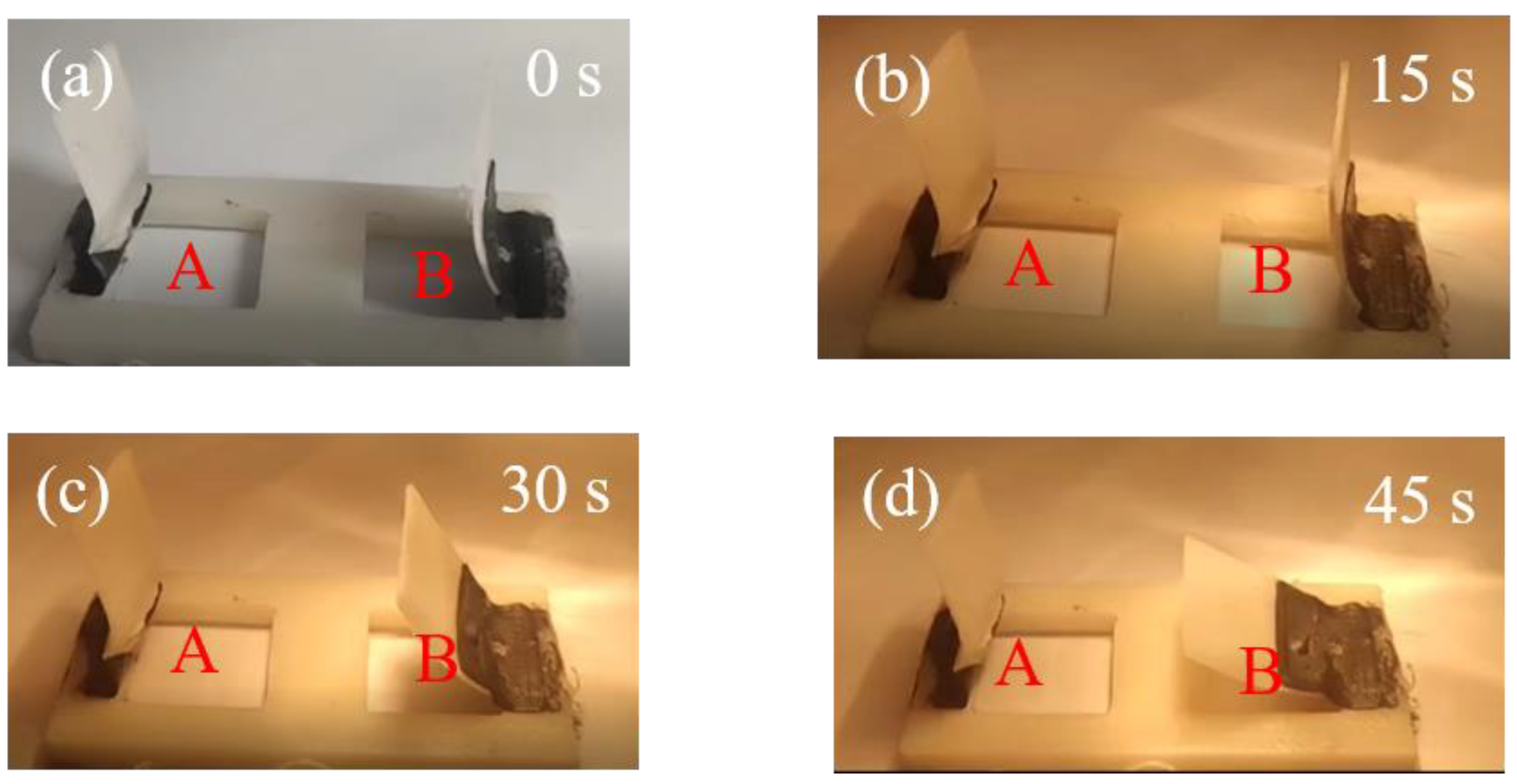

3.6. Programmable Thermal Management by Shape Memory Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, T.; Zhai, Y.; He, S.; Gan, W.; Wei, Z.; Heidarinejad, M.; Dalgo, D.; Mi, R.; Zhao, X.; Song, J.; et al. A radiative cooling structural material. Science 2019, 364, 760–763. [Google Scholar] [CrossRef] [PubMed]

- Rogelj, J.; Luderer, G.; Pietzcker, R.C.; Kriegler, E.; Schaeffer, M.; Krey, V.; Riahi, K. Energy system transformations for limiting end-of-century warming to below 1.5 °C. Nat. Clim. Chang. 2015, 5, 519–527. [Google Scholar] [CrossRef]

