Phase-Change Microcapsules with a Stable Polyurethane Shell through the Direct Crosslinking of Cellulose Nanocrystals with Polyisocyanate at the Oil/Water Interface of Pickering Emulsion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of NCC/PU Capsules Loaded with n-Octadecane

2.3. Characterization of the NCC/PU Capsules

3. Results and Discussion

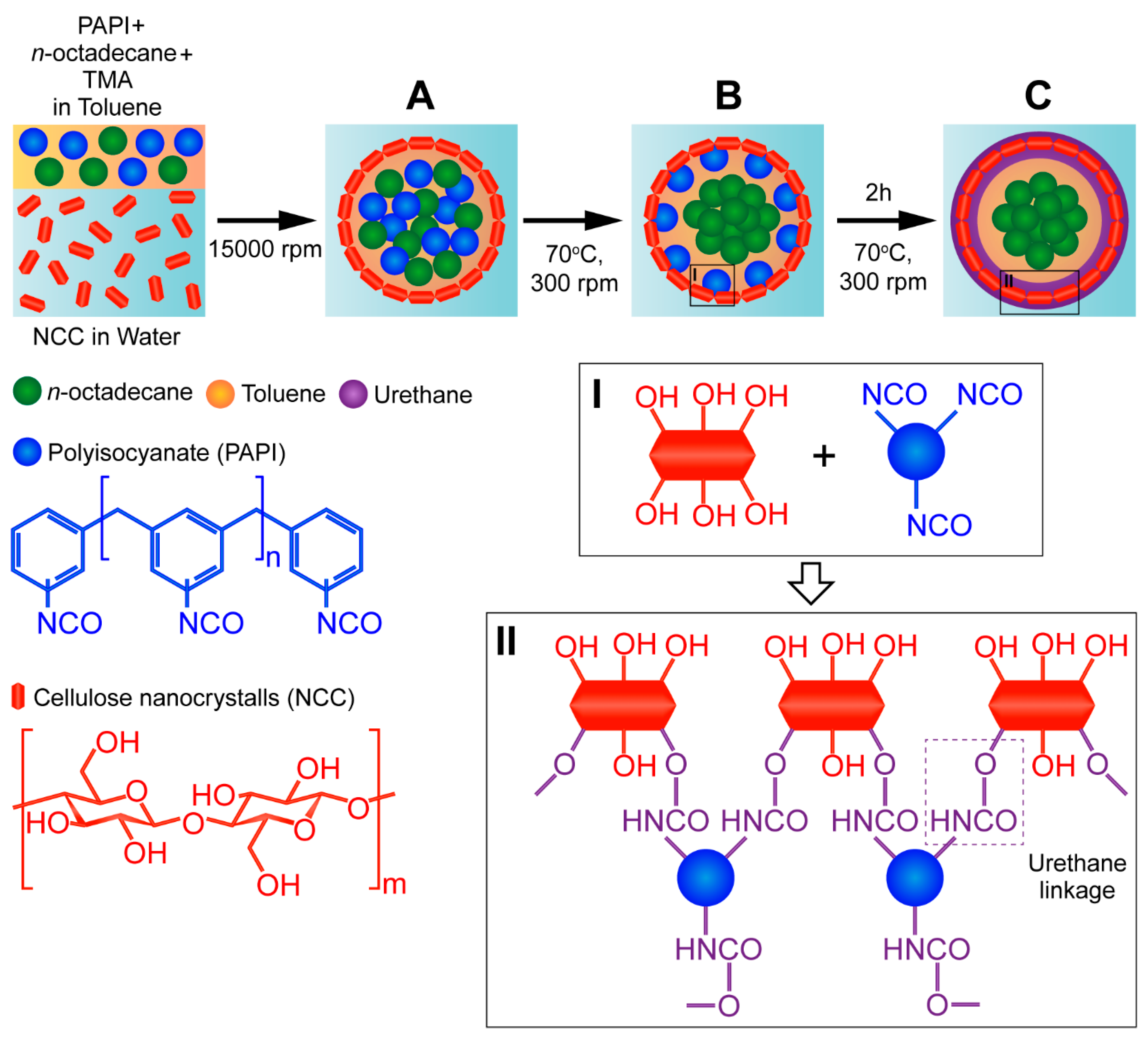

3.1. Synthesis of NCC/PU Capsules

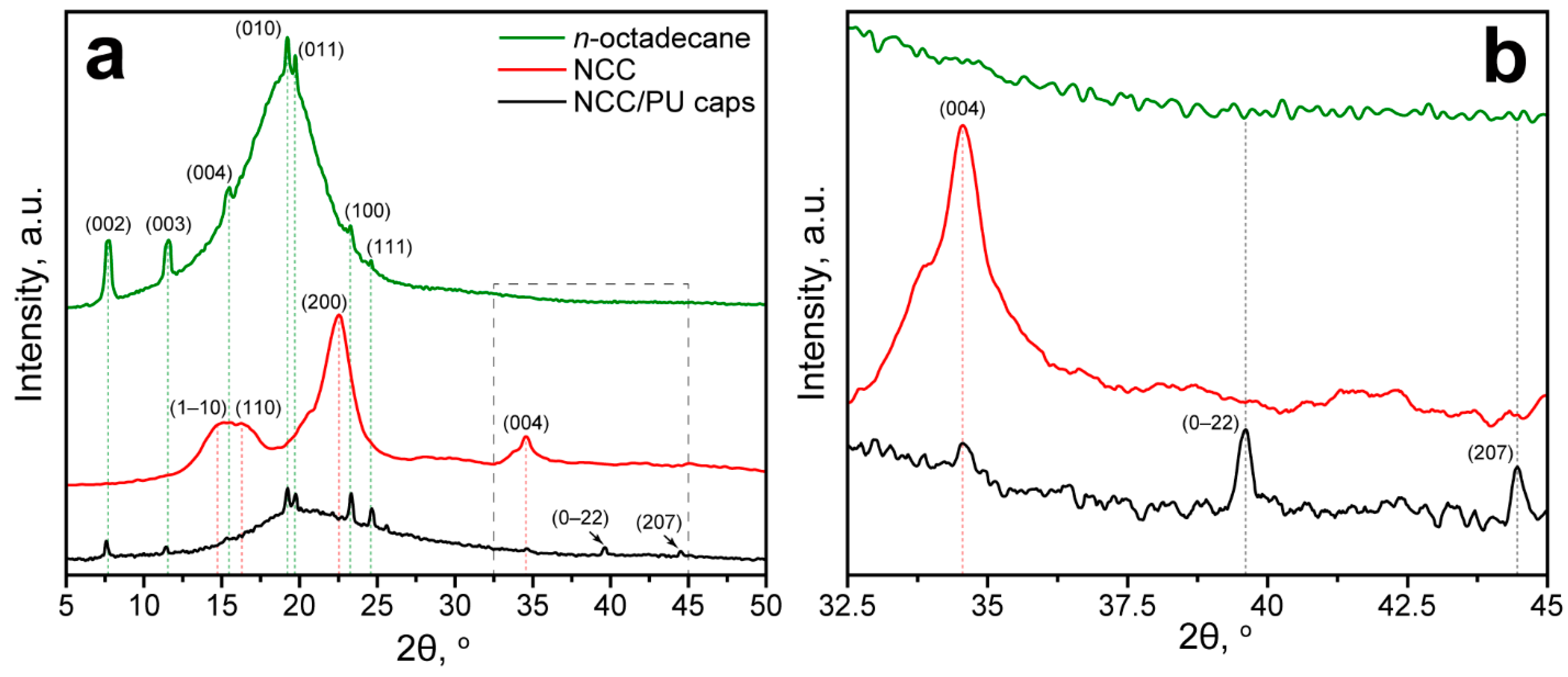

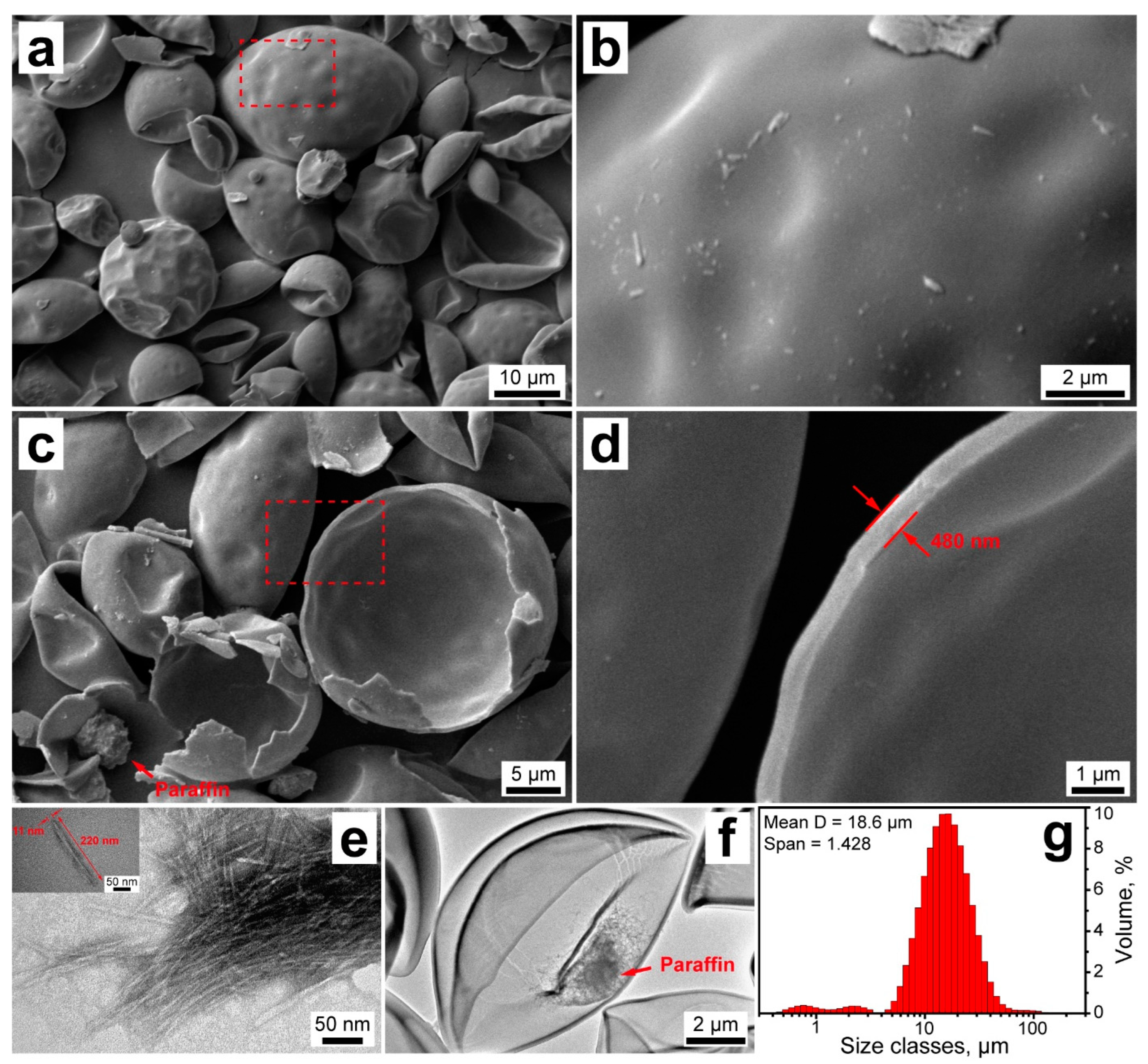

