Evaluation of the Mechanical Properties and Drilling of Glass Bead/Fiber-Reinforced Polyamide 66 (PA66)-Based Hybrid Polymer Composites

Abstract

:1. Introduction

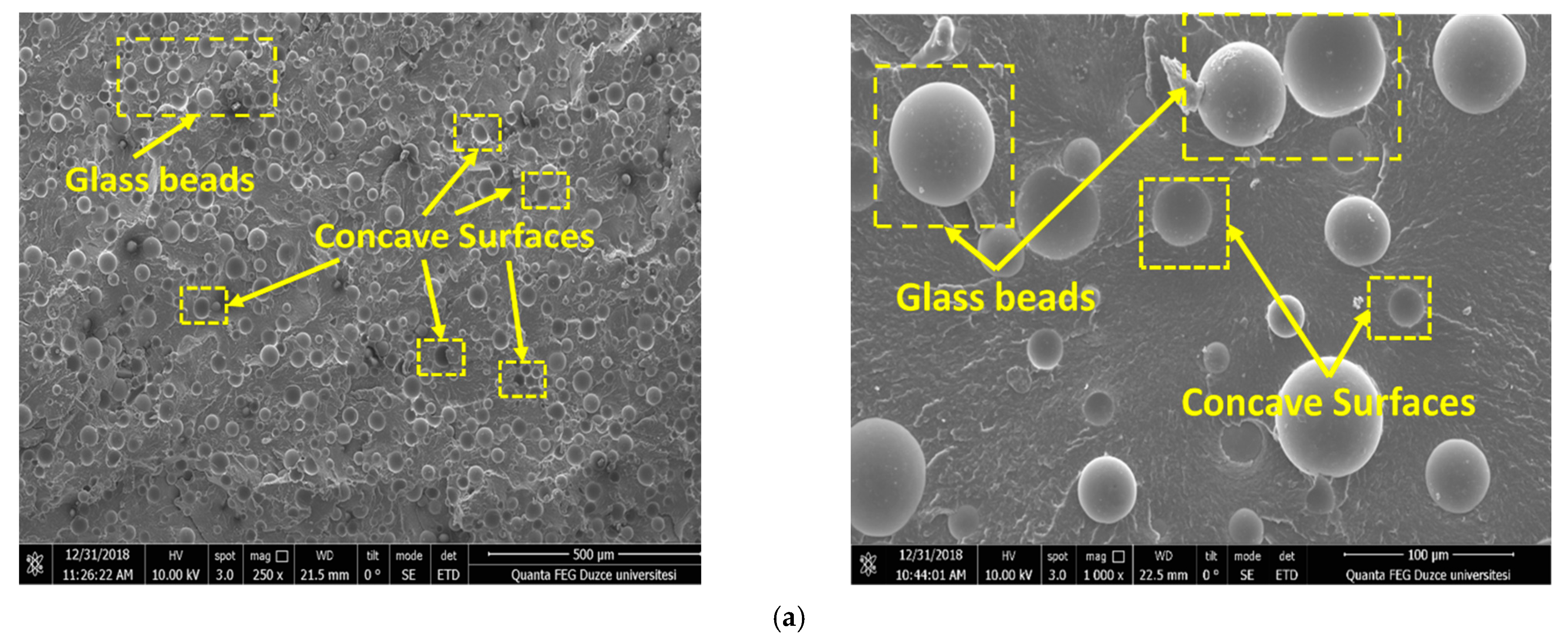

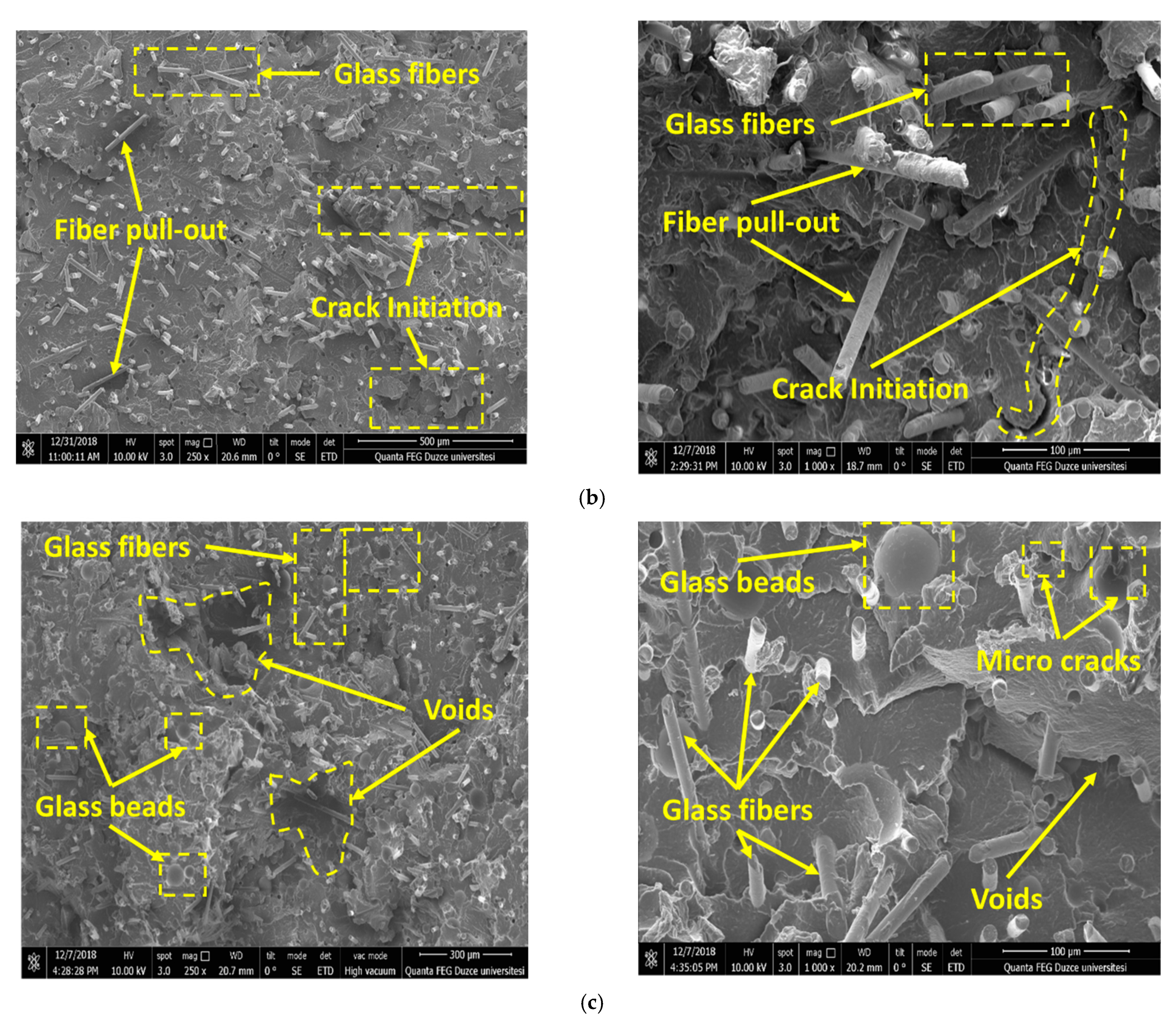

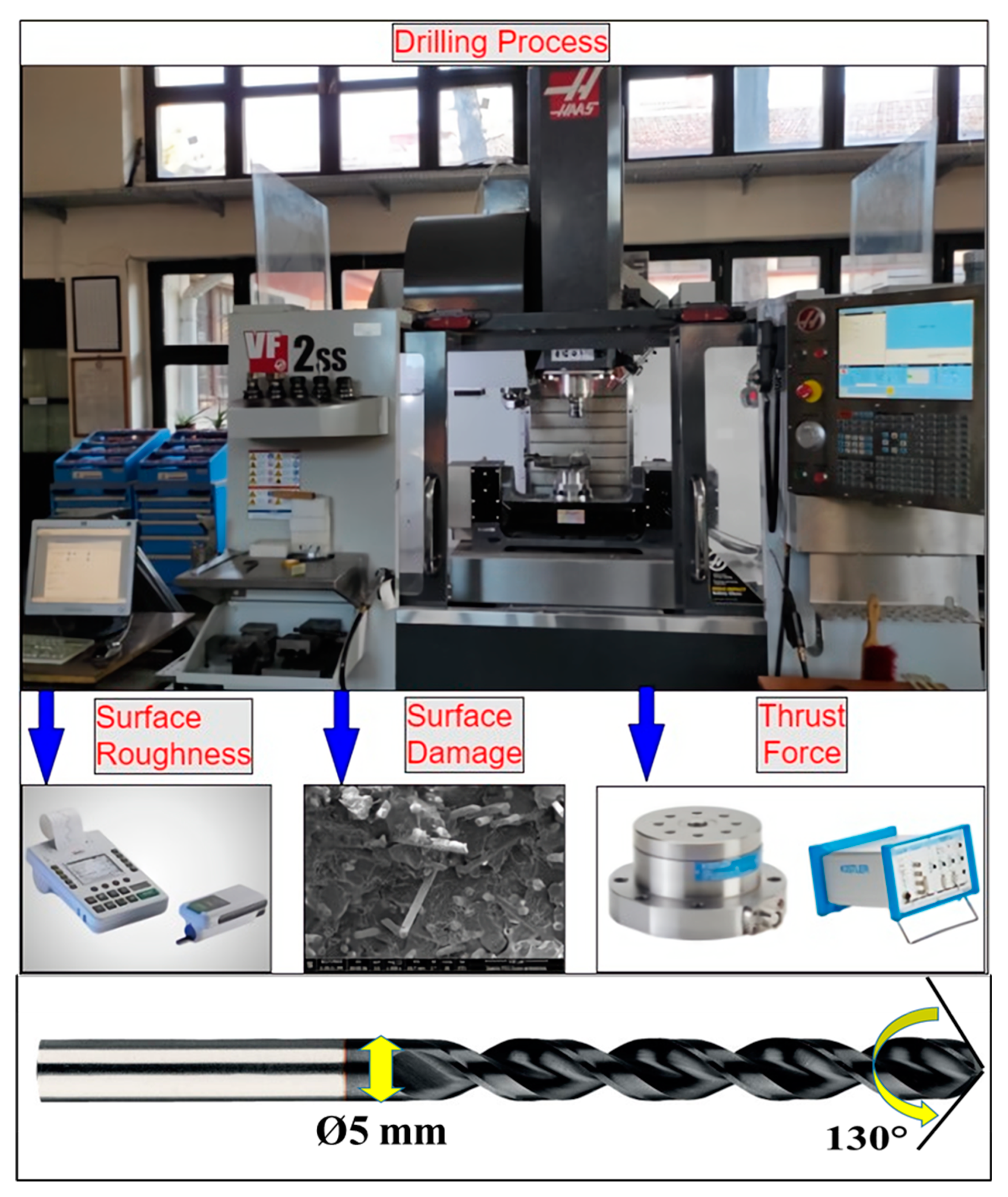

2. Materials and Methods

3. Results and Discussion

3.1. Mechanical Properties

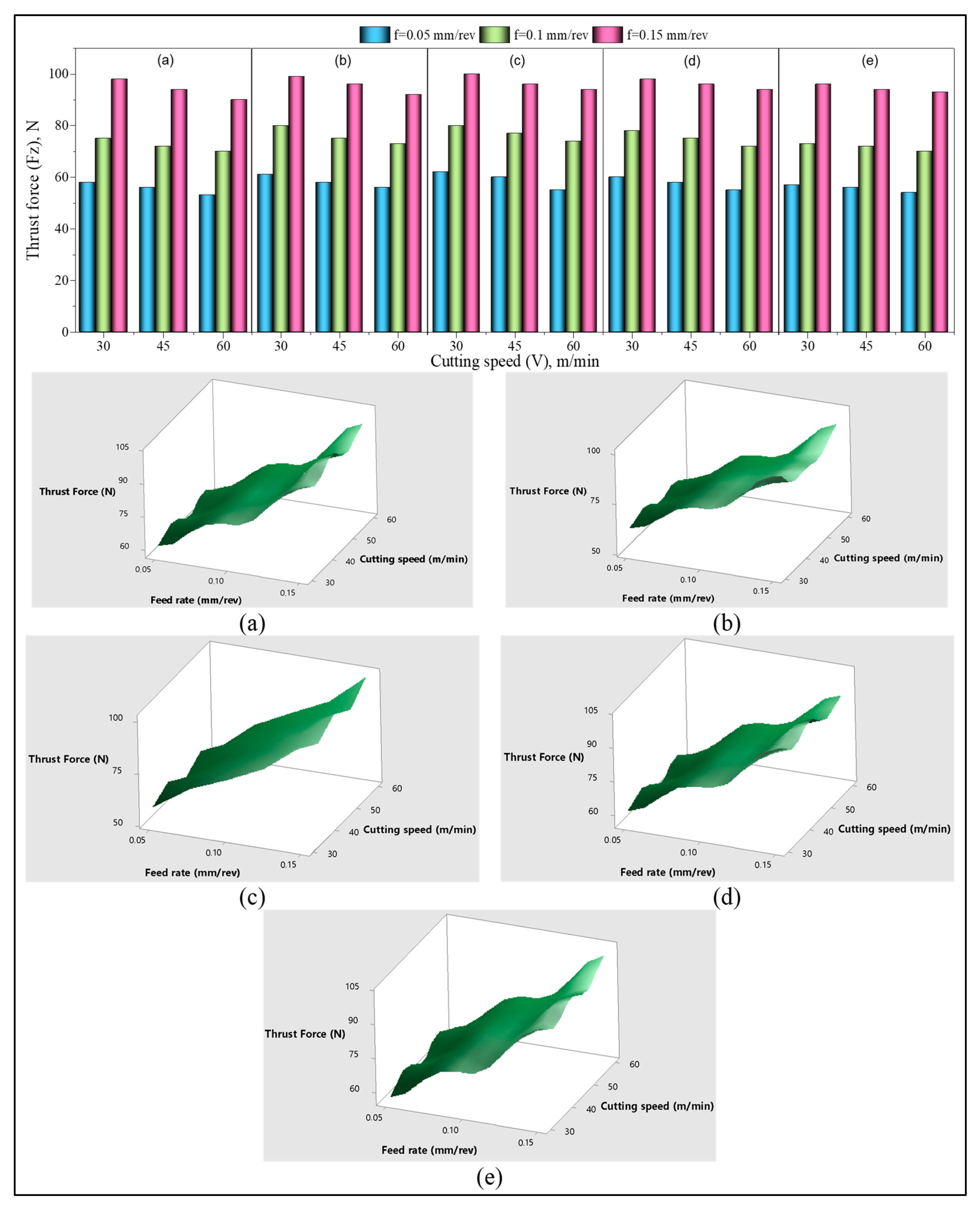

3.2. Assessment of Thrust Force (Fz)

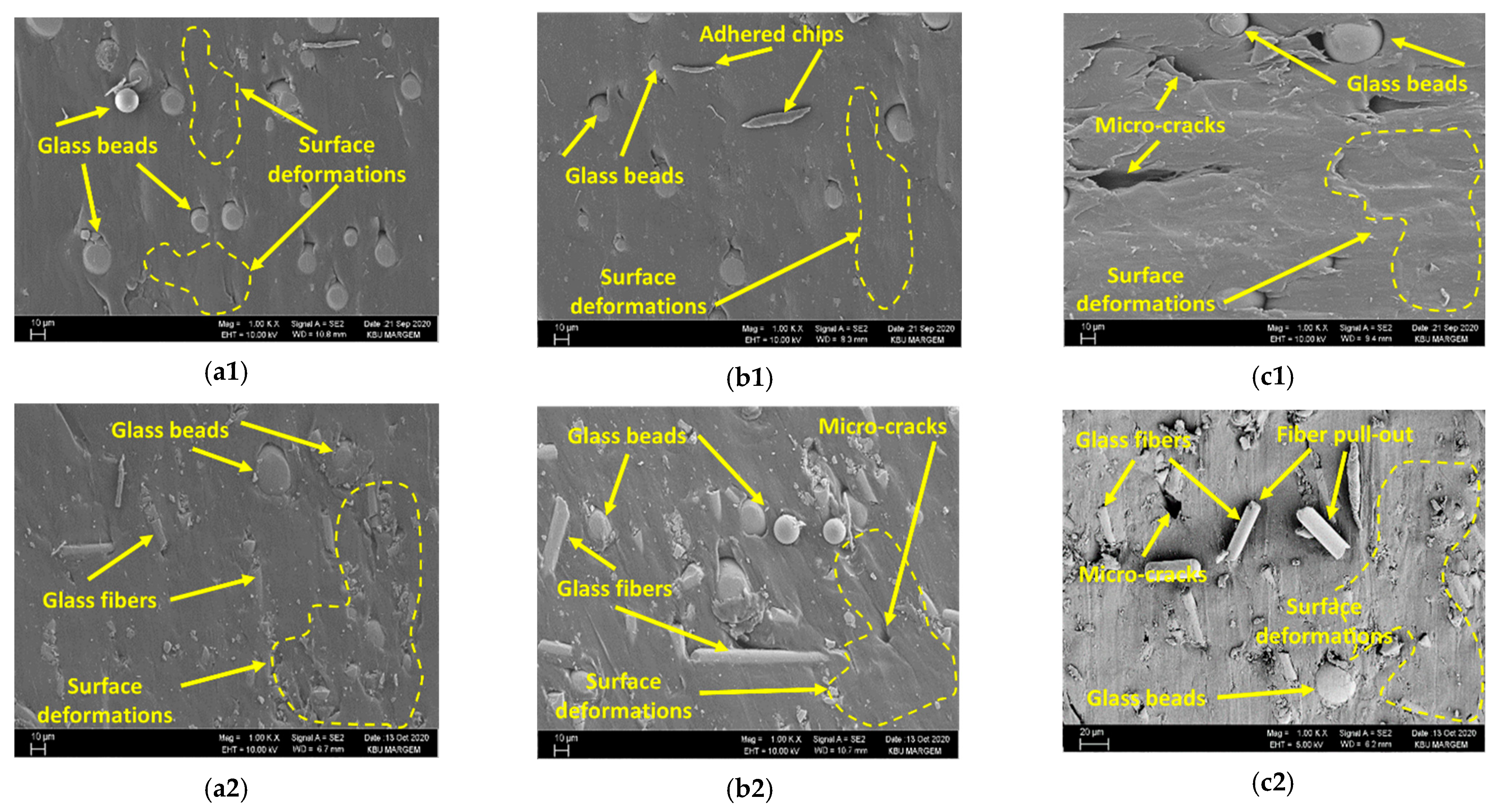

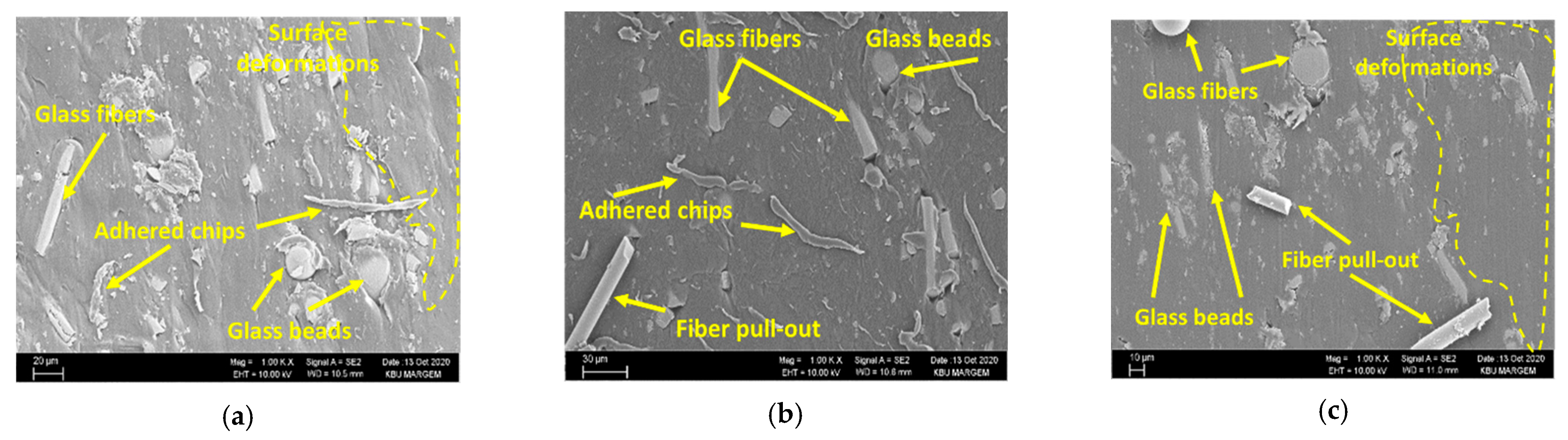

3.3. Assessment of Surface Texture by Surface Roughness (Ra)

4. Conclusions

- The sample reinforced with 30% GF has the highest strength, coefficient of elasticity, impact strength, and hardness. Impressive improvements were obtained for the strength—approximately 92% (142 MPa)—and the sample exhibited a coefficient of elasticity of approximately 186% (8390 MPa) compared to PA66.

