Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions

Abstract

1. Introduction

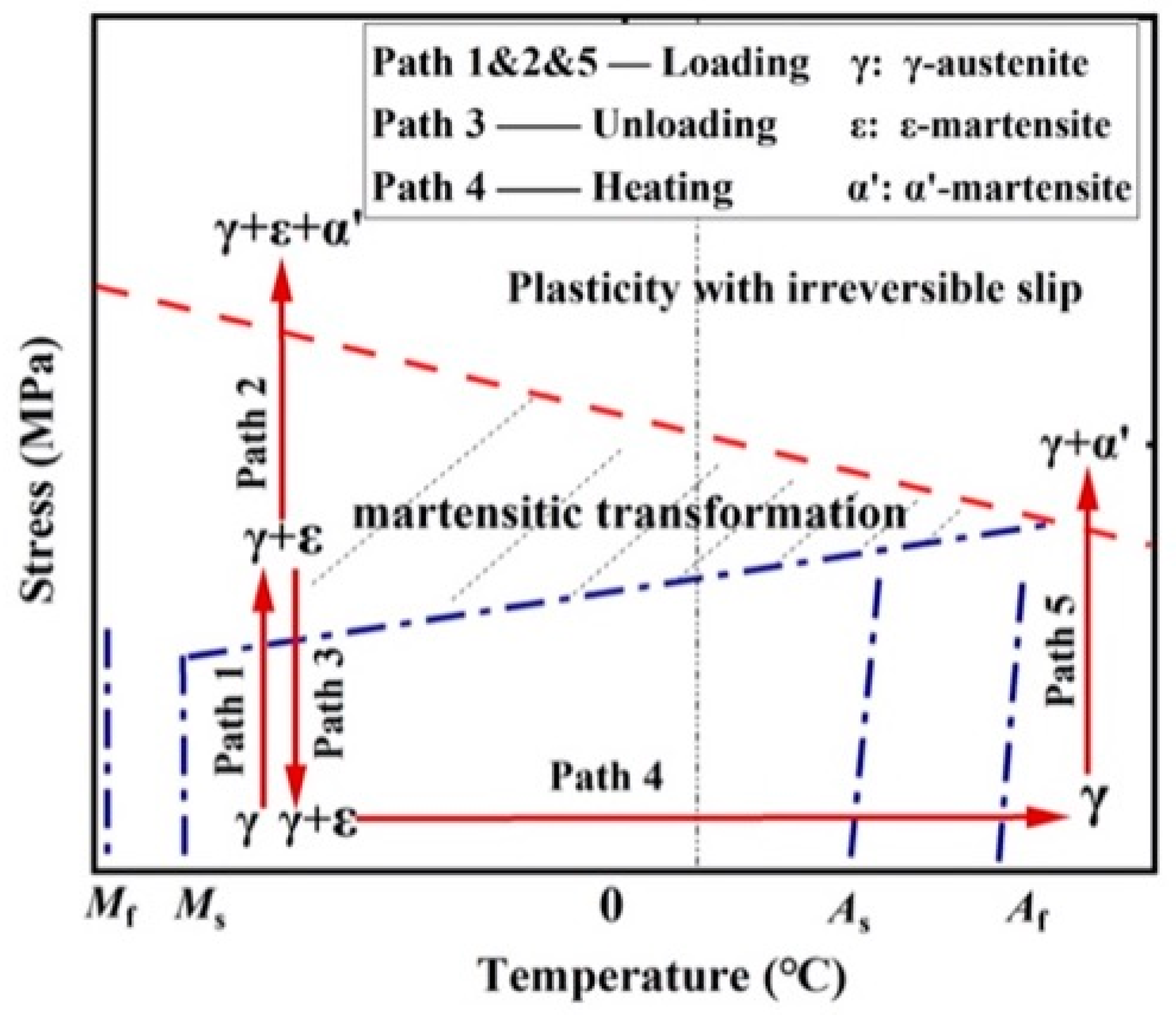

1.1. Shape Memory Effect

1.2. Brief Introduction to the Iron-Based SMAs (FeSMAs)

1.3. Fatigue Behavior of Iron-Based SMAs under Mechanical Loading

1.4. Civil Engineering Applications

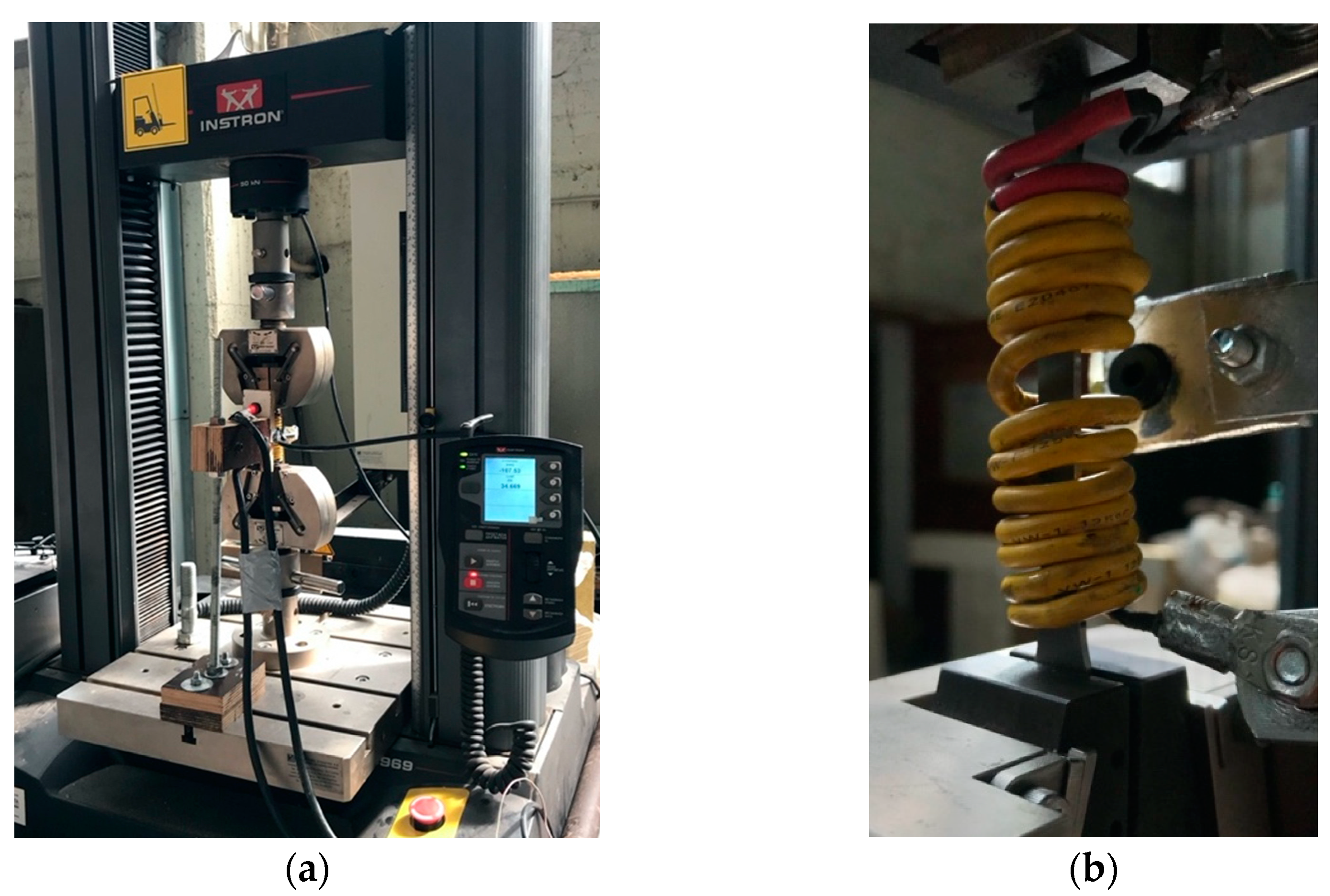

2. Materials and Methods

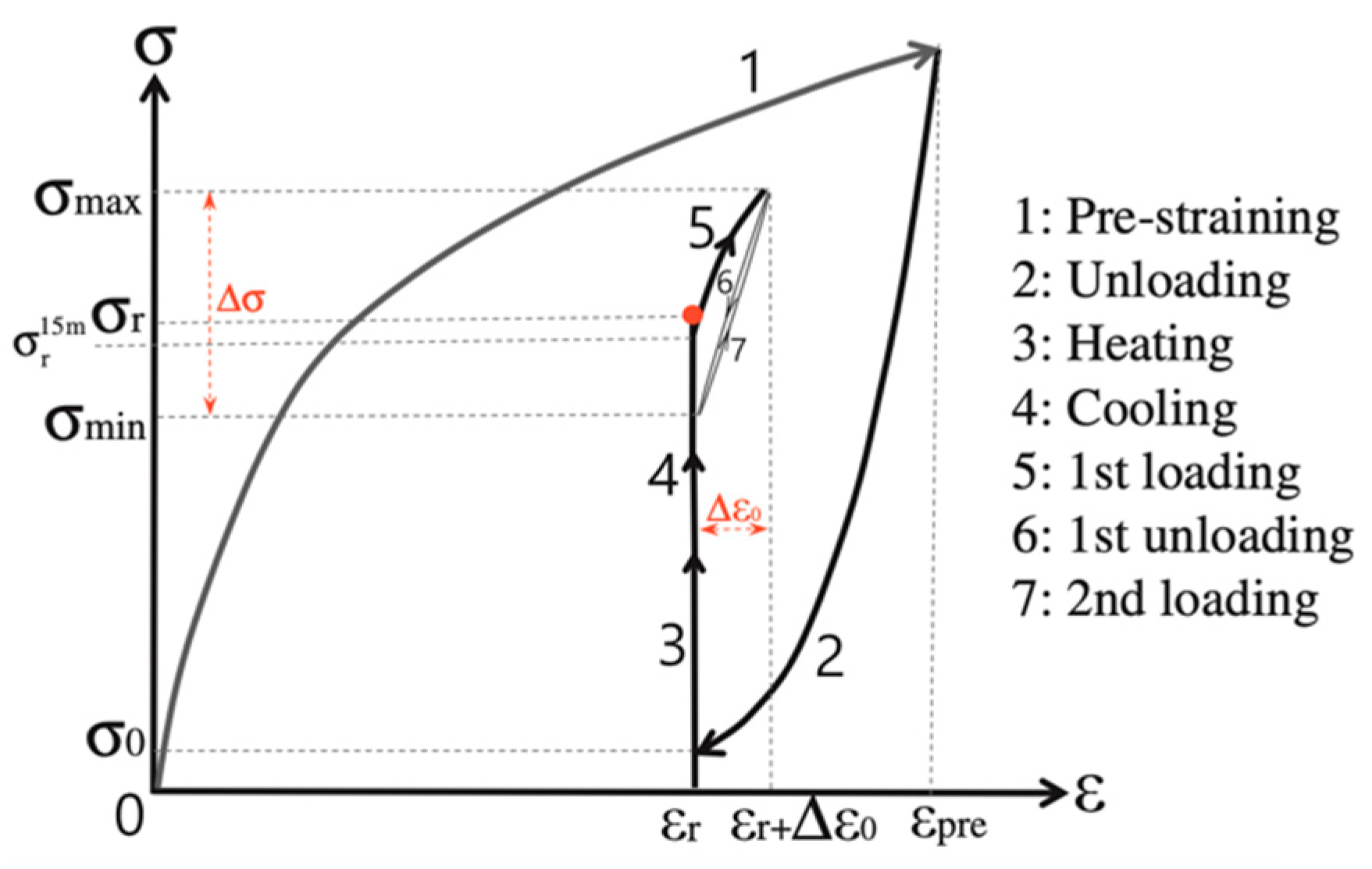

2.1. Tensile Test Procedure

2.2. Low-Cycle Fatigue Test Procedure

- Loading frequency: Four different frequencies are examined: 0.5, 1, 2 and 4 Hz, which are imposed on the samples C1, C2, C3 and C4, respectively.

- Level of pre-strain: Pre-strain values are denoted as εr in Figure 8. For the present study, pre-strain values of 1.85%, 1.80%, 1.90% and 2% were imposed on the specimens C1, C2, C3 and C4, respectively.

- Limit stress target value: Thermal expansion, which occurs at the beginning of the heating process, induces stress drop [40]. In order to avoid the formation of compressive stresses during that phase, setting a lower stress limit is practical. While Ghafoori et al. [40] employ a stable lower limit of 50 MPa, the present study uses four different ones: 125, 70, 120 and 150 MPa on samples C1, C2, C3 and C4, respectively.

