Achieving High Strength and High Conductivity of Cu-6 wt%Ag Sheets by Controlling the Aging Cooling Rate

Abstract

1. Introduction

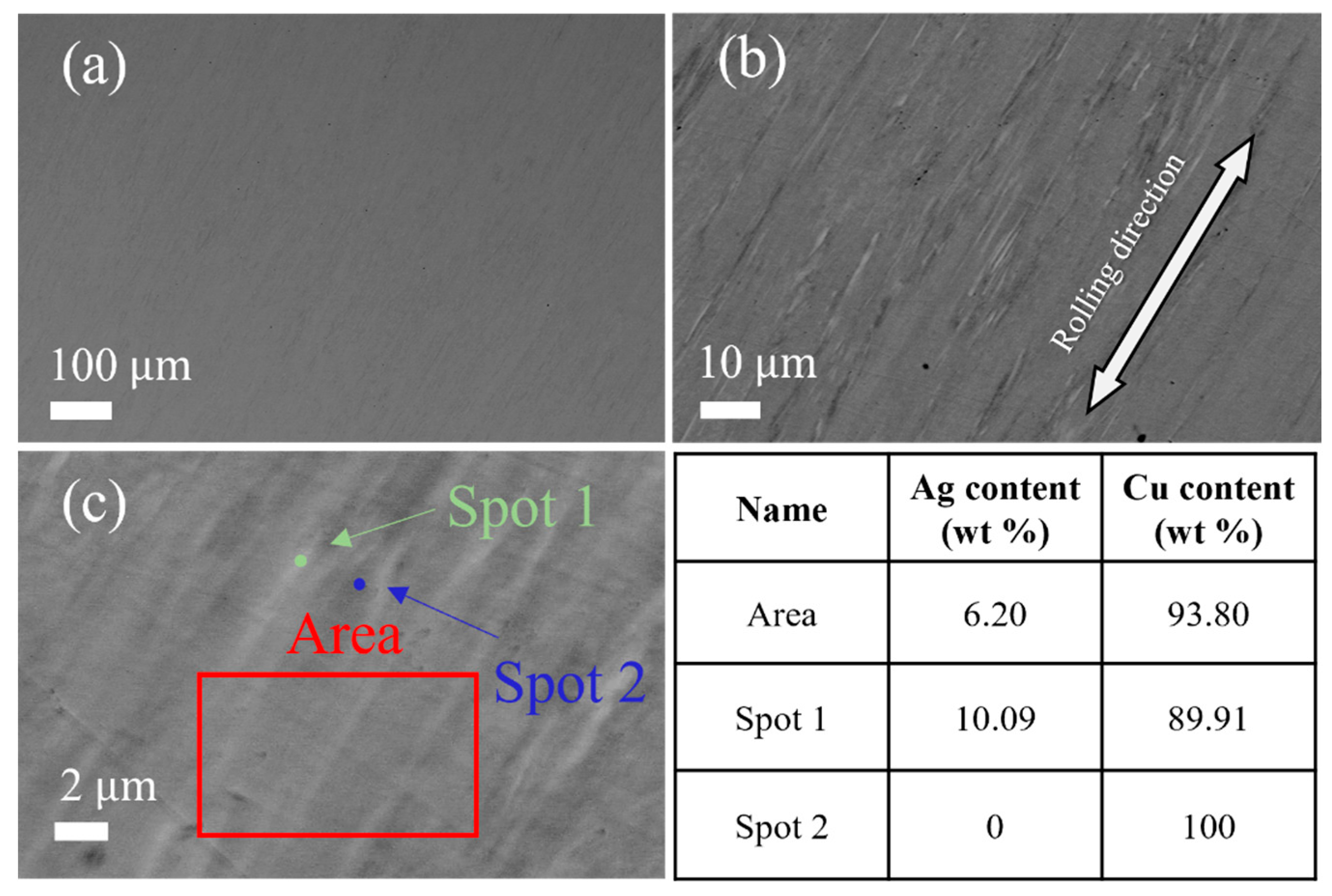

2. Materials and Methods

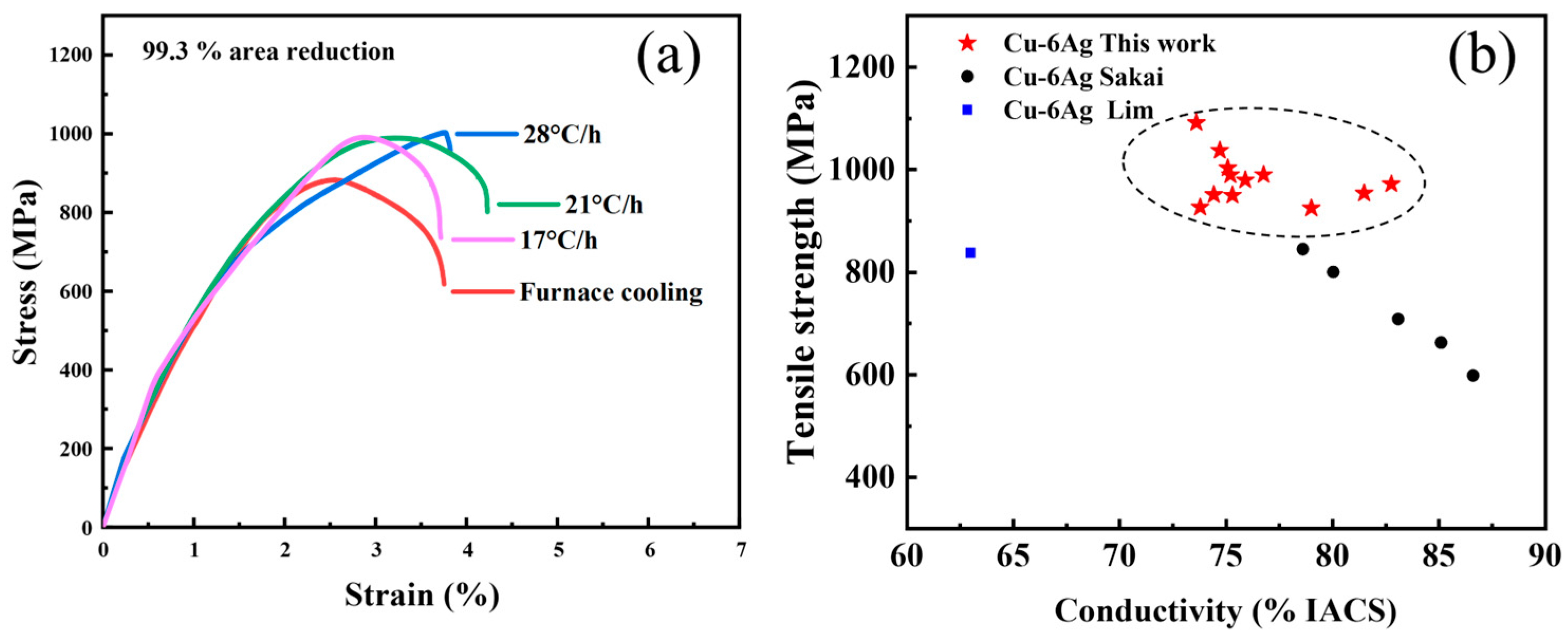

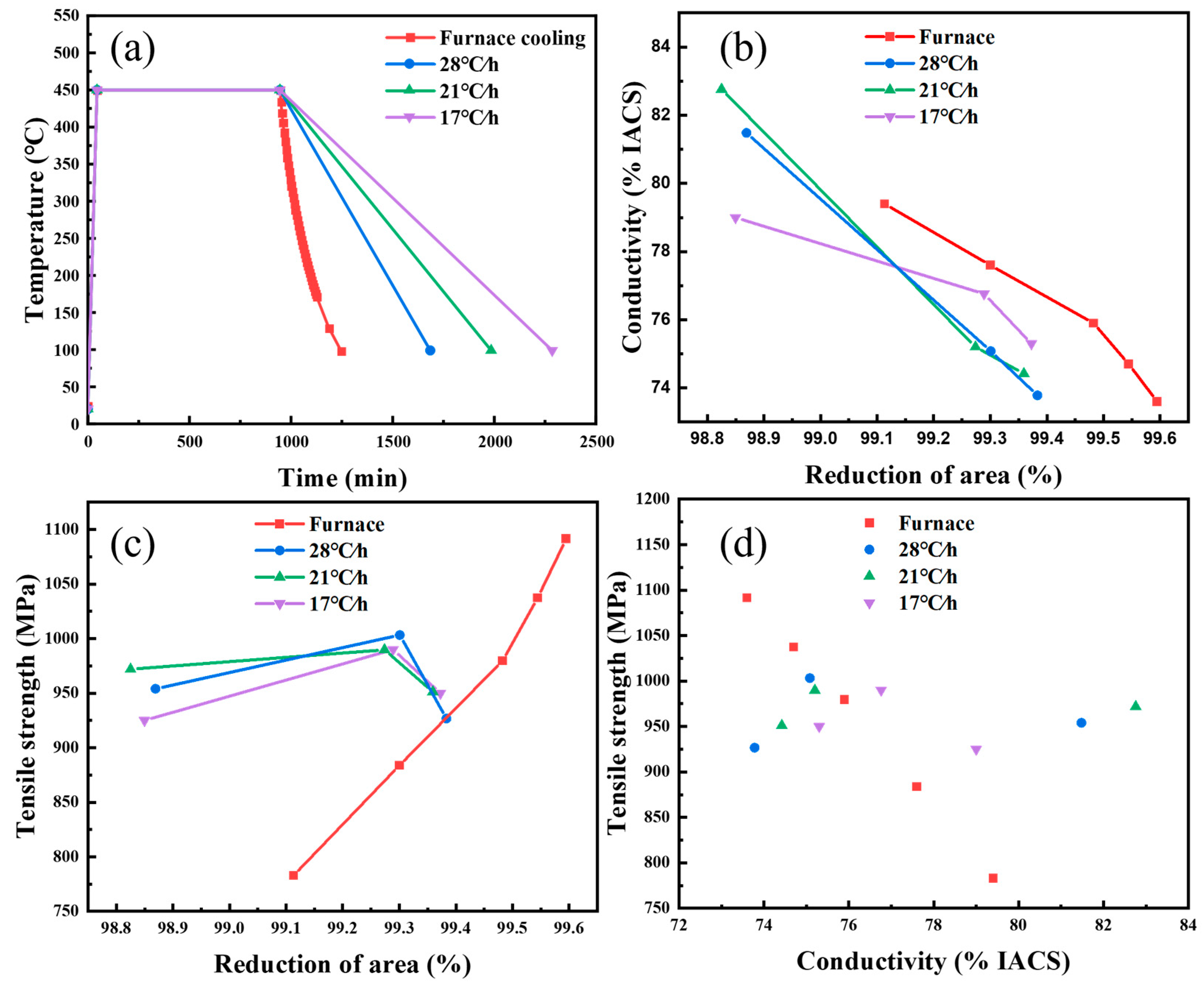

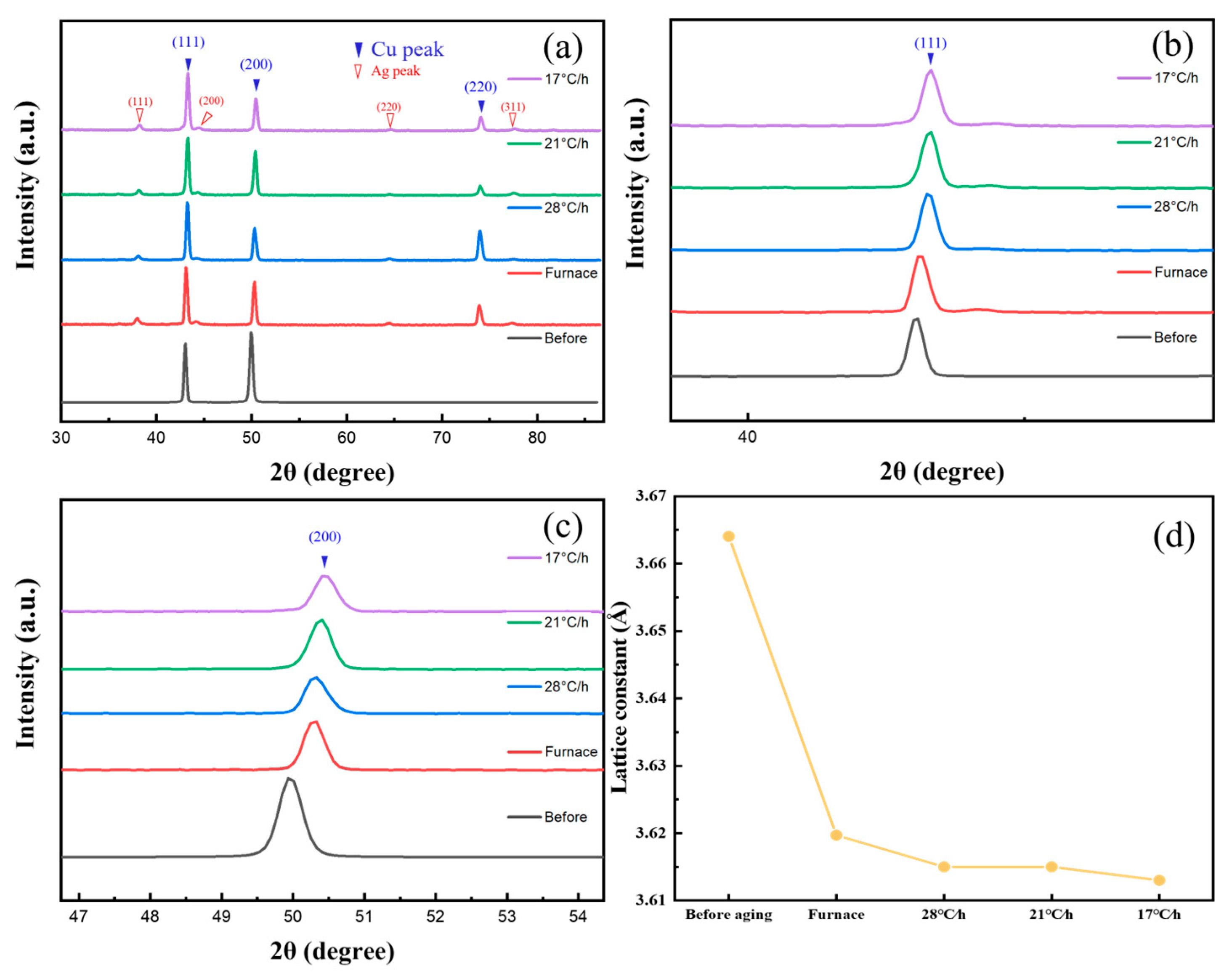

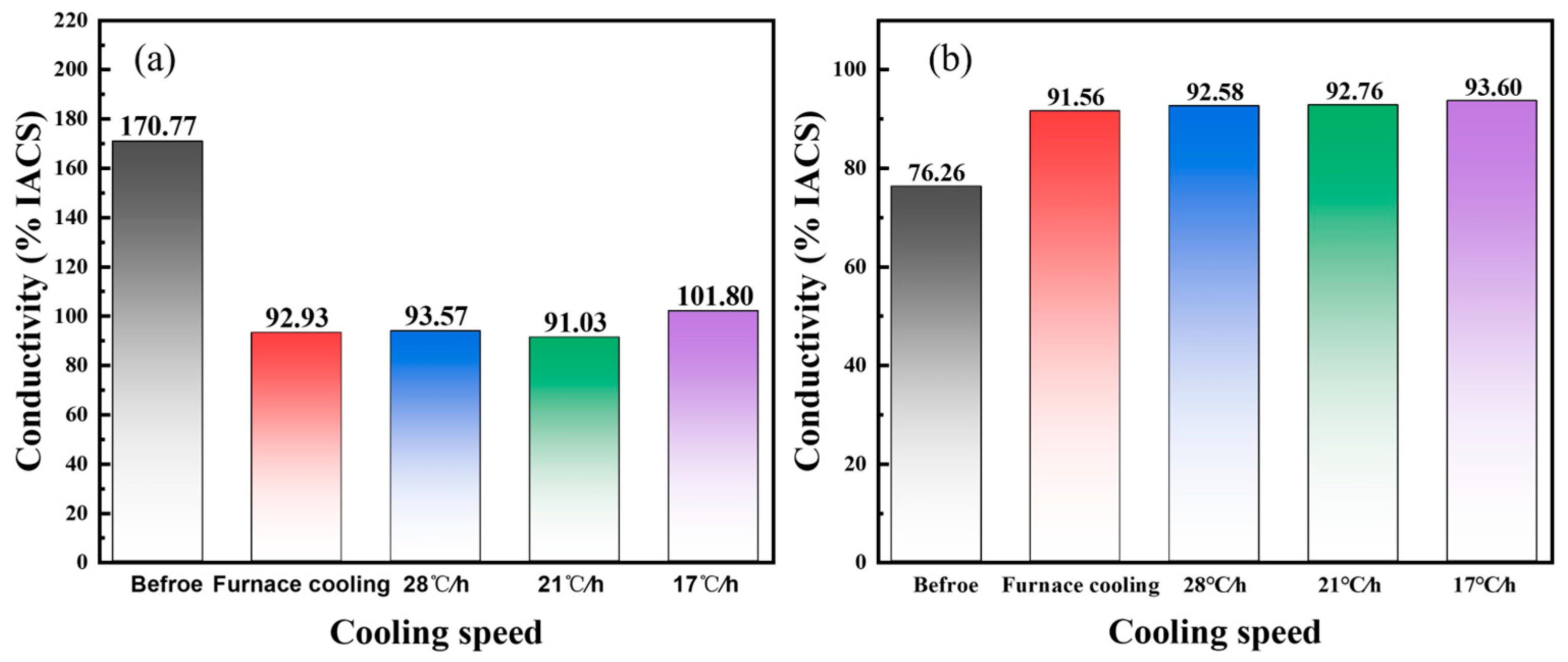

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, H.; Fu, H.; Xie, M.; Xie, J. Effect of Ag content and drawing strain on microstructure and properties of