On the Fabrication and Characterization of Polymer-Based Waveguide Probes for Use in Future Optical Cochlear Implants

Abstract

1. Introduction

2. Waveguide Design and Fabrication Process

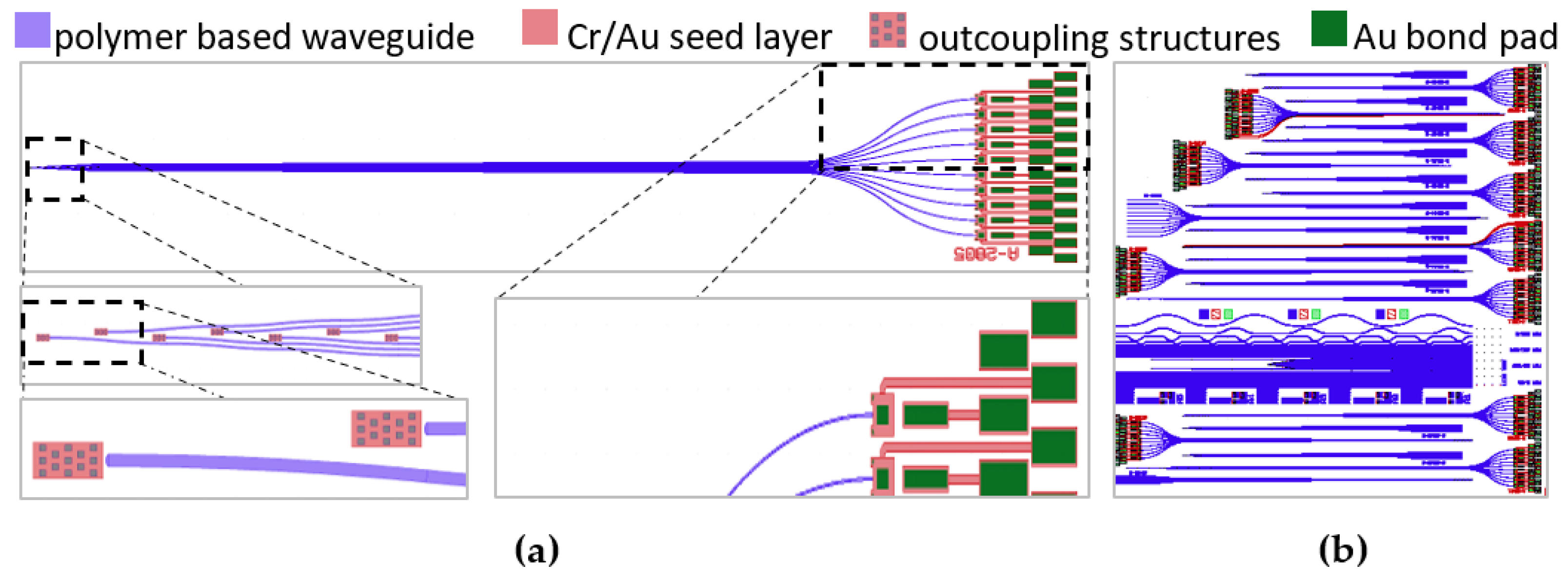

2.1. Design of the Flexible Polymer-Based Waveguides

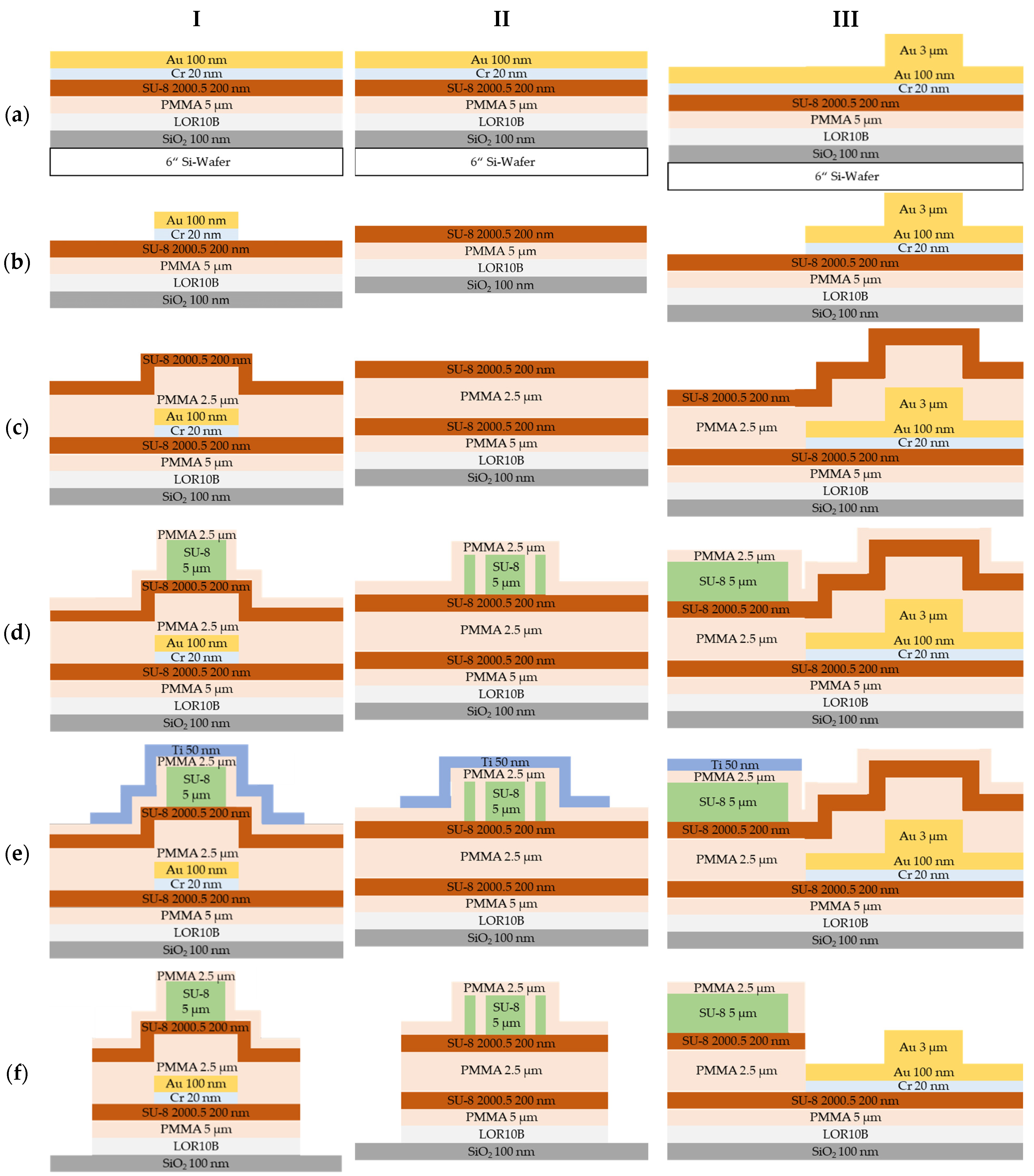

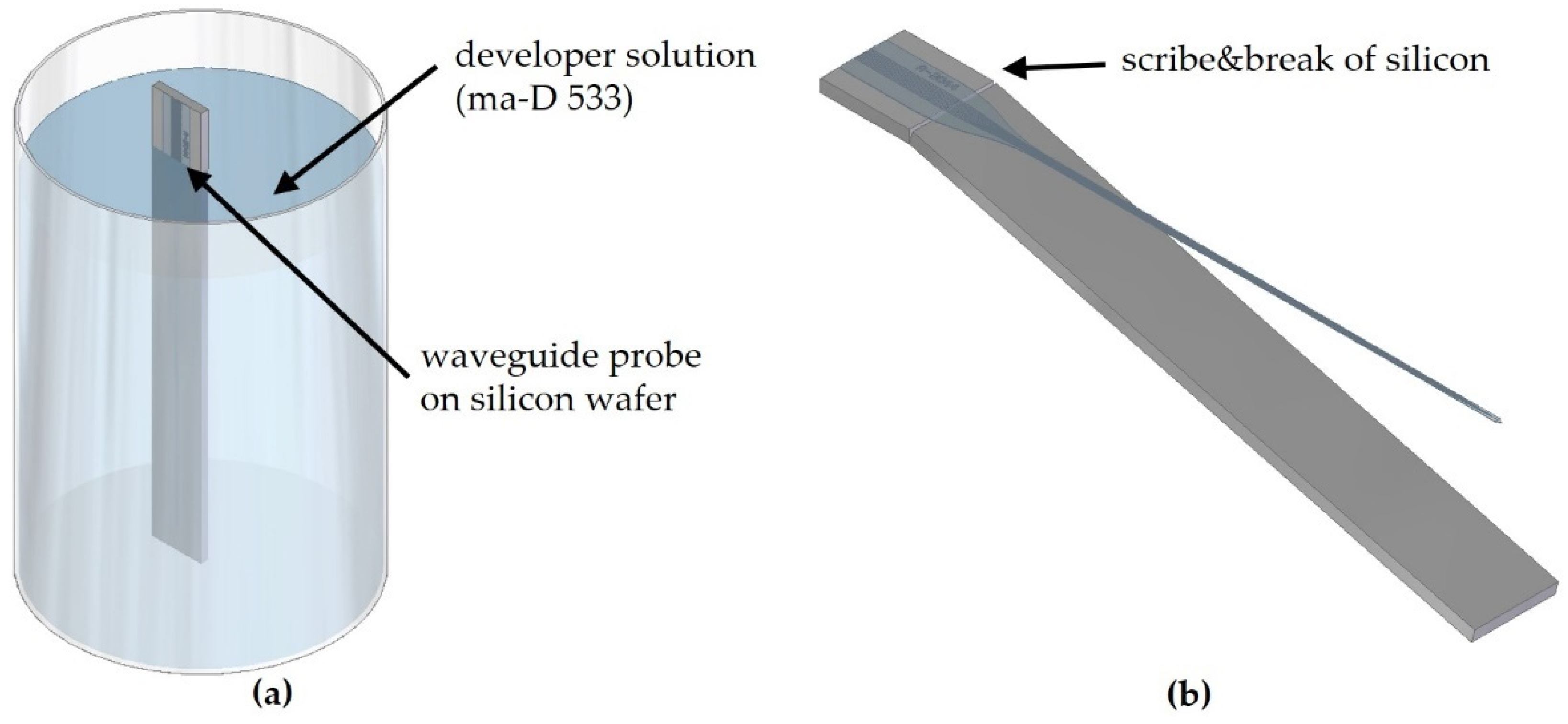

