In Situ Construction of TiC-Ti3SiC2 Gradient Hybrid Interphase Coated SiC Fibers for Suppression of Specular Reflection and Non-Specular Scattering

Abstract

1. Introduction

2. Experiment

2.1. Preparation of Ti3SiC2/SiC Fibers

2.2. Characterization

3. Results and Discussion

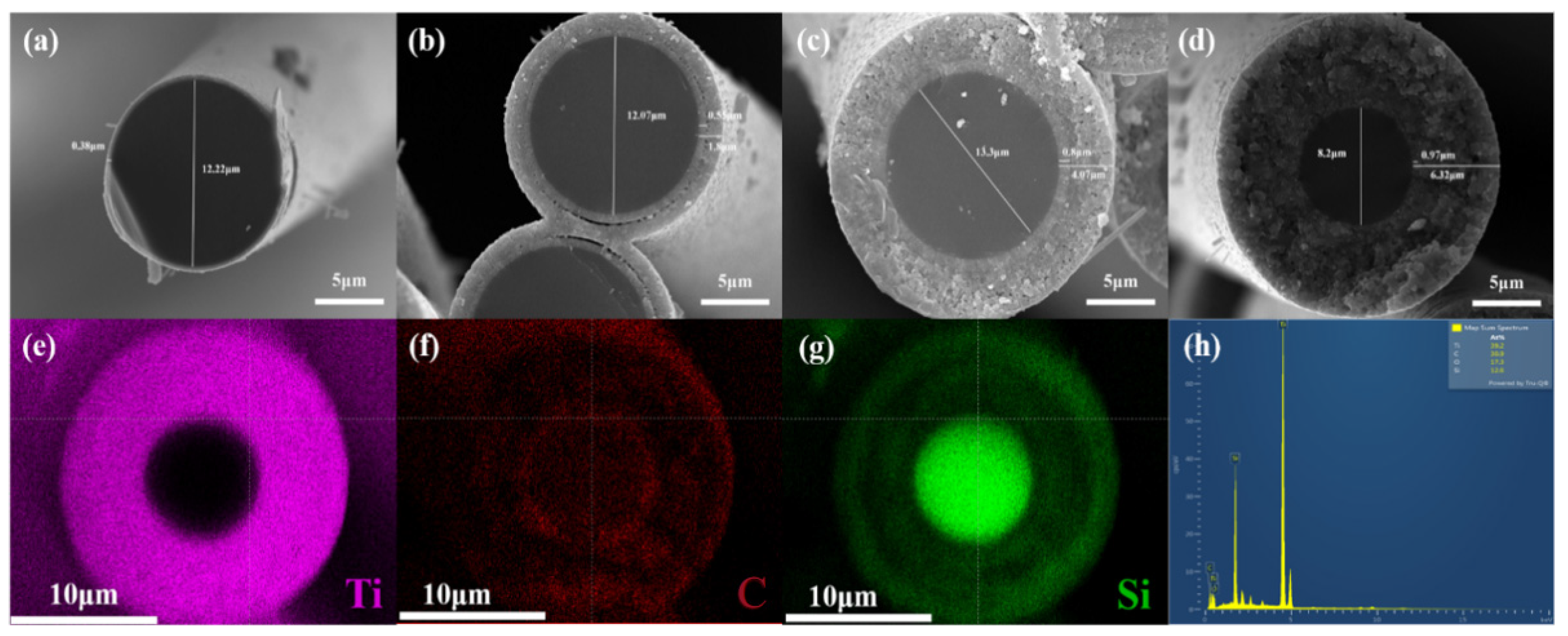

3.1. Microstructure and Phase Analysis

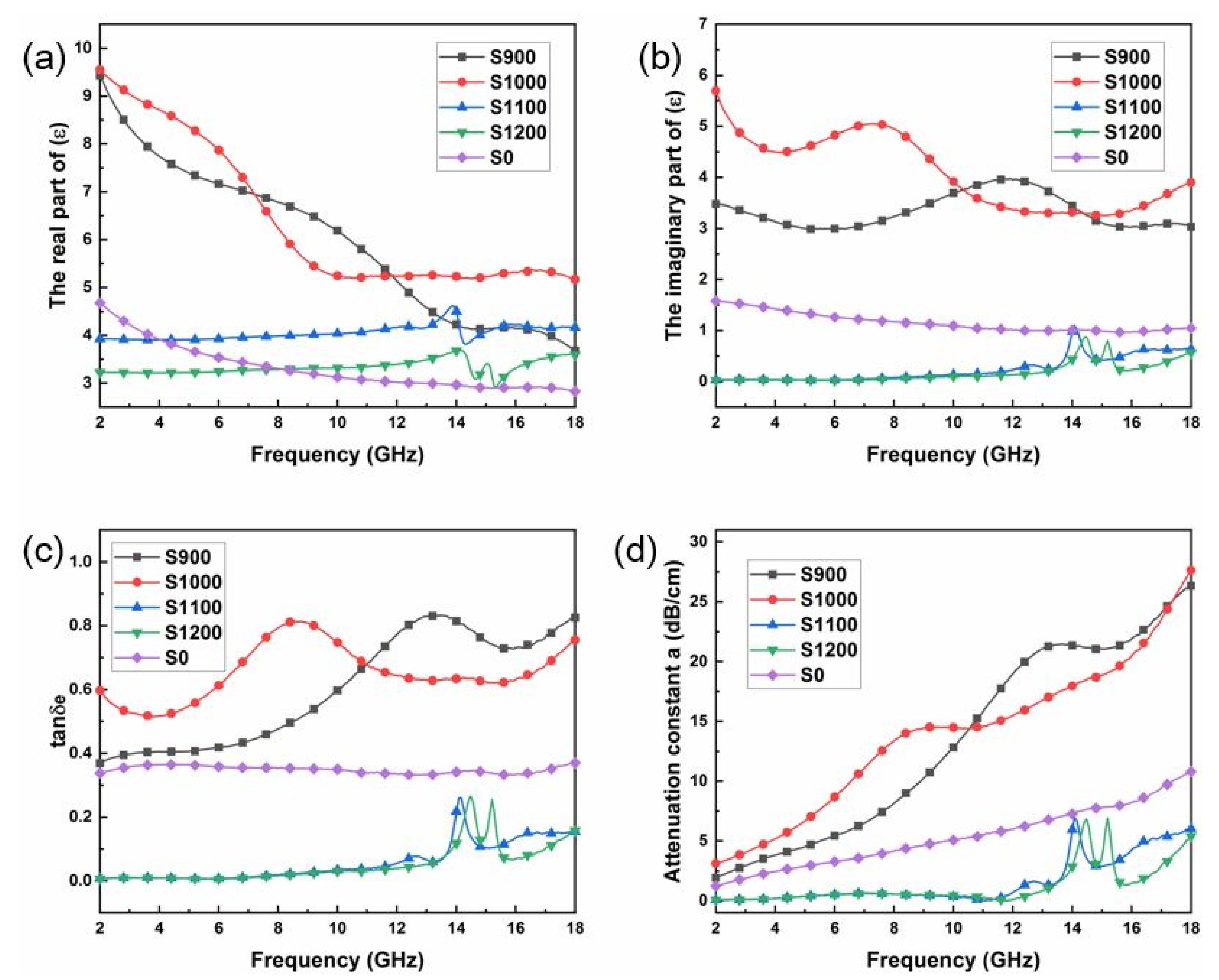

3.2. Dielectric Loss Properties

3.3. Specular Reflection Suppression

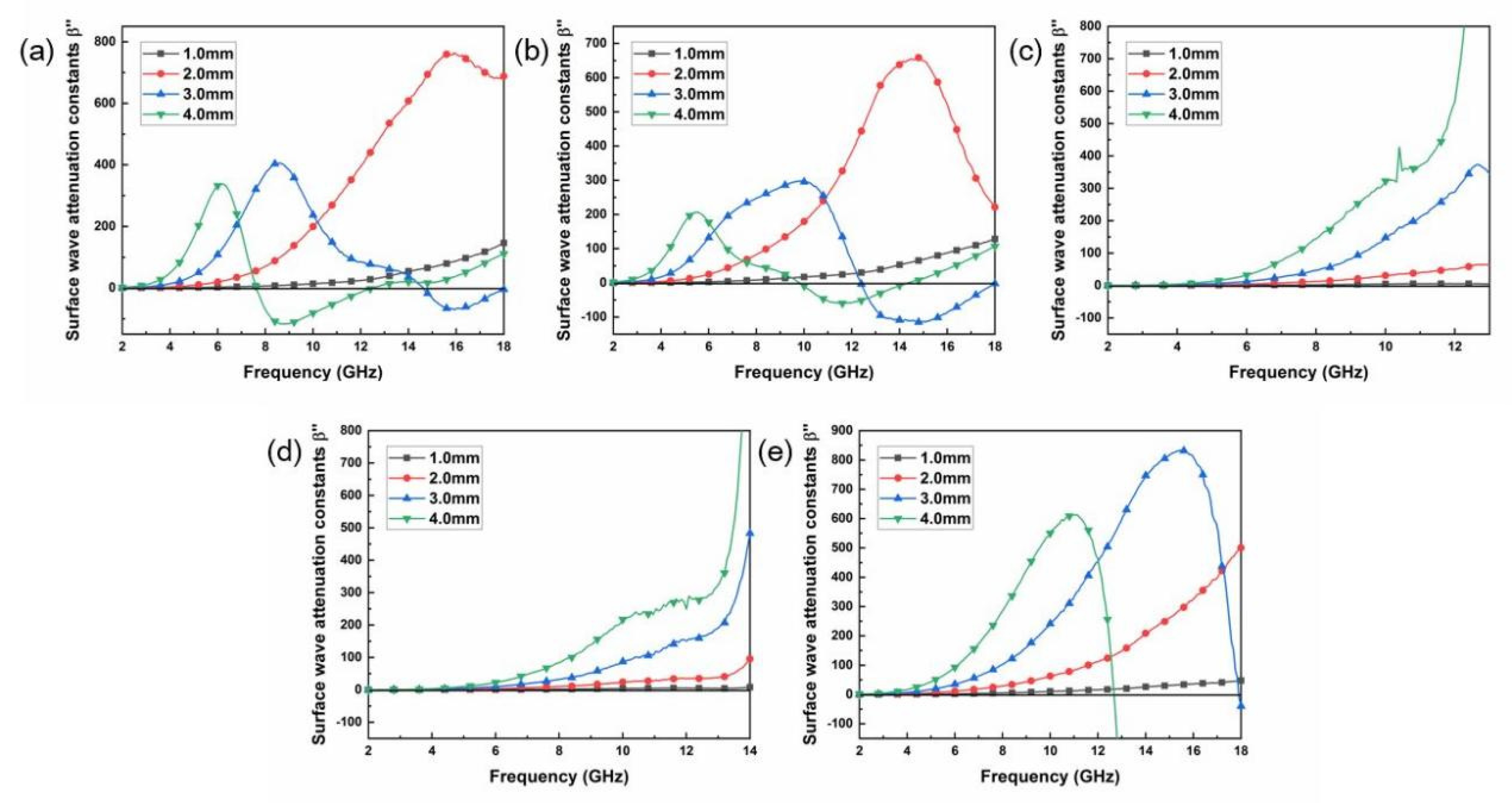

3.4. Non-Specular Scattering Suppression

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Lim, W.G.; Yu, J.W. Scattering by a dielectric-loaded conducting wedge with concaved edge: TE case. Prog. Electromagn. Res. 2009, 89, 85–100. [Google Scholar] [CrossRef][Green Version]

