Influence of High-Pressure Torsion Processing on the Tribological Properties of Aluminum Metal Matrix Composites

Abstract

1. Introduction

- Study the effect of Al MMC sample processing methods on their tribological characteristics.

- Study the effect of the processing method on the worn surface morphologies of samples, and wear test balls and wear diapers.

2. Materials and Methods

3. Results and Discussion

3.1. Wear Characteristics

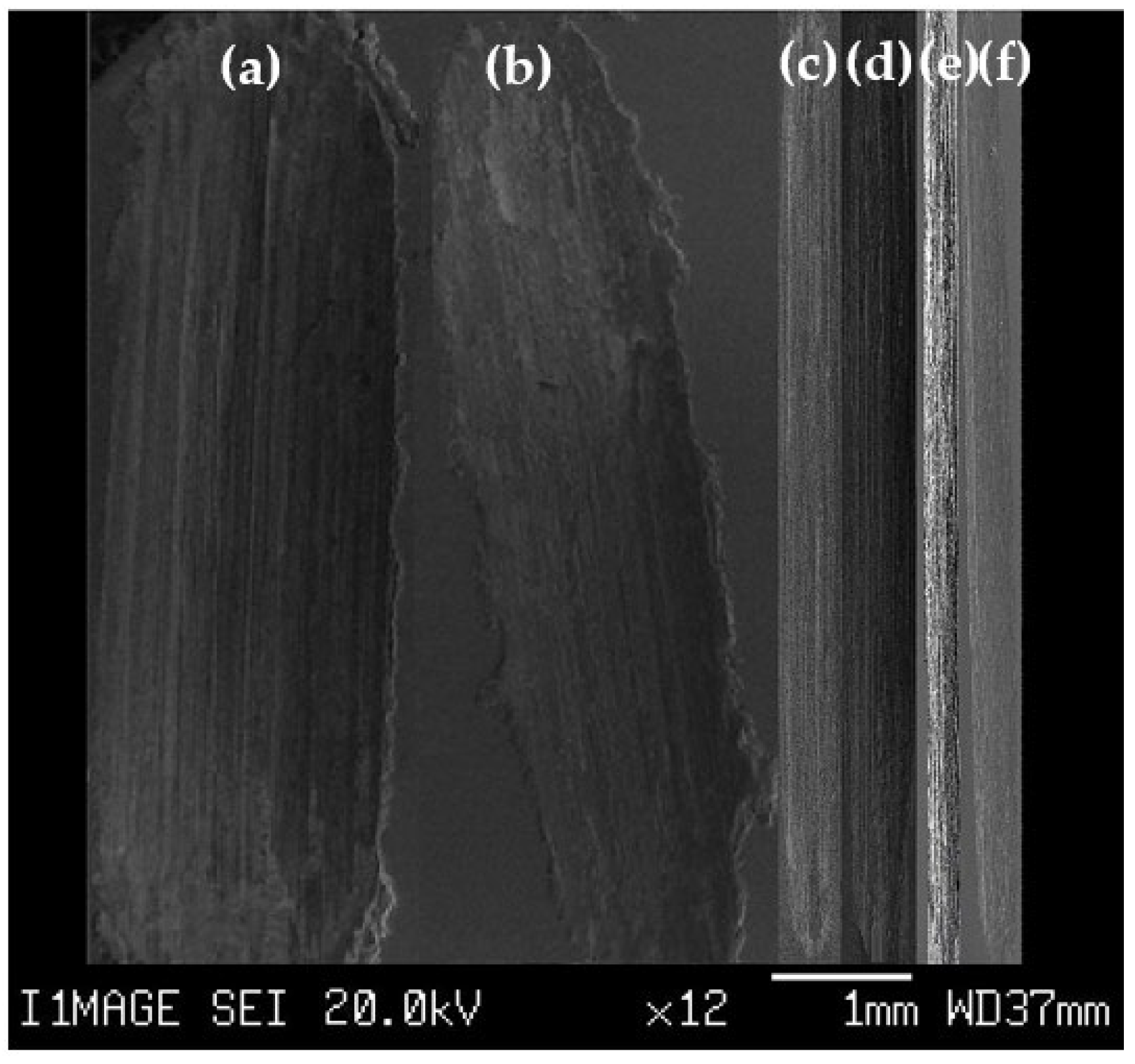

3.1.1. Wear Scars

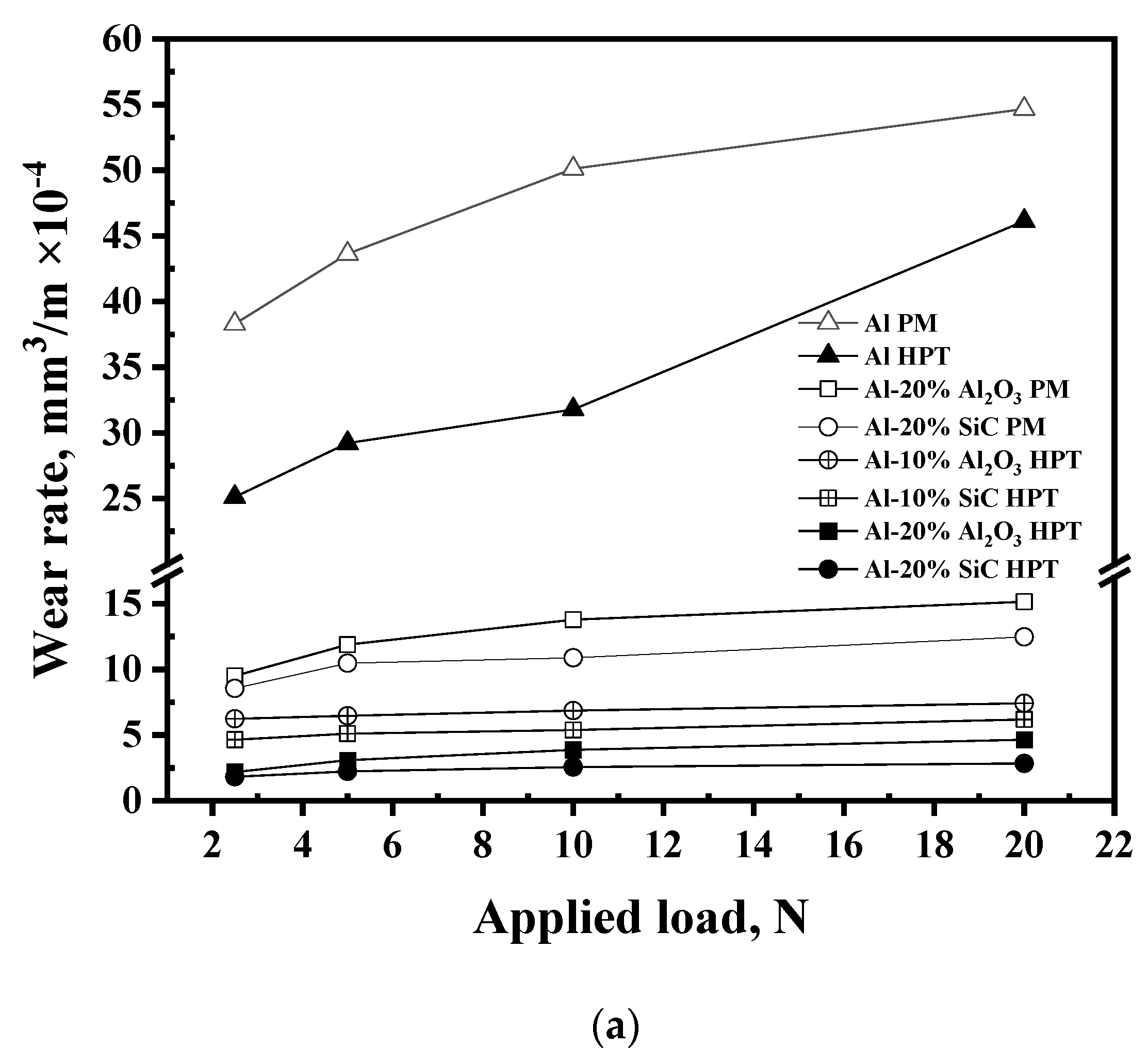

3.1.2. Wear Rate Results

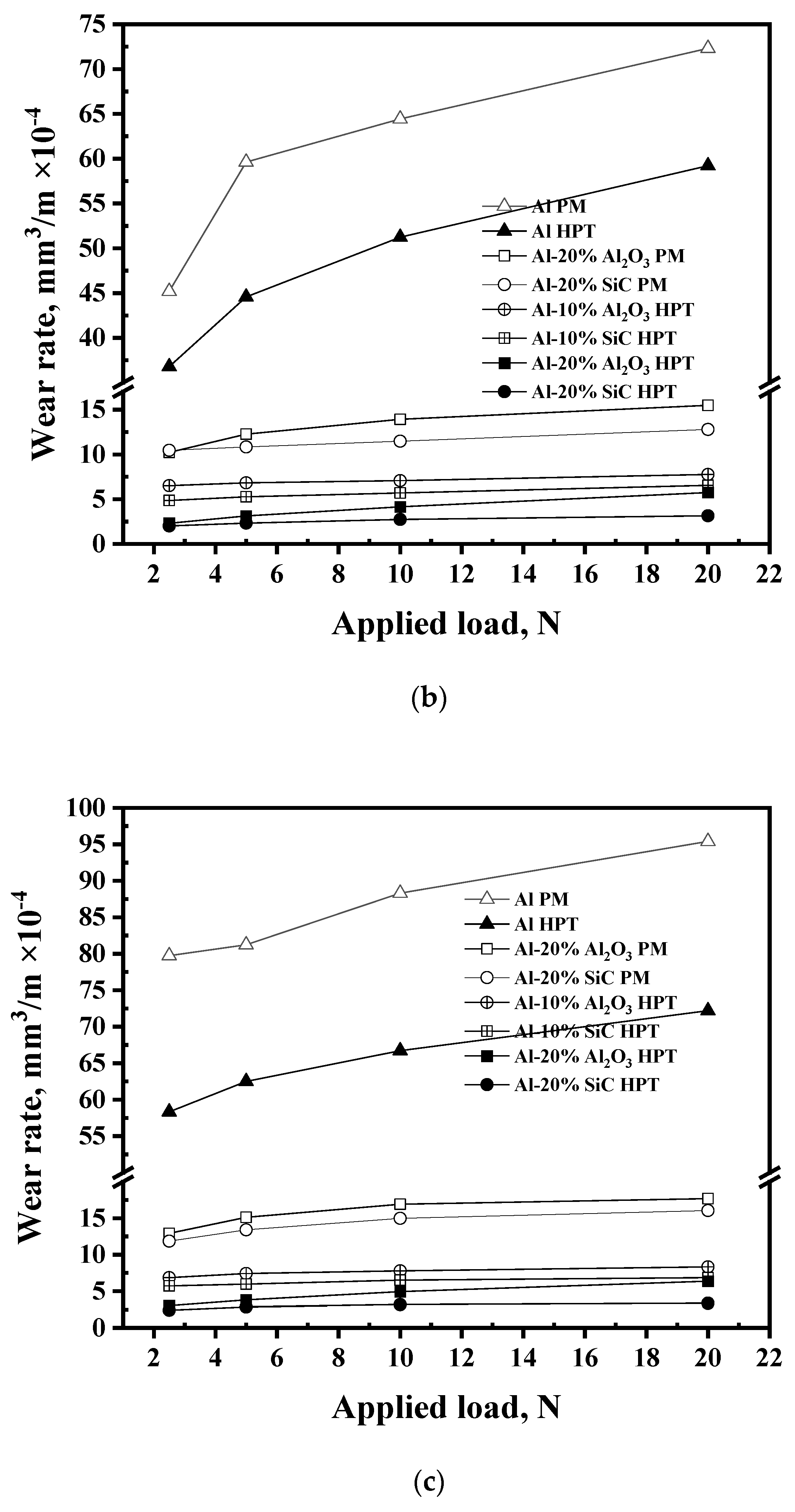

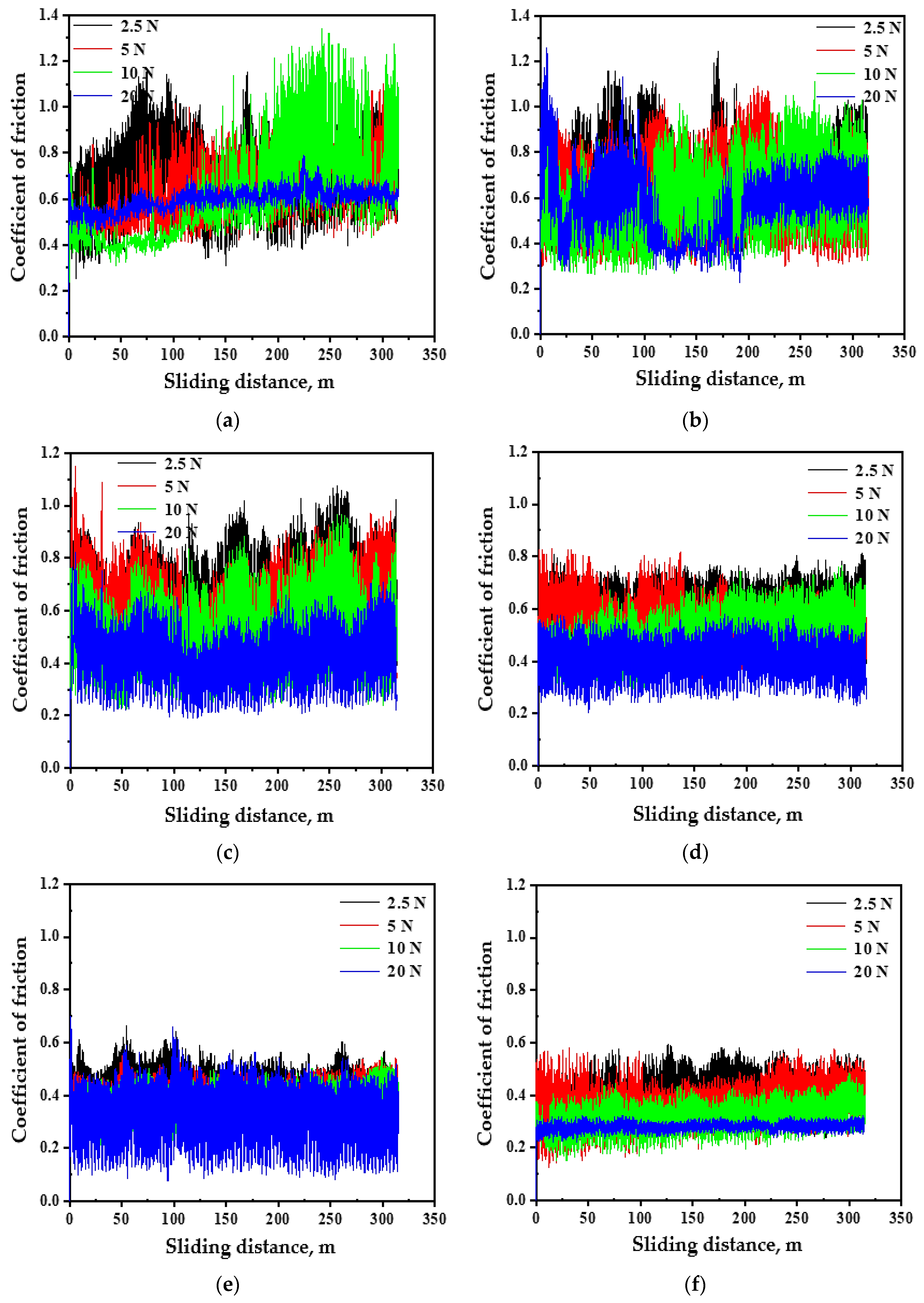

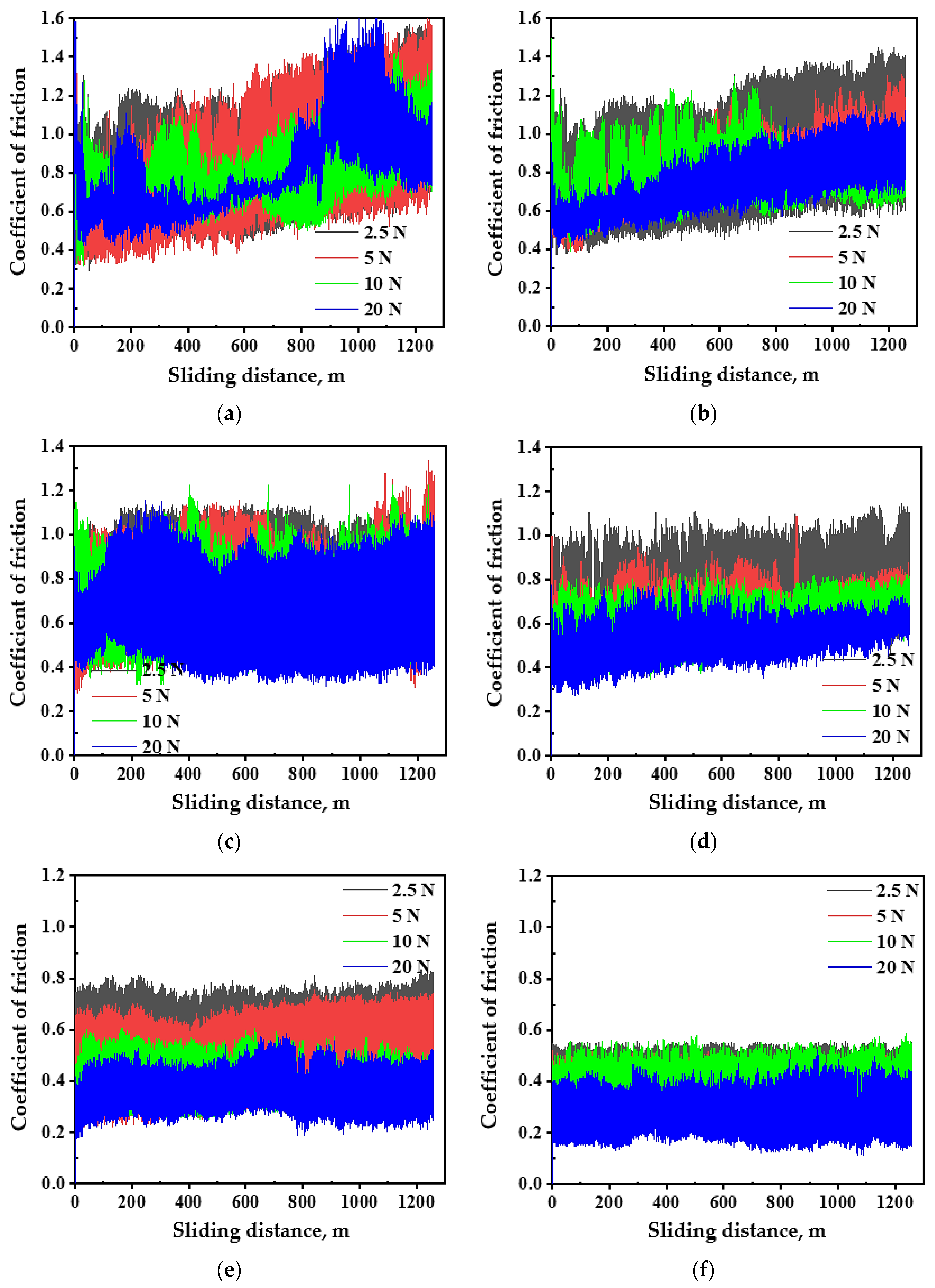

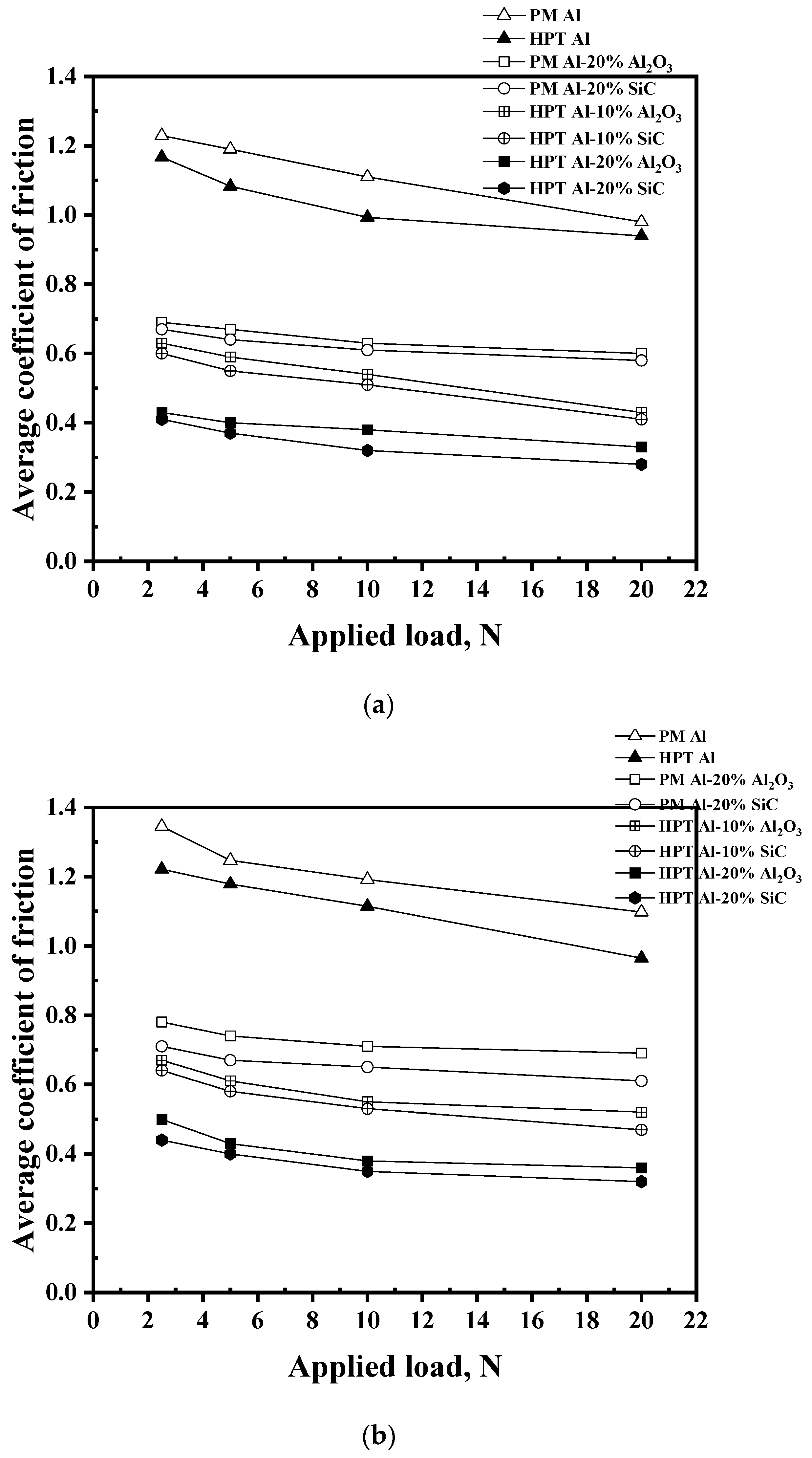

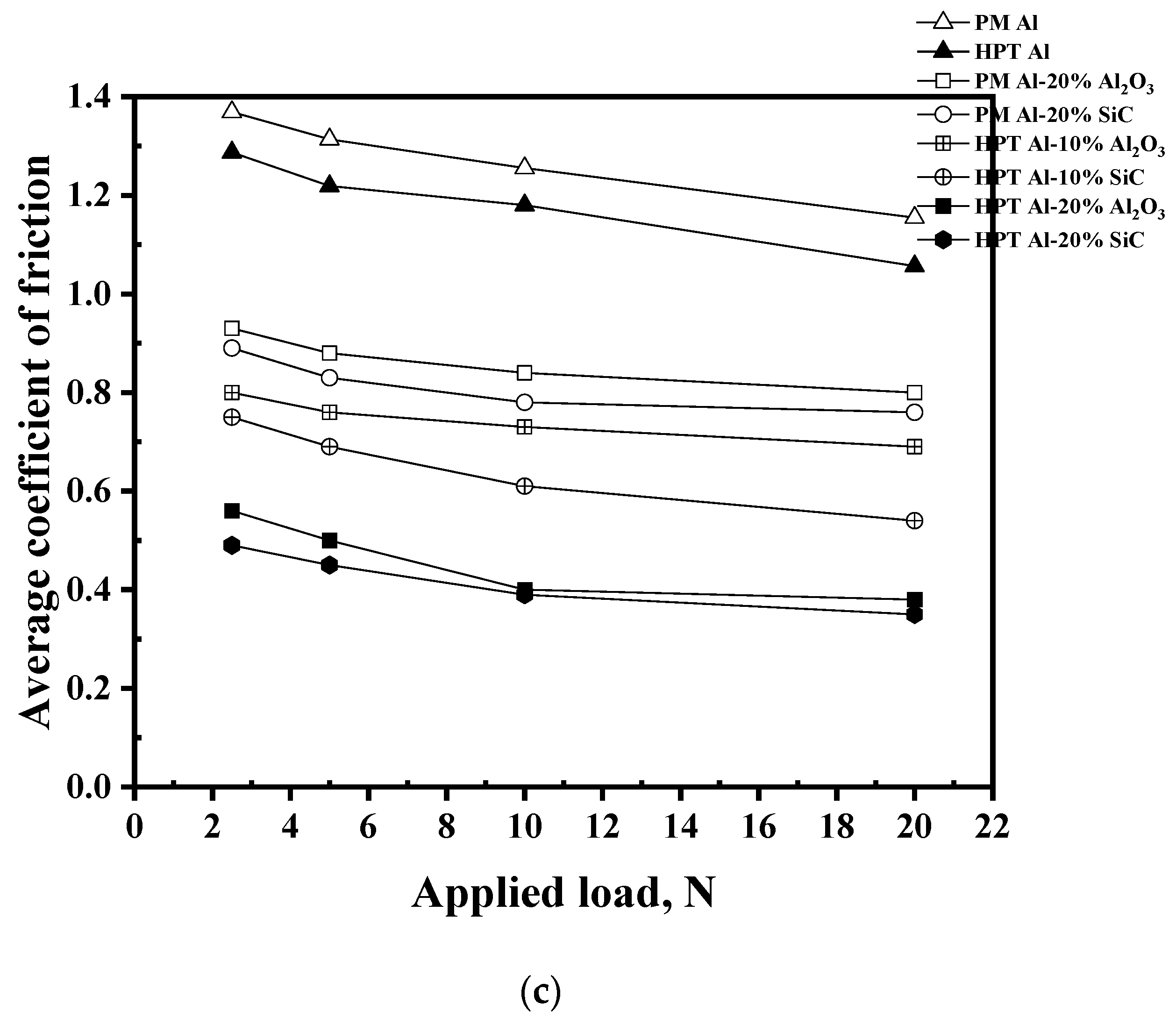

