Mechanical Performance of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements

Abstract

:1. Introduction

2. Materials and Methods

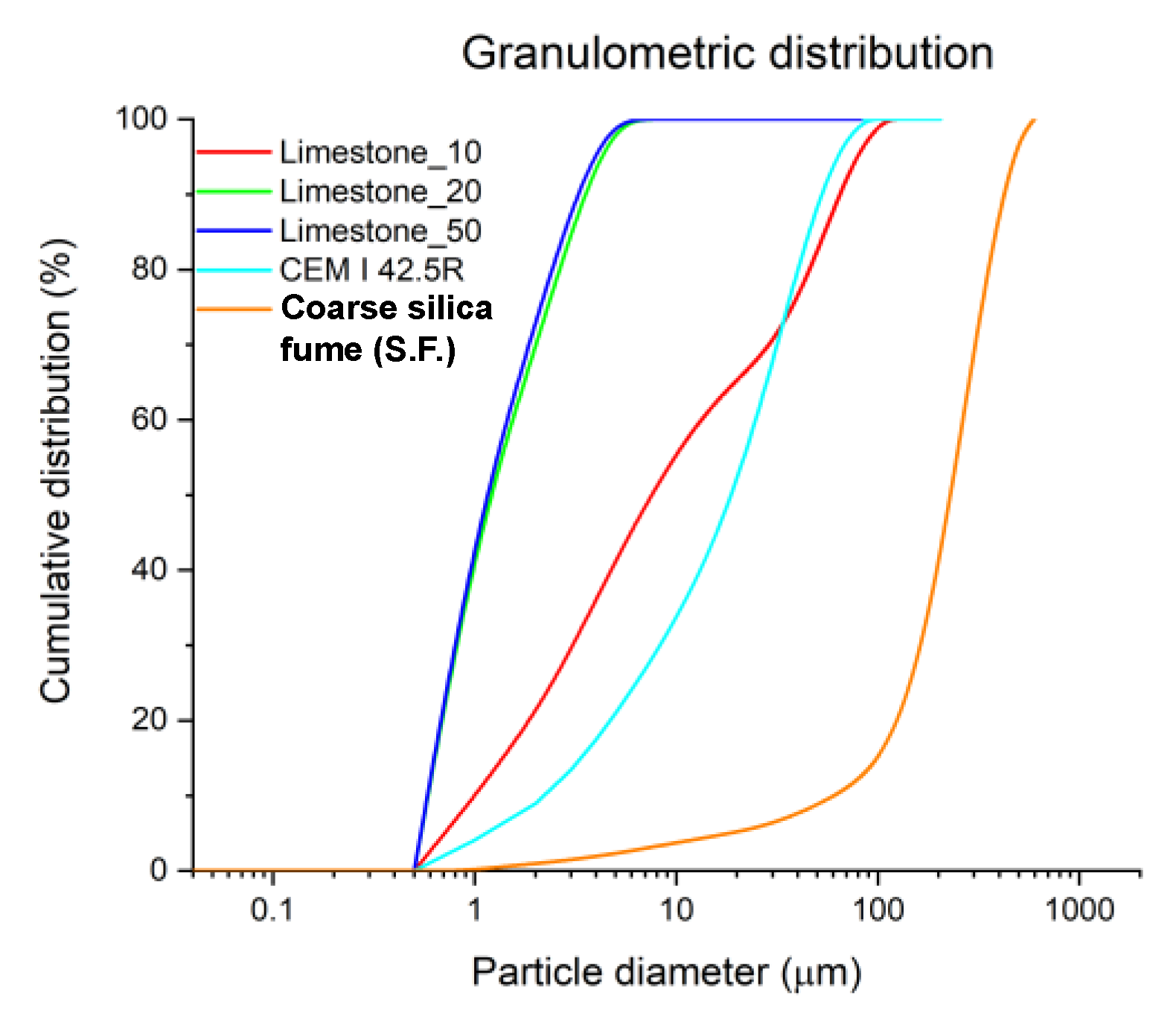

2.1. Raw Materials

2.2. Ternary Cement Mix Design

2.3. Mechanical Strength

3. Results and Discussion

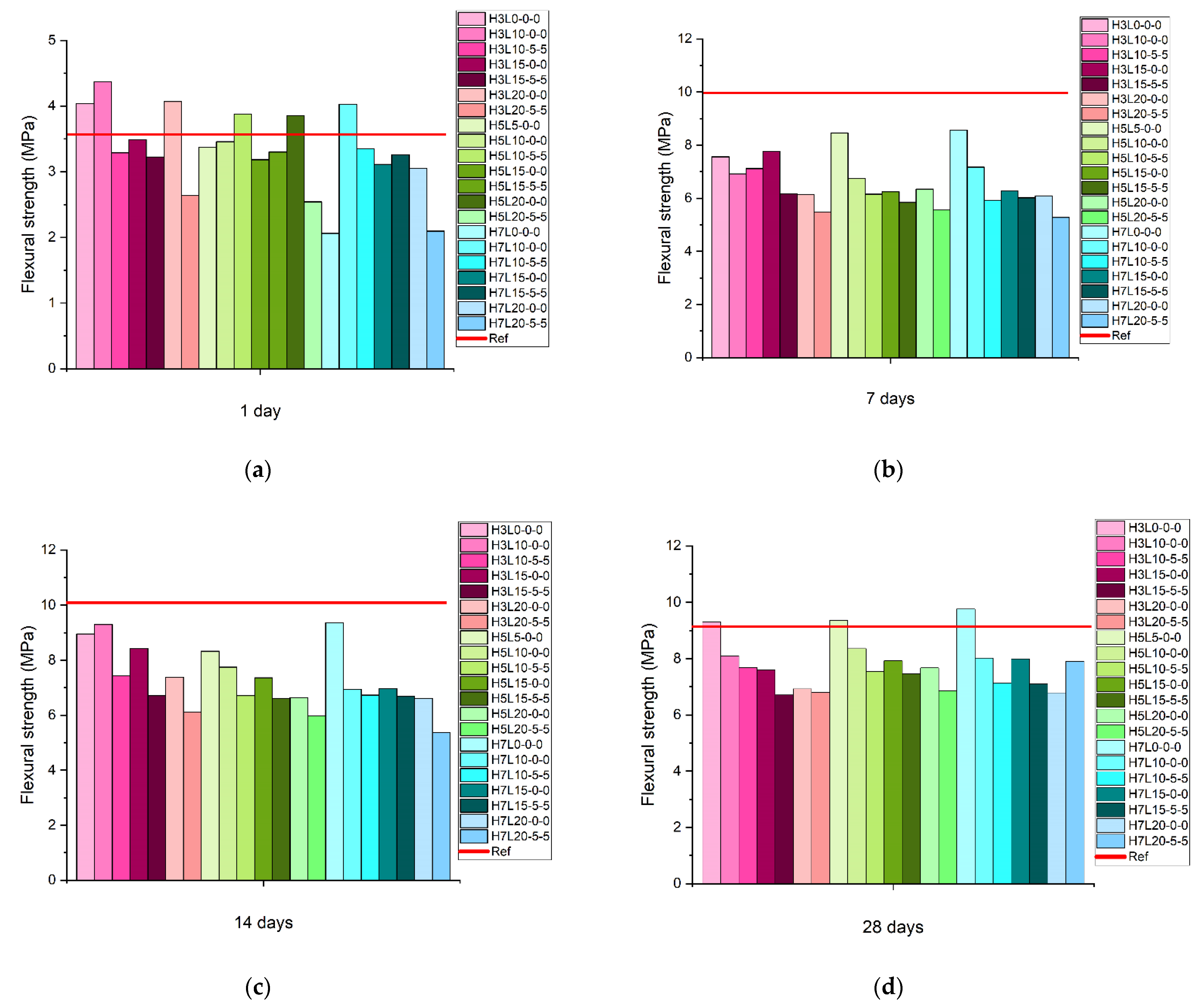

3.1. Flexural Strength

3.2. Compressive Strength

4. Conclusions

- The coarse silica fume has a less impact on the nucleation effect than the ground limestone at early ages (1 day).

- The nucleation and filler effects at early ages are less pronounced in coarse and very fine limestone powder. Furthermore, limestone with a fineness similar to that of cement is more effective, with regard to the mechanical strength, than the finest limestone.

- The highest compressive strength at 28 days is reached with the lowest silica fume content (3%). Accordingly, the coarse silica fume enhances compressive strength due to the pozzolanic reaction at low levels of replacement. By contrast, higher substitution contents provide a slight dilution effect, which will reduce the mechanical performance of cement-based materials.