2.2. Wafer-Level Fabrication of the Flexible Polymer-Based Waveguides

3. Waveguide Characterization

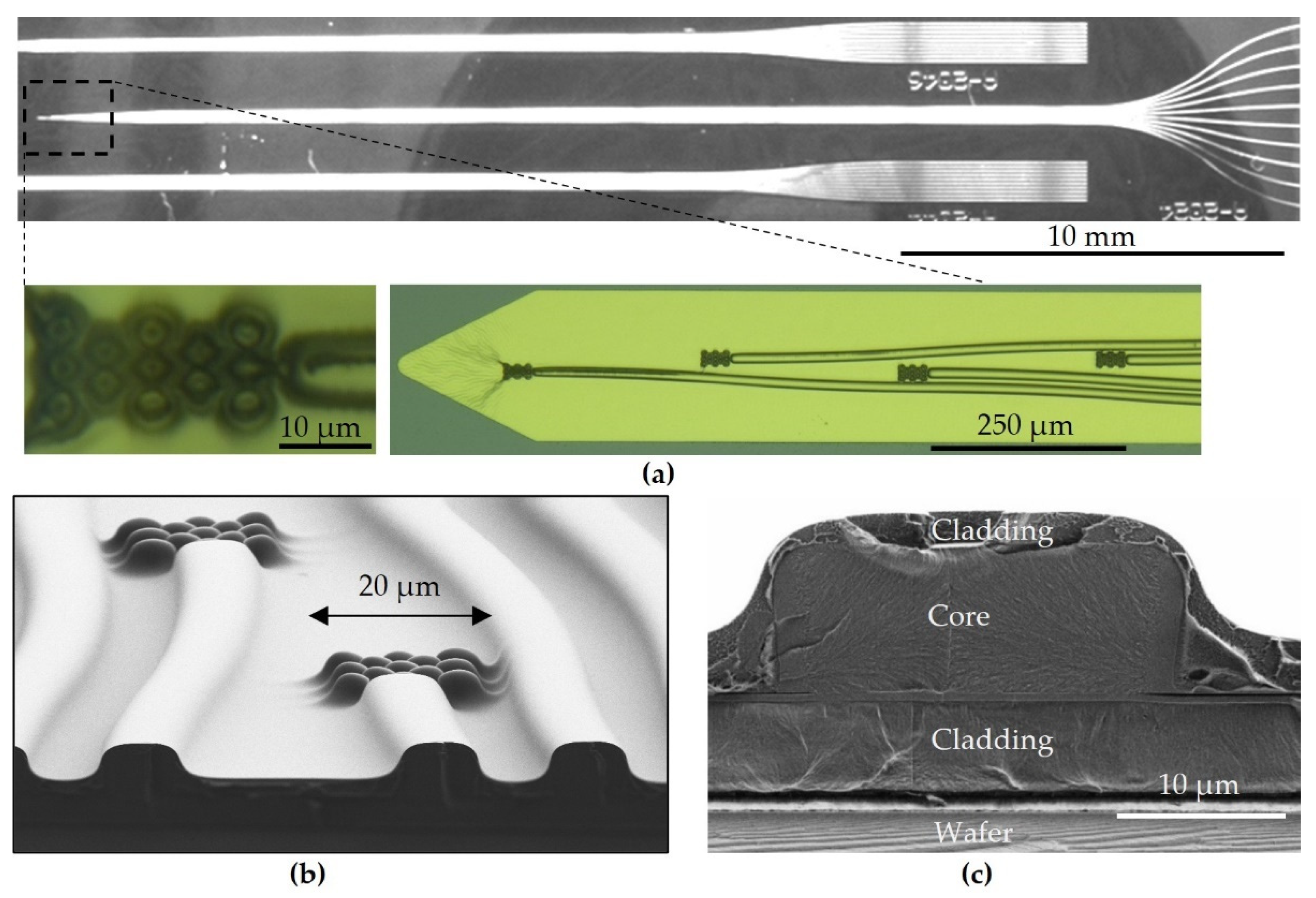

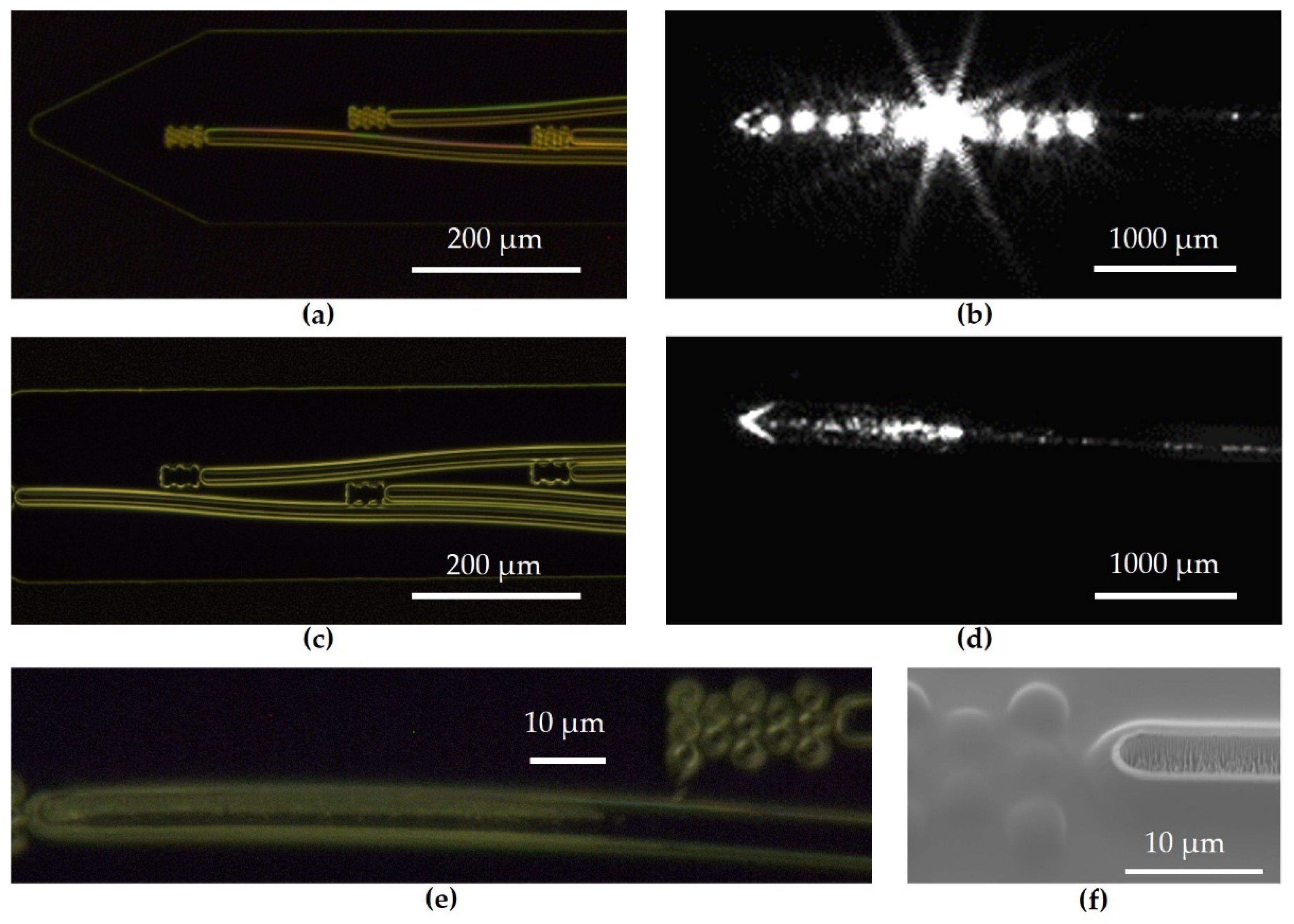

3.1. Bright- and Dark-Field Microscopy