- Among the six samples produced, the very best mechanical properties were obtained within the sample PA66 + 20% GF + 10% GB, with 127 MPa for lastingness and 7470 MPa for the modulus of elasticity.

- Thrust forces show an increasing trend of about 100–200% with higher feed rate values consistent with the graphs, while a decreasing tendency of about 50–100% is observed with increasing cutting speed. The ANOVA supports the experimental graphs that indicate that the feed rate is noticed because of the major factor on the thrust force (96.94%).

- Surface roughness indicates a decreasing tendency of about 50–100% with the rise in cutting speed. Additionally, a rise in the surface roughness is observed with the rise of 100–200% of the feed rate. This is consistent with the ANOVA results, which prove the validity of the graphs showing that material type (31.33%), cutting speed (3.65%), and feed rate (63.59%) affected the surface roughness at several levels.

- A major recommendation from this study is that a suitable combination should be preferred for the optimum machinability and mechanical properties of GF/GB-reinforced polymers instead of only using glass fibers or glass beads.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sharma, S.; Singh, J.; Gupta, M.K.; Mia, M.; Dwivedi, S.P.; Saxena, A.; Chattopadhyaya, S.; Singh, R.; Pimenov, D.Y.; Korkmaz, M.E. Investigation on mechanical, tribological and microstructural properties of Al–Mg–Si–T6/SiC/muscovite-hybrid metal-matrix composites for high strength applications. J. Mater. Res. Technol. 2021, 12, 1564–1581. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Koklu, U.; Morkavuk, S.; Featherston, C.; Haddad, M.; Sanders, D.; Aamir, M.; Pimenov, D.Y.; Giasin, K. The effect of cryogenic machining of S2 glass fibre composite on the hole form and dimensional tolerances. Int. J. Adv. Manuf. Technol. 2021, 115, 125–140. [Google Scholar] [CrossRef]