3.2. Friction Characteristics

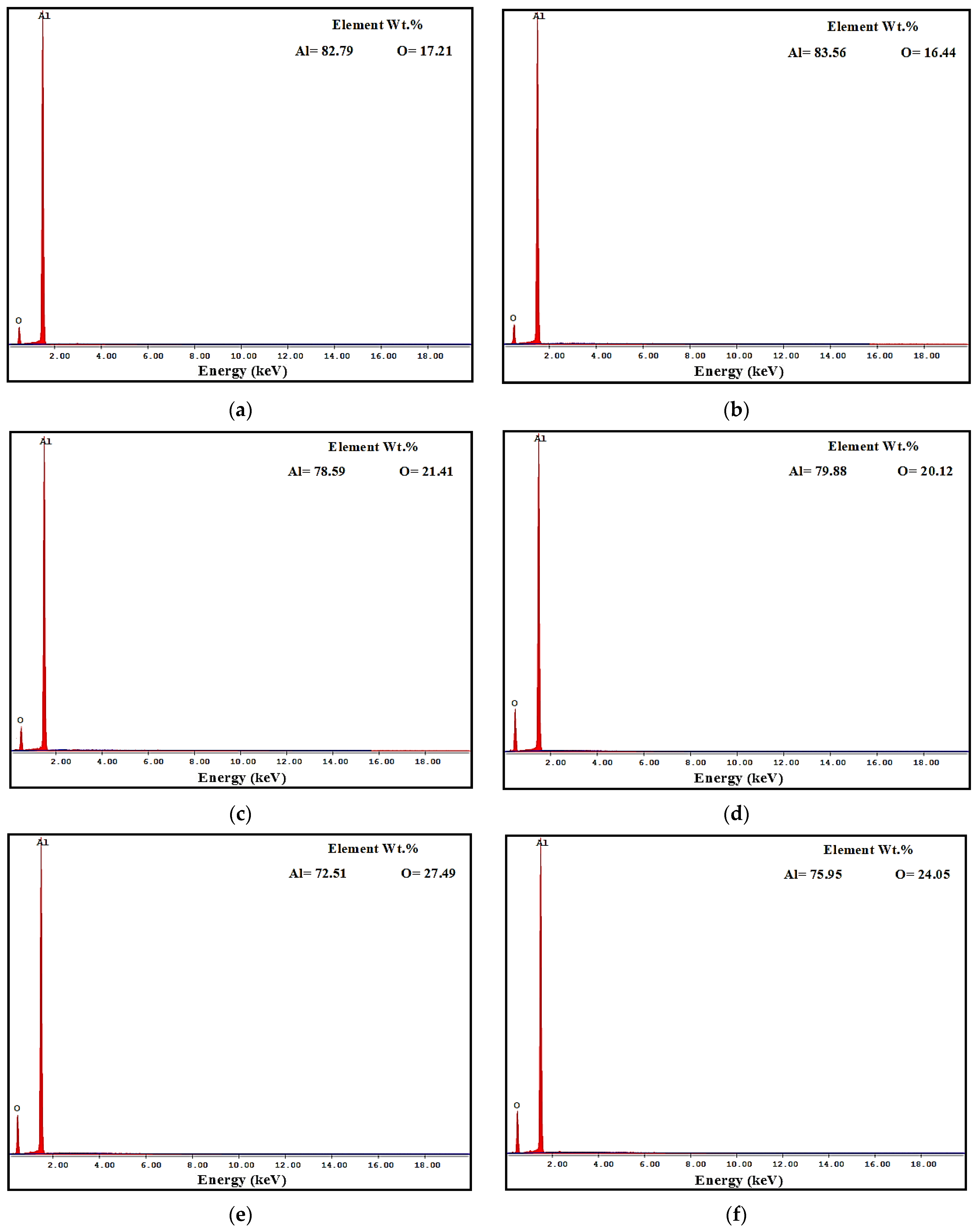

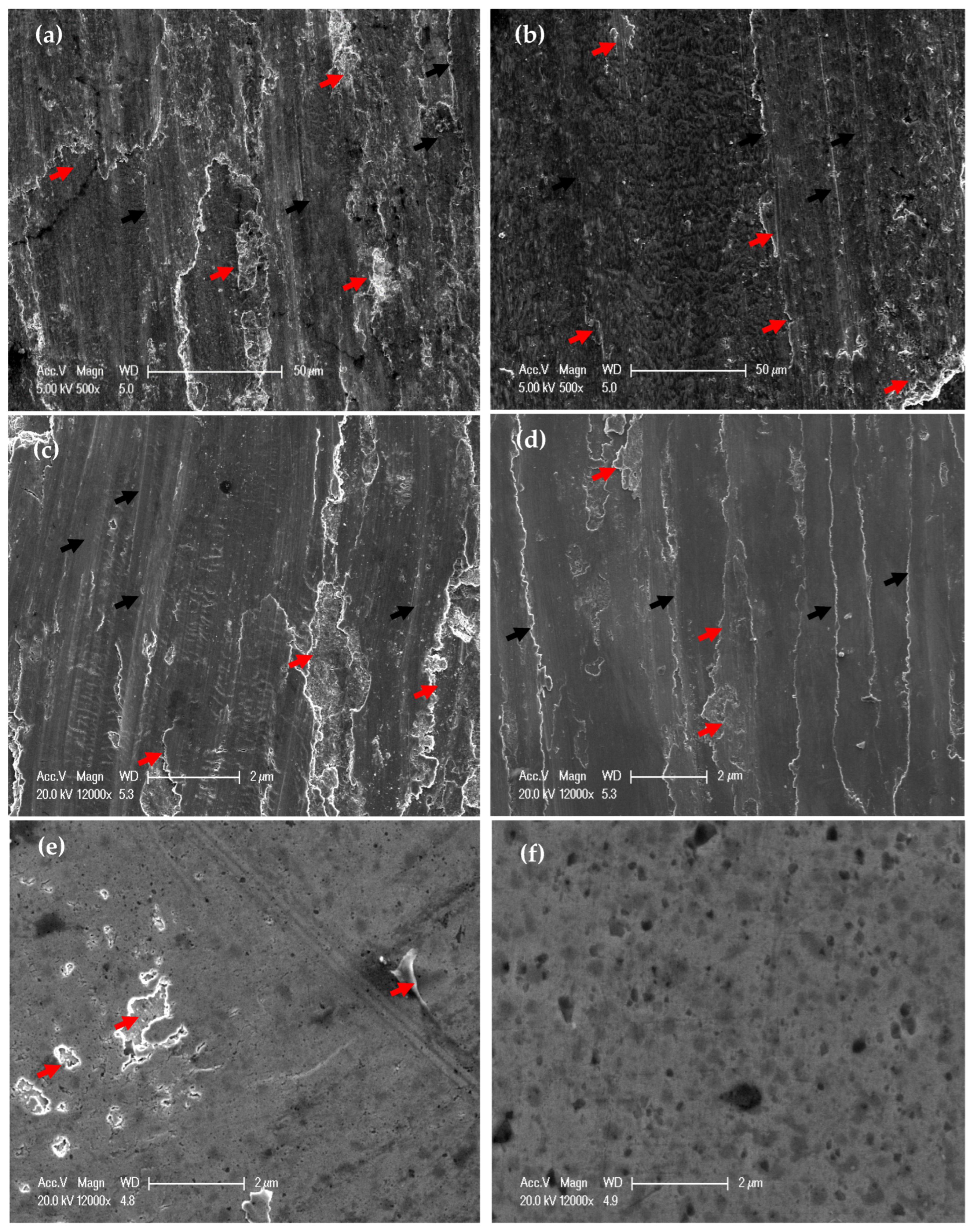

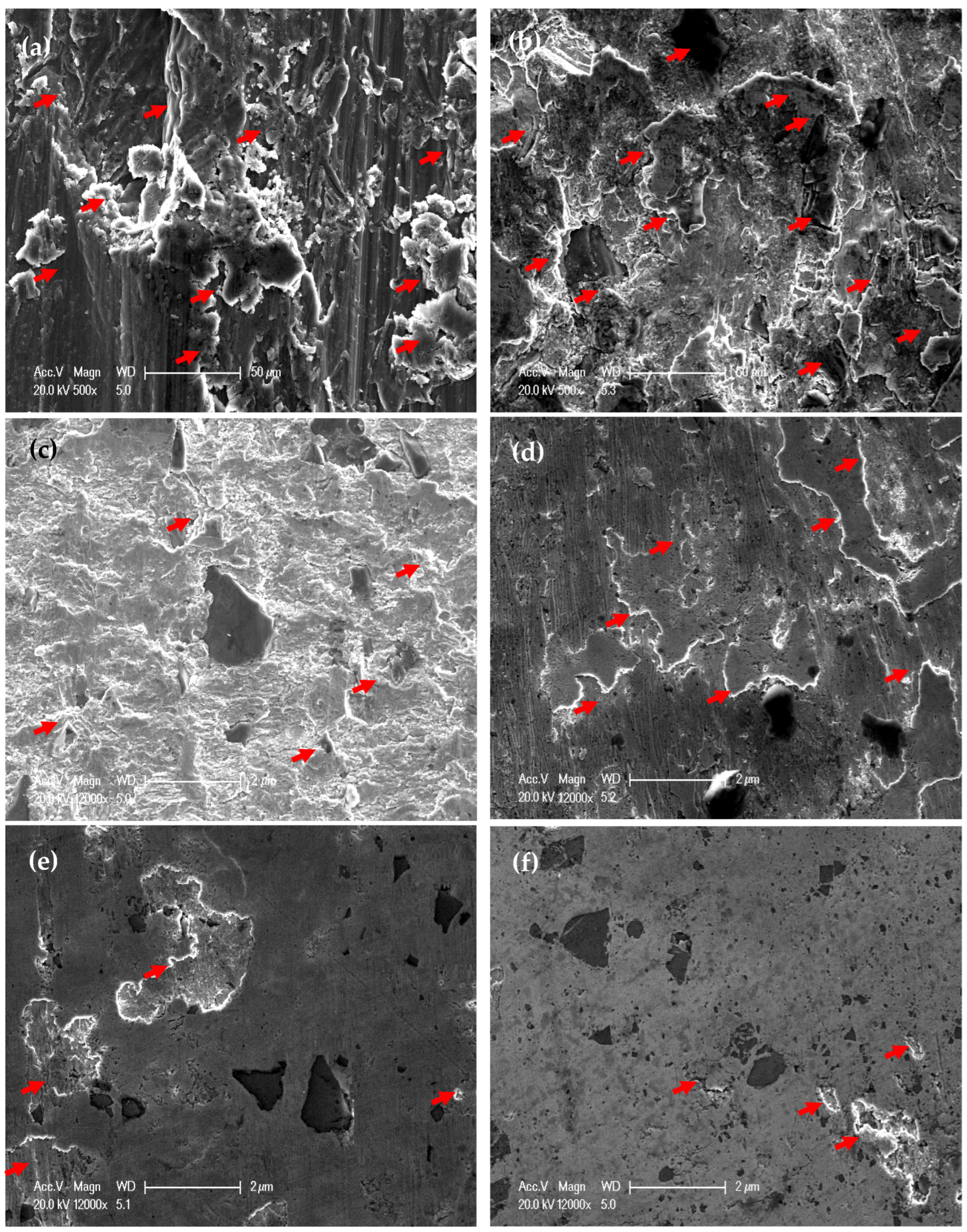

3.3. Worn Surface Morphology

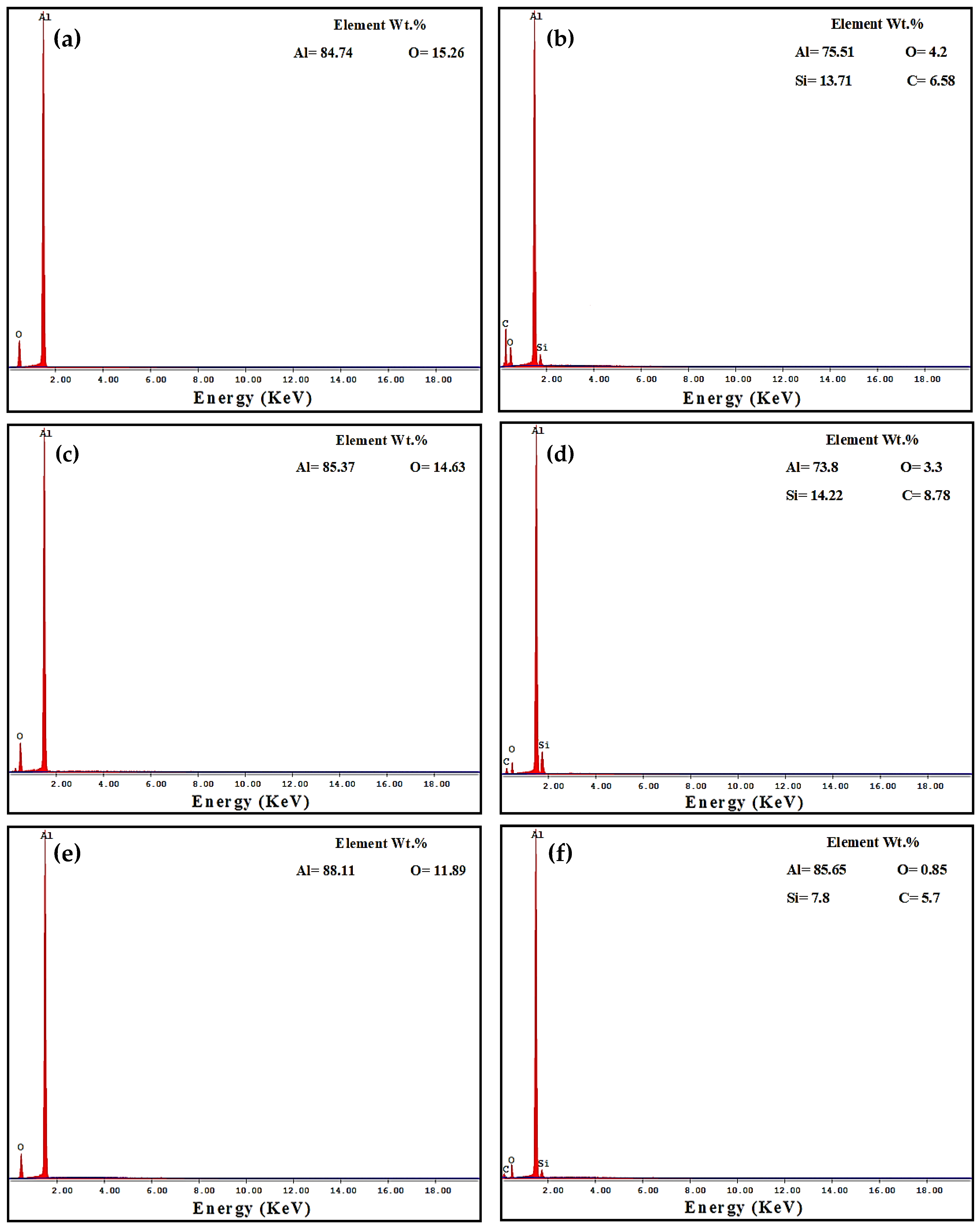

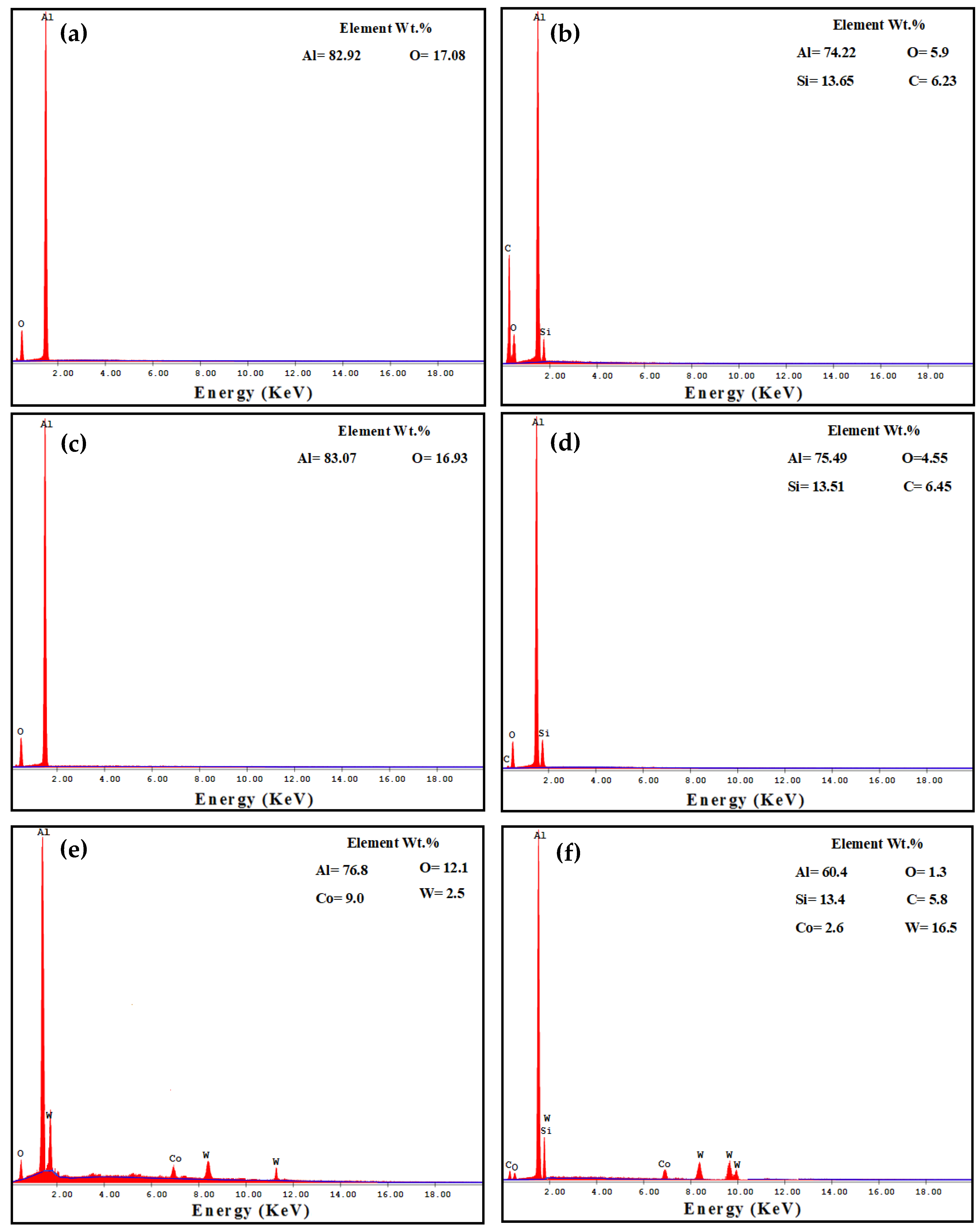

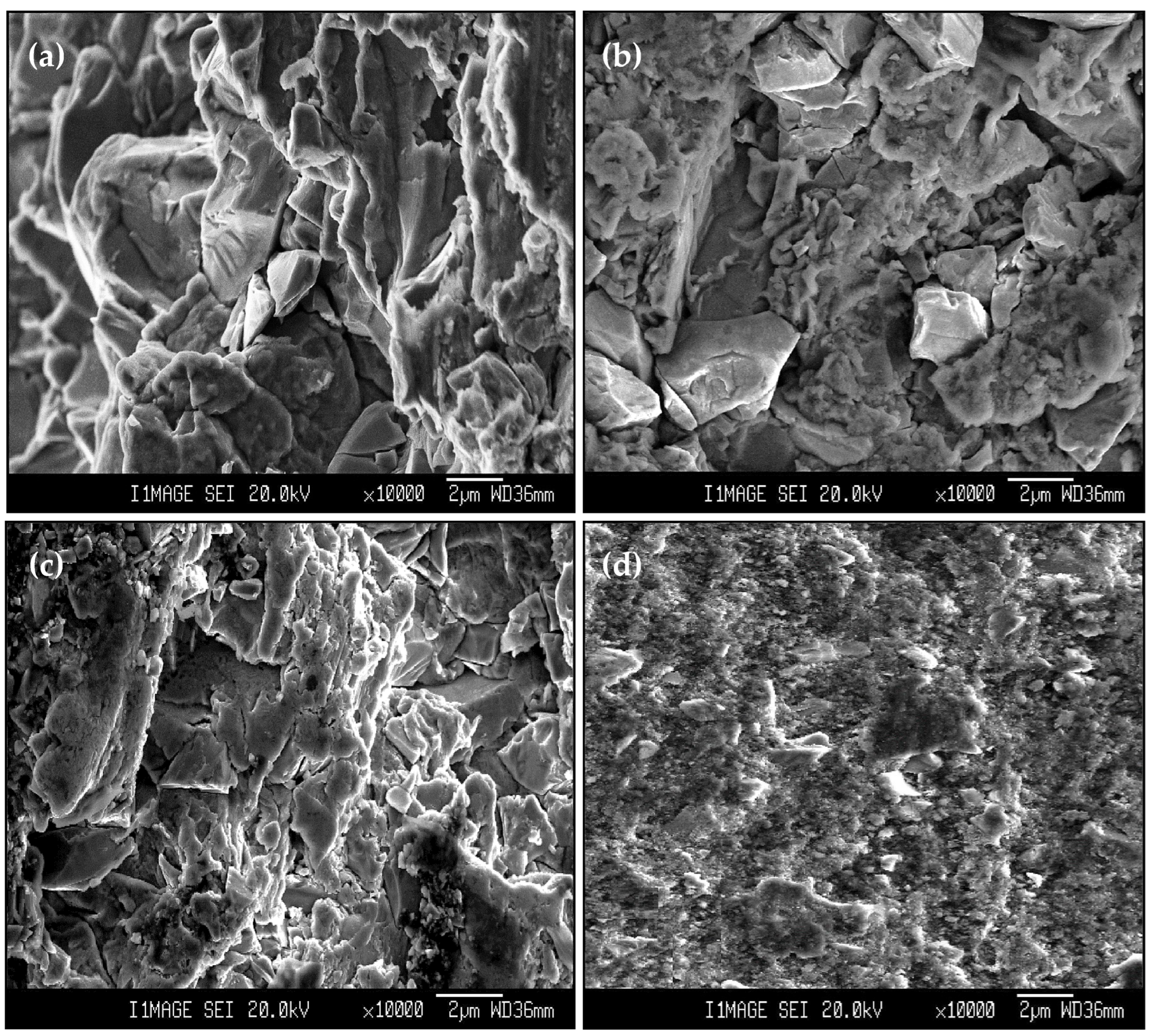

3.4. Morphology of WC Ball Surface and Wear Debris

4. Conclusions

- The formation of Al MMCs using PM and HPT processing decreases the wear scar widths of Al by 76–78 and 80–83% and its wear rate by 72–85.2 and 87.8–95.8%.

- HPT processing of Al and Al MMCs significantly enhances their wear resistance. The HPT processing increased the Al and Al MMC samples’ wear resistance over those of the PM counterparts by 16–81%.

- The HPT processing of Al and Al MMCs reduces their COF values and improves their frictional properties.

