Assessment of the Undrained Shear Strength and Settlement of Organic Soils under Embankment Loading Using Artificial Neural Networks

Abstract

1. Introduction

2. Materials and Methods

2.1. Characteristics of the Test Sites

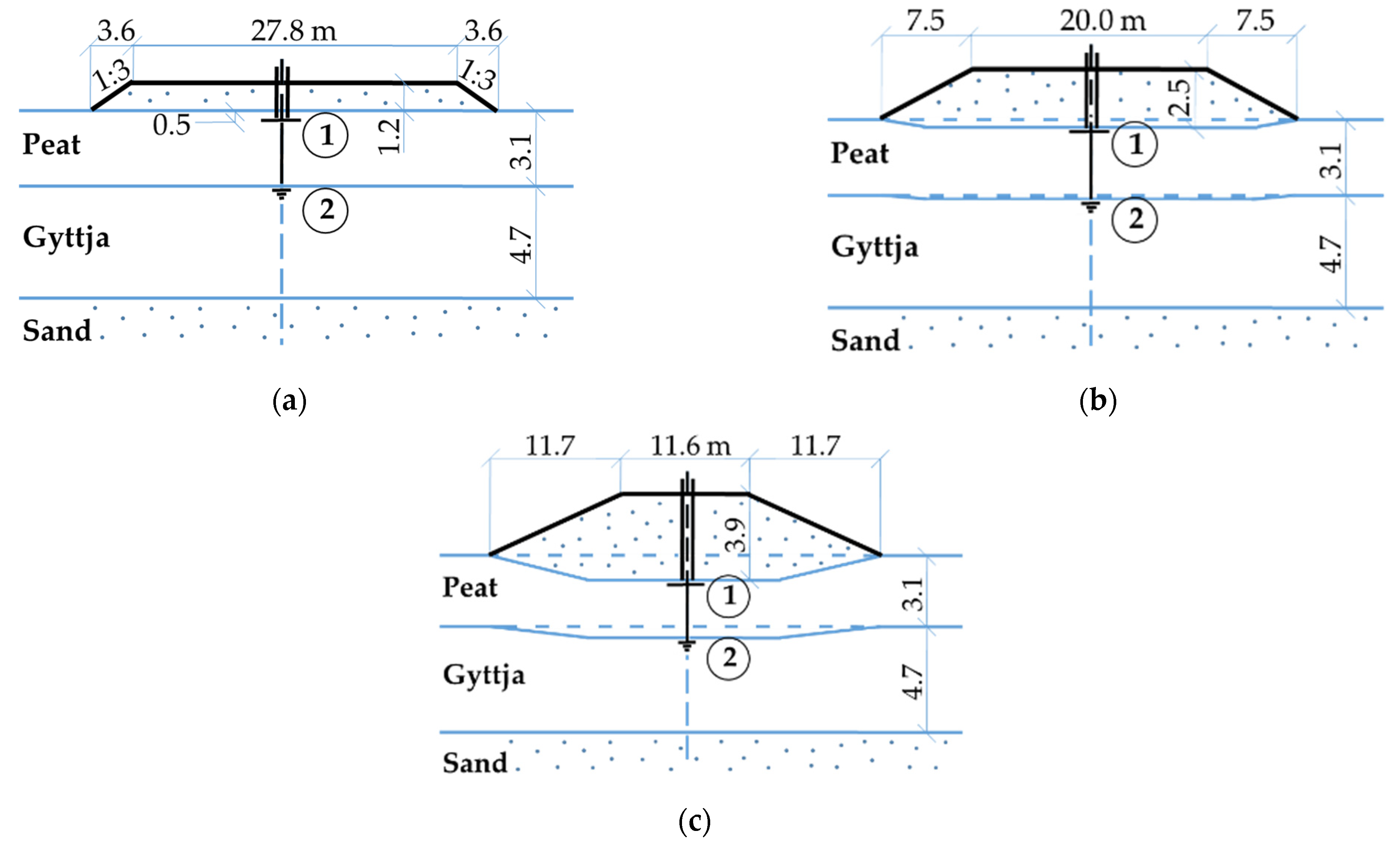

2.1.1. Białośliwie Site

2.1.2. Antoniny Site

2.1.3. Wonieść Site

