Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete

Abstract

1. Introduction

2. Experimental Program

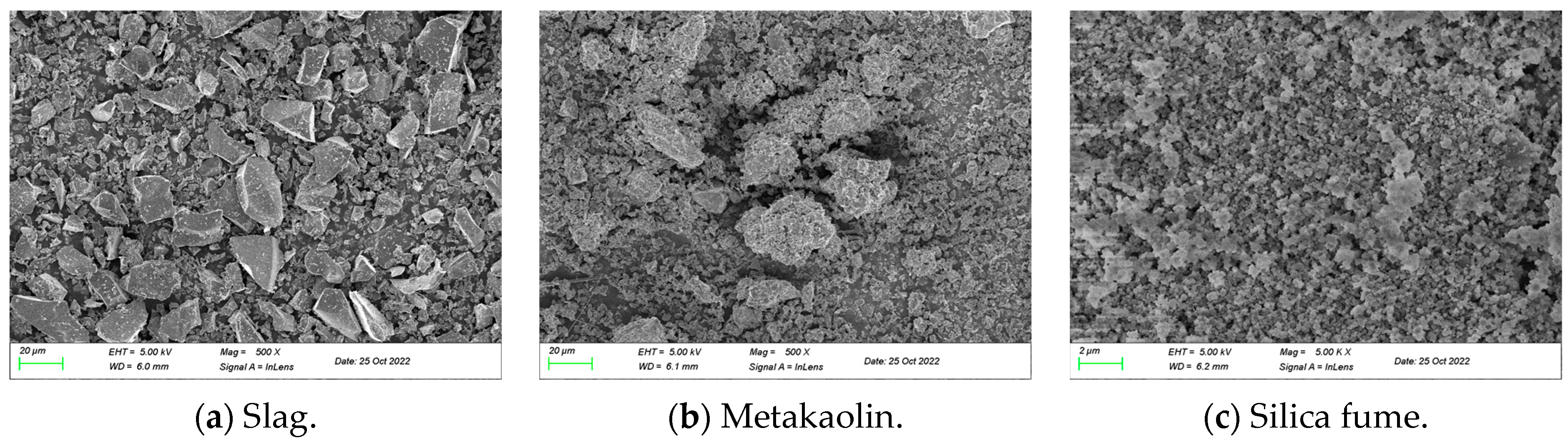

2.1. Raw Materials

2.2. Mix Proportions

2.3. Specimens Preparations

2.4. Testing Methods

3. Results and Discussions

3.1. Compression Test

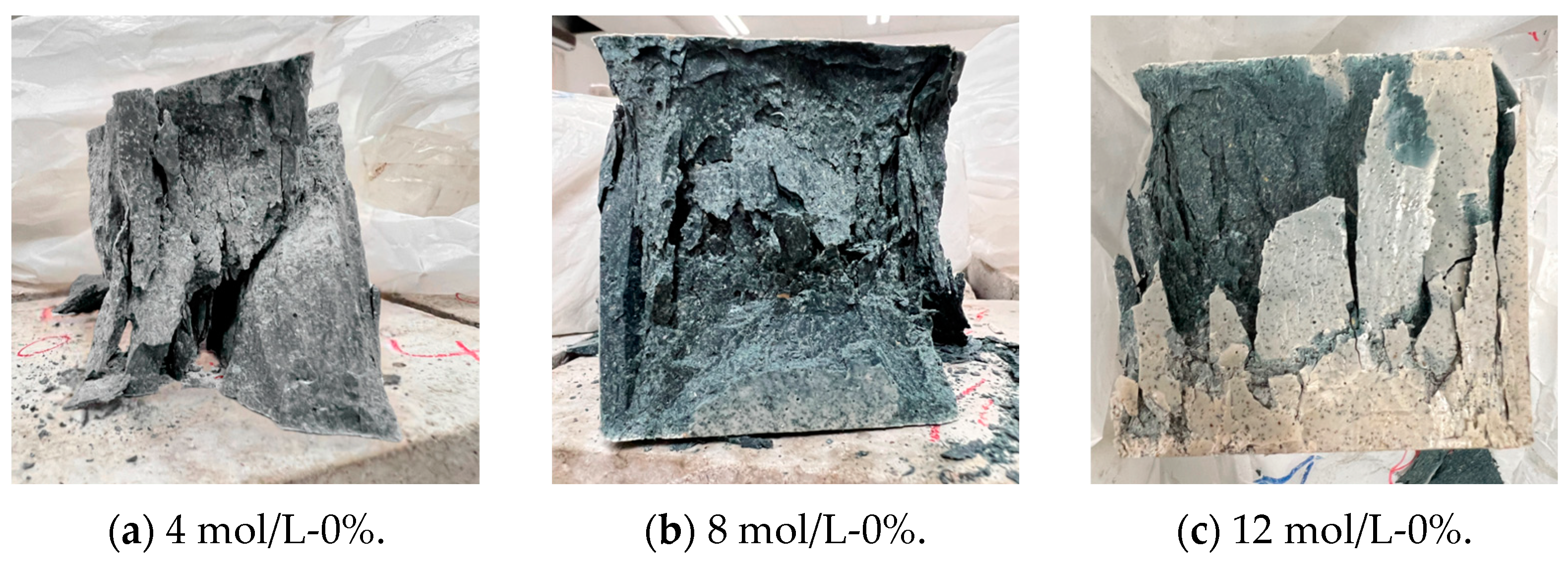

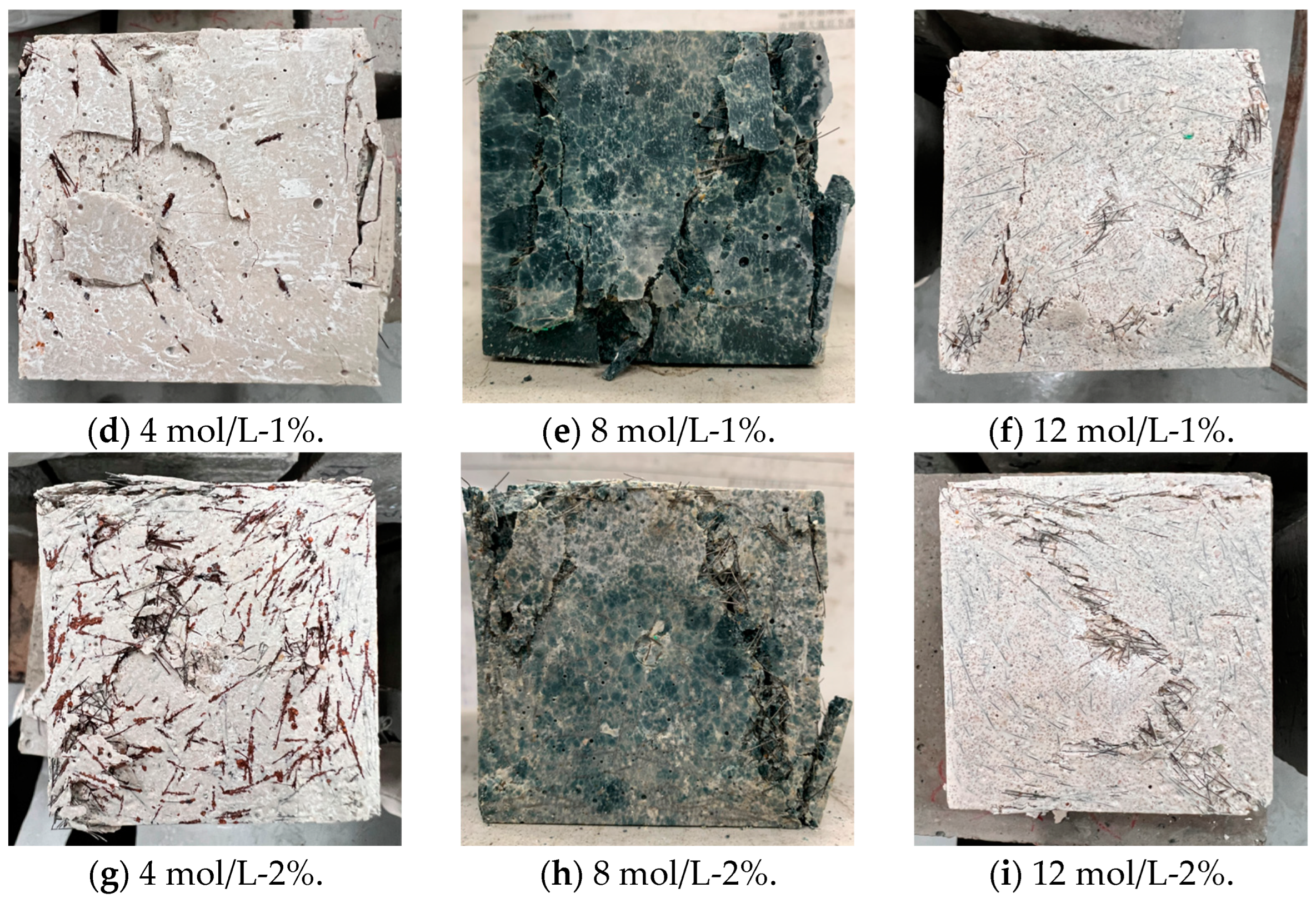

3.1.1. Failure Modes

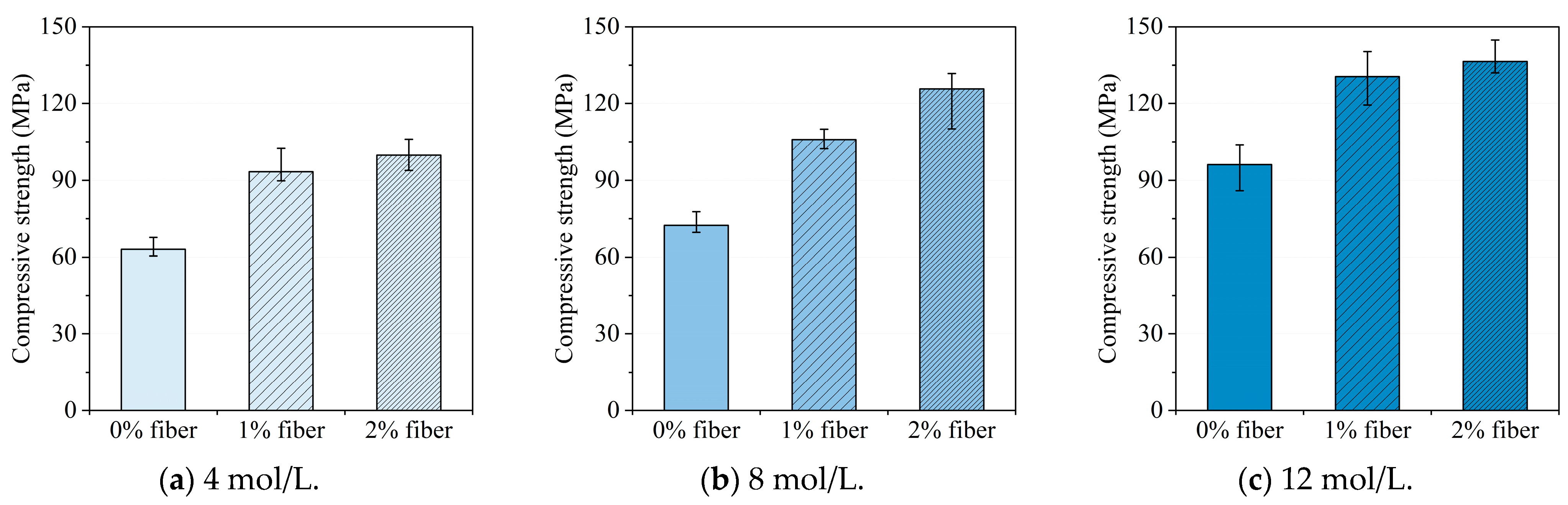

3.1.2. Influence of Fiber Dosage on Compressive Strength

3.1.3. Influence of NaOH Solution Concentration on Compressive Strength

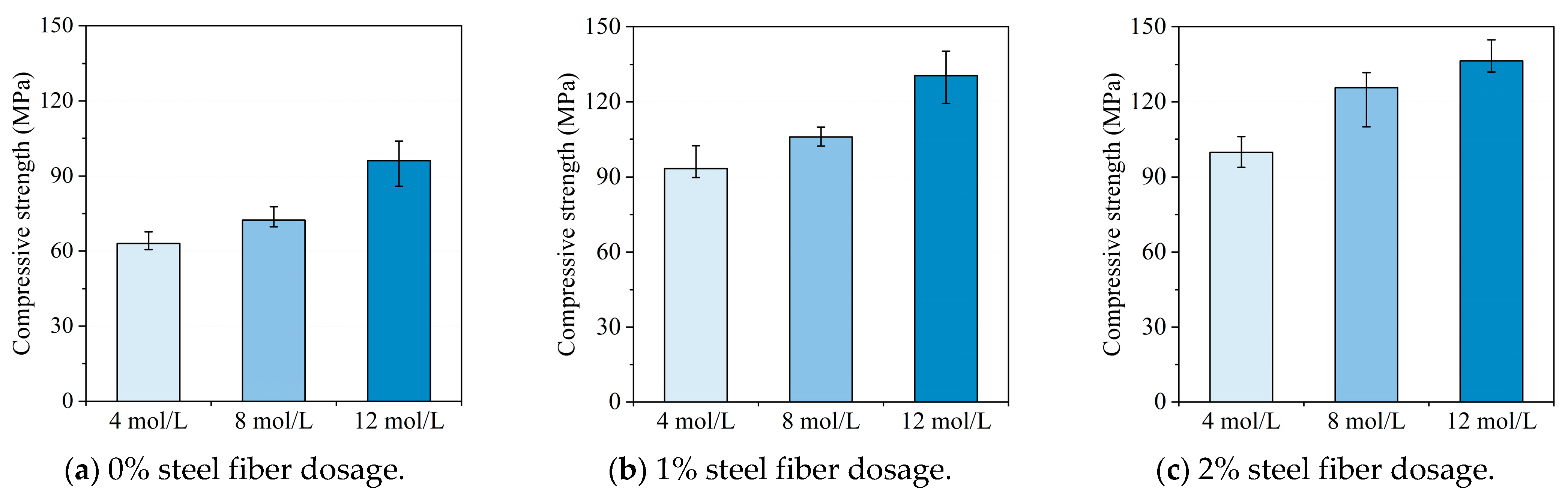

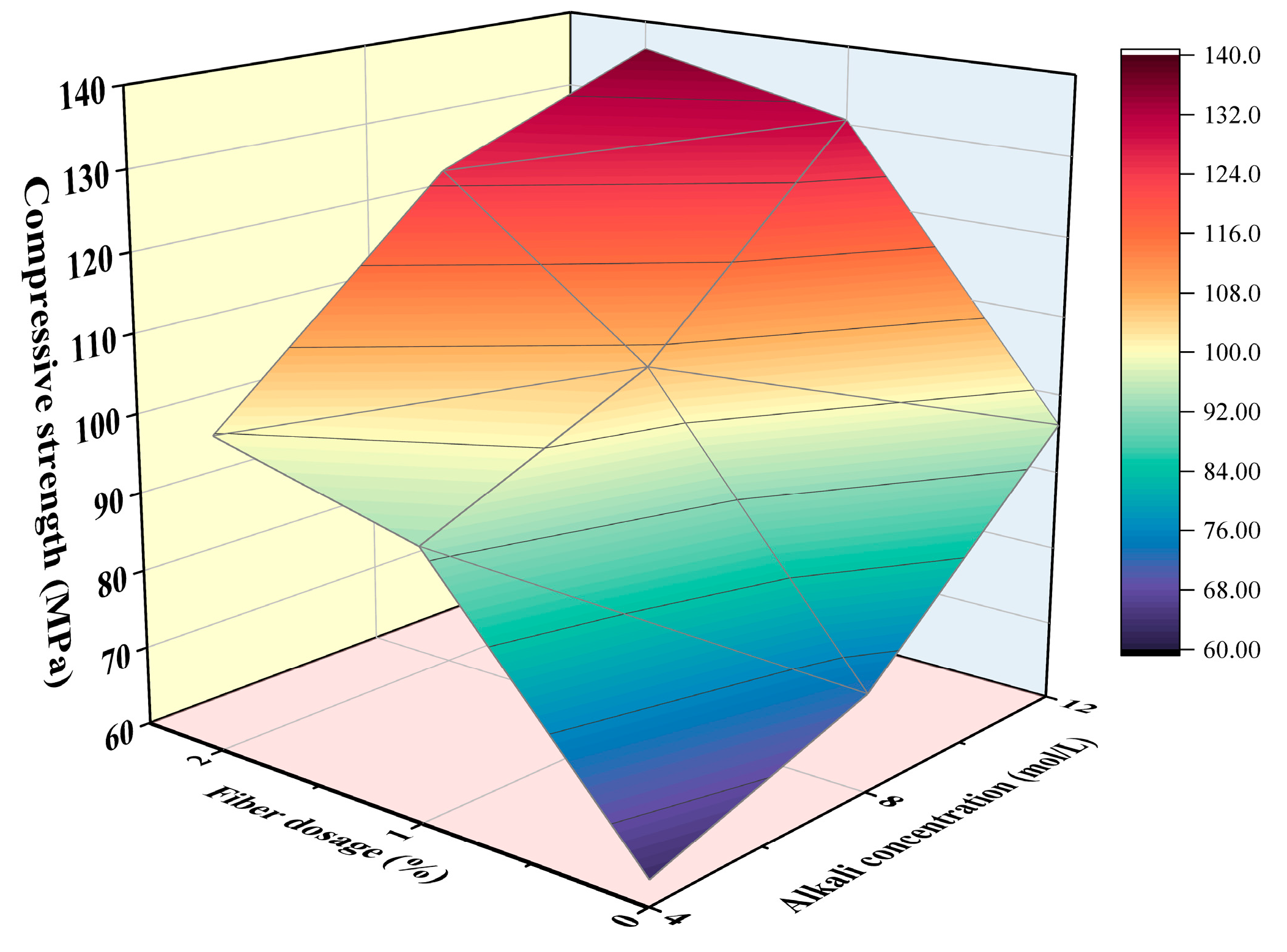

3.1.4. Combined Influence of Fiber Dosage and NaOH Solution Concentration

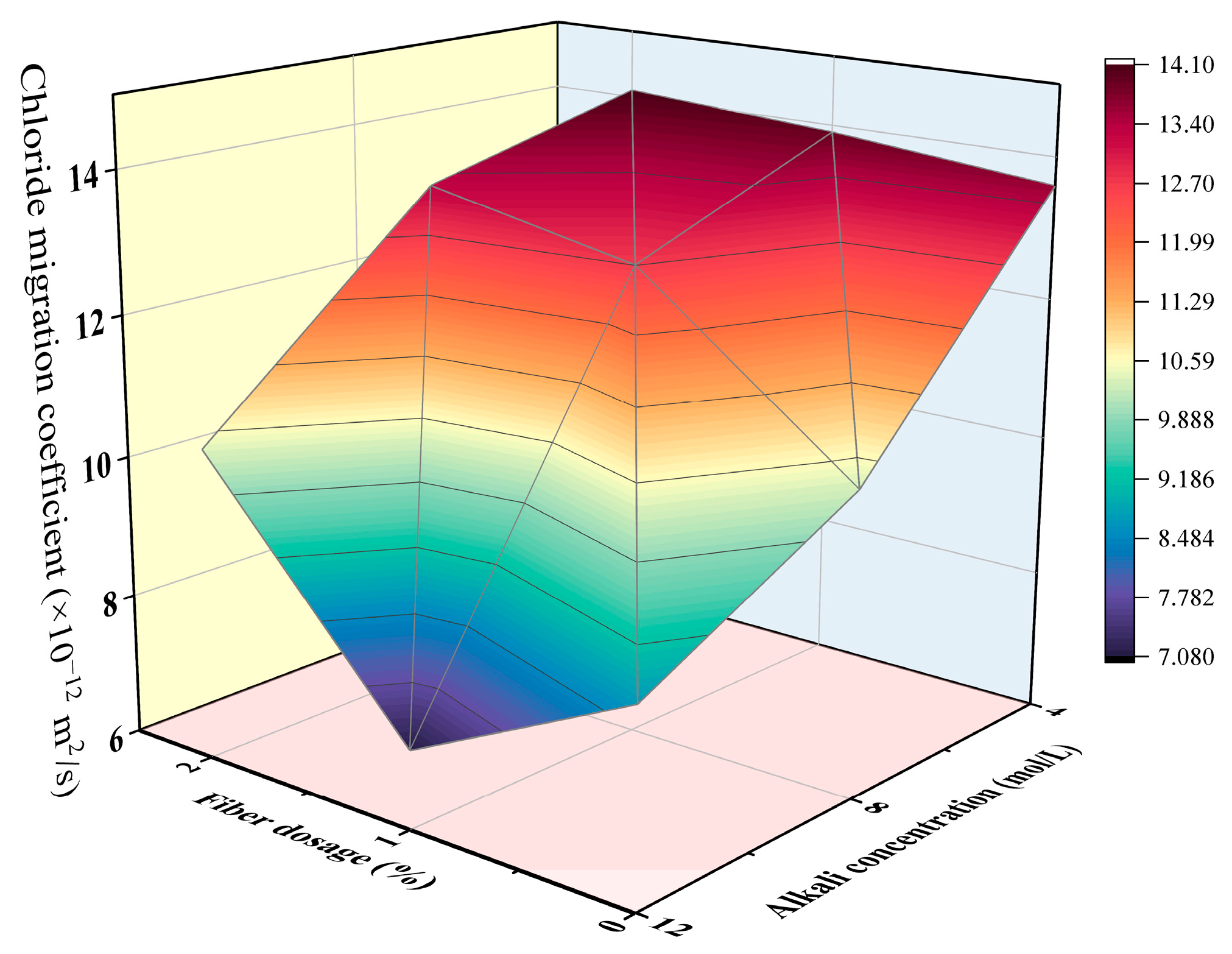

3.2. Rapid Chloride Migration Test