- The Al and Al MMC processing methods affected the wear mechanism and worn surface morphologies. The worn surface microstructure observations and analyses of the samples and the WC balls proved the wear mechanism results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, R.F. Principles of Composite Material Mechanics, 4th ed.; McGraw Hill International Inc.: New York, NY, USA; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Clyne, T.W.; Withers, P.J. An Introduction to Metal Matrix Composites, 2nd ed.; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Ralph, B.; Yuen, H.C.; Lee, W.B. The processing of metal matrix composites—An overview. J. Mater. Process. Technol. 1997, 63, 339–353. [Google Scholar] [CrossRef]

- Mallick, P.K. Composites Engineering Handbook, 1st ed.; Marcel Dekker Inc.: New York, NY, USA, 1997. [Google Scholar]

- Hausner, H.H. Modern Developments in Powder Metallurgy, 1st ed.; Plenum Press: New York, NY, USA, 1966. [Google Scholar]

- Bezzina, S.; Moustafa, E.B.; Taha, M.A. Effects of metastable θ′ precipitates on the strengthening, wear and electrical behaviors of Al 2519-SiC/fly ash hybrid nanocomposites synthesized by powder metallurgy technique. Silicon 2022, 14, 8381–8395. [Google Scholar] [CrossRef]

- Okumuş, M.; Bülbül, B. Study of microstructural, mechanical, thermal and tribological properties of graphene oxide reinforced Al–10Ni metal matrix composites prepared by mechanical alloying method. Wear 2022, 510–511, 204511. [Google Scholar] [CrossRef]