- Singer, R.; Ollick, A.M.; Elhadary, M. Effect of cross-head speed and temperature on the mechanical properties of polypropylene and glass fiber reinforced polypropylene pipes. Alex. Eng. J. 2021, 60, 4947–4960. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Abd-Elwahed, M.S.; Najjar, I.; Melaibari, A.; Ahmed, K.I.; Zitoune, R.; Eltaher, M.A. Heat-Affected Zone and Mechanical Analysis of GFRP Composites with Different Thicknesses in Drilling Processes. Polymers 2021, 13, 2246. [Google Scholar] [CrossRef]

- Foraboschi, P. Strengthening of Reinforced Concrete Beams Subjected to Concentrated Loads Using Externally Bonded Fiber Composite Materials. Materials 2022, 15, 2328. [Google Scholar] [CrossRef]

- Rahman, M.B.; Zhu, L. Low-Velocity Impact Response on Glass Fiber Reinforced 3D Integrated Woven Spacer Sandwich Composites. Materials 2022, 15, 2311. [Google Scholar] [CrossRef]

- Li, M.; Gan, G.; Zhang, Y.; Yang, X. Thermal damage of CFRP laminate in fiber laser cutting process and its impact on the mechanical behavior and strain distribution. Arch. Civ. Mech. Eng. 2019, 19, 1511–1522. [Google Scholar] [CrossRef]

- O’ Connor, H.J.; Dowling, D.P. Comparison between the properties of polyamide 12 and glass bead filled polyamide 12 using the multi jet fusion printing process. Addit. Manuf. 2020, 31, 100961. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhao, G.; Zaini, J.; Gupta, M.K.; Jamil, M.; He, N.; Nauman, M.M.; Mikolajczyk, T.; Pimenov, D.Y. Between-the-Holes Cryogenic Cooling of the Tool in Hole-Making of Ti-6Al-4V and CFRP. Materials 2021, 14, 795. [Google Scholar] [CrossRef]

- Danish, M.; Gupta, M.K.; Rubaiee, S.; Ahmed, A.; Mahfouz, A.; Jamil, M. Machinability investigations on CFRP composites: A comparison between sustainable cooling conditions. Int. J. Adv. Manuf. Technol. 2021, 114, 3201–3216. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Davim, J.P. On the Machining Temperature and Hole Quality of CFRP Laminates When Using Diamond-Coated Special Drills. J. Compos. Sci. 2022, 6, 45. [Google Scholar] [CrossRef]

