Effects of Nozzle Details on Print Quality and Hardened Properties of Underwater 3D Printed Concrete

Abstract

1. Introduction

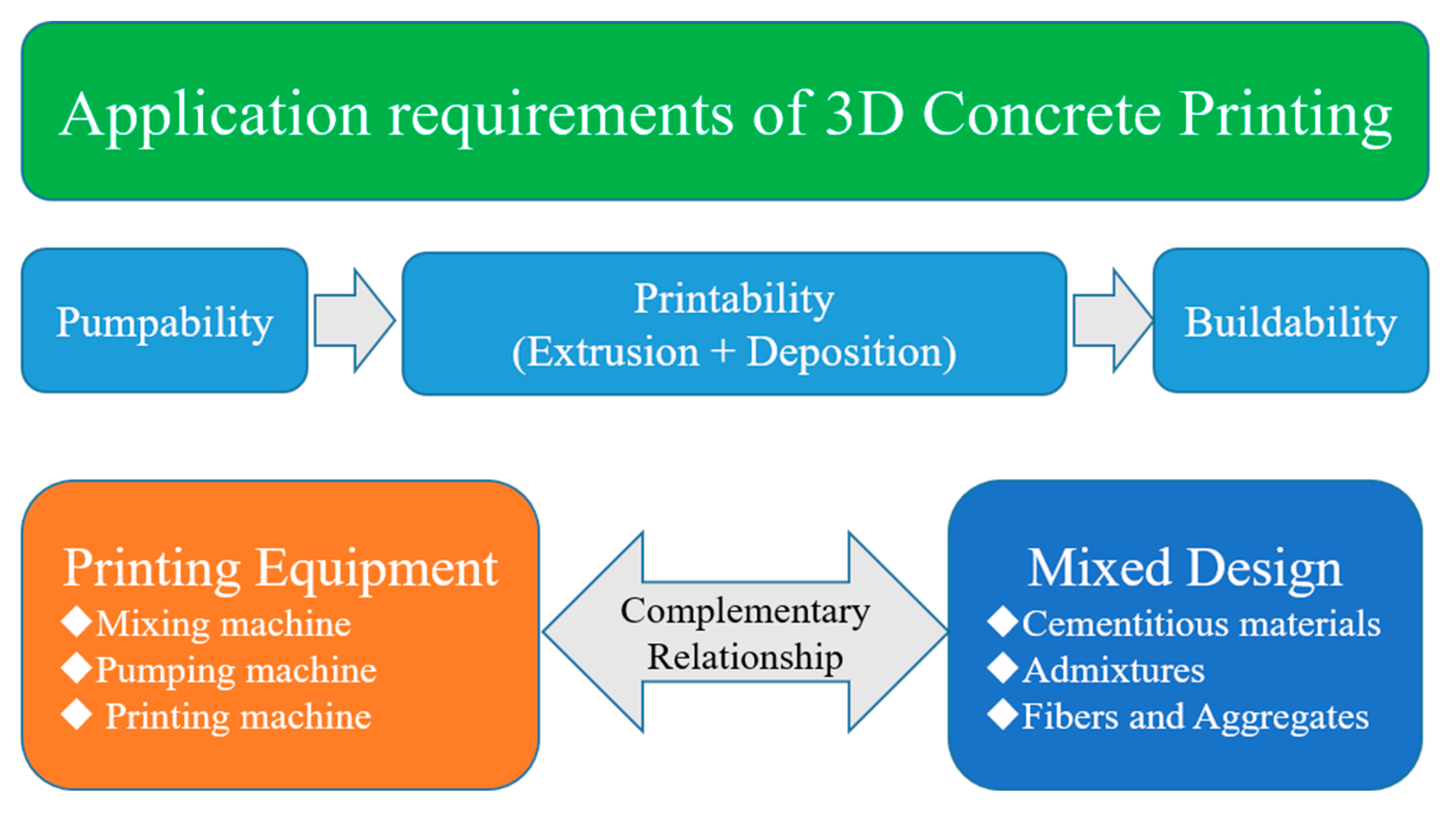

2. Development Methodology of 3DCP System

2.1. Pumpability

2.2. Printability

2.3. Buildability

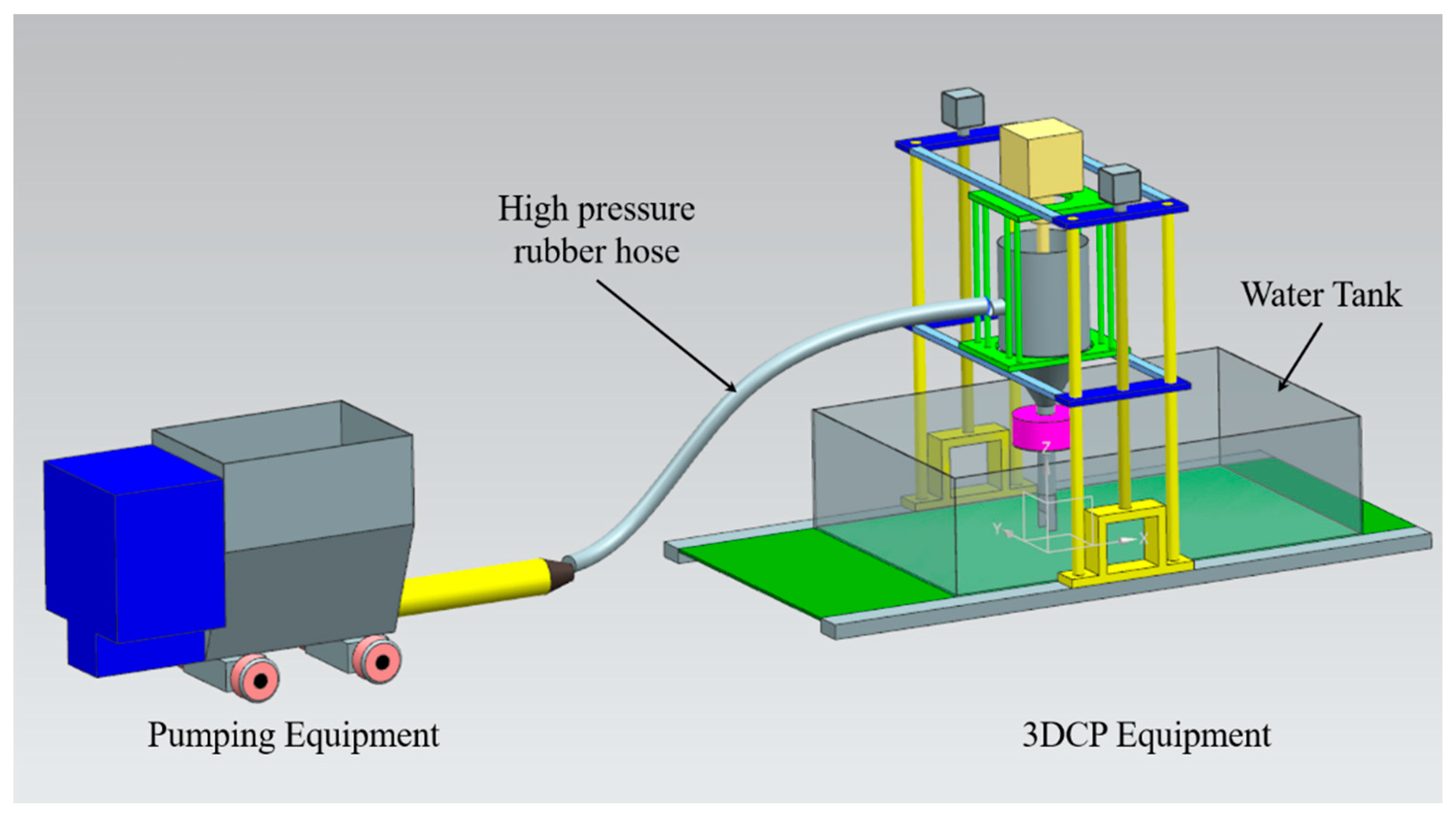

3. Underwater 3DCP System

3.1. 3DCP System

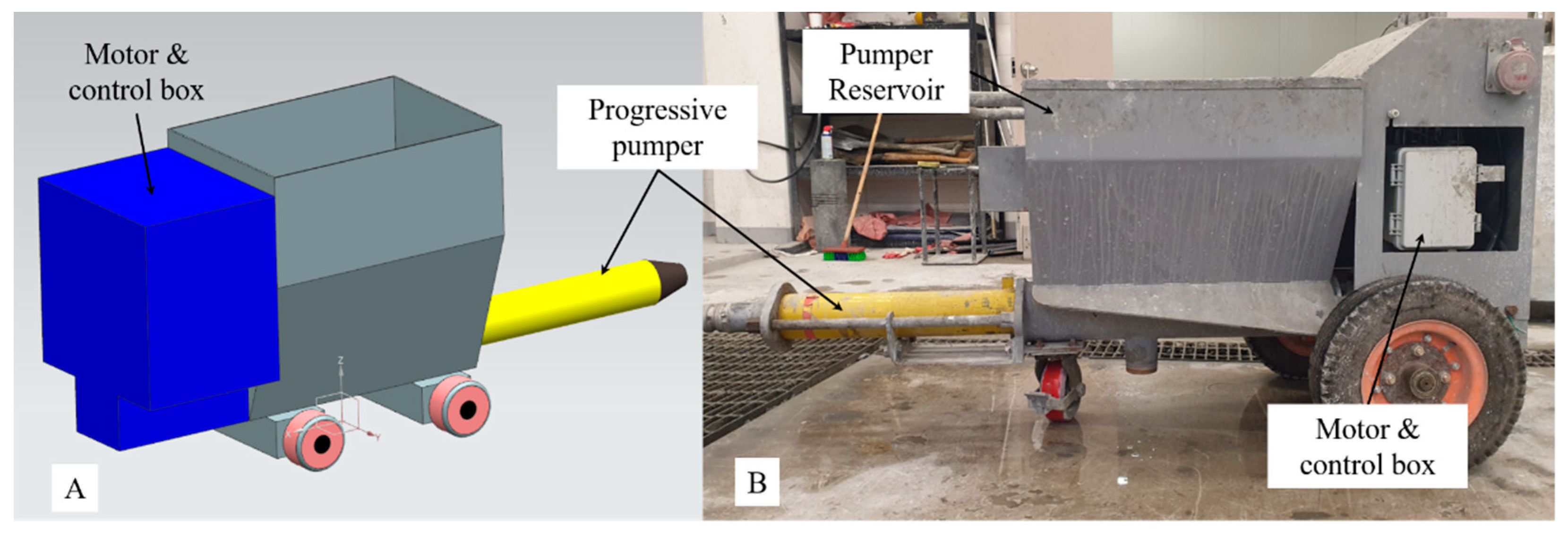

3.1.1. Pumping Equipment of 3DCP System

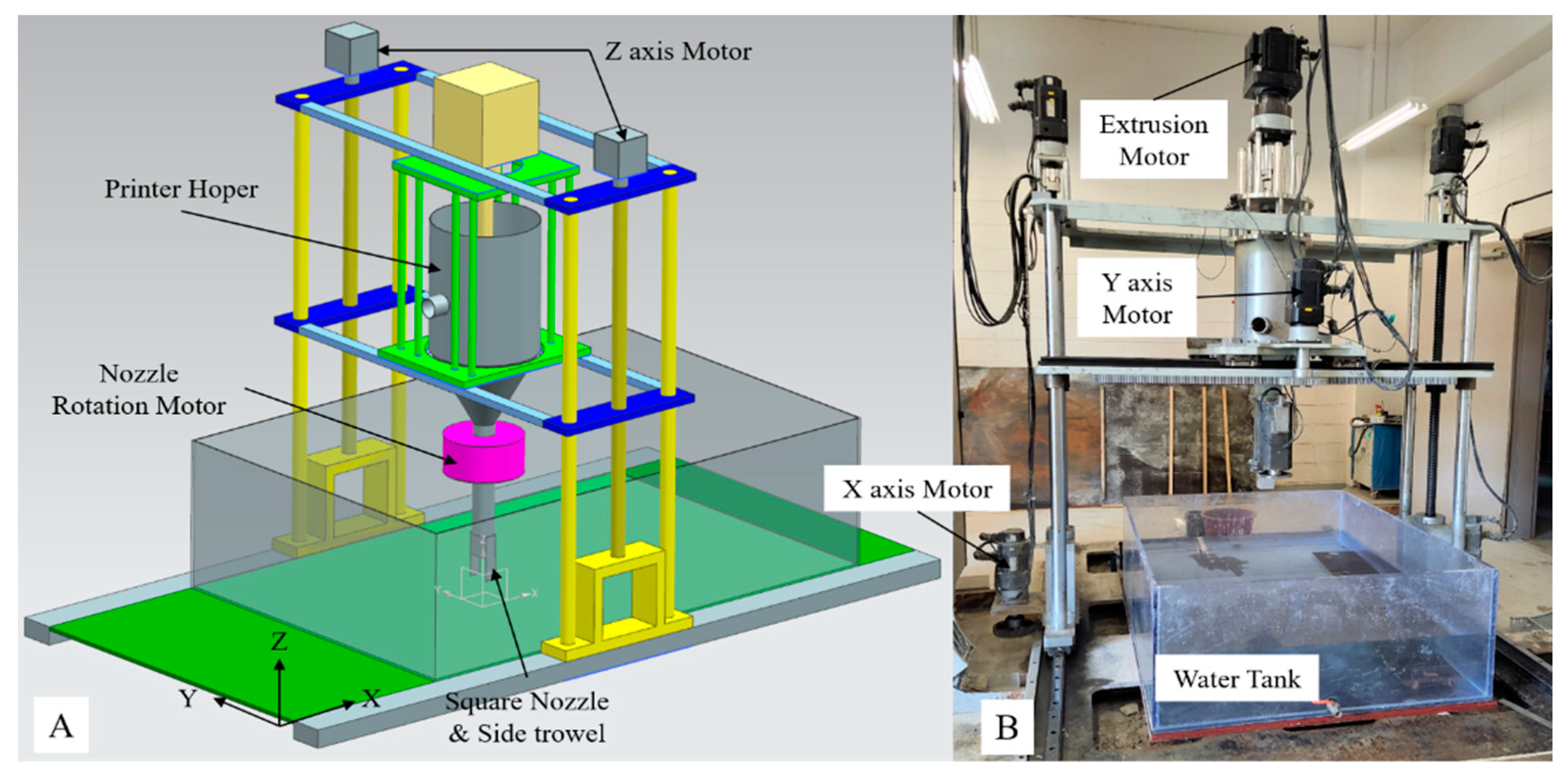

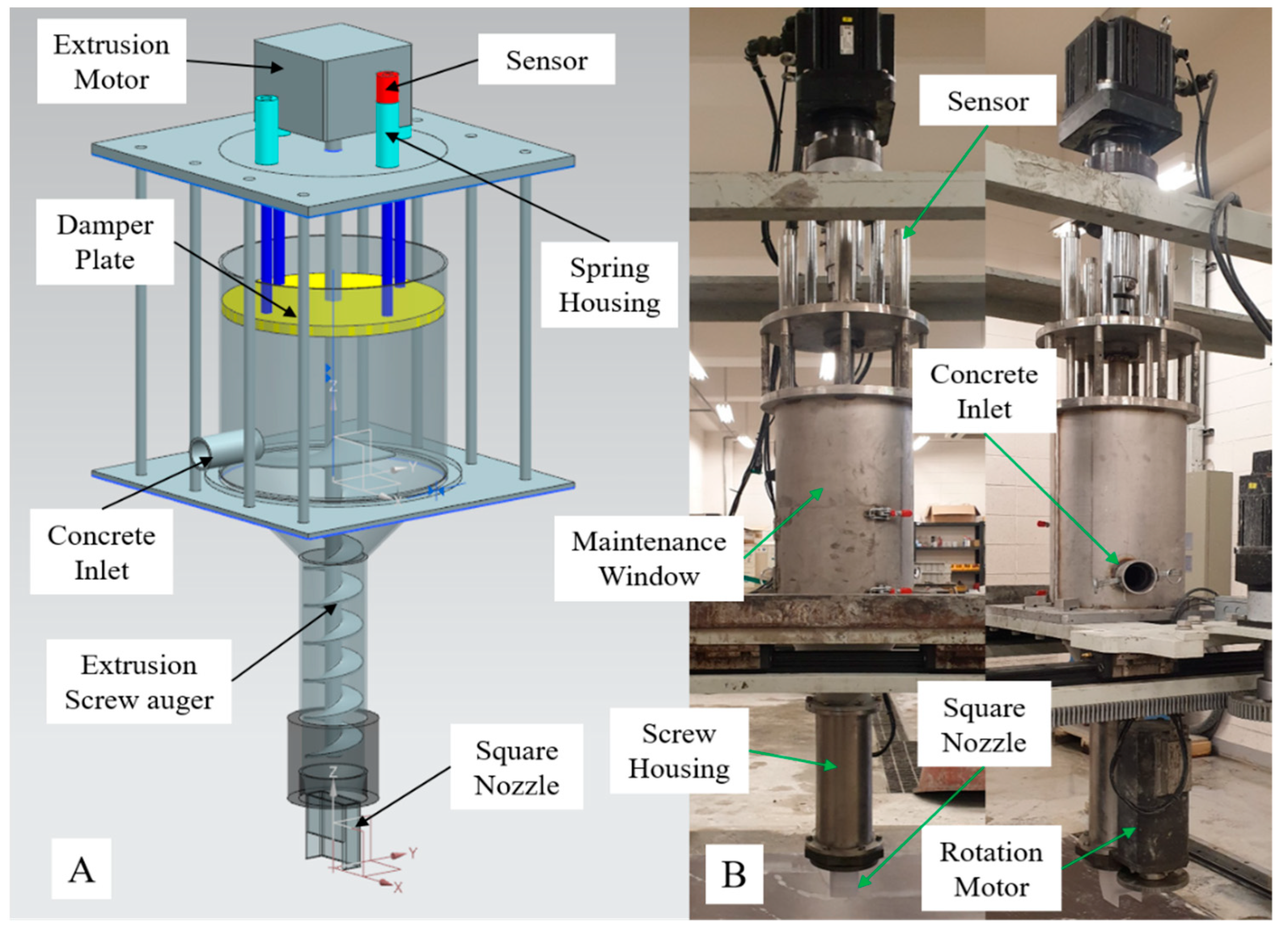

3.1.2. Printing Equipment of 3DCP System

- (1)

- The transferred mixture has the characteristic that it does not flow well under its own weight. Actuation of the pressure plate by a spring transmits an appropriate pressure to the mixture. Thus, when the extrusion motor is operated, the printing material is extruded to the nozzle tip at a constant speed using a screw auger.

- (2)

- The sensors (photo sensors) connected to the pressure plate detect the amount of mixture transferred to the enclosed space of the printer hopper. The sensors consist of an upper limiter and a lower limiter. If the amount of mixture supplied is large, the pressure plate rises and touches the upper limiter, sending a stop signal to the pump. If no mixture is supplied, the plate moves down, touches the lower limiter, and sends an activation signal to the pump. Sending a signal in this way controls the operation of the progressive pump automatically.

- (3)

- It buffers the pulsation problem of the pumping device and the explosion problem of compressed air bubbles, which intermittently occur when transferring the mixture to the print hopper.