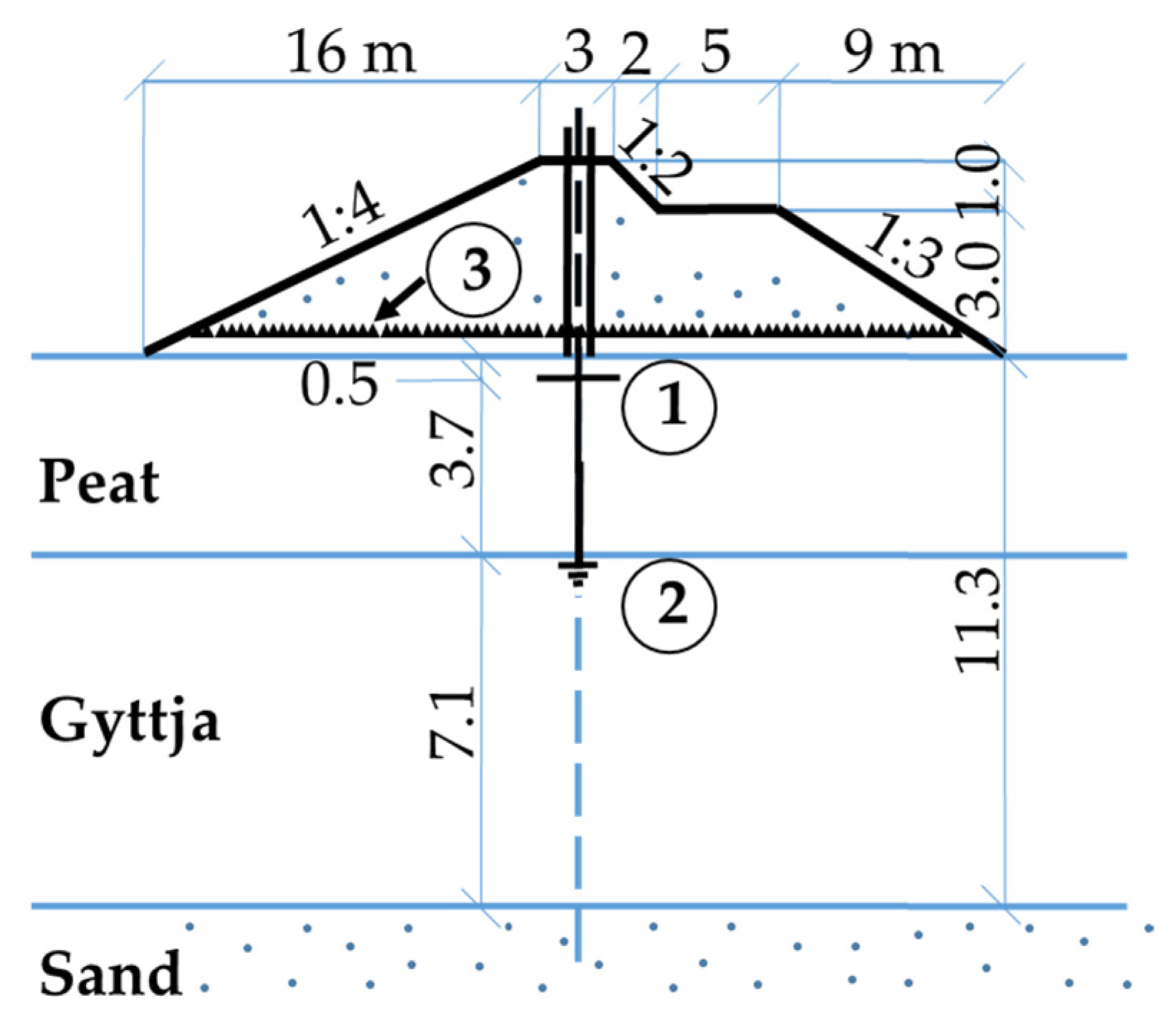

2.1.4. Koszyce Site

2.2. Characteristics of the Tested Organic Soils

2.2.1. Białośliwie Site

2.2.2. Antoniny Site

2.2.3. Wonieść Site

2.2.4. Koszyce Site

2.3. Settlement and Undrained Shear Strength Measurements

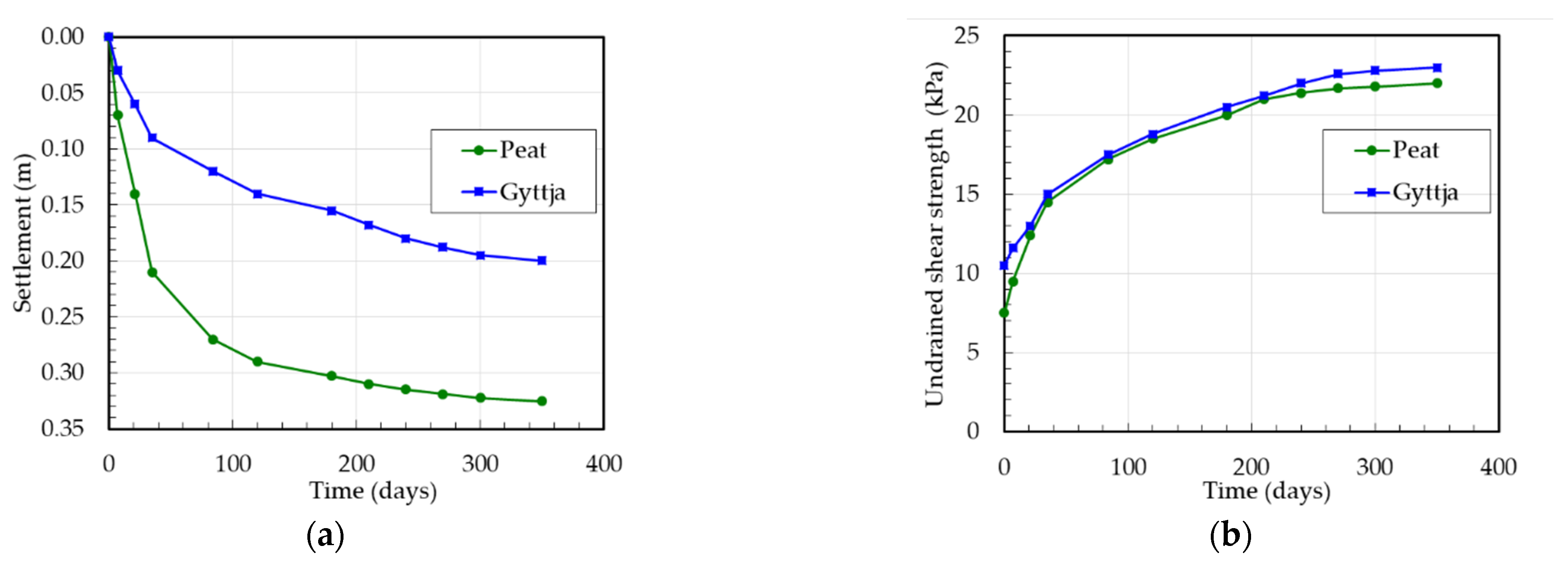

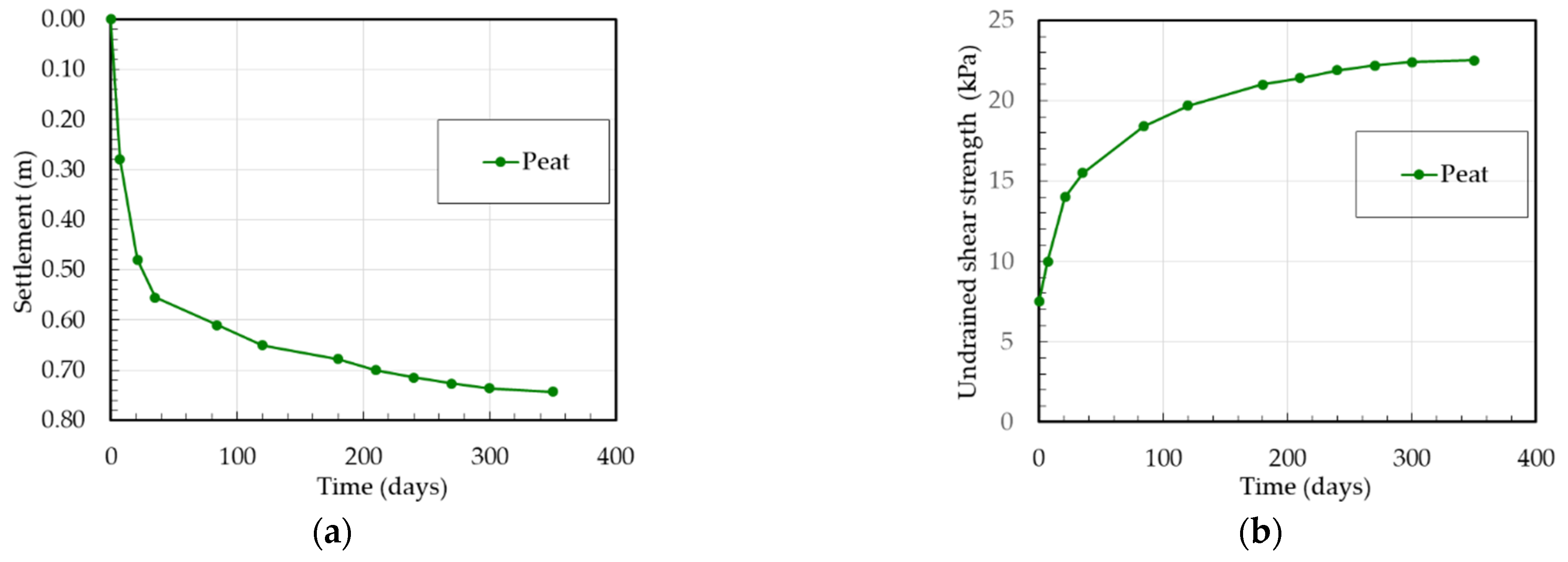

