Preliminary Study of New Low-Temperature Hard Abrasion Resistant Fe-P and Fe-P-X (X = C or/and B) Casting Alloys

Abstract

1. Introduction

2. Scientific Background

3. Experiments

3.1. Production of Alloys

3.2. Research Methods

4. Results and Discussion

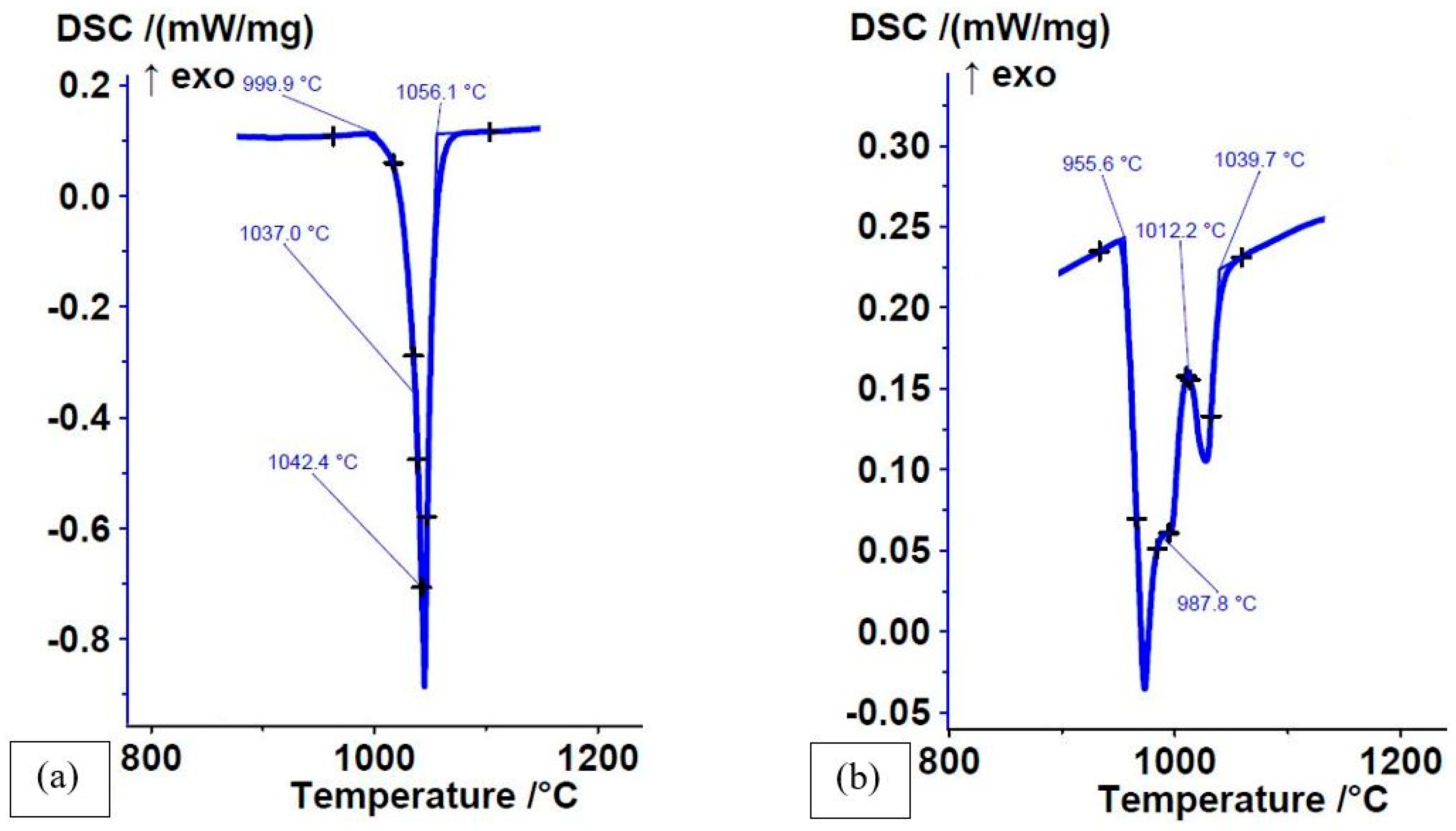

4.1. Chemical Compositions and Melting Ranges

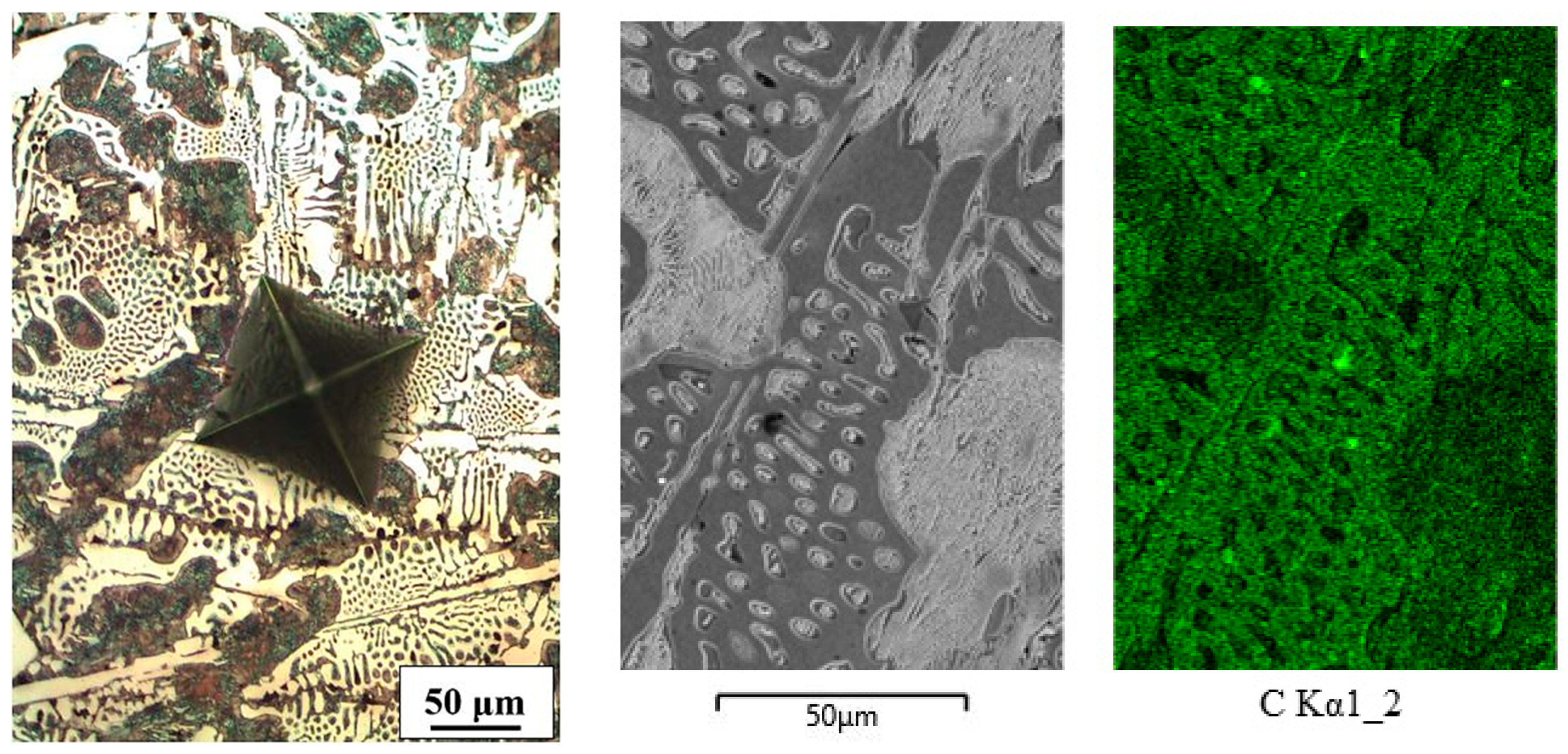

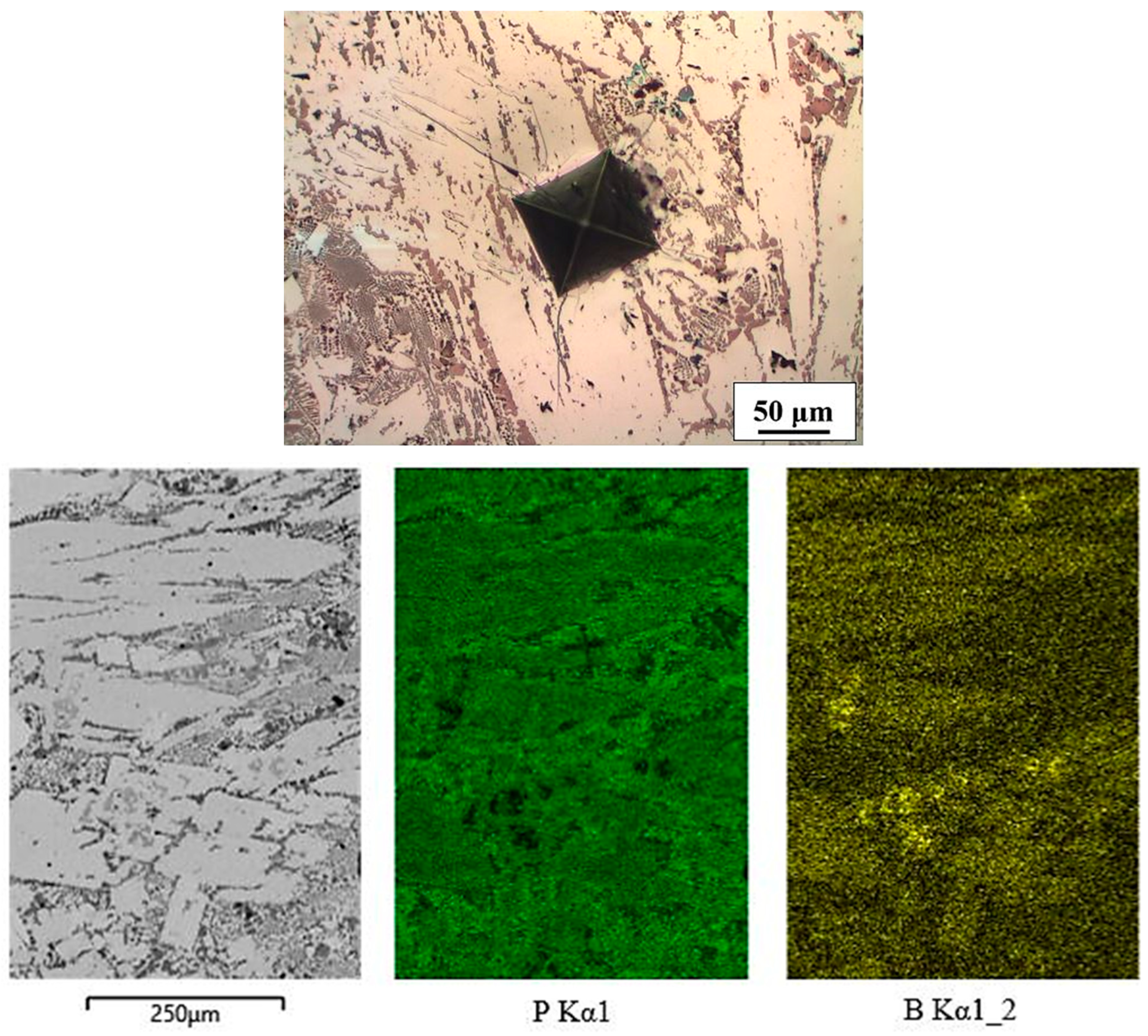

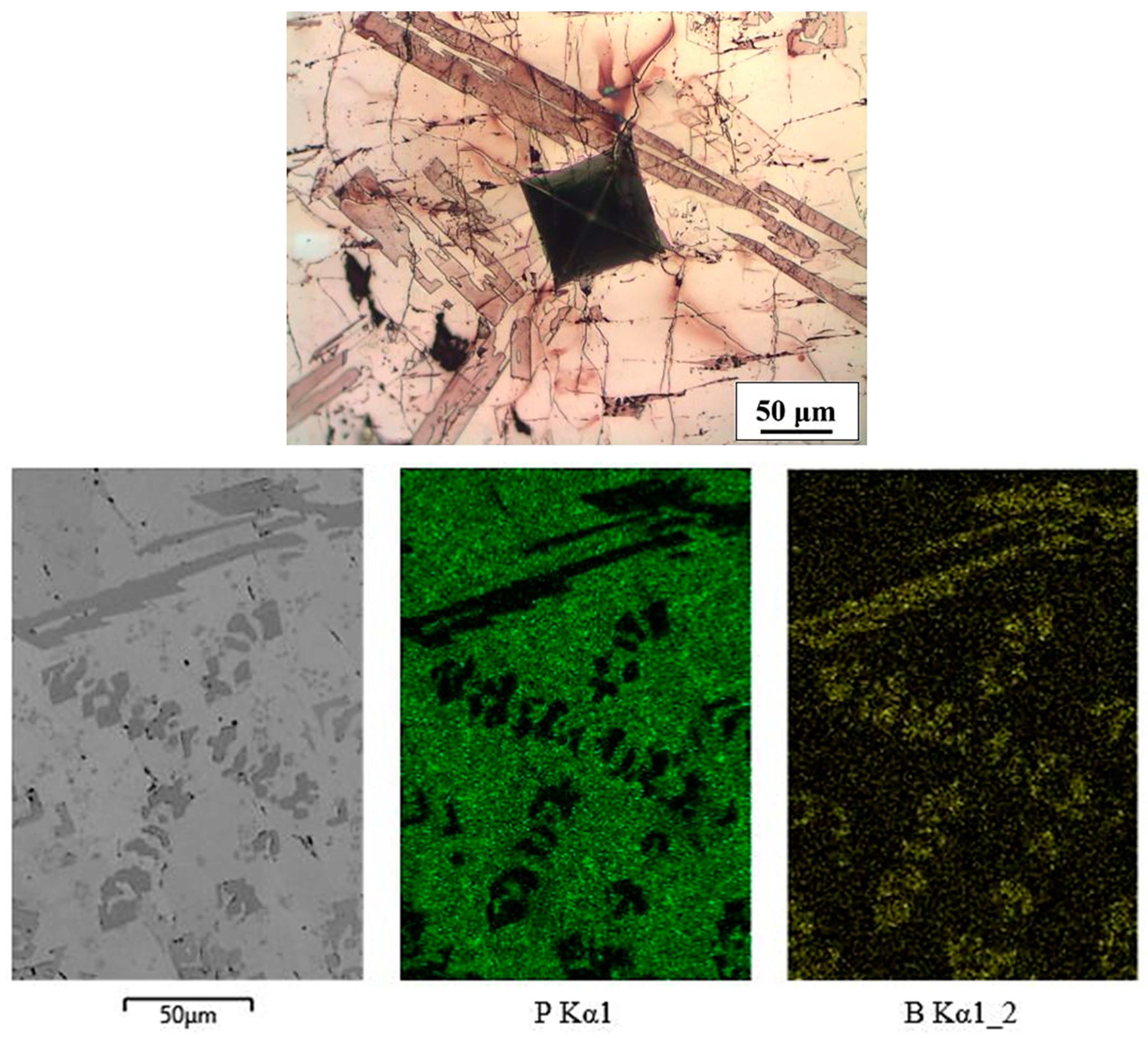

