Defect Detection of Composite Material Terahertz Image Based on Faster Region-Convolutional Neural Networks

Abstract

1. Introduction

2. Principles and Methods

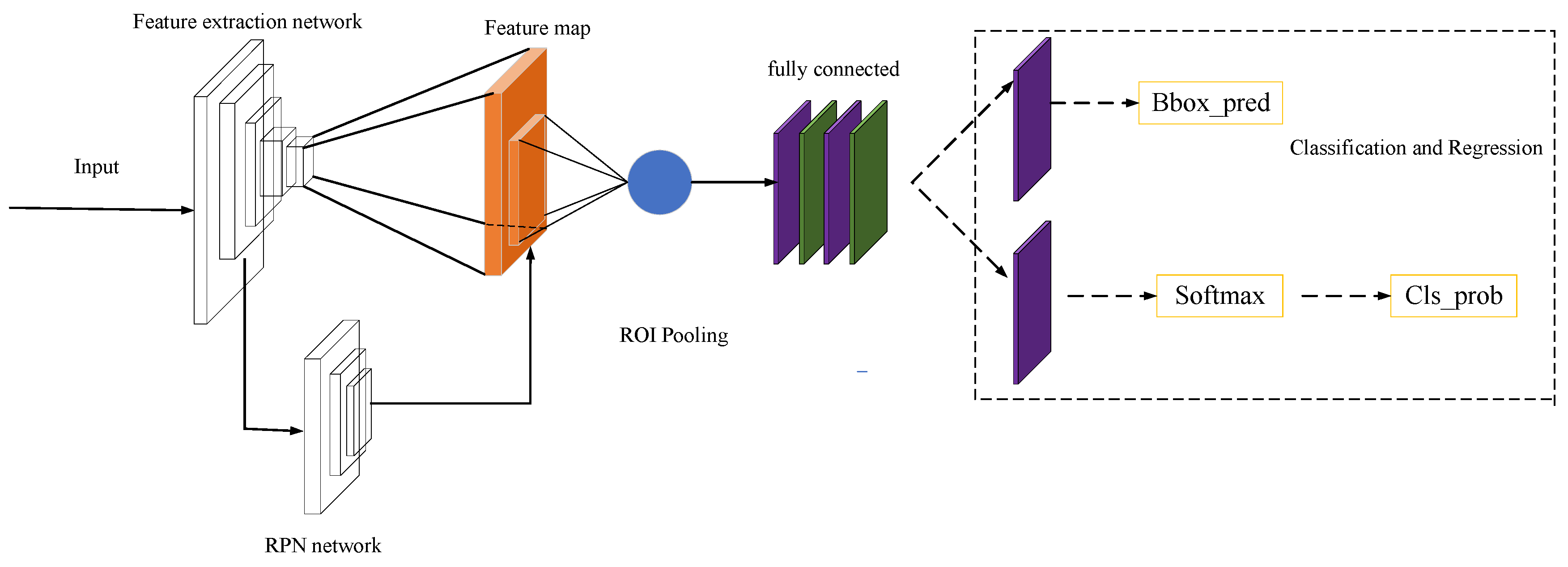

2.1. Faster R-CNN

- (1)

- Feature extraction network. The feature extraction of the input image mainly uses convolutional neural network to obtain the feature map of the image.

- (2)

- Candidate region generation network RPN (region proposal network). It is used to generate candidate regions where detection targets may exist. A more accurate detected region is obtained by classifying and regressing the predefined anchor frames on the feature map obtained in the previous step. RPN can improve the efficiency of candidate region selection and greatly reduce network time consumption.

- (3)

- ROI (region of interest) pooling. On the one hand, the corresponding feature vectors are extracted for the candidate regions. On the other hand, the feature maps corresponding to the candidate regions are adjusted to a fixed size to facilitate subsequent accurate classification.

- (4)

- Classification and regression. Softmax is used to classify the feature vectors to determine the categories. Then the exact position is selected for the detection box by using bbox_pred.

