Mechanical Properties of Hybrid PVA–Natural Curaua Fiber Composites

Abstract

:1. Introduction

1.1. Curaua Fiber

1.2. SHCC with Curaua Fiber

1.3. Hybrid SHCC

2. Materials and Methods

2.1. Materials

2.1.1. Matrix

2.1.2. PVA Fiber

2.1.3. Curaua Fiber

2.1.4. Composites

2.2. Testing Methods

2.2.1. Compressive Strength

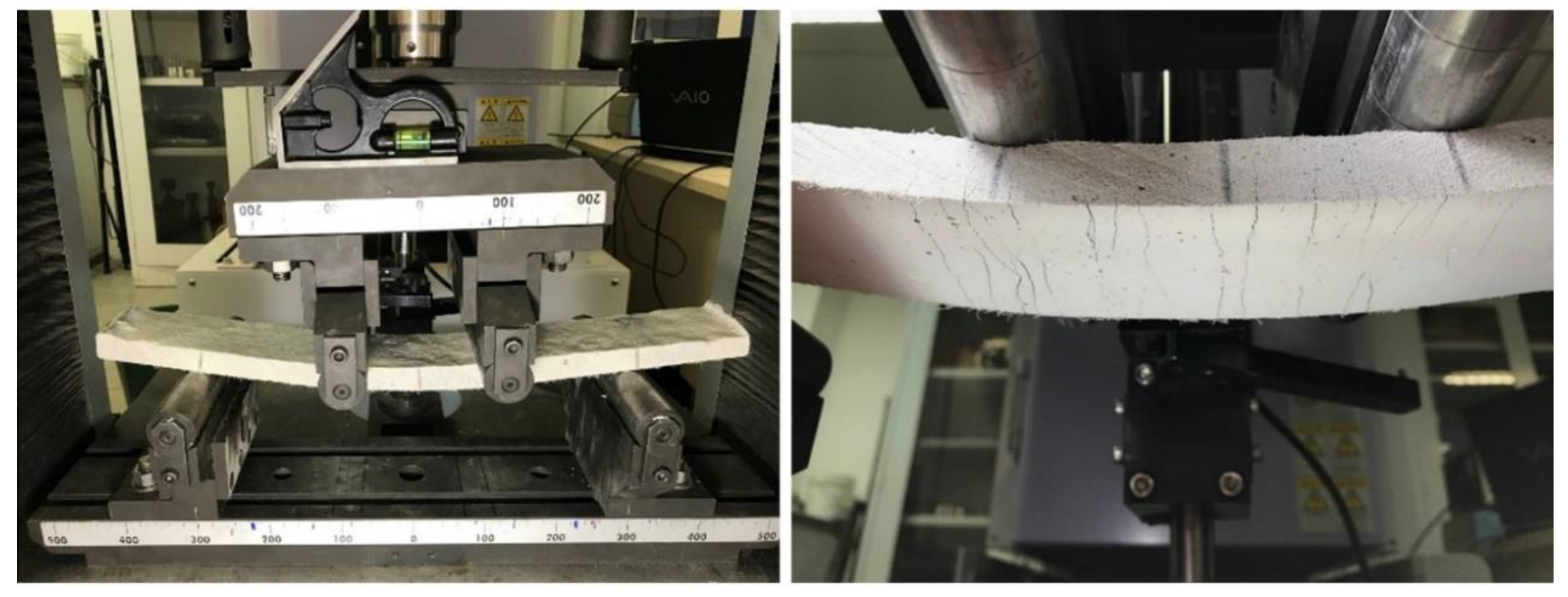

2.2.2. Flexural Strength

2.2.3. Tensile Strength and Crack Width Analysis

2.2.4. Matrix Workability

3. Results and Discussion

3.1. Thermal Analysis of the Cementitious Paste

3.2. Composites

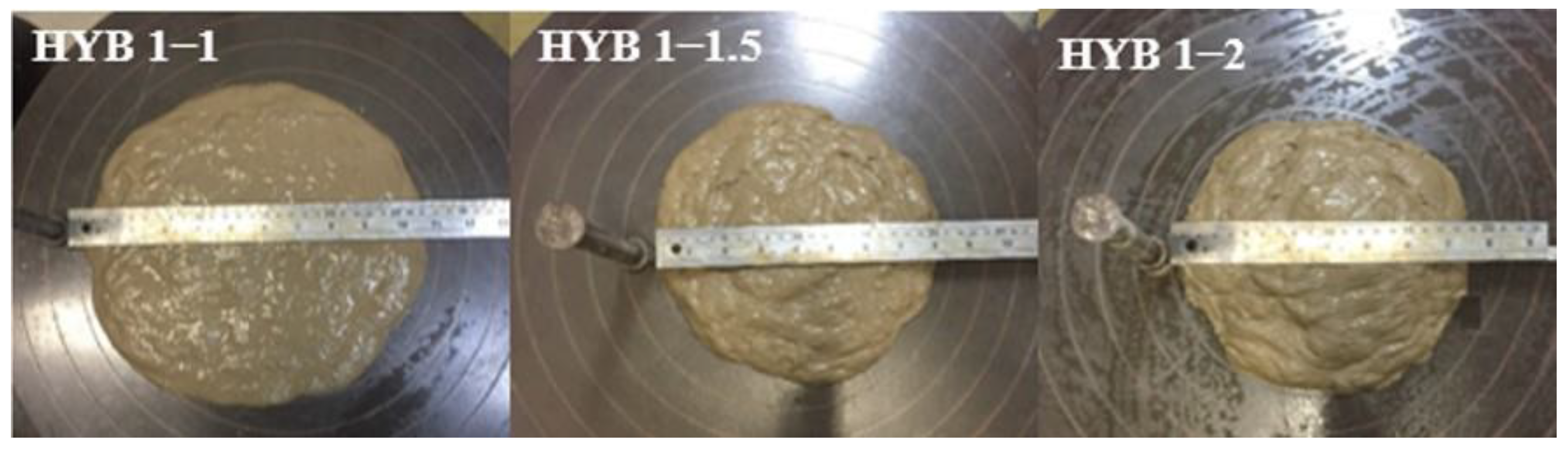

3.2.1. Mix Workability

3.2.2. Compressive Strength

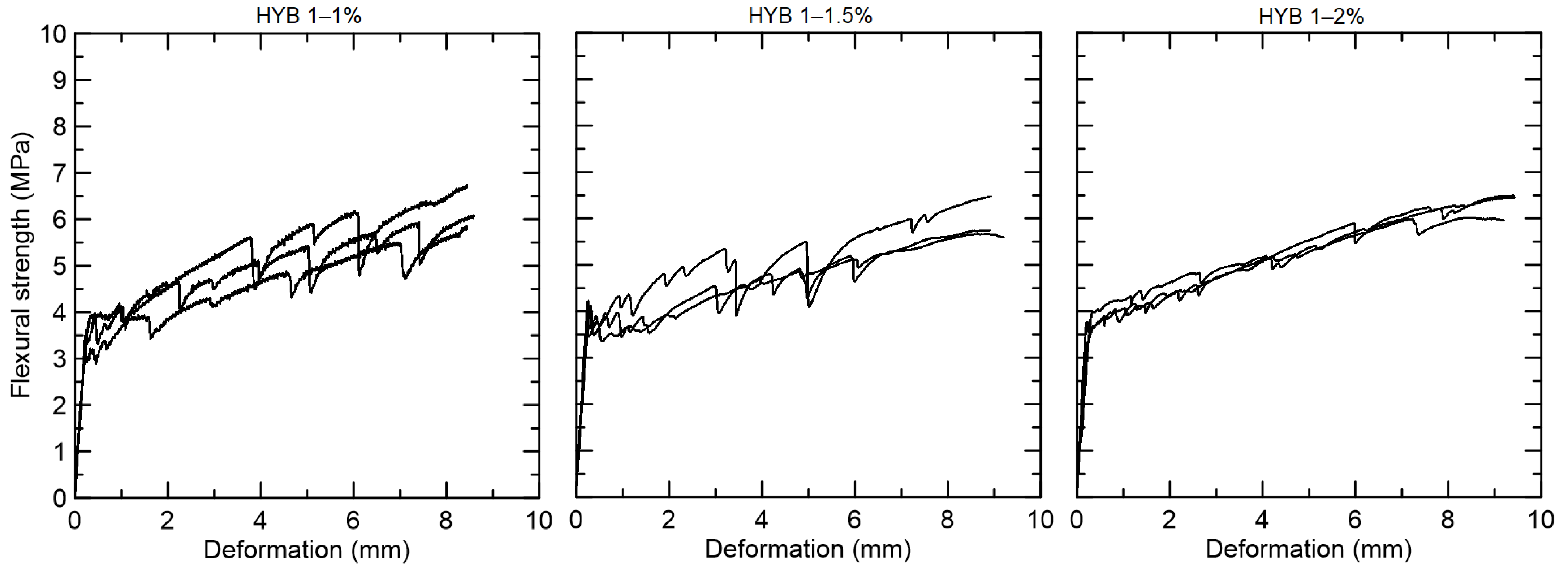

3.2.3. Flexural Strength

3.2.4. Tensile Strength

4. Conclusions

- -

- Workability of the mix is mostly influenced by the total fiber volume, and with a higher fiber volume, there are lower table flow spread values. All of the studied compositions presented good casting capacity.

- -

- Compressive strength is influenced by total fiber volume, and the higher the total fiber volume, the lower the compressive strength, especially for high volume fractions of vegetable fibers.

- -