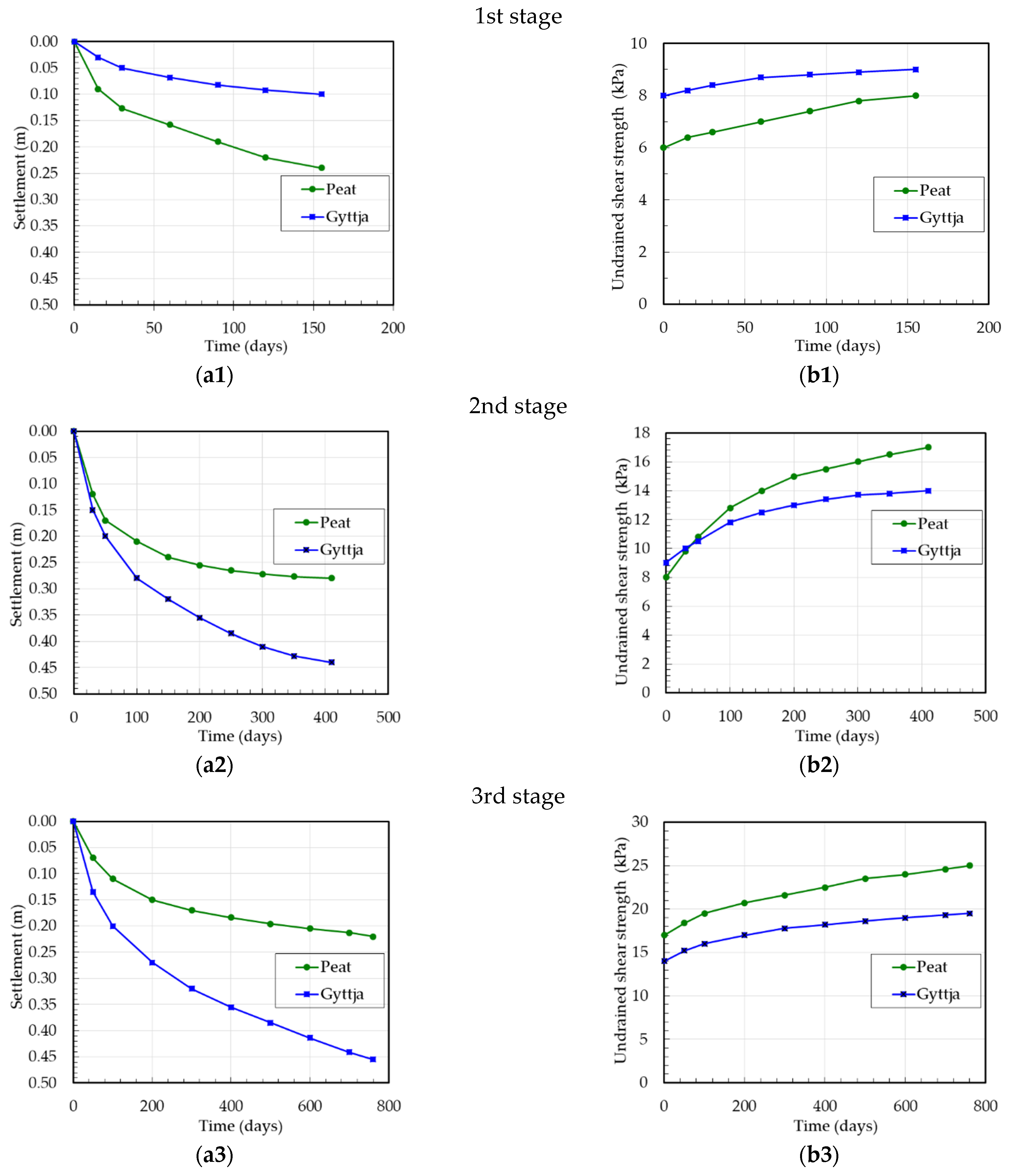

2.3.1. Białośliwie Site

2.3.2. Antoniny Site

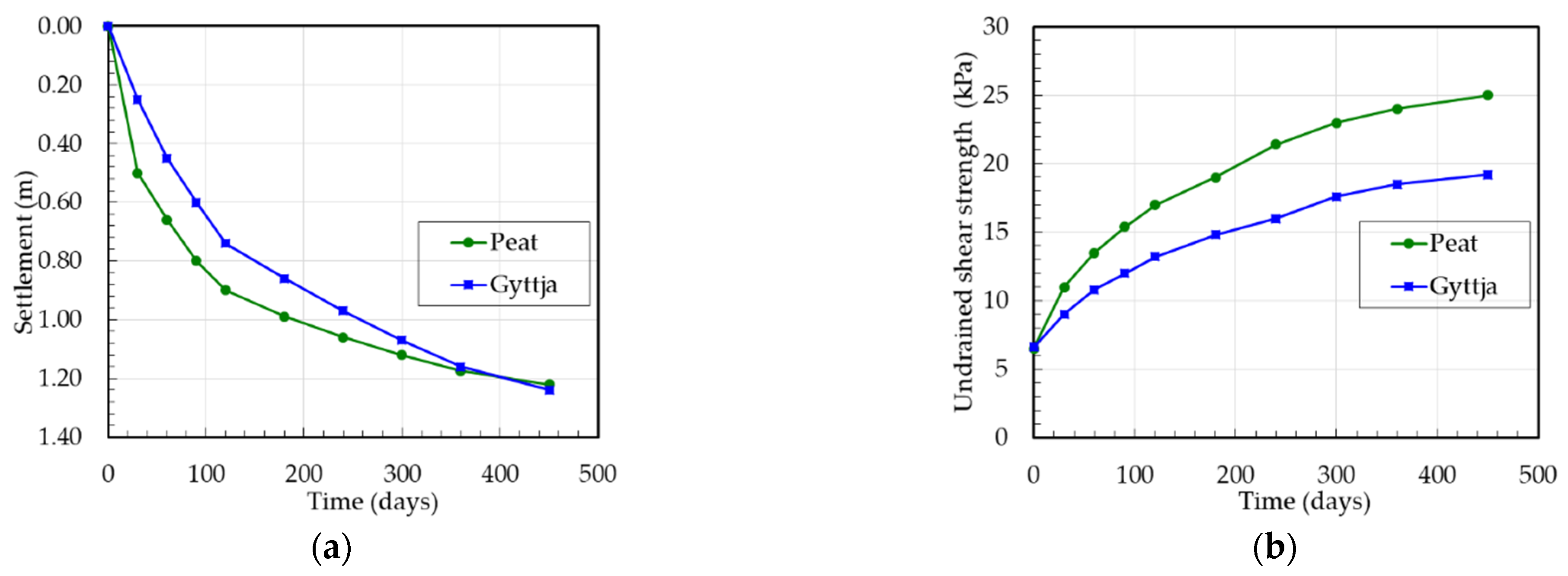

2.3.3. Wonieść Site

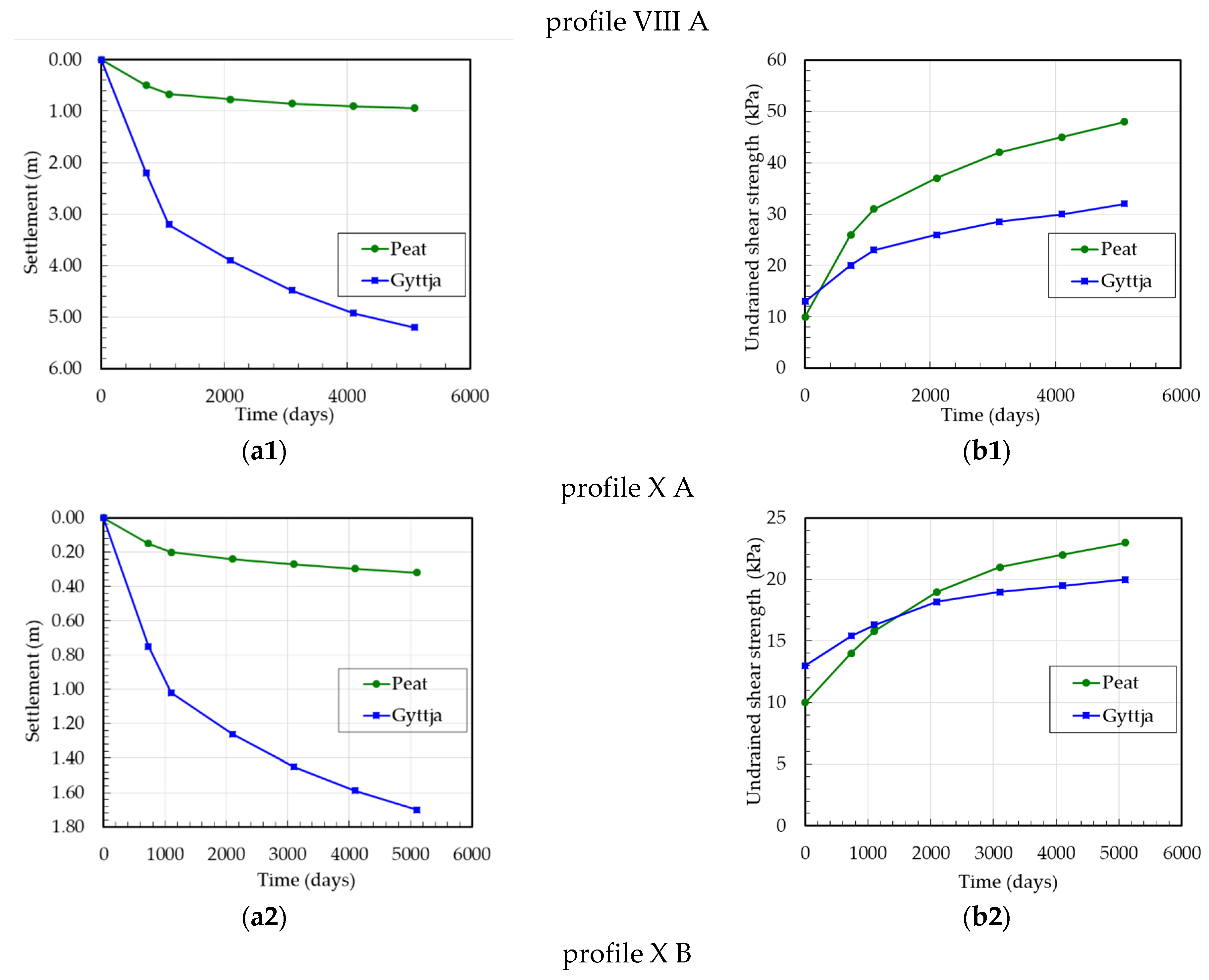

2.3.4. Koszyce Site

3. Results

4. Analysis of Test Results

4.1. Statistical Analysis of Results

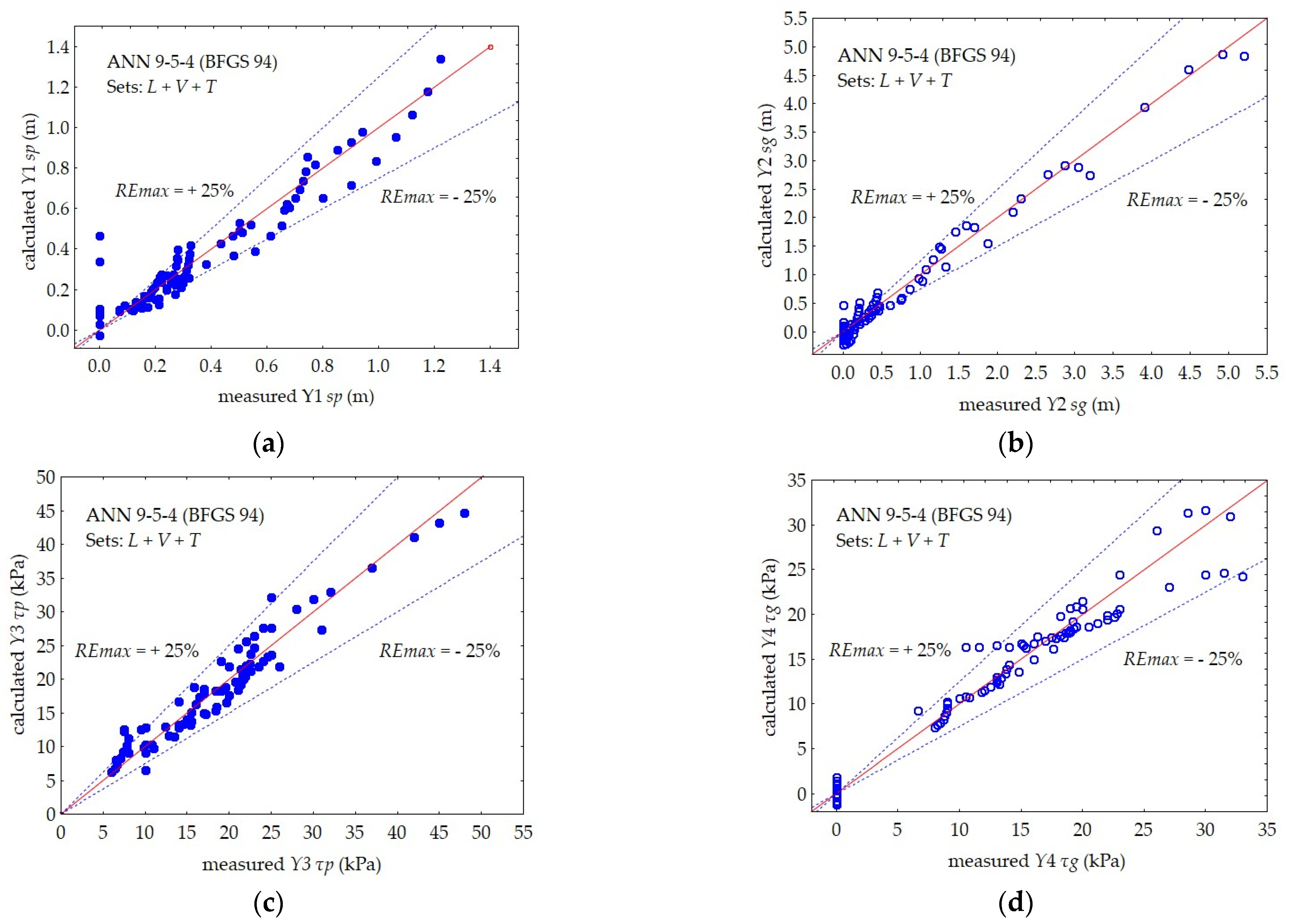