- Apparently, the loss in compressive strength at high limestone replacement levels is independent of its particle size. Nevertheless, a concern of the blending process of the ultrafine limestone is the proper dispersion of the particles.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Council of the European Union. ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality; COM/2021/550 Final; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; Council of the European Union: Brussels, Belgium, 2021; Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52021DC0550&from=EN (accessed on 8 September 2021).

- European Commission. A New Industrial Strategy for Europe. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee and the Committee of the Regions; European Comission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/info/sites/info/files/communication-eu-industrial-strategymarch-2020_en.pdf (accessed on 8 May 2021).

- Sanjuán, M.A.; Argiz, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake in the Roadmap 2050 of the Spanish Cement Industry. Energies 2020, 13, 3452. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C.; Mora, P.; Zaragoza, A. Carbon Dioxide Uptake by Cement-Based Materials: A Spanish Case Study. Appl. Sci. 2020, 10, 339. [Google Scholar] [CrossRef] [Green Version]

- WBCSD; IEA. Technology Roadmap: Low-Carbon Transition in the Cement Industry; IEA: Paris, France, 2018. [Google Scholar]

- Wongkeo, W.; Thongsanitgarn, P.; Ngamjarurojana, A.; Chaipanich, A. Compressive strength and chloride resistance of self-compacting concrete containing high level fly ash and silica fume. Mater. Des. 2014, 64, 261–269. [Google Scholar] [CrossRef]

- Bonavetti, V.L.; Castellano, C.; Donza, H.; Rahhal, V.F.; Irassar, E.F. Cement with silica fume and granulated blast-furnace slag: Strength behavior and hydration. Mater. Construcc. 2014, 64, e025. [Google Scholar] [CrossRef] [Green Version]

- Courard, L.; Michel, F. Limestone fillers cement-based composites: Effects of blast furnace slags on fresh and hardened properties. Constr. Build. Mater. 2014, 51, 439–445. [Google Scholar] [CrossRef] [Green Version]

- Lo, F.-H.; Lee, M.-G.; Lo, S.-L. Effect of coal ash and rice husk ash partial replacement in ordinary Portland cement on pervious concrete. Constr. Build. Mater. 2021, 286, 122947. [Google Scholar] [CrossRef]

- Reiterman, P.; Jaskulski, R.; Kubissa, W.; Holčapek, O.; Keppert, M. Assessment of Rational Design of Self-Compacting Concrete Incorporating Fly Ash and Limestone Powder in Terms of Long-Term Durability. Materials 2020, 13, 2863. [Google Scholar] [CrossRef]

- Bentz, D.P. Activation energies of high-volume fly ash ternary blends: Hydration and setting. Cem. Concr. Compos. 2014, 53, 214–223. [Google Scholar] [CrossRef]

- Cao, M.; Ming, X.; He, K.; Li, L.; Shen, S. Effect of macro-, micro- and nano-calcium carbonate on properties of cementitious composites—A review. Materials 2019, 12, 781. [Google Scholar] [CrossRef] [Green Version]

- Kępniak, M.; Woyciechowski, P.; Franus, W. Transition Zone Enhancement with Waste Limestone Powder as a Reason for Concrete Compressive Strength Increase. Materials 2021, 14, 7254. [Google Scholar] [CrossRef]

- Menéndez, E.; Sanjuán, M.Á.; García-Roves, R.; Argiz, C.; Recino, H. Sustainable and Durable Performance of Pozzolanic Additions to Prevent Alkali-Silica Reaction (ASR) Promoted by Aggregates with Different Reaction Rates. Appl. Sci. 2020, 10, 9042. [Google Scholar] [CrossRef]

- Roux, N.; Andrade, C.; Sanjuan, M.A. Experimental Study of Durability of Reactive Powder Concretes. J. Mater. Civ. Eng. 1996, 8, 1–6. [Google Scholar] [CrossRef]

- Marchetti, G.; Rahhal, V.F.; Irassar, E.F. Influence of packing density and water film thickness on early-age properties of cement pasteswith limestone filler and metakaolin. Mater. Struct. 2017, 50, 111. [Google Scholar] [CrossRef]

- Knop, Y.; Peled, A. Packing density modeling of blended cement with limestone having different particle sizes. Constr. Build. Mater. 2016, 102, 44–50. [Google Scholar] [CrossRef]