- Composites reinforced with 2% PVA fiber presented deflection-hardening behavior and strain-hardening behavior. Similar behavior was achieved with a combination of 1% PVA fiber and 1.5% curaua fiber. The hybrid composites presented lower strain capacity in comparison to only-PVA fiber composites.

- -

- The application of short curaua fiber, along PVA fiber, creates an opportunity to achieve the strain-hardening behavior of composites with a lower volume of PVA fiber and similar workability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Van Zijl, G.P.A.G.; Wittmann, F.H.; Oh, B.H.; Kabele, P.; Toledo Filho, R.D.; Fairbairn, E.M.R.; Slowik, V.; Ogawa, A.; Hoshiro, H.; Mechtcherine, V.; et al. Durability of strain-hardening cement-based composites (SHCC). Mater. Struct. 2012, 45, 1447–1463. [Google Scholar] [CrossRef]

- Yang, E.H.; Li, V.C. Strain-hardening fiber cement optimization and component tailoring by means of a micromechanical model. Constr. Build. Mater. 2010, 24, 130–139. [Google Scholar] [CrossRef]

- Mitamura, H.; Sakata, N.; Akashiro, K.; Suda, K.; Hiraishi, T. Repair construction of steel deck with highly ductile fiber reinforced cement composites—Construction of Mihara bridge. Bridg. Found. 2005, 39, 88–91. [Google Scholar]