directionally solidified Cu-Ag alloy. Vacuum 2018, 154, 190–199. [Google Scholar] [CrossRef]

- Grünberger, W.; Heilmaier, M.; Schultz, L. Development of high-strength and high-conductivity conductor materials for pulsed high-field magnets at Dresden. Phys. B Phys. Condens. Matter 2001, 294, 643–647. [Google Scholar] [CrossRef]

- Fuchs, G.; Krabbes, G.; Schatzle, P.; Gruss, S.; Verges, P.; Muller, K.H.; Fink, J.; Schultz, L.; Eschrig, H. Bulk superconducting magnets with fields beyond 14T. Phys. B-Condens. Matter 2001, 294, 398–401. [Google Scholar] [CrossRef]

- Freudenberger, J.; Kozlova, N.; Gaganov, A.; Schultz, L.; Witte, H.; Jones, H. Magnetoresistance up to 50 T of highly strengthened Cu-Ag conductors for pulsed high field magnets. Cryogenics 2006, 46, 724–729. [Google Scholar] [CrossRef]

- Embury, J.D.; Ke, H. Conductor materials for high field magnets. Curr. Opin. Solid State Mater. Sci. 1998, 3, 304–308. [Google Scholar] [CrossRef]

- Sakai, Y.; Inoue, K. High-strength, and high-conductivity Cu-Ag alloy sheets: New promising conductor for high-fieid Bitter coils. Magn. IEEE Trans. 