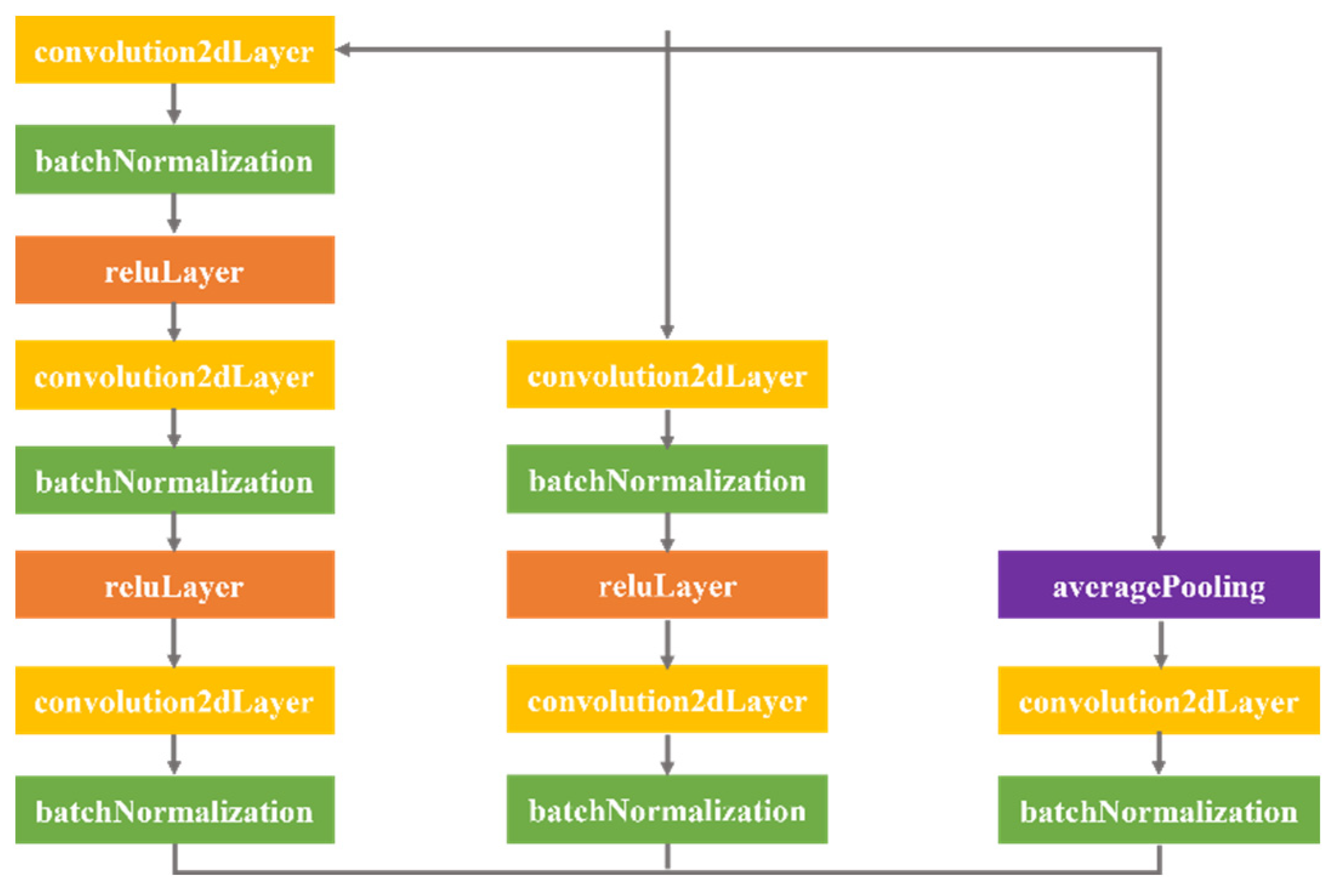

2.2. The Improved Faster R-CNN

- (1)

- Backbone network improvement

- (2)

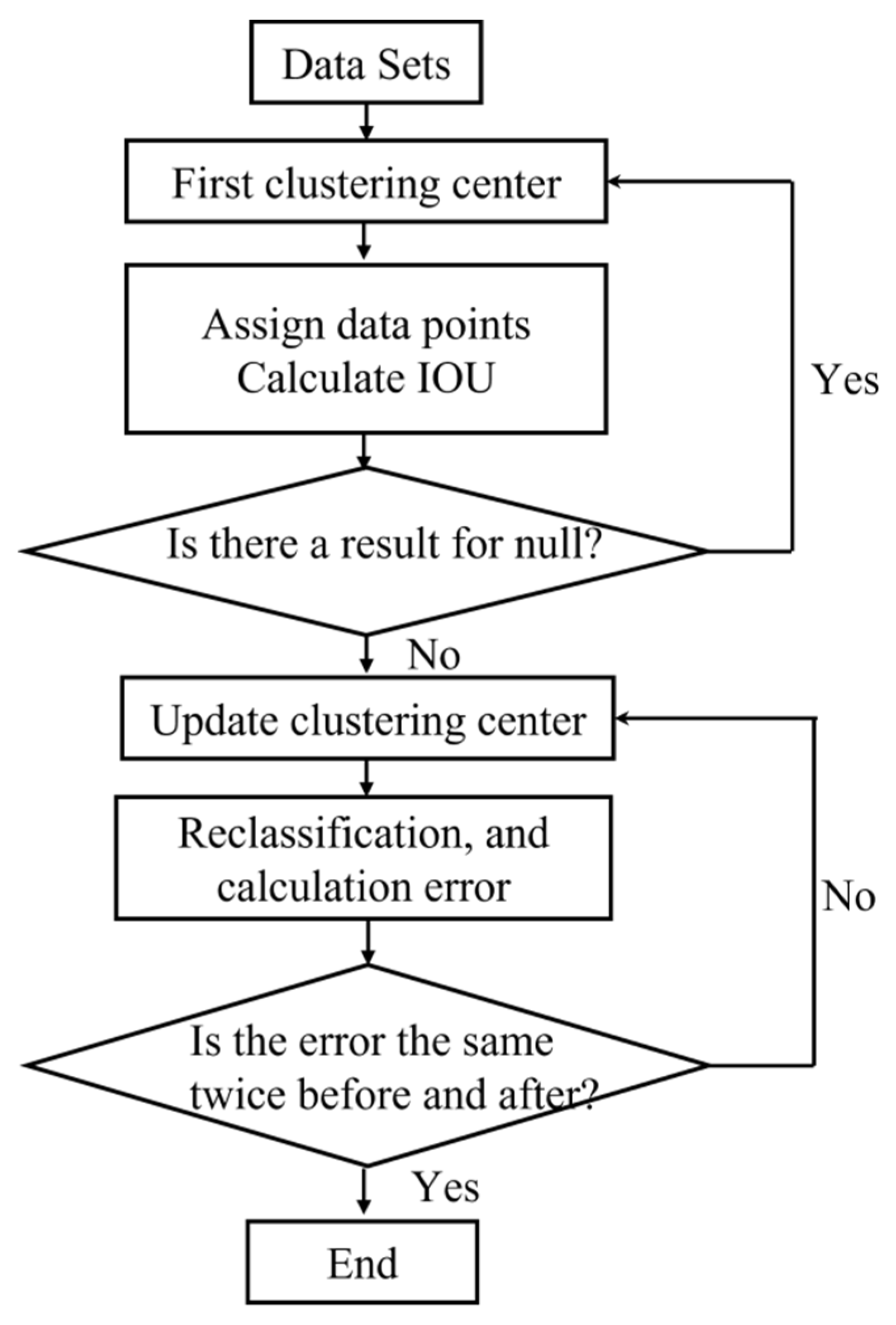

- Anchor boxes for resetting datasets

- (3)

- Bayesian optimisation network training hyperparameter

- ①

- Determine the maximum number of iterations N.

- ②

- Use the collection function to obtain the evaluation point xi.