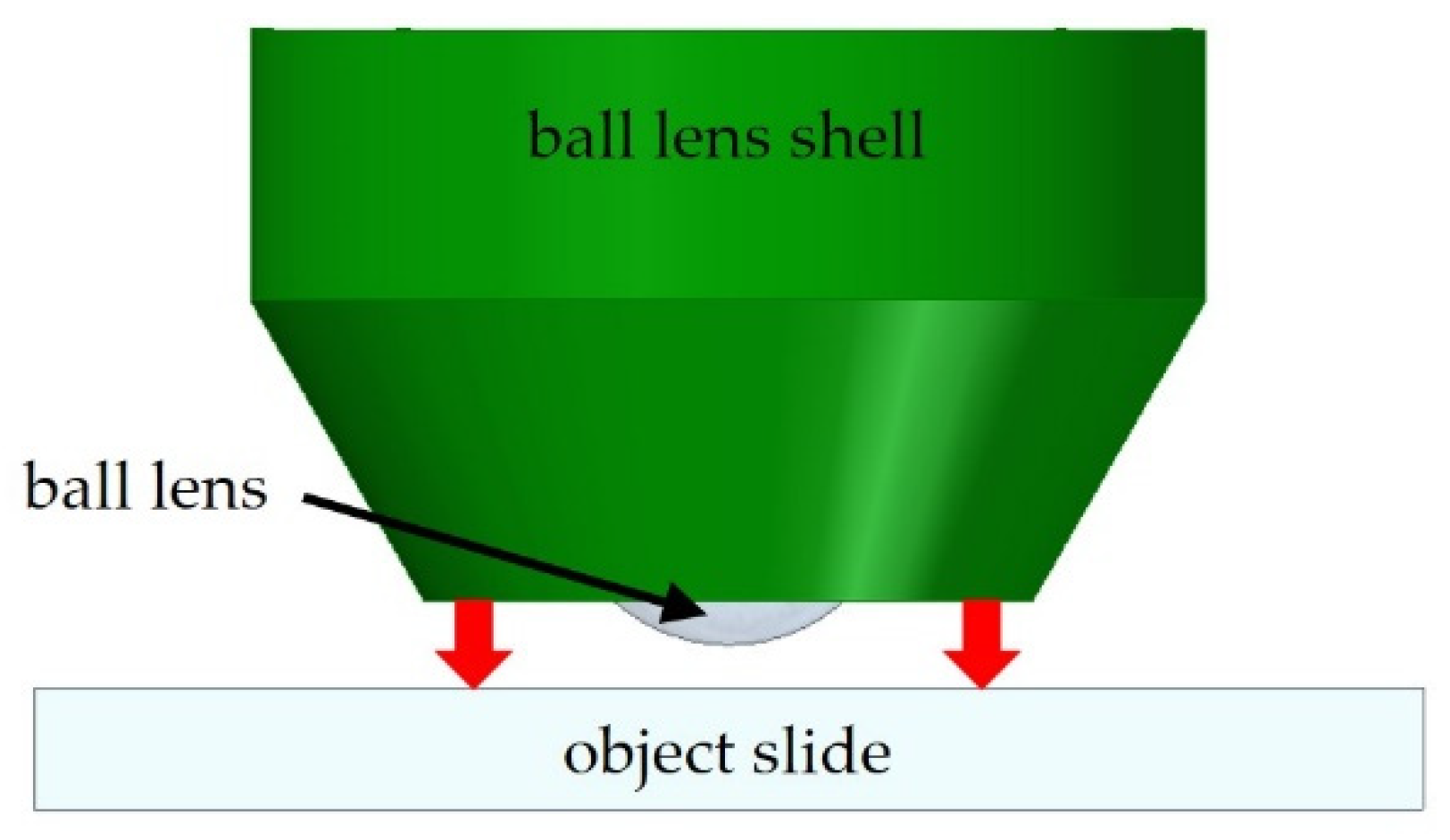

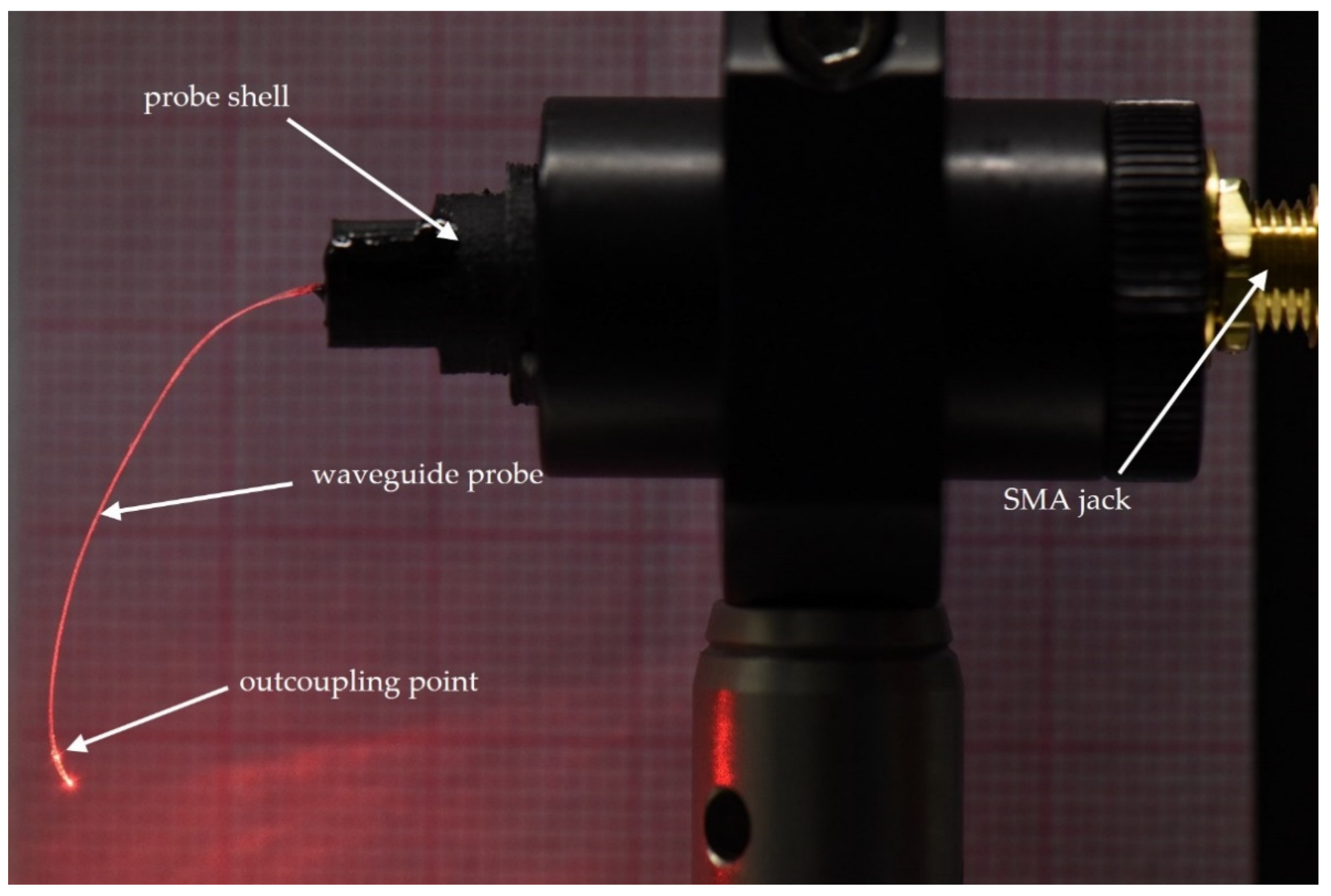

3.2. Scattered Light Detection Setup

3.3. Probe Diagnostics

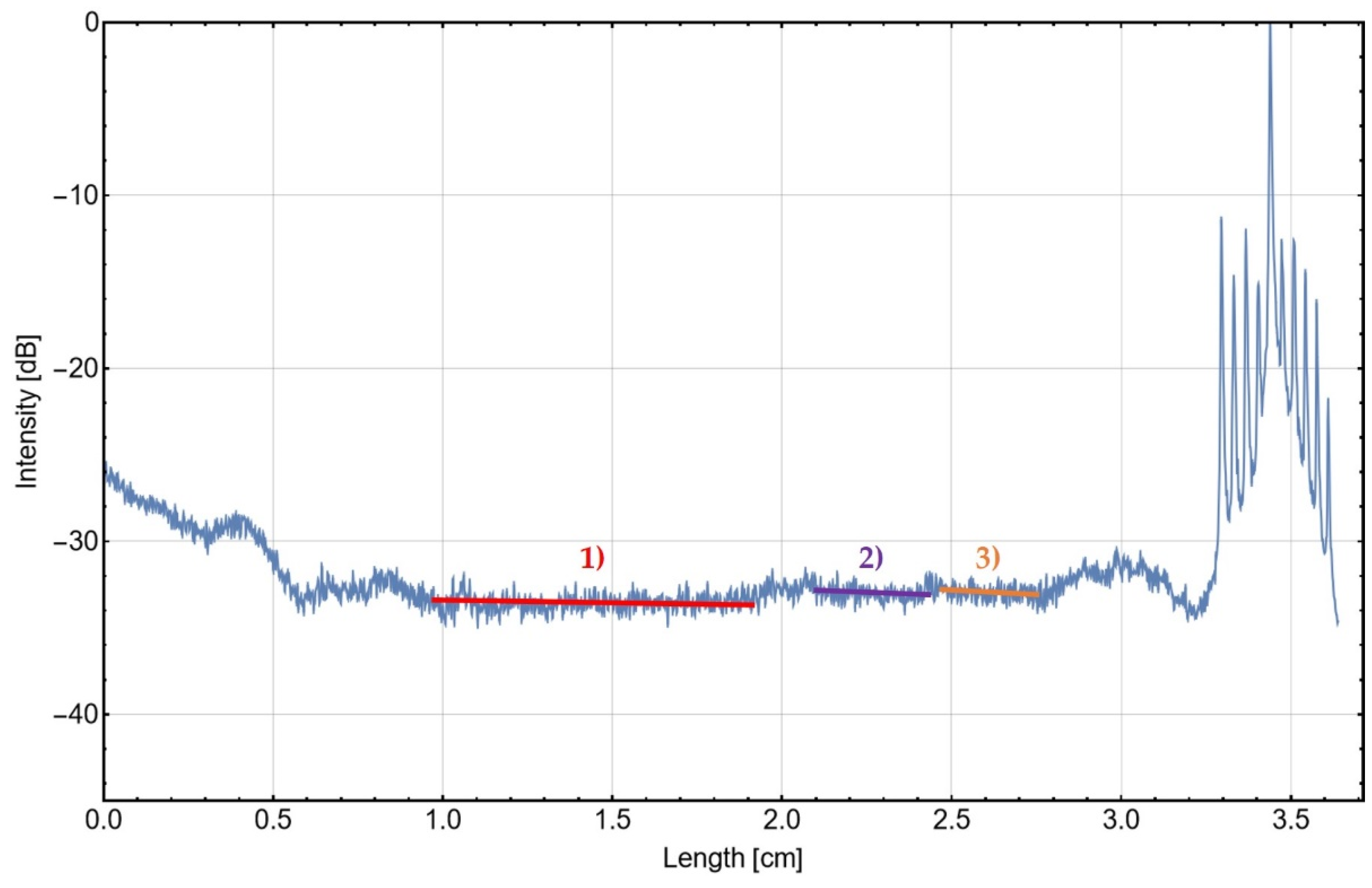

3.4. Scattering Loss Analysis