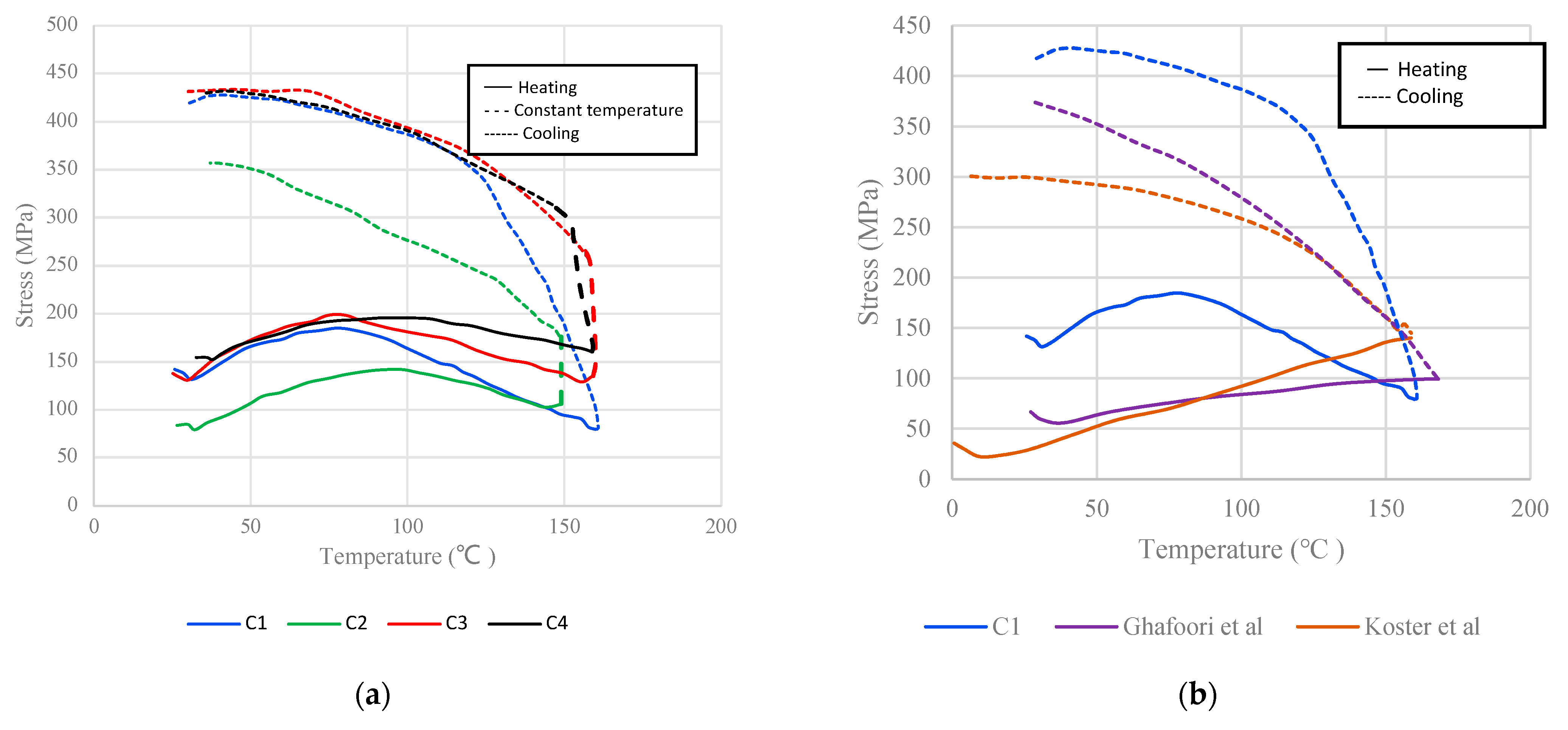

3. Results

3.1. Tensile Tests

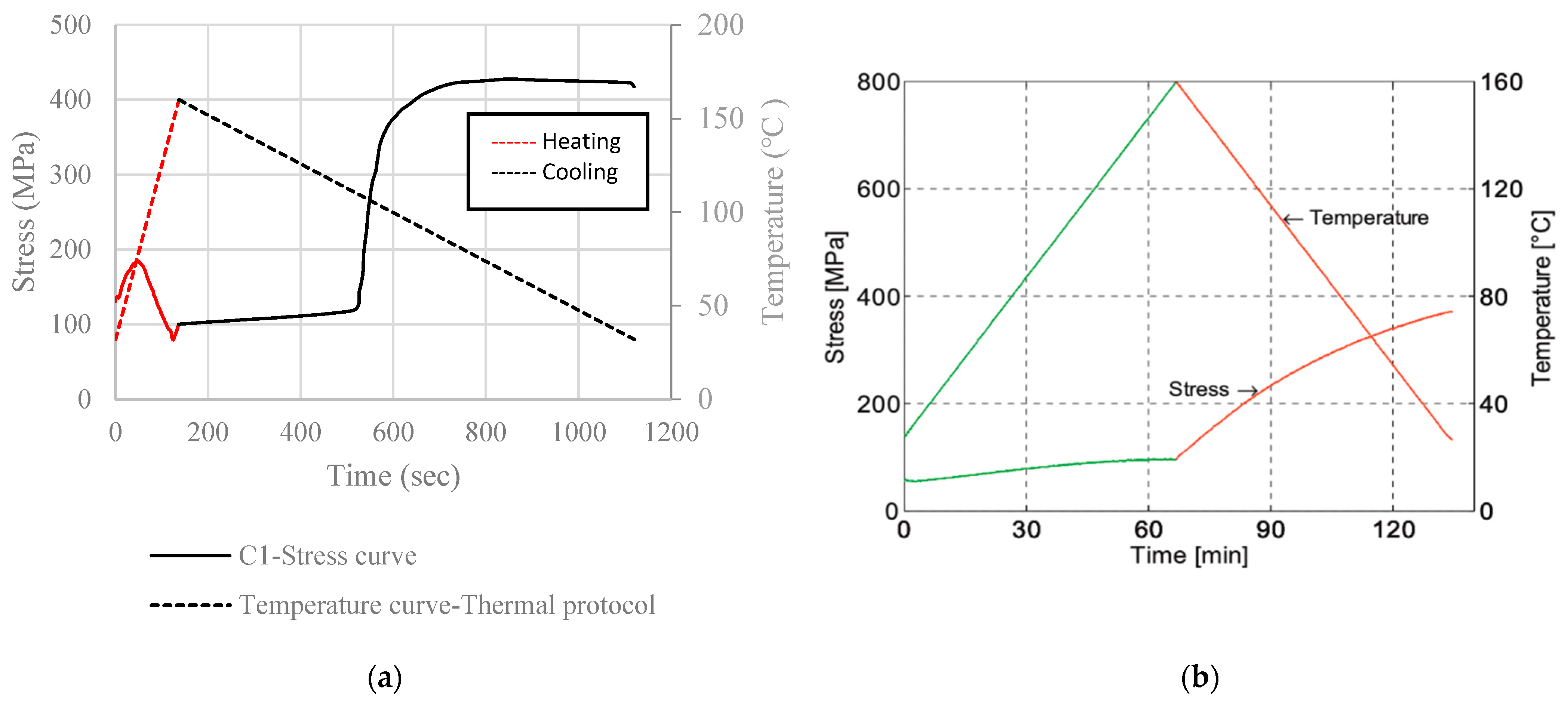

3.2. Low-Cycle Fatigue Tests

4. Discussion

4.1. Tensile Tests

4.2. Low-Cycle Fatigue Tests

5. Conclusions

- Cyclic loading was applied with four different frequencies (i.e., different strain rates) that were missing from the literature. It was shown that while at 0.5, 1 and 2 Hz, the behavior of the alloy was similar, at 4 Hz, a hysteresis loop was observed. This finding confirms the alloy’s energy-dissipating capacity.

- The studied alloy demonstrated a significant recovery stress, which was largely maintained after the fatigue tests. After the loading cycles, a small drop in the recovery stress, around 2–3% was observed. Moreover, the measured recovery stress decrease, during the 15 min hold time, was relatively small.

- The experimental results are promising in terms of the on-field prestress feasibility. Recovery stress values are high enough, although accuracy can be an issue that needs careful handling.

