Enhancement of Bond Performance of Advanced Composite Materials Used in Cable Bridge Structures Based on Tensile Tests

Abstract

:1. Introduction

2. Materials and Methods

2.1. FRP

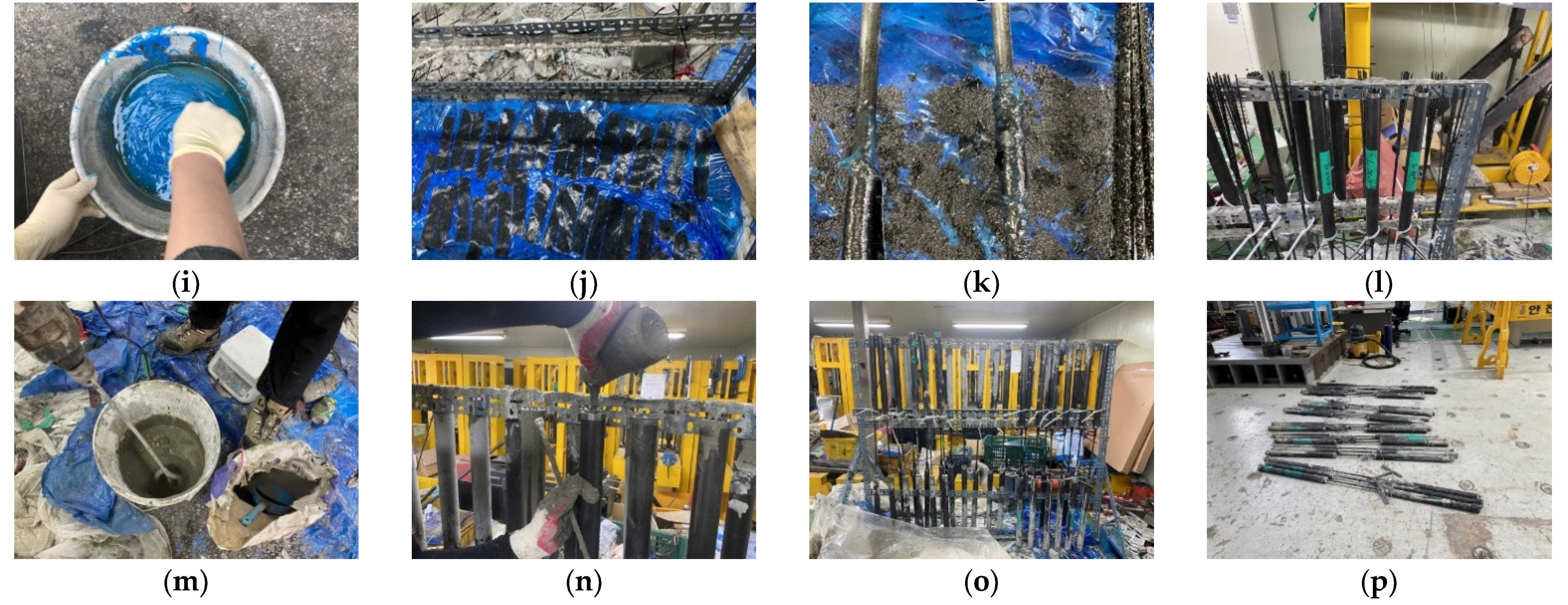

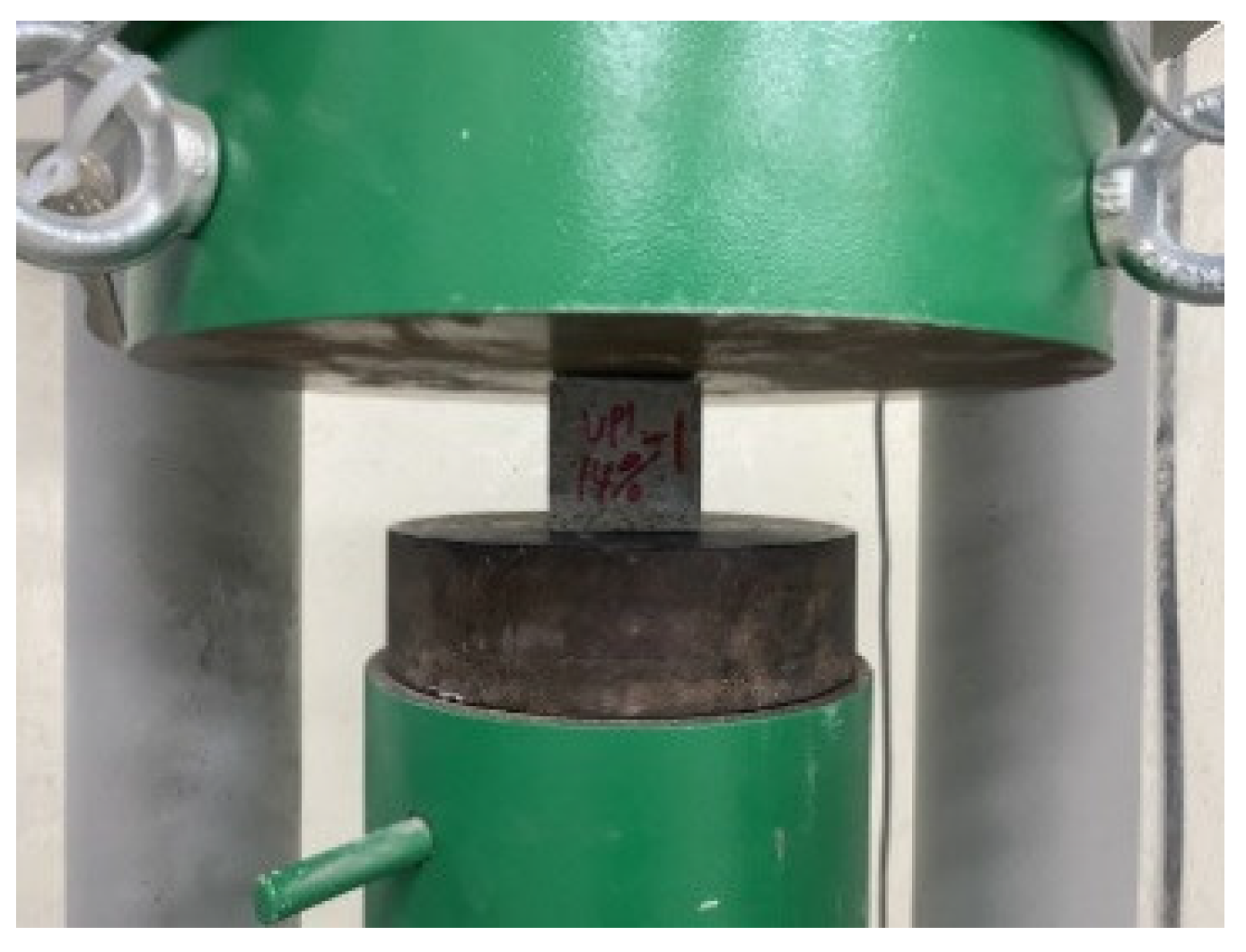