4.2. Analysis of Results Using Artificial Neural Networks

- 9–5–4 network for simultaneous prediction of four dependent variables Y1-Y4 for a subsoil consisting of two layers—peat and gyttja,

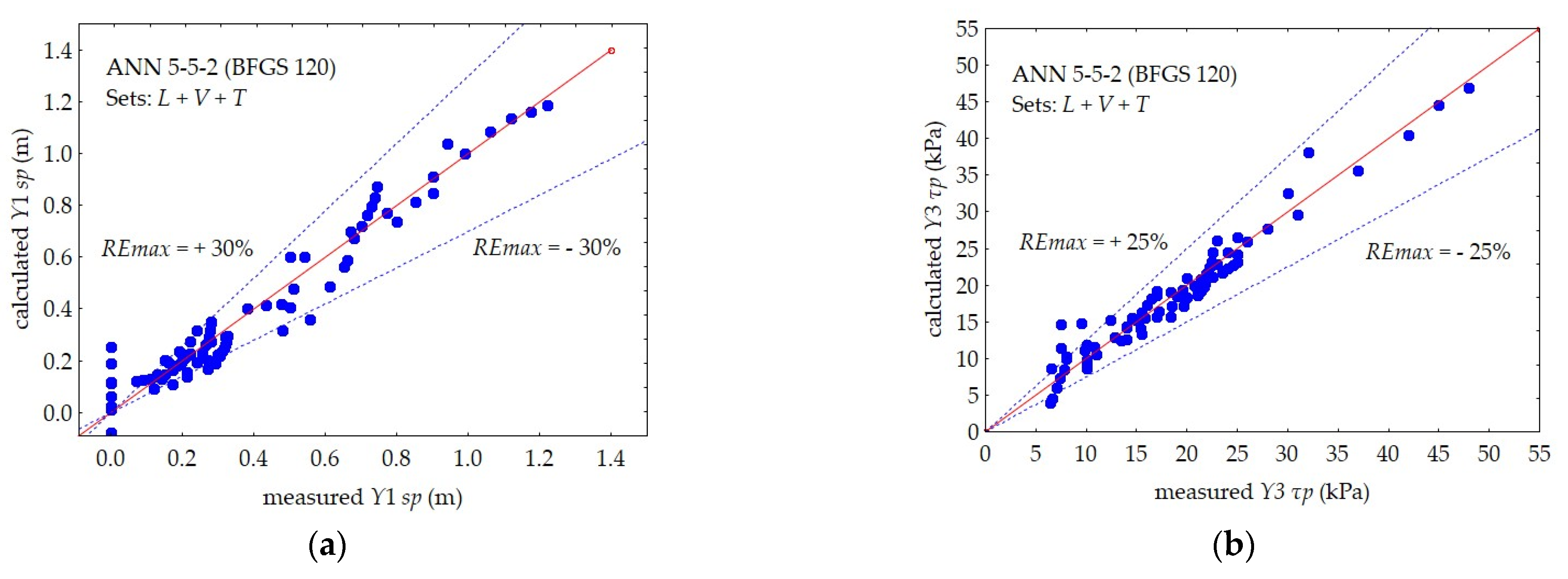

- 5–5–2 network for simultaneous prediction of two dependent variables Y1 and Y3 when the subsoil is single-layer—only from peat,

