Research of Low-Temperature Performance of Polyphosphoric Acid-Modified Asphalt

Abstract

1. Introduction

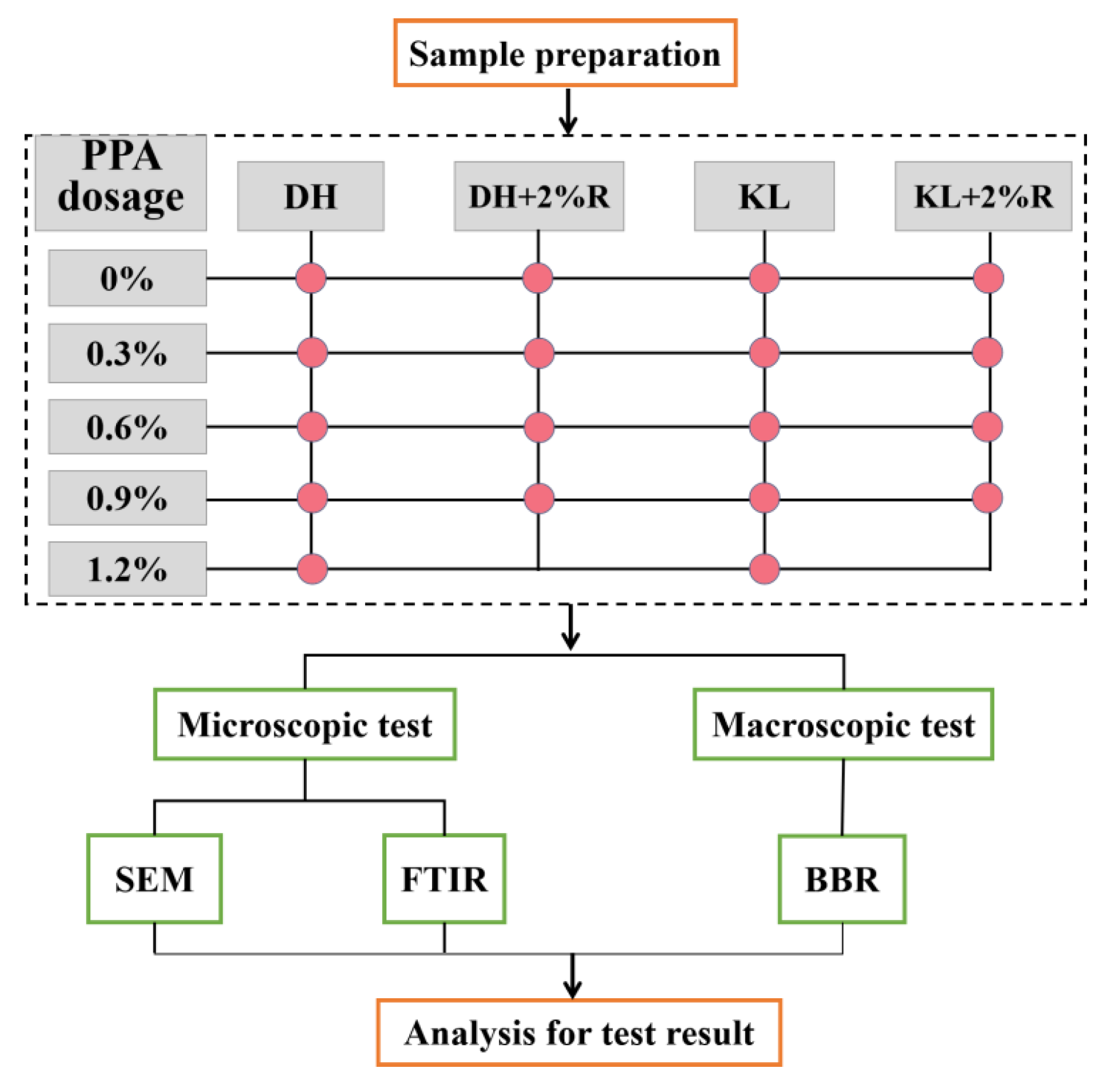

2. Materials and Methods

2.1. Materials

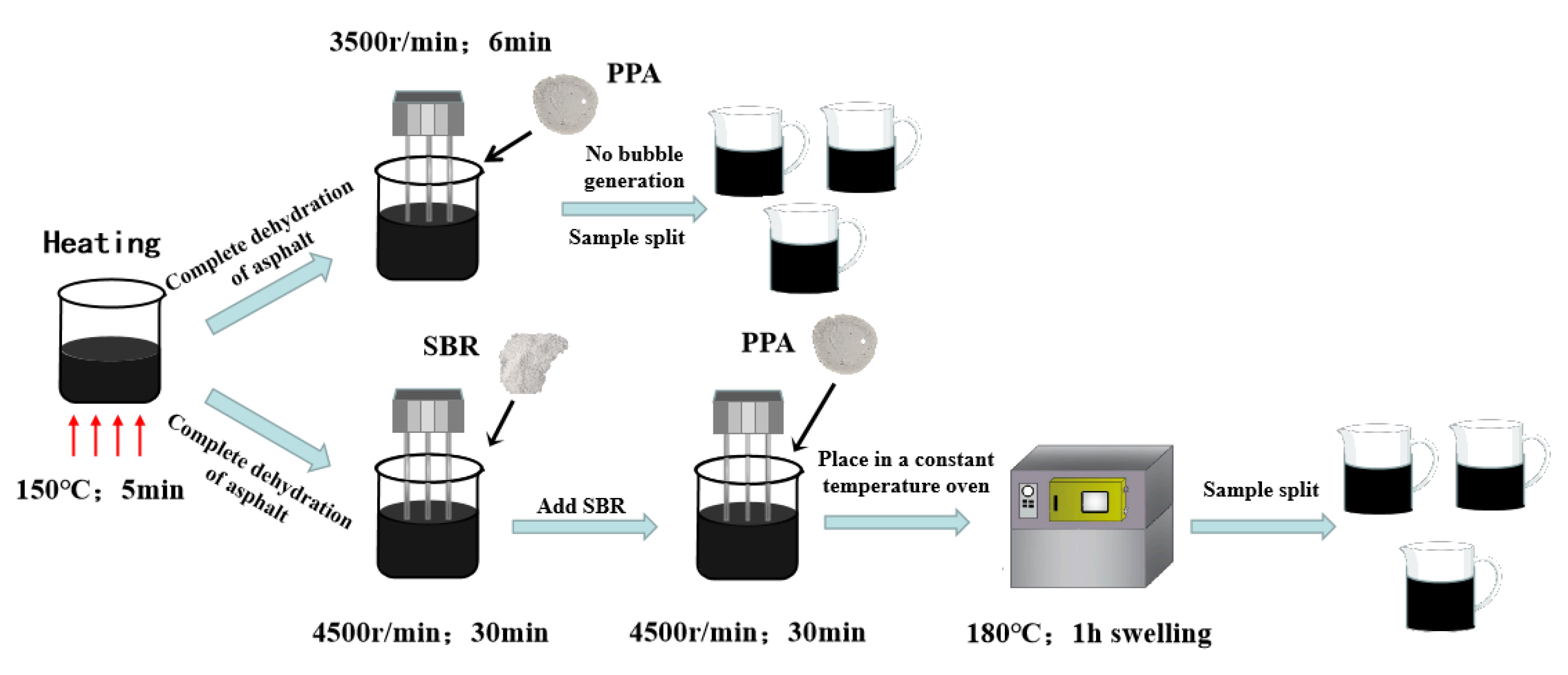

2.2. Sample Preparation

2.3. Asphalt Binder Test Method

3. Results and Analysis

3.1. Compatibility and Micro-Mechanism of the PPA-Modified Asphalt

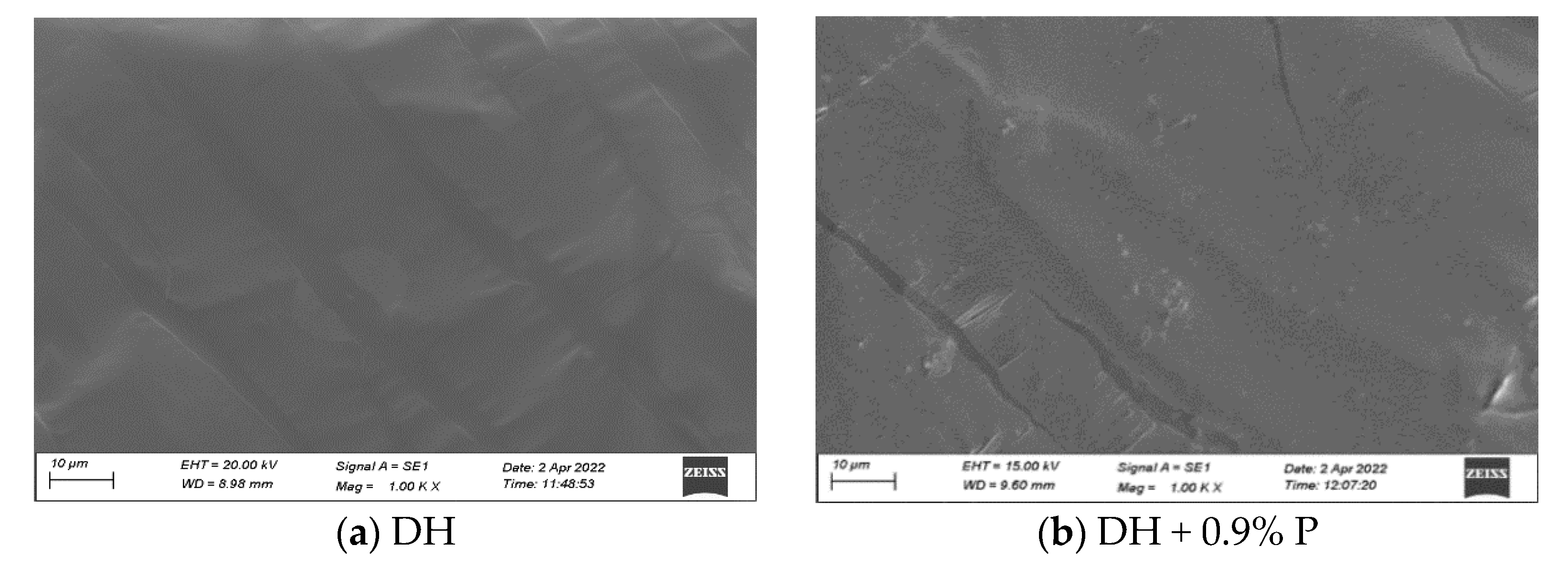

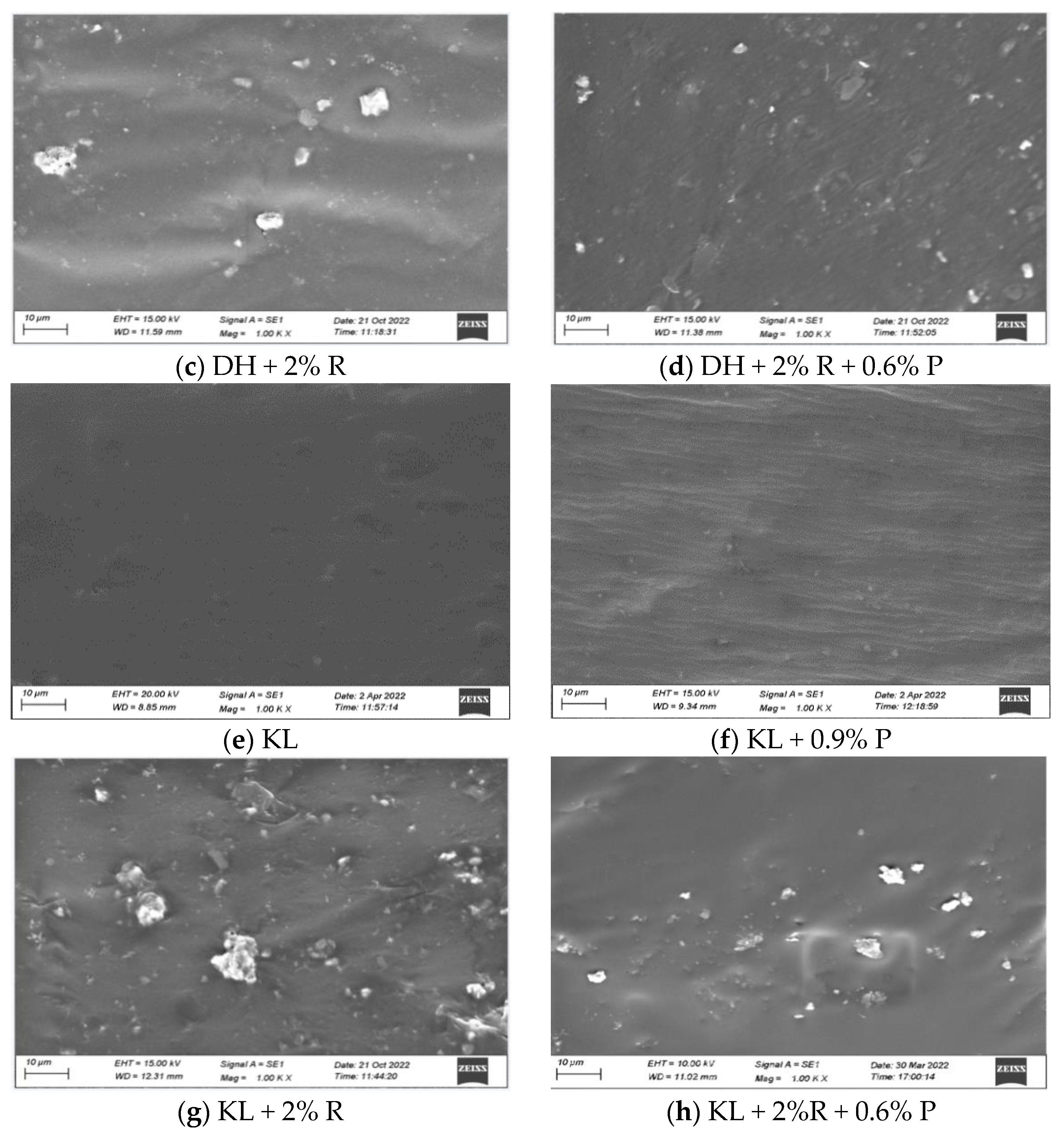

3.1.1. SEM Image Analysis

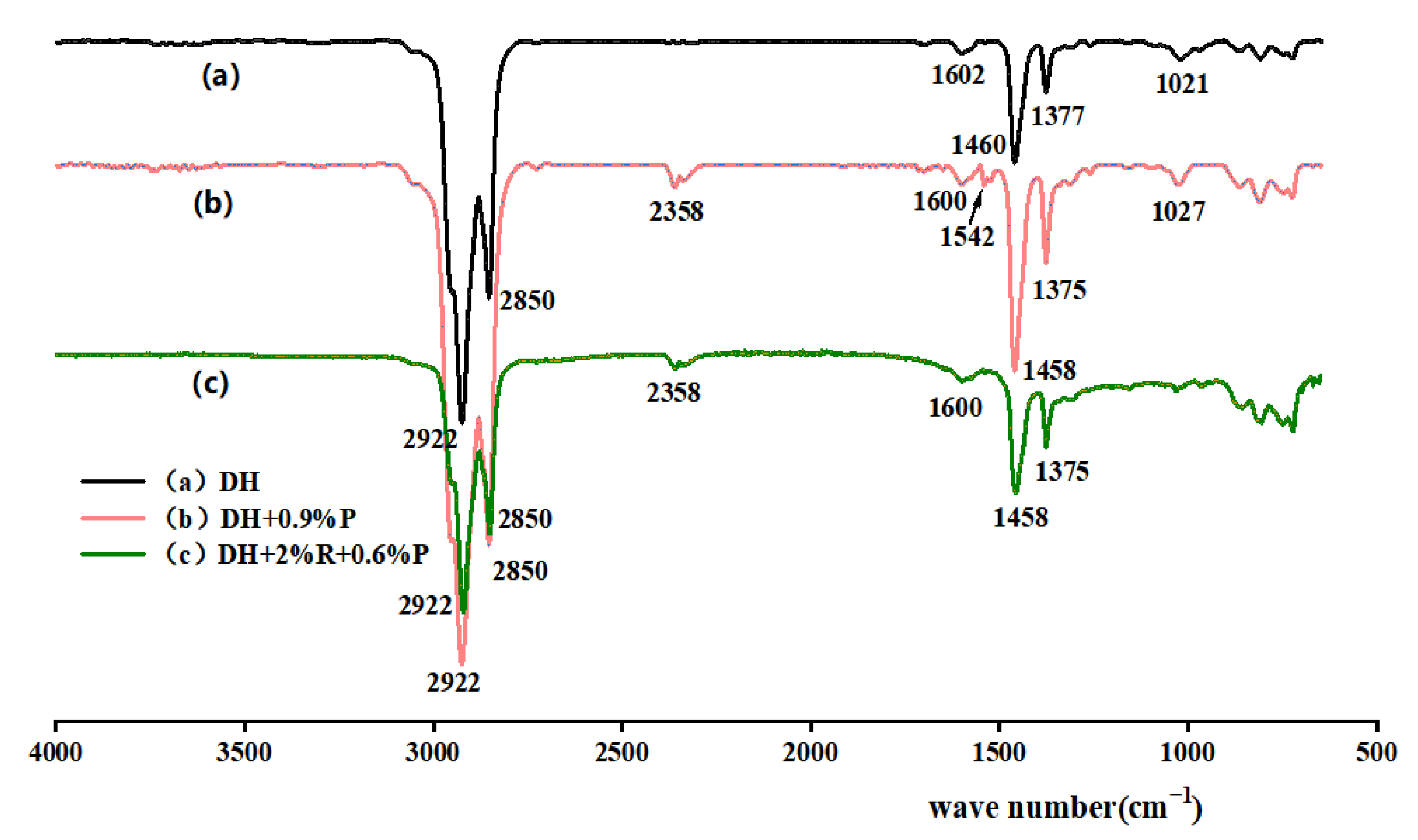

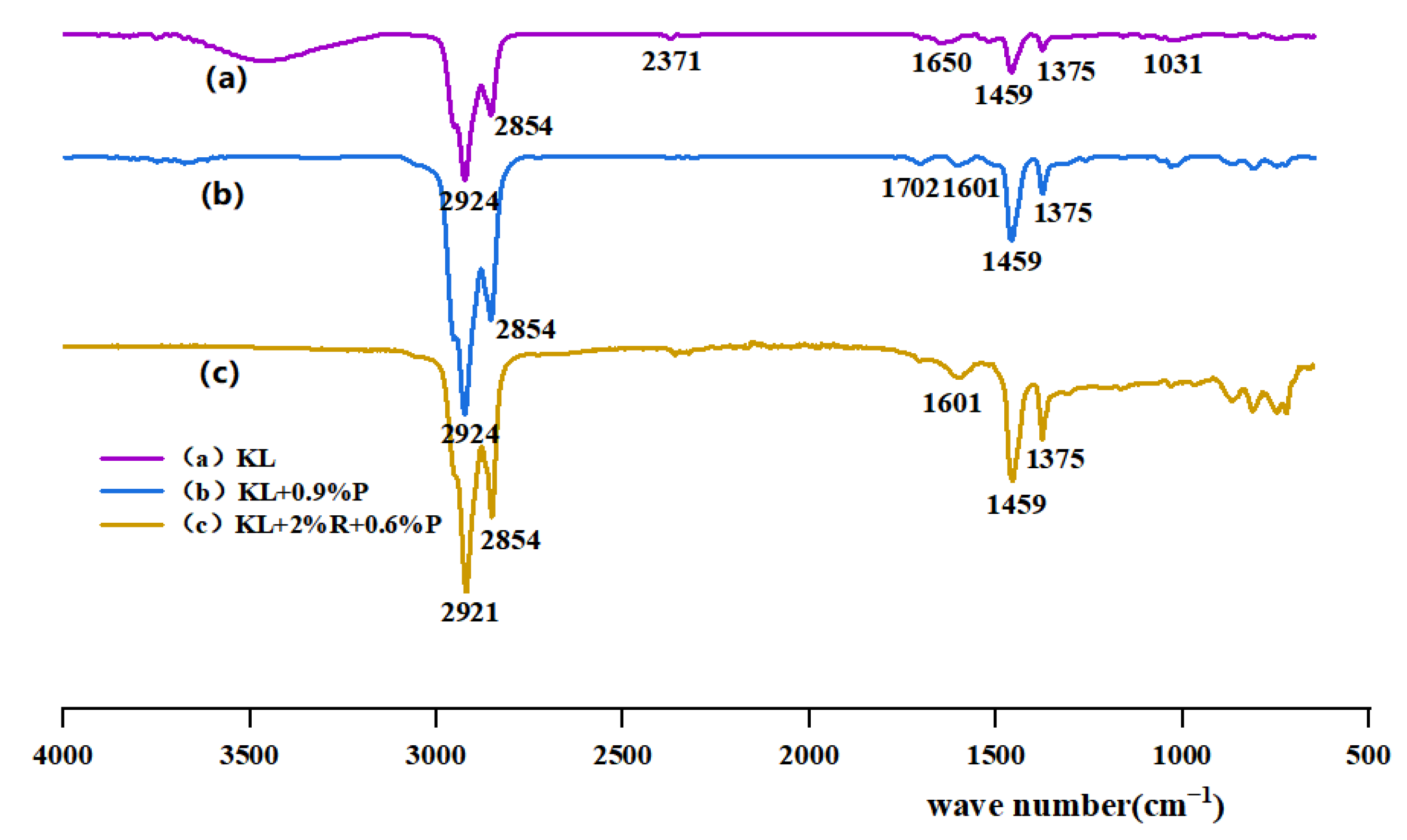

3.1.2. Mechanism Analysis of Asphalt Modification

3.2. Analysis of Indicators in Low-Temperature BBR Test

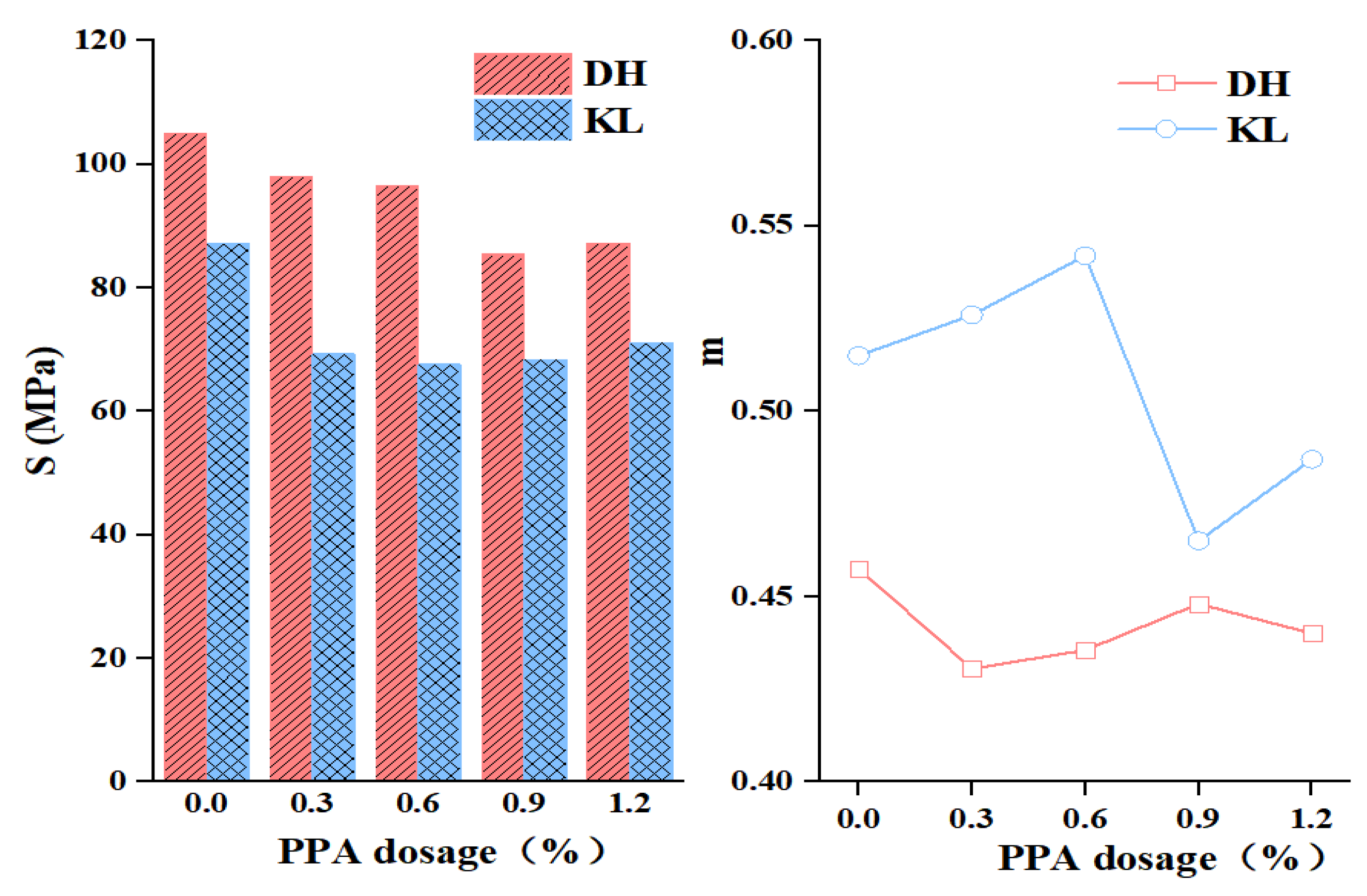