- International Renewable Energy Agency; International Energy Agency; Renewable Energy Policy Network Century. Renewable Energy Policies in a Time of Transition; International Energy Agency: Paris, France, 2020. [Google Scholar]

- Yoon, J. Design-to-fabrication with thermo-responsive shape memory polymer applications for building skins. Archit. Sci. Rev. 2021, 64, 72–86. [Google Scholar] [CrossRef]

- Yi, H.; Kim, D.; Kim, Y.; Kim, D.; Koh, J.-S.; Kim, M.-J. 3D-printed attachable kinetic shading device with alternate actuation: Use of shape-memory alloy (SMA) for climate-adaptive responsive architecture. Automat. Constr. 2020, 114, 103151. [Google Scholar] [CrossRef]

- Kim, H.; Clayton, M.J. A multi-objective optimization approach for climate- adaptive building envelope design using parametric behavior maps. Build. Environ. 2020, 185, 107292. [Google Scholar] [CrossRef]

- Rizi, R.A.; Eltaweel, A. A user detective adaptive facade towards improving visual and thermal comfort. J. Build. Eng. 2021, 33, 101554. [Google Scholar] [CrossRef]

- Yi, H.; Kim, Y. Prototyping of 4D-printed self-shaping building skin in architecture: Design, fabrication, and investigation of a two-way shape memory composite (TWSMC) façade panel. J. Build. Eng. 2021, 43, 103076. [Google Scholar] [CrossRef]

- Li, X.; Sun, B.; Sui, C.; Nandi, A.; Fang, H.; Peng, Y.; Tan, G.; Hsu, P.C. Integration of daytime radiative cooling and solar heating for year-round energy saving in buildings. Nat. Commun. 2020, 11, 6101. [Google Scholar] [CrossRef]

- Tolley, M.T.; Felton, S.M.; Miyashita, S.; Aukes, D.; Rus, D.; Wood, R.J. Self-folding origami: Shape memory composites activated by uniform heating. Smart Mater. Struct. 2014, 23, 94006. [Google Scholar] [CrossRef]

- Wu, J.; Yuan, C.; Ding, Z.; Isakov, M.; Mao, Y.; Wang, T.; Dunn, M.L.; Qi, H.J. Multi-shape active composites by 3D printing of digital shape memory polymers. Sci. Rep. 2016, 6, 24224. [Google Scholar] [CrossRef]

- Zhang, Q.; Lv, Y.; Wang, Y.; Yu, S.; Li, C.; Ma, R.; Chen, Y. Temperature-dependent dual-mode thermal management device with net zero energy for year-round energy saving. Nat. Commun. 2022, 13, 4874. [Google Scholar] [CrossRef] [PubMed]

- Vazquez, E.; Randall, C.; Duarte, J.P. Shape-changing architectural skins: A review on materials, design and fabrication strategies and performance analysis. J. Facade Des. Eng. 2019, 7, 93–114. [Google Scholar]

- Joshi, S.; Rawat, K.; Karunakaran, C.; Rajamohan, V.; Mathew, A.T.; Koziol, K.; Thakur, V.K.; Balan, A.S.S. 4D printing of materials for the future: Opportunities and challenges. Appl. Mater. Today 2020, 18, 100490. [Google Scholar] [CrossRef]

- Yuan, C.; Wang, F.; Qi, B.; Ding, Z.; Rosen, D.W.; Ge, Q. 3D printing of multi-material composites with tunable shape memory behavior. Mater. Des. 2020, 193, 108785. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, X.Y.; Zheng, M.; Moorlag, C.; Yang, J.; Wang, Z.L. 3D printing of thermo-reversible polyurethanes with targeted shape memory and precise in situ self-healing properties. J. Mater. Chem. A 2019, 7, 6972–6984. [Google Scholar] [CrossRef]

- Garces, I.T.; Ayranci, C. Advances in additive manufacturing of shape memory polymer composites. Rapid Prototyp. J. 2021, 27, 379–398. [Google Scholar] [CrossRef]

- Momeni, F.; Liu, X.; Ni, J. A review of 4D printing. Mater. Des. 2017, 122, 42–79. [Google Scholar] [CrossRef]

- Fiorito, F.; Sauchelli, M.; Arroyo, D.; Pesenti, M.; Imperadori, M.; Masera, G.; Ranzi, G. Shape morphing solar shading: A review. Renew. Sust. Energ. Rev. 2016, 55, 863–884. [Google Scholar] [CrossRef]

- Zhao, H.R.; Ding, J.H.; Shao, Z.Z.; Xu, B.Y.; Zhou, Q.B.; Yu, H.B. High-quality Boron Nitride Nanosheets and Their Bioinspired Thermally Conductive Papers. ACS Appl. Mater. Interfaces 2019, 11, 37247–37255. [Google Scholar] [CrossRef]