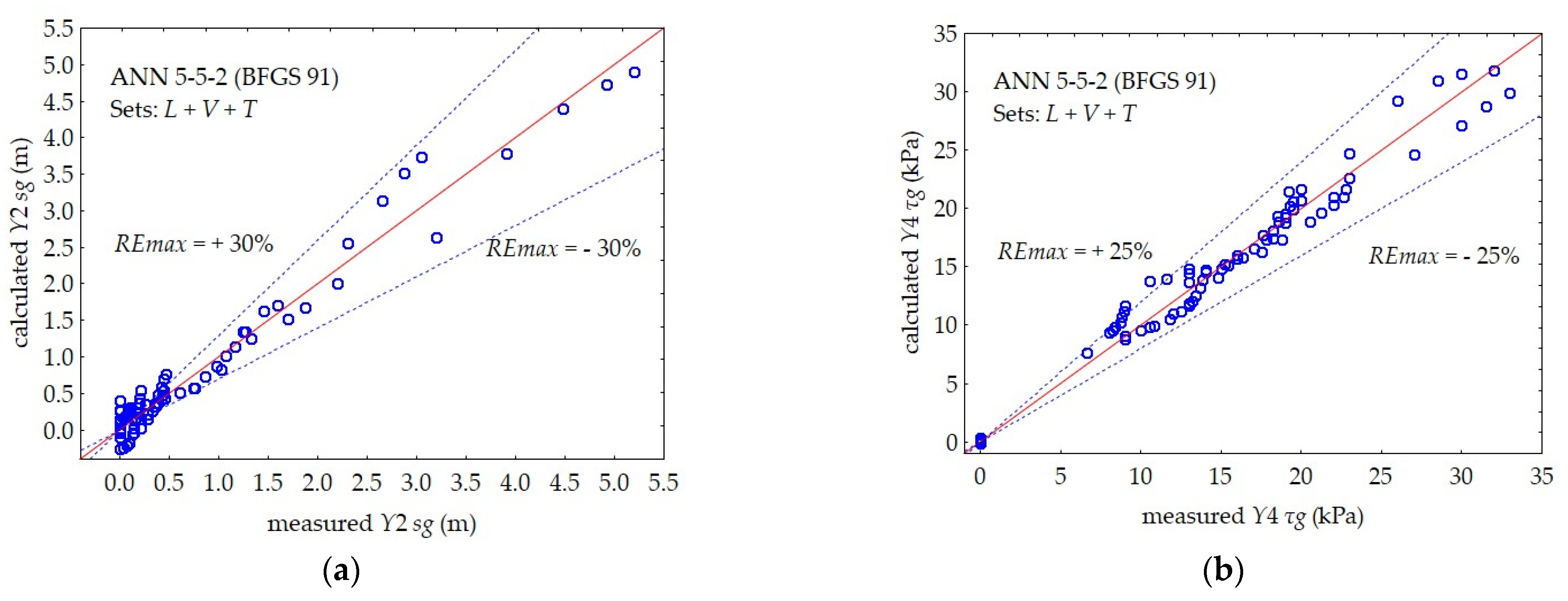

- 5–5–2 network for simultaneous prediction of two dependent variables Y2 and Y4 when the subsoil is single-layered—only from gyttja.

| Output-Parameter | Architecture of ANN | R2 | ±REmax in Set (L + V + T) (%) | Formula Number | ||

|---|---|---|---|---|---|---|

| L | V | T | ||||

| Y1 sp | 9–5–4 (BFGS 94) | 0.914 | 0.910 | 0.943 | 25 | (9) |

| Y2 sg | 0.960 | 0.984 | 0.976 | 25 | ||

| Y3 τp | 0.960 | 0.982 | 0.986 | 25 | ||

| Y4 τg | 0.954 | 0.982 | 0.970 | 25 | ||

| Y1 sp | 5–5–2 (BFGS 120) | 0.946 | 0.856 | 0.931 | 30 | (10) |

| Y3 τp | 0.952 | 0.944 | 0.910 | 25 | ||

| Y2 sg | 5–5–2(BFGS 91) | 0.984 | 0.954 | 0.949 | 30 | (11) |

| Y4 τg | 0.980 | 0.978 | 0.982 | 25 | ||

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wolski, W.; Hartlen, J. (Eds.) Embankments on Organic Soils; Elsevier: Amsterdam, The Netherlands, 1996; Volume 80. [Google Scholar]

- Balkema, A.A. CUR Building on Soft Soils; Report 162; CUR, Ed.; Routledge: Oxfordshire, UK, 1996. [Google Scholar]

- Duncan, J.M.; Wright, S.G. Soil Strength and Slope Stability; John Willey & Sons: Hoboken, NJ, USA, 2005. [Google Scholar]

- Ladd, C.C. Stability evaluation during staged construction. J. Geotech. Eng. Div. 1991, 117, 540–615. [Google Scholar] [CrossRef]

- Barden, L. Primary and secondary compression of clay and peat. Géotechnique 1968, 18, 1–24. [Google Scholar] [CrossRef]

- Šuklje, L. The analysis of the consolidation process by the Isotaches method. In Proceedings of the 4th International Conference Soil Mechanics Foundation Engineering, London, UK, 12–24 August 1957; pp. 200–206. Available online: https://www.issmge.org/uploads/publications/1/41/1957_01_0044.pdf (accessed on 7 October 2022).

- Watabe, Y.; Udaka, K.; Nakatani, Y.; Leroueil, S. Long-term consolidation behaviour interpreted with isotache concept for worldwide clays. Soils Found. 2012, 52, 449–464. [Google Scholar] [CrossRef]

- Christensen, R.W.; Wu, T.H. Analysis of Clay Deformations as a Rate Process. J. Soil Mech. Found. Div. 1964, 90, 125–157. [Google Scholar] [CrossRef]

- Janbu, N. The resistance concept applied to deformations of soils. In Proceedings of the 7th International Conference Soil Mechanics Foundation Engineering, Mexico City, Mexico, 29 August 1969; pp. 191–196. Available online: https://www.issmge.org/uploads/publications/1/38/1969_01_0024.pdf (accessed on 7 October 2022).

- Yaid, Y.P.; Campanella, R.G. Time-dependent behaviour of undisturbed clay. J. Geotech. Eng. Div. 1977, 103, 693–709. [Google Scholar]

- Tavenas, F.; Leroueil, S.; La Rochelle, P.; Roy, M. Creep behaviour of an undisturbed lightly over consolidated clay. Can. Geotech. J. 1978, 15, 402–423. [Google Scholar] [CrossRef]

- Lechowicz, Z.; Szymański, A. Creep behaviour of organic soils. Ann. Wars. Agricult. Univ. Land Recl. 1988, 24, 99–106. [Google Scholar]

- Acharya, M.P.; Hendry, M.T.; Martin, C.D. Creep behaviour of intact and remoulded fibrous peat. Acta Geotech. 2018, 13, 399–417. [Google Scholar] [CrossRef]

- Larsson, R. Behaviour of Organic Clay and Gyttja; Report No. 38; Swedish Geotechnical Institute: Linköping, Sweden, 1990.

- Edil, T. Recent advances in geotechnical characterization and construction over peats and organic soils. In Proceedings of the 2nd International Conference on Advances in Soft Soil Engineering and Technology, Putrajava, Malaysia, 2–4 July 2003; pp. 3–23. [Google Scholar]

- Long, M. Review of peat strength, peat characterisation and constitutive modelling of peat with reference to landslides. Stud. Geotech. Mech. 2005, 27, 67–90. [Google Scholar]

- Lechowicz, Z.; Batory, J.; Hyb, W. Variability assessment of undrained shear strength of organic soils obtained from field vane tests. Ann. Wars. Agric. Univ. Land Recl. 2004, 35, 161–170. [Google Scholar]

- Lechowicz, Z. An evaluation of the increase in shear strength of organic soils. In Proceedings of the International Workshop on Advances in Understanding and Modelling the Mechanical Behaviour of Peat, Balkema, Delft, The Netherlands, 16–18 June 1994; pp. 167–179, ISBN 90-5410-366-3. [Google Scholar]

- O’Kelly, B.O. Measurement, interpretation and recommended use of laboratory strength properties of fibrous peat. Geotech. Res. 2017, 4, 136–171. [Google Scholar] [CrossRef]

- Boylan, N.; Long, M. Evaluation of peat strength for stability assessments. Geotech. Eng. 2014, 167, 421–430. [Google Scholar] [CrossRef]

- Ching, J.; Phoon, K.-K. Multivariate distribution for undrained shear strengths under various test procedures. Can. Geotech. J. 2013, 50, 907–923. [Google Scholar] [CrossRef]