1994, 30, 2114–2117. [Google Scholar] [CrossRef]

- Asano, T.; Kiyoshi, T.; Watanabe, K. Investigation of 15 to 24 MW Resistive Insert Magnets Built Into a 20 T empty Ø440 mm Room-Temperature Bore Superconducting Outsert Magnet. IEEE Trans. Appl. Supercond. 2012, 22, 4301404. [Google Scholar] [CrossRef]

- Freudenberger, J.; Grunberger, W.; Botcharova, E.; Gaganov, A.; Schultz, L. Mechanical properties of Cu-based micro- and macrocomposites. Adv. Eng. Mater. 2002, 4, 677–681. [Google Scholar] [CrossRef]

- Spencer, K.; Lecouturier, F.; Thilly, L.; Embury, J.D. Established and emerging materials for use as high-field magnet conductors. Adv. Eng. Mater. 2004, 6, 290–297. [Google Scholar] [CrossRef]

- Schneider-Muntau, H.J. Pulsed monocoil magnets for highest fields. Curr. Appl. Phys. 2006, 6, 54–58. [Google Scholar] [CrossRef]

- An, B.; Xin, Y.; Niu, R.; Xiang, Z.; Wang, E.; Han, K. Nucleation and growth of discontinuous precipitates in Cu-Ag alloys. Mater. Res. Express 2022, 9, 026530. [Google Scholar] [CrossRef]