3.2.1. Creep Stiffness Modulus (S) and Creep Rate (m)

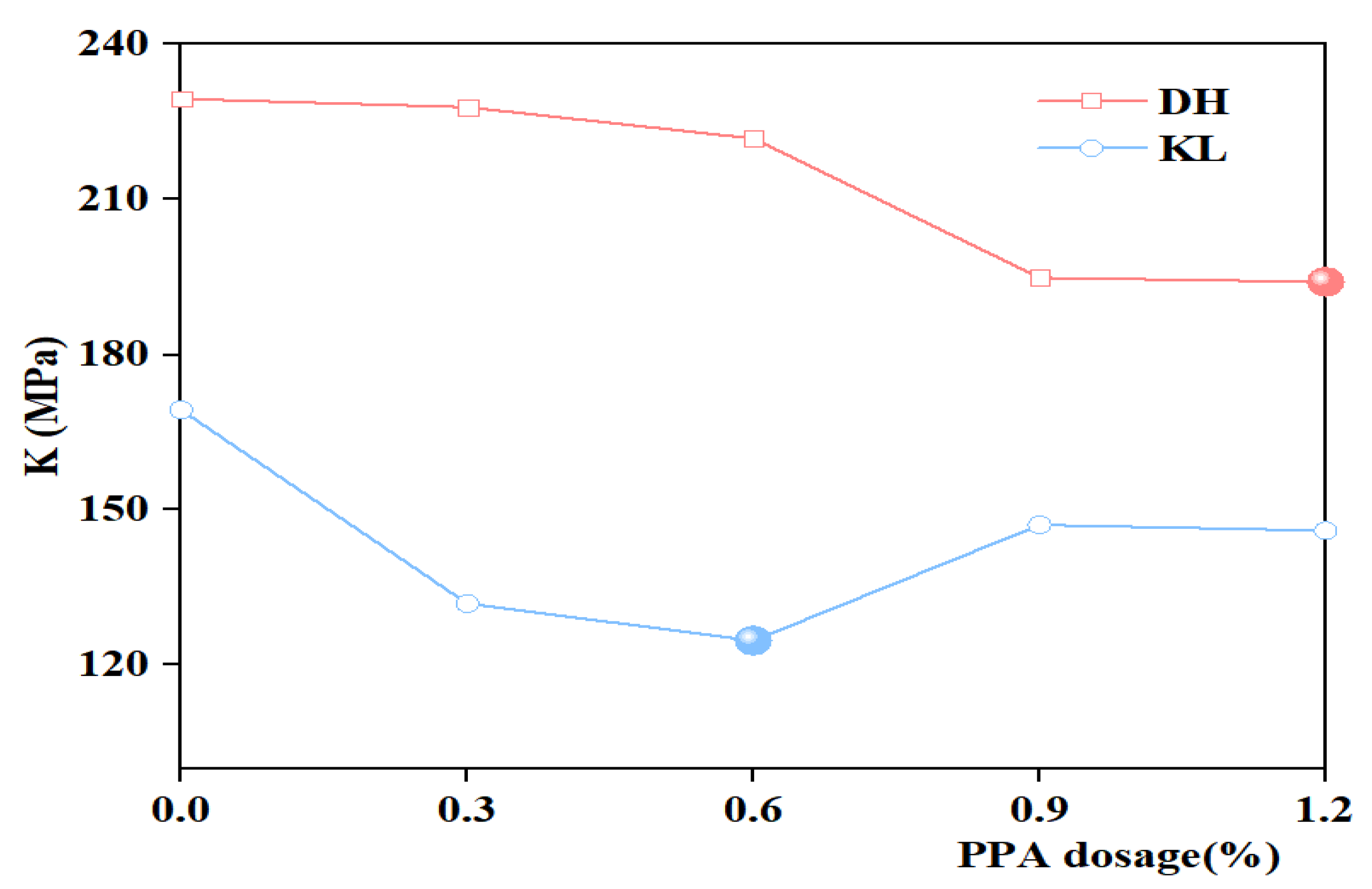

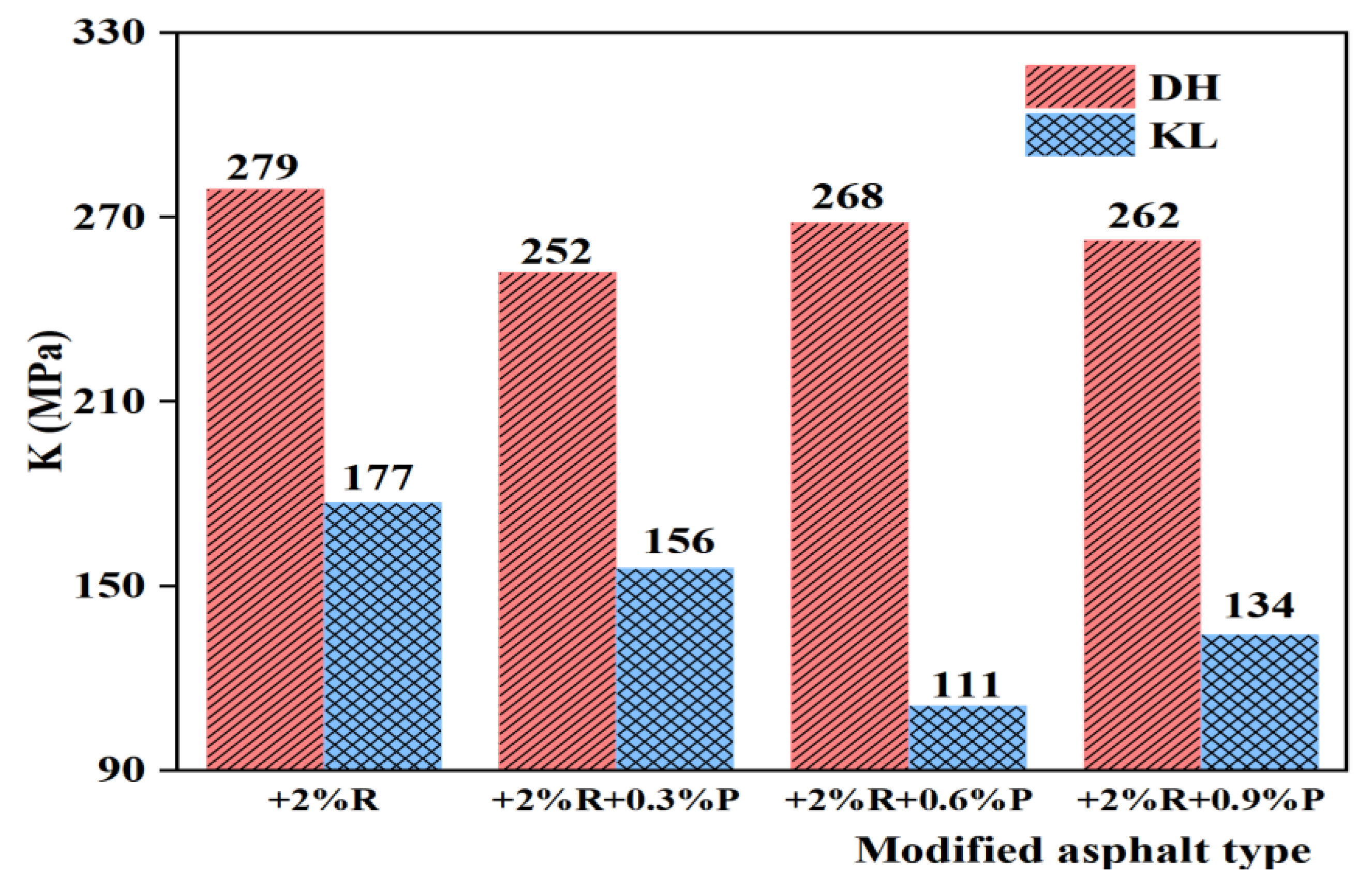

3.2.2. K Index

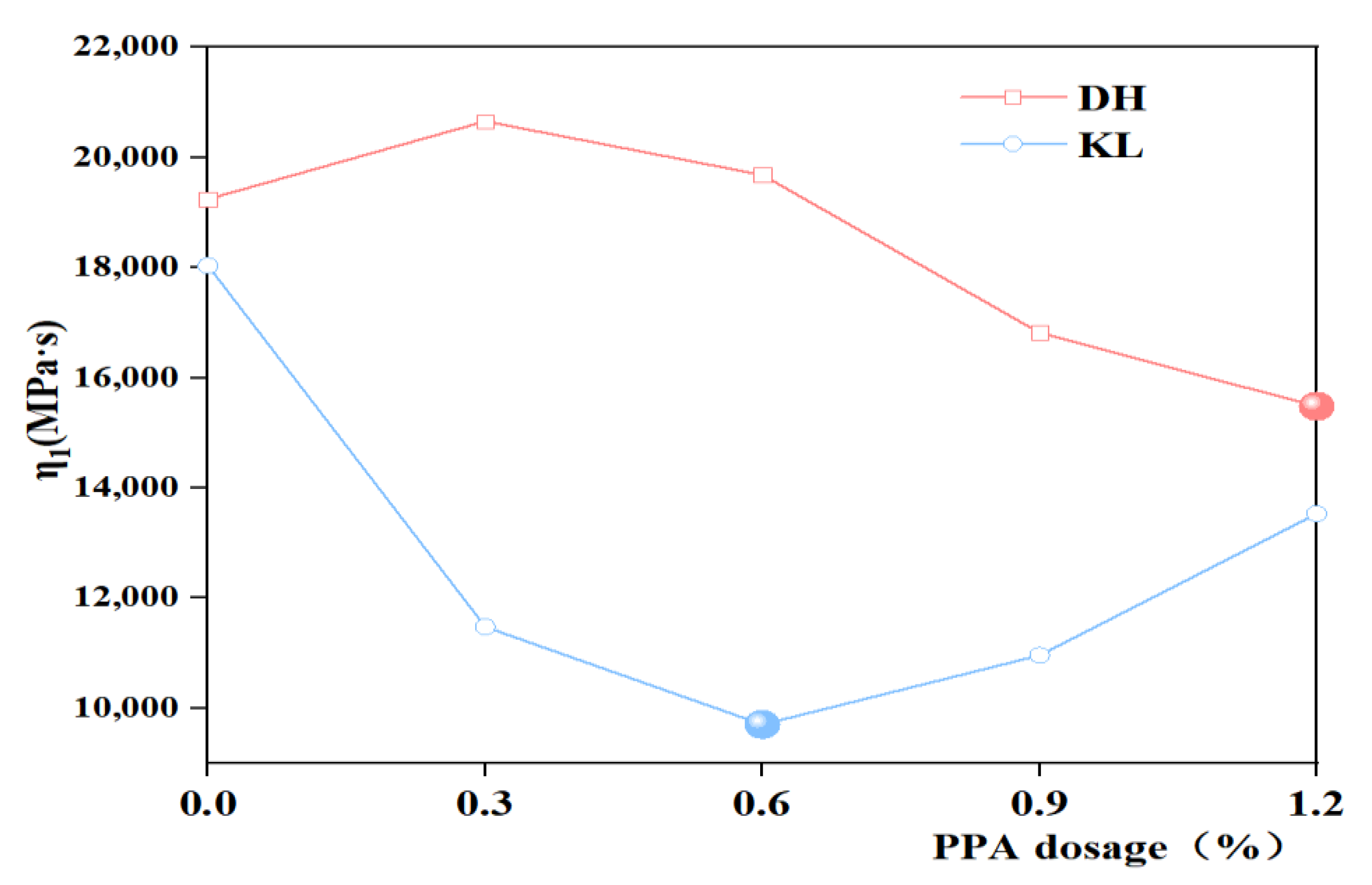

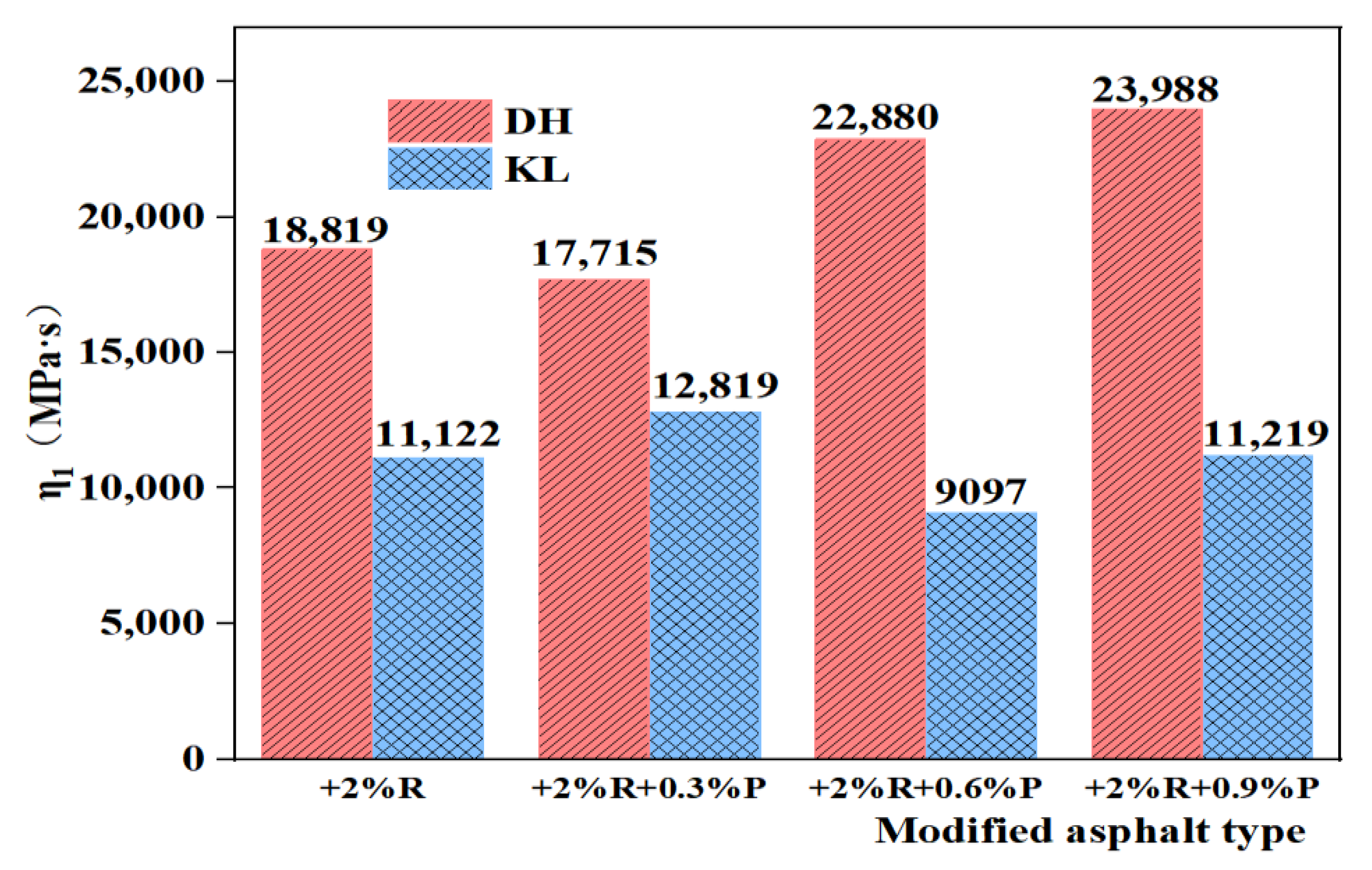

3.2.3. Viscous Flow (η1)

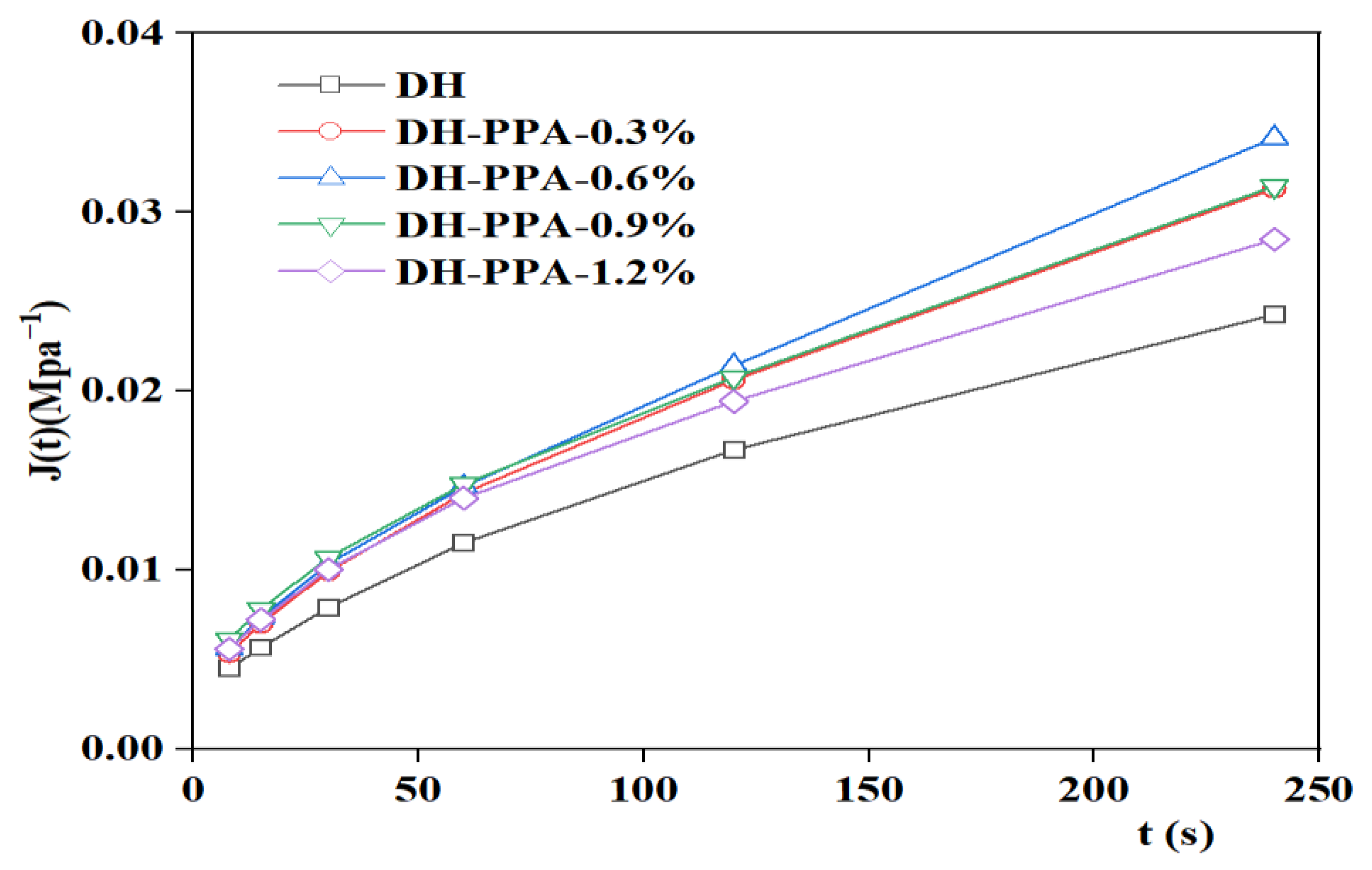

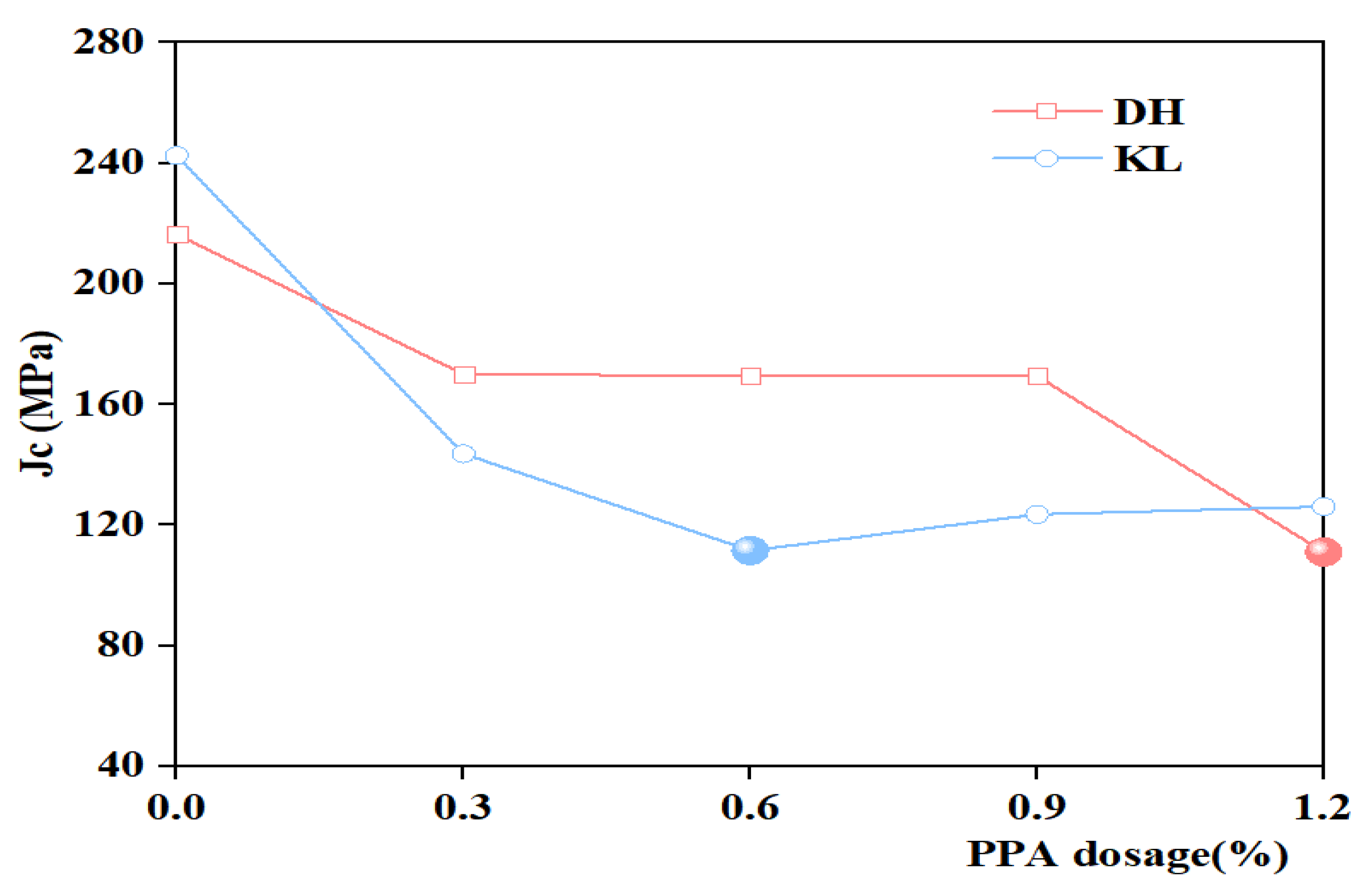

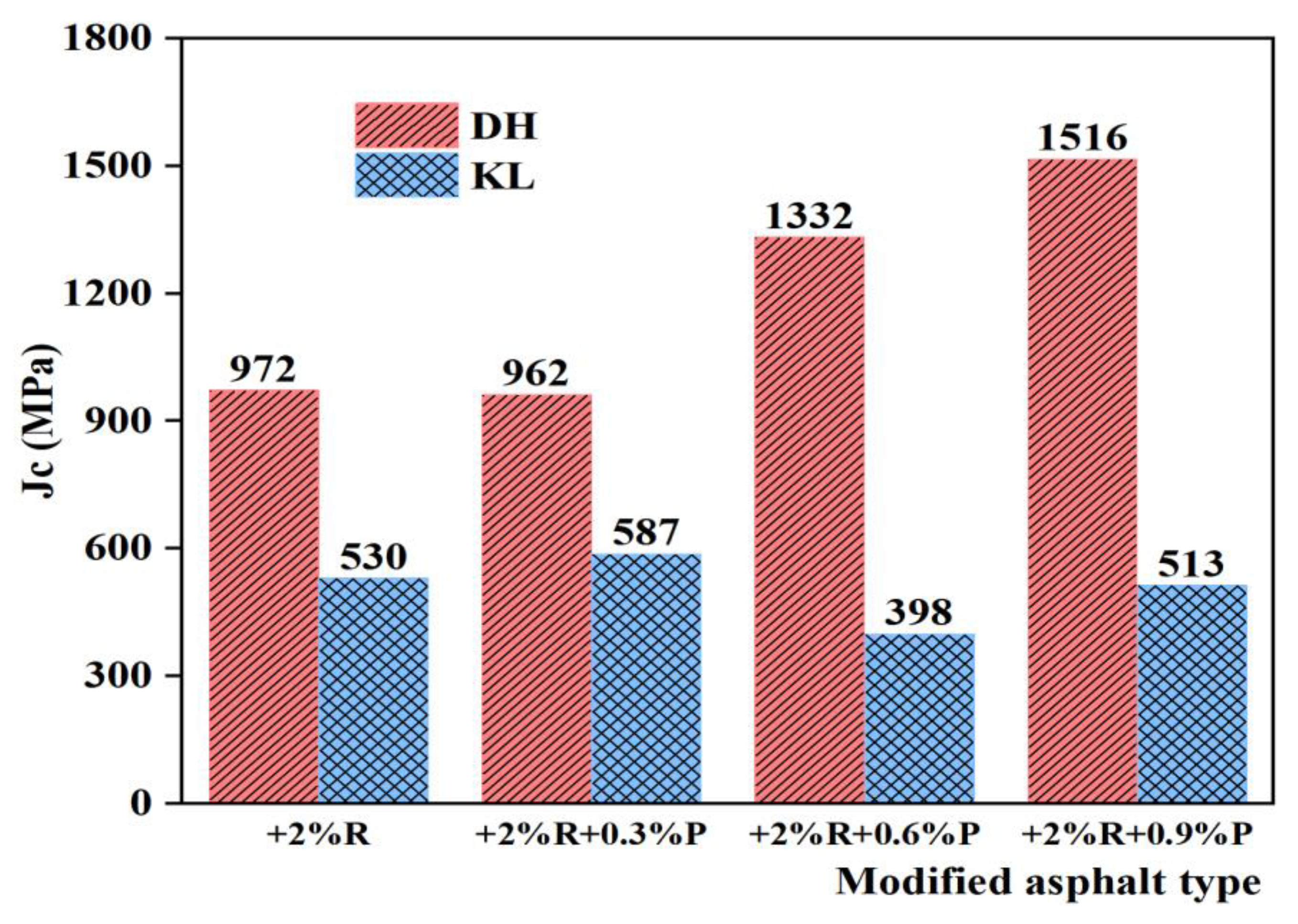

3.2.4. Low Temperature Integrated Flexibility (Jc)

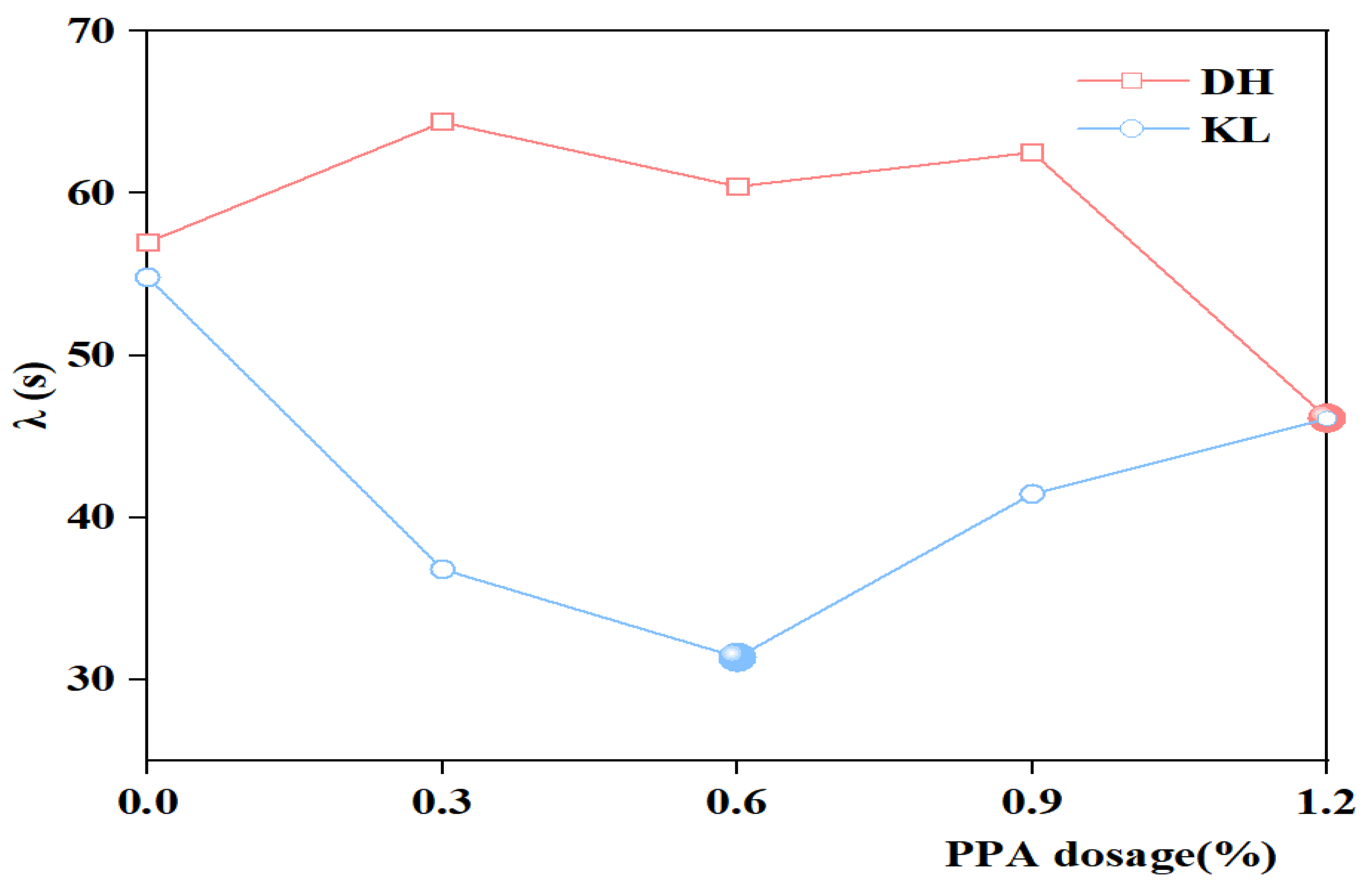

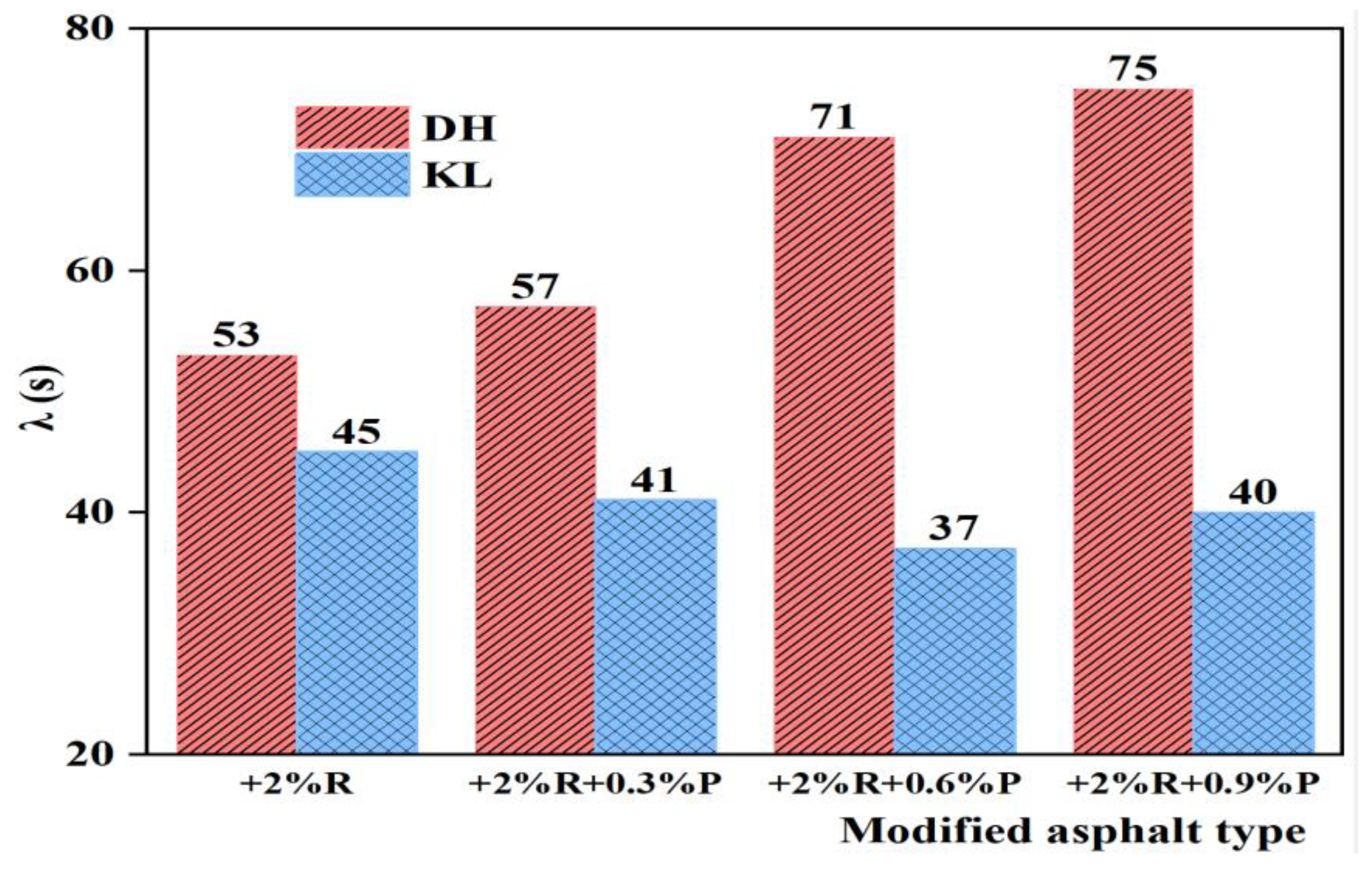

3.2.5. Relaxation Time (λ)

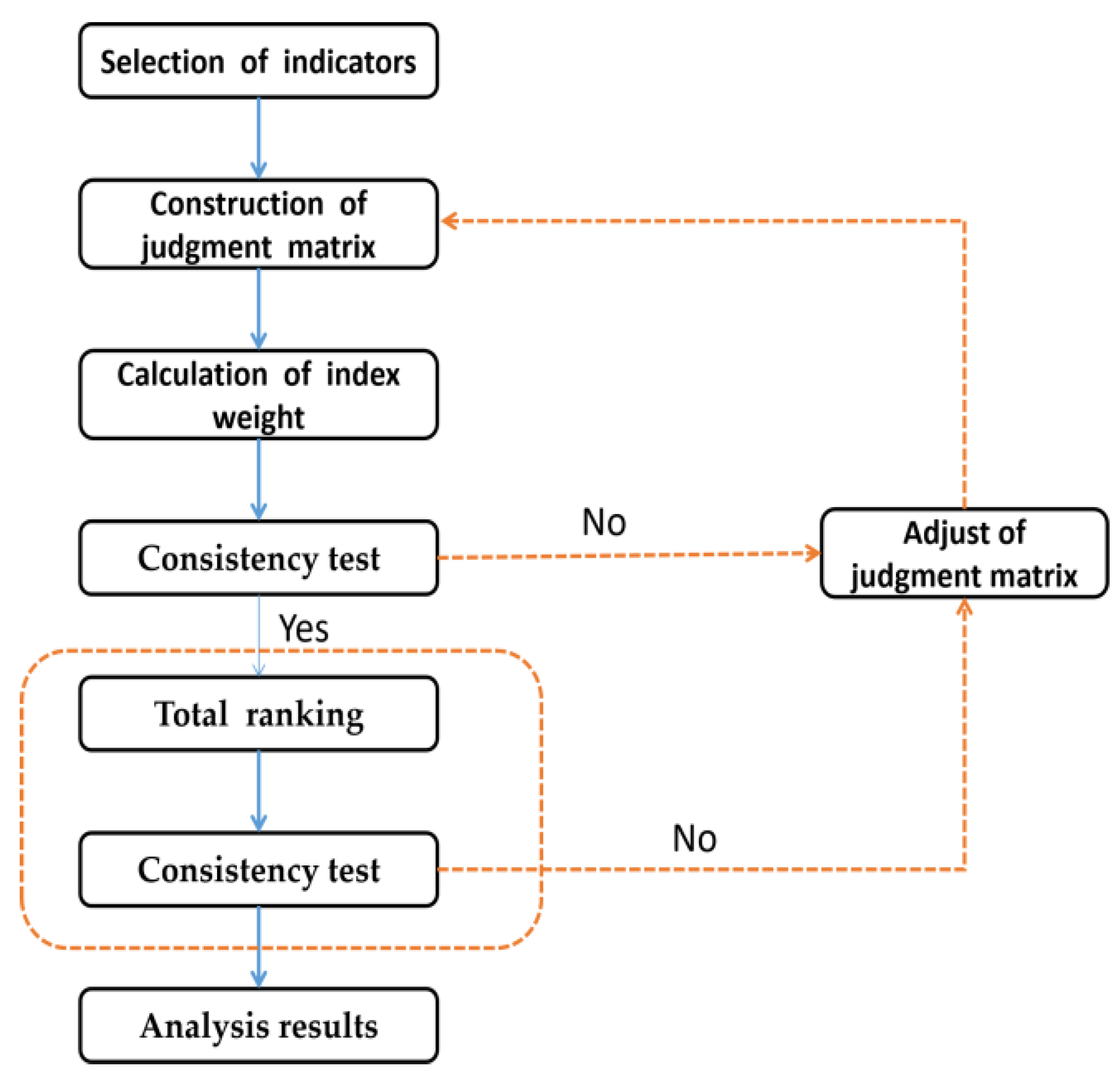

3.3. Selection of Low-Temperature Performance Indicators for Asphalt

3.3.1. Construction of AHP Hierarchy

3.3.2. Construction of the Judgment Matrix A for the Goal and Criterion Layers and Consistency Test