3.2. Structure of NCC/PU Capsules

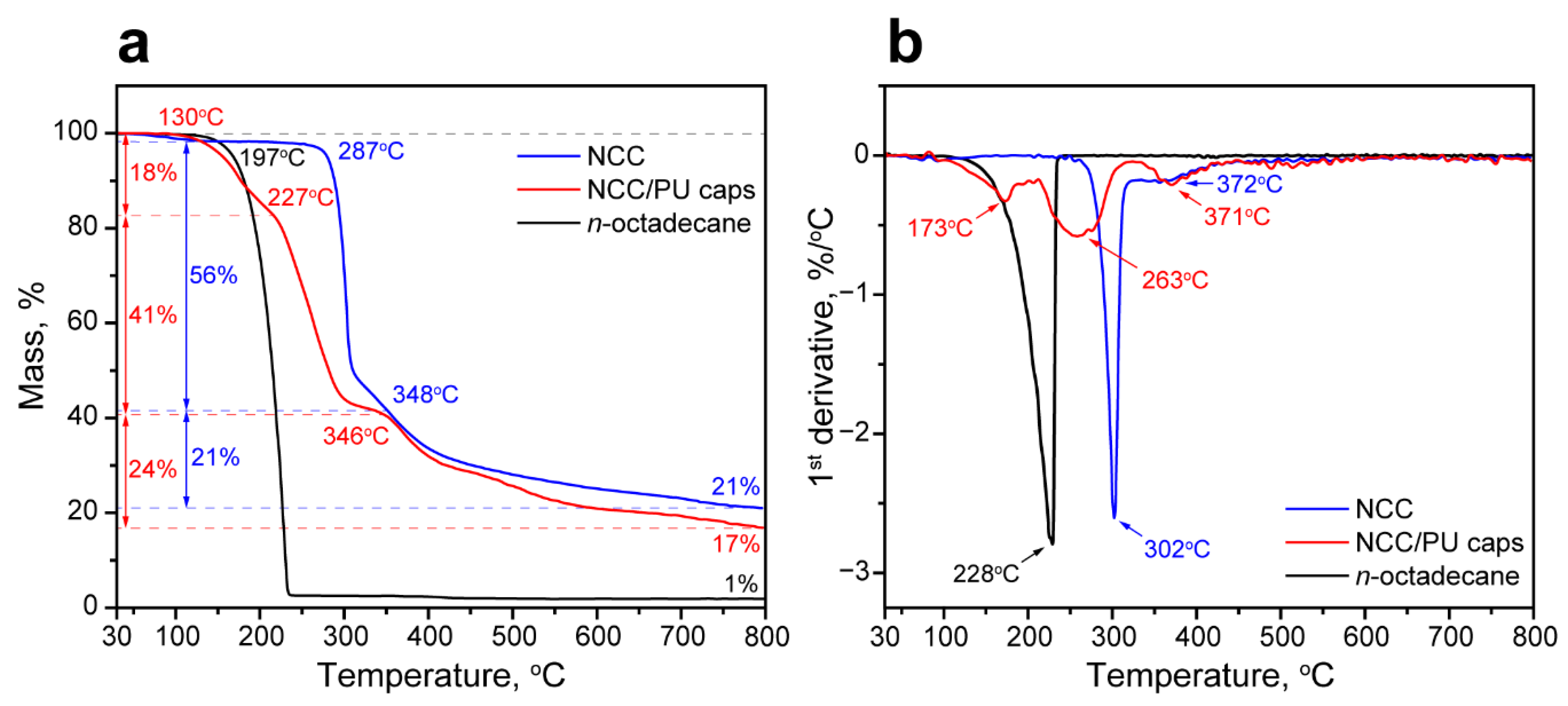

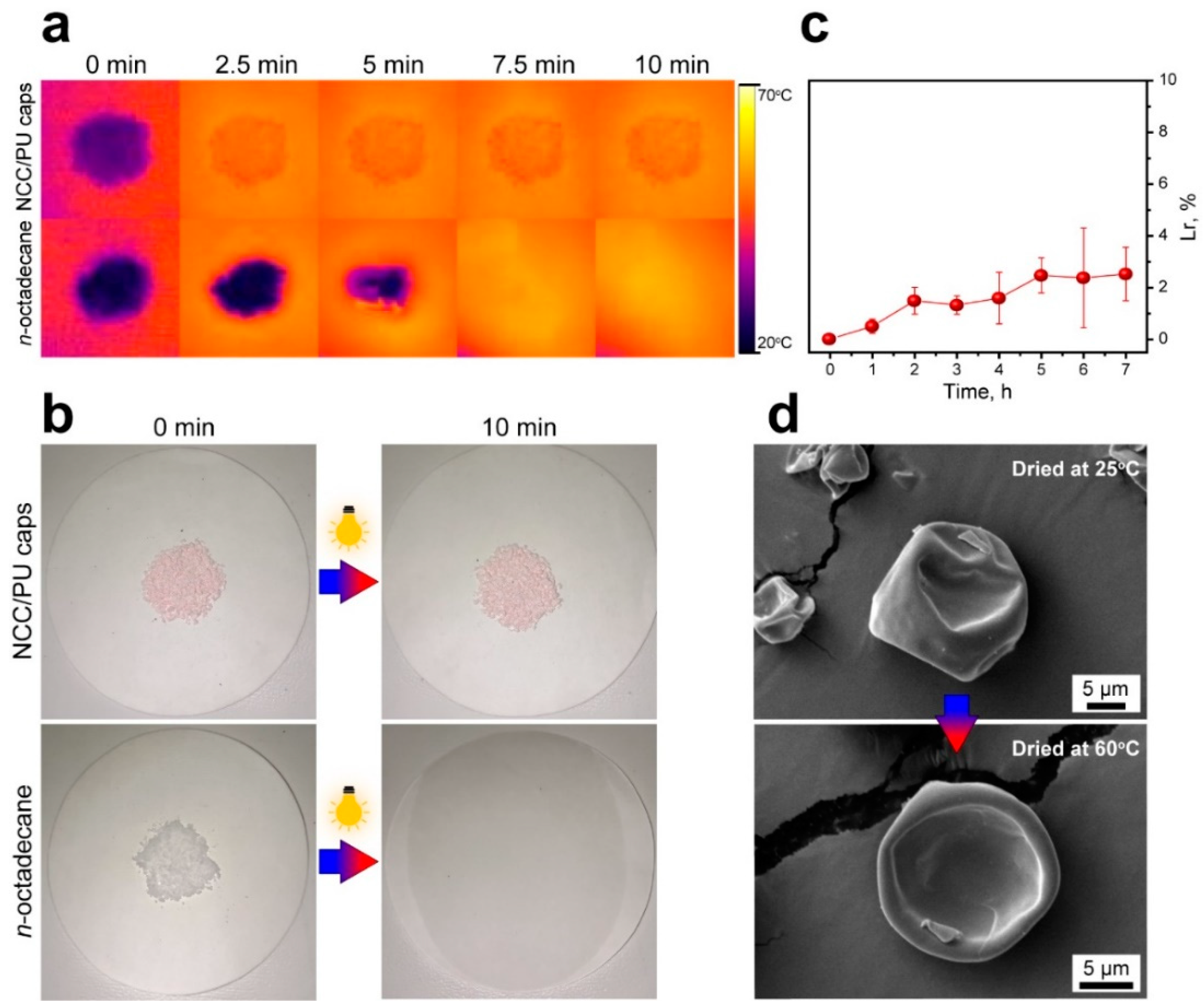

3.3. Latent Heat Storage Performance, Thermal and Shape Stability of NCC/PU Capsules

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Aftab, W.; Usman, A.; Shi, J.; Yuan, K.; Qin, M.; Zou, R. Phase change material-integrated latent heat storage systems for sustainable energy solutions. Energy Environ. Sci. 2021, 14, 4268–4291. [Google Scholar] [CrossRef]