- Feng, C.P.; Bai, L.; Shao, Y.; Bao, R.Y.; Liu, Z.Y.; Yang, M.B.; Chen, J.; Ni, H.Y.; Yang, W. A Facile Route to Fabricate Highly Anisotropic Thermally Conductive Elastomeric POE/NG Composites for Thermal Management. Adv. Mater. Interfaces 2018, 5, 1700946. [Google Scholar] [CrossRef]

- Wan, Y.J.; Li, G.; Yao, Y.M.; Zeng, X.L.; Zhu, P.L.; Sun, R. Recent Advances in Polymer-based Electronic Packaging Materials. Compos. Commun. 2020, 19, 154–167. [Google Scholar] [CrossRef]

- Teunis, V.M.; Shahram, J.; Amir, A.Z. Programming 2D/3D shape-shifting with hobbyist 3D printers. Mater. Horiz. 2017, 4, 1064. [Google Scholar]

| Crystalline Surface | (002) | (101) | (004) | I(002)/I(101) |

|---|---|---|---|---|

| PDF card (P-6m2 (187)) | 67% | 15.3% | 4.0% | 4.38 |

| Tape Casting 5% h-BN | 91.3% | 2.3% | 4.1% | 22.27 |

| Tape Casting 10% h-BN | 93.1% | 1.2% | 3.1% | 30.03 |

| Tape Casting 5% OH-BNNS | 96.2% | 0.4% | 2.7% | 35.62 |

| Tape Casting 10% OH-BNNS | 97.5% | 0.5% | 1.9% | 51.32 |

| 3D printing 5% h-BN | 93.1% | 1.1% | 3.2% | 29.09 |

| 3D printing 10% h-BN | 95.2% | 0.9% | 2.4% | 39.67 |

| 3D printing 5% OH-BNNS | 96.1% | 0.4% | 1.9% | 50.57 |

| 3D printing 10% OH-BNNS | 97.5% | 0.2% | 1.2% | 81.25 |

| Time | 0 s | 30 s | 60 s | 90 s | 120 s | 150 s | |

|---|---|---|---|---|---|---|---|

| Tape-Casting | |||||||

| PLA |  |  |  |  |  |  | |

| h-BN (20%) |  |  |  |  |  |  | |

| OH-BNNS (20%) |  |  |  |  |  |  | |

| OH-BNNS (20%) + Graphene (5%) |  |  |  |  |  |  | |

| Time | 0 s | 30 s | 60 s | 90 s | 120 s | 150 s | |

|---|---|---|---|---|---|---|---|

| 3D Printing | |||||||

| PLA |  |  |  |  |  |  | |

| h-BN (20%) |  |  |  |  |  |  | |

| OH-BNNS (20%) |  |  |  |  |  |  | |

| OH-BNNS (20%) + Graphene (5%) |  |  |  |  |  |  | |

| Light | Shadow | Programmable Target | Original | Results | |

|---|---|---|---|---|---|

| Window A | + | + | close | open | open |

| Window B | + | 0 | close | open | close |

| Light | Shadow | Programmable Target | Original | Results | |

|---|---|---|---|---|---|

| Window A | + | 0 | close | open | close |

| Window B | + | + | close | open | open |

| Window C | + | 0 | open | close | open |

| Window D | + | + | open | close | close |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Z.; Zhang, Y.; Niu, Y.; Chen, X.; Song, J. Solar-Radiation-Dependent Anisotropic Thermal Management Device with Net Zero Energy from 4D Printing Shape Memory Polymer-Based Composites. Materials 2023, 16, 3805. https://doi.org/10.3390/ma16103805

Wang Z, Zhang Y, Niu Y, Chen X, Song J. Solar-Radiation-Dependent Anisotropic Thermal Management Device with Net Zero Energy from 4D Printing Shape Memory Polymer-Based Composites. Materials. 2023; 16(10):3805. https://doi.org/10.3390/ma16103805

Chicago/Turabian StyleWang, Zhuo, Yao Zhang, Yanhui Niu, Xuejian Chen, and Jianrong Song. 2023. "Solar-Radiation-Dependent Anisotropic Thermal Management Device with Net Zero Energy from 4D Printing Shape Memory Polymer-Based Composites" Materials 16, no. 10: 3805. https://doi.org/10.3390/ma16103805

APA StyleWang, Z., Zhang, Y., Niu, Y., Chen, X., & Song, J. (2023). Solar-Radiation-Dependent Anisotropic Thermal Management Device with Net Zero Energy from 4D Printing Shape Memory Polymer-Based Composites. Materials, 16(10), 3805. https://doi.org/10.3390/ma16103805