3.3.3. Construction of the Comparison Matrix Pi from the Criterion Layer to the Alternative Layer (Comparison Matrix of the i-th Scheme to the Criterion Layer)

3.3.4. Total AHP Ranking and the Consistency Test

4. Conclusions

- (1)

- Based on SEM images: After the addition of PPA, the particle size of the asphalt surface and agglomeration degree of SBR-modified asphalt were reduced, indicating that PPA can effectively improve the compatibility of SBR and neat asphalt.

- (2)

- Based on the FTIR test: The infrared spectrum of PPA-modified asphalt showed the disappearance and generation of absorption peaks at 1725 cm−1–1480 cm−1, 2358 cm−1, and 2387 cm−1, which indicated that the chemical reaction occurred when PPA was added into the neat asphalt, and phosphate ester was formed. In the infrared spectra of PPA/SBR modified asphalt, the characteristic peaks disappear and produce at 1000 cm−1–1600 cm−1 and 1600 cm−1, indicating that the composite modification was mainly chemical.

- (3)

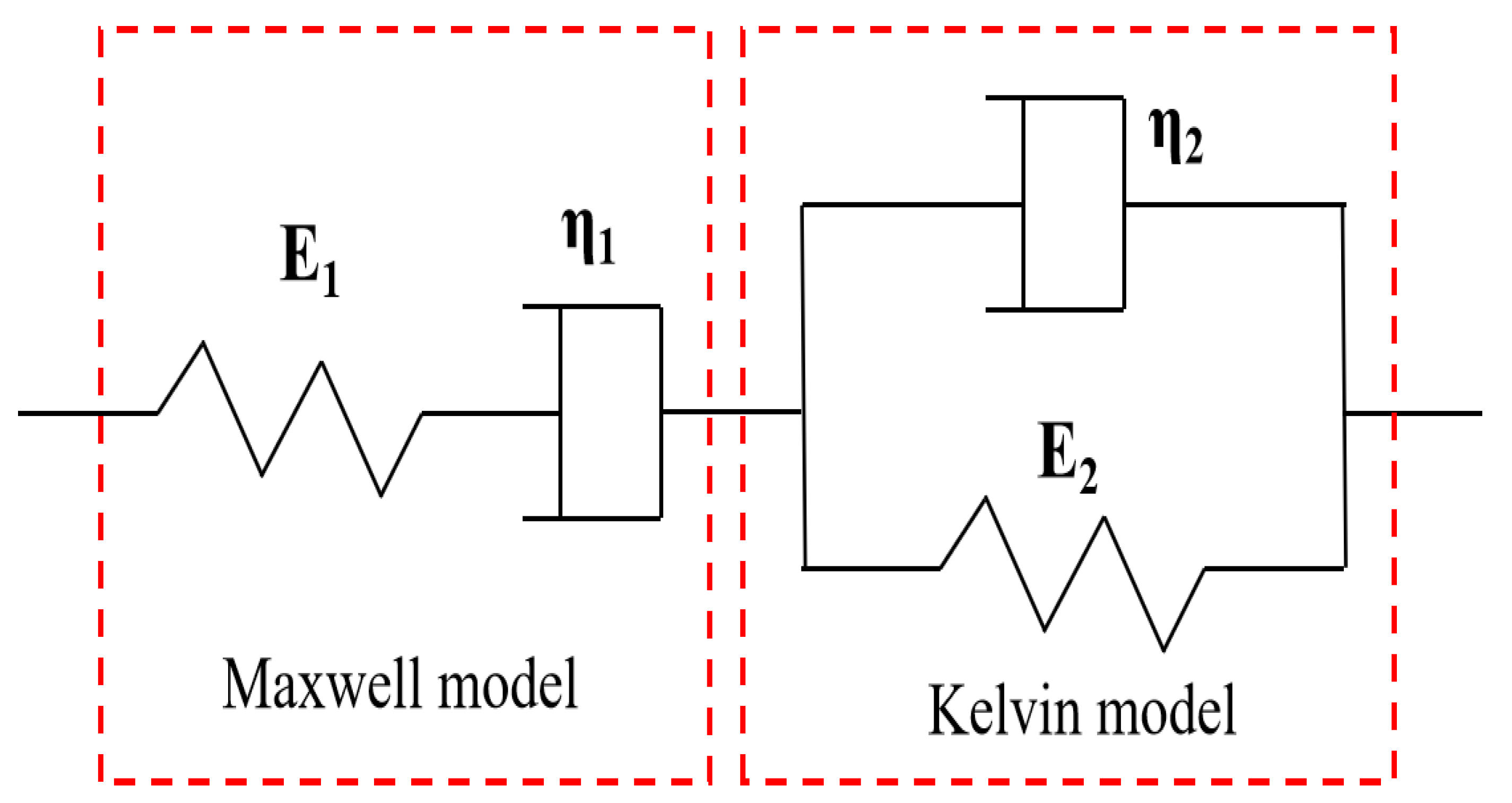

- Based on the BBR test: The low-temperature performance of PPA-modified asphalt was evaluated comprehensively by the Burgers model. The low-temperature performance of asphalt with different PPA dosages evaluated only by creep stiffness modulus (S) or creep rate (m) leads to different trends, which cannot accurately evaluate the low-temperature performance of modified asphalt. Additionally, a good correlation