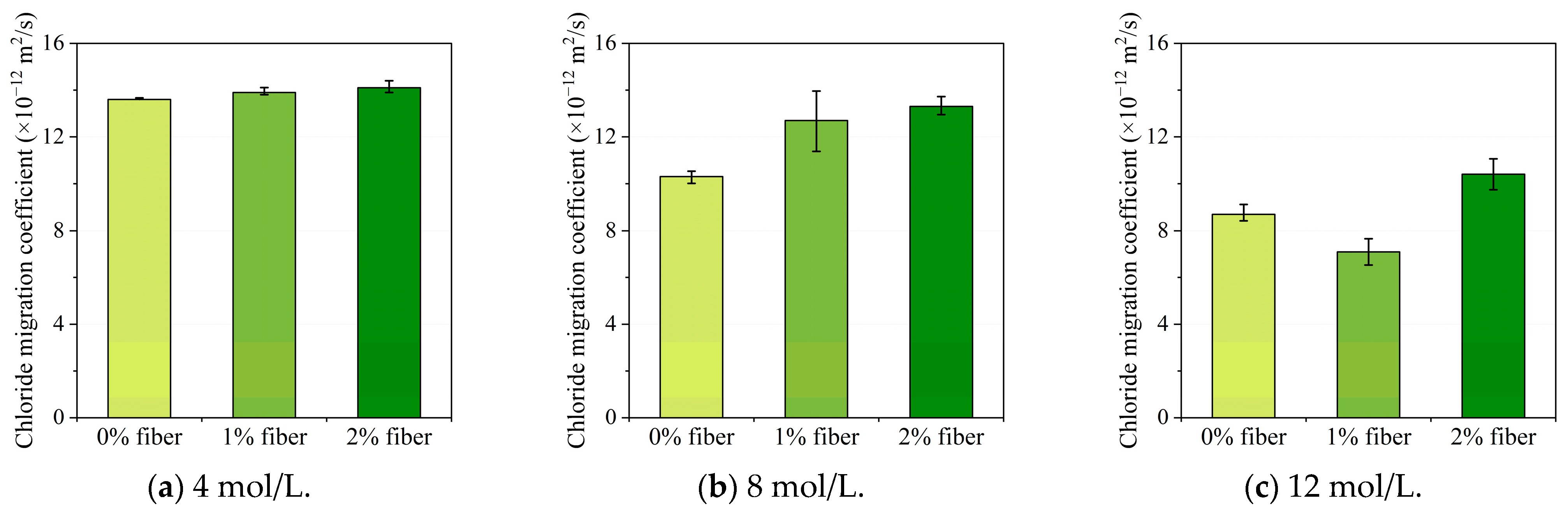

3.2.1. Influence of Fiber Dosage on Chloride Penetration Resistance

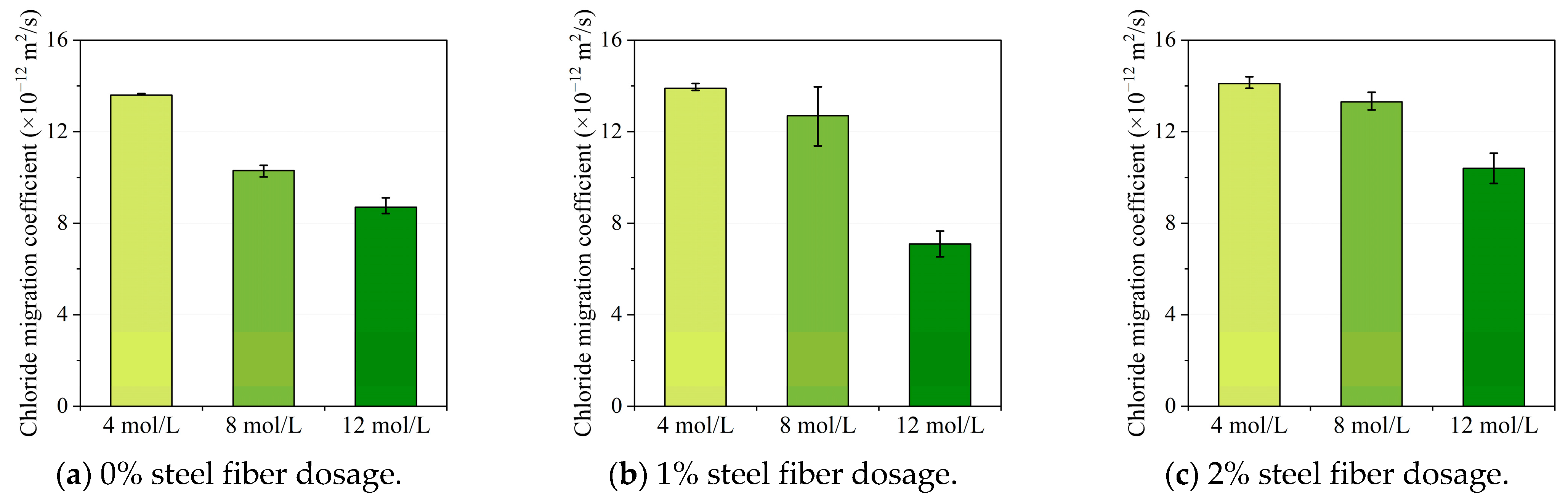

3.2.2. Influence of NaOH Solution Concentration on Chloride Penetration Resistance

4. Conclusions

- The addition of steel fibers can effectively limit cracks propagation because of the bridging effect. The maximum compressive strength of geopolymer concrete without steel fibers can reach 100 MPa, and adding steel fibers up to 2% can further increase the compressive strength to 140 MPa.

- Increasing the molarity of alkali activator solution within the range of 12 mol/L can improve compressive strength due to the facilitated geopolymerization reaction. More significant improvement in compressive strength was observed when the sodium hydroxide concentration increased from 8 mol/L to 12 mol/L.