- Madaschi, A.; Gajo, A. One-dimensional response of peaty soils subjected to a wide range of oedometric conditions. Géotechnique 2015, 65, 274–286. [Google Scholar] [CrossRef]

- Hendry, M.T.; Sharma, J.S.; Martin, C.D.; Barbour, S.L. Effect of fibre content and structure on anisotropic elastic stiffness and shear strength of peat. Can. Geotech. J. 2012, 49, 403–415. [Google Scholar] [CrossRef]

- El Mouchi, A.; Siddiqua, S.; Wijewickreme, D.; Polinder, H. A Review to Develop new Correlations for Geotechnical Properties of Organic Soils. Geotech. Geol. Eng. 2021, 39, 3315–3336. [Google Scholar] [CrossRef]

- Trafford, A.; Long, M. Relationship between Shear-Wave Velocity and Undrained Shear Strength of Peat. J. Geotech. Geoenviron. Eng. 2020, 146, 04020057. [Google Scholar] [CrossRef]

- Barden, L. Time dependent deformation of normally consolidated clays and peats. J. Soil Mech. Found. Div. 1969, 95, 1–31. [Google Scholar] [CrossRef]

- Berry, P.L.; Poskitt, T.J. The consolidation of peat. Géotechnique 1972, 22, 27–52. [Google Scholar] [CrossRef]

- Den Haan, E.J. A compression model for non-brittle soft clays and peat. Géotechnique 1996, 46, 1–16. [Google Scholar] [CrossRef]

- Yin, J.-H.; Zhu, J.-G.; Graham, J. A new elastic viscoplastic model for time-dependent behaviour of normally and overconsolidated clays: Theory and verification. Can. Geotech. J. 2002, 39, 157–173. [Google Scholar] [CrossRef]

- Wheeler, S.J.; Näätänen, A.; Karstunen, M.; Lojander, M. An anisotropic elastoplastic model for soft clays. Can. Geotech. J. 2003, 40, 403–418. [Google Scholar] [CrossRef]

- Grimstad, G.; Degago, S.A.; Nordal, S.; Karstunen, M. Modeling creep and rate effects in structured anisotropic soft clays. Acta Geotech. 2010, 5, 69–81. [Google Scholar] [CrossRef]

- Karstunen, M.; Yin, Z.-Y. Modelling time-dependent behaviour of Murro test embankment. Géotechnique 2010, 60, 735–749. [Google Scholar] [CrossRef]

- Yin, Z.-Y.; Karstunen, M. Modelling strain-rate-dependency of natural soft clays combined with anisotropy and destructuration. Acta Mech. Solida Sin. 2011, 24, 216–230. [Google Scholar] [CrossRef]

- Yin, Z.-Y.; Xu, Q.; Yu, C. Elastic viscoplastic modeling for natural soft clays considering nonlinear creep. ASCE Int. J. Geomech. 2015, 15, A6014001. [Google Scholar] [CrossRef]

- Sivasithamparam, N.; Karstunen, M.; Bonnier, P. Modelling creep behaviour of anisotropic soft soils. Comput. Geotech. 2015, 69, 46–57. [Google Scholar] [CrossRef]

- Mirjalili, M.; Kimoto, S.; Oka, F.; Hattori, T. Long-term consolidation analysis of a large-scale embankment construction on soft clay deposits using an elasto-viscoplastic model. Soils Found. 2012, 52, 18–37. [Google Scholar] [CrossRef]

- Zwanenburg, C.; Den Haan, E.J.; Kruse, G.A.M.; Koelewijn, A.R. Failure of a trial embankment on peat in Booneschans, the Netherlands. Géotechnique 2012, 62, 479–490. [Google Scholar] [CrossRef]

- Hendry, M.T.; Martin, C.D.; Barbour, S.L. Measurement of cyclic response of railway embankments and underlying soft peat foundations to heavy axle loads. Can. Geotech. J. 2013, 50, 467–480. [Google Scholar] [CrossRef]

- Zwanenburg, C.; Jardine, R.J. Laboratory, in situ and full-scale load tests to assess flood embankment stability on peat. Géotechnique 2015, 65, 309–326. [Google Scholar] [CrossRef]

- Draper, N.R.; Smith, H. Applied Regression Analysis, 3rd ed.; Wiley: New York, NY, USA, 1998. [Google Scholar]

- Moayedi, H.; Mosallanezhad, M.; Rashid, A.S.A.; Jusoh, W.A.W.; Muazu, M.A. A systematic review and meta-analysis of artificial neural network application in geotechnical engineering: Theory and application. Neural Comput. Appl. 2019, 32, 495–518. [Google Scholar] [CrossRef]

- Kordnaeij, A.; Kalantary, F.; Kordtabar, B.; Mola-Abasi, H. Prediction of recompression index using GMDH-type neural network based on geotechnical soil properties. Soils Found. 2015, 55, 1335–1345. [Google Scholar] [CrossRef]

- Sulewska, M.J.; Zabielska-Adamska, K. Data compression by principal component analysis (PCA) in modelling of soil density parameters based on soil granulation. Geol. Q. 2015, 59, 400–407. [Google Scholar] [CrossRef]

- Ghaboussi, J. Biologically inspired soft computing methods in structural mechanics and engineering. Struct. Eng. Mech. 2001, 11, 485–502. [Google Scholar] [CrossRef]

- Moayedi, H.; Bui, D.T.; Dounis, A.; Foong, L.K.; Kalantar, B. Novel nature-inspired hybrids of neural computing for estimating soil shear strength. Appl. Sci. 2019, 9, 4643. [Google Scholar] [CrossRef]

- Bishop, C. Neural Networks for Pattern Recognition; Oxford University Press: Northamptonshire, UK, 1995. [Google Scholar]

- Patterson, D. Artificial Neural Networks; Prentice Hall: Singapore, 1996. [Google Scholar]

- Shahin, M.A.; Jaksa, M.B.; Maier, H.R. Artificial neural network applications in geotechnical engineering. Aust. Geomech. 2001, 36, 49–62. [Google Scholar]

- Shahin, M.A.; Maier, H.R.; Jaksa, M.B. Predicting settlement of shallow foundation using neural networks. J. Geotech. Geoenv. Eng. 2002, 128, 785–793. [Google Scholar] [CrossRef]

- Chik, Z.; Aljanabi, Q.A.; Kasa, A.; Taha, M.R. Tenfold cross validation artificial neural network modeling of the settlement behavior of a stone column under a highway embankment. Arab. J. Geosci. 2014, 7, 4877–4887. [Google Scholar] [CrossRef]

- Szymański, A.; Lechowicz, Z. Back analysis of organic subsoil settlements. Ann. Wars. Agric. Univ. Land Recl. 1986, 22, 45–51. [Google Scholar]

- Wolski, W.; Szymański, A.; Mirecki, J.; Lechowicz, Z.; Larsson, R.; Hartlen, J.; Garbulewski, K.; Bergdahl, U. Two Stage-Constructed Embankments on Organic Soils; Report No. 32; Swedish Geotechnical Institute: Linköping, Sweden, 1988.

- Wolski, W.; Szymański, A.; Lechowicz, Z.; Larsson, R.; Hartlen, J.; Bergdahl, U. Full-Scale Failure Test on Stage-Constructed Test Fill on Organic Soil; Report No. 36; Swedish Geotechnical Institute: Linköping, Sweden, 1989.

- Bąkowski, J.; Lechowicz, Z. Stability analysis of staged embankment on organic subsoil using the load path method. Ann. Wars. Agric. Univ. Land Recl. 2004, 35, 79–88. [Google Scholar]

- Lechowicz, Z.; Fukue, M.; Rabarijoely, S.; Sulewska, M.J. Evaluation of the undrained shear strength of organic soils from a dilatometer test using artificial neural networks. Appl. Sci. 2018, 8, 1395. [Google Scholar] [CrossRef]

- Lechowicz, Z. An evaluation of the increase in shear strength of organic soils under embankment loading. In Monograph; WULS: Warsaw, Poland, 1992. (In Polish) [Google Scholar]

- Lechowicz, Z.; Rabarijoely, S. Evaluation of organic subsoil conditions after large deformations. In Proceedings of the 2nd International Conference on Problematic Soils, Petaling Jaya, Malaysia, 3–5 December 2005; Volume 3, pp. 1075–1082. [Google Scholar]

- Larsson, R.; Nilson, G.; Rogbeck, J. Determination of Organic Content, Carbonate Content and Sulphur Content in Soils; Report No. 27E; Swedish Geotechnical Institute: Linköping, Sweden, 1987.