2.2. Specimen Preparation Process

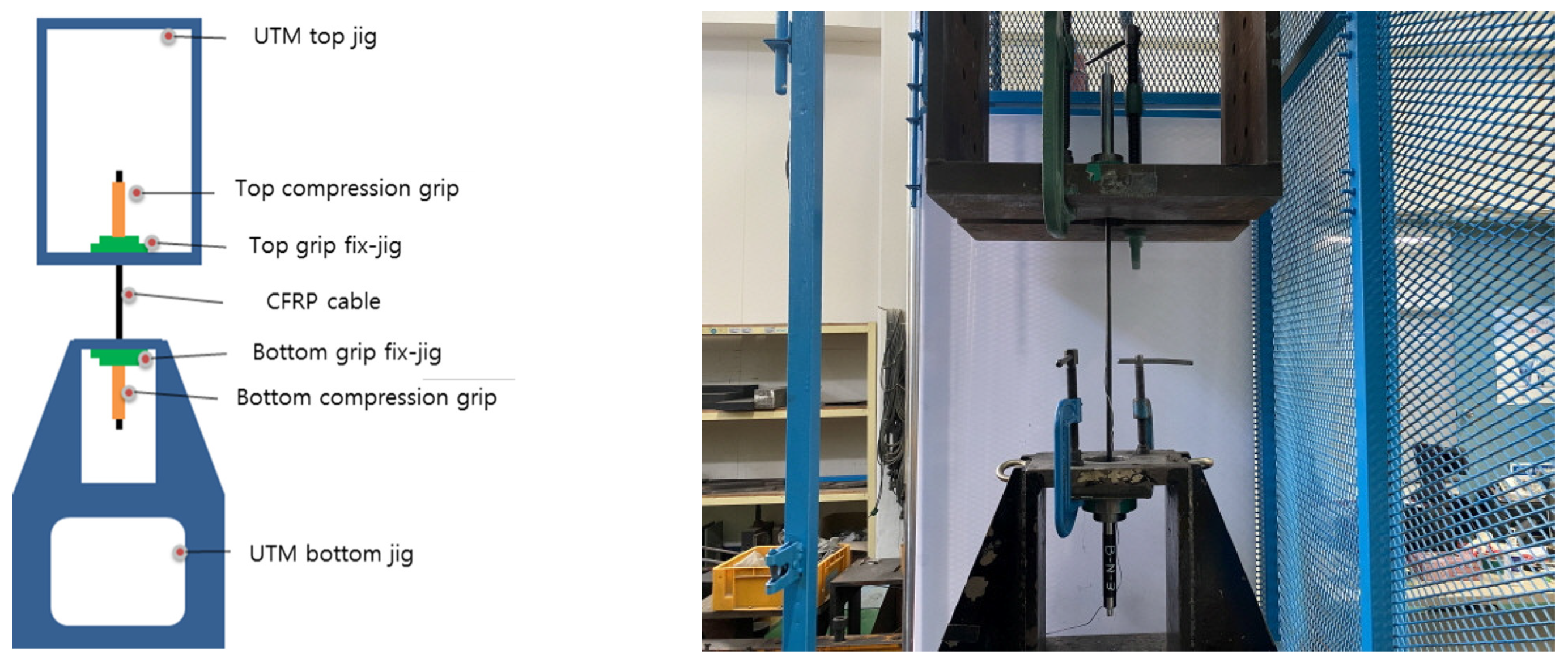

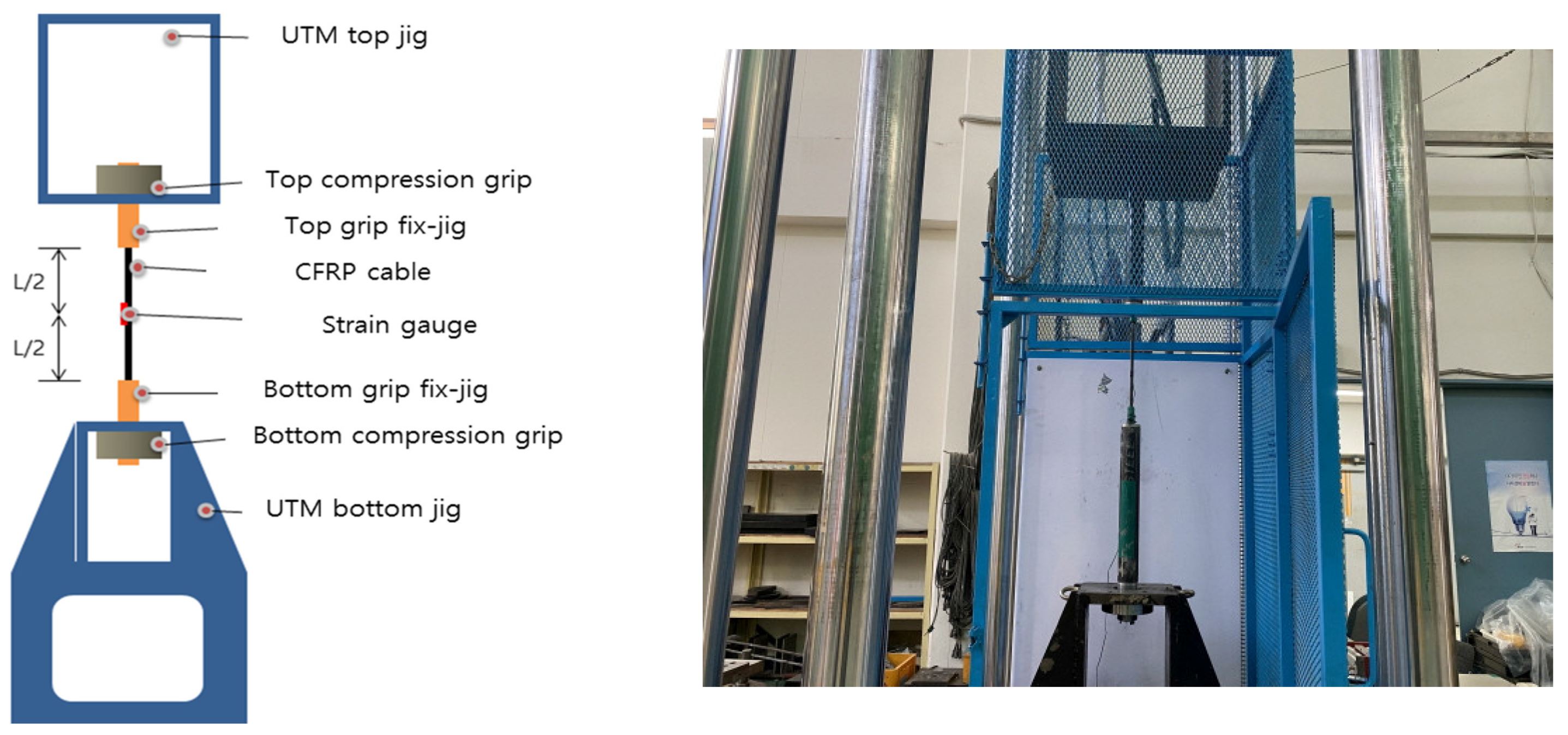

2.3. Tensile Test Method with the Sample Specimens

2.4. Tensile Test Results with the Sample Specimen