- ③

- Evaluate the objective function value yi by using the evaluation point xi.

- ④

- Update the probabilistic proxy model after integrating data Dt.

- ⑤

- Return to step ② and continue iterating if the current number of iterations n is the maximum number of iterations N; otherwise, output xi.

2.3. Evaluation Indicators

- (1)

- Recall and precision

- (2)

- Average precision (AP)

- (3)

- mAP

3. Experiments and Equipment

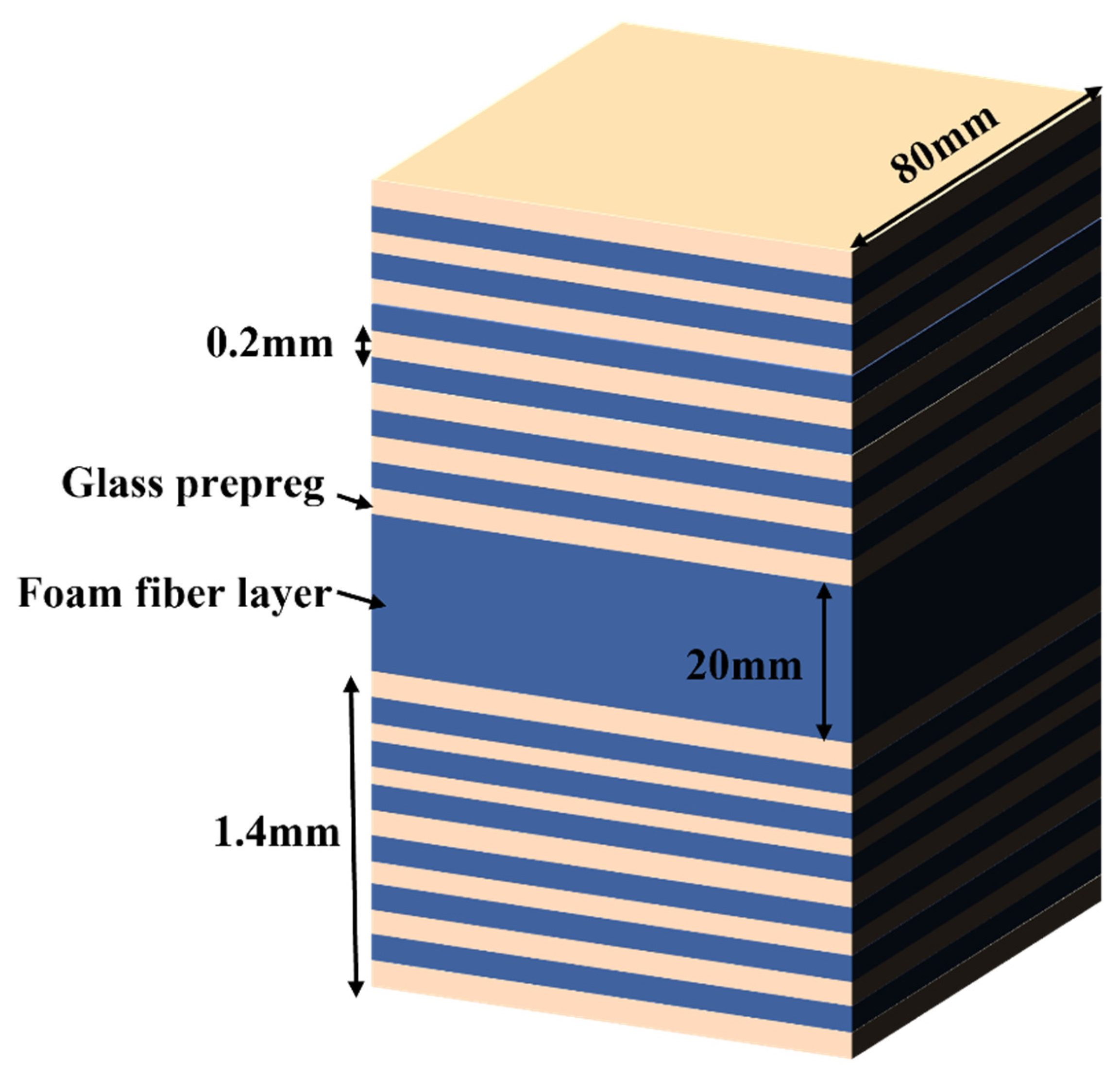

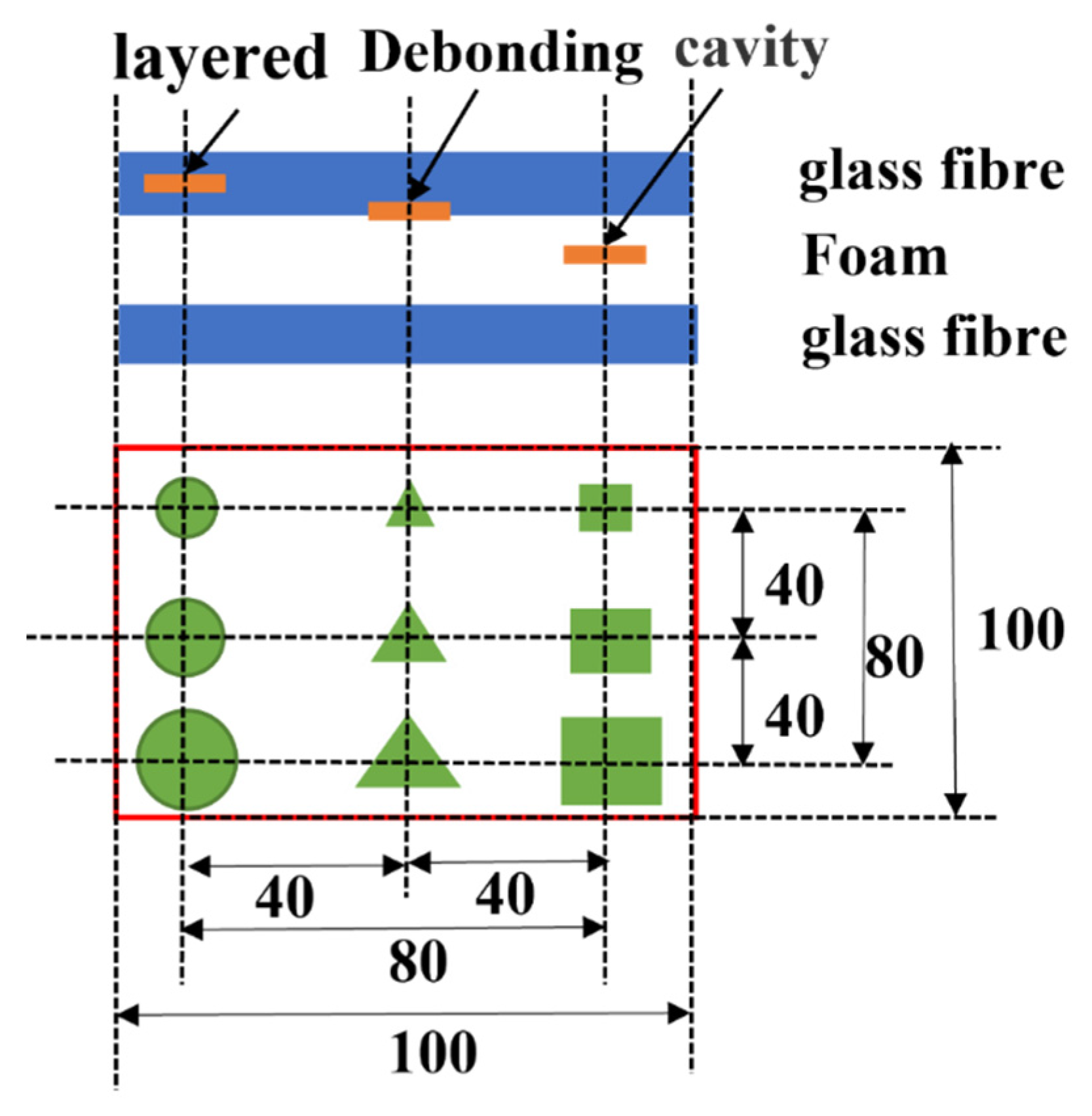

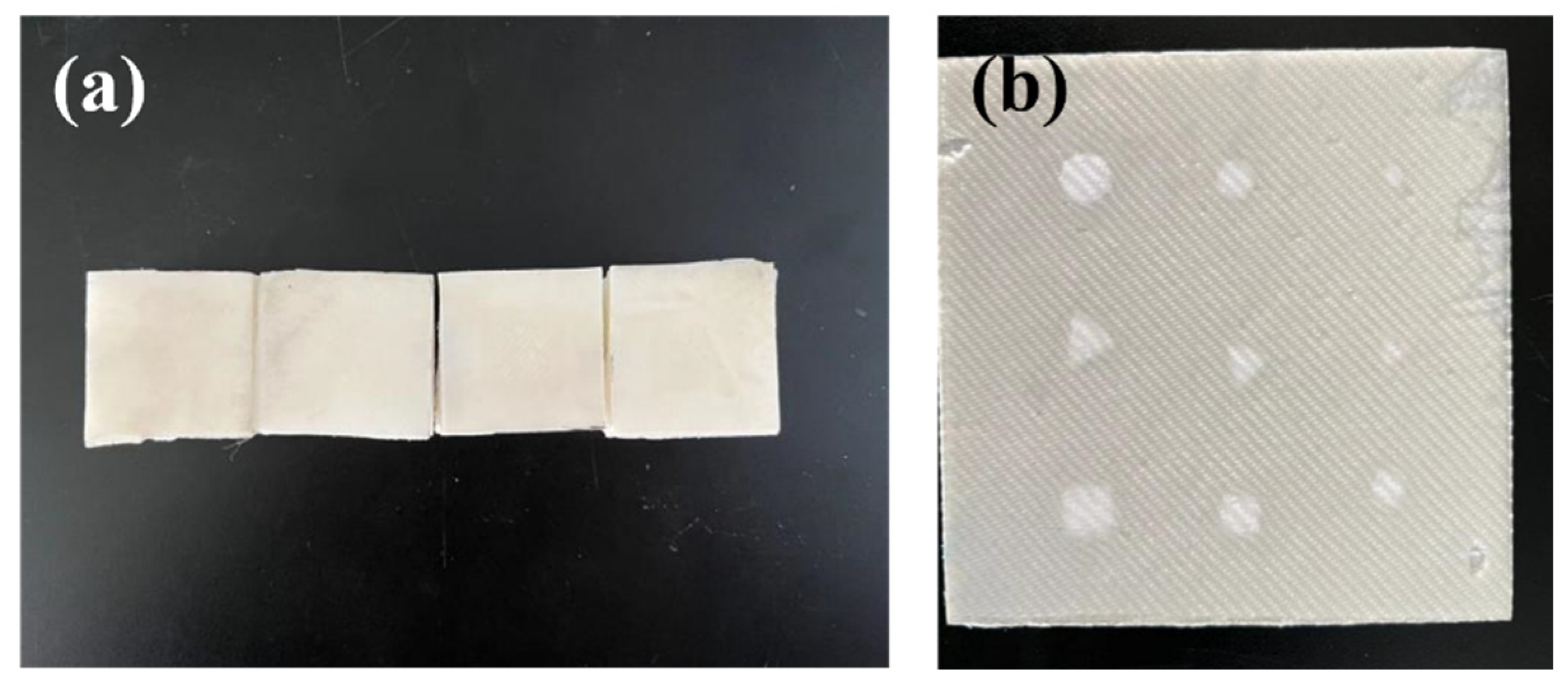

3.1. Preparation of Samples

