Analysis of SAW Temperature Properties in KTiOPO4 Single Crystal

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Fan, T.Y.; Huang, C.E.; Hu, B.Q.; Eckardt, R.C.; Fan, Y.X.; Byer, R.L.; Feigelson, R.S. Second harmonic generation and accurate index of refraction measurements in flux-grown KTiOP04. Appl. Opt. 1987, 26, 2390–2394. [Google Scholar] [CrossRef] [PubMed]

- Vanherzeele, H.; Bierlein, J.D. Magnitude of the nonlinear-optical coefficients of KTiOPO4. Opt. Lett. 1992, 17, 982–984. [Google Scholar] [CrossRef] [PubMed]

- Hansson, G.; Karlsson, H.; Wang, S.; Laurell, F. Transmission Measurements in KTP and Isomorphic Compounds. Appl. Opt. 2000, 39, 5058–5069. [Google Scholar] [CrossRef] [PubMed]

- Wakui, K.; Takahashi, H.; Furusawa, A.; Sasaki, M. Photon subtracted squeezed states generated with periodically poled KTiOPO4. Opt. Express 2007, 15, 3568–3574. [Google Scholar] [CrossRef] [PubMed]

- Mamrashev, A.; Nikolaev, N.; Antsygin, V.; Andreev, Y.; Lanskii, G.; Meshalkin, A. Optical Properties of KTP Crystals and Their Potential for Terahertz Generation. Crystals 2018, 8, 310. [Google Scholar] [CrossRef]

- Hagerman, M.E.; Poeppelmeier, K.R. Review of the Structure and Processing-Defect-Property Relationships of Potassi-um Titanyl Phosphate: A Strategy for Novel Thin-Film Photonic Devices. Chem. Mater. 1995, 7, 602–621. [Google Scholar] [CrossRef]

- Savatinova, I.; Savova, I.; Liarokapis, E.; Ziling, C.C.; Atuchin, V.V.; Armenise, M.N.; Passaro, V.M.N. A comparative analysis of Rb:KTP and Cs:KTP optical waveguides. J. Phys. D Appl. Phys. 1998, 31, 1667–1672. [Google Scholar] [CrossRef]

- Atuchin, V.V.; Alekseeva, O.A.; Kesler, V.G.; Pokrovsky, L.D.; Sorokina, N.I.; Voronkova, V.I. Chemical shifts of atomic core levels and structure of K1−xTi1−xSbxOPO4, x=0–0.23, solid solutions. J. Solid State Chem. 2006, 179, 2349–2355. [Google Scholar] [CrossRef]

- Atuchin, V.V.; Kesler, V.G.; Meng, G.; Lin, Z.S. The electronic structure of RbTiOPO4 and the effects of the A-site cation substitution in KTiOPO4-family crystals. J. Phys. Condens. Matter 2012, 24, 405503. [Google Scholar] [CrossRef]

- Dong, X.; Huang, L.; Hu, C.; Zeng, H.; Lin, Z.; Wang, X.; Ok, K.M.; Zou, G. CsSbF2SO4: An Excellent Ultraviolet Nonlinear Optical Sulfate with a KTiOPO4 (KTP)-Type Structure. Angew. Chem. Int. Ed. 2019, 58, 6528–6534. [Google Scholar] [CrossRef]

- Yang, F.; Wang, L.; Huang, L.; Zou, G. The study of structure evolvement of KTiOPO4 family and their nonlinear optical properties. Co-ord. Chem. Rev. 2020, 423, 213491. [Google Scholar] [CrossRef]

- Jiang, C.; Jiang, X.; Wu, C.; Huang, Z.; Lin, Z.; Humphrey, M.G.; Zhang, C. Isoreticular Design of KTiOPO4-like Deep-Ultraviolet Transparent Materials Exhibiting Strong Second-Harmonic Generation. J. Am. Chem. Soc. 2022, 144, 20394–20399. [Google Scholar] [CrossRef]