3. Experiments for the Improvement of Cable Bond Performance

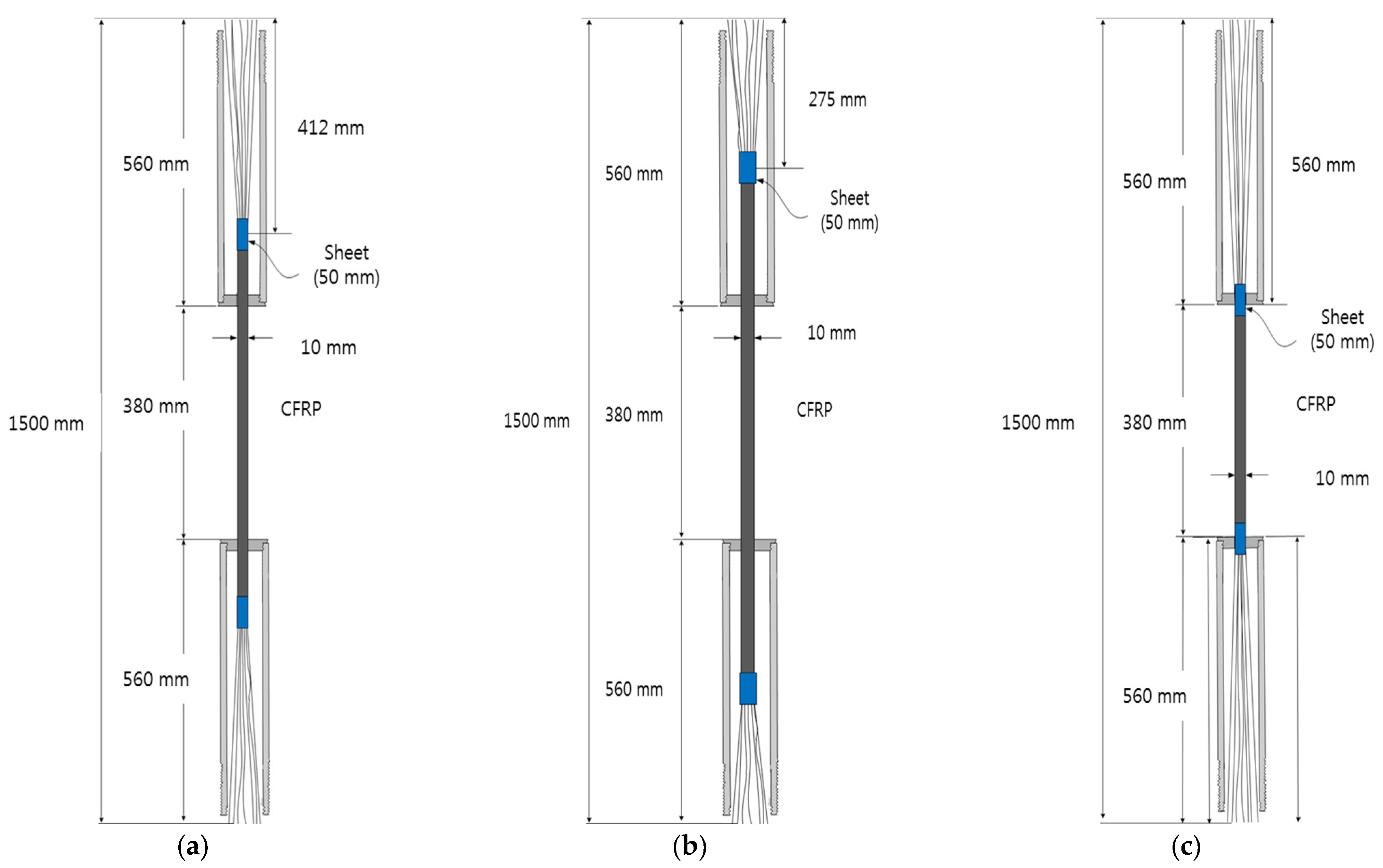

3.1. Variation of Parameter Values with Respect to the Fabrication Method of the CFRP Bond Performance Specimens

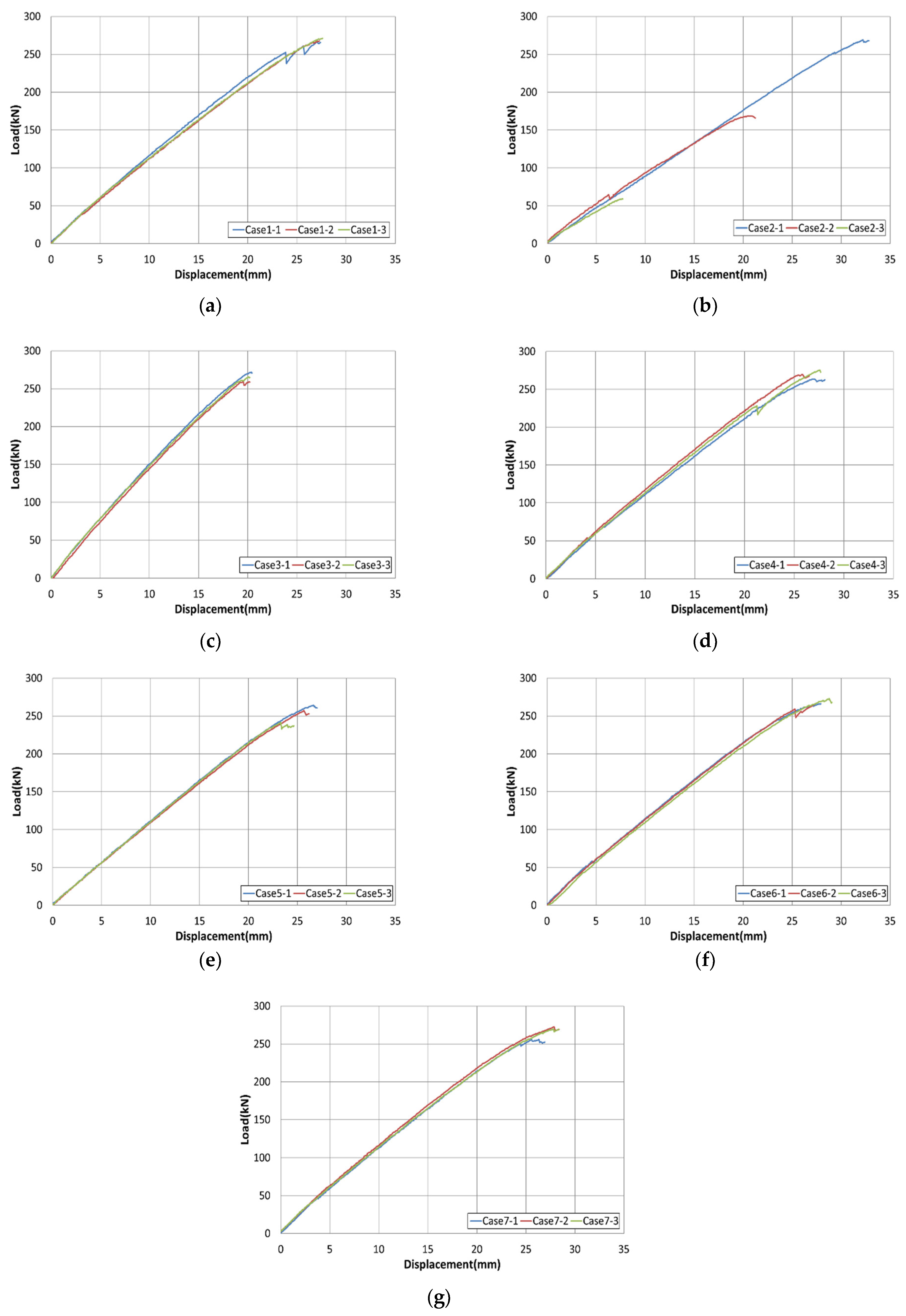

3.2. Test Results with Respect to Different Parameters for Assessing CFRP Bond Performance

3.3. Experiments with Different CFRP Round Mold Dimensions

3.4. Experimental Results with Different CFRP Round Mold Dimensions

4. Conclusions

- (1)