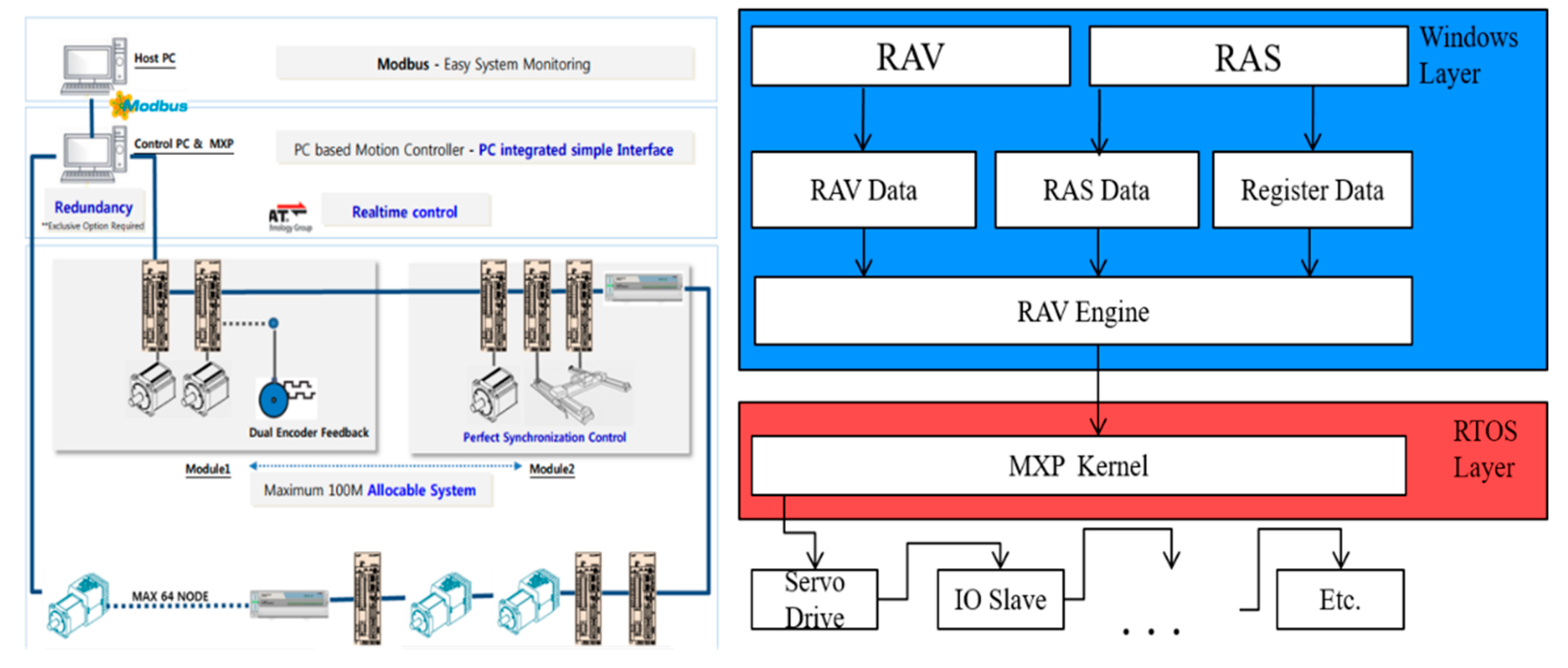

3.2. 3DCP Operation System

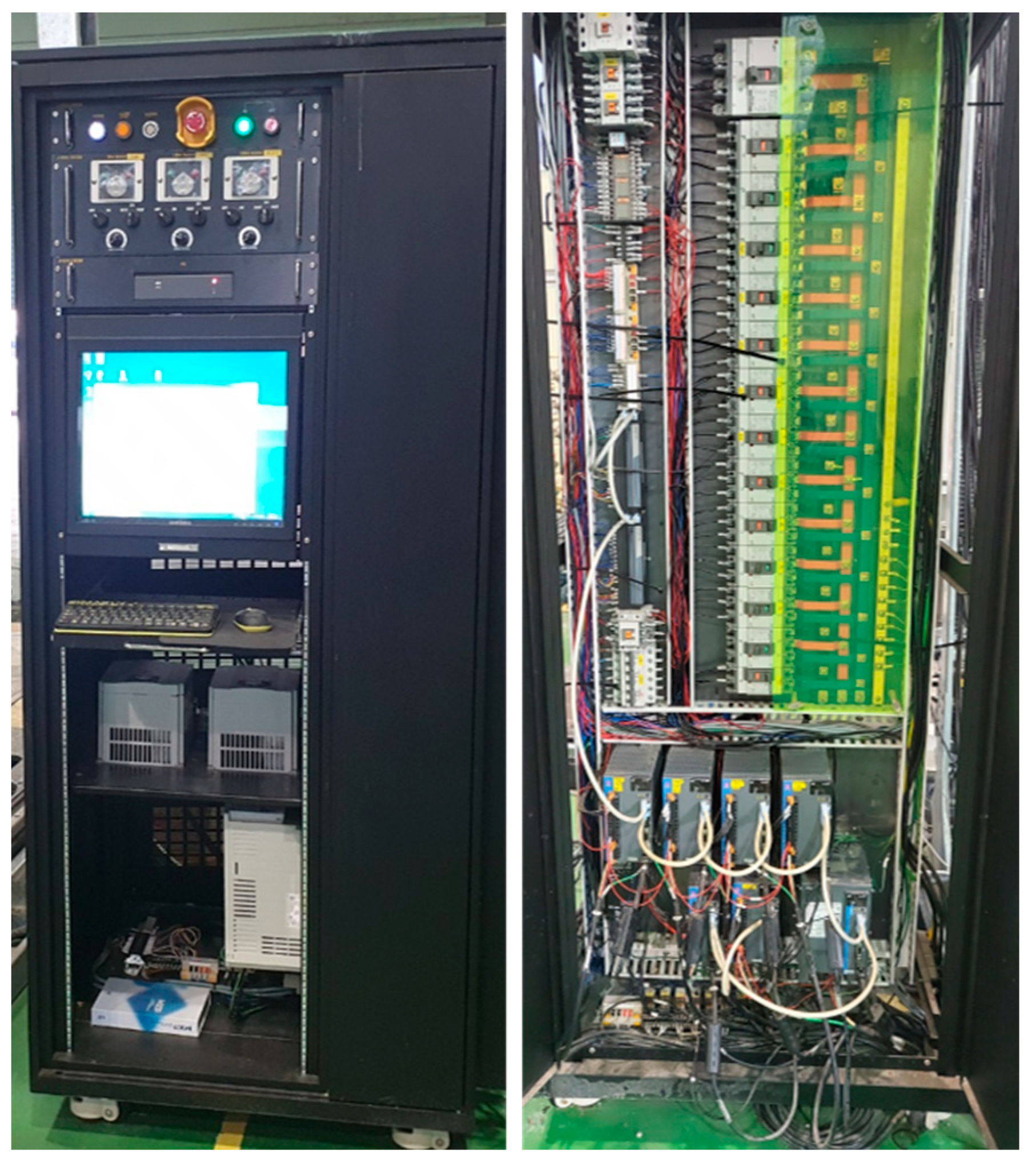

3.2.1. Control Module of 3DCP Equipment

3.2.2. HMI (Human Machine Interface) of 3DCP Operation

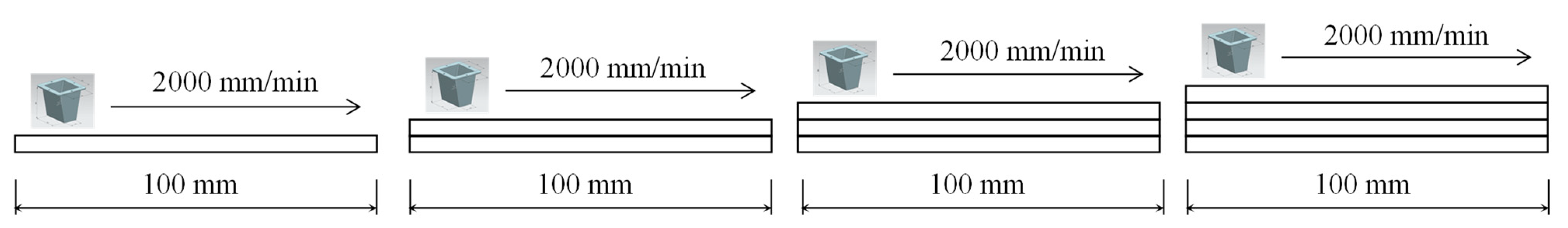

4. Straight-Line Printing Test

4.1. Printing Materials

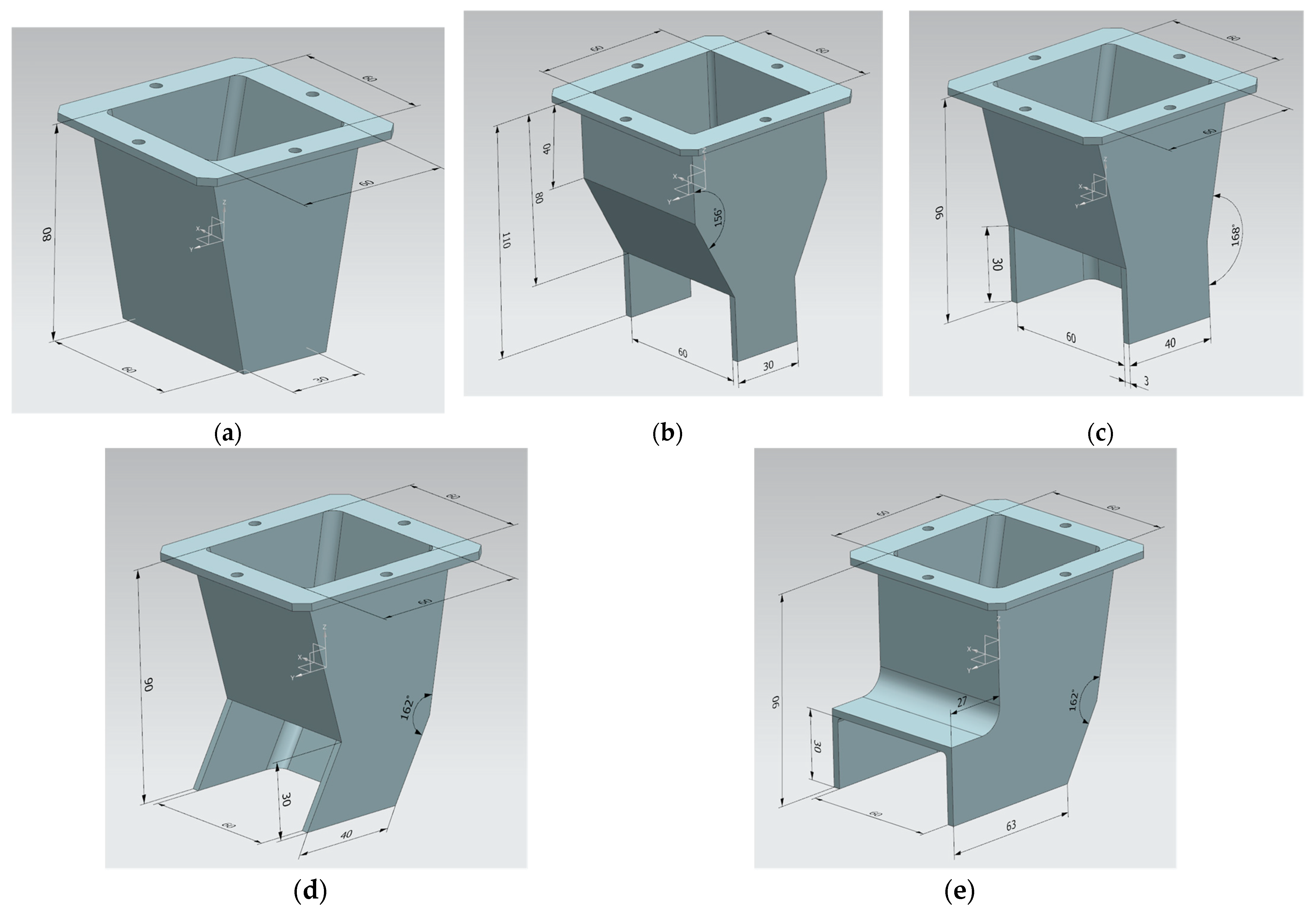

4.2. Nozzle

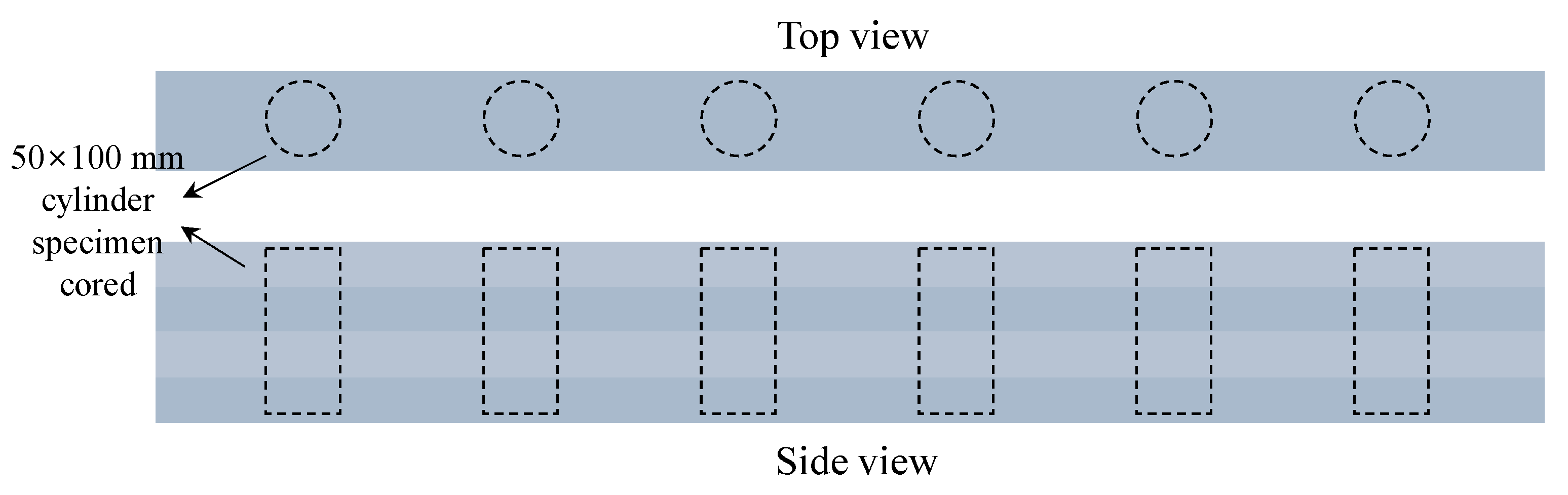

4.3. Evaluation Method

4.4. Evaluation Results

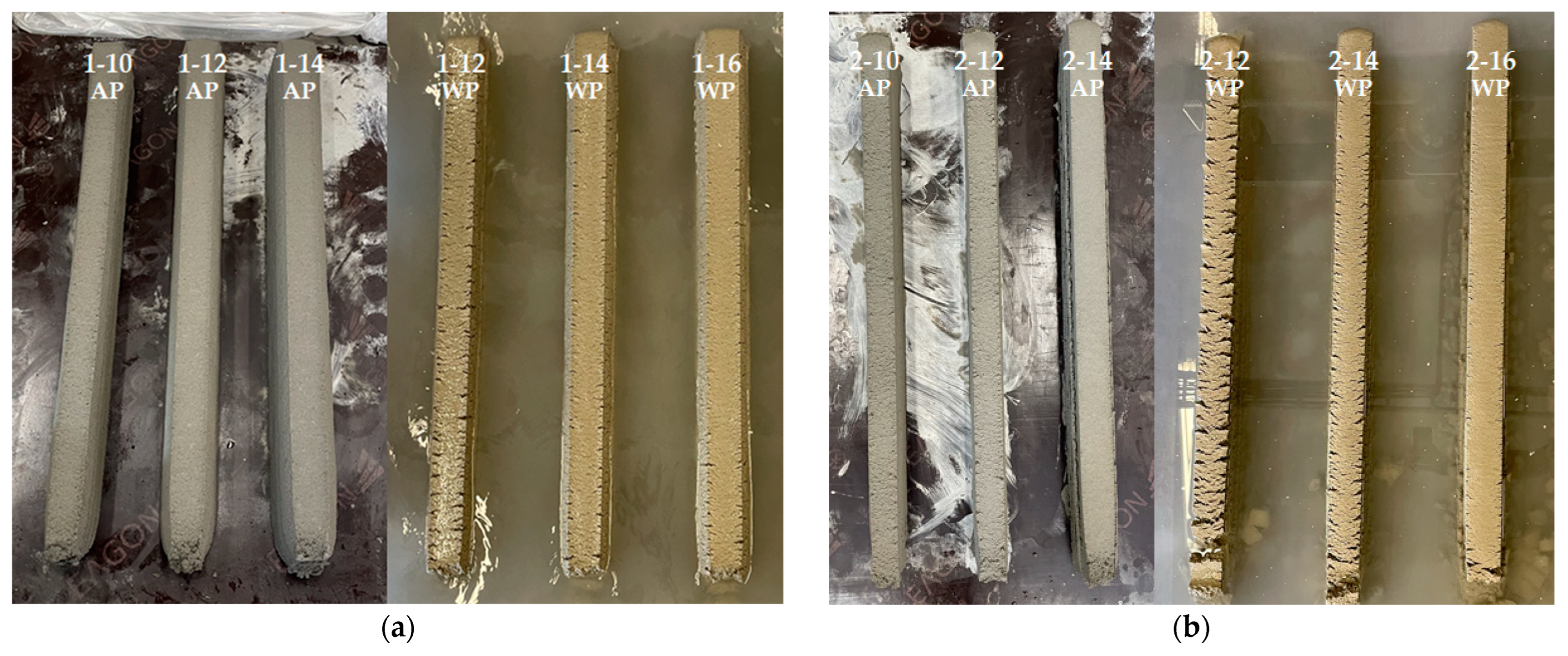

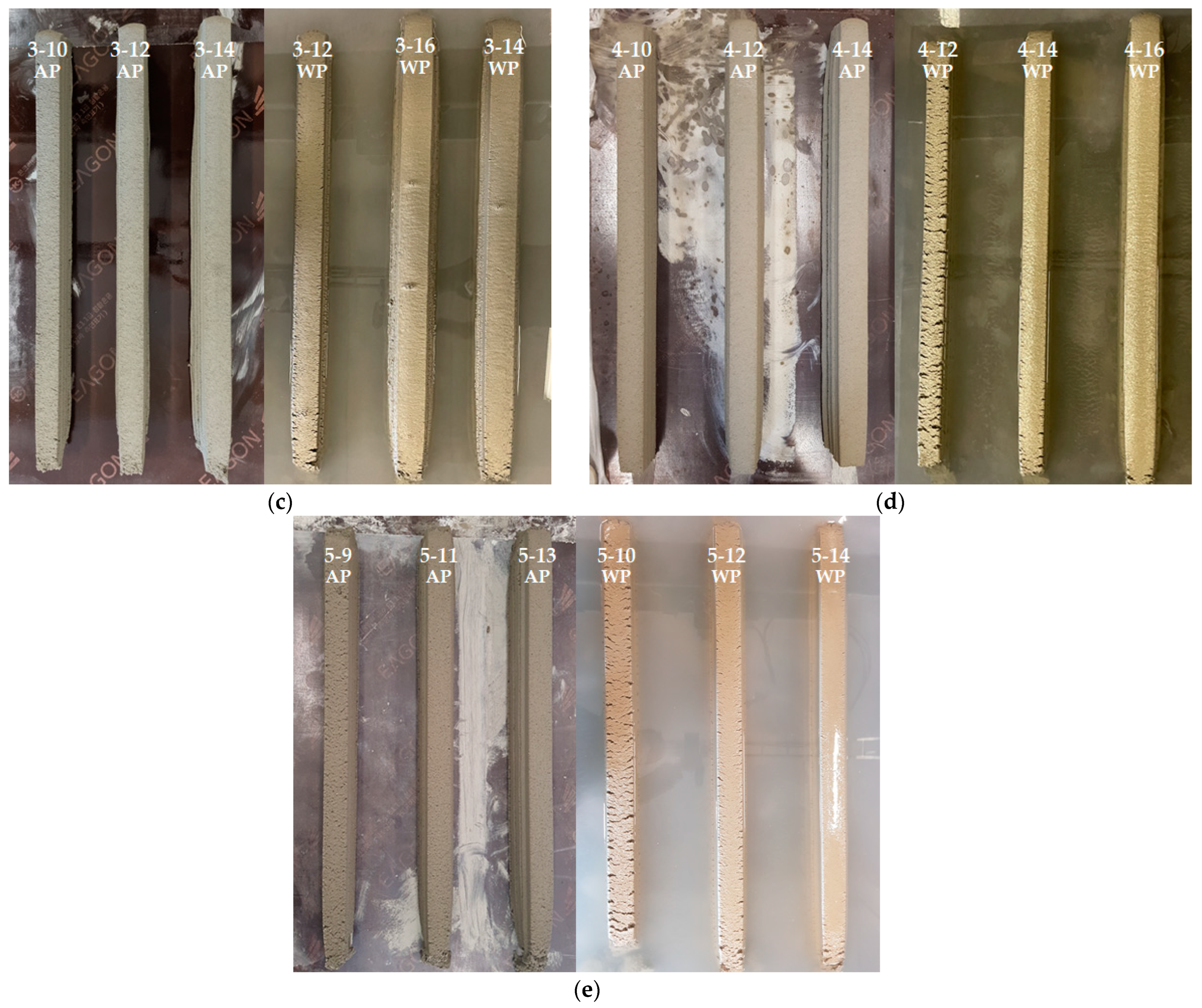

4.4.1. Print Quality

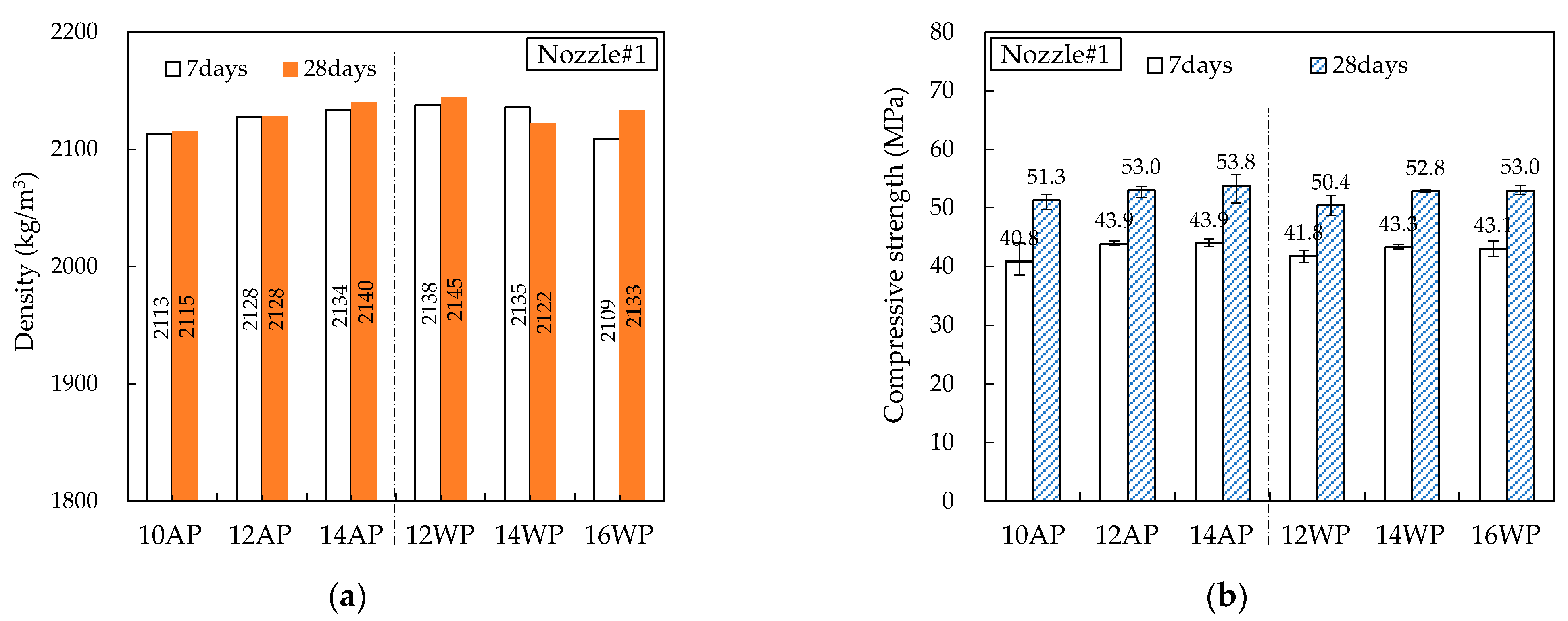

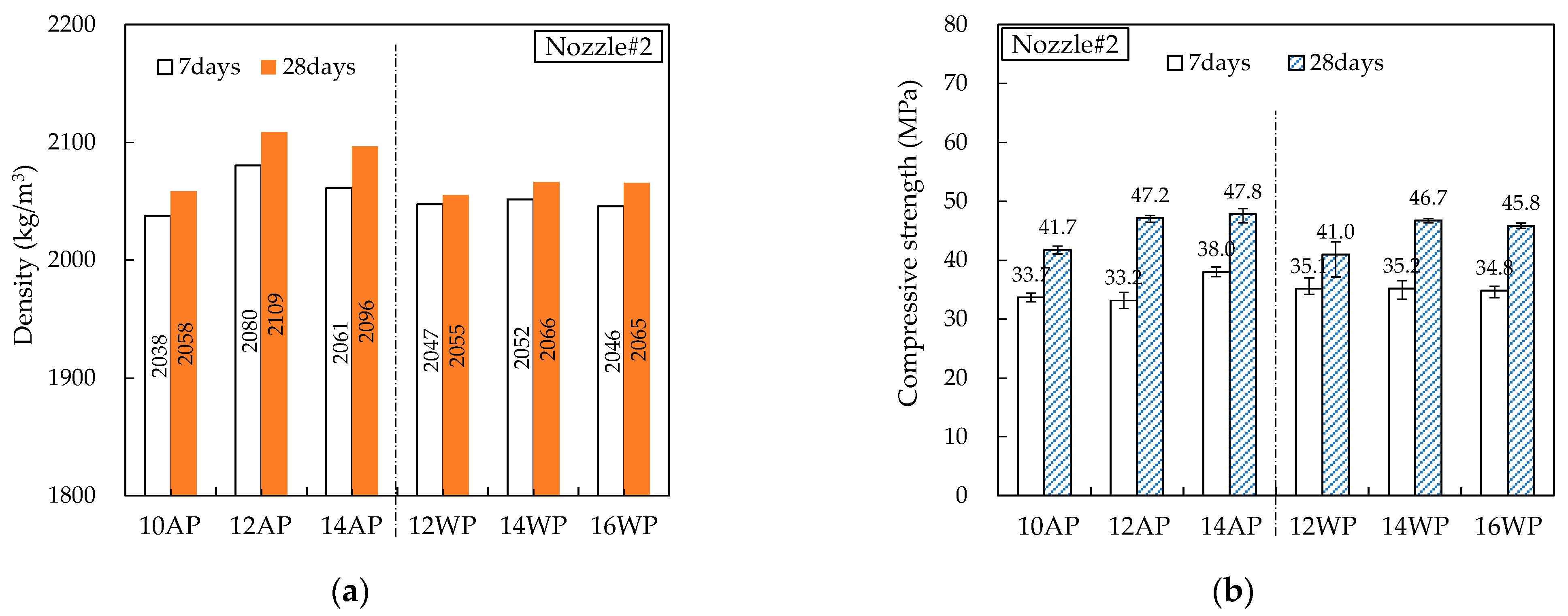

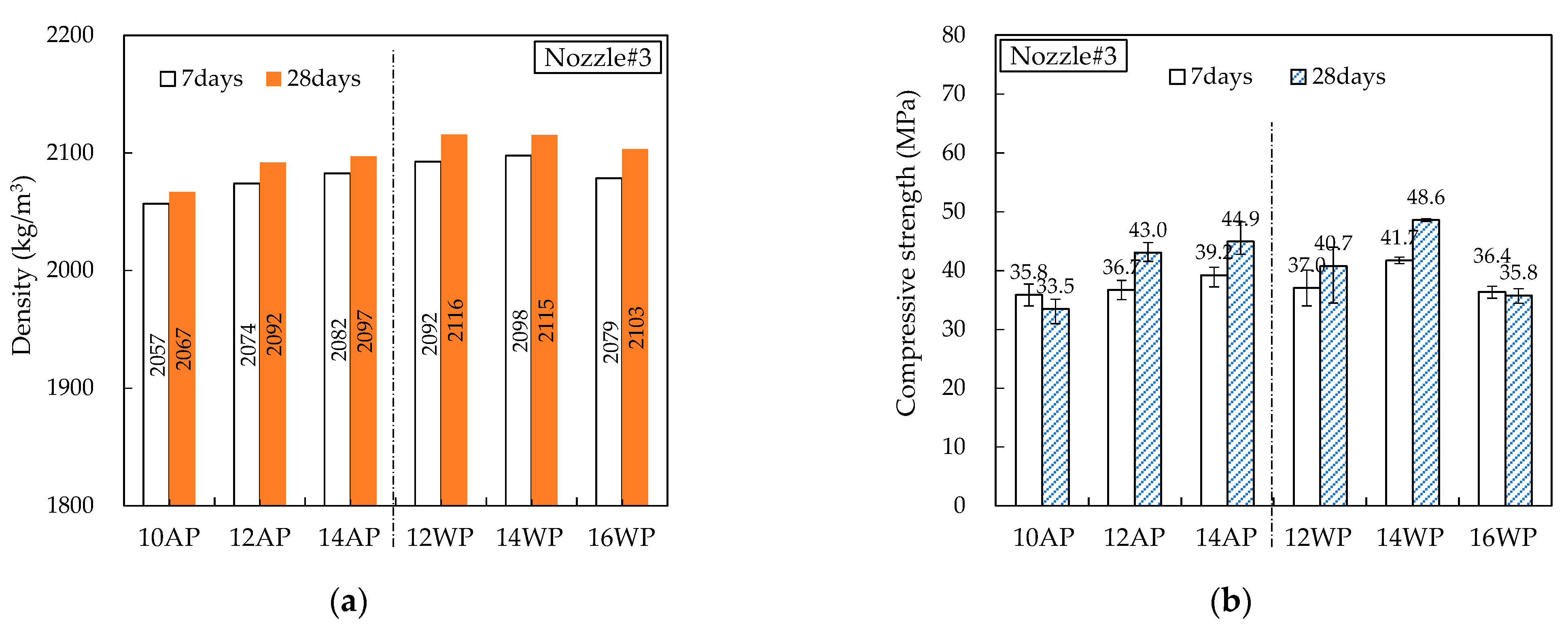

4.4.2. Hardened Properties

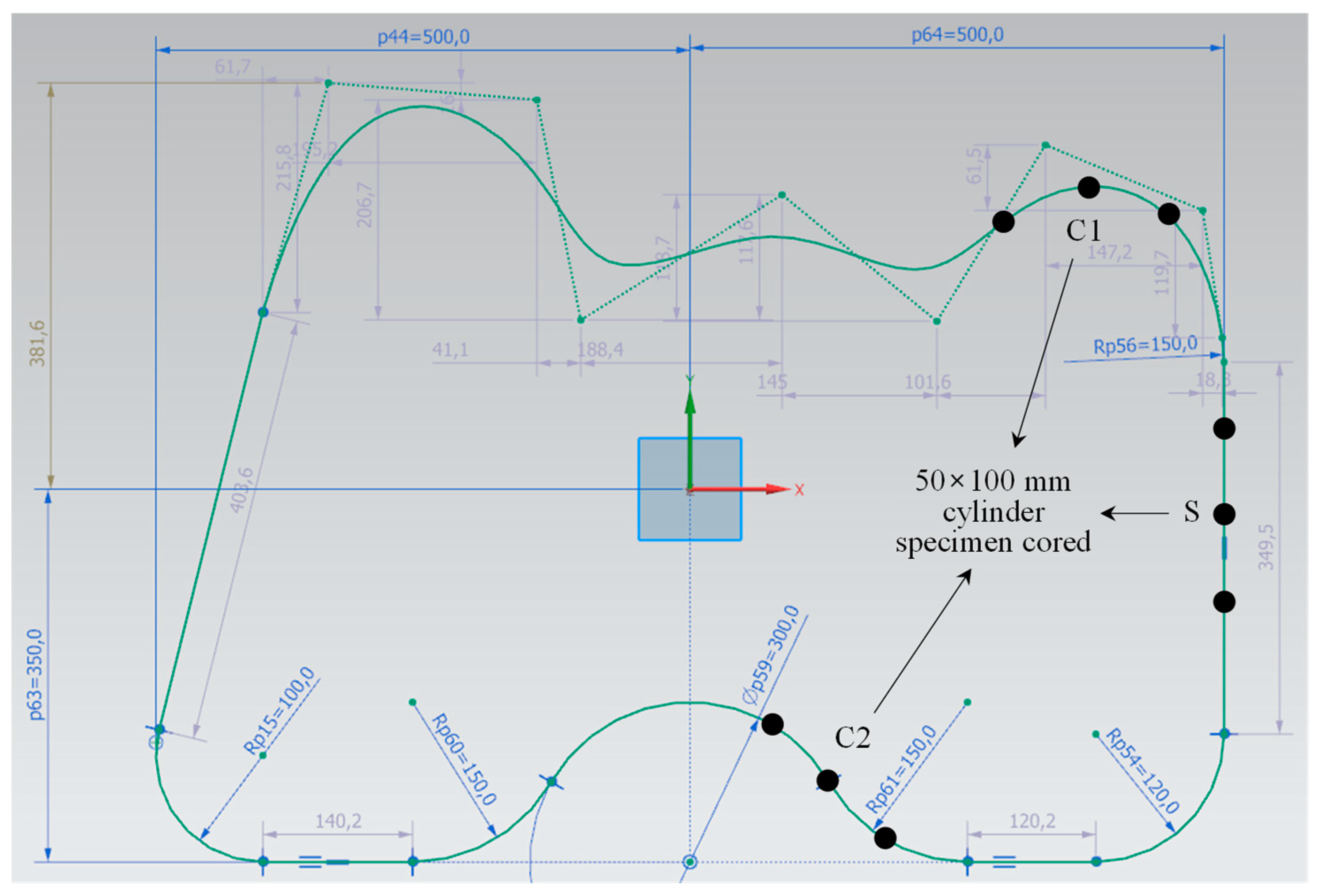

5. Curved Shape Printing Test