- Zhu, X.; Xiao, Z.; An, J.; Jiang, H.; Jiang, Y.; Li, Z. Microstructure and properties of Cu-Ag alloy prepared by continuously directional solidification. J. Alloys Compd. 2021, 883, 160769. [Google Scholar] [CrossRef]

- Guo, S.L.; Liu, S.P.; Liu, J.C.; Gao, Z.S.; Li, D.F.; Liu, Z.G. Investigation on Strength, Ductility and Electrical Conductivity of Cu-4Ag Alloy Prepared by Cryorolling and Subsequent Annealing Process. J. Mater. Eng. Perform. 2019, 28, 6809–6815. [Google Scholar] [CrossRef]

- Ko, Y.G.; Namgung, S.; Lee, B.U.; Shin, D.H. Mechanical and electrical responses of nanostructured Cu-3 wt%Ag alloy fabricated by ECAP and cold rolling. J. Alloys Compd. 2010, 504, S448–S451. [Google Scholar] [CrossRef]

- Straumal, B.B.; Pontikis, V.; Kilmametov, A.R.; Mazilkin, A.A.; Dobatkin, S.V.; Baretzky, B. Competition between precipitation and dissolution in Cu-Ag alloys under high pressure torsion. Acta Mater. 2017, 122, 60–71. [Google Scholar] [CrossRef]

- An, B.L.; Niu, R.M.; Xin, Y.; Starch, W.L.; Xiang, Z.L.; Su, Y.F.; Goddard, R.E.; Lu, J.; Siegrist, T.M.; Wang, E.A.; et al. Suppression of discontinuous precipitation and strength improvement by Sc doping in Cu-6 wt%Ag alloys. J. Mater. Sci. Technol. 2023, 135, 80–96. [Google Scholar] [CrossRef]

- Ning, Y.T.; Zhang, X.H.; Wu, Y.J. Electrical conductivity of Cu-Ag in situ filamentary composites. Trans. Nonferrous Met. Soc. China 2007, 17, 378–383. [Google Scholar] [CrossRef]

- Zhang, B.B.; Tao, N.R.; Lu, K. A high strength and high electrical conductivity bulk Cu-Ag alloy strengthened with nanotwins. Scr. Mater. 2017, 129, 39–43. [Google Scholar] [CrossRef]

- Gaganov, A.; Freudenberger, J.; Botcharova, E.; Schultz, L. Effect of Zr additions on the microstructure, and the mechanical and electrical properties of Cu-7 wt.%Ag alloys. Mat. Sci. Eng. A-Struct. 2006, 437, 313–322. [Google Scholar] [CrossRef]

- Xie, M.W.; Huang, W.; Chen, H.M.; Gong, L.K.; Xie, W.B.; Wang, H.; Yang, B. Microstructural evolution and strengthening mechanisms in cold-rolled Cu-Ag alloys. J. Alloys Compd. 2021, 851, 156893. [Google Scholar] [CrossRef]

- Chen, G.; Shen, J.Z.; Zhu, Q.; Yao, S.J.; Wang, C.J.; Zhang, P. Tensile deformation and fracture behaviours of cold rolled Cu-3wt.%Ag-0.5wt.%Zr thin sheets with different annealed microstructures. Mat. Sci. Eng. A-Struct. 2019, 756, 27–34. [Google Scholar] [CrossRef]

- Li, R.; Wang, E.G.; Zuo, X.W. Co-Precipitation, Strength and Electrical Resistivity of Cu-26 wt % Ag-0.1 wt % Fe alloy. Materials 2017, 10, 1383. [Google Scholar] [CrossRef] [PubMed]

- Zuo, X.W.; Guo, R.; Zhao, C.C.; Zhang, L.; Wang, E.G.; Han, K. Microstructure and properties of Cu-6wt% Ag composite thermomechanical-processed after directionally solidifying with magnetic field. J. Alloys Compd. 2016, 676, 46–53. [Google Scholar] [CrossRef]

- Cho, H.; Lee, B.S.; Jo, H.H. Development of high strength and high conductivity Cu-Ag alloy for medical ultrasound equipment. Surf. Rev. Lett. 2010, 17, 93–97. [Google Scholar] [CrossRef]

- Liu, J.B.; Meng, L.; Zeng, Y.W. Microstructure evolution and properties of Cu-Ag microcomposites with different Ag content. Mat. Sci. Eng. A-Struct. 2006, 435, 237–244. [Google Scholar] [CrossRef]