- Khanna, N.; Agrawal, C.; Pimenov, D.Y.; Singla, A.K.; Machado, A.R.; da Silva, L.R.R.; Gupta, M.K.; Sarikaya, M.; Krolczyk, G.M. Review on design and development of cryogenic machining setups for heat resistant alloys and composites. J. Manuf. Process. 2021, 68, 398–422. [Google Scholar] [CrossRef]

- Yaşar, N.; Günay, M. Experimental investigation on novel drilling strategy of CFRP laminates using variable feed rate. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 150. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Abd-Elwahed, M.S.; Eltaher, M.A.; Najjar, I.; Melaibari, A.; Ahmed, K.I. Thermo-Mechanical and Delamination Properties in Drilling GFRP Composites by Various Drill Angles. Polymers 2021, 13, 1884. [Google Scholar] [CrossRef]

- Khanna, N.; Pusavec, F.; Agrawal, C.; Krolczyk, G.M. Measurement and evaluation of hole attributes for drilling CFRP composites using an indigenously developed cryogenic machining facility. Measurement 2020, 154, 107504. [Google Scholar] [CrossRef]

- Yaşar, N.; Günay, M. The Influences of Varying Feed Rate on Hole Quality and Force in Drilling CFRP Composite. Gazi Univ. J. Sci. 2017, 30, 39–50. [Google Scholar]

- Zhang, C.; Zhang, X.; Duan, Y.; Xia, Y.; Ming, Y.; Zhu, Y. Deformation Resistance Performance of Carbon Fiber-Reinforced Plastic Machined by Controlling Drilling Area Temperature below the Glass Transition Temperature. Materials 2021, 14, 1394. [Google Scholar] [CrossRef]

- Rodríguez, A.; Calleja, A.; de Lacalle, L.N.L.; Pereira, O.; Rubio-Mateos, A.; Rodríguez, G. Drilling of CFRP-Ti6Al4V stacks using CO2-cryogenic cooling. J. Manuf. Process. 2021, 64, 58–66. [Google Scholar] [CrossRef]

- Kacalak, W.; Lipiński, D.; Różański, R.; Królczyk, G.M. Assessment of the classification ability of parameters characterizing surface topography formed in manufacturing and operation processes. Measurement 2021, 170, 108715. [Google Scholar] [CrossRef]

- Erden, M.A.; Yaşar, N.; Korkmaz, M.E.; Ayvacı, B.; Nimel Sworna Ross, K.; Mia, M. Investigation of microstructure, mechanical and machinability properties of Mo-added steel produced by powder metallurgy method. Int. J. Adv. Manuf. Technol. 2021, 114, 2811–2827. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Çakıroğlu, R.; Yaşar, N.; Özmen, R.; Günay, M. Finite Element Analysis of Thrust Force in Drilling of Al2014 Aluminum Alloy. El-Cezerî J. Sci. Eng. 2019, 6, 193–199. [Google Scholar]

- Korkmaz, M.E.; Yaşar, N. FEM modelling of turning of AA6061-T6: Investigation of chip morphology, chip thickness and shear angle. J. Prod. Syst. Manuf. Sci. 2021, 2, 50–58. [Google Scholar]

- Latha, B.; Senthilkumar, V.S.; Palanikumar, K. Modeling and optimization of process parameters for delamination in drilling glass fiber reinforced plastic (GRFP) composites. Mach. Sci. Technol. 2011, 15, 172–191. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Senthil Kumar, M.; Zitoune, R.; Davim, J.P. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Gaitonde, V.N.; Karnik, S.R.; Rubio, J.C.C.; de Oliveira Leite, W.; Davim, J.P. Experimental studies on hole quality and machinability characteristics in drilling of unreinforced and reinforced polyamides. J. Compos. Mater. 2012, 48, 21–36. [Google Scholar] [CrossRef]

- Ficici, F.; Ayparcasi, Z. Effects of cutting parameters on delamination during drilling of Polyphthalamide (PPA) matrix composite material with 30% glass fiber reinforcement. Acta Phys. Pol. A 2015, 127, 1118–1120. [Google Scholar] [CrossRef]

- Palanikumar, K.; Srinivasan, T.; Rajagopal, K.; Latha, B. Thrust Force Analysis in Drilling Glass Fiber Reinforced/Polypropylene (GFR/PP) Composites. Mater. Manuf. Process. 2016, 31, 581–586. [Google Scholar] [CrossRef]

- Ramesh, B.; Elayaperumal, A.; Satishkumar, S.; Kumar, A. Drilling of pultruded and liquid composite moulded glass/epoxy thick composites: Experimental and statistical investigation. Measurement 2018, 114, 109–121. [Google Scholar] [CrossRef]

- Mudhukrishnan, M.; Hariharan, P.; Palanikumar, K. Measurement and analysis of thrust force and delamination in drilling glass fiber reinforced polypropylene composites using different drills. Measurement 2020, 149, 106973. [Google Scholar] [CrossRef]

- Mohan, N.S.; Kulkarni, S.M.; Ramachandra, A. Delamination analysis in drilling process of glass fiber reinforced plastic (GFRP) composite materials. J. Mater. Process. Technol. 2007, 186, 265–271. [Google Scholar] [CrossRef]