- Larsson, R.; Bergdahl, U.; Eriksson, L. Evaluation of Shear Strength in Cohesive Soils with Special Reference to Swedish Practice and Experience; SGI: Linköping, Sweden, 1984; Volume 3, pp. 1–32.

- StatSoft Polska Ltd. STATISTICA—Package Documentation; Polish Edition 2002; StatSoft Polska Ltd.: Kraków, Poland, 2002. (In Polish) [Google Scholar]

| Variables | Notations | Minimum | Maximum | Average | Standard Deviation of Sample |

|---|---|---|---|---|---|

| X1 σp | Vertical stress on peat layer, (kPa) | 19 | 100 | 43.1 | 24.6 |

| X2 σg | Vertical stress on gyttja layer, (kPa) | 0 | 95 | 34.2 | 26.7 |

| X3 hp | Thickness of peat layer, (m) | 1.5 | 3.7 | 2.5 | 0.8 |

| X4 hg | Thickness of gyttja layer, (m) | 0.0 | 14.0 | 6.2 | 5.0 |

| X5 wp | Water content of peat, (%) | 232 | 650 | 438.5 | 149.1 |

| X6 wg | Water content of gyttja, (%) | 0 | 150 | 102.6 | 45.8 |

| X7 t | Time, (days) | 0 | 5100 | 732.6 | 1294.4 |

| X8 τp0 | Initial undrained shear strength of peat, (kPa) | 6.0 | 17.0 | 9.1 | 3.2 |

| X9 τg0 | Initial undrained shear strength of gyttja, (kPa) | 0 | 14.0 | 9.2 | 4.5 |

| Y1 sp | Settlement of peat layer, (m) | 0.00 | 1.22 | 0.38 | 0.31 |

| Y2 sg | Settlement of gyttja layer, (m) | 0.00 | 5.20 | 0.74 | 1.17 |

| Y3 τp | Undrained shear strength of peat, (kPa) | 6.0 | 48.0 | 18.6 | 8.5 |

| Y4 τg | Undrained shear strength of gyttja, (kPa) | 0.0 | 33.0 | 14.4 | 8.4 |

| No. | Site/ Variable | X1 σp (kPa) | X2 σg (kPa) | X3 hp (m) | X4 hg (m) | X5 wp (%) | X6 wg (%) | X7 t (days) | X8 τp0 (kPa) | X9 τg0 (kPa) | Y1 sp (m) | Y2 sg (m) | Y3 τp (kPa) | Y4 τg (kPa) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Białośliwie No. 2 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 0 | 7.5 | 10.5 | 0.000 | 0.000 | 7.5 | 10.5 |

| 2 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 7 | 7.5 | 10.5 | 0.070 | 0.030 | 9.5 | 11.6 | |

| 3 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 21 | 7.5 | 10.5 | 0.140 | 0.060 | 12.4 | 13.0 | |

| 4 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 35 | 7.5 | 10.5 | 0.210 | 0.090 | 14.5 | 15.0 | |

| 5 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 84 | 7.5 | 10.5 | 0.270 | 0.120 | 17.2 | 17.5 | |

| 6 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 120 | 7.5 | 10.5 | 0.290 | 0.140 | 18.5 | 18.8 | |

| 7 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 180 | 7.5 | 10.5 | 0.303 | 0.155 | 20.0 | 20.5 | |

| 8 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 210 | 7.5 | 10.5 | 0.310 | 0.168 | 21.0 | 21.2 | |

| 9 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 240 | 7.5 | 10.5 | 0.315 | 0.180 | 21.4 | 22.0 | |

| 10 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 270 | 7.5 | 10.5 | 0.319 | 0.188 | 21.7 | 22.6 | |

| 11 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 300 | 7.5 | 10.5 | 0.323 | 0.195 | 21.8 | 22.8 | |

| 12 | 35 | 32 | 1.50 | 2.00 | 410 | 120 | 350 | 7.5 | 10.5 | 0.326 | 0.200 | 22.0 | 23.0 | |

| 13 | Białośliwie No. 4 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 0 | 7.5 | 0.0 | 0.000 | 0.000 | 7.5 | 0.0 |

| 14 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 7 | 7.5 | 0.0 | 0.280 | 0.000 | 10.0 | 0.0 | |

| 15 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 21 | 7.5 | 0.0 | 0.480 | 0.000 | 14.0 | 0.0 | |

| 16 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 35 | 7.5 | 0.0 | 0.555 | 0.000 | 15.5 | 0.0 | |

| 17 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 84 | 7.5 | 0.0 | 0.610 | 0.000 | 18.4 | 0.0 | |

| 18 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 120 | 7.5 | 0.0 | 0.650 | 0.000 | 19.7 | 0.0 | |

| 19 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 180 | 7.5 | 0.0 | 0.678 | 0.000 | 21.0 | 0.0 | |

| 20 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 210 | 7.5 | 0.0 | 0.700 | 0.000 | 21.4 | 0.0 | |

| 21 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 240 | 7.5 | 0.0 | 0.715 | 0.000 | 21.9 | 0.0 | |

| 22 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 270 | 7.5 | 0.0 | 0.727 | 0.000 | 22.2 | 0.0 | |

| 23 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 300 | 7.5 | 0.0 | 0.736 | 0.000 | 22.4 | 0.0 | |

| 24 | 40 | 0 | 3.50 | 0.00 | 430 | 0 | 350 | 7.5 | 0.0 | 0.743 | 0.000 | 22.5 | 0.0 | |

| 25 | Antoniny No. 1/1 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 0 | 6.0 | 8.0 | 0.000 | 0.000 | 6.0 | 8.0 |

| 26 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 15 | 6.0 | 8.0 | 0.090 | 0.030 | 6.4 | 8.2 | |

| 27 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 30 | 6.0 | 8.0 | 0.127 | 0.050 | 6.6 | 8.4 | |

| 28 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 60 | 6.0 | 8.0 | 0.158 | 0.068 | 7.0 | 8.7 | |

| 29 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 90 | 6.0 | 8.0 | 0.190 | 0.082 | 7.4 | 8.8 | |

| 30 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 120 | 6.0 | 8.0 | 0.220 | 0.092 | 7.8 | 8.9 | |

| 31 | 21 | 20 | 2.60 | 4.70 | 310 | 110 | 155 | 6.0 | 8.0 | 0.240 | 0.100 | 8.0 | 9.0 | |

| 32 | Antoniny No. 1/2 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 0 | 8.0 | 9.0 | 0.000 | 0.000 | 8.0 | 9.0 |

| 33 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 30 | 8.0 | 9.0 | 0.120 | 0.150 | 9.8 | 10.0 | |

| 34 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 50 | 8.0 | 9.0 | 0.170 | 0.200 | 10.8 | 10.5 | |

| 35 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 100 | 8.0 | 9.0 | 0.210 | 0.280 | 12.8 | 11.8 | |

| 36 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 150 | 8.0 | 9.0 | 0.240 | 0.320 | 14.0 | 12.5 | |

| 37 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 200 | 8.0 | 9.0 | 0.255 | 0.355 | 15.0 | 13.0 | |

| 38 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 250 | 8.0 | 9.0 | 0.265 | 0.385 | 15.5 | 13.4 | |

| 39 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 300 | 8.0 | 9.0 | 0.272 | 0.410 | 16.0 | 13.7 | |

| 40 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 350 | 8.0 | 9.0 | 0.277 | 0.428 | 16.5 | 13.8 | |

| 41 | 20 | 19 | 2.36 | 4.60 | 274 | 106 | 410 | 8.0 | 9.0 | 0.280 | 0.440 | 17.0 | 14.0 | |