- Ye, G.; Liu, X.; De Schutter, G.; Poppe, A.M.; Taerwe, L. Influence of limestone powder used as filler in SCC on hydration and microstructure of cement pastes. Cem. Concr. Compos. 2007, 29, 94–102. [Google Scholar] [CrossRef]

- Moon, G.D.; Oh, S.; Jung, S.H.; Choi, Y.C. Effects of the fineness of limestone powder and cement on the hydration and strength development of PLC concrete. Constr. Build. Mater. 2017, 135, 129–136. [Google Scholar] [CrossRef]

- Zajac, M.; Rossberg, A.; Le Saout, G.; Lothenbach, B. Influence of limestone and anhydrite on the hydration of Portland cements. Cem. Concr. Compos. 2014, 46, 99–108. [Google Scholar] [CrossRef]

- Balonis, M.; Glasser, F.P. The density of cement phases. Cem. Concr. Res. 2009, 39, 733–739. [Google Scholar] [CrossRef]

- De Weerdt, K.; Kjellsen, K.O.; Sellevold, E.; Justnes, H. Synergy between fly ash and limestone powder in ternary cements. Cem. Concr. Compos. 2011, 33, 30–38. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; Carro-López, D.; de Brito, J.; Martínez-Abella, F.; Seara-Paz, S.; Gutiérrez-Mainar, S. Comparison of ground bottom ash and limestone as additions in blended cements. Mater. Struct 2017, 50, 84. [Google Scholar] [CrossRef]

- Dhandapani, Y.; Santhanam, M.; Kaladharan, G.; Ramanathan, S. Towards ternary binders involving limestone additions—A review. Cem. Concr. Res. 2021, 143, 106396. [Google Scholar] [CrossRef]

- Fernández, Á.; Alonso, M.C.; García-Calvo, J.L.; Lothenbach, B. Influence of the synergy between mineral additions and Portland cement in the physical-mechanical properties of ternary binders. Mater. Construcc. 2016, 66, e097. [Google Scholar] [CrossRef] [Green Version]

- Mohamed, A.R.; Elsalamawy, M.; Ragab, M. Modeling the influence of limestone addition on cement hydration. Alex. Eng. J. 2015, 54, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Sanjuán, M.Á.; Argiz, C.; Gálvez, J.C.; Moragues, A. Effect of silica fume fineness on the improvement of Portland cement strength performance. Constr. Build. Mater. 2015, 96, 55–64. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Andrade, C. Reactive Powder Concrete: Durability and Applications. Appl. Sci. 2021, 11, 5629. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of silica fume on mechanical properties of high-strength concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Wild, S.; Sabir, B.B.; Khatib, J.M. Factors influencing strength development of concrete containing silica fume. Cem. Concr. Res. 1995, 25, 1567–1580. [Google Scholar] [CrossRef]

- Wong, H.S.; Razak, H.A. Efficiency of calcined kaolin and silica fume as cement replacement material for strength performance. Cem. Concr. Res. 2005, 35, 696–702. [Google Scholar] [CrossRef] [Green Version]

- Bentur, A.; Goldman, A.; Cohen, M.D. Contribution of transition zone to the strength of high-quality silica fume concretes. In ‘Bonding in Cementitious Composites’, Proceedings of Materials Research Society Symposium, 1st ed.; Mindess, S., Shah, S.P., Eds.; Materials Research Society: Pittsburgh, PA, USA, 1987; Volume 114, pp. 97–103. [Google Scholar] [CrossRef]

- Bhanja, S.; Sengupta, B. Influence of silica fume on the tensile strength of concrete. Cem. Concr. Res. 2005, 35, 743–747. [Google Scholar] [CrossRef]

- EN 13263-1:2005+A1:2009; Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2009.

- EN 16622:2015; Silica-Calcium Fume for Concrete—Definitions, Requirements and Conformity Criteria. European Committee for Standardization (CEN): Brussels, Belgium, 2015.

- EN 196-2:2014; Method of Testing Cement—Part 2: Chemical Analysis of Cement. European Committee for Standardization (CEN): Brussels, Belgium, 2014.

- EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. Spanish Association for Standardization (UNE): Madrid, Spain, 2016.