- The non-steady chloride migration coefficient measured using the RCM test ranged from 6.5 × 10−12 m2/s to 14.1 × 10−12 m2/s. A higher steel fiber dosage slightly decreased the chloride penetration resistance, which is possibly attributed to steel fibers corrosion, current enrichment, and rising temperatures due to fiber segregation.

- A higher alkali concentration in the alkali activator solution could significantly mitigate chloride penetration, which is mainly because the facilitated geopolymerization reaction in a higher alkali environment can result in a lower porosity and decrease chloride penetration depth.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yuan, C.F.; Xu, S.W.; Raza, A.; Wang, C.; Wang, D. Influence and Mechanism of Curing Methods on Mechanical Properties of Manufactured Sand UHPC. Materials 2022, 15, 6183. [Google Scholar] [CrossRef]

- Wang, D.H.; Shi, C.J.; Wu, Z.M.; Xiao, J.F.; Huang, Z.Y.; Fang, Z. A review on ultra high performance concrete: Part II. Hydration, microstructure and properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly Ultra-High Performance Concrete (UHPC) with efficient cement and mineral admixtures uses. Cement Concrete Comp. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Xu, D.; Cui, Y.S.; Li, H.; Yang, K.; Xu, W.; Chen, Y.X. On the future of Chinese cement industry. Cement Concrete Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Xu, S.Y.; Gao, P.W.; Huang, L.L.; Tang, L.L.; Gu, X.Q.; Wang, L.M. Experimental Research on Mechanical and Shrinkage Properties of Alkali Activated Low-Carbon Green Concrete. Materials 2022, 15, 5984. [Google Scholar] [CrossRef]