- Japan Society of Civil Engineers Recommendations for Design and Construction of High Performance Fiber Reinforced Cement Composites with Multiple Fine Cracks (HPFRCC). Concr. Eng. Ser. 2008, 82, 6–10.

- Fukuyama, H. Application of High Performance Fiber Reinforced Cementitious Composites for Damage Mitigation of Building Structures Case study on Damage Mitigation of RC Buildings with Soft First Story. J. Adv. Concr. Technol. 2006, 4, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Li, V.C.; Fischer, G.; Lepech, M. Shotcreting with ECC. Spritzbeton-Tag. 2009, 1–16. [Google Scholar]

- Liu, H.; Zhang, Q.; Gu, C.; Su, H.; Li, V.C. Influence of micro-cracking on the permeability of engineered cementitious composites. Cem. Concr. Compos. 2016, 72, 104–113. [Google Scholar] [CrossRef]

- Şahmaran, M.; Li, V. Engineered Cementitious Composites. Transp. Res. Rec. J. Transp. Res. Board 2010, 2164, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Zhang, P.; Wittmann, F.H.; Zhang, S.; Müller, H.S.; Zhao, T. Self-healing of Cracks in Strain Hardening Cementitious Composites Under Different Environmental Conditions. In Strain-Hardening Cement-Based Composites; Mechtcherine, V., Slowik, V., Kabele, P., Eds.; Springer: Dordrecht, The Netherlands, 2018; pp. 600–607. [Google Scholar]