- The heating and cooling rate has a profound effect, significantly changing the thermomechanical behavior of the material.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lagoudas, D.C. Shape Memory Alloys, Modeling and Engineering Applications; Springer: New York, NY, USA, 2008. [Google Scholar] [CrossRef]

- Hartl, D.J.; Lagoudas, D. Aerospace applications of shape memory alloys. Proc. Inst. Mech. Eng. Part G J. Aerosp. Eng. 2007, 4, 535–552. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials 2022, 15, 1723. [Google Scholar] [CrossRef] [PubMed]

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ⇄ϵ transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1984, 30, 1177–1183. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Yamaji, Y.; Mori, T. Orientation and composition dependencies of shape memory effect IN Fe-Mn-Si alloys. Acta Met. 1984, 32, 539–547. [Google Scholar] [CrossRef]

- Murakami, M.; Otsuka, H.; Suzuki, H.; Matsuda, S. Complete shape memory effect in polycrystalline Fe-Mn-Si alloys. Trans-Actions Iron Steel Inst. Jpn. 1986, 27, 985–990. [Google Scholar]

- Otsuka, H.; Yamada, H.; Maruyama, T.; Tanahashi, H.; Matsuda, S.; Murakami, M. Effects of alloying additions on Fe-Mn-Si shape memory alloys. ISIJ Int. 1990, 30, 674–679. [Google Scholar] [CrossRef]

- Otsuka, H. Fe-Mn-Si Based Shape Memory Alloys. MRS Proc. 1991, 246, 309–320. [Google Scholar] [CrossRef]

- Tsuzaki, K.; Natsume, Y.; Kurokawa, Y.; Maki, T. Improvement of the shape memory effect in Fe-Mn-Si alloys by the addition of carbon. Scr. Met. Mater. 1992, 27, 471–473. [Google Scholar] [CrossRef]

- Jian, L.; Wayman, C. Shape memory effect and related phenomena in a microalloyed Fe-Mn-Si alloy. Mater. Charact. 1994, 32, 215–227. [Google Scholar] [CrossRef]

- Kajiwara, S.; Liu, D.; Kikuchi, T.; Shinya, N. Remarkable improvement of shape memory effect in Fe-Mn-Si based shape memory alloys by producing NbC precipitates. Scr. Mater. 2001, 44, 2809–2814. [Google Scholar] [CrossRef]

- Ariapour, A.; Perovic, D.D.; Yakubtsov, I. Shape-memory effect and strengthening mechanism in a Nb and N-doped Fe-Mn-Si-based alloy. Met. Mater. Trans. A 2001, 32, 1621–1628. [Google Scholar] [CrossRef]

- Wen, Y.; Yan, M.; Li, N. Effects of carbon addition and aging on the shape memory effect of Fe–Mn–Si–Cr–Ni alloys. Scr. Mater. 2004, 50, 441–444. [Google Scholar] [CrossRef]

- Farjami, S.; Hiraga, K.; Kubo, H. Shape Memory Effect and Crystallographic Investigation in VN Containing Fe-Mn-Si-Cr Alloys. Mater. Trans. 2004, 45, 930–935. [Google Scholar] [CrossRef]

- Otsuka, K.; Shimizu, K. MRS International Meeting on Advanced Materials. In Proceeding of the MRS International Meeting on Advanced Materials, Tokyo, Japan, 31 May–3 June 1988; Volume 9. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, MA, USA, 1998. [Google Scholar]

- Watanabe, Y.; Mori, Y.; Sato, A. Training effect in Fe-Mn-Si shape-memory alloys. J. Mater. Sci. 1993, 28, 1509–1514. [Google Scholar] [CrossRef]

- Wang, D.F.; Chen, Y.R.; Gong, F.Y.; Liu, D.Z.; Liu, W.X. The Effect of Thermomechanical Training on the Microstructures of Fe-Mn-Si Shape Memory Alloy. J. Phys. Colloq. 1995, 05, 527–530. [Google Scholar] [CrossRef][Green Version]

- Chung, C.; Shuchuan, C.; Zuyao), T.H. Thermomechanical training behavior and its dynamic mechanical analysis in an Fe-Mn-Si shape memory alloy. Mater. Charact. 1996, 37, 227–236. [Google Scholar] [CrossRef]