- Sun, B.B.; Sun, Y.B.; Ye, G.; De Schutter, G. A mix design methodology of slag and fly ash-based alkali-activated paste. Cement Concrete Comp. 2022, 126, 104368. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Mo, K.H.; Abdalla, J.A.; Hawileh, R.A.; Ariyachandra, E. Biomass ashes from agricultural wastes as supplementary cementitious materials or aggregate replacement in cement/geopolymer concrete: A comprehensive review. J. Build. Eng. 2021, 40, 102332. [Google Scholar] [CrossRef]

- Papa, E.; Medri, V.; Landi, E.; Ballarin, B.; Miccio, F. Production and characterization of geopolymers based on mixed compositions of metakaolin and coal ashes. Mater. Des. 2014, 56, 409–415. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.J.; Wang, Q.; Zhang, Z.H.; Ou, Z.H. Composition design and performance of alkali-activated cements. Mater. Struct. 2017, 50, 1–11. [Google Scholar] [CrossRef]

- Elyamany, H.E.; Abd Elmoaty, A.M.; Elshaboury, A.M. Setting time and 7-day strength of geopolymer mortar with various binders. Constr. Build. Mater. 2018, 187, 974–983. [Google Scholar] [CrossRef]

- Nakum, A.V.; Arora, N.K. The impact of alkaline solution to fly ash ratio with different molarities of sodium hydroxide on self-compacted geopolymer concrete. Mater. Today-Proc. 2022, 62, 4168–4176. [Google Scholar] [CrossRef]

- Skariah Thomas, B.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Cleaner Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Ma, C.K.; Awang, A.Z.; Omar, W. Structural and material performance of geopolymer concrete: A review. Constr. Build. Mater. 2018, 186, 90–102. [Google Scholar] [CrossRef]