3.5. Bending Loss Analysis

4. Application of Waveguide Probes

4.1. Single-Channel Module Assembly

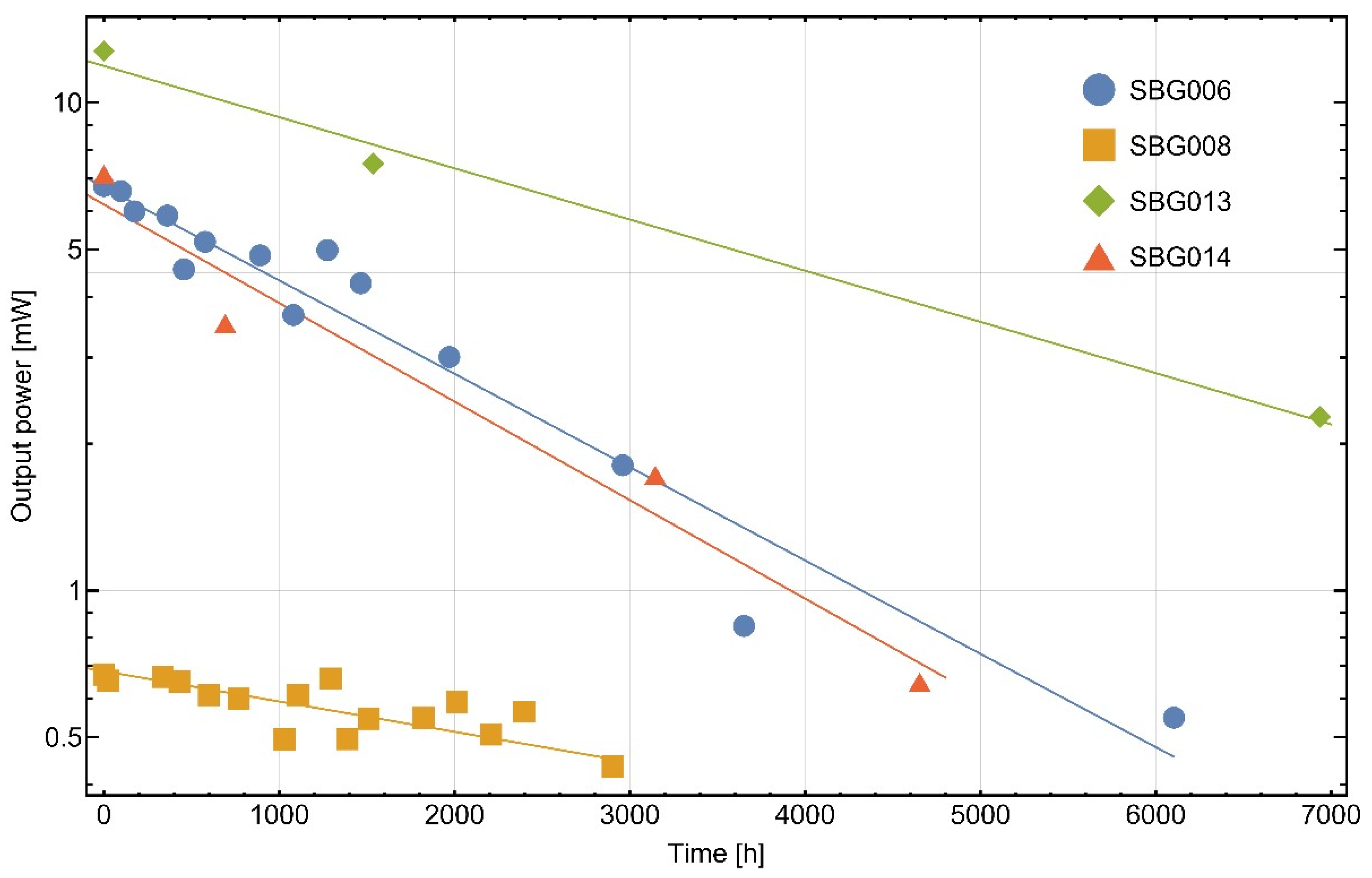

4.2. Module Degradation Tests

5. Cochlear Implantation

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Zeng, F.-G. Celebrating the one millionth cochlear implant. JASA Express Lett. 2022, 2, 077201. [Google Scholar] [CrossRef] [PubMed]