| 42 | Antoniny No. 1/3 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 0 | 17.0 | 14.0 | 0.000 | 0.000 | 17.0 | 14.0 |

| 43 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 50 | 17.0 | 14.0 | 0.070 | 0.135 | 18.4 | 15.2 | |

| 44 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 100 | 17.0 | 14.0 | 0.110 | 0.200 | 19.5 | 16.0 | |

| 45 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 200 | 17.0 | 14.0 | 0.150 | 0.270 | 20.7 | 17.0 | |

| 46 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 300 | 17.0 | 14.0 | 0.170 | 0.320 | 21.6 | 17.8 | |

| 47 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 400 | 17.0 | 14.0 | 0.184 | 0.355 | 22.5 | 18.2 | |

| 48 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 500 | 17.0 | 14.0 | 0.196 | 0.385 | 23.5 | 18.6 | |

| 49 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 600 | 17.0 | 14.0 | 0.205 | 0.414 | 24.0 | 19.0 | |

| 50 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 700 | 17.0 | 14.0 | 0.213 | 0.441 | 24.6 | 19.3 | |

| 51 | 19 | 18 | 2.08 | 4.16 | 232 | 91 | 760 | 17.0 | 14.0 | 0.220 | 0.455 | 25.0 | 19.5 | |

| 52 | Wonieść | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 0 | 6.5 | 6.6 | 0.000 | 0.000 | 6.5 | 6.6 |

| 53 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 30 | 6.5 | 6.6 | 0.500 | 0.250 | 11.0 | 9.0 | |

| 54 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 60 | 6.5 | 6.6 | 0.660 | 0.450 | 13.5 | 10.8 | |

| 55 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 90 | 6.5 | 6.6 | 0.800 | 0.600 | 15.4 | 12.0 | |

| 56 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 120 | 6.5 | 6.6 | 0.900 | 0.740 | 17.0 | 13.2 | |

| 57 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 180 | 6.5 | 6.6 | 0.990 | 0.860 | 19.0 | 14.8 | |

| 58 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 240 | 6.5 | 6.6 | 1.060 | 0.970 | 21.4 | 16.0 | |

| 59 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 300 | 6.5 | 6.6 | 1.120 | 1.070 | 23.0 | 17.6 | |

| 60 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 360 | 6.5 | 6.6 | 1.175 | 1.160 | 24.0 | 18.5 | |

| 61 | 70 | 60 | 3.70 | 7.10 | 500 | 150 | 450 | 6.5 | 6.6 | 1.220 | 1.240 | 25.0 | 19.2 | |

| 62 | Koszyce VIII A | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 0 | 10.0 | 13.0 | 0.000 | 0.000 | 10.0 | 13.0 |

| 63 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 730 | 10.0 | 13.0 | 0.500 | 2.200 | 26.0 | 20.0 | |

| 64 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 1100 | 10.0 | 13.0 | 0.670 | 3.200 | 31.0 | 23.0 | |

| 65 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 2100 | 10.0 | 13.0 | 0.770 | 3.900 | 37.0 | 26.0 | |

| 66 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 3100 | 10.0 | 13.0 | 0.850 | 4.480 | 42.0 | 28.5 | |

| 67 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 4100 | 10.0 | 13.0 | 0.900 | 4.920 | 45.0 | 30.0 | |

| 68 | 100 | 95 | 2.00 | 14.00 | 650 | 130 | 5100 | 10.0 | 13.0 | 0.940 | 5.200 | 48.0 | 32.0 | |

| 69 | Koszyce X A | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 0 | 10.0 | 13.0 | 0.000 | 0.000 | 10.0 | 13.0 |

| 70 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 730 | 10.0 | 13.0 | 0.150 | 0.750 | 14.0 | 15.4 | |

| 71 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 1100 | 10.0 | 13.0 | 0.200 | 1.020 | 15.8 | 16.3 | |

| 72 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 2100 | 10.0 | 13.0 | 0.240 | 1.260 | 19.0 | 18.2 | |

| 73 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 3100 | 10.0 | 13.0 | 0.270 | 1.450 | 21.0 | 19.0 | |

| 74 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 4100 | 10.0 | 13.0 | 0.297 | 1.590 | 22.0 | 19.5 | |

| 75 | 35 | 32 | 2.00 | 14.00 | 650 | 130 | 5100 | 10.0 | 13.0 | 0.320 | 1.700 | 23.0 | 20.0 | |

| 76 | Koszyce X B | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 0 | 10.0 | 13.0 | 0.000 | 0.000 | 10.0 | 13.0 |

| 77 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 730 | 10.0 | 13.0 | 0.280 | 1.320 | 17.0 | 19.0 | |

| 78 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 1100 | 10.0 | 13.0 | 0.380 | 1.870 | 20.0 | 22.0 | |

| 79 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 2100 | 10.0 | 13.0 | 0.434 | 2.300 | 25.0 | 27.0 | |

| 80 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 3100 | 10.0 | 13.0 | 0.475 | 2.650 | 28.0 | 30.0 | |

| 81 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 4100 | 10.0 | 13.0 | 0.510 | 2.870 | 30.0 | 31.5 | |

| 82 | 65 | 60 | 2.00 | 14.00 | 650 | 130 | 5100 | 10.0 | 13.0 | 0.540 | 3.040 | 32.0 | 33.0 |

| Variable | X1 σp | X3 hp | X5 wp | X7 t | X8 τp0 | Y1 sp | Y3 τp |

|---|---|---|---|---|---|---|---|

| X1 σp | 1.000 | ||||||

| X3 hp | 0.169 | 1.000 | |||||

| X5 wp | 0.779 | −0.026 | 1.000 | ||||

| X7 t | 0.400 | −0.272 | 0.591 | 1.000 | |||

| X8 τp0 | −0.187 | −0.378 | −0.220 | 0.170 | 1.000 | ||

| Y1 sp | 0.617 | 0.542 | 0.382 | 0.252 | −0.288 | 1.000 | |

| Y3 τp | 0.535 | −0.165 | 0.400 | 0.683 | 0.331 | 0.602 | 1.000 |

| Variable | X2 σg | X4 hg | X6 wg | X7 t | X9 τg0 | Y2 sg | Y4 τg |

|---|---|---|---|---|---|---|---|

| X2 σg | 1.000 | ||||||

| X4 hg | 0.757 | 1.000 | |||||

| X6 wg | 0.713 | 0.632 | 1.000 | ||||

| X7 t | 0.450 | 0.666 | 0.257 | 1.000 | |||

| X9 τg0 | 0.481 | 0.619 | 0.714 | 0.391 | 1.000 | ||

| Y2 sg | 0.744 | 0.723 | 0.369 | 0.821 | 0.402 | 1.000 | |

| Y4 τg | 0.678 | 0.647 | 0.709 | 0.639 | 0.815 | 0.713 | 1.000 |

| Formula | R2 | ±SEE | ±REmax (%) | Formula Number |

|---|---|---|---|---|

| 0.632 | 0.193 | 60 | (4) | |

| 0.881 | 0.411 | 60 | (5) | |

| 0.699 | 4.750 | 40 | (6) | |

| 0.888 | 2.895 | 35 | (7) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lechowicz, Z.; Sulewska, M.J. Assessment of the Undrained Shear Strength and Settlement of Organic Soils under Embankment Loading Using Artificial Neural Networks. Materials 2023, 16, 125. https://doi.org/10.3390/ma16010125

Lechowicz Z, Sulewska MJ. Assessment of the Undrained Shear Strength and Settlement of Organic Soils under Embankment Loading Using Artificial Neural Networks. Materials. 2023; 16(1):125. https://doi.org/10.3390/ma16010125

Chicago/Turabian StyleLechowicz, Zbigniew, and Maria Jolanta Sulewska. 2023. "Assessment of the Undrained Shear Strength and Settlement of Organic Soils under Embankment Loading Using Artificial Neural Networks" Materials 16, no. 1: 125. https://doi.org/10.3390/ma16010125

APA StyleLechowicz, Z., & Sulewska, M. J. (2023). Assessment of the Undrained Shear Strength and Settlement of Organic Soils under Embankment Loading Using Artificial Neural Networks. Materials, 16(1), 125. https://doi.org/10.3390/ma16010125