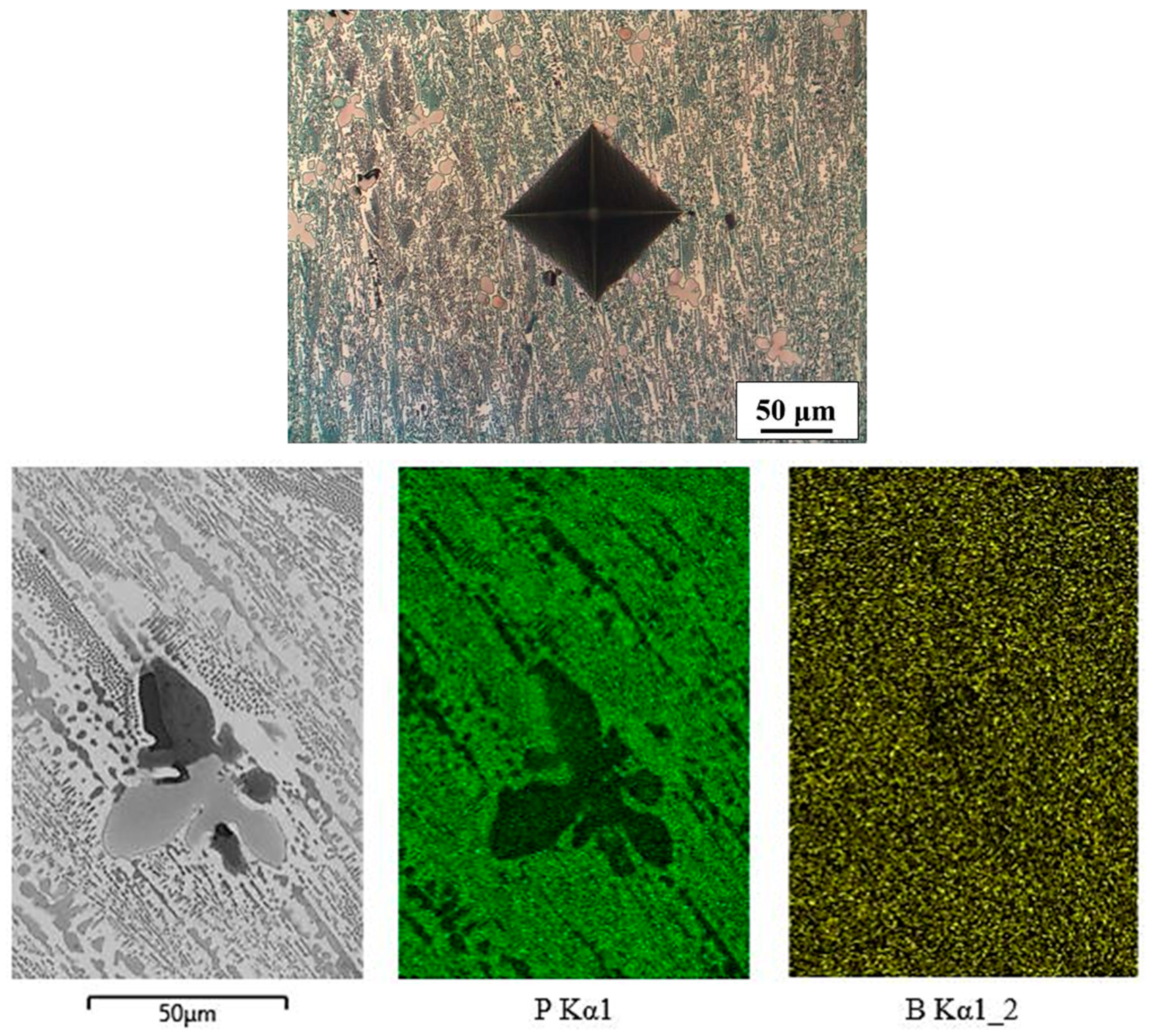

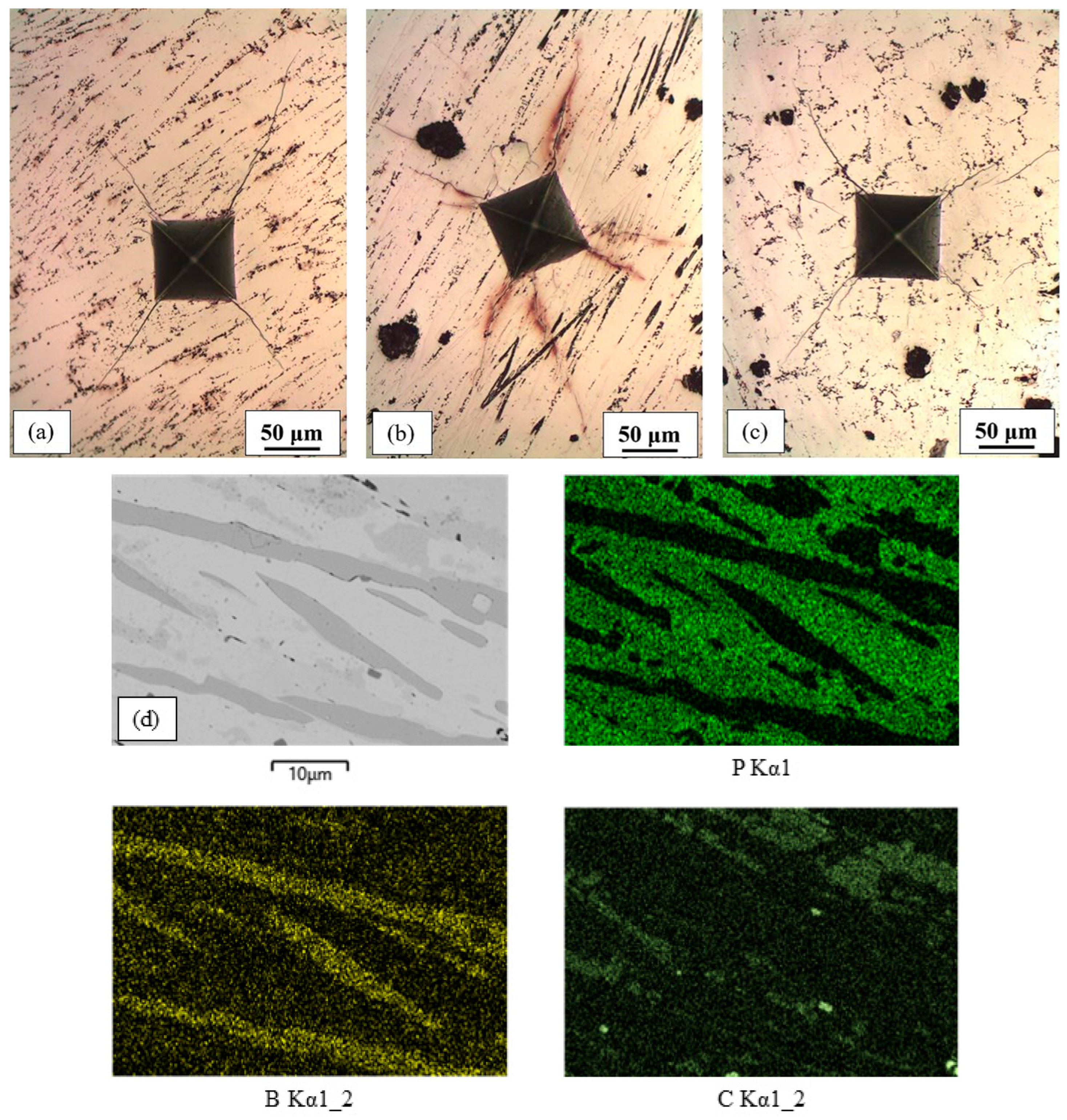

4.2. Microstructure and Hardness of As-Cast State at High Cooling Rates

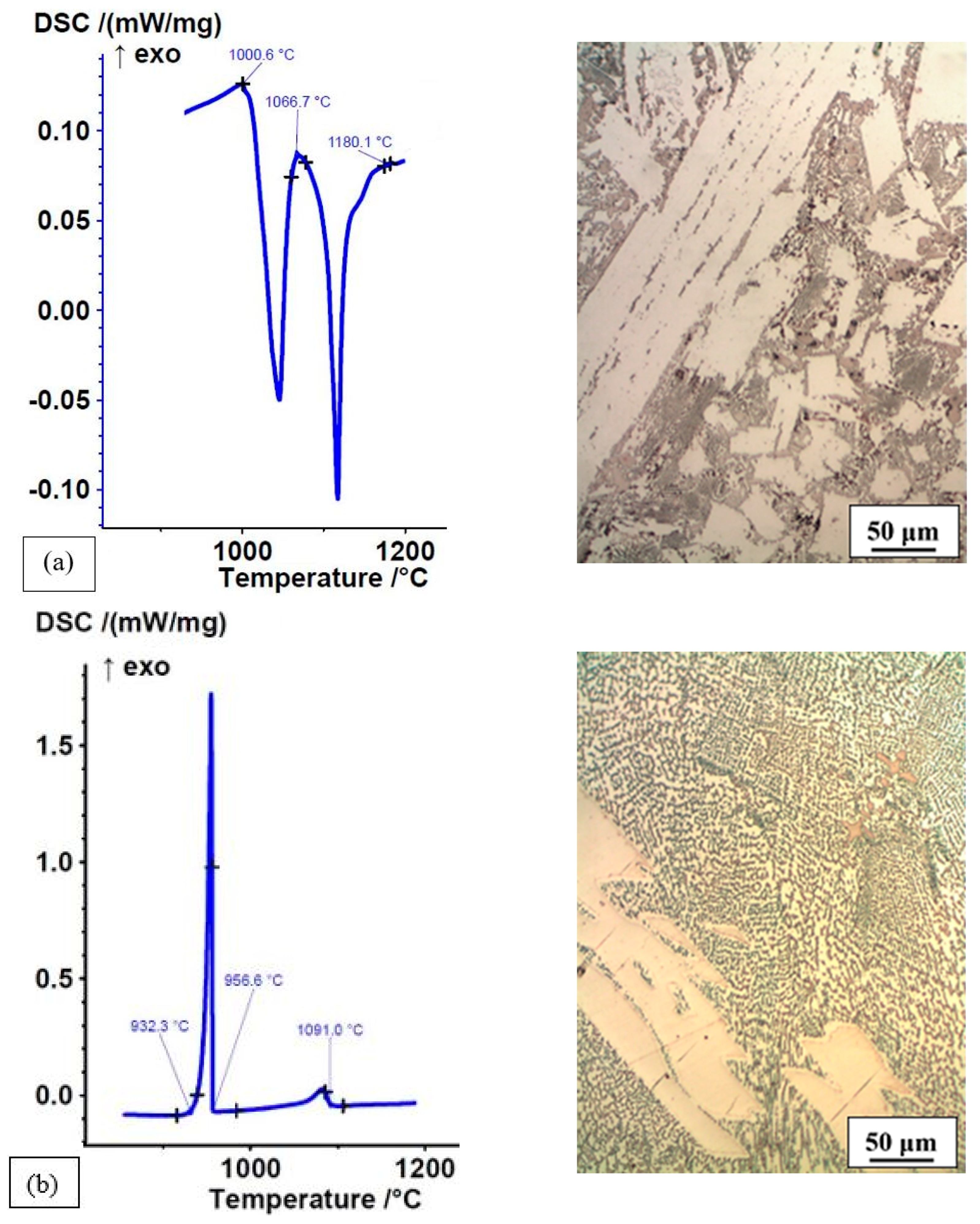

4.3. DSC Analysis and Microstructure

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gundlach, R.B.; Doane, D.V. Alloy Cast Irons. In ASM Handbook; Properties and Selection: Irons, Steels, and High Performance Alloys; ASM International: Materials Park, OH, USA, 2008; Volume 1, pp. 85–104. [Google Scholar]