- Zhao, C.; Zuo, X.; Wang, E.; Niu, R.; Han, K. Simultaneously increasing strength and electrical conductivity in nanostructured Cu–Ag composite. Mater. Sci. Eng. A 2016, 625, 296–304. [Google Scholar] [CrossRef]

- Zuo, X.; Han, K.; Zhao, C.; Niu, R.; Wang, E. Precipitation and dissolution of Ag in ageing hypoeutectic alloys. J. Alloys Compd. 2015, 622, 69–72. [Google Scholar] [CrossRef]

- Tang, L.S.; Xie, W.B.; Xiao, X.P.; Chen, H.M.; Wang, H.; Yang, B. Evolution of microstructure and properties of Cu-4.5 wt.% Ag alloy prepared by vacuum horizontal continuous casting in solid solution and aging treatment. Mater. Res. Express 2020, 7, 126517. [Google Scholar] [CrossRef]

- Sakai, Y.; Hibaru, T.; Miura, K.; Matsuo, A.; Kawaguchi, K.; Kindo, K. Development of High Strength-High Conductivity Cu-6 wt% Ag Alloy for High Field Magnet. MRS Adv. 2016, 1, 1137–1148. [Google Scholar] [CrossRef]

- Choi, E.A.; Lee, S.J.; Ahn, J.H.; Choe, S.; Lee, K.H.; Lim, S.H.; Choi, Y.S.; Han, S.Z. Enhancement of strength and electrical conductivity for hypo-eutectic Cu-12Ag alloy. J. Alloys Compd. 2023, 931, 167506. [Google Scholar] [CrossRef]

- Sakai, Y.; Inoue, K.; Maeda, H. New high-strength, high-conductivity Cu-Ag alloy sheets. Acta Metall. Mater. 1995, 43, 1517–1522. [Google Scholar] [CrossRef]

- Lim, M.S.; Song, J.S.; Hong, S.I. Microstructural and mechanical stability of Cu-6 wt. % Ag alloy. J. Mater. Sci. 2000, 35, 4557–4561. [Google Scholar] [CrossRef]

- Wirth, R.; Gleiter, H. Is discontinuous (cellular) precipitation an effect of a structural transformation in the migrating phase boundary? Acta Metall. 1981, 29, 1825–1830. [Google Scholar] [CrossRef]

- Gaganov, A.; Freudenberger, J.; Grunberger, W.; Schultz, L. Microstructural evolution and its effect on the mechanical properties of Cu-Ag microcomposites. Z. Metallk. 2004, 95, 425–432. [Google Scholar] [CrossRef]

- Gupta, S.P. Kinetics of discontinuous precipitation and dissolution in Cu-Ag alloys. Can. Metall. Q. 1998, 37, 141–159. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Ru, Y.; Zuo, T.; Xue, J.; Wu, Y.; Gao, Z.; Liu, Y.; Xiao, L. Achieving High Strength and High Conductivity of Cu-6 wt%Ag Sheets by Controlling the Aging Cooling Rate. Materials 2023, 16, 3632. https://doi.org/10.3390/ma16103632

Zhang Z, Ru Y, Zuo T, Xue J, Wu Y, Gao Z, Liu Y, Xiao L. Achieving High Strength and High Conductivity of Cu-6 wt%Ag Sheets by Controlling the Aging Cooling Rate. Materials. 2023; 16(10):3632. https://doi.org/10.3390/ma16103632

Chicago/Turabian StyleZhang, Zhongyuan, Yadong Ru, Tingting Zuo, Jiangli Xue, Yue Wu, Zhaoshun Gao, Yongsheng Liu, and Liye Xiao. 2023. "Achieving High Strength and High Conductivity of Cu-6 wt%Ag Sheets by Controlling the Aging Cooling Rate" Materials 16, no. 10: 3632. https://doi.org/10.3390/ma16103632

APA StyleZhang, Z., Ru, Y., Zuo, T., Xue, J., Wu, Y., Gao, Z., Liu, Y., & Xiao, L. (2023). Achieving High Strength and High Conductivity of Cu-6 wt%Ag Sheets by Controlling the Aging Cooling Rate. Materials, 16(10), 3632. https://doi.org/10.3390/ma16103632