- Shannon, R.V. Multichannel electrical stimulation of the auditory nerve in man. II. Channel interaction. Hear. Res. 1983, 12, 1–16. [Google Scholar] [CrossRef] [PubMed]

- Kral, A.; Hartmann, R. Spatial resolution of cochlear implants: The electrical field and excitation of auditory afferents. Hear. Res. 1998, 121, 11–28. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.-G. Trends in cochlear implants. Trends Amplif. 2004, 8, 1–34. [Google Scholar] [CrossRef] [PubMed]

- Miller, C.A.; Abbas, P.J. Electrical excitation of the acoustically sensitive auditory nerve: Singlefiber responses to electric pulse train. J. Assoc. Res. Otolaryngol. 2006, 7, 195–210. [Google Scholar] [CrossRef][Green Version]

- Caldwell, M.T.; Jiam, N.T. Assessment and improvement of sound quality in cochlear implant users. Laryngoscope Investig. Otolaryngol. 2017, 2, 119–124. [Google Scholar] [CrossRef]

- Richter, C.-P.; Rajguru, S.M. Spread of cochlear excitation during stimulation with pulsed infrared radiation: Inferior colliculus measurements. J. Neural Eng. 2011, 8, 056006. [Google Scholar] [CrossRef]

- Hernandez, V.H.; Gehrt, A. Optogenetic stimulation of the auditory pathway. J. Clin. Investig. 2014, 124, 1114–1129. [Google Scholar] [CrossRef]

- Dieter, A.; Duque-Afonso, C.J. Near physiological spectral selectivity of cochlear optogenetics. Nat. Commun. 2019, 10, 1962. [Google Scholar] [CrossRef]

- Dieter, A.; Klein, E. µLED-based optical cochlear implants for spectrally selective activation of the auditory nerve. EMBO Mol. Med. 2020, 12, e12387. [Google Scholar] [CrossRef]

- Crick, F.H. Thinking about the brain. Sci. Am. 1979, 241, 219–232. [Google Scholar] [CrossRef] [PubMed]

- Nagel, G.; Szellas, T. Channelrhodopsin-2, a directly light-gated cation-selective membrane channel. Proc. Natl. Acad. Sci. USA 2003, 100, 13940–13945. [Google Scholar] [CrossRef] [PubMed]

- Boyden, E.S.; Zhang, F. Millisecond-timescale, genetically targeted optical control of neural activity. Nat. Neurosci. 2005, 8, 1263–1268. [Google Scholar] [CrossRef] [PubMed]

- Goßler, C.; Bierbrauer, C. GaN-based micro-LED arrays on flexible substrates for optical cochlear implants. J. Phys. D Appl. Phys. 2014, 47, 205401. [Google Scholar] [CrossRef]

- Klein, E.; Goßler, C. High-density µLED-based optical cochlear implant with improved thermomechanical behavior. Front. Neurosci. 2018, 12, 659. [Google Scholar] [CrossRef]

- Reddy, J.W.; Lassiter, M. Parylene photonics: A flexible, broadband optical waveguide platform with integrated micromirrors for biointerfaces. Microsyst. Nanoeng. 2020, 6, 85. [Google Scholar] [CrossRef]

- Schwaerzle, M.; Paul, O. Compact silicon-based optrode with integrated laser diode chips, SU-8 waveguides and platinum electrodes for optogenetic applications. J. Micromech. Microeng. 2017, 27, 065004. [Google Scholar] [CrossRef]

- Kampasi, K.; English, D.F. Dual color optogenetic control of neural populations using low-noise, multishank optoelectrodes. Microsyst. Nanoeng. 2018, 4, 10. [Google Scholar] [CrossRef]

- Marcatili, E.A. Bends in optical dielectric guides. Bell Syst. Tech. J. 1969, 48, 2103–2132. [Google Scholar] [CrossRef]

- Marcuse, D. Influence of curvature on the losses of doubly clad fibers. Appl. Opt. 1982, 21, 4208–4213. [Google Scholar] [CrossRef]

- Ebeling, K.J. Integrated Optoelectronics; Springer: Berlin/Heidelberg, Germany, 1993. [Google Scholar]

- Lacey, J.P.; Payne, F.P. Radiation loss from planar waveguides with random wall imperfections. IEE Proc. J. (Optoelectron.) 1990, 137, 282–289. [Google Scholar] [CrossRef]

- Payne, F.P.; Lacey, J.P. A theoretical analysis of scattering loss from planar optical waveguides. Opt. Quantum Electron. 1994, 26, 977–986. [Google Scholar] [CrossRef]

- Wang, X.-B.; Sun, J. Thermal UV treatment on SU-8 polymer for integrated optics. Opt. Mater. Express 2014, 4, 509–517. [Google Scholar] [CrossRef]

- Sun, X.; Xie, Y. Effect of film compatibility on electro-optic properties of dye doped polymer DR1/SU-8. Appl. Surf. Sci. 2013, 285, 469–476. [Google Scholar] [CrossRef]

- Nordstrom, M.; Zauner, D.A. Single-Mode Waveguides With SU-8 Polymer Core and Cladding for MOEMS Applications. J. Light. Technol. 2017, 25, 1284–1289. [Google Scholar] [CrossRef]

- Alt, M.T.; Fiedler, E. Let There Be Light-Optoprobes for Neural Implants. Proc. IEEE 2016, 105, 101–138. [Google Scholar] [CrossRef]

- Leal-Junior, A.G.; Marques, C. FBG-Embedded 3-D Printed ABS Sensing Pads: The Impact of Infill Density on Sensitivity and Dynamic Range in Force Sensors. IEEE Sens. J. 2018, 18, 8381–8388. [Google Scholar] [CrossRef]