- Latha, B.; Senthilkumar, V.S. Fuzzy Rule Based Modeling of Drilling Parameters for Delamination in Drilling GFRP Composites. J. Reinf. Plast. Compos. 2008, 28, 951–964. [Google Scholar] [CrossRef]

- Karnik, S.R.; Gaitonde, V.N.; Rubio, J.C.; Correia, A.E.; Abrão, A.M.; Davim, J.P. Delamination analysis in high speed drilling of carbon fiber reinforced plastics (CFRP) using artificial neural network model. Mater. Des. 2008, 29, 1768–1776. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Chen, Y.-H.; An, Q.-L.; Cai, X.-J.; Ming, W.-W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Çelik, A.; Lazoglu, I.; Kara, A.; Kara, F. Investigation on the performance of SiAlON ceramic drills on aerospace grade CFRP composites. J. Mater. Process. Technol. 2015, 223, 39–47. [Google Scholar] [CrossRef]

- Davim, J.P.; Reis, P.; António, C.C. Experimental study of drilling glass fiber reinforced plastics (GFRP) manufactured by hand lay-up. Compos. Sci. Technol. 2004, 64, 289–297. [Google Scholar] [CrossRef]

- Yazman, Ş. The effects of back-up on drilling machinability of filament wound GFRP composite pipes: Mechanical characterization and drilling tests. J. Manuf. Process. 2021, 68, 1535–1552. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mahapatra, S.S.; Lamberti, L.; Pruncu, C.I. Prediction of welding responses using AI approach: Adaptive neuro-fuzzy inference system and genetic programming. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 53. [Google Scholar] [CrossRef]

- Boy, M.; Yaşar, N.; Çiftçi, İ. Experimental investigation and modelling of surface roughness and resultant cutting force in hard turning of AISI H13 Steel. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 12039. [Google Scholar] [CrossRef]

- Hashemi, S. Effect of temperature on tensile properties of injection moulded short glass fibre and glass bead filled ABS hybrids. Express Polym. Lett. 2008, 2, 474–484. [Google Scholar] [CrossRef]

- Singh, M.M.; Kumar, H.; Kumar, G.H.; Sivaiah, P.; Nagesha, K.V.; Ajay, K.M.; Vijaya, G. Determination of Strength Parameters of Glass Fibers Reinforced Composites for Engineering Applications. Silicon 2020, 12, 1–11. [Google Scholar] [CrossRef]

- Agrawal, A.; Chandraker, S.; Sharma, A. Physical, Mechanical and Sliding Wear Behavior of Solid Glass Microsphere Filled Epoxy Composites. Mater. Today Proc. 2020, 29, 420–426. [Google Scholar] [CrossRef]

- Yaşar, N. Thrust force modelling and surface roughness optimization in drilling of AA-7075: FEM and GRA. J. Mech. Sci. Technol. 2019, 33, 4771–4781. [Google Scholar] [CrossRef]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber–reinforced composites: A review on material, manufacturing, and machinability. J. Thermoplast. Compos. Mater. 2019, 34, 238–284. [Google Scholar] [CrossRef]

- Korkmaz, M.E. Verification of Johnson-Cook parameters of ferritic stainless steel by drilling process: Experimental and finite element simulations. J. Mater. Res. Technol. 2020, 9, 6322–6330. [Google Scholar] [CrossRef]

- Azmi, A.I. Chip formation studies in machining fibre reinforced polymer composites. Int. J. Mater. Prod. Technol. 2013, 46, 32–46. [Google Scholar] [CrossRef]

- Wongpajan, R.; Mathurosemontri, S.; Takematsu, R.; Xu, H.Y.; Uawongsuwan, P.; Thumsorn, S.; Hamada, H. Interfacial Shear Strength of Glass Fiber Reinforced Polymer Composites by the Modified Rule of Mixture and Kelly-Tyson Model. Energy Procedia 2016, 89, 328–334. [Google Scholar] [CrossRef] [Green Version]

- Yaşar, N.; Günay, M.; Kılık, E.; Ünal, H. Multiresponse optimization of drillability factors and mechanical properties of chitosan-reinforced polypropylene composite. J. Thermoplast. Compos. Mater. 2020, 0892705720939163. [Google Scholar] [CrossRef]

- Quadrini, F.; Squeo, E.A.; Tagliaferri, V. Machining of glass fiber reinforced polyamide. Express Polym. Lett. 2007, 1, 810–816. [Google Scholar] [CrossRef]

- Zimmermann, M.; Heberger, L.; Schneider, F.; Effgen, C.; Aurich, J.C. Investigation of Chip Formation and Workpiece Load When Machining Carbon-fiber-reinforced-polymer (CFRP). Procedia Manuf. 2016, 6, 124–131. [Google Scholar] [CrossRef] [Green Version]

- Gaitonde, V.N.; Karnik, S.R.; Rubio, J.C.; Abrão, A.M.; Correia, A.E.; Davim, J.P. Surface roughness analysis in high-speed drilling of unreinforced and reinforced polyamides. J. Compos. Mater. 2011, 46, 2659–2673. [Google Scholar] [CrossRef]