- ASTM A 532/A532M-93a; Standard Specification for Abrasion-Resistant Cast Irons. ASTM International: West Conshohocken, PA, USA, 2008.

- Standard EN 12513; Founding-Abrasion Resistant Cast Irons. CEN: Brusels, Belgium, 2011.

- Katavić, I.; Uetz, K.; Sommer, K. Widerstand gegen abrasiven verschleiss und dynamische bruchzähigkeit weisser vanadingusseisen. Wear 1983, 87, 251–260. [Google Scholar] [CrossRef]

- Standard EN 14700; Welding Consumables for Hard-Facing. CEN: Brusels, Belgium, 2014.

- UTP. Welding Guide; UTP: Seri Iskandar, Malaysia, 2012. [Google Scholar]

- Lincoln Electric. Welding Consumables; Lincoln Electric: Hong Kong, China, 2017. [Google Scholar]

- Day, W. Iron Alloy Resistant to Abrasion. Patent CH666908A5, 24 October 1983. [Google Scholar]

- Dolman, K.F. Tough, Wear and Abrasion-Resistant High Chromium Hypereutectic White Iron. Patent EP0147422A1, 30 May 1984. [Google Scholar]

- Sun, D.; Ref, Z.; Xuan, Z.; Qiu, X.; Yin, S.; Gu, X. New High-Chromium Alloy Cast Irons Surfacing Material. Patent CN102335798A, 31 August 2011. [Google Scholar]

- Zhi, X.; Han, Y.; Liu, J.; Wang, J. Vanadium-Containing Hypereutectic High Chromium Cast Iron and Manufacturing Method Thereof. Patent CN104451370B, 30 December 2014. [Google Scholar]

- Cheney, J.L. Crack Resistant Hardfacing Alloys. Patent US20150354036A1, 8 June 2015. [Google Scholar]

- Cheney, J.L.; Eibl, C. Tough and Wear Resistant Ferrous Alloys Containing Multiple Hardphases. Patent US20160168670A1, 15 December 2015. [Google Scholar]

- Ebor, C. Chrome-Free and Low Chromium Antifriction Alloy. Patent CN108350528A, 1 September 2016. [Google Scholar]

- Radon, R.; Radon, R. Hypereutectic White Iron Alloys Comprising Chromium, Boron and Nitrogen and Articles Made Therefrom. Patent US9580777B1, 8 February 2016. [Google Scholar]

- Shchepochkina, Y.A. Alloy. Patent RU2647053C1, 4 May 2017. [Google Scholar]