can be obtained by fitting the Burgers model with the low-temperature creep flexibility. Considering the deformation and stress relaxation of asphalt, the K index and the Burgers model-based η1, Jc, and λ were selected to evaluate the low-temperature performance of asphalt. The multi-indicator analysis shows that the recommended PPA dosage is 1.2% for DH asphalt, 0.6% for KL asphalt, 0.3% for DH-PPA/SBR-modified asphalt, and 0.6% for KL-PPA/SBR-modified asphalt.

- (4)

- The indicators η1, Jc, λ, and K were analyzed by AHP. The results showed that Jc has the highest weight value of 0.3501, with a heavy calculation burden. It is recommended to use this indicator in the research work for evaluating the low-temperature performance of PPA-modified asphalt. The weight value of λ (0.2745) is also large but simple to calculate and can be used in practical engineering.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Porto, M.; Caputo, P.; Loise, V.; Eskandarsefat, S.; Teltayev, B.; Oliviero Rossi, C. Bitumen and Bitumen Modification: A Review on Latest Advances. Appl. Sci. 2019, 9, 742. [Google Scholar] [CrossRef]

- Han, Y.; Cui, B.; Tian, J.; Ding, J.; Ni, F.; Lu, D. Evaluating the effects of styrene-butadiene rubber (SBR) and polyphosphoric acid (PPA) on asphalt adhesion performance. Constr. Build. Mater. 2022, 321, 126028. [Google Scholar] [CrossRef]

- Han, Y.; Ding, J.; Han, D.; Zhao, Z.; Ma, X.; Ni, F. Evaluating the thermal aging-induced raveling potential of thin friction course (TFC). Constr. Build. Mater. 2022, 321, 126160. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J. The research for high-performance SBR compound modified asphalt. Constr. Build. Mater. 2010, 24, 410–418. [Google Scholar] [CrossRef]

- Li, X.; Pei, J.; Shen, J.; Li, R. Experimental Study on the High-Temperature and Low-Temperature Performance of Polyphosphoric Acid/Styrene-Butadiene-Styrene Composite-Modified Asphalt. Adv. Mater. Sci. Eng. 2019, 2019, 6384360. [Google Scholar] [CrossRef]

- Fu, G. Research on Modification Mechanisms of Polyphosphoric Acid on Asphalt and the Performance of Polyphosphoric Acid Modified Asphalt Mixture. Master’s Thesis, Dalian University of Technology, Dalian, China, 2017. [Google Scholar]