- Huang, H.; Shen, X.-d. Analysis of variance for testing method of cement in determination of strength. Prog. Nat. Sci. Mater. Int. 2011, 21, 341–346. [Google Scholar] [CrossRef] [Green Version]

- Sanjuán, M.A.; Estévez, E.; Argiz, C.; del Barrio, D. Effect of curing time on granulated blast-furnace slag cement mortars carbonation. Cem. Concr. Compos. 2018, 90, 257–265. [Google Scholar] [CrossRef]

- Gołaszewski, J.; Cygan, G.; Gołaszewska, M. Analysis of the effect of various types of limestone as a main constituent of cement on the chosen properties of cement pastes and mortars. Arch. Civ. Eng. 2019, 65, 75–86. [Google Scholar] [CrossRef] [Green Version]

- De Weerdt, K.; Ben Haha, M.; Le Saout, G.; Kjellsen, K.O.O.; Justnes, H.; Lothenbach, B. Hydration mechanisms of ternary Portland cements containing limestone powder and fly ash. Cem. Concr. Res. 2011, 41, 279–291. [Google Scholar] [CrossRef]

- Vance, K.; Aguayo, M.; Oey, T.; Sant, G.; Neithalath, N. Hydration and strength development in ternary Portland cement blends containing limestone and fly ash or metakaolin. Cem. Concr. Compos. 2013, 39, 93–103. [Google Scholar] [CrossRef]

- Ibáñez-Gosálvez, J.; Real-Herraiz, T.; Ortega, J.M. Microstructure, Durability and Mechanical Properties of Mortars Prepared Using Ternary Binders with Addition of Slag, Fly Ash and Limestone. Appl. Sci. 2021, 11, 6388. [Google Scholar] [CrossRef]

- De Weerdt, K.; Sellevold, E.; Kjellsen, K.O.; Justnes, H. Fly ash–limestone ternary cements: Effect of component fineness. Adv. Cem. Res. 2011, 23, 203–214. [Google Scholar] [CrossRef]

- Fernández, A.; Lothenbach, B.; Alonso, M.C.; García Calvo, J.L. Thermodynamic modelling of short and long term hydration of ternary binders. Influence of Portland cement composition and blast furnace slag content. Constr. Build. Mater. 2018, 166, 510–521. [Google Scholar] [CrossRef]

- Kasaniya, M.; Thomas, M.D.A.; Moffatt, E.G. Development of rapid and reliable pozzolanic reactivity test method. ACI Mater. J. 2019, 116, 145–154. [Google Scholar] [CrossRef]

- Chen, J.J.; Kwan, A.K.H.; Ng, P.L.; Li, L.G. Packing density improvement through addition of limestone fines, superfine cement and condensed silica fume. J. Mater. Sci. Chem. Eng. 2016, 4, 29–36. [Google Scholar] [CrossRef]

- Winters, D.; Boakye, K.; Simske, S. Toward Carbon-Neutral Concrete through Biochar–Cement–Calcium Carbonate Composites: A Critical Review. Sustainability 2022, 14, 4633. [Google Scholar] [CrossRef]

- Bonavetti, V.; Donza, H.; Menéndez, G.; Cabrera, O.; Irassar, E.F. Limestone filler cement in low w/c concrete: A rational use of energy. Cem. Concr. Res. 2003, 33, 865–871. [Google Scholar] [CrossRef]

- Mohammadi, I.; South, W. The influence of the higher limestone content of General Purpose cement according to high-strength concrete test results and construc-tion field data. Mater. Struct. 2016, 49, 4621–4636. [Google Scholar] [CrossRef]

- Proske, T.; Rezvani, M.; Palm, S.; Müller, C.; Graubner, C.-A.A. Concretes made of efficient multi-composite cements with slag and limestone. Cem. Concr. Compos. 2018, 89, 107–119. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; Eiras-López, J.; Seara-Paz, S. Comparing circulating fluidised bed fly ash and limestone as additions for cement. Mag. Concr. Res. 2019, 71, 1302–1311. [Google Scholar] [CrossRef]