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Sanjayan, J.G.; Nematollahi, B. 3D concrete printing for construction applications. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–11. [Google Scholar]

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Nerella, V.N.; Nather, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos. 2019, 95, 260–270. [Google Scholar] [CrossRef]

- Buswell, R.A.; Leal de Silva, W.R.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Nerella, V.N.; Mechtcherine, V. Extrusion of cement-based materials-an overview. RILEM Tech. Lett. 2019, 3, 91–97. [Google Scholar] [CrossRef]

- Bester, F.; van den Heever, M.; Kruger, J.; van Zijl, G. Reinforcing digitally fabricated concrete: A systems approach review. Addit. Manuf. 2021, 37, 101737. [Google Scholar] [CrossRef]

- Kruger, J.; Zeranka, S.; van Zijl, G. An ab initio approach for thixotropy characterisation of (nanoparticle-infused) 3D printable concrete. Construct. Build. Mater. 2019, 224, 372–386. [Google Scholar] [CrossRef]

- Suiker, A.S.J. Mechanical performance of wall structures in 3D printing processes: Theory, design tools and experiments. Int. J. Mech. Sci. 2018, 137, 145–170. [Google Scholar] [CrossRef]

- Wolfs, R.J.M.; Bos, F.P.; Salet, T.A.M. Early age mechanical behaviour of 3D printed concrete: Numerical modelling and experimental testing. Cem. Concr. Res. 2018, 106, 103–116. [Google Scholar] [CrossRef]

- Van den Heever, M.; Bester, F.; Pourbehi, M.; Kruger, J.; Cho, S.; van Zijl, G. Characterizing the fissility of 3D concrete printed elements via the cohesive zone method. In Proceedings of the Second RILEM International Conference on Concrete and Digital Fabrication, Online, 6–9 July 2020; pp. 489–499. [Google Scholar]