- Onuaguluchi, O.; Banthia, N. Plant-based natural fibre reinforced cement composites: A review. Cem. Concr. Compos. 2016, 68, 96–108. [Google Scholar] [CrossRef]

- Reis, I.N.R.d.S.; Lameira, O.A.; Cordeiro, I.M.C.C. Desenvolvimento do Curauá (Ananas Erectifolius l.b. Smith) a Partir de Adubação Orgânica e de Npk. Semin. Iniciação Científica Embrapa Amaz. Orient.-VIII 2004, 332–334. [Google Scholar]

- Da Silveira Andrade, A.C.d.S.; Cordeiro, I.M.C.; Ferreira, G.C.; Neves, G.A.M.N. Potencialidades e usos do curauá em plantios florestais, 1st ed.; EDUFRA: Belém, Brazil, 2011; ISBN 978-85-7295-064-0. [Google Scholar]

- Gutiérrez, M.C.; De Paoli, M.A.; Felisberti, M.I. Cellulose acetate and short curauá fibers biocomposites prepared by large scale processing: Reinforcing and thermal insulating properties. Ind. Crops Prod. 2014, 52, 363–372. [Google Scholar] [CrossRef]

- D’Almeida, A.L.F.S.; Melo Filho, J.A.; Toledo Filho, R.D. Use of curaua fibers as reinforcement in cement composites. Chem. Eng. Trans. 2009, 17, 1717–1722. [Google Scholar] [CrossRef]

- Ferreira, S.R.; de Andrade Silva, F.; Lima, P.R.L.; Toledo Filho, R.D. Effect of hornification on the structure, tensile behavior and fiber matrix bond of sisal, jute and curaua fiber cement based composite systems. Constr. Build. Mater. 2017, 139, 551–561. [Google Scholar] [CrossRef]

- Soltan, D.G.; das Neves, P.; Olvera, A.; Savastano Junior, H.; Li, V.C. Introducing a curauá fiber reinforced cement-based composite with strain-hardening behavior. Ind. Crops Prod. 2017, 103, 1–12. [Google Scholar] [CrossRef]

- Zukowski, B.; de Andrade Silva, F.; Toledo Filho, R.D. Design of strain hardening cement-based composites with alkali treated natural curauá fiber. Cem. Concr. Compos. 2018, 89, 150–159. [Google Scholar] [CrossRef]

- Zukowski, B.; dos Santos, E.R.F.; dos Santos Mendonça, Y.G.; de Andrade Silva, F.; Toledo Filho, R.D. The durability of SHCC with alkali treated curaua fiber exposed to natural weathering. Cem. Concr. Compos. 2018, 94, 116–125. [Google Scholar] [CrossRef]

- Liu, J.; Lv, C. Properties of 3D-Printed Polymer Fiber-Reinforced Mortars: A Review. Polymers 2022, 14, 1315. [Google Scholar] [CrossRef]

- Coelho de Carvalho, L.M.; Dal Toé Casagrande, M. Mechanical behaviour of reinforced sand with natural curauá fibers through full scale direct shear tests. E3S Web Conf. 2019, 92, 1–5. [Google Scholar] [CrossRef]

- Liu, J.C.; Tan, K.H. Fire resistance of strain hardening cementitious composite with hybrid PVA and steel fibers. Constr. Build. Mater. 2017, 135, 600–611. [Google Scholar] [CrossRef]

- Yu, J.; Lu, C.; Chen, Y.; Leung, C.K.Y. Experimental determination of crack-bridging constitutive relations of hybrid-fiber Strain-Hardening Cementitious Composites using digital image processing. Constr. Build. Mater. 2018, 173, 359–367. [Google Scholar] [CrossRef]

- Yu, J.; Chen, Y.; Leung, C.K.Y. Micromechanical modeling of crack-bridging relations of hybrid-fiber Strain-Hardening Cementitious Composites considering interaction between different fibers. Constr. Build. Mater. 2018, 182, 629–636. [Google Scholar] [CrossRef]