- Ivrissimtzis, L.P.; Marhefka, R.J. Edge-wave diffraction for flat-plate structures. Microw. Antennas Propagation. IEE Proc. 1994, 141, 30–36. [Google Scholar] [CrossRef]

- Hu, X.J.; Ge, D.B. Study on Conformal FDTD for Electromagnetic Scattering by Targets with Thin Coating. Prog. Electromagn. Res. 2008, 79, 305–319. [Google Scholar] [CrossRef][Green Version]

- Oraizi, H.; Abdolali, A. Ultra Wide Band RCS Optimization of Multilayerd Cylindrical Structures for Arbitrarily Polarized Incident Plane Waves. Prog. Electromagn. Res. 2008, 78, 129–157. [Google Scholar] [CrossRef]

- Yan, W.Z.; Du, Y.; Wu, H.; Liu, D.; Wu, B.I. EM Scattering from a Long Dielectric Circular Cylinder. Prog. Electromagn. Res. 2008, 85, 39–67. [Google Scholar] [CrossRef][Green Version]

- Ding, D.Z.; Chen, R.S. Electromagnetic Scattering by Conducting Bor Coated with Chiral Media Above a Lossy Half-Space. Prog. Electromagn. Res. 2010, 104, 385–401. [Google Scholar] [CrossRef]

- Chen, H.Y.; Deng, L.J.; Zhou, P.H.; Xie, J.; Zhu, Z.W. Improvement of surface electromagnetic waves attenuation with resistive loading. Prog. Electromagn. Res. Lett. 2011, 26, 143–152. [Google Scholar] [CrossRef][Green Version]

- Chen, H.Y.; Lu, H.P.; Xie, J.L.; Deng, L.J. Improvement of Surface Waves Attenuation Performance With a Magnetic Thin Film Loading. IEEE Trans. Magn. 2014, 50, 1–5. [Google Scholar] [CrossRef]