- Atuchin, V.V.; Kesler, V.G.; Maklakova, N.Y.; Pokrovsky, L.D.; Semenenko, V.N. Study of KTiOPO4 surface by X-ray photoelectron spectroscopy and reflection high-energy electron diffraction. Surf. Interface Anal. 2002, 34, 320–323. [Google Scholar] [CrossRef]

- Atuchin, V.; Maklakova, N.Y.; Pokrovsky, L.; Semenenko, V. Restoration of KTiOPO4 surface by annealing. Opt. Mater. 2003, 23, 363–367. [Google Scholar] [CrossRef]

- Rusov, V.A.; Gorchakov, A.V.; Belostotsky, A.L.; Sapojnikov, V.K.; Kaplun, A.B.; Meshalkin, A.B.; Shapovalov, V.N. KTiOPO4 electro-optical devices with extinction ratio up to 1:1000. Proc. SPIE 2001, 4350, 117–119. [Google Scholar] [CrossRef]

- Wang, X.; Yuan, X.; Li, W.; Qi, J.; Wang, S.; Shen, D. Flux growth of large potassium titanyl phosphate crystals and their electro-optical applications. J. Cryst. Growth 2002, 237–239, 672–676. [Google Scholar] [CrossRef]

- Roth, M.; Tseitlin, M. Growth of large size high optical quality KTP-type crystals. J. Cryst. Growth 2010, 312, 1059–1064. [Google Scholar] [CrossRef]

- Buritskii, K.S.; Dianov, E.M.; Kiselev, A.B.; Maslov, V.A.; Shcherbakov, E.A. Excitation of surface acoustic waves in Rb:KTP. Electron. Lett. 1991, 27, 1896–1897. [Google Scholar] [CrossRef]

- Chu, D.K.T.; Bierlein, J.D.; Hunsperger, R.G. Piezoelectric and acoustic properties of potassium titanyl phosphate (KTP) and its isomorphs. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 683–687. [Google Scholar] [CrossRef]

- Chu, D.K.T.; Hsiung, H.; Cheng, L.K.; Bierlein, J.D. Curie temperatures and dielectric properties of doped and undoped KTiOPO4 and isomorphs. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1993, 40, 819–824. [Google Scholar] [CrossRef]

- Chu, D.K.T.; Bierlein, J.D. Surface acoustic wave and Bleustein–Gulyaev wave generation in KTiOPO4crystals. Appl. Phys. Lett. 1993, 63, 2041–2043. [Google Scholar] [CrossRef]

- El Baroudi, A.; Le Pommellec, J.Y. Bleustein–Gulyaev waves in a finite piezoelectric material loaded with a viscoelastic fluid. Wave Motion 2021, 101, 102695. [Google Scholar] [CrossRef]

- Elhady, A.; Abdel-Rahman, E. Measurement of the electric permittivity using Bleustein–Gulyaev wave sensor. J. Micromech. Microeng. 2022, 32, 034004. [Google Scholar] [CrossRef]

- Elhady, A.; Basha, M.; Abdel-Rahman, E.M. Analysis of tunable Bleustein–Gulyaev permittivity sensors. J. Appl. Phys. 2021, 129, 164501. [Google Scholar] [CrossRef]

- Cui, W.; Mu, L.; Duan, X.; Pang, W.; Reed, M.A. Trapping of sub-100 nm nanoparticles using gigahertz acoustofluidic tweezers for biosensing applications. Nanoscale 2019, 11, 14625–14634. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Das, P.K.; Bhethanabotla, V.R. Surface acoustic waves in biosensing applications. Sens. Actuators Rep. 2021, 3, 100041. [Google Scholar] [CrossRef]

- Zu, H.; Wu, H.; Wang, Q.-M. High-Temperature Piezoelectric Crystals for Acoustic Wave Sensor Applications. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2016, 63, 486–505. [Google Scholar] [CrossRef]

- Huang, J.; Cegla, F.; Wickenden, A.; Coomber, M. Simultaneous Measurements of Temperature and Viscosity for Viscous Fluids Using an Ultrasonic Waveguide. Sensors 2021, 21, 5543. [Google Scholar] [CrossRef]