- Kruger, J.; van Zijl, G. A comprehensive review on lack-of-fusion in digital concrete fabrication. Addit. Manuf. 2021, 37, 101654. [Google Scholar]

- Asprone, D.; Menna, C.; Bos, F.P.; Salet, T.A.M.; Mata-Falcon, J.; Kaufmann, W. Rethinking reinforcement for digital fabrication with concrete. Cem. Concr. Res. 2018, 112, 111–121. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Grafe, J.; Nerella, V.N.; Spaniol, E.; Hertel, M.; Fussel, U. 3D-printed steel reinforcement for digital concrete construction-manufacture, mechanical properties and bond behavior. Construct. Build. Mater. 2018, 179, 125–137. [Google Scholar] [CrossRef]

- Mazhoud, B.; Perrot, A.; Picandet, V.; Rangerad, D.; Eric, C. Underwater 3D printing of cement-based mortar. Constr. Build. Mater. 2019, 214, 458–467. [Google Scholar] [CrossRef]

- Woo, S.J.; Yang, J.M.; Lee, H.; Kwon, H.K. Comparison of properties of 3D-printed mortar in air vs. underwater. Materials 2021, 14, 5888. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Kasten, K. Testing pumpability of concrete using sliding pipe rheometer. Constr. Build. Mater. 2014, 53, 312–323. [Google Scholar] [CrossRef]

- Paul, S.C.; van Zijl, G.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L. Printable properties of cementitious material containing copper tailings for extrusion based 3D printing. Constr. Build. Mater. 2018, 162, 613–627. [Google Scholar] [CrossRef]

- Kwon, H.K. Experimentation and Analysis of Contour Crafting (CC) Process using Ceramic Materials. Ph.D. Thesis, University of Southern California, Los Angeles, CA, USA, 2002. [Google Scholar]