- Takudzwa Muzhanje, A.; Hassan, M.A.; Hassan, H. Phase change material based thermal energy storage applications for air conditioning: Review. Appl. Therm. Eng. 2022, 214, 118832. [Google Scholar] [CrossRef]

- Nair, A.M.; Wilson, C.; Huang, M.J.; Griffiths, P.; Hewitt, N. Phase change materials in building integrated space heating and domestic hot water applications: A review. J. Energy Storage 2022, 54, 105227. [Google Scholar] [CrossRef]

- Iqbal, K.; Sun, D. Development of thermal stable multifilament yarn containing micro-encapsulated phase change materials. Fiber. Polym. 2015, 16, 1156–1162. [Google Scholar] [CrossRef]

- Yi, S.; Sun, S.; Deng, Y.; Feng, S. Preparation of composite thermochromic and phase-change materials by the sol–gel method and its application in textiles. J. Text. Inst. 2015, 106, 1071–1077. [Google Scholar] [CrossRef]

- Bahaidarah, H.M.S.; Baloch, A.A.B.; Gandhidasan, P. Uniform cooling of photovoltaic panels: A review. Renew. Sustain. Energy Rev. 2016, 57, 1520–1544. [Google Scholar] [CrossRef]

- Sathe, T.M.; Dhoble, A.S. A review on recent advancements in photovoltaic thermal techniques. Renew. Sustain. Energy Rev. 2017, 76, 645–672. [Google Scholar] [CrossRef]

- Arshad, A.; Ali, H.M.; Ali, M.; Manzoor, S. Thermal performance of phase change material (PCM) based pin-finned heat sinks for electronics devices: Effect of pin thickness and PCM volume fraction. Appl. Therm. Eng. 2017, 112, 143–155. [Google Scholar] [CrossRef]

- Jiang, Z.Y.; Qu, Z.G. Lithium–ion battery thermal management using heat pipe and phase change material during discharge–charge cycle: A comprehensive numerical study. Appl. Energy 2019, 242, 378–392. [Google Scholar] [CrossRef]

- Xie, Y.; Tang, J.; Shi, S.; Xing, Y.; Wu, H.; Hu, Z.; Wen, D. Experimental and numerical investigation on integrated thermal management for lithium-ion battery pack with composite phase change materials. Energy Convers. Manag. 2017, 154, 562–575. [Google Scholar] [CrossRef]

- IEA. Renewables. 2019. Available online: https://www.iea.org/reports/renewables-2019 (accessed on 17 November 2022).

- IEA. Heating. Available online: https://www.iea.org/reports/heating (accessed on 17 November 2022).

- Abdel-Mawla, M.A.; Hassan, M.A.; Khalil, A. Phase change materials in thermally activated building systems: A comprehensive review. Int. J. Energy Res. 2022, 46, 11676–11717. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, G.; Wu, G.; Liu, S.; Gao, L. Thermally adaptive walls for buildings applications: A state of the art review. Energy Build. 2022, 271, 112314. [Google Scholar] [CrossRef]

- Kong, L.B.; Li, T.; Hng, H.H.; Boey, F.; Zhang, T.; Li, S. Waste thermal energy harvesting (III): Storage with phase change materials. In Mechanical and Thermal Energies; Springer: Berlin/Heidelberg, Germany, 2014; pp. 481–592. [Google Scholar]

- Nazir, H.; Batool, M.; Osorio, F.J.B.; Isaza-Ruiz, M.; Xu, X.H.; Vignarooban, K.; Phelan, P.; Inamuddin; Kannan, A.M. Recent developments in phase change materials for energy storage applications: A review. Int. J. Heat Mass Transfer 2019, 129, 491–523. [Google Scholar] [CrossRef]

- Voronin, D.V.; Mendgaziev, R.I.; Rubtsova, M.I.; Cherednichenko, K.A.; Demina, P.A.; Abramova, A.M.; Shchukin, D.G.; Vinokurov, V. Facile synthesis of shape-stable phase-change composites via the adsorption of stearic acid onto cellulose microfibers. Mater. Chem. Front. 2022, 6, 1033–1045. [Google Scholar] [CrossRef]