- Ramu, G.; Bauri, R. Effect of equal channel angular pressing (ECAP) on microstructure and properties of Al–SiCp composites. Mater. Des. 2009, 30, 3554–3559. [Google Scholar] [CrossRef]

- Arab, M.S.; El Mahallawy, N.; Shehata, F.; Agwa, M.A. Refining SiCp in reinforced Al–SiC composites using equal-channel angular pressing. Mater. Des. 2014, 64, 280–286. [Google Scholar] [CrossRef]

- Chang, S.-Y.; Park, K.-T. Effect of Equal Channel Angular Pressing on the Distribution of Reinforcements in the Discontinuous Metal Matrix Composites. Mater. Trans. 2002, 43, 757–761. [Google Scholar] [CrossRef]

- Derakhshandeh, H.R.; Jenabali Jahromi, A. An investigation on the capability of equal channel angular pressing for consolidation of aluminum and aluminum composite powder. Mater. Des. 2011, 32, 3377–3388. [Google Scholar] [CrossRef]

- Alexandrov, I.V.; Islamgaliev, R.K.; Valiev, R.Z.; Zhu, Y.T.; Lowe, T.C. Microstructures and properties of nanocomposites obtained through SPTS consolidation of powders. Metall. Mater. Trans. A 1998, 29, 2253–2260. [Google Scholar] [CrossRef]

- Ashida, M.; Horita, Z.; Kita, T.; Kato, A. Production of Al/Al2O3 Nanocomposites through Consolidation by High-Pressure Torsion. Mater. Trans. 2012, 53, 13–16. [Google Scholar] [CrossRef]

- Ashida, M.; Horita, Z. Effects of ball milling and high-pressure torsion for improving mechanical properties of Al–Al2O3 nanocomposites. J. Mater. Sci. 2012, 47, 7821–7827. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Islamgaliev, R.K.; Kuzmina, N.F.; Li, Y.; Langdon, T.G. Strengthening and grain refinement in an Al-6061 metal matrix composite through intense plastic straining. Scr. Mater. 1998, 40, 117–122. [Google Scholar] [CrossRef]

- Gode, C.; Yilmazer, H.; Ozdemir, I.; Todaka, Y. Microstructural refinement and wear property of Al–Si–Cu composite subjected to extrusion and high-pressure torsion. Mater. Sci. Eng. A 2014, 618, 377–384. [Google Scholar] [CrossRef]

- Sabirov, I.; Pippan, R. Characterization of tungsten fragmentation in a W–25%Cu composite after high-pressure torsion. Mater. Charact. 2007, 58, 848–853. [Google Scholar] [CrossRef]

- Abd El Aal, M.I. Effect of high-pressure torsion processing on the microstructure evolution and mechanical properties of consolidated micro size Cu and Cu-SiC powders. Adv. Powder Technol. 2017, 28, 2135–2150. [Google Scholar] [CrossRef]

