Performance of Reinforced Foam and Geopolymer Concretes against Prolonged Exposures to Chloride in a Normal Environment

Abstract

1. Introduction

2. Experimental Methodology

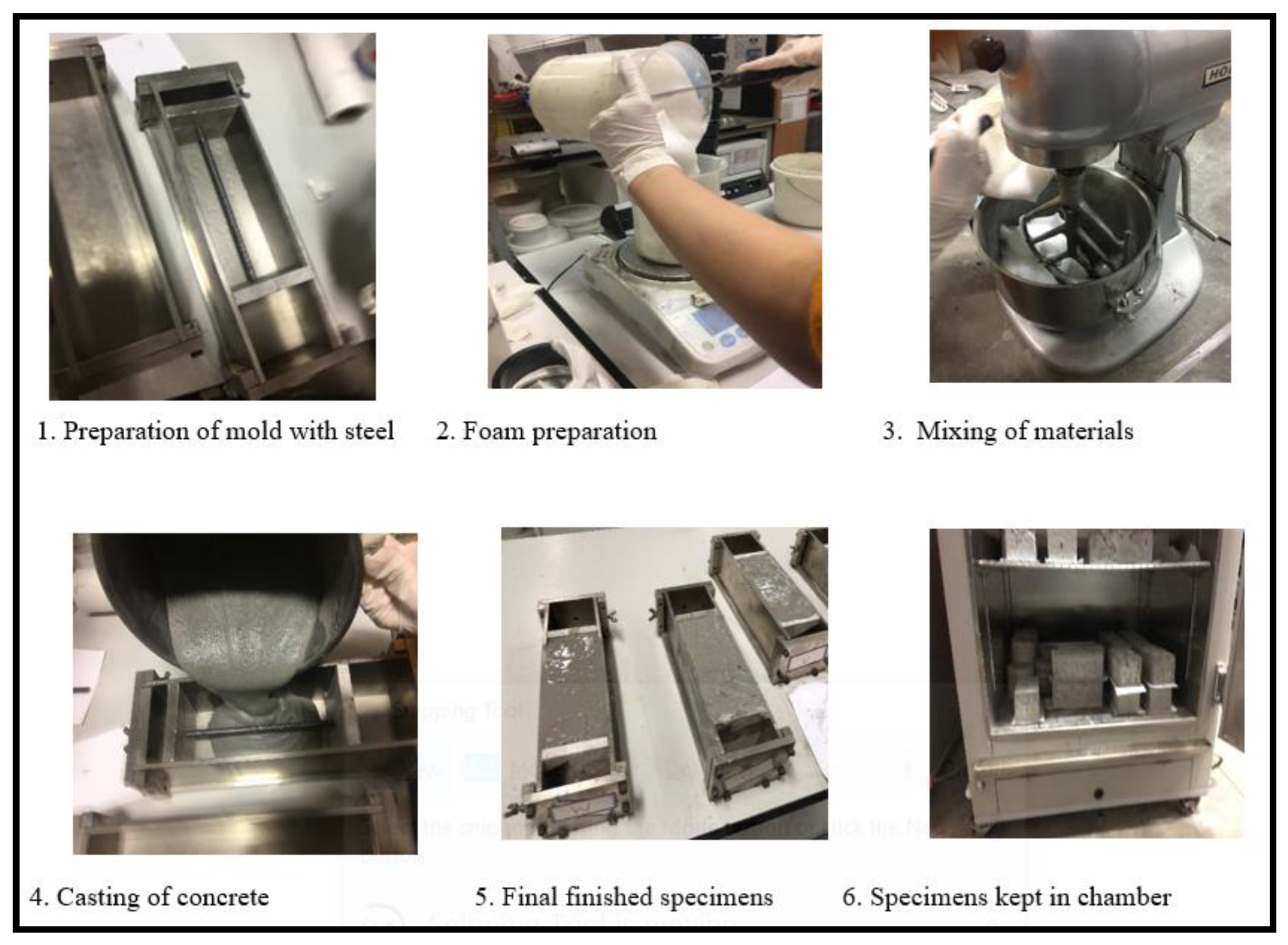

2.1. Specimens Preparation

2.2. Tests for the Performance of FC and GPC

2.2.1. Corrosion Assessment

2.2.2. Mechanical Performance

2.2.3. Fractography

3. Results

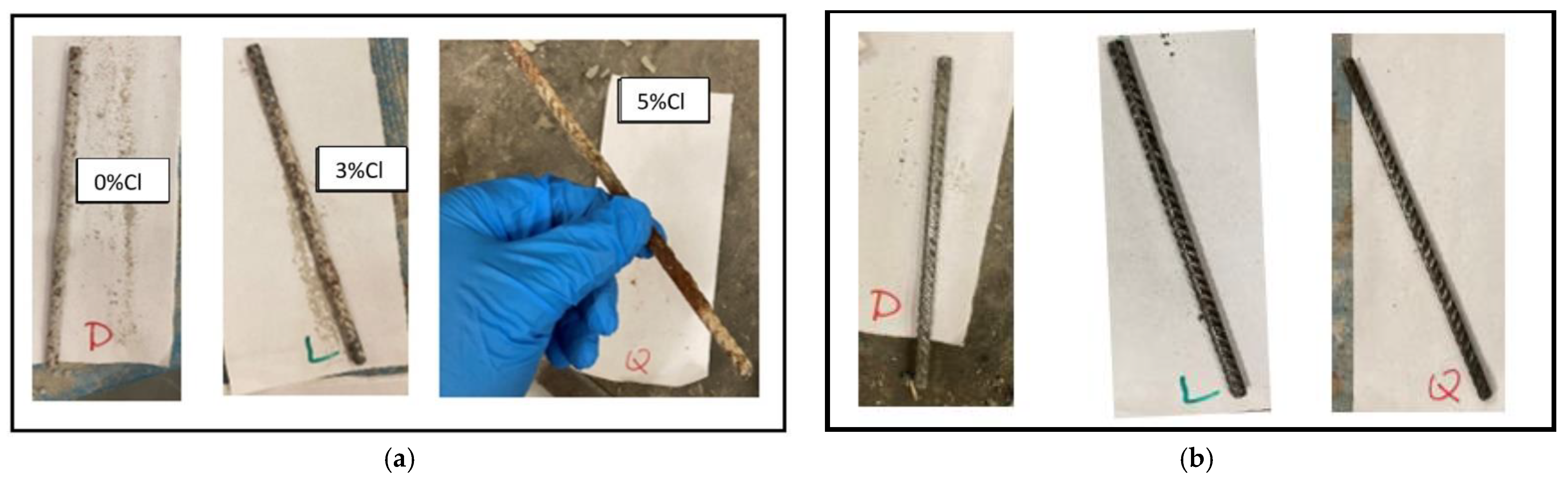

3.1. Time Dependent Degradation of Reinforced Foam Concrete

Long-Term Corrosion Rates for FC

3.2. Long Term Corrosion Rates of Steel in GPC

Comparison of FC and GPC

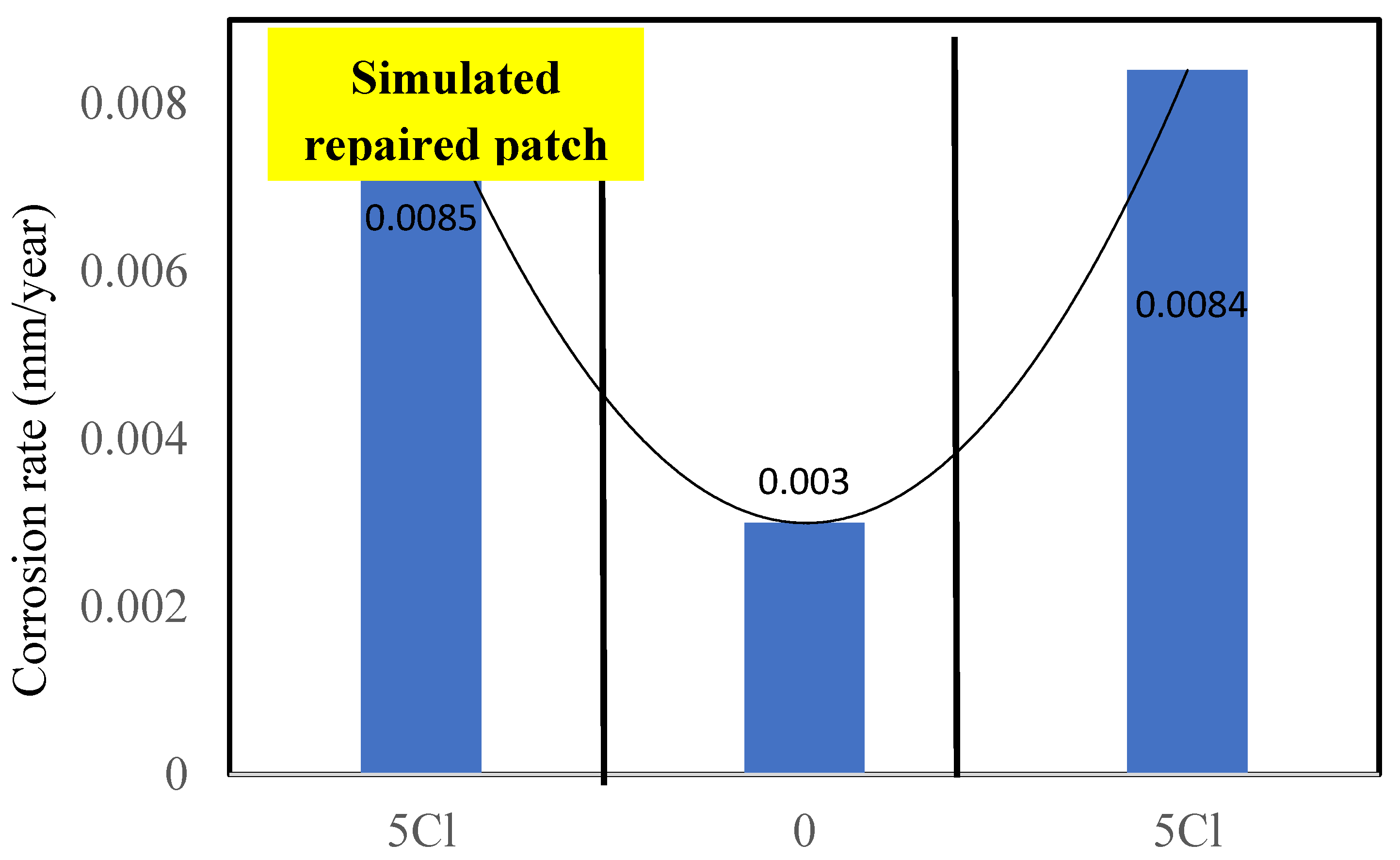

3.3. Behavior of Simulated Corroded Repaired Patches with FC and GPC

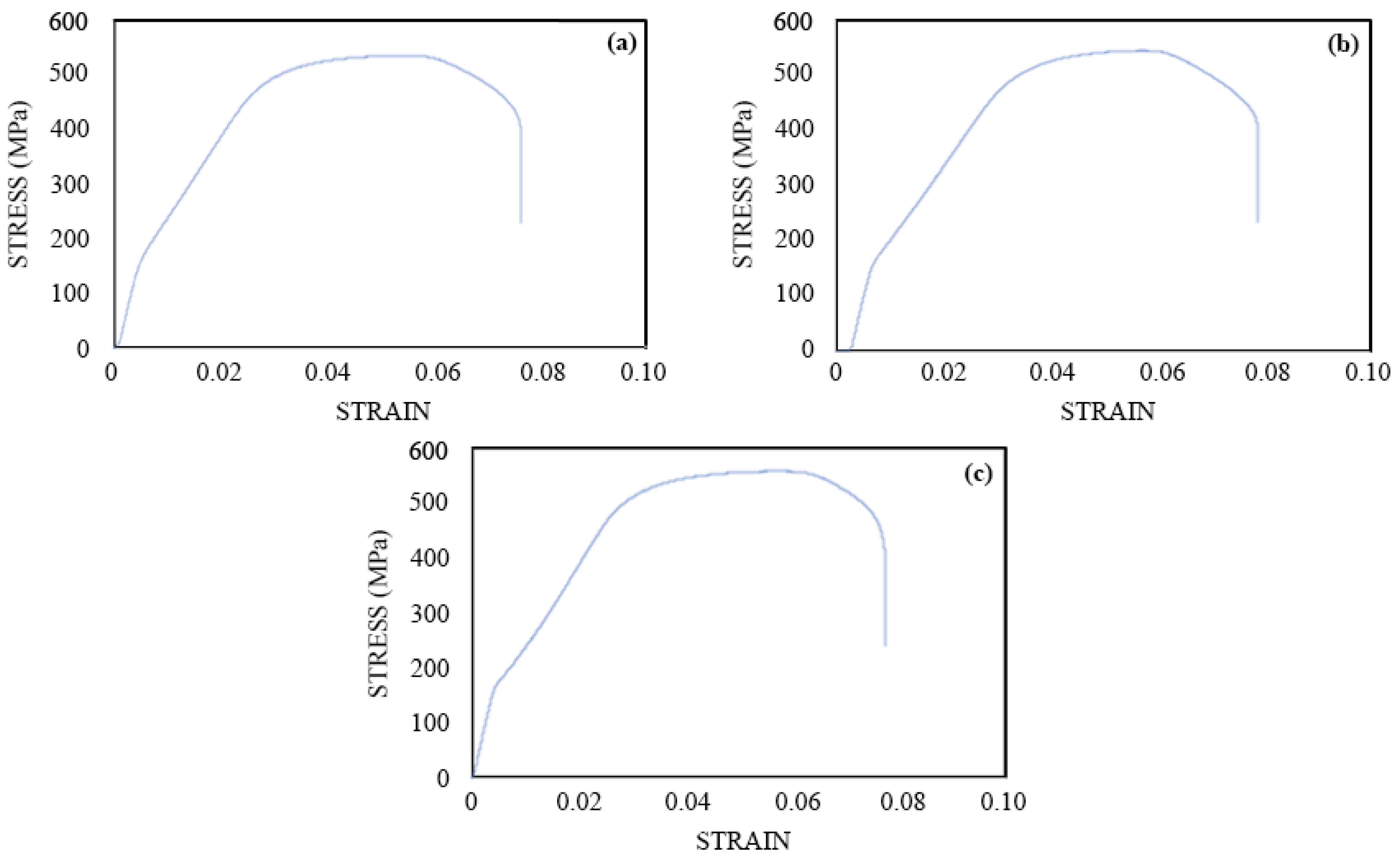

3.4. Long Term Mechanical Performance of Corroded Steel in FC and GPC

3.4.1. Reinforcement from FC Tested

3.4.2. Reinforcement from GPC Tested

3.4.3. Comparison of Mechanical Performance of FC and GPC

4. Discussion

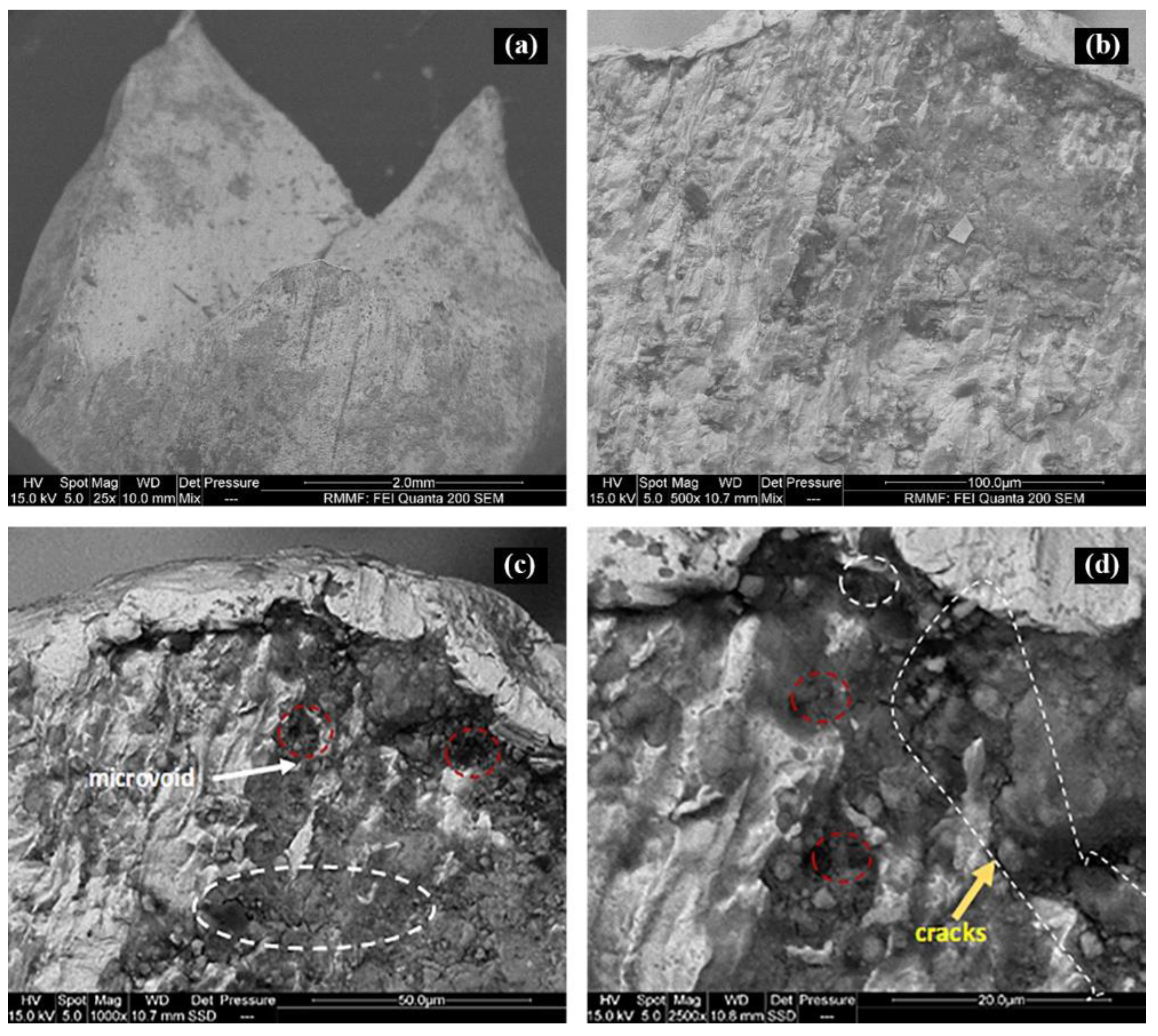

4.1. Fractographic Examination of the Corroded Reinforcement

4.2. Models for the Long-Term Corrosion Rates of FC

5. Conclusions