- Cai, S.; Pan, H. Selective detection of cadmium ions using plasmonic optical fiber gratings functionalized with bacteria. Opt. Express 2020, 28, 19740–19749. [Google Scholar] [CrossRef]

- Rahlves, M.; Rezem, M.; Günther, A. Towards fabrication and application of polymer based photonics networks and sensors. In Proceedings of the SPIE 10545, MOEMS and Miniaturized Systems XVII, San Francisco, CA, USA, 22 February 2018. [Google Scholar]

- Yamagiwa, S.; Ishida, M. Flexible optrode array: Parylene-film waveguide arrays with microelectrodes for optogenetics. In Proceedings of the 2015 Transducers—2015 18th International Conference on Solid-State Sensors, Actuators and Microsystems (TRANSDUCERS), Anchorage, AK, USA, 21–25 June 2015; pp. 277–280. [Google Scholar]

- Nazempour, R.; Zhang, Q. Biocompatible and Implantable Optical Fibers and Waveguides for Biomedicine. Materials 2018, 11, 1283. [Google Scholar] [CrossRef]

- Baskent, D.; Shannon, R.V. Interactions between cochlear implant electrode insertion depth and frequency-place mapping. J. Acoust. Soc. Am. 2005, 117, 1405. [Google Scholar] [CrossRef]

- Stöver, T.; Lenarz, T. Biomaterials in cochlear implants. GMS Curr. Top. Otorhinolaryngol. Head Neck Surg. 2009, 8, Doc10. [Google Scholar] [PubMed]

- Keppeler, D.; Kampshoff, C.A. Multiscale photonic imaging of the native and implanted cochlea. Proc. Natl. Acad. Sci. USA 2021, 118, e2014472118. [Google Scholar] [CrossRef] [PubMed]

- Rebscher, S.J.; Hetherington, A. Considerations for the design of future cochlear implant electrode arrays: Electrode array stiffness, size and depth of insertion. J. Rehabil. Res. Dev. 2008, 45, 731–748. [Google Scholar] [CrossRef] [PubMed]

| Structure Parameters/Measurement Results | Radius 1 | Radius 2 | Radius 3 |

|---|---|---|---|

| 2.5 mm | 1 mm | 0.5 mm | |

| Geometrical parameters | |||

| Bending angle θ [°] | 30 | 45 | 45 |

| Distance s along one bend [cm] | 5.24 | 3.14 | 1.57 |

| Straight distance ∆d [cm] | 5.0 | 3.0 | 1.5 |

| Difference between straight and bent waveguide ∆s [cm] | 0.24 | 0.14 | 0.07 |

| Number of bends N | 2 | 4 | 3 |

| Straight distance between P1 and P2 [cm] | 1.81 | 1.81 | 1.35 |

| Total intensity loss between P1 and P2 [dB] | 3.33 | 13.50 | 17.00 |

| Total length between P1 and P2 [cm] | 1.86 | 1.87 | 1.37 |

| Scattered light attenuation parameter S = 1.04 dB/cm | |||

| Total scattering losses [dB] | 2.97 | 2.99 | 2.19 |

| Total bending losses [dB] | 0.36 | 10.51 | 14.81 |

| 2.51 | 1.01 | 0.50 | |

| 0.54 | 5.25 | 9.87 | |

| 3.73 | 6.43 | 10.71 | |

| Scattered light attenuation parameter S = 0.78 dB/cm | |||

| Total scattering losses [dB] | 1.45 | 1.46 | 1.07 |

| Total bending losses [dB] | 1.88 | 12.04 | 15.93 |

| 1.22 | 0.49 | 0.25 | |

| 2.83 | 6.02 | 10.62 | |

| 4.05 | 6.51 | 10.87 | |

| Scattered light attenuation parameter S = 0.30 dB/cm | |||

| Total scattering losses [dB] | 0.56 | 0.57 | 0.42 |

| Total bending losses [dB] | 2.77 | 12.93 | 16.59 |

| 0.48 | 0.19 | 0.10 | |

| 4.15 | 6.47 | 11.06 | |

| 4.63 | 6.66 | 11.15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Helke, C.; Reinhardt, M.; Arnold, M.; Schwenzer, F.; Haase, M.; Wachs, M.; Goßler, C.; Götz, J.; Keppeler, D.; Wolf, B.; et al. On the Fabrication and Characterization of Polymer-Based Waveguide Probes for Use in Future Optical Cochlear Implants. Materials 2023, 16, 106. https://doi.org/10.3390/ma16010106

Helke C, Reinhardt M, Arnold M, Schwenzer F, Haase M, Wachs M, Goßler C, Götz J, Keppeler D, Wolf B, et al. On the Fabrication and Characterization of Polymer-Based Waveguide Probes for Use in Future Optical Cochlear Implants. Materials. 2023; 16(1):106. https://doi.org/10.3390/ma16010106

Chicago/Turabian StyleHelke, Christian, Markus Reinhardt, Markus Arnold, Falk Schwenzer, Micha Haase, Matthias Wachs, Christian Goßler, Jonathan Götz, Daniel Keppeler, Bettina Wolf, and et al. 2023. "On the Fabrication and Characterization of Polymer-Based Waveguide Probes for Use in Future Optical Cochlear Implants" Materials 16, no. 1: 106. https://doi.org/10.3390/ma16010106

APA StyleHelke, C., Reinhardt, M., Arnold, M., Schwenzer, F., Haase, M., Wachs, M., Goßler, C., Götz, J., Keppeler, D., Wolf, B., Schaeper, J., Salditt, T., Moser, T., Schwarz, U. T., & Reuter, D. (2023). On the Fabrication and Characterization of Polymer-Based Waveguide Probes for Use in Future Optical Cochlear Implants. Materials, 16(1), 106. https://doi.org/10.3390/ma16010106