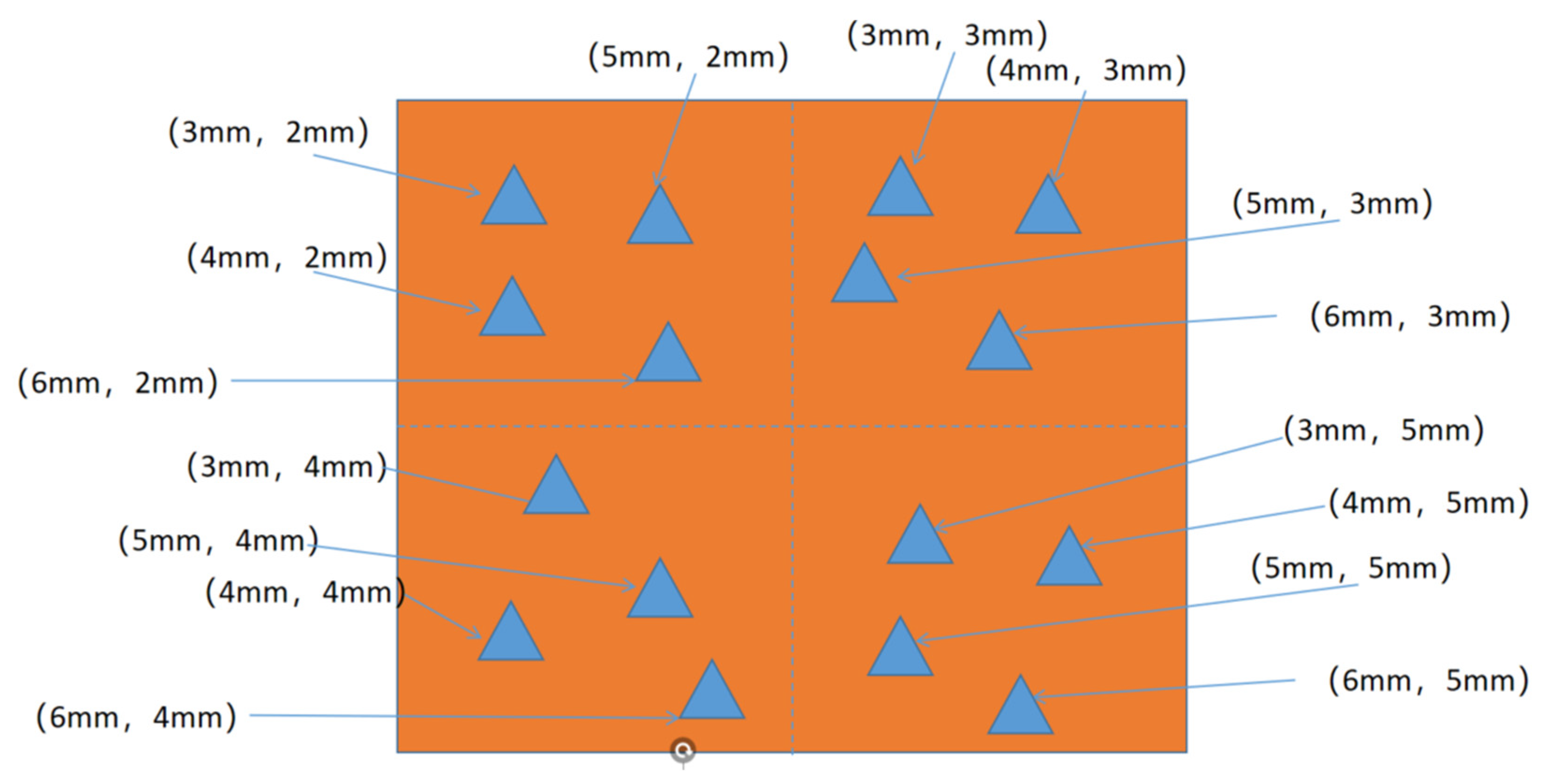

3.2. Artificial Defect Preset

- (1)

- Delamination defects. In the process of glass fibre material prefabrication, the delamination defect is represented by adding polytetrafluoroethylene (PTFE) flakes in between the middle of the third and fourth prepreg layers. Because the refractive index of PTFE is close to that of air, it can replace the delamination effect with the thickness of 0.2 mm.

- (2)

- Debonding defects. When the glass fibre material is glued to the foam, a PTFE sheet is placed. It can replace the state without gluing, and the thickness of a PTFE sheet is 0.2 mm.