- Pirtsul, A.E.; Rubtsova, M.I.; Mendgaziev, R.I.; Cherednichenko, K.A.; Kruglov, V.V.; Komlev, A.S.; Lomova, M.V.; Vinokurov, V.; Voronin, D.V. Phase-change composites for bimodal solar/electromagnetic energy storage based on magnetite-modified cellulose microfibers. Mater. Lett. 2022, 327, 132997. [Google Scholar] [CrossRef]

- Rodríguez-Cumplido, F.; Pabón-Gelves, E.; Chejne-Jana, F. Recent developments in the synthesis of microencapsulated and nanoencapsulated phase change materials. J. Energy Storage 2019, 24, 100821. [Google Scholar] [CrossRef]

- Shchukina, E.; Shchukin, D.G. Nanocontainer-Based Active Systems: From Self-Healing Coatings to Thermal Energy Storage. Langmuir 2019, 35, 8603–8611. [Google Scholar] [CrossRef]

- Shchukina, E.M.; Graham, M.; Zheng, Z.; Shchukin, D.G. Nanoencapsulation of phase change materials for advanced thermal energy storage systems. Chem. Soc. Rev. 2018, 47, 4156–4175. [Google Scholar] [CrossRef] [Green Version]

- Huang, Y.; Stonehouse, A.; Abeykoon, C. Encapsulation methods for phase change materials—A critical review. Int. J. Heat Mass Transfer 2023, 200, 123458. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, D. Innovative design of microencapsulated phase change materials for thermal energy storage and versatile applications: A review. Sustain. Energ. Fuels 2019, 3, 1091–1149. [Google Scholar] [CrossRef]

- De Castro, P.F.; Shchukin, D.G. New Polyurethane/Docosane Microcapsules as Phase-Change Materials for Thermal Energy Storage. Chem. Eur. J. 2015, 21, 11174–11179. [Google Scholar] [CrossRef] [PubMed]

- De Castro, P.F.; Ahmed, A.; Shchukin, D.G. Confined-Volume Effect on the Thermal Properties of Encapsulated Phase Change Materials for Thermal Energy Storage. Chem. Eur. J. 2016, 22, 4389–4394. [Google Scholar] [CrossRef] [PubMed]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes, 2nd ed.; Smithers Rapra Technology Ltd.: Shawbury, UK, 2016; Volume 1, p. 374. [Google Scholar]

- Ionescu, M. Chemistry and Technology of Polyols for Polyurethanes, 2nd ed.; Smithers Rapra Technology Ltd.: Shawbury, UK, 2016; Volume 2, p. 422. [Google Scholar]

- Sikdar, P.; Dip, T.M.; Dhar, A.K.; Bhattacharjee, M.; Hoque, M.S.; Ali, S.B. Polyurethane (PU) based multifunctional materials: Emerging paradigm for functional textiles, smart, and biomedical applications. J. Appl. Polym. Sci. 2022, 139, e52832. [Google Scholar] [CrossRef]

- Kedzior, S.A.; Gabriel, V.A.; Dubé, M.A.; Cranston, E.D. Nanocellulose in Emulsions and Heterogeneous Water-Based Polymer Systems: A Review. Adv. Mater. 2021, 33, 2002404. [Google Scholar] [CrossRef] [PubMed]

- García, A.; Gandini, A.; Labidi, J.; Belgacem, N.; Bras, J. Industrial and crop wastes: A new source for nanocellulose biorefinery. Ind. Crops. Prod. 2016, 93, 26–38. [Google Scholar] [CrossRef]

- Yoo, Y.; Martinez, C.; Youngblood, J.P. Synthesis and Characterization of Microencapsulated Phase Change Materials with Poly(urea−urethane) Shells Containing Cellulose Nanocrystals. ACS Appl. Mater. Interfaces 2017, 9, 31763–31776. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Cathala, B.; Capron, I. Modulation of Cellulose Nanocrystals Amphiphilic Properties to Stabilize Oil/Water Interface. Biomacromolecules 2012, 13, 267–275. [Google Scholar] [CrossRef]

- Dai, H.; Wu, J.; Zhang, H.; Chen, Y.; Ma, L.; Huang, H.; Huang, Y.; Zhang, Y. Recent advances on cellulose nanocrystals for Pickering emulsions: Development and challenge. Trends Food Sci. Technol. 2020, 102, 16–29. [Google Scholar] [CrossRef]

- Li, J.; Hitchcock, A.P.; Stöver, H.D.H.; Shirley, I. A New Approach to Studying Microcapsule Wall Growth Mechanisms. Macromolecules 2009, 42, 2428–2432. [Google Scholar] [CrossRef]

- Ashida, K. Polyurethane and Related Foams: Chemistry and Technology; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2007; p. 153. [Google Scholar]