- The corrosion rates were found to increase three-fold and four-fold for 3 and 5% admixed chloride content FC specimens as compared to the control specimen with 0% chloride after 803 days, respectively.

- The specimens with higher (5%) chloride contents suffered degradation of the tensile strength of their reinforcements. The tensile strengths of the reinforcements embedded in 5% chloride-contaminated FC and GPC specimen were found to be 536.2 and 529.6 MPa, respectively. The tensile strengths of reinforcement in their control specimens were found to be 552.2 and 556.21 MPa, respectively.

- FC showed more resilience as compared to the GPC, with respect to both the corrosion rate and mechanical behavior after 803 days. The corrosion rates of FC were found to be 5% lower than those of GPC. The degradation of reinforcement was found to be 2.89% in FC, while in GPC it was found to be 4.78% as compared to the control specimen.

- The fractography of the reinforcing steel indicated the presence of microcracks that induced degradation in the ultimate tensile strength. It was probably due to the chloride-enhanced hydrogen embrittlement that caused the formation of microcracks within the microstructure of the reinforcing steel in FC and GPC.

- A model for the long-term corrosion rates of FC as the function of the corrosion rates of GPC and chloride content was developed with a very high R2 and low standard error estimate. A correlation model for the corrosion rates between FC and GPC was also developed with R2 = 0.84.

- The simulated repaired patches of reinforced FC showed slightly higher corrosion rates as compared to the GPC. The corrosion rates of the repaired section with FC were twice than those of GPC after 810 days. This was probably due to the migration of chloride, oxygen, and moisture from the surrounding chloride-rich environment to the reinforcing steel in the repaired section in FC due to its microstructure and cavities as compared to GPC.

- The test results suggest that the test duration could be even longer for such experiments to observe significant variation of the mechanical properties. Moreover, investigations for the porous structure and solid phases of the GPC and FC should be carried out as the scope of future research.