- Giurgiutiu, V.; Xu, B.; Liu, W. Development and Testing of High-temperature Piezoelectric Wafer Active Sensors for Extreme Environments. Struct. Health Monit. 2010, 9, 513–525. [Google Scholar] [CrossRef]

- Taziev, R.M.; Kolosovsky, E.A.; Kozlov, A.S. Deformation-sensitive cuts for surface acoustic waves in α-quartz. In Proceedings of the 1993 IEEE International Frequency Control Symposium, Salt Lake City, UT, USA, 2–4 June 1993. [Google Scholar] [CrossRef]

- Taziev, R.M. Stress, temperature and pressure behavior of SAW on langasite plates. In Proceedings of the 2001 IEEE International Frequncy Control Symposium and PDA Exhibition (Cat. No.01CH37218), Seattle, WA, USA, 8 June 2001. [Google Scholar] [CrossRef]

- Go, D.B.; Atashbar, M.Z.; Ramshani, Z.; Chang, H.-C. Surface acoustic wave devices for chemical sensing and microfluidics: A review and perspective. Anal. Methods 2017, 9, 4112–4134. [Google Scholar] [CrossRef]

- Wu, G.; Kong, L.; Fan, M.; Yu, F.; Jiang, C.; Cheng, X.; Zhao, X. Electro-elastic features of YBa3(PO4)3 and YbBa3(PO4)3 crystals with pure face-shear mode for acoustic wave sensor applications. J. Materiomics 2021, 7, 828–836. [Google Scholar] [CrossRef]

- Caliendo, C.; Hamidullah, M. Guided acoustic wave sensors for liquid environments. J. Phys. D: Appl. Phys. 2019, 52, 153001. [Google Scholar] [CrossRef]

- Collins, D.J.; Ma, Z.; Ai, Y. Highly Localized Acoustic Streaming and Size-Selective Submicrometer Particle Concentration Using High Frequency Microscale Focused Acoustic Fields. Anal. Chem. 2016, 88, 5513–5522. [Google Scholar] [CrossRef] [PubMed]

- Jin, S.; Ye, G.; Cao, N.; Liu, X.; Dai, L.; Wang, P.; Wang, T.; Wei, X. Acoustics-Controlled Microdroplet and Microbubble Fusion and Its Application in the Synthesis of Hydrogel Microspheres. Langmuir 2022, 38, 12602–12609. [Google Scholar] [CrossRef] [PubMed]

- Athanassiadis, A.G.; Ma, Z.; Moreno-Gomez, N.; Melde, K.; Choi, E.; Goyal, R.; Fischer, P. Ultrasound-Responsive Systems as Components for Smart Materials. Chem. Rev. 2021, 122, 5165–5208. [Google Scholar] [CrossRef]

- Tayebi, M.; Yang, D.; Collins, D.J.; Ai, Y. Deterministic Sorting of Submicrometer Particles and Extracellular Vesicles Using a Combined Electric and Acoustic Field. Nano Lett. 2021, 21, 6835–6842. [Google Scholar] [CrossRef]

- Zhou, J.; Habibi, R.; Akbaridoust, F.; Neild, A.; Nosrati, R. Paper-Based Acoustofluidics for Separating Particles and Cells. Anal. Chem. 2020, 92, 8569–8578. [Google Scholar] [CrossRef]

- Wu, Z.; Cai, H.; Ao, Z.; Nunez, A.; Liu, H.; Bondesson, M.; Guo, S.; Guo, F. A Digital Acoustofluidic Pump Powered by Localized Fluid-Substrate Interactions. Anal. Chem. 2019, 91, 7097–7103. [Google Scholar] [CrossRef]

- Reyes, C.; Fu, L.; Suthanthiraraj, P.P.A.; Owens, C.E.; Shields, C.W., IV; López, G.P.; Charbonneau, P.; Wiley, B.J. The Limits of Primary Radiation Forces in Bulk Acoustic Standing Waves for Concentrating Nanoparticles. Part. Part. Syst. Charact. 2018, 35, 1700470. [Google Scholar] [CrossRef]