- Liu, D.Z.; Kajiwara, S.; Kikuchi, T.; Shinya, N. Atomic force microscopy study on microstructural changes by ‘training’ in Fe-Mn-Si-based shape memory alloys. Philos. Mag. 2003, 83, 2875–2897. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Kikuchi, T.; Ogawa, K.; Yin, F.X.; Kajiwara, S.; Kushibe, A.; Ogawa, T. Internal Friction of Fe-Mn-Si-Based Shape Memory Alloys Containing Nb and C and Their Application as a Seismic Damping Material. Key Eng. Mater. 2006, 319, 53–58. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Sahu, P.; Kikuchi, T.; Ogawa, K.; Kajiwara, S.; Kushibe, A.; Higashino, M.; Ogawa, T. Vibration mitigation by the reversible fcc/hcp martensitic transformation during cyclic tension–compression loading of an Fe–Mn–Si-based shape memory alloy. Scr. Mater. 2006, 54, 1885–1890. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Tsuzaki, K. Effect of alloying composition on low-cycle fatigue properties and microstructure of Fe–30Mn–(6−x)Si–xAl TRIP/TWIP alloys. Mater. Sci. Eng. A 2013, 587, 192–200. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Effect of γ to ε martensitic transformation on low-cycle fatigue behaviour and fatigue microstructure of Fe–15Mn–10Cr–8Ni–xSi austenitic alloys. Acta Mater. 2016, 105, 207–218. [Google Scholar] [CrossRef]

- Fang, C.; Wang, W.; Ji, Y.; Yam, M. Superior low-cycle fatigue performance of iron-based SMA for seismic damping application. J. Constr. Steel Res. 2021, 184, 106817. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Nikulin, I.; Ogawa, K.; Sekido, K.; Takamori, S.; Maruyama, T.; Chiba, Y.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Designing Fe–Mn–Si alloys with improved low-cycle fatigue lives. Scr. Mater. 2015, 99, 49–52. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Microstructure Evolution Associated with a Superior Low-Cycle Fatigue Resistance of the Fe-30Mn-4Si-2Al Alloy. Met. Mater. Trans. A 2015, 46, 5103–5113. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Kushibe, A.; Inoue, Y.; Otsuka, H.; Tsuzaki, K. Effect of strain amplitude on the low-cycle fatigue behavior of a new Fe–15Mn–10Cr–8Ni–4Si seismic damping alloy. Int. J. Fatigue 2016, 88, 132–141. [Google Scholar] [CrossRef]

- Tasaki, W.; Sawaguchi, T.; Nikulin, I.; Sekido, K.; Tsuchiya, K. Effect of Deformation Temperature on Low-Cycle Fatigue Properties of Fe-28Mn-6Si-5Cr Shape Memory Alloy. Mater. Trans. 2016, 57, 639–646. [Google Scholar] [CrossRef]

- Alagha, A.N.; Hussain, S.; Zaki, W. Additive manufacturing of shape memory alloys: A review with emphasis on powder bed systems. Mater. Des. 2021, 204, 109654. [Google Scholar] [CrossRef]

- Ferretto, I.; Kim, D.; Della Ventura, N.; Shahverdi, M.; Lee, W.; Leinenbach, C. Laser powder bed fusion of a Fe–Mn–Si shape memory alloy. Addit. Manuf. 2021, 46, 102071. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloys for prestressed near-surface mounted strengthening of reinforced concrete beams. Constr. Build. Mater. 2016, 112, 28–38. [Google Scholar] [CrossRef]

- Shahverdi, M.; Czaderski, C.; Annen, P.; Motavalli, M. Strengthening of RC beams by iron-based shape memory alloy bars embedded in a shotcrete layer. Eng. Struct. 2016, 117, 263–273. [Google Scholar] [CrossRef]

- Izadi, M.; Ghafoori, E.; Shahverdi, M.; Motavalli, M.; Maalek, S. Development of an iron-based shape memory alloy (Fe-SMA) strengthening system for steel plates. Eng. Struct. 2018, 174, 433–446. [Google Scholar] [CrossRef]

- Strieder, E.; Aigner, C.; Petautschnig, G.; Horn, S.; Marcon, M.; Schwenn, M.; Zeman, O.; Castillo, P.; Wan-Wendner, R.; Bergmeister, K. Strengthening of Reinforced Concrete Beams with Externally Mounted Sequentially Activated Iron-Based Shape Memory Alloys. Materials 2019, 12, 345. [Google Scholar] [CrossRef] [PubMed]