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Roychand, R.; De Silva, S.; Law, D.; Setunge, S. Micro and nano engineered high volume ultrafine fly ash cement composite with and without additives. Int. J. Concr. Struct. Mater. 2016, 10, 113–124. [Google Scholar] [CrossRef]

- Roychand, R.; De Silva, S.; Law, D.; Setunge, S. High volume fly ash cement composite modified with nano silica, hydrated lime and set accelerator. Mater. Struct. 2016, 49, 1997–2008. [Google Scholar] [CrossRef]

- Szoke, S.S.; Nahlawi, K.; Casilio, J. Enhancing sustainability through structural concrete system selection. In Proceedings of the Institution of Civil Engineers-Engineering Sustainability; Thomas Telford Ltd.: London, UK; pp. 57–63.

- Islam, M.M.U.; Li, J.; Wu, Y.-F.; Roychand, R.; Saberian, M. Design and strength optimization method for the production of structural lightweight concrete: An experimental investigation for the complete replacement of conventional coarse aggregates by waste rubber particles. Resour. Conserv. Recycl. 2022, 184, 106390. [Google Scholar] [CrossRef]

- Roychand, R.; De Silva, S.; Setunge, S. Nanosilica Modified High-Volume Fly Ash and Slag Cement Composite: Environmentally Friendly Alternative to OPC. J. Mater. Civ. Eng. 2018, 30, 04018043. [Google Scholar] [CrossRef]

- Marvila, M.T.; Azevedo, A.R.; Delaqua, G.C.; Mendes, B.C.; Pedroti, L.G.; Vieira, C.M. Performance of geopolymer tiles in high temperature and saturation conditions. Constr. Build. Mater. 2021, 286, 122994. [Google Scholar] [CrossRef]

- Masoule, M.S.T.; Bahrami, N.; Karimzadeh, M.; Mohasanati, B.; Shoaei, P.; Ameri, F.; Ozbakkaloglu, T. Lightweight geopolymer concrete: A critical review on the feasibility, mixture design, durability properties and microstructure. Ceram. Int. 2022, 48, 10347–10371. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Chinnu, S.; Abdalla, J.A.; Hawileh, R.A.; Siddika, A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Roychand, R.; Patel, S.; Halder, P.; Kundu, S.; Hampton, J.; Bergmann, D.; Surapaneni, A.; Shah, K.; Pramanik, B.K. Recycling biosolids as cement composites in raw, pyrolyzed and ashed forms: A waste utilisation approach to support circular economy. J. Build. Eng. 2021, 38, 102199. [Google Scholar] [CrossRef]