- Chen, H.Y.; Deng, L.J.; Zhou, P.H. Suppression of Surface Wave from Finite Conducting Surfaces with Impedance Loading at Margins. J. Electromagn. Waves Appl. 2010, 24, 1977–1989. [Google Scholar] [CrossRef]

- Hwang, R.B.; Peng, S.T. Surface-wave suppression of resonance-type periodic structures. IEEE Trans. Antennas Propag. 2003, 51, 1221–1229. [Google Scholar] [CrossRef]

- Voland, R.T.; Huebner, L.D.; McClinton, C.R. X-43A Hypersonic vehicle technology development. Acta Astronaut. 2006, 59, 181–191. [Google Scholar] [CrossRef]

- Harsha, P.; Keel, L.; Castrogiovanni, A.; Sherrill, R. X-43A Vehicle Design and Manufacture. In Proceedings of the AIAA/CIRA 13th International Space Planes and Hypersonics Systems and Technologies Conference, Capua, Italy, 16–20 May 2005. [Google Scholar] [CrossRef]

- Marshall, L.; Bahm, C.; Corpening, G.; Sherrill, R. Overview With Results and Lessons Learned of the X-43A Mach 10 Flight. In Proceedings of the AIAA/CIRA 13th International Space Planes and Hypersonics Systems and Technologies Conference, Capua, Italy, 16–20 May 2005. [Google Scholar]

- Duan, S.; Zhu, D.; Jia, H.; Zhou, W.; Luo, F. Enhanced mechanical and dielectric properties of SiCf/SiC composites with silicon oxycarbide interphase. Ceram. Int. 2018, 44, 631–637. [Google Scholar] [CrossRef]

- Li, M.; Zhou, X.; Yang, H.; Du, S.; Huang, Q. The critical issues of SiC materials for future nuclear systems. Scr. Mater. 2017, 143, 149–153. [Google Scholar] [CrossRef]

- Sun, X.; Yin, X.; Fan, X.; Ma, X.; Cao, X.; Cheng, L.; Zhang, L. Oxidation resistance of SiC/SiC composites containing SiBC matrix fabricated by liquid silicon infiltration. J. Eur. Ceram. Soc. 2018, 38, 479–485. [Google Scholar] [CrossRef]

- Mu, Y.; Zhou, W.; Hu, Y.; Wang, H.; Luo, F.; Ding, D.; Qing, Y. Temperature-dependent dielectric and microwave absorption properties of SiCf/SiC–Al2O3 composites modified by thermal cross-linking procedure. J. Eur. Ceram. Soc. 2015, 35, 2991–3003. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, H.; Wang, J.; Tang, G. Dielectric properties of the SiC fiber-reinforced SiC matrix composites with the CVD SiC interphases. J. Alloy. Compd. 2010, 491, 248–251. [Google Scholar] [CrossRef]

- Mu, Y.; Zhou, W.; Luo, F.; Zhu, D. Effects of BN/SiC dual-layer interphase on mechanical and dielectric properties of SiCf/SiC composites. Ceram. Int. 2014, 40, 3411–3418. [Google Scholar] [CrossRef]

- Ding, D.; Shi, Y.; Wu, Z.; Zhou, W.; Luo, F.; Chen, J. Electromagnetic interference shielding and dielectric properties of SiCf/SiC composites containing pyrolytic carbon interphase. Carbon 2013, 60, 552–555. [Google Scholar] [CrossRef]

- Han, T.; Luo, R.; Cui, G.; Wang, L. Effect of fibre directionality on the microwave absorption properties of 3D braided SiCf/SiC composites. Ceram. Int. 2019, 45, 7797–7803. [Google Scholar] [CrossRef]

- Han, T.; Luo, R.; Cui, G.; Wang, L. Effect of SiC nanowires on the high-temperature microwave absorption properties of SiCf/SiC composites. J. Eur. Ceram. Soc. 2019, 39, 1743–1756. [Google Scholar] [CrossRef]

- Mo, R.; Yin, X.; Ye, F.; Liu, X.; Ma, X.; Li, Q.; Zhang, L.; Cheng, L. Electromagnetic wave absorption and mechanical properties of silicon carbide fibers reinforced silicon nitride matrix composites. J. Eur. Ceram. Soc. 2018, 39, 743–754. [Google Scholar] [CrossRef]

- Filbert-Demut, I.; Bei, G.; Höschen, T.; Riesch, J.; Travitzky, N.; Greil, P. Influence of Ti3SiC2 Fiber Coating on Interface and Matrix Cracking in an SiC Fiber-Reinforced Polymer-Derived Ceramic. Adv. Eng. Mater. 2015, 17, 1142–1148. [Google Scholar] [CrossRef]