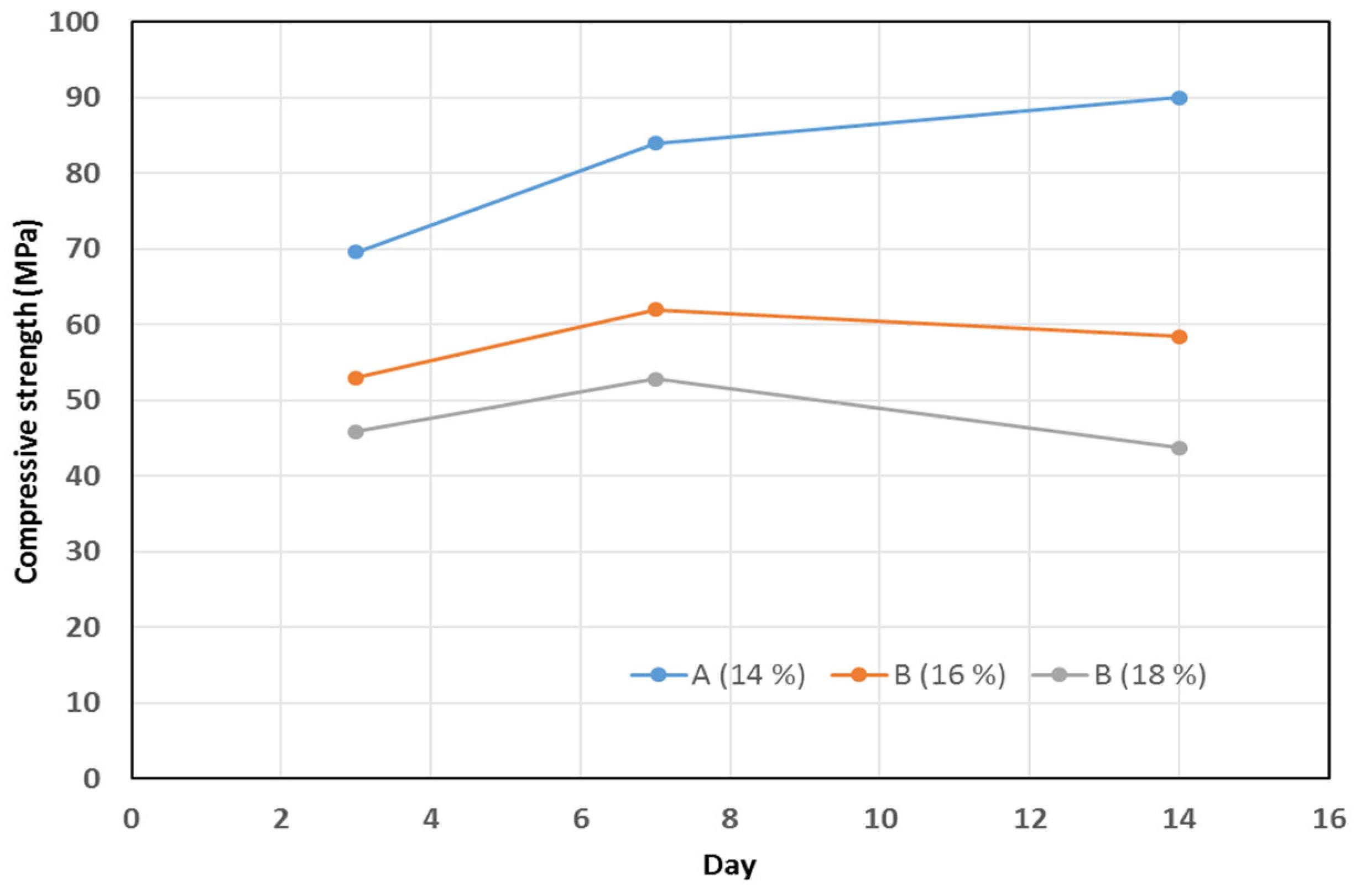

- When the compressive strengths of mortars from manufacturers, A (14%), B (16%), and C (18%) were compared, the average 3-day strength of the product A was 1.5 times that of product C, the average 7-day strength of the product A was 1.6 times that of the product C, and the average 14-day strength of the product A was 2.0 times that product C. Evidently, the strengths of products from manufacturer A were superior, and as the amount of water decreased, the strength response improved.

- (2)

- From the tests performed to compare the bond strength based on different fabrication methods, the following conditions need to be satisfied for sufficient expression of the bond performance: the amount of water used to make mortar should not be more than 16%, regardless of the manufacturer; the depth of splitting should not be less than 75%; the direction of mortar could be either upward or downward; and fiber-sheet reinforcement ought to be used. For the control specimen and most of the other specimens, flower-shaped fracture occured in the center part that indicated application of equal loading at the top and bottom steel pipe mold parts during tensile testing.

- (3)

- Regarding the experiments conducted based on variations of the parameters of round steel pipe mold, steel pipe failure occurred in Case A; in Cases B, C (slip), and D, flower-shaped fractures were observed. Moreover, in the process of specimen preparation and placement, larger dimensions caused the weight of the steel pipe to increase. This caused inconvenience in its use. In Cases B and C, there was considerable inconvenience in the process of preparation and placement. In Case D, workability improved as the length of the steel pipe decreased, and a superior performance was achieved compared with other specimens.