- Roychand, R.; Pramanik, B.K.; Zhang, G.; Setunge, S. Recycling steel slag from municipal wastewater treatment plants into concrete applications–A step towards circular economy. Resour. Conserv. Recycl. 2020, 152, 104533. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Roychand, R.; Saberian, M.; Li, J.; Zhang, G. Application of COVID-19 single-use shredded nitrile gloves in structural concrete: Case study from Australia. Sci. Total Environ. 2021, 812, 151423. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Roychand, R.; Saberian, M.; Li, J.; Zhang, G.; Setunge, S. A sustainable approach on the utilisation of COVID-19 plastic based isolation gowns in structural concrete. Case Stud. Constr. Mater. 2022, 17, e01408. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Saberian, M.; Li, J.; Roychand, R.; Zhang, G. Preliminary evaluation of the feasibility of using polypropylene fibres from COVID-19 single-use face masks to improve the mechanical properties of concrete. J. Clean. Prod. 2021, 296, 126460. [Google Scholar] [CrossRef] [PubMed]

- Saberian, M.; Li, J.; Kilmartin-Lynch, S.; Boroujeni, M. Repurposing of COVID-19 single-use face masks for pavements base/subbase. Sci. Total Environ. 2021, 769, 145527. [Google Scholar] [CrossRef] [PubMed]

- Moradi, N.; Tavana, M.H.; Habibi, M.R.; Amiri, M.; Moradi, M.J.; Farhangi, V. Predicting the Compressive Strength of Concrete Containing Binary Supplementary Cementitious Material Using Machine Learning Approach. Materials 2022, 15, 5336. [Google Scholar] [CrossRef]

- Wang, L.; Luo, R.; Zhang, W.; Jin, M.; Tang, S. Effects of fineness and content of phosphorus slag on cement hydration, permeability, pore structure and fractal dimension of concrete. Fractals 2021, 29, 2140004. [Google Scholar] [CrossRef]

- Roychand, R. Performance of Micro and Nano Engineered High Volume Fly Ash Cement Composite. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2017. [Google Scholar]

- Amran, M.; Al-Fakih, A.; Chu, S.; Fediuk, R.; Haruna, S.; Azevedo, A.; Vatin, N. Long-term durability properties of geopolymer concrete: An in-depth review. Case Stud. Constr. Mater. 2021, 15, e00661. [Google Scholar] [CrossRef]

- Gamal, H.A.; El-Feky, M.; Alharbi, Y.R.; Abadel, A.A.; Kohail, M. Enhancement of the concrete durability with hybrid nano materials. Sustainability 2021, 13, 1373. [Google Scholar] [CrossRef]

- Pather, B.; Ekolu, S.; Quainoo, H. Effects of aggregate types on acid corrosion attack upon fly–Ash geopolymer and Portland cement concretes–Comparative study. Constr. Build. Mater. 2021, 313, 125468. [Google Scholar] [CrossRef]

- Roychand, R.; Li, J.; De Silva, S.; Saberian, M.; Law, D.; Pramanik, B.K. Development of zero cement composite for the protection of concrete sewage pipes from corrosion and fatbergs. Resour. Conserv. Recycl. 2021, 164, 105166. [Google Scholar] [CrossRef]

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H. Geopolymer foam concrete: An emerging material for sustainable construction. Constr. Build. Mater. 2014, 56, 113–127. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Amran, Y.M.; Farzadnia, N.; Ali, A.A. Properties and applications of foamed concrete; a review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Wei, S.; Yiqiang, C.; Yunsheng, Z.; Jones, M. Characterization and simulation of microstructure and thermal properties of foamed concrete. Constr. Build. Mater. 2013, 47, 1278–1291. [Google Scholar] [CrossRef]

- Batool, F.; Bindiganavile, V. Air-void size distribution of cement based foam and its effect on thermal conductivity. Constr. Build. Mater. 2017, 149, 17–28. [Google Scholar] [CrossRef]

- Nambiar, E.K.; Ramamurthy, K. Air-void characterisation of foam concrete. Cem. Concr. Res. 2007, 37, 221–230. [Google Scholar] [CrossRef]

- Hilal, A.; Thom, N.; Dawson, A. Effect of additives on void structure of foamed concrete. In Proceedings of the 34th Cement and Concrete Science Conference, Sheffield, UK, 14–16 September 2014. [Google Scholar]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On void structure and strength of foamed concrete made without/with additives. Constr. Build. Mater. 2015, 85, 157–164. [Google Scholar] [CrossRef]