- Merrick, S.; Kotecki, D.; Wu, J. Surfacing. In Welding Handbook, 8th ed.; Oates, W.R., Saitta, A.M., Eds.; AWS: Miami, FL, USA, 1998; Volume 4, pp. 391–436. [Google Scholar]

- Santhaman, A.T.; Tierney, P.; Hunt, J.L. Cemented carbides (Table 1, no pages in electronic version). In ASM Handbook; ASM International: Materials Park, OH, USA, 2008; Volume 2, pp. 950–977. [Google Scholar]

- Roberts, G.; Krauss, G.; Kennedy, R. Tool Steels, 5th ed.; ASM International: Materials Park, OH, USA, 1998; pp. 59, 83–85. [Google Scholar]

- Schumann, H. Metallographie, 12th ed.; VEB Deutscher Verlag für Grundstoffindustrie: Leipzig, Germany, 1987; pp. 322–330, 475–490. [Google Scholar]

- Bhadeshia, H.K.D.H. Cementite. Int. Mater. Rev. 2019, 65, 1–27. [Google Scholar] [CrossRef]

- Ma, S.; Zhang, J. Wear resistant High Boron Cast Alloy-a Review. Rev. Adv. Mater. Sci. 2016, 44, 54–62. [Google Scholar]

- Zhang, J.; Liu, J.; Liao, H.; Zeng, M.; Ma, S. A review on relationship between morphology of boride of Fe-B alloys and the wear/corrosion resistant properties and mechanisms. J. Mater. Res. Technol. 2019, 8, 6308–6320. [Google Scholar] [CrossRef]

- Vitkova, S.; Kjuchukova, M.; Raichevski, G. Electrochemical preparation of amorphous Fe-P alloys. J. Appl. Electrochem. 1988, 18, 673–678. [Google Scholar] [CrossRef]

- Hoor, F.S.; Ahmed, M.F.; Mayana, S.M. Electroless deposition of Fe-P, Fe-P-Pt alloys. Indian J. Chem. Technol. 2000, 7, 213–215. [Google Scholar]

- Nowacki, J. Phosphorus in iron alloys surface engineering. Mater. Manuf. Eng. 2007, 24, 57–67. [Google Scholar]

- Buchtik, M.; Krystýnova, M.; Másilko, J.; Wasserbauer, J. The Effect of Heat Treatment on Properties of Ni-P Coatings Deposited on a AZ91 Magnesium Alloy. Coatings 2019, 9, 461. [Google Scholar] [CrossRef]

- Abbasi, H.R.; Bazdar, M.; Halvaee, A. Effect of phosphorus as an alloying element on microstructure and mechanical properties of pearlitic gray cast iron. Mater. Sci. Eng. A 2017, 444, 314–327. [Google Scholar] [CrossRef]

- White, C.V. Gray Iron. In ASM Handbook; ASM International: Materials Park, OH, USA, 2008; Volume 1, pp. 12–32. [Google Scholar]

- Jenkins, L.R.; Forrest, R.D. Ductile Iron. In ASM Handbook; ASM International: Materials Park, OH, USA, 2008; Volume 1, pp. 33–55. [Google Scholar]

- Stefanscu, D.M. Compacted Graphite Iron. In ASM Handbook; ASM International: Materials Park, OH, USA, 2008; Volume 1, pp. 56–70. [Google Scholar]

- Malleable, I. ASM Handbook; ASM International: Materials Park, OH, USA, 2008; Volume 1, pp. 71–84. [Google Scholar]

- De Cooman, B.; Speer, J.G. Fundamentals of Steel Product Physical Metallurgy; AIST: Warrendal, PA, USA, 2011; pp. 49–55. [Google Scholar]

- Zorc, B.; Bernetič, J.; Nagode, A. Effects of welding residual stresses and phosphorus segregation on cleavage delamination fracture in thick S355 J2 G3+N steel plate. Eng. Fail. Anal. 2014, 40, 8–14. [Google Scholar] [CrossRef]

- Spyrydonova, I.M.; Sukhova, O.V.; Karpenko, N.V.; Dyad’kov, A.V. Application of Fe-P-B Alloys in Developing Wear-Resistant Composite Materials. J. Superhard Mater. 2013, 35, 97–104. [Google Scholar] [CrossRef]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Baker, H. (Ed.) ASM Handbook; ASM International: Materials Park, OH, USA, 1992; Volume 3. [Google Scholar]

- Gundlach, B.R. High-Alloy White Irons. In ASM Handbook; ASM International: Materials Park, OH, USA, 2007; Volume 15, pp. 678–685. [Google Scholar]

- Varner, J.R. Fracture Modes and Appearances in ceramics. In ASM Handbook; Becker, W.T., Shipley, R.J., Eds.; ASM International: Materials Park, OH, USA, 2008; Volume 11, pp. 662–670. [Google Scholar]