- (4)

- Finally, in this study, various experiments were conducted with different parameters aimed to increase bond performance and the maximum CFRP load. Therefore, in future research, additional studies need to be conducted on more diverse specimen fabrication parameters and methods, and on the dimensions of steel pipe mold, so that they can be applicable to all types of fibers.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Shin, H.M.; Lee, J.H. Reinforced Concrete, 11th ed.; Dong Myeong: Paju City, Korea, 2013. [Google Scholar]

- Shin, H.M. Prestressed Concrete, 10th ed.; Dong Myeong: Paju City, Korea, 2012. [Google Scholar]

- Kim, T.K.; Choi, S.J.; Kim, J.H.J.; Chu, Y.S.; Yu, E. Performance based evaluation of carbonation resistance of concrete according to various curing conditions from climate change effect. Int. J. Concr. Struct. Mater. 2017, 11, 687–700. [Google Scholar] [CrossRef]

- Ma, Z.; Zhu, F.; Ba, G. Effects of freeze-thaw damage on the bond behavior of concrete and enhancing measures. Constr. Build. Mater. 2019, 196, 375–385. [Google Scholar] [CrossRef]

- Farahani, A.; Taghaddos, H.; Shekarchi, M. Prediction of long-term chloride diffusion in silica fume concrete in a marine environment. Cem. Concr. Compos. 2015, 59, 10–17. [Google Scholar] [CrossRef]

- Mehta, P.K.; Paulo, J.M.M. Concrete (Microstructure, Properties, and Materials), 3rd ed.; McGraw Hill: New York, NY, USA, 2006. [Google Scholar]

- Sidney, M.; Francis, Y.; David, D. Concrete, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 2003. [Google Scholar]

- Moon, C.K. Polymer Matrix Composites, 3rd ed.; Sigmapress: Seoul, Korea, 2010. [Google Scholar]

- Sim, J.S.; Kwak, K.H.; Park, S.Y.; Oh, H.S. FRP-Strengthened RC Structures, 1st ed.; Cheong Moon Gak: Paju City, Korea, 2006. [Google Scholar]

- ACI 440.06-08; Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures. American Concrete Institute (ACI): Indianapolis, IN, USA, 2008.

- American Association of State Highway Transportation Officials (AASHTO). Guide Specifications for the Design of Concrete Bridge Beams Prestressed with Carbon Fiber-Reinforced Polymer (CFRP) Systems; American Association of State Highway Transportation Officials (AASHTO): Washington, DC, USA, 2018. [Google Scholar]

- ACI 440R.3R-12; Guide Test Methods for Fiber-Reinforced Polymer (FRP) Composites for Reinforcing or Strengthening Concrete and Masonry Structures. American Concrete Institute (ACI): Indianapolis, IN, USA, 2020.

- ASTM D 7913; Standard Test Method for Tensile Properties of Fiber Reinforced Polymer Matrix Composite Bars. American Society for Testing and Materials (ASTM): West Conshohocken, PA, USA, 2020.

- KS F ISO 10406-1; Fibre-Reinforced Polymer (FRP) Reinforcement of Concrete—Test Methods—Part 1: FRP Bars and Grids. Korea Standards Association (KSA): Seoul, Korea, 2017.

- Jiang, T.Y.; Fang, Z. Experimental investigation on the performance of wedge-bond anchors for CFRP tendons. Chi. Civ. Eng. J. 2010, 43, 79–87. [Google Scholar]

- Cai, D.S.; Yin, J.; Liu, R.G. Experimental and analytical investigation into the stress performance of composite anchors for CFRP tendons. Compos. Part B Eng. 2015, 79, 530–534. [Google Scholar] [CrossRef]

- Al-Mayah, A.; Soudki, K.; Plumtree, A. Development and assessment of a new CFRP rod–anchor system for prestressed concrete. Appl. Compos. Mater. 2006, 13, 321–334. [Google Scholar] [CrossRef]

- Yang, Y.; Fahmy, M.F.; Guan, S.; Pan, Z.; Zhan, Y.; Zhao, T. Properties and applications of FRP cable on long-span cable-supported bridges: A review. Compos. Part B Eng. 2020, 190, 107934. [Google Scholar] [CrossRef]

- Damiani, M.; Quadrino, A.; Nisticò, N. FRP Cables to prestress RC beams: State of the art vs. a split wedge anchorage system. Buildings 2021, 11, 209. [Google Scholar] [CrossRef]

- Ruiz Emparanza, A.; De Caso, Y.; Basalo, F.; Kampmann, R.; Adarraga Usabiaga, I. Evaluation of the bond-to-concrete properties of GFRP rebars in marine environments. Infrastructures 2018, 3, 44. [Google Scholar] [CrossRef] [Green Version]

- Emparanza, A.R.; Basalo, F.D.C.Y.; Kampmann, R.; Nanni, A. Bond evaluation of GFRP reinforcing bars embedded in concrete under aggressive environments. CICE 2018, 21, 931–937. [Google Scholar]

- Platt, S.; Harries, K.A. Geometry, material properties and bond performance of prototype titanium reinforcing bars. Constr. Build. Mater. 2018, 187, 1253–1266. [Google Scholar] [CrossRef]

- Basran, B.; Donmez, E.T. Investigation of bond strength between GFRP wrapped steel reinforcement and concrete with pullout test. Hitt. J. Sci. Eng. 2020, 7, 321–327. [Google Scholar] [CrossRef]

- Taha, A.; Alnahhal, W. Bond durability and service life prediction of BFRP bars to steel FRC under aggressive environmental conditions. Compos. Struct. 2021, 269, 114034. [Google Scholar] [CrossRef]