- Lu, C.; Yu, J.; Leung, C.K.Y. Tensile performance and impact resistance of Strain Hardening Cementitious Composites (SHCC) with recycled fibers. Constr. Build. Mater. 2018, 171, 566–576. [Google Scholar] [CrossRef]

- Yu, J.; Yao, J.; Lin, X.; Li, H.; Lam, J.Y.K.; Leung, C.K.Y.; Sham, I.M.L.; Shih, K. Tensile performance of sustainable Strain-Hardening Cementitious Composites with hybrid PVA and recycled PET fibers. Cem. Concr. Res. 2018, 107, 110–123. [Google Scholar] [CrossRef]

- Yun, H. Do Effect of accelerated freeze-thaw cycling on mechanical properties of hybrid PVA and PE fiber-reinforced strain-hardening cement-based composites (SHCCs). Compos. Part B Eng. 2013, 52, 11–20. [Google Scholar] [CrossRef]

- Choi, W.C.; Jang, S.J.; Yun, H. Do Bond and cracking behavior of lap-spliced reinforcing bars embedded in hybrid fiber reinforced strain-hardening cementitious composite (SHCC). Compos. Part B Eng. 2017, 108, 35–44. [Google Scholar] [CrossRef]

- Melo Filho, J.D.A. Durabilidade Química e Térmica e Comportamento Mecânico de Compósitos de alto Desempenho Reforçados Com Fibras de Sisal João; Universidade Federal do Rio de Janeiro, COPPE/UFRJ: Rio de Janeiro, Brazil, 2012. [Google Scholar]

- 3-1. RECS15/RECS100L/RFS400—Kuralon. Available online: http://kuralon-frc.kuraray.com/product-application/for-mortar/recs (accessed on 4 March 2022).

- Zukowski, B.; de Andrade Silva, F.; Toledo Filho, R.D. The Influence of Hot Water Washing Cycles on Tensile Properties of Curauá Fiber. In Proceedings of the 17th International Conference on Non-Conventional Materials and Technologies (17th NOCMAT 2017), Merida, Mexico, 26–29 November 2017; pp. 516–526. [Google Scholar]

- Fan, L.T.; Gharpuray, M.M.; Lee, Y.H. Biotechnology Monographs—Cellulose Hydrolysis; Springer: Berlin, Germany, 1987; Volume 3, ISBN 978-3-642-72577-7. [Google Scholar]

- Zhou, J.; Qian, S.; Ye, G.; Copuroglu, O.; van Breugel, K.; Li, V.C. Improved fiber distribution and mechanical properties of engineered cementitious composites by adjusting the mixing sequence. Cem. Concr. Compos. 2012, 34, 342–348. [Google Scholar] [CrossRef]

- ABNT NBR 13276; Argamassa para assentamento e revestimento de paredes e tetos—Preparo da mistura e determinação o índice de consistência. Brazilian National Standards Organization: Sao Paulo, Brazil, 2002.

- Dweck, J.; Buchler, P.M.; Cartledge, F.K. The effect of different bentonites on cement hydration during solidification/stabilization of tannery wastes. J. Therm. Anal. Calorim. 2001, 64, 1011–1016. [Google Scholar] [CrossRef]

| Fiber | Diameter (µm) | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Failure Strain (%) | Reference |