- Dassanayake, R.S.; Dissanayake, N.; Fierro, J.S.; Abidi, N.; Quitevis, E.L.; Boggavarappu, K.; Thalangamaarachchige, V.D. Characterization of cellulose nanocrystals by current spectroscopic techniques. Appl. Spectrosc. Rev. 2021, 57, 1–26. [Google Scholar] [CrossRef]

- Delebecq, E.; Pascault, J.-P.; Boutevin, B.; Ganachaud, F. On the Versatility of Urethane/Urea Bonds: Reversibility, Blocked Isocyanate, and Non-isocyanate Polyurethane. Chem. Rev. 2013, 113, 80–118. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Hori, N.; Takemura, A. Influence of NCO/OH ratio on preparation of four agricultural wastes liquefied polyols based polyurethane foams. Polym. Degrad. Stab. 2020, 179, 109256. [Google Scholar] [CrossRef]

- Pangon, A.; Dillon, G.P.; Runt, J. Influence of mixed soft segments on microphase separation of polyurea elastomers. Polymer 2014, 55, 1837–1844. [Google Scholar] [CrossRef]

- Mishra, A.K.; Chattopadhyay, D.K.; Sreedhar, B.; Raju, K.V.S.N. FT-IR and XPS studies of polyurethane-urea-imide coatings. Prog. Org. Coat. 2006, 55, 231–243. [Google Scholar] [CrossRef]

- Chung, O.; Jeong, S.-G.; Yu, S.; Kim, S. Thermal performance of organic PCMs/micronized silica composite for latent heat thermal energy storage. Energy Build. 2014, 70, 180–185. [Google Scholar] [CrossRef]

- Liu, Z.; Jiang, L.; Fu, X.; Zhang, J.; Lei, J. Preparation and characterization of n-octadecane-based reversible gel as form-stable phase change materials for thermal energy storage. J. Therm. Anal. Calorim. 2020, 140, 2159–2170. [Google Scholar] [CrossRef]

- Yu, S.; Wang, X.; Wu, D. Microencapsulation of n-octadecane phase change material with calcium carbonate shell for enhancement of thermal conductivity and serving durability: Synthesis, microstructure, and performance evaluation. Appl. Energy 2014, 114, 632–643. [Google Scholar] [CrossRef]

- Gong, J.; Li, J.; Xu, J.; Xiang, Z.; Mo, L. Research on cellulose nanocrystals produced from cellulose sources with various polymorphs. RSC Adv. 2017, 7, 33486–33493. [Google Scholar] [CrossRef] [Green Version]

- Mahmud, M.M.; Perveen, A.; Jahan, R.A.; Matin, M.A.; Wong, S.Y.; Li, X.; Arafat, M.T. Preparation of different polymorphs of cellulose from different acid hydrolysis medium. Int. J. Biol. Macromol. 2019, 130, 969–976. [Google Scholar] [CrossRef]

- He, Z.; Jiang, S.; Li, Q.; Wang, J.; Zhao, Y.; Kang, M. Facile and cost-effective synthesis of isocyanate microcapsules via polyvinyl alcohol-mediated interfacial polymerization and their application in self-healing materials. Compos. Sci. Technol. 2017, 138, 15–23. [Google Scholar] [CrossRef]

- Kalashnikova, I.; Bizot, H.; Bertoncini, P.; Cathala, B.; Capron, I. Cellulosic nanorods of various aspect ratios for oil in water Pickering emulsions. Soft Matter 2013, 9, 952–959. [Google Scholar] [CrossRef]

- Faden, M.; Höhlein, S.; Wanner, J.; König-Haagen, A.; Brüggemann, D. Review of Thermophysical Property Data of Octadecane for Phase-Change Studies. Materials 2019, 12, 2974. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xie, B.; Liu, G.; Jiang, S.; Zhao, Y.; Wang, D. Crystallization Behaviors of n-Octadecane in Confined Space: Crossover of Rotator Phase from Transient to Metastable Induced by Surface Freezing. J. Phys. Chem. B 2008, 112, 13310–13315. [Google Scholar] [CrossRef]

- Wu, X.Z.; Ocko, B.M.; Sirota, E.B.; Sinha, S.K.; Deutsch, M.; Cao, B.H.; Kim, M.W. Surface Tension Measurements of Surface Freezing in Liquid Normal Alkanes. Science 1993, 261, 1018–1021. [Google Scholar] [CrossRef] [PubMed]

- Kraack, H.; Sirota, E.B.; Deutsch, M. Measurements of homogeneous nucleation in normal-alkanes. J. Chem. Phys. 2000, 112, 6873–6885. [Google Scholar] [CrossRef]

- Yamagishi, Y.; Sugeno, T.; Ishige, T.; Takeuchi, H.; Pyatenko, A.T. An Evaluation of Microencapsulated PCM for Use in Cold Energy Transportation Medium. In Proceedings of the 31st Intersociety Energy Conversion Engineering Conference, Washington, DC, USA, 11–16 August 1996; pp. 2077–2083. [Google Scholar]