- Taha, A.; Alnahhal, W.; Alnuaimi, N. Bond durability of basalt FRP bars to fiber reinforced concrete in a saline environment. Compos. Struct. 2020, 243, 112277. [Google Scholar] [CrossRef]

- Jung, K.S.; Park, K.T.; You, Y.J.; Seo, D.W.; Kim, B.C.; Park, J.S. Evaluation of bond strength for FRP hybrid bar according to coating methods using silica sands. J. Korea Acad. Ind. Coop. Soc. 2017, 18, 118–125. [Google Scholar]

- Godat, A.; Aldaweela, S.; Aljaberi, H.; Al Tamimi, N.; Alghafri, E. Bond strength of FRP bars in recycled-aggregate concrete. Constr. Build. Mater. 2021, 267, 120919. [Google Scholar] [CrossRef]

- You, Y.J.; Kim, J.H.J.; Park, K.T.; Seo, D.W.; Lee, T.H. Modification of rule of mixtures for tensile strength estimation of circular GFRP rebars. Polymers 2017, 9, 682. [Google Scholar] [CrossRef] [Green Version]

- Oh, H.S.; Sim, J.S.; Kang, T.S. An experimental study on the fatigue flexural bonding characteristic of concrete beam reinforced with GFRP rebar. J. Korea Inst. Concr. Struct. Maint. Insp. 2008, 12, 101–108. (In Korean) [Google Scholar]

- Rudenko, A.; Biryukov, A.; Kerzhentsev, O.; Fediuk, R.; Vatin, N.; Vasilev, Y.; Klyuev, S.; Amran, M.; Szelag, M. Nano-and micro-modification of building reinforcing bars of various types. Crystals 2021, 11, 323. [Google Scholar] [CrossRef]

- Kim, M.J.; Kim, H.G.; Lee, Y.J.; Kim, D.H.; Jo, M.S.; Kim, K.H. Evaluation of bond properties of a fabric-reinforced cementitious matrix for strengthening of concrete structures. Appl. Sci. 2020, 10, 3767. [Google Scholar] [CrossRef]

- Ali, S.; Sheikh, M.N.; NS Hadi, M. Behavior of axially loaded plain and fiber-reinforced geopolymer concrete columns with glass fiber-reinforced polymer cages. Struct. Concr. 2021, 22, 1800–1816. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Triantafillou, T.C. Fiber-reinforced polymer composites for construction—State-of-the-art review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Ministry of Science and ICT, and Transport. Structural Performance Improvement of Infrastructures Using FRP Composites; Report No. KICT 2017-109; Korea Institute of Civil Engineering and Building Technology: Goyang, Korea, 2017. (In Korean) [Google Scholar]

- ACI 440R-96; Report on Fiber Reinforced Plastic Reinforcement for Concrete Structures. American Concrete Institute (ACI): Indianapolis, IN, USA, 2002.

- Kim, T.K.; Jung, W.T. Improvement of anchorage performance of carbon fiber-reinforced polymer cables. Polymers 2022, 14, 1239. [Google Scholar] [CrossRef] [PubMed]

- KS F 4042; Polymer Modified Cement Mortar for Maintenance in Concrete Structure. Korea Standards Association (KSA): Seoul, Korea, 2017.

- KS D 3562; Carbon Steel Pipes for Pressure Service. Korea Standards Association (KSA): Seoul, Korea, 2021.

| Specimens | CFRP Cable | |||

|---|---|---|---|---|

| Maximum Load (kN) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Fracture Location | |

| 1 | 239 | 3048 | 190 | fracture (slip) |

| 2 | 231 | 2945 | 190 | fracture (slip) |

| 3 | 215 | 2743 | 184 | fracture (slip) |

| 4 | 208 | 2654 | 187 | fracture (slip) |

| 5 | 225 | 2868 | 184 | fracture (slip) |

| Avg. | 224 | 2851 | 187 | - |

| Case | Type of Mortar | Depth of Splitting | Direction of Mortar Injection | Fiber Sheet Reinforcement | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| (Amount of Water %) | (Ratio to Steel Pipe Length) | Upward | Downward | Y | N | |||||

| Manufacturer A | Manufacturer B | |||||||||

| 14% | 16% | 18% | 50% | 75% | 100% | |||||

| Case1 (C) | O | O | O | O | ||||||

| Case 2 | O | O | O | O | ||||||

| Case 3 | O | O | O | O | ||||||

| Case 4 | O | O | O | O | ||||||

| Case 5 | O | O | O | O | ||||||

| Case 6 | O | O | O | O | ||||||

| Case 7 | O | O | O | O | ||||||

| Manufacturers | Day | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|

| # 1 | # 2 | # 3 | Avg. | ||

| A (14%) | 3 | 66.2 | 70.6 | 72.1 | 69.6 |

| 7 | 88.3 | 79.7 | 84.0 | 84.0 | |

| 14 | 96.3 | 93.3 | - | 90.0 | |

| B (16%) | 3 | 50.6 | 54.0 | 54.3 | 53.0 |

| 7 | 68.3 | 58.8 | 58.8 | 62.0 | |

| 14 | 55.6 | 57.6 | 62.0 | 58.4 | |

| B (18%) | 3 | 46.1 | 44.4 | 47.3 | 45.9 |

| 7 | 55.0 | 55.0 | 48.5 | 52.8 | |

| 14 | 49.1 | 38.2 | - | 43.7 | |

| Specimens | Maximum Load (kN) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Fracture Image |