- Hilal, A.A.; Thom, N.H.; Dawson, A.R. On entrained pore size distribution of foamed concrete. Constr. Build. Mater. 2015, 75, 227–233. [Google Scholar] [CrossRef]

- Jones, M.; McCarthy, A. Preliminary views on the potential of foamed concrete as a structural material. Mag. Concr. Res. 2005, 57, 21–31. [Google Scholar] [CrossRef]

- Hao, Y.; Yang, G.; Liang, K. Development of fly ash and slag based high-strength alkali-activated foam concrete. Cem. Concr. Compos. 2022, 128, 104447. [Google Scholar] [CrossRef]

- Jones, M.; McCarthy, A. Utilising unprocessed low-lime coal fly ash in foamed concrete. Fuel 2005, 84, 1398–1409. [Google Scholar] [CrossRef]

- Bagheri, A.; Rastegar, M.M. Effects of foam content on chloride ingress and steel corrosion in foamed concrete. Mag. Concr. Res. 2021, 73, 356–365. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. Durability performance of reinforced waste-based geopolymer foam concrete under exposure to various corrosive environments. Case Stud. Constr. Mater. 2021, 15, e00703. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Law, D. A state-of-the-art review on the durability of geopolymer concrete for sustainable structures and infrastructure. Constr. Build. Mater. 2021, 291, 123381. [Google Scholar] [CrossRef]

- Omer, L.M.; Gomaa, M.S.; Sufe, W.H.; Elsayed, A.A.; Elghazaly, H.A. Enhancing corrosion resistance of RC pipes using geopolymer mixes when subjected to aggressive environment. J. Eng. Appl. Sci. 2022, 69, 3. [Google Scholar] [CrossRef]

- Li, W.; Shumuye, E.D.; Shiying, T.; Wang, Z.; Zerfu, K. Eco-friendly fibre reinforced geopolymer concrete: A critical review on the microstructure and long-term durability properties. Case Stud. Constr. Mater. 2022, 16, e00894. [Google Scholar] [CrossRef]

- Pasupathy, K.; Ramakrishnan, S.; Sanjayan, J. Enhancing the chemical foaming process using superplasticizer in aerated geopolymer concrete. Constr. Build. Mater. 2022, 324, 126535. [Google Scholar] [CrossRef]

- Sobhan, K.; Martinez, F.J.; Reddy, D.V. Corrosion resistance of fiber-reinforced geopolymer structural concrete in a simulated marine environment. Can. J. Civ. Eng. 2022, 49, 310–317. [Google Scholar] [CrossRef]

- Kong, L.; Zhao, W.; Xuan, D.; Wang, X.; Liu, Y. Application potential of alkali-activated concrete for antimicrobial induced corrosion: A review. Constr. Build. Mater. 2022, 317, 126169. [Google Scholar] [CrossRef]

- Dehkordi, E.R.; Moodi, F.; GivKashi, M.R.; Ramezanianpour, A.A.; Khani, M. Software simulation of chloride ions penetration into composite of pre-fabricated geopolymer permanent formworks (PGPFs) and substrate concrete. J. Build. Eng. 2022, 51, 104344. [Google Scholar] [CrossRef]

- Kumar, S.; Das, C.S.; Lao, J.; Alrefaei, Y.; Dai, J.-G. Effect of sand content on bond performance of engineered geopolymer composites (EGC) repair material. Constr. Build. Mater. 2022, 328, 127080. [Google Scholar] [CrossRef]

- Fan, L.; Zhong, W.; Zhang, Y. Effect of the composition and concentration of geopolymer pore solution on the passivation characteristics of reinforcement. Constr. Build. Mater. 2022, 319, 126128. [Google Scholar] [CrossRef]

- Wasim, M.; Ngo, T.D.; Abid, M. Investigation of long-term corrosion resistance of reinforced concrete structures constructed with various types of concretes in marine and various climate environments. Constr. Build. Mater. 2020, 237, 117701. [Google Scholar] [CrossRef]

- ASTM G1-03(2017)e1; Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- Wasim, M.; Ngo, T.D. Failure analysis of structural steel subjected to long term exposure of hydrogen. Eng. Fail. Anal. 2020, 114, 104606. [Google Scholar] [CrossRef]

- Hussain, R.R.; Ishida, T.; Wasim, M. Oxygen Transport and Corrosion of Steel in Concrete under Varying Concrete Cover, w/c, and Moisture. ACI Mater. J. 2012, 109. [Google Scholar]