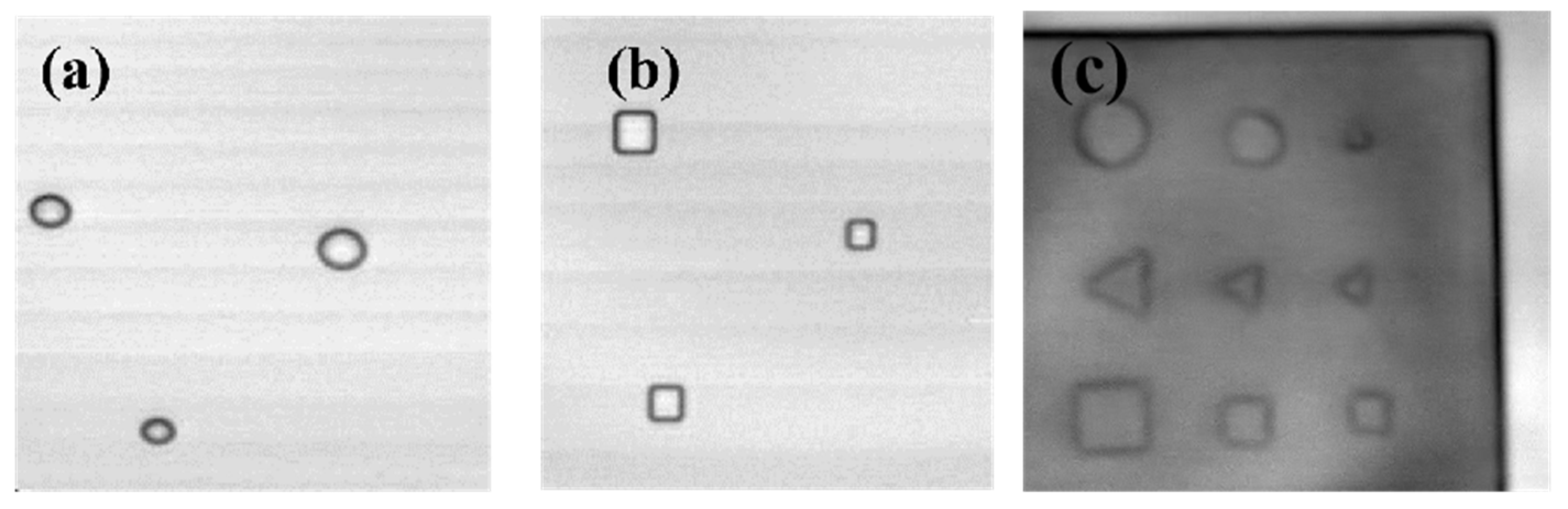

- (3)

- Hollow defects. This involves the setting of cavities of different sizes, shapes, and depths on the surface of the foam.