- Frigione, G.; Marra, S. Relationship between particle size distribution and compressive strength in Portland cement. Cem. Concr. Res. 1976, 6, 113–127. [Google Scholar] [CrossRef]

| Chemical Composition (%) | CEM I 42.5 R | Coarse Silica Fume | Limestone |

|---|---|---|---|

| CaO | 63.02 | 0.39 | 46.26 |

| SiO2 | 19.80 | 96.09 | 3.35 |

| Al2O3 | 4.55 | 0.14 | 1.57 |

| SO3 | 3.16 | 0.09 | 0.07 |

| Fe2O3 | 2.67 | 0.07 | 0.37 |

| MgO | 1.93 | 0.12 | 0.30 |

| K2O | 0.89 | 0.42 | 0.22 |

| Na2O | 0.29 | 0.19 | 0.05 |

| SrO | 0.07 | 0.02 | |

| Cl− | 0.03 | ||

| TiO2 | 0.22 | 0.06 | |

| P2O5 | 0.15 | ||

| MnO | 0.01 | ||

| LOI 1 | 3.21 | 2.50 | 47.70 |

| Na2Oeq 1 | 0.88 | 0.47 | 0.20 |

| CEM I 42.5 R | Coarse Silica Fume | Limestone | |||

|---|---|---|---|---|---|

| C3S | 66.48% | Amorphous | 99.12% | Calcite | 93.25% |

| Amorphous | 11.36% | Quartz | 0.88% | Quartz | 2.04% |

| C4AF | 6.97% | Amorphous | 4.74% | ||

| Gypsum | 6.38% | ||||

| C2S | 5.99% | ||||

| C3A | 2.44% | ||||

| Calcite | 0.38% | ||||

| Raw Materials | Density (g/cm3) | Specific Surface Area, Blaine (cm2/g) |

|---|---|---|

| CEM I 42.5R | 3.16 | 3522 |

| Limestone 10 | 2.77 | 8001 |

| Limestone 20 | 2.64 | 25,857 |

| Limestone 50 | 2.77 | 25,944 |

| Coarse silica fume | 1.85 | 451 |

| Code | CEM I | Coarse Silica Fume | Limestone 10 | Limestone 20 | Limestone 50 |

|---|---|---|---|---|---|

| Reference 1 | 100 | 0 | 0 | 0 | 0 |

| H3L0-0-0 | 97 | 3 | 0 | 0 | 0 |

| H3L10-0-0 | 87 | 10 | 0 | 0 | |

| H3L10-5-5 | 77 | 10 | 5 | 5 | |

| H3L15-0-0 | 82 | 15 | 0 | 0 | |

| H3L-15-5-5 | 72 | 15 | 5 | 5 | |

| H3L20-0-0 | 77 | 20 | 0 | 0 | |

| H3L20-5-5 | 67 | 20 | 5 | 5 | |

| H5L5-0-0 | 95 | 5 | 0 | 0 | 0 |

| H5-10-0-0 | 85 | 10 | 0 | 0 | |

| H5L10-5-5 | 75 | 10 | 5 | 5 | |

| H5L15-0-0 | 80 | 15 | 0 | 0 | |

| H5L15-5-5 | 70 | 15 | 5 | 5 | |

| H5L20-0-0 | 75 | 20 | 0 | 0 | |

| H5L20-5-5 | 65 | 20 | 5 | 5 | |

| H7L0-0-0 | 93 | 7 | 0 | 0 | 0 |

| H7L10-0-0 | 83 | 10 | 0 | 0 | |

| H7L10-5-5 | 73 | 10 | 5 | 5 | |

| H7L15-0-0 | 78 | 15 | 0 | 0 | |

| H7L15-5-5 | 68 | 15 | 5 | 5 | |

| H7L20-0-0 | 73 | 20 | 0 | 0 | |

| H7L20-5-5 | 63 | 20 | 5 | 5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanjuán, M.Á.; Menéndez, E.; Recino, H. Mechanical Performance of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements. Materials 2022, 15, 2933. https://doi.org/10.3390/ma15082933

Sanjuán MÁ, Menéndez E, Recino H. Mechanical Performance of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements. Materials. 2022; 15(8):2933. https://doi.org/10.3390/ma15082933

Chicago/Turabian StyleSanjuán, Miguel Ángel, Esperanza Menéndez, and Hairon Recino. 2022. "Mechanical Performance of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements" Materials 15, no. 8: 2933. https://doi.org/10.3390/ma15082933

APA StyleSanjuán, M. Á., Menéndez, E., & Recino, H. (2022). Mechanical Performance of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements. Materials, 15(8), 2933. https://doi.org/10.3390/ma15082933