- Sun, B.B.; Ye, G.; de Schutter, G. A review: Reaction mechanism and strength of slag and fly ash-based alkali-activated materials. Constr. Build. Mater. 2022, 326, 126843. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Provis, J.L.; Ma, X.; Reid, A.; Wang, H. Efflorescence and subflorescence induced microstructural and mechanical evolution in fly ash-based geopolymers. Cement Concrete Comp. 2018, 92, 165–177. [Google Scholar] [CrossRef]

- Douglas, E.; Bilodeau, A.; Brandstetr, J.; Malhotra, V.M. Alkali activated ground granulated blast-furnace slag concrete: Preliminary investigation. Cement Concrete Res. 1991, 21, 101–108. [Google Scholar] [CrossRef]

- Puligilla, S.; Mondal, P. Role of slag in microstructural development and hardening of fly ash-slag geopolymer. Cement Concrete Res. 2013, 43, 70–80. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Effect of Curing Conditions on the Performance of Geopolymer Concrete Based on Granulated Blast Furnace Slag and Metakaolin. J Mater Civil Eng 2021, 33, 04020501. [Google Scholar] [CrossRef]

- Peng, H.; Li, Y.; Luo, D.; Liu, Y.; Cai, C. Analysis of reaction level and factors of alkali activated metakaolin/GGBFS. J. Build. Mater. 2020, 23, 1390–1397. [Google Scholar]

- Su, M.; Zhong, Q.Y.; Peng, H. Regularized multivariate polynomial regression analysis of the compressive strength of slag-metakaolin geopolymer pastes based on experimental data. Constr. Build. Mater. 2021, 303, 124529. [Google Scholar] [CrossRef]

- Chang, H.; Wang, X.; Wang, Y.; Li, C.; Guo, Z.; Fan, S.; Zhang, H.; Feng, P. Chloride binding behavior of cement paste influenced by metakaolin dosage and chloride concentration. Cement Concrete Comp. 2023, 135, 104821. [Google Scholar] [CrossRef]

- Wetzel, A.; Middendorf, B. Influence of silica fume on properties of fresh and hardened ultra-high performance concrete based on alkali-activated slag. Cement Concrete Comp. 2019, 100, 53–59. [Google Scholar] [CrossRef]

- Lao, J.C.; Xu, L.Y.; Huang, B.T.; Dai, J.G.; Shah, S.P. Strain-hardening Ultra-High-Performance Geopolymer Concrete (UHPGC): Matrix design and effect of steel fibers. Compos Commun 2022, 30, 101081. [Google Scholar] [CrossRef]

- Liu, Y.W.; Zhang, Z.H.; Shi, C.J.; Zhu, D.J.; Li, N.; Deng, Y.L. Development of ultra-high performance geopolymer concrete (UHPGC): Influence of steel fiber on mechanical properties. Cement Concrete Comp. 2020, 112, 103670. [Google Scholar] [CrossRef]

- Kathirvel, P.; Sreekumaran, S. Sustainable development of ultra high performance concrete using geopolymer technology. J. Build. Eng. 2021, 39, 102267. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Sammak, M. An assessment of the effect of Na2SiO3/NaOH ratio, NaOH solution concentration, and aging on the fracture properties of ultra-high-performance geopolymer concrete: The application of the work of fracture and size effect methods. Structures 2022, 39, 434–443. [Google Scholar] [CrossRef]

- Guo, B.B.; Qiao, G.F.; Han, P.; Fu, Q. Numerical study on effects of the degree of water saturation on ICCP of chloride-contaminated RC structures. J. Build. Eng. 2022, 45, 103619. [Google Scholar] [CrossRef]

- Yu, Q.; Guo, B.B.; Li, C.J. Effects of CO2 Concentration and the Uptake on Carbonation of Cement-Based Materials. Materials 2022, 15, 6445. [Google Scholar] [CrossRef]

- Yang, L.F.; Pathirage, M.; Su, H.Z.; Alnaggar, M.; Di Luzio, G.; Cusatis, G. Computational modeling of temperature and relative humidity effects on concrete expansion due to alkali-silica reaction. Cement Concrete Comp. 2021, 124, 104237. [Google Scholar] [CrossRef]

- Xia, J.; Chen, J.J.; Li, T.; Shen, J.; Liu, Q.F.; Jin, W.L. Modeling of corrosion mechanism of steel bars in chloride-contaminated concrete with transverse cracks. Mag. Concr. Res. 2022, 1–38. [Google Scholar] [CrossRef]

- Ambily, P. Development of Ultra High Performance Concretes Using Geopolymer as Binder and Copper Slag as Filler. Ph.D. Thesis, CEG, Anna University, Guindy, Chennai, 2013. [Google Scholar]

- Qaidi, S.M.A.; Atrushi, D.S.; Mohammed, A.S.; Ahmed, H.U.; Faraj, R.H.; Emad, W.; Tayeh, B.A.; Najm, H.M. Ultra-high-performance geopolymer concrete: A review. Constr. Build. Mater. 2022, 346, 128495. [Google Scholar] [CrossRef]

- Mousavinejad, S.H.G.; Sammak, M. Strength and chloride ion penetration resistance of ultra-high-performance fiber reinforced geopolymer concrete. Structures 2021, 32, 1420–1427. [Google Scholar] [CrossRef]