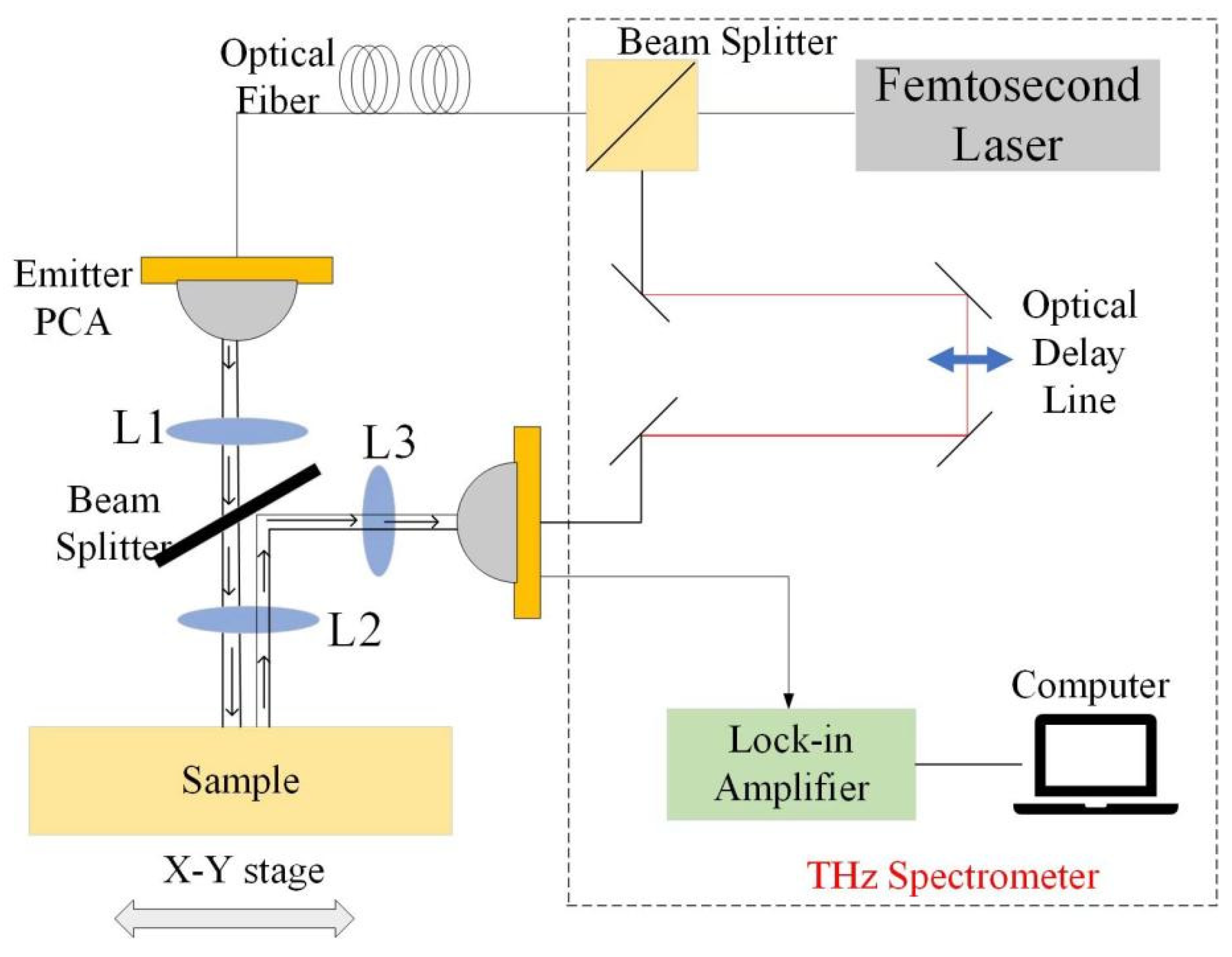

3.3. THz-TDS Experimental System

3.4. Data Acquisition and Preprocessing

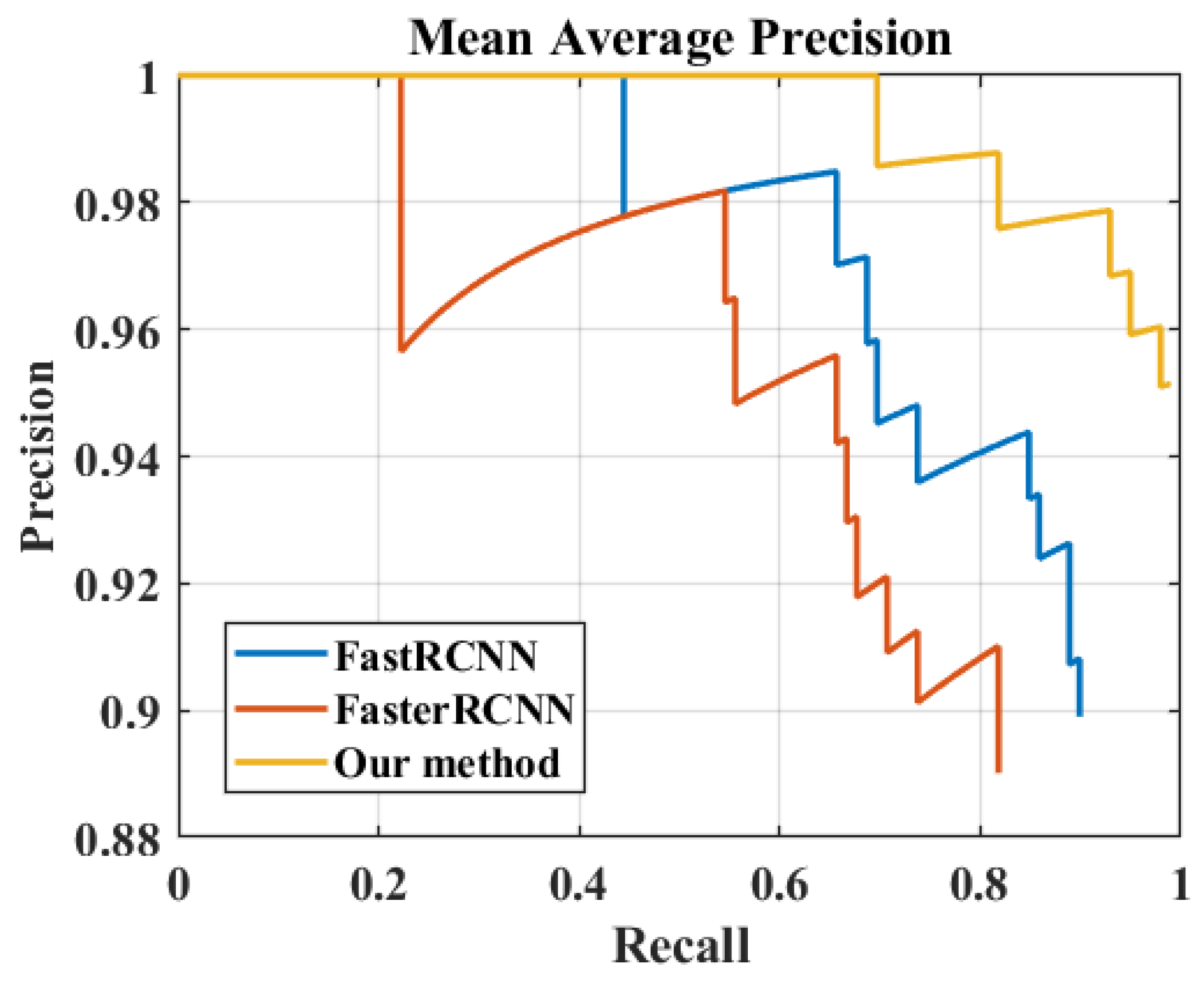

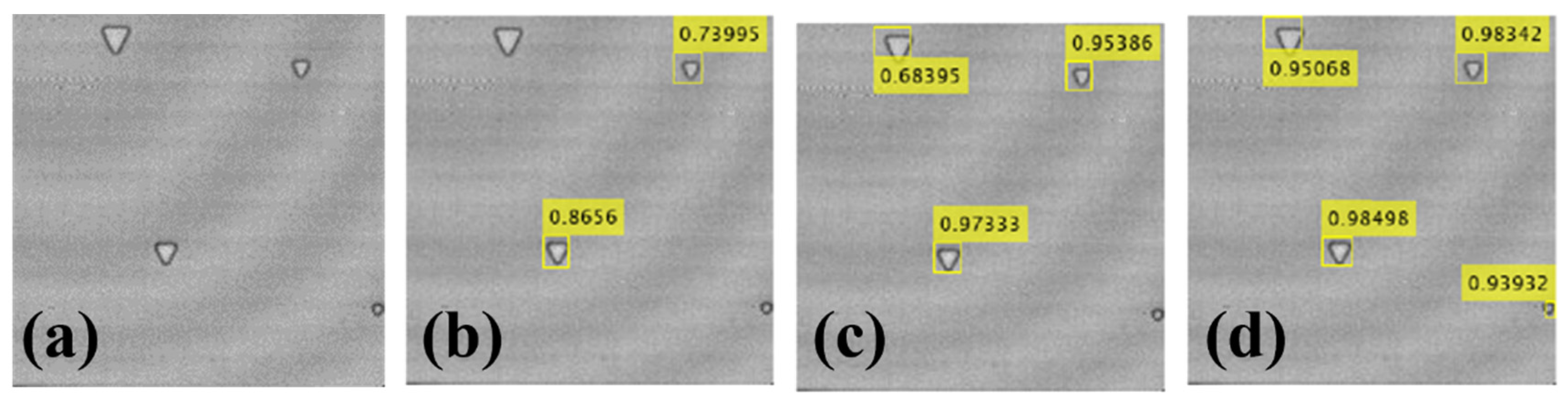

4. Results and Discussions

Result of Resetting Dataset Anchor Box

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Castellano, A.; Fraddosio, A.; Piccioni, M.D. Quantitative analysis of QSI and LVI damage in GFRP unidirectional composite laminates by a new ultrasonic approach. Compos. Part B Eng. 2018, 151, 106–117. [Google Scholar] [CrossRef]

- Bozheng, W.; Lihong, D.; Haidou, W.; Jiajie, K.; Wei, G.; Ming, X.; Ai, M. Research and Application of Laser Infrared Thermography in Material Defect Detection. Mater. Rev. 2020, 34, 127–132. [Google Scholar]

- Yu, F.L.; Yu, R.Q.; Liao, L.W.; Liu, L. Application of Micro-magnetic Detection Technique in Glass Fibers. Fail. Anal. Prev. 2019, 14, 232–239. [Google Scholar]