- Aal, M. Recycling of Al chips and Al chips composites using high-pressure torsion. Mater. Res. Express 2021, 8, 056514. [Google Scholar] [CrossRef]

- Ali Alhamidi, A.; Edalati, K.; Horita, Z. Production of Nanograined Intermetallics using High-pressure Torsion. Mater. Res. 2013, 16, 672–678. [Google Scholar] [CrossRef]

- Edalati, K.; Toh, S.; Watanabe, M.; Horita, Z. In situ production of bulk intermetallic-based nanocomposites and nanostructured intermetallics by high-pressure torsion. Scr. Mater. 2012, 66, 386–389. [Google Scholar] [CrossRef]

- Sabirov, I.; Kolednik, O.; Pippan, R. Homogenization of metal matrix composites by high-pressure torsion. Metall. Mater. Trans. A 2005, 36, 2861–2870. [Google Scholar] [CrossRef]

- Jahedi, M.; Paydar, M.H.; Knezevic, M. Enhanced microstructural homogeneity in metal-matrix composites developed under high-pressure-double-torsion. Mater. Charact. 2015, 104, 92–100. [Google Scholar] [CrossRef]

- Mishra, R.S.; Valiev, R.Z.; McFadden, S.X.; Islamgaliev, R.K.; Mukherjee, A.K. Severe plastic deformation processing and high strain rate superplasticity in an aluminum matrix composite. Scr. Mater. 1999, 40, 1151–1155. [Google Scholar] [CrossRef]

- Pippan, R.; Scheriau, S.; Hohenwarter, A.; Hafok, M. Advantages and Limitations of HPT: A Review. Mater. Sci. Forum 2008, 584–586, 16–21. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.; El-Fahhar, H.H.; Mohamed, A.Y.; Gadallah, E.A. The Mechanical Properties of Aluminum Metal Matrix Composites Processed by High-Pressure Torsion and Powder Metallurgy. Materials 2022, 15, 8827. [Google Scholar] [CrossRef] [PubMed]

- Rahimian, M.; Ehsani, N.; Parvin, N.; Baharvandi, H.R. The effect of particle size, sintering temperature and sintering time on the properties of Al–Al2O3 composites, made by powder metallurgy. J. Mater. Process. Technol. 2009, 209, 5387–5393. [Google Scholar] [CrossRef]

- El-Kady, O.; Fathy, A. Effect of SiC particle size on the physical and mechanical properties of extruded Al matrix nanocomposites. Mater. Des. 2014, 54, 348–353. [Google Scholar] [CrossRef]

- Bermúdez, M.D.; Martínez-Nicolás, G.; Carrión, F.J.; Martínez-Mateo, I.; Rodríguez, J.A.; Herrera, E.J. Dry and lubricated wear resistance of mechanically-alloyed aluminium-base sintered composites. Wear 2001, 248, 178–186. [Google Scholar] [CrossRef]

- Abouelmagd, G. Hot deformation and wear resistance of P/M aluminium metal matrix composites. J. Mater. Process. Technol. 2004, 155–156, 1395–1401. [Google Scholar] [CrossRef]

- Ünlü, B.S. Investigation of tribological and mechanical properties Al2O3–SiC reinforced Al composites manufactured by casting or P/M method. Mater. Des. 2008, 29, 2002–2008. [Google Scholar] [CrossRef]

- Rahimian, M.; Parvin, N.; Ehsani, N. The effect of production parameters on microstructure and wear resistance of powder metallurgy Al–Al2O3 composite. Mater. Des. 2011, 32, 1031–1038. [Google Scholar] [CrossRef]

- Darmiani, E.; Danaee, I.; Golozar, M.A.; Toroghinejad, M.R.; Ashrafi, A.; Ahmadi, A. Reciprocating wear resistance of Al–SiC nano-composite fabricated by accumulative roll bonding process. Mater. Des. 2013, 50, 497–502. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.; El Mahallawy, N.; Shehata, F.A.; Abd El Hameed, M.; Yoon, E.Y.; Kim, H.S. Wear properties of ECAP-processed ultrafine grained Al–Cu alloys. Mater. Sci. Eng. A 2010, 527, 3726–3732. [Google Scholar] [CrossRef]

- El Aal, M.I.A. The effect of the pre-homogenization treatment on the fracture characteristics and wear properties of ECAPed Al–Cu alloys. Mater. Sci. Eng. A 2012, 539, 308–323. [Google Scholar] [CrossRef]

- Li, J.; Wongsa-Ngam, J.; Xu, J.; Shan, D.; Guo, B.; Langdon, T.G. Wear resistance of an ultrafine-grained Cu-Zr alloy processed by equal-channel angular pressing. Wear 2015, 326–327, 10–19. [Google Scholar] [CrossRef]

- El Aal, M.I.A. The influence of ECAP and HPT processing on the microstructure evolution, mechanical properties and tribology characteristics of an Al6061 alloy. J. Mater. Res. Technol. 2020, 9, 12525–12546. [Google Scholar] [CrossRef]

- Aal, M.I.A.E.; Kim, H.S. Wear properties of high pressure torsion processed ultrafine grained Al–7%Si alloy. Mater. Des. 2014, 53, 373–382. [Google Scholar] [CrossRef]

- Edalati, K.; Ashida, M.; Horita, Z.; Matsui, T.; Kato, H. Wear resistance and tribological features of pure aluminum and Al–Al2O3 composites consolidated by high-pressure torsion. Wear 2014, 310, 83–89. [Google Scholar] [CrossRef]

- Abd El Aal, M.I.; Kim, H.S. Effect of the fabrication method on the wear properties of copper silicon carbide composites. Tribol. Int. 2018, 128, 140–154. [Google Scholar] [CrossRef]

- Abd El Aal, M.I. Wear properties of copper and copper composites powders consolidated by high-pressure torsion. Friction 2020, 8, 433–450. [Google Scholar] [CrossRef]

- Abd El Aal, M.I. Wear and mechanical properties of Al chips and Al chips composites recycled by high-pressure torsion. J. Mater. Res. Technol. 2021, 14, 407–427. [Google Scholar] [CrossRef]

- Mahallawy, N.E.; Shehata, F.A.; Hameed MA, E.; Aal, M.I.A.E.; Kim, H.S. 3D FEM simulations for the homogeneity of plastic deformation in Al–Cu alloys during ECAP. Mater. Sci. Eng. A 2010, 527, 1404–1410. [Google Scholar] [CrossRef]

- Archard, J.F. Contact and Rubbing of Flat Surfaces. J. Appl. Phys. 1953, 24, 981–988. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Aal, M.I.A.; El-Fahhar, H.H.; Mohamed, A.Y.; Gadallah, E.A. Influence of High-Pressure Torsion Processing on the Tribological Properties of Aluminum Metal Matrix Composites. Materials 2023, 16, 216. https://doi.org/10.3390/ma16010216

El Aal MIA, El-Fahhar HH, Mohamed AY, Gadallah EA. Influence of High-Pressure Torsion Processing on the Tribological Properties of Aluminum Metal Matrix Composites. Materials. 2023; 16(1):216. https://doi.org/10.3390/ma16010216

Chicago/Turabian StyleEl Aal, Mohamed Ibrahim Abd, Hossam Hemdan El-Fahhar, Abdelkarim Yousif Mohamed, and Elshafey Ahmed Gadallah. 2023. "Influence of High-Pressure Torsion Processing on the Tribological Properties of Aluminum Metal Matrix Composites" Materials 16, no. 1: 216. https://doi.org/10.3390/ma16010216

APA StyleEl Aal, M. I. A., El-Fahhar, H. H., Mohamed, A. Y., & Gadallah, E. A. (2023). Influence of High-Pressure Torsion Processing on the Tribological Properties of Aluminum Metal Matrix Composites. Materials, 16(1), 216. https://doi.org/10.3390/ma16010216