- Xu, X.; Wang, G.; Jiao, W.; Ji, W.; Jiang, M.; Zhang, X. Multi-level sorting of nanoparticles on multi-step optical waveguide splitter. Opt. Express 2018, 26, 29262–29271. [Google Scholar] [CrossRef]

- Ota, N.; Yalikun, Y.; Suzuki, T.; Lee, S.W.; Hosokawa, Y.; Goda, K.; Tanaka, Y. Enhancement in acoustic focusing of micro and nanoparticles by thinning a microfluidic device. R. Soc. Open Sci. 2019, 6, 181776. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Tang, L.; Ji, N.; Liu, G.; Wang, J.; Jiang, H.; Cao, W. Temperature dependence of full set tensor properties of KTiOPO4 single crystal measured from one sample. J. Appl. Phys. 2016, 119, 124104. [Google Scholar] [CrossRef]

- Taziev, R.M. FEM/BEM for Simulation of LSAW Devices. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2007, 54, 2060–2069. [Google Scholar] [CrossRef]

- Campbell, J.J.; Jones, W.R. A method for estimating optimal crystal cuts and propagation directions for excitation of piezoelectric surface waves. IEEE Trans. Sonics Ultrason. 1968, 15, 209–217. [Google Scholar] [CrossRef]

- Farnell, G.W. SAW Propagation in Piezoelectric Solids; Wave Electronics; Wilkinson, C.D.W., Collins, J.H., Dunsmuir, R., Masotti, L., De La Rue, R.M., Eds.; Elsevier Scientific Publishing Company: Amsterdam, The Netherlands, 1976; pp. 1–24. [Google Scholar]

- Slobodnik, A.J. Surface acoustic waves and SAW materials. Proc. IEEE 1976, 64, 581–595. [Google Scholar] [CrossRef]

- Morgan, D.P. Surface Acoustic Wave Filters: With Applications to Electronic Communications and Signal Processing; Academic Press: Amsterdam, The Netherlands, 2007; p. 448. ISBN 9780123725370. [Google Scholar]

- Xu, H.; Jin, H.; Dong, S.; Chen, J.; Song, X.; Xuan, W.; Shi, L.; Huang, S.; Zhang, P.; Luo, J. A langasite surface acoustic wave wide-range temperature sensor with excellent linearity and high sensitivity. AIP Adv. 2021, 11, 015143. [Google Scholar] [CrossRef]

- FlexPDE6. Available online: https://www.pdesolutions.com (accessed on 30 July 2016).

- Bright, V.M.; Hunt, W.D. Analysis of Bleustein–Gulyaev wave propagation under thin periodic metal electrodes. J. Appl. Phys. 1991, 70, 594–602. [Google Scholar] [CrossRef]

- Soluch, W. Calculation of Bleustein-Gulyaev wave parameters in KTiOPO4 crystal. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 1995, 42, 977. [Google Scholar] [CrossRef]

- Baghai-Wadji, A.-R.; Plessky, V.P.; Simonian, A.V. Propagation of Rayleigh type SAW in periodic structures with resonating elements. Sov. Phys. Acoust. 1992, 38, 442–449. [Google Scholar]

- Garova, E.A.; Maradudin, A.A.; Mayer, A.P. Interaction of Rayleigh waves with randomly distributed oscillators on the surface. Phys. Rev. B 1999, 59, 13291–13296. [Google Scholar] [CrossRef]

- Wegert, H.; Mayer, E.A.; Reindl, L.M.; Ruile, W.; Mayer, A.P. Interaction of SAWs with resonating structures on the surface. In Proceedings of the 2010 IEEE International Ultrasonics Symposium, San Diego, CA, USA, 11–14 October 2010; pp. 185–188. [Google Scholar] [CrossRef]

- Baghai-Wadji, A.R.; Maradudin, A.A. Shear horizontal surface acoustic waves on large amplitude gratings. Appl. Phys. Lett. 1991, 59, 1841–1843. [Google Scholar] [CrossRef]

- Maradudin, A.A.; Ryan, P.; McGurn, A.R. Shear horizontal acoustic surface shape resonances. Phys. Rev. B 1988, 38, 3068–3074. [Google Scholar] [CrossRef]