|---|---|---|---|---|

| Case 1-1 | 267.0 | 3401.3 | 178.8 | flower-shaped fracture |

| Case 1-2 | 267.7 | 3410.2 | 180.5 | flower-shaped fracture |

| Case 1-3 | 271.1 | 3453.5 | 185.3 | flower-shaped fracture |

| Case-1 Avg. (Avg.) | 268.6 | 3421.7 | 181.5 | |

| Case 2-1 | 269.0 | 3426.8 | 183.3 | flower-shaped fracture |

| Case 2-2 | 168.6 | 2147.8 | 172.4 | slip |

| Case 2-3 | 59.0 | 751.6 | 170.5 | slip |

| Case-2 Avg. | 165.5 | 2108.3 | 175.4 | |

| Case 3-1 | 271.9 | 3463.7 | 182.3 | flower-shaped fracture |

| Case 3-2 | 259.9 | 3310.8 | 179.1 | flower-shaped fracture |

| Case 3-3 | 265.8 | 3386.0 | 185.3 | flower-shaped fracture |

| Case-3 Avg. | 265.9 | 3387.3 | 182.2 | |

| Case 4-1 | 263.4 | 3355.4 | 186.3 | flower-shaped fracture |

| Case 4-2 | 269.5 | 3433.1 | 184.6 | flower-shaped fracture |

| Case 4-3 | 275.5 | 3509.6 | 183.5 | flower-shaped fracture |

| Case-4 Avg. | 269.5 | 3433.1 | 184.8 | |

| Case 5-1 | 264.1 | 3364.3 | 180.7 | flower-shaped fracture |

| Case 5-2 | 257.2 | 3276.4 | 177.4 | flower-shaped fracture |

| Case 5-3 | 241.4 | 3075.2 | 184.9 | flower-shaped fracture |

| Case-5 Avg. | 254.2 | 3238.2 | 181.0 | |

| Case 6-1 | 266.2 | 3391.1 | 185.1 | flower-shaped fracture |

| Case 6-2 | 266.3 | 3392.4 | 178.7 | flower-shaped fracture |

| Case 6-3 | 272.9 | 3476.4 | 184.5 | flower-shaped fracture |

| Case-6 Avg. | 268.4 | 3419.1 | 182.8 | |

| Case 7-1 | 256.1 | 3262.4 | 182.5 | flower-shaped fracture |

| Case 7-2 | 272.5 | 3471.3 | 184.1 | flower-shaped fracture |

| Case 7-3 | 269.9 | 3438.2 | 182.6 | flower-shaped fracture |

| Case-7 Avg. | 266.2 | 3391.1 | 183.1 |

| Specimens | Case A | Case B | Case C | Case D |

|---|---|---|---|---|

| steel pipe length (mm) | 560 | 560 | 560 | 410 |

| outer diameter (mm) | 42.7 | 42.7 | 60.5 | 42.7 |

| thickness (mm) | 4.9 | 6.4 | 8.7 | 4.9 |

| screw tab pitch (mm) | 1.5 | 1.5 | 1.5 | 1.5 |

| screw tab length (mm) | 100 | 100 | 100 | 100 |

| Specimens | Maximum Load (kN) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Fracture Image |

|---|---|---|---|---|

| Case A-1 | 192 | 2445.9 | 180.1 | steel pipe failure |

| Case A-2 | 195.1 | 2485.4 | 177.1 | steel pipe failure |

| Case A-3 | 191.3 | 2426.9 | 182.5 | steel pipe failure |

| Case-A Avg. | 192.8 | 2456.1 | 179.9 | |

| Case B-1 | 282.3 | 3596.2 | 181.6 | flower-shaped fracture |

| Case B-2 | 279.8 | 3564.3 | 182.3 | flower-shaped fracture |

| Case B-3 | 283.0 | 3605.1 | 181.8 | flower-shaped fracture |

| Case-B Avg. | 281.7 | 3588.5 | 181.9 | |

| Case C-1 | 286.6 | 3651.0 | 186.2 | flower-shaped fracture |

| Case C-2 | 285.1 | 3631.8 | 183.1 | fracture (slip) |

| Case C-3 | 262.5 | 3343.9 | 182.4 | flower-shaped fracture (slip) |

| Case-C Avg. | 278.1 | 3542.7 | 183.9 | |

| Case D-1 | 277.2 | 3531.2 | 182.1 | flower-shaped fracture |

| Case D-2 | 267.6 | 3408.9 | 183.6 | fracture (slip) |

| Case D-3 | 280.2 | 3569.4 | 182.6 | flower-shaped fracture |

| Case-D Avg. | 275.0 | 3503.2 | 182.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, T.-K.; Jung, W.-T. Enhancement of Bond Performance of Advanced Composite Materials Used in Cable Bridge Structures Based on Tensile Tests. Materials 2022, 15, 2948. https://doi.org/10.3390/ma15082948

Kim T-K, Jung W-T. Enhancement of Bond Performance of Advanced Composite Materials Used in Cable Bridge Structures Based on Tensile Tests. Materials. 2022; 15(8):2948. https://doi.org/10.3390/ma15082948

Chicago/Turabian StyleKim, Tae-Kyun, and Woo-Tai Jung. 2022. "Enhancement of Bond Performance of Advanced Composite Materials Used in Cable Bridge Structures Based on Tensile Tests" Materials 15, no. 8: 2948. https://doi.org/10.3390/ma15082948

APA StyleKim, T.-K., & Jung, W.-T. (2022). Enhancement of Bond Performance of Advanced Composite Materials Used in Cable Bridge Structures Based on Tensile Tests. Materials, 15(8), 2948. https://doi.org/10.3390/ma15082948