- Panneerselvam, T.; Raghuraman, S.; Kandavel, T.K.; Mahalingam, K. Evaluation and analysis of delamination during drilling on Sisal-Glass Fibres Reinforced Polymer. Measurement 2020, 154, 107462. [Google Scholar] [CrossRef]

- Merino-Pérez, J.L.; Royer, R.; Ayvar-Soberanis, S.; Merson, E.; Hodzic, A. On the temperatures developed in CFRP drilling using uncoated wc-co tools part I: Workpiece constituents, cutting speed and heat dissipation. Compos. Struct. 2015, 123, 161–168. [Google Scholar] [CrossRef] [Green Version]

- Amini, S.; Baraheni, M.; Hakimi, E. Enhancing dimensional accuracy and surface integrity by helical milling of carbon fiber reinforced polymers. Int. J. Light. Mater. Manuf. 2019, 2, 362–372. [Google Scholar] [CrossRef]

| Parameters | Levels | ||||

|---|---|---|---|---|---|

| Cutting speed (m/min) | 30 | 45 | 60 | ||

| Feed rate (mm/rev) | 0.05 | 0.1 | 0.15 | ||

| % ratio of reinforcements | 30% GFR | 30% GB | 20% GFR + 10% GB | 15% GFR + 15% GB | 10% GFR + 20% GB |

| Materials | Tensile Strength, MPa | Young Modulus, MPa | Strain at Fracture % | Izod Impact Energy kJ/m2 | Hardness (Shore D) |

|---|---|---|---|---|---|

| PA66 + 30% GB | 58.9 | 4210 | 5.6 | 4.69 | 79.8 |

| PA66 + 30% GFR | 142 | 8390 | 5.1 | 7.46 | 82.9 |

| PA66 + 20% GFR + 10% GB | 127 | 7470 | 5.4 | 4.79 | 82.3 |

| PA66 + 15% GFR + 15% GB | 112.1 | 6203 | 5.3 | 5.1 | 81.7 |

| PA66 + 10% GFR + 20% GB | 96.9 | 5160 | 5.6 | 6.17 | 81 |

| Source | DoF | SS | MS | F | p | PCR (%) |

|---|---|---|---|---|---|---|

| M | 4 | 97.30 | 24.33 | 47.10 | 0.000 | 0.87 |

| Vc | 2 | 213.30 | 106.67 | 206.45 | 0.000 | 1.90 |

| f | 2 | 10,904.10 | 5452.07 | 10,552.39 | 0.000 | 96.94 |

| M × Vc | 8 | 12.70 | 1.58 | 3.06 | 0.027 | 0.11 |

| M × f | 8 | 10.50 | 1.32 | 2.55 | 0.053 | 0.09 |

| V × f | 4 | 1.70 | 0.43 | 0.84 | 0.521 | 0.02 |

| Error | 16 | 8.30 | 0.52 | 0.07 | ||

| Total | 44 | 11,248.00 | 100.00 |

| Source | DoF | SS | MS | F | p | PCR (%) |

|---|---|---|---|---|---|---|

| M | 4 | 0.179347 | 0.044837 | 430.43 | 0.000 | 31.33 |

| Vc | 2 | 0.020938 | 0.010469 | 100.50 | 0.000 | 3.65 |

| f | 2 | 0.364084 | 0.182042 | 1747.61 | 0.000 | 63.59 |

| M × Vc | 8 | 0.000840 | 0.000105 | 1.01 | 0.467 | 0.15 |

| M × f | 8 | 0.005627 | 0.000703 | 6.75 | 0.001 | 0.98 |

| V × f | 4 | 0.000022 | 0.000006 | 0.05 | 0.994 | 0.01 |

| Error | 16 | 0.001667 | 0.000104 | 0.29 | ||

| Total | 44 | 0.572524 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Demirsöz, R.; Yaşar, N.; Korkmaz, M.E.; Günay, M.; Giasin, K.; Pimenov, D.Y.; Aamir, M.; Unal, H. Evaluation of the Mechanical Properties and Drilling of Glass Bead/Fiber-Reinforced Polyamide 66 (PA66)-Based Hybrid Polymer Composites. Materials 2022, 15, 2765. https://doi.org/10.3390/ma15082765

Demirsöz R, Yaşar N, Korkmaz ME, Günay M, Giasin K, Pimenov DY, Aamir M, Unal H. Evaluation of the Mechanical Properties and Drilling of Glass Bead/Fiber-Reinforced Polyamide 66 (PA66)-Based Hybrid Polymer Composites. Materials. 2022; 15(8):2765. https://doi.org/10.3390/ma15082765

Chicago/Turabian StyleDemirsöz, Recep, Nafiz Yaşar, Mehmet Erdi Korkmaz, Mustafa Günay, Khaled Giasin, Danil Yurievich Pimenov, Muhammad Aamir, and Huseyin Unal. 2022. "Evaluation of the Mechanical Properties and Drilling of Glass Bead/Fiber-Reinforced Polyamide 66 (PA66)-Based Hybrid Polymer Composites" Materials 15, no. 8: 2765. https://doi.org/10.3390/ma15082765

APA StyleDemirsöz, R., Yaşar, N., Korkmaz, M. E., Günay, M., Giasin, K., Pimenov, D. Y., Aamir, M., & Unal