- Socié, L.; Benchabane, S.; Robert, L.; Khelif, A.; Laude, V. Surface acoustic wave guiding in a diffractionless high aspect ratio transducer. Appl. Phys. Lett. 2013, 102, 113508. [Google Scholar] [CrossRef]

- Oliner, A.A. Acoustic Surface Waves; Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 1978; Volume 24, p. 334. [Google Scholar] [CrossRef]

- Frazer, T.D.; Knobloch, J.L.; Hoogeboom-Pot, K.M.; Nardi, D.; Chao, W.; Falcone, R.W.; Murnane, M.M.; Kapteyn, H.C.; Hernandez-Charpak, J.N. Engineering Nanoscale Thermal Transport: Size- and Spacing-Dependent Cooling of Nanostructures. Phys. Rev. Appl. 2019, 11, 024042. [Google Scholar] [CrossRef]

- Ronchi, A.; Sterzi, A.; Gandolfi, M.; Belarouci, A.; Giannetti, C.; Del Fatti, N.; Banfi, F.; Ferrini, G. Discrimination of nano-objects via cluster analysis techniques applied to time-resolved thermo-acoustic microscopy. Ultrasonics 2021, 114, 106403. [Google Scholar] [CrossRef]

- Nardi, D.; Travagliati, M.; Siemens, M.E.; Li, Q.; Murnane, M.M.; Kapteyn, H.C.; Ferrini, G.; Parmigiani, F.; Banfi, F. Probing Thermomechanics at the Nanoscale: Impulsively Excited Pseudosurface Acoustic Waves in Hypersonic Phononic Crystals. Nano Lett. 2011, 11, 4126–4133. [Google Scholar] [CrossRef]

- Gandolfi, M.; Peli, S.; Diego, M.; Danesi, S.; Giannetti, C.; Alessandri, I.; Zannier, V.; Demontis, V.; Rocci, M.; Beltram, F.; et al. Ultrafast Photoacoustic Nanometrology of InAs Nanowires Mechanical Properties. J. Phys. Chem. C 2022, 126, 6361–6372. [Google Scholar] [CrossRef]

- Smagin, N.; Djoumi, L.; Herth, E.; Vanotti, M.; Fall, D.; Blondeau-Patissier, V.; Duquennoy, M.; Ouaftouh, M. Fast time-domain laser Doppler vibrometry characterization of surface acoustic waves devices. Sens. Actuators A Phys. 2017, 264, 96–106. [Google Scholar] [CrossRef]

- Elhady, A.; Abdel-Rahman, E.M. Characterization of Shear Horizontal Waves Using a 1D Laser Doppler Vibrometer. Sensors 2021, 21, 2467. [Google Scholar] [CrossRef]