- Build, N.T. 492. Concrete, mortar and cement-based repair materials: Chloride migration coefficient from non-steady-state migration experiments. Nord. Method 1999. [Google Scholar]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Khan, T.M.Y.; Khadar, S.D.A. Molarity activity effect on mechanical and microstructure properties of geopolymer concrete: A review. Case Stud. Constr. Mat. 2022, 16, e01014. [Google Scholar] [CrossRef]

- Wan, X.M.; Shen, C.; Wang, P.G.; Zhao, T.J.; Lu, Y. A study on fracture toughness of ultra-high toughness geopolymer composites based on Double-K Criterion. Constr. Build. Mater. 2020, 251, 118851. [Google Scholar] [CrossRef]

- Meng, Z.Z.; Liu, Q.F.; Xia, J.; Cai, Y.X.; Zhu, X.J.; Zhou, Y.; Pel, L. Mechanical-transport-chemical modeling of electrochemical repair methods for corrosion-induced cracking in marine concrete. Comput. Aided Civ. Inf. 2022, 37, 1854–1874. [Google Scholar] [CrossRef]

- Bao, J.W.; Wang, L.C. Combined effect of water and sustained compressive loading on chloride penetration into concrete. Constr. Build. Mater. 2017, 156, 708–718. [Google Scholar] [CrossRef]

- Noushini, A.; Castel, A.; Aldred, J.; Rawal, A. Chloride diffusion resistance and chloride binding capacity of fly ash-based geopolymer concrete. Cement Concrete Comp. 2020, 105, 103290. [Google Scholar] [CrossRef]

- Vincler, J.P.; Sanchez, T.; Turgeon, V.; Conciatori, D.; Sorelli, L. A modified accelerated chloride migration tests for UHPC and UHPFRC with PVA and steel fibers. Cement Concrete Res. 2019, 117, 38–44. [Google Scholar] [CrossRef]

- Yuan, Q.; Shi, C.J.; He, F.Q.; De Schutter, G.; Audenaert, K.; Zheng, K. Effect of hydroxyl ions on chloride penetration depth measurement using the colorimetric method. Cement Concrete Res. 2008, 38, 1177–1180. [Google Scholar] [CrossRef]

| SiO2 | Al2O3 | CaO | Fe2O3 | MgO | K2O | SO3 | LOI | |

|---|---|---|---|---|---|---|---|---|

| Metakaolin | 57.22 | 38.98 | 0.92 | 0.73 | 0.26 | 0.23 | 0.18 | 1.39 |

| Slag | 30.37 | 15.08 | 42.19 | 0.27 | 8.03 | 0.56 | 2.11 | 0.85 |

| Silica fume | 98.23 | 0.27 | 0.28 | 0.06 | - | 0.14 | 0.95 | 0.06 |

| Samples | Slag (kg/m3) | Metakaolin (kg/m3) | Silica Fume (kg/m3) | River Sand (kg/m3) | Waterglass (kg/m3) | NaOH Molarity (mol/L) | Steel Fiber (Vol. %) |

|---|---|---|---|---|---|---|---|

| M4-0% | 641 | 321 | 107 | 388 | 279 | 4 | 0 |

| M4-1% | 641 | 321 | 107 | 388 | 279 | 4 | 1 |

| M4-2% | 641 | 321 | 107 | 388 | 279 | 4 | 2 |

| M8-0% | 641 | 321 | 107 | 388 | 279 | 8 | 0 |

| M8-1% | 641 | 321 | 107 | 388 | 279 | 8 | 1 |

| M8-2% | 641 | 321 | 107 | 388 | 279 | 8 | 2 |

| M12-0% | 641 | 321 | 107 | 388 | 279 | 12 | 0 |

| M12-1% | 641 | 321 | 107 | 388 | 279 | 12 | 1 |

| M12-2% | 641 | 321 | 107 | 388 | 279 | 12 | 2 |

| Samples | M4-0% | M4-1% | M4-2% | M8-0% | M8-1% | M8-2% | M12-0% | M12-1% | M12-2% |

|---|---|---|---|---|---|---|---|---|---|

| Compressive strengths (MPa) | 63.1 | 93.4 | 99.8 | 72.3 | 105.9 | 125.6 | 96.1 | 130. 6 | 136. 3 |

| Samples | M4-0% | M4-1% | M4-2% | M8-0% | M8-1% | M8-2% | M12-0% | M12-1% | M12-2% |

|---|---|---|---|---|---|---|---|---|---|

| chloride migration coefficients (×10−12 m2/s) | 13.6 | 13.9 | 14.1 | 10.3 | 12.7 | 13.3 | 8.7 | 7.1 | 10.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Chen, J.; Xia, J. Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete. Materials 2023, 16, 181. https://doi.org/10.3390/ma16010181

Zhang Y, Chen J, Xia J. Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete. Materials. 2023; 16(1):181. https://doi.org/10.3390/ma16010181

Chicago/Turabian StyleZhang, Yufei, Jiejing Chen, and Jin Xia. 2023. "Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete" Materials 16, no. 1: 181. https://doi.org/10.3390/ma16010181

APA StyleZhang, Y., Chen, J., & Xia, J. (2023). Compressive Strength and Chloride Resistance of Slag/Metakaolin-Based Ultra-High-Performance Geopolymer Concrete. Materials, 16(1), 181. https://doi.org/10.3390/ma16010181