- Wang, L.; Wang, Z.; Li, C. High temperature rheological properties of polyphosphoric acid modifier asphalt. Acta Mater. Compos. Sin. 2017, 34, 1610–1616. [Google Scholar]

- Sarnowski, M. Rheological properties of road bitumen binders modified with SBS polymer and polyphosphoric acid. Roads Bridg.-Drog. I Mosty 2015, 14, 47–65. [Google Scholar]

- Liu, Z.; Li, S.; Wang, Y. Waste engine oil and polyphosphoric acid enhanced the sustainable self-healing of asphalt binder and its fatigue behavior. J. Clean. Prod. 2022, 339, 130767. [Google Scholar] [CrossRef]

- Wei, J.; Shi, S.; Zhou, Y.; Li, P.; Chen, Z.; Guan, Y. Rheological property of polyphosphoric acid modified asphalt. J. Tranffic Transp. Eng. 2019, 19, 14–26. [Google Scholar]

- Fu, G.; Zhao, Y.; Sun, Q. Modification mechanisms of polyphosphoric acid and SBS on asphalt. Acta Mater. Compos. Sinaca 2017, 34, 7. [Google Scholar]

- Song, R.; Sha, A.; Shi, K.; Li, J.; Li, X.; Zhang, F. Polyphosphoric acid and plasticizer modified asphalt: Rheological properties and modification mechanism. Constr. Build. Mater. 2021, 309, 125158. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Rossi, C.O.; Oliviero, C.; Seta, L.; Lupi, F.R.; Caputo, P. Low temperature rheology of polyphosphoric acid (PPA) added bitumen. Constr. Build. Mater. 2012, 36, 592–596. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, D.; Fu, X. Low-Temperature performance of polyphosphoric acid composite modified asphalt. J. Build. Mater. 2017, 20, 996–1000. [Google Scholar]

- Aflaki, S.; Hajikarimi, P.; Fini, E.H.; Zada, B. Comparing Effects of Biobinder with Other Asphalt Modifiers on Low-Temperature Characteristics of Asphalt. J. Mater. Civ. Eng. 2014, 26, 429–439. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, W.; Wei, M.; Ouyang, X.; Wang, Y. Analysis of rheological properties of polyphosphoric acid modified asphalt. J. Mater. Sci. Eng. 2020, 38, 5. [Google Scholar]

- Liu, H.; Zhang, M.; Huang, L.; Chang, R.; Hao, P. Rheological and anti-aging propertied of polyphosphoric acid composite styrene butadiene styrene modified asphalt. J. Southeast Univ. 2016, 46, 1290–1295. [Google Scholar]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Rossi, C.O.; Caputo, P.; Falvo, T. Rheological effects on bitumen of polyphosphoric acid (PPA) addition. Constr. Build. Mater. 2013, 40, 397–404. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Z.; Li, C. Low temperature performance of polyphosphoric acid asphalt and polyphosphoric acid-SBS modifier asphalt. Acta Mater. Compos. Sin. 2017, 34, 329–335. [Google Scholar]

- Thomas, K.P.; Turner, T.F. Polyphosphoric-acid modification of asphalt binders: Impact on rheological and thermal properties. Road Mater. Pavement Des. 2008, 9, 181–205. [Google Scholar] [CrossRef]

- Edwards, Y.; Tasdemir, Y.; Isacsson, U. Rheological effects of commercial waxes and polyphosphoric acid in bitumen 160/220—High and medium temperature performance. Constr. Build. Mater. 2007, 21, 1899–1908. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, X.; Zou, G. Investigation into Low-temperature performance of asphalt mixtures based on glass transition temperature. J. South China Univ. Technol. 2010, 38, 89–93. [Google Scholar]

- Huang, W.; Fu, X.; Li, Y.; Liu, S. Evaluation of low temperature performance and correlation analysis on low temperature indexes of SBS modified asphalts. J. Build. Mater. 2017, 20, 456–463. [Google Scholar]

- Huang, Q.; Liu, A.; Yan, E. Multi-index evaluation and study of low temperature performance of high modified asphalt. Highway 2022, 67, 42–48. [Google Scholar]

- Zhou, Y.; Wei, J.; Shi, S.; Gao, J.; Duan, X.; Chen, Y. Properties of composite-modified asphalt with polyphosphoric acid and rubber powder. J. Chang. Univ. 2018, 38, 9–17. [Google Scholar]

- Zhang, M. Research on the Microstructure and Technical Performance of Polyphosphoric Acid Modified Asphalt. Ph.D. Thesis, Chang’an University, Xi’an, China, 2012. [Google Scholar]

- AASHTO T 313-2012; Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR). American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Tan, Y.; Fu, Y.; Ji, L.; Meng, D. Low-temperature evaluation index of rubber asphalt. J. Harbin Inst. Technol. 2016, 48, 66–70. [Google Scholar]

- Wang, W.; Luo, R.; Feng, G.; Wang, L.G. Impact factors in rotational viscosity tests. J. Wuhan Univ. Technol. 2016, 40, 514–518. [Google Scholar]

- Wang, K.; Hao, P. Analysis of asphalt low temperature performance and viscoelasticity based on BBR test. J. Liaoning Tech. Univ. 2016, 35, 1138–1143. [Google Scholar]

- Dong, Y.; Tan, Y.; Liu, H.; Li, Z. Development and application of fibre grating inclinometer for monitoring the rock and soil slope deformation. Highway 2015, 60, 176–182. [Google Scholar]

- Saaty, T.L. How to make a decision: The analytic hierarchy process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

| Test Items | Unit | Test Results | Test Methods (JTG E20-2011) | ||

|---|---|---|---|---|---|

| DH | KL | ||||

| Softening point (R&B) | °C | 53.1 | 49.5 | T 0606 | |

| Ductility (50 mm/min, 10 °C) | cm | 39.7 | >100 | T 0605 | |

| Needle penetration (25 °C, 5 s, 100 g) | 0.1 mm | 64.2 | 93.5 | T 0604 | |

| Solubility | % | 99.9 | 99.9 | T 0607 | |

| Density (15 °C) | g/cm3 | 1.033 | 1.031 | T 0603 | |

| Flash point | °C | 279 | 283 | T 0611 | |

| RTFOT * Residues | Mass change | % | 0.47 | 0.58 | T 0610 |

| Residual needle penetration rate (25 °C) | % | 70.2 | 64.3 | T 0604 | |

| Residual ductility (10 °C) | cm | 14.1 | 9.5 | T 0605 | |

| Technical Specifications | Unit | Measured Value |

|---|---|---|

| Granularity | Mesh | 10~80 |

| Combined styrene content | % | 10~50 |

| Mooney viscosity | ML | 45~65 |

| tensile stress at 300% elongation | MPa | 15 |

| Tensile strength | MPa | 25 |

| PPA Types | Test Indicators | |||

|---|---|---|---|---|

| P2O5 (Mass Fraction) (%) | Chloride (Cl, %) | Heavy Metals (Pb, %) | Iron (Fe, %) | |

| PPA-110 | 82.0 | ≤0.001 | ≤0.003 | ≤0.002 |

| PPA Dosage (%) | BBR Indicators | Test Data Corresponding to Different Neat Asphalts | |

|---|---|---|---|

| DH | KL | ||

| 0 | S (MPa) | 105 | 87.2 |

| m | 0.458 | 0.515 | |

| 0.3 | S (MPa) | 98.1 | 69.3 |

| m | 0.431 | 0.526 | |

| 0.6 | S (MPa) | 96.6 | 67.6 |

| m | 0.436 | 0.542 | |

| 0.9 | S (MPa) | 85.4 | 68.4 |

| m | 0.440 | 0.465 | |

| 1.2 | S (MPa) | 87.3 | 71.1 |

| m | 0.448 | 0.487 | |

| Asphalt Specimens | BBR Indicators | Test Data Corresponding to Different Neat Asphalts | |

|---|---|---|---|

| DH | KL | ||

| +2% R | S (MPa) | 118 | 88.9 |

| m | 0.423 | 0.417 | |

| +2% R + 0.3% P | S (MPa) | 91 | 77.9 |

| m | 0.417 | 0.501 | |

| +2% R + 0.6% P | S (MPa) | 109 | 57.9 |

| m | 0.407 | 0.522 | |

| +2% R + 0.9% P | S (MPa) | 106 | 68.3 |

| m | 0.404 | 0.510 | |

| Consistency Test Indicators | P1 | P2 | P3 |

|---|---|---|---|

| Wpi | 0.2688 | 0.2741 | 0.0742 |

| 0.1464 | 0.1095 | 0.2869 | |

| 0.4491 | 0.4960 | 0.2609 | |

| 0.1358 | 0.1204 | 0.3780 | |

| CI | 0.0666 | 0.0414 | 0.0638 |

| RI | 0.89 | 0.89 | 0.89 |

| CR | 0.0749 | 0.0465 | 0.0659 |

| Indicators | P1 | P2 | P3 | Total Weight |

|---|---|---|---|---|

| K | 0.2688 | 0.2741 | 0.0742 | 0.1555 |

| η1 | 0.1464 | 0.1095 | 0.2869 | 0.2198 |

| Jc | 0.4491 | 0.4960 | 0.2609 | 0.3501 |

| λ | 0.1358 | 0.1204 | 0.3780 | 0.2745 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, J.; Huang, M.; Zhou, Y.; Li, P.; Yu, F.; Ju, H.; Shi, S. Research of Low-Temperature Performance of Polyphosphoric Acid-Modified Asphalt. Materials 2023, 16, 111. https://doi.org/10.3390/ma16010111

Wei J, Huang M, Zhou Y, Li P, Yu F, Ju H, Shi S. Research of Low-Temperature Performance of Polyphosphoric Acid-Modified Asphalt. Materials. 2023; 16(1):111. https://doi.org/10.3390/ma16010111

Chicago/Turabian StyleWei, Jianguo, Meiyan Huang, Yuming Zhou, Ping Li, Fan Yu, Haolong Ju, and Song Shi. 2023. "Research of Low-Temperature Performance of Polyphosphoric Acid-Modified Asphalt" Materials 16, no. 1: 111. https://doi.org/10.3390/ma16010111

APA StyleWei, J., Huang, M., Zhou, Y., Li, P., Yu, F., Ju, H., & Shi, S. (2023). Research of Low-Temperature Performance of Polyphosphoric Acid-Modified Asphalt. Materials, 16(1), 111. https://doi.org/10.3390/ma16010111