- Wang, Y.; Chen, Z.; Zhao, Z.; Zhang, L.; Kang, K.; Zhang, Y. Restoration of terahertz signals distorted by atmospheric water vapor absorption. J. Appl. Phys. 2009, 105, 103105. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Chang, T.; Hu, Q.; Yang, X. Terahertz spectroscopic study of aeronautical composite matrix resins with different dielectric properties. Optik 2018, 168, 101–111. [Google Scholar] [CrossRef]

- Cheng, Z. Progress in terahertz nondestructive testing. Chin. J. Sci. Instrum. 2008, 29, 1563–1568. [Google Scholar]

- Guo, X.D.; Wang, Q.; Gu, X.H.; Chen, X.A.; Fan, X.W. Analysis of Terahertz Spectroscopic Inspection Experiment for Glass Fiber Composite Material Defects. Infrared Technol. 2015, 37, 764–768. [Google Scholar]

- Zhang, D.D.; Ren, J.J.; Li, L.J.; Qiao, X.L.; Gu, J. Teraherz nondestructive testing technology for glass fiber honeycomb composites. J. Photonics 2019, 48, 163–171. [Google Scholar]

- Wang, Q.; Zhou, H.; Xia, R.; Liu, Q.; Zhao, B.Y. Time Segmented Image Fusion Based Multi-Depth Defects Imaging Method in Composites With Pulsed Terahertz. IEEE Access 2020, 8, 155529–155537. [Google Scholar] [CrossRef]

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.Y.; Berg, A.C. Ssd: Single shot multibox detector. In Proceedings of the European Conference on Computer Vision, Amsterdam, The Netherlands, 8–16 October 2016; Springer: Cham, Switzerland, 2014; pp. 21–37. [Google Scholar]

- Bochkovskiy, A.; Wang, C.Y.; Liao, H.Y.M. Yolov4: Optimal speed and accuracy of object detection. arXiv 2020, arXiv:2004.10934. [Google Scholar]

- Ge, Z.; Liu, S.; Wang, F.; Li, Z.; Sun, J. YOLOX: Exceeding YOLO Series. In Proceedings of the 2021 IEEE Conference on Computer Vision and Pattern Recognition, Nashville, TN, USA, 20–25 June 2016. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, Faster, Stronger. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Grishick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the 2014 IEEE Conference on Computer Vision and Pattern Recognition, Columbis, OH, USA, 23–28 June 2014. [Google Scholar]

- Girshick, R. Fast R-CNN. In Proceedings of the 2015 IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 1440–1448. [Google Scholar]

- Ren, S.; He, K.; Grishick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016. [Google Scholar]

- He, K.; Gkioxari, G.; Dollar, P.; Grishick, R. Mask R-CNN. arXiv 2018, arXiv:1703.06870. [Google Scholar]

- Hou, B.; Yang, M.; Sun, X. Real-Time Object Detection for Millimeter-Wave Images Based on Improved Faster Regions with Convolutional Neural Networks. Laser Optoelectron. Prog. 2019, 56, 31009. [Google Scholar]

- Lin, T.Y.; Goyal, P.; Girshick, R.; He, K.; Dollár, P. Focal Loss for Dense Object Detection. IEEE Trans. Pattern Anal. Mach. Intell. 2020, 42, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Xue, F.; Liang, D.; Yu, Y.; Pan, J.X.; Wu, T.P. Multi-object Segmentation, Detection and Recognition in Active Terahertz Imaging. Infrared 2020, 41, 13–25. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the 2016 IEEE Conference on computer vision and pattern recognition, Las Vegas, NV, USA, 27–29 June 2016; pp. 770–778. [Google Scholar]

- Chollet, F. Xception: Deep Learning with Depthwise Separable Convolutions. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017. [Google Scholar]

- Lin, T.Y.; Dollár, P.; Girshick, R.; He, K.; Hariharan, B.; Belongie, S. Feature Pyramid Networks for Object Detection. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition, Honolulu, HI, USA, 21–26 July 2017; pp. 2117–2125. [Google Scholar]

| Hyperparameters | Minimum Value | Maximum Value |

|---|---|---|

| Initial Learn Rate | 1 × 10−4 | 1 |

| Momentum | 0.8 | 0.99 |

| L2 Regularisation | 1 × 10−5 | 1 × 10−2 |

| Models | Backbone | Average Accuracy Value/% | |

|---|---|---|---|

| Unused Data Enhancement | Data Enhancement | ||

| Fast R-CNN | ResNet50 | 76.52 | 79.04 |

| Faster R-CNN | ResNet50 | 84.39 | 88.12 |

| Improved Faster R-CNN | ResNet50 | 95.50 | 98.35 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, X.; Liu, P.; Wang, S.; Wu, B.; Zhang, K.; Yang, B.; Wu, X. Defect Detection of Composite Material Terahertz Image Based on Faster Region-Convolutional Neural Networks. Materials 2023, 16, 317. https://doi.org/10.3390/ma16010317

Yang X, Liu P, Wang S, Wu B, Zhang K, Yang B, Wu X. Defect Detection of Composite Material Terahertz Image Based on Faster Region-Convolutional Neural Networks. Materials. 2023; 16(1):317. https://doi.org/10.3390/ma16010317

Chicago/Turabian StyleYang, Xiuwei, Pingan Liu, Shujie Wang, Biyuan Wu, Kaihua Zhang, Bing Yang, and Xiaohu Wu. 2023. "Defect Detection of Composite Material Terahertz Image Based on Faster Region-Convolutional Neural Networks" Materials 16, no. 1: 317. https://doi.org/10.3390/ma16010317

APA StyleYang, X., Liu, P., Wang, S., Wu, B., Zhang, K., Yang, B., & Wu, X. (2023). Defect Detection of Composite Material Terahertz Image Based on Faster Region-Convolutional Neural Networks. Materials, 16(1), 317. https://doi.org/10.3390/ma16010317