- Chen, Z.; Shan, F.; Cao, L.; Fang, G. Preparation and thermal properties of n-octadecane/molecular sieve composites as form-stable thermal energy storage materials for buildings. Energy Build. 2012, 49, 423–428. [Google Scholar] [CrossRef]

- Merlini, A.; Claumann, C.; Zibetti, A.W.; Coirolo, A.; Rieg, T.; Machado, R.A.F. Kinetic Study of the Thermal Decomposition of Cellulose Nanocrystals with Different Crystal Structures and Morphologies. Ind. Eng. Chem. Res. 2020, 59, 13428–13439. [Google Scholar] [CrossRef]

- Roman, M.; Winter, W.T. Effect of Sulfate Groups from Sulfuric Acid Hydrolysis on the Thermal Degradation Behavior of Bacterial Cellulose. Biomacromolecules 2004, 5, 1671–1677. [Google Scholar] [CrossRef]

- Oenema, J.; Liu, H.; Coensel, N.D.; Eschenbacher, A.; Van de Vijver, R.; Weng, J.; Li, L.; Wang, C.; Van Geem, K.M. Review on the pyrolysis products and thermal decomposition mechanisms of polyurethanes. J. Anal. Appl. Pyrolysis 2022, 168, 105723. [Google Scholar] [CrossRef]

- Zhao, Q.; He, F.; Zhang, Q.; Fan, J.; He, R.; Zhang, K.; Yan, H.; Yang, W. Microencapsulated phase change materials based on graphene Pickering emulsion for light-to-thermal energy conversion and management. Sol. Energy Mater. Sol. Cells 2019, 203, 110204. [Google Scholar] [CrossRef]

- Graham, M.; Smith, J.; Bilton, M.; Shchukina, E.; Novikov, A.A.; Vinokurov, V.; Shchukin, D.G. Highly Stable Energy Capsules with Nano-SiO2 Pickering Shell for Thermal Energy Storage and Release. ACS Nano 2020, 14, 8894–8901. [Google Scholar] [CrossRef] [PubMed]

| Sample | DSC | TGA/DTGA | |||||||

|---|---|---|---|---|---|---|---|---|---|

| TM, °C | ΔHM, J/g | TC, °C | ΔHC, J/g | E, % | Ton, °C * | MRDT, °C * | Weight Loss, % * | Residue at 800 °C, % * | |

| n-octadecane | 30.4 | 197 | 17.4 | 196 | - | 197 | 228 | 99 | 1 |

| PU/NCC capsules | 28.5 | 79 | 13.7 | 78 | 40 | 150, 227, 346 | 173, 263, 371 | 18, 41, 24 | 17 |

| NCC | - | - | - | - | - | 287, 348 | 302, 372 | 56, 21 | 21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Voronin, D.; Mendgaziev, R.; Sayfutdinova, A.; Kugai, M.; Rubtsova, M.; Cherednichenko, K.; Shchukin, D.; Vinokurov, V. Phase-Change Microcapsules with a Stable Polyurethane Shell through the Direct Crosslinking of Cellulose Nanocrystals with Polyisocyanate at the Oil/Water Interface of Pickering Emulsion. Materials 2023, 16, 29. https://doi.org/10.3390/ma16010029

Voronin D, Mendgaziev R, Sayfutdinova A, Kugai M, Rubtsova M, Cherednichenko K, Shchukin D, Vinokurov V. Phase-Change Microcapsules with a Stable Polyurethane Shell through the Direct Crosslinking of Cellulose Nanocrystals with Polyisocyanate at the Oil/Water Interface of Pickering Emulsion. Materials. 2023; 16(1):29. https://doi.org/10.3390/ma16010029

Chicago/Turabian StyleVoronin, Denis, Rais Mendgaziev, Adeliya Sayfutdinova, Maria Kugai, Maria Rubtsova, Kirill Cherednichenko, Dmitry Shchukin, and Vladimir Vinokurov. 2023. "Phase-Change Microcapsules with a Stable Polyurethane Shell through the Direct Crosslinking of Cellulose Nanocrystals with Polyisocyanate at the Oil/Water Interface of Pickering Emulsion" Materials 16, no. 1: 29. https://doi.org/10.3390/ma16010029

APA StyleVoronin, D., Mendgaziev, R., Sayfutdinova, A., Kugai, M., Rubtsova, M., Cherednichenko, K., Shchukin, D., & Vinokurov, V. (2023). Phase-Change Microcapsules with a Stable Polyurethane Shell through the Direct Crosslinking of Cellulose Nanocrystals with Polyisocyanate at the Oil/Water Interface of Pickering Emulsion. Materials, 16(1), 29. https://doi.org/10.3390/ma16010029