- Rezapour, M.; Ghassemieh, M.; Motavalli, M.; Shahverdi, M. Numerical Modeling of Unreinforced Masonry Walls Strengthened with Fe-Based Shape Memory Alloy Strips. Materials 2021, 14, 2961. [Google Scholar] [CrossRef]

- Khalil, W.; Mikolajczak, A.; Bouby, C.; Ben Zineb, T. A constitutive model for Fe-based shape memory alloy considering martensitic transformation and plastic sliding coupling: Application to a finite element structural analysis. J. Intell. Mater. Syst. Struct. 2012, 23, 1143–1160. [Google Scholar] [CrossRef]

- Abouali, S.; Shahverdi, M.; Ghassemieh, M.; Motavalli, M. Nonlinear simulation of reinforced concrete beams retrofitted by near-surface mounted iron-based shape memory alloys. Eng. Struct. 2019, 187, 133–148. [Google Scholar] [CrossRef]

- Ghafoori, E.; Hosseini, E.; Leinenbach, C.; Michels, J.; Motavalli, M. Fatigue behavior of a Fe-Mn-Si shape memory alloy used for prestressed strengthening. Mater. Des. 2017, 133, 349–362. [Google Scholar] [CrossRef]

- Leinenbach, C.; Lee, W.; Lis, A.; Arabi-Hashemi, A.; Cayron, C.; Weber, B. Creep and stress relaxation of a FeMnSi-based shape memory alloy at low temperatures. Mater. Sci. Eng. A 2016, 677, 106–115. [Google Scholar] [CrossRef]

- Lee, W.; Weber, B.; Feltrin, G.; Czaderski, C.; Motavalli, M.; Leinenbach, C. Phase transformation behavior under uniaxial deformation of an Fe–Mn–Si–Cr–Ni–VC shape memory alloy. Mater. Sci. Eng. A 2013, 581, 1–7. [Google Scholar] [CrossRef]

- Khalil, W.; Saint-Sulpice, L.; Chirani, S.A.; Bouby, C.; Mikolajczak, A.; Ben Zineb, T. Experimental analysis of Fe-based shape memory alloy behavior under thermomechanical cyclic loading. Mech. Mater. 2013, 63, 1–11. [Google Scholar] [CrossRef]

- Koster, M.; Lee, W.; Schwarzenberger, M.; Leinenbach, C. Cyclic deformation and structural fatigue behavior of an FE–Mn–Si shape memory alloy. Mater. Sci. Eng. A 2015, 637, 29–39. [Google Scholar] [CrossRef]

| Specimen | Pre-Strain (%) | Unloading Target Value (MPa) | Residual Strain ε (%) | Recovery Stress σr (MPa) | Recovery Stress after 15′ σr15min (MPa) |

|---|---|---|---|---|---|

| C1 | 1.85 | 125 | 1.50 | 427 | 418 |

| C2 | 1.80 | 70 | 1.30 | 354 | 347 |

| C3 | 1.90 | 120 | 1.40 | 424 | 416 |

| C4 | 2.00 | 150 | 1.50 | 437 | 428 |

| Specimen | Stress Drop Due to Relaxation (MPa) | Stress Drop Percentage (%) | Cyclic Loading Frequency (Hz) | Recovery Stress after Cyclic Loading σr (MPa) | |

| C1 | 9 | 2.10 | 0.5 | 404 | |

| C2 | 7 | 2.00 | 1 | 340 | |

| C3 | 8 | 1.90 | 2 | 409 | |

| C4 | 9 | 2.10 | 4 | 420 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marinopoulou, E.; Katakalos, K. Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions. Materials 2023, 16, 237. https://doi.org/10.3390/ma16010237

Marinopoulou E, Katakalos K. Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions. Materials. 2023; 16(1):237. https://doi.org/10.3390/ma16010237

Chicago/Turabian StyleMarinopoulou, Eva, and Konstantinos Katakalos. 2023. "Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions" Materials 16, no. 1: 237. https://doi.org/10.3390/ma16010237

APA StyleMarinopoulou, E., & Katakalos, K. (2023). Thermomechanical Fatigue Testing on Fe-Mn-Si Shape Memory Alloys in Prestress Conditions. Materials, 16(1), 237. https://doi.org/10.3390/ma16010237