|---|---|---|---|---|---|---|

| PVA | 1.30 | 1.30 | 600–2500 | 5–50 | 6–17 | [19] |

| PE | 7–150 | 0.96 | 200–300 | 5–6 | 3–4 | [19] |

| PP | 20–70 | 0.91 | 300–700 | 3.5–11 | 15–25 | [19] |

| Curaua | 90 | 1.29 | 605 | 23 | 2.5 | [20] |

| Cement | Metakaolin | Fly Ash | Sand | Water | Glenium | Rheomac | |

|---|---|---|---|---|---|---|---|

| kg/m3 | 361.85 | 289.85 | 434.22 | 542.78 | 417.97 | 24.67 | 0.87 |

| Oxide | Cement | Metakaolin | Fly Ash |

|---|---|---|---|

| Al2O3 | 3.78 | 41.69 | 28.24 |

| SiO2 | 13.64 | 51.85 | 51.58 |

| Fe2O3 | - | 1.91 | - |

| TiO2 | 0.30 | 1.38 | 1.3 |

| SO3 | 3.97 | 1.09 | 1.51 |

| K2O | 0.39 | 1.89 | 3.39 |

| ZrO2 | - | 0.03 | - |

| BaO | - | - | - |

| Cr2O3 | - | 0.01 | - |

| MnO | 0.06 | - | 1.51 |

| ZnO | 0.05 | - | - |

| SrO | 0.30 | - | - |

| CaO | 73.09 | - | 1.94 |

| CuO | 0.02 | - | - |

| Composite | PVA | Curaua | Total |

|---|---|---|---|

| PVA 0.5 | 0.5 | 0 | 0.5 |

| PVA 1 | 1 | 0 | 1 |

| PVA 2 | 2 | 0 | 2 |

| HYB 0.5–2 | 0.5 | 2 | 2.5 |

| HYB 0.5–2.5 | 0.5 | 2.5 | 3 |

| HYB 0.5–3 | 0.5 | 3 | 3.5 |

| HYB 1–1 | 1 | 1 | 2 |

| HYB 1–1.5 | 1 | 1.5 | 2.5 |

| HYB 1–2 | 1 | 2 | 3 |

| Composite | Compressive Strength [MPa] | Flexural Strength at First Crack [MPa] | Tensile Strength at First Crack [MPa] | Tensile Maximum Strength [MPa] | Table Flow [mm] |

|---|---|---|---|---|---|

| PVA 0.5 | 45.53 ± 2.04 | 5.18 ± 0.24 | 1.50 ± 0.09 | 1.50 ± 0.09 | 385 |

| PVA 1 | 41.46 ± 1.18 | 5.77 ± 0.74 | 1.65 ± 0.26 | 2.39 ± 0.34 | 340 |

| PVA 2 | 35.86 ± 1.76 | 5.72 ± 0.24 | 1.95 ± 0.12 | 3.12 ± 0.23 | 260 |

| HYB 0.5–2 | 29.59 ± 1.22 | 3.90 ± 0.04 | 2.07 ± 0.32 | 2.07 ± 0.32 | 200 |

| HYB 0.5–2.5 | 29.74 ± 0.85 | 4.49 ± 0.42 | 2.06 ± 0.23 | 2.06 ± 0.23 | 190 |

| HYB 0.5–3 | 26.26 ± 0.84 | 3.92 ± 0.55 | 1.63 ± 0.04 | 1.82± 0.11 | 185 |

| HYB 1–1 | 32.24 ± 0.74 | 3.56 ± 0.29 | 1.39 ± 0.18 | 1.91 ± 0.18 | 265 |

| HYB 1–1.5 | 31.93 ± 1.21 | 4.01 ± 0.26 | 1.92 ± 0.10 | 2.53 ± 0.20 | 210 |

| HYB 1–2 | 29.77 ± 192 | 3.96 ± 0.20 | 1.84 ± 0.06 | 2.23 ± 0.19 | 195 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zukowski, B.; dos Santos Mendonça, Y.G.; Tavares, I.J.K.; Toledo Filho, R.D. Mechanical Properties of Hybrid PVA–Natural Curaua Fiber Composites. Materials 2022, 15, 2808. https://doi.org/10.3390/ma15082808

Zukowski B, dos Santos Mendonça YG, Tavares IJK, Toledo Filho RD. Mechanical Properties of Hybrid PVA–Natural Curaua Fiber Composites. Materials. 2022; 15(8):2808. https://doi.org/10.3390/ma15082808

Chicago/Turabian StyleZukowski, Bartosz, Yasmim Gabriela dos Santos Mendonça, Igor José Koury Tavares, and Romildo Dias Toledo Filho. 2022. "Mechanical Properties of Hybrid PVA–Natural Curaua Fiber Composites" Materials 15, no. 8: 2808. https://doi.org/10.3390/ma15082808

APA StyleZukowski, B., dos Santos Mendonça, Y. G., Tavares, I. J. K., & Toledo Filho, R. D. (2022). Mechanical Properties of Hybrid PVA–Natural Curaua Fiber Composites. Materials, 15(8), 2808. https://doi.org/10.3390/ma15082808