- Ćorić, D.; Ćurković, L.; Majić Renjo, M. Statistical analysis of Vickers indentation fracture toughness of Y-TZP ceramics. Trans. Famena XLI-2 2017, 41, 1–16. [Google Scholar] [CrossRef]

| Alloy # | Fe | Mn | P | B | C | Si | ≈TS-L (°C) |

|---|---|---|---|---|---|---|---|

| Fe-C | rest | 0.66 | 0.015 | / | 2.95 | 0.82 | 1137–1290 |

| Fe-B | rest | 1.24 | 0.51 | 4.3 | 0.11 | 0.26 | 1110–1170 |

| Fe-P(1) | rest | 0.76 | 10.4 | / | 0.11 | 0.19 | 1050–1070 * |

| Fe-P(2) | rest | 1.23 | 14.9 | / | 0.05 | 0.08 | 1035–1160 * |

| Fe-P-C | rest | 1.57 | 7.4 | / | 2.20 | 0.34 | 954–990 |

| Fe-P-B(1) | rest | 0.77 | 7.0 | 2.1 | 0.08 | 0.21 | 1012–1180 |

| Fe-P-B(2) | rest | 1.40 | 9.3 | 2.5 | 0.09 | 0.21 | 1053–1220 |

| Fe-P-B(3) | rest | 0.57 | 7.6 | 0.73 | 0.07 | 0.08 | 1000–1056 |

| Fe-P-B-C(1) | rest | 1.0 | 7.2 | 1.3 | 1.62 | 0.16 | 954–1082 |

| Fe-P-B-C(2) | rest | 3.8 | 6.8 | 2.1 | 1.50 | 0.53 | 956–1189 |

| Fe-P-B-C(3) | rest | 1.3 | 7.1 | 2.6 | 1.21 | 0.23 | 956–1212 |

| Fe-P-B-C(4) | rest | 1.9 | 7.5 | 0.74 | 0.62 | 0.50 | 956–1040 |

| Alloy | HV10 | Microhardness HV0.3 and 0.5 # | |||||

|---|---|---|---|---|---|---|---|

| Min. | Max. | SD sH | Mean HV/HRC | ΔHV | Eutectic | White Phases (Primary and Uneven Shapes) | |

| Fe-C | 450 | 492 | 15.1 | 470/45.5 | 42 | 639–714 | 348, 452 * |

| Fe-B | 490 | 528 | 11.7 | 505/47 | 38 | 501, 543 | 1099, 1215 |

| Fe-P(1) | 565 | 606 | 13.8 | 589/52.5 | 41 | 677, 715 | 890, 927 |

| Fe-P(2) | 605 | 709 | 36.0 | 678/57 | 104 | ? | 890, 999 |

| Fe-P-C | 620 | 774 | 53.3 | 715/59 | 154 | 835, 883 | 927, 966 (1) |

| Fe-P-B(1) | 678 | 789 | 40.2 | 718/59 | 111 | 746, 779 | 1174, 1391 |

| Fe-P-B(2) | 710 | 824 | 39.6 | 771/61.5 | 114 | ? | 1043, 1119 ** 1324, 1391 ** |

| Fe-P-B(3) | 562 | 608 | 16.4 | 588/52.5 | 46 | 705, 746 | 441, 498 *** |

| Fe-P-B-C(1) | 740 | 943 | 74.2 | 875/65 | 203 | 829, 855 | 966, 1025 |

| Fe-P-B-C(2) | 679 | 868 | 75.5 | 787/62 | 189 | 855, 883 | 1061, 1226 |

| Fe-P-B-C(3) | 742 | 857 | 41.5 | 805/62.5 | 115 | 842, 862 | 1129, 1261 |

| Fe-P-B-C(4) | 631 | 756 | 42.6 | 699/58 | 125 | 817, 883 | 974, 1025 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zorc, M.; Nagode, A.; Burja, J.; Kosec, B.; Bizjak, M.; Zorc, B. Preliminary Study of New Low-Temperature Hard Abrasion Resistant Fe-P and Fe-P-X (X = C or/and B) Casting Alloys. Materials 2023, 16, 3766. https://doi.org/10.3390/ma16103766

Zorc M, Nagode A, Burja J, Kosec B, Bizjak M, Zorc B. Preliminary Study of New Low-Temperature Hard Abrasion Resistant Fe-P and Fe-P-X (X = C or/and B) Casting Alloys. Materials. 2023; 16(10):3766. https://doi.org/10.3390/ma16103766

Chicago/Turabian StyleZorc, Matija, Aleš Nagode, Jaka Burja, Borut Kosec, Milan Bizjak, and Borut Zorc. 2023. "Preliminary Study of New Low-Temperature Hard Abrasion Resistant Fe-P and Fe-P-X (X = C or/and B) Casting Alloys" Materials 16, no. 10: 3766. https://doi.org/10.3390/ma16103766

APA StyleZorc, M., Nagode, A., Burja, J., Kosec, B., Bizjak, M., & Zorc, B. (2023). Preliminary Study of New Low-Temperature Hard Abrasion Resistant Fe-P and Fe-P-X (X = C or/and B) Casting Alloys. Materials, 16(10), 3766. https://doi.org/10.3390/ma16103766