- Lee, H.J.; Kim, J.H.; Moon, J.H.; Kim, W.W.; Seo, E.A. Evaluation of the mechanical properties of a 3D-printed mortar. Materials 2019, 12, 4104. [Google Scholar] [CrossRef]

- Roussel, N. Rheological requirements for printable concretes. Cem. Concr. Res. 2018, 112, 76–85. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Qian, Y.; Tan, M.J. Printability region for 3D concrete printing using slump and slump flow test. Compos. Part B Eng. 2019, 174, 106968. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Gan, Y.; Çopuroğlu, O.; Veer, F.; Schlangen, E. A review of printing strategies, sustainable cementitious materials and characterization methods in the context of extrusion-based 3D concrete printing. J. Build. Eng. 2022, 45, 103599. [Google Scholar] [CrossRef]

- Khoshnevis, B. Automated construction by contour crafting–related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Nather, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Ji, G.; Ding, T.; Xiao, J.; Du, S.; Li, J.; Duan, Z. A 3D printed ready-mixed concrete power distribution substation: Materials and construction technology. Materials 2019, 12, 1–14. [Google Scholar] [CrossRef] [PubMed]

- LS Mecapion. Motion Controller Product Introduction. 2022. Available online: https://www.lsmecapion.com/bbs/board.php?bo_table=pd_motion_mxp (accessed on 7 October 2022).

- ASTM C150; American Society for Testing and Materials. Standard Specification for Portland Cement. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM C1240; American Society for Testing and Materials. Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2020.

- Meurer, M.; Classen, M. Mechanical properties of hardened 3D printed concretes and mortars-Development of a consistent experimental characterization strategy. Materials 2021, 14, 752. [Google Scholar] [CrossRef] [PubMed]

- ASTM C1437; American Society for Testing and Materials. Standard Test Method for Flow of Hydraulic Cement Mortar. ASTM International: West Conshohocken, PA, USA, 2020.

- Kazemian, A.; Yuan, X.; Meier, R.; Khoshnevis, B. Performance-based testing of Portland cement concrete for construction-scale 3D printing. In 3D Concrete Printing Technology; Elsevier: Amsterdam, The Netherlands, 2019; pp. 13–35. [Google Scholar]

- BS EN 12390-7:2009; Testing Hardened Concrete-Density of Hardened Concrete. British Standards Institution: London, UK, 2009.

- ASTM C39/C39M; American Society for Testing and Materials. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2014.

| Moving Distance | Drive Guide Type | Repetition Accuracy | |

|---|---|---|---|

| X1-axis | 2500 mm | Guide rail & Rack gears | +0.05 mm |

| X2-axis | 2500 mm | Guide rail & Rack gears | +0.05 mm |

| Y1-axis | 1200 mm | Guide rail & Rack gears | +0.05 mm |

| Z1-axis | 1500 mm | Ball screw | +0.02 mm |

| Z2-axis | 1500 mm | Ball screw | +0.02 mm |

| A-axis | - | Spur gear | +0.02° |

| Spindle axis | - | Screw auger | +0.01° |

| Rated Power (W) | Rated Revolution per Min (rpm) | Rated Torque (N.m) | Brake | Encoder | Motor Reducer | |

|---|---|---|---|---|---|---|

| X1-axis | 1.5 K | 3000 | 4.77 | o | Serial 19 bit | 10:1 |

| X2-axis | 1.5 K | 3000 | 4.77 | o | Serial 19 bit | 10:1 |

| Y1-axis | 1.5 K | 3000 | 4.77 | o | Serial 19 bit | 10:1 |

| Z1-axis | 1.5 K | 3000 | 4.77 | o | Serial 19 bit | 10:1 |

| Z2-axis | 1.5 K | 3000 | 4.77 | o | Serial 19 bit | 10:1 |

| A-axis | 0.75 K | 3000 | 2.39 | o | Serial 19 bit | 10:1 |

| Spindle axis | 5.5 K | 2000 | 26.35 | o | Serial 19 bit | 20:1 |

| Printing Test | W/B (%) | Unit Weight (kg/m3) | Admixture (%) | Slump Flow (mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W | C | SF | S | VMA | HRWRA | (1) | (2) | |||

| Straight line | Nozzle#1 | 38.4 | 250 | 586 | 66 | 1310 | 2.0 | 0.7 | 120 | 128 |

| Nozzle#2 | 0.7 | 113 | 119 | |||||||

| Nozzle#3 | 0.7 | 111 | 118 | |||||||

| Nozzle#4 | 0.7 | 117 | 123 | |||||||

| Nozzle#5 | 0.8 | 114 | 119 | |||||||

| Curved shape | 0.5 | 110 | 114 | |||||||

| Printing Test | Specimen | Free of Surface Defects | Deformation Degree | Dimensional Consistency | Overall Print Quality | |

|---|---|---|---|---|---|---|

| Straight line | Nozzle#1 | 1–10 AP | 2 | 4 | 2 | 2.7 |

| 1–12 AP | 1 | 5 | 2 | 2.7 | ||

| 1–14 AP | 1 | 5 | 2 | 2.7 | ||

| 1–10 WP | 4 | 4 | 2 | 3.3 | ||

| 1–12 WP | 3 | 5 | 2 | 3.3 | ||

| 1–14 WP | 3 | 5 | 2 | 3.3 | ||

| Nozzle#2 | 2–10 AP | 2 | 2 | 1 | 1.7 | |

| 2–12 AP | 2 | 2 | 1 | 1.7 | ||

| 2–14 AP | 1 | 3 | 1 | 1.7 | ||

| 2–12 WP | 5 | 2 | 1 | 2.7 | ||

| 2–14 WP | 4 | 3 | 1 | 2.7 | ||

| 2–16 WP | 3 | 4 | 1 | 2.7 | ||

| Nozzle#3 | 3–10 AP | 2 | 2 | 1 | 1.7 | |

| 3–12 AP | 1 | 3 | 1 | 1.7 | ||

| 3–14 AP | 1 | 4 | 1 | 2.0 | ||

| 3–12 WP | 3 | 3 | 1 | 2.3 | ||

| 3–14 WP | 2 | 4 | 1 | 2.3 | ||

| 3–16 WP | 1 | 5 | 1 | 2.3 | ||

| Nozzle#4 | 4–10 AP | 1 | 2 | 1 | 1.3 | |

| 4–12 AP | 1 | 2 | 1 | 1.3 | ||

| 4–14 AP | 1 | 3 | 1 | 1.7 | ||

| 4–12 WP | 4 | 2 | 1 | 2.3 | ||

| 4–14 WP | 2 | 3 | 1 | 2.0 | ||

| 4–16 WP | 1 | 5 | 1 | 2.3 | ||

| Nozzle#5 | 5–9 AP | 3 | 2 | 1 | 2.0 | |

| 5–11 AP | 2 | 3 | 1 | 2.0 | ||

| 5–13 AP | 1 | 4 | 1 | 2.0 | ||

| 5–10 WP | 4 | 3 | 1 | 2.7 | ||

| 5–12 WP | 2 | 4 | 1 | 2.3 | ||

| 5–14 WP | 1 | 5 | 1 | 2.3 | ||

| Curved shape | 3 | 3 | 3 | 3.0 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.-M.; Park, I.-B.; Lee, H.; Kwon, H.-K. Effects of Nozzle Details on Print Quality and Hardened Properties of Underwater 3D Printed Concrete. Materials 2023, 16, 34. https://doi.org/10.3390/ma16010034

Yang J-M, Park I-B, Lee H, Kwon H-K. Effects of Nozzle Details on Print Quality and Hardened Properties of Underwater 3D Printed Concrete. Materials. 2023; 16(1):34. https://doi.org/10.3390/ma16010034

Chicago/Turabian StyleYang, Jun-Mo, In-Beom Park, Hojae Lee, and Hong-Kyu Kwon. 2023. "Effects of Nozzle Details on Print Quality and Hardened Properties of Underwater 3D Printed Concrete" Materials 16, no. 1: 34. https://doi.org/10.3390/ma16010034

APA StyleYang, J.-M., Park, I.-B., Lee, H., & Kwon, H.-K. (2023). Effects of Nozzle Details on Print Quality and Hardened Properties of Underwater 3D Printed Concrete. Materials, 16(1), 34. https://doi.org/10.3390/ma16010034