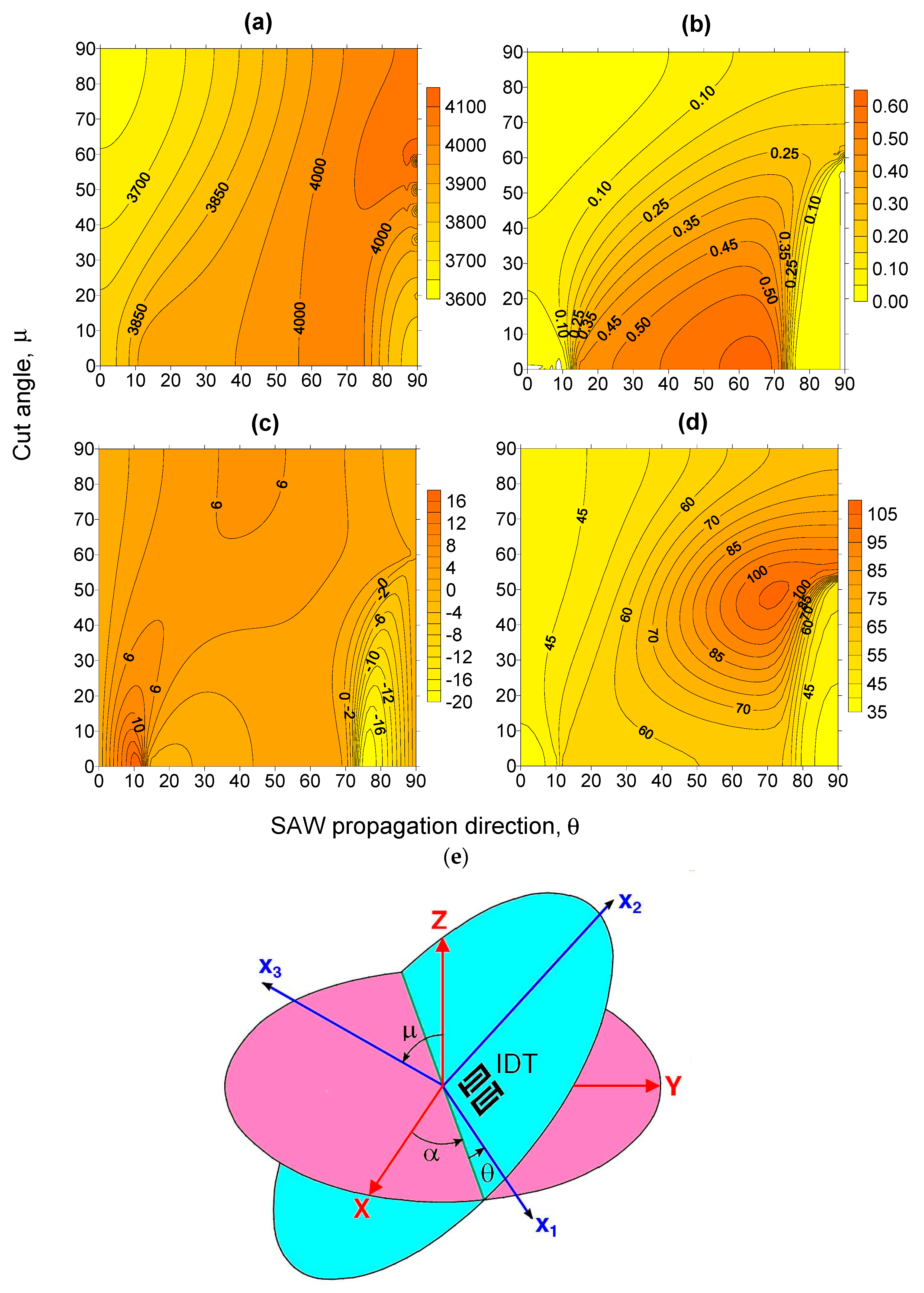

| Crystal Cut and Wave Propagation Direction | Wave Type | Velocity, m/s | ΔV/V, % | TCD, ppm/°C |

|---|---|---|---|---|

| Y,X | BGW | 4289 | 0.018 | 35 |

| X,Y | BGW | 4484 | 0.037 | 41 |

| Z,X | PSAW | 3967 | 0.46 | 57 |

| Z,Y | PSAW | 4113 | 0.66 | 62 |

| Z,X + 70° | SAW | 4047 | 0.59 | 61 |

| X,Z | SAW | 3927 | 0.13 | 72 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Taziev, R.; Atuchin, V. Analysis of SAW Temperature Properties in KTiOPO4 Single Crystal. Materials 2023, 16, 69. https://doi.org/10.3390/ma16010069

Taziev R, Atuchin V. Analysis of SAW Temperature Properties in KTiOPO4 Single Crystal. Materials. 2023; 16(1):69. https://doi.org/10.3390/ma16010069

Chicago/Turabian StyleTaziev, Rinat, and Victor Atuchin. 2023. "Analysis of SAW Temperature Properties in KTiOPO4 Single Crystal" Materials 16, no. 1: 69. https://doi.org/10.3390/ma16010069

APA StyleTaziev, R., & Atuchin, V. (2023). Analysis of SAW Temperature Properties in KTiOPO4 Single Crystal. Materials, 16(1), 69. https://doi.org/10.3390/ma16010069