- Serdar, M.; Žulj, L.V.; Bjegović, D. Long-term corrosion behaviour of stainless reinforcing steel in mortar exposed to chloride environment. Corros. Sci. 2013, 69, 149–157. [Google Scholar] [CrossRef]

- Ghods, P. Multi-Scale Investigation of the Formation and Breakdown of Passive Films on Carbon Steel Rebar in Concrete. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2010. [Google Scholar]

- Wasim, M.; Li, C.-Q.; Mahmoodian, M.; Robert, D. Mechanical and microstructural evaluation of corrosion and hydrogen-induced degradation of steel. J. Mater. Civ. Eng. 2019, 31, 04018349. [Google Scholar] [CrossRef]

- Wasim, M.; Djukic, M.B. Hydrogen embrittlement of low carbon structural steel at macro-, micro-and nano-levels. Int. J. Hydrog. Energy 2020, 45, 2145–2156. [Google Scholar] [CrossRef]

| Foam of Sodium Silicate (g) | Fly Ash (g) | Slag (g) | Water (g) | NaCl (g) | |

|---|---|---|---|---|---|

| 3% Cl | 5% Cl | ||||

| 50 | 200 | 200 | 160 | 20 | 33.3 |

| Coarse Aggregate of 14 mm (kg/m3) | Sand (kg/m3) | Fly Ash (kg/m3) | Slag (kg/m3) | Water (kg/m3) | NaCl (kg/m3) | |

|---|---|---|---|---|---|---|

| 3% Cl | 5% Cl | |||||

| 1071 | 526 | 196 | 196 | 196 | 17.25 | 29 |

| Specimen | Type of Concrete | Temperature (°C) | Humidity (%) | Duration (days) | Testing/ Measurement |

|---|---|---|---|---|---|

| 3% Cl admixed (L) | FC | 24 | 50 | 803 | Corrosion rates and Tensile strength |

| GPC | 24 | 50 | 803 | ||

| 5% Cl admixed (Q) | FC | 24 | 50 | 803 | |

| GPC | 24 | 50 | 803 | ||

| Controlled (D) | FC | 24 | 50 | 803 | |

| GPC | 24 | 50 | 803 | ||

| Simulated patch repair | GPC—Left End Section (5% Cl) | 24 | 50 | 810 | |

| GPC—Middle Section (0% Cl) | 24 | 50 | 810 | ||

| GPC—Right End Section (5% Cl) | 24 | 50 | 810 | ||

| FC—Left End Section (5%Cl) | 24 | 50 | 810 | ||

| FC—Middle Section (0% Cl) | 24 | 50 | 810 | ||

| FC—Right End Section (5% Cl) | 24 | 50 | 810 |

| FC | GPC | Cl | ||

|---|---|---|---|---|

| Pearson Correlation | FCcr | 1.000 | 0.902 | 0.943 |

| GPCcr | 0.902 | 1.000 | 0.994 | |

| Cl | 0.943 | 0.994 | 1.000 | |

| Sig. (1-tailed) | FCcr | 0.0 | 0.142 | 0.108 |

| GPCcr | 0.142 | 0.0 | 0.034 | |

| Cl | 0.108 | 0.034 | 0.0 | |

| N | FCcr | 3 | 3 | 3 |

| GPCcr | 3 | 3 | 3 | |

| Cl | 3 | 3 | 3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wasim, M.; Roychand, R.; Barnes, R.T.; Talevski, J.; Law, D.; Li, J.; Saberian, M. Performance of Reinforced Foam and Geopolymer Concretes against Prolonged Exposures to Chloride in a Normal Environment. Materials 2023, 16, 149. https://doi.org/10.3390/ma16010149

Wasim M, Roychand R, Barnes RT, Talevski J, Law D, Li J, Saberian M. Performance of Reinforced Foam and Geopolymer Concretes against Prolonged Exposures to Chloride in a Normal Environment. Materials. 2023; 16(1):149. https://doi.org/10.3390/ma16010149

Chicago/Turabian StyleWasim, Muhammad, Rajeev Roychand, Rhys Thomas Barnes, Jason Talevski, David Law, Jie Li, and Mohammad Saberian. 2023. "Performance of Reinforced Foam and Geopolymer Concretes against Prolonged Exposures to Chloride in a Normal Environment" Materials 16, no. 1: 149. https://doi.org/10.3390/ma16010149

APA StyleWasim, M., Roychand, R., Barnes, R. T., Talevski, J., Law, D., Li, J., & Saberian, M. (2023). Performance of Reinforced Foam and Geopolymer Concretes against Prolonged Exposures to Chloride in a Normal Environment. Materials, 16(1), 149. https://doi.org/10.3390/ma16010149