- Lee, H.G.; Kim, D.; Park, J.Y.; Kim, W.J. Formation of Ti3SiC2 interphase coating on SiCf/SiC composite by electrophoretic deposition. Int. J. Appl. Ceram. Technol. 2018, 15, 602–610. [Google Scholar] [CrossRef]

- Li, S.; Ni, N.; Wu, B.; Li, C.; Ding, Q.; He, Z. Ti3SiC2 interphase coating in SiCf/SiC composites: Effect of the coating fabrication atmosphere and temperature. J. Eur. Ceram. Soc. 2021, 41, 5850–5862. [Google Scholar] [CrossRef]

- Gao, H.; Luo, F.; Nan, H.; Wen, Q.; Qing, Y.; Wang, C.; Zhou, W.; Zhu, D. Improved mechanical and microwave absorption properties of SiC fiber/mullite matrix composite using hybrid SiC/Ti3SiC2 fillers. J. Alloy. Compd. 2019, 791, 51–59. [Google Scholar] [CrossRef]

- Zhang, S.; Jiao, Q.; Zhao, Y.; Li, H.; Wu, Q. Preparation of rugby-shaped CoFe2O4 particles and their microwave absorbing properties. J. Mater. Chem. A 2014, 2, 18033–18039. [Google Scholar] [CrossRef]

- Luo, H.; Gong, R.; Wang, X.; Song, K.; Zhu, C.; Wang, L. Synthesis and excellent microwave absorption properties of reduced graphene oxide/FeNi3/Fe3O4 composite. New J. Chem. 2016, 40, 6238–6243. [Google Scholar] [CrossRef]

- Zhao, B.; Shao, G.; Fan, B.; Xie, Y.; Zhang, R. Preparation and electromagnetic wave absorption of chain-like CoNi by a hydrothermal route. J. Magn. Magn. Mater. 2014, 372, 195–200. [Google Scholar] [CrossRef]

- Zhang, X.J.; Wang, G.S.; Cao, W.Q.; Wei, Y.Z.; Liang, J.F.; Guo, L.; Cao, M.S. Enhanced Microwave Absorption Property of Reduced Graphene Oxide (RGO)-MnFe2O4 Nanocomposites and Polyvinylidene Fluoride. ACS Appl. Mater. Interfaces 2014, 6, 7471–7478. [Google Scholar] [CrossRef]

- Li, H.; Huang, Y.; Sun, G.; Yan, X.; Yang, Y.; Wang, J.; Zhang, Y. Directed Growth and Microwave Absorption Property of Crossed ZnO Netlike Micro-/Nanostructures. J. Phys. Chem. C 2010, 114, 10088–10091. [Google Scholar] [CrossRef]

- Ling, R.T.; Scholler, J.D.; Ufimtsev, P.Y. The Propagation and Excitation of Surface Waves in an Absorbing Layer. Prog. Electromagn. Res. 1998, 19, 49–91. [Google Scholar] [CrossRef]

- Ufimtsev, P.Y.; Ling, R.T.; Scholler, J.D. Transformation of surface waves in homogeneous absorbing layers. IEEE Trans. Antennas Propag. 2002, 48, 214–222. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, H.; Li, Y.; Luo, H.; Zou, Y.; He, J. In Situ Construction of TiC-Ti3SiC2 Gradient Hybrid Interphase Coated SiC Fibers for Suppression of Specular Reflection and Non-Specular Scattering. Materials 2023, 16, 292. https://doi.org/10.3390/ma16010292

Yang H, Li Y, Luo H, Zou Y, He J. In Situ Construction of TiC-Ti3SiC2 Gradient Hybrid Interphase Coated SiC Fibers for Suppression of Specular Reflection and Non-Specular Scattering. Materials. 2023; 16(1):292. https://doi.org/10.3390/ma16010292

Chicago/Turabian StyleYang, Haitang, Yinrui Li, Heng Luo, Yangjun Zou, and Jun He. 2023. "In Situ Construction of TiC-Ti3SiC2 Gradient Hybrid Interphase Coated SiC Fibers for Suppression of Specular Reflection and Non-Specular Scattering" Materials 16, no. 1: 292. https://doi.org/10.3390/ma16010292

APA StyleYang, H., Li, Y., Luo, H., Zou, Y., & He, J. (2023). In Situ Construction of TiC-Ti3SiC2 Gradient Hybrid Interphase Coated SiC Fibers for Suppression of Specular Reflection and Non-Specular Scattering. Materials, 16(1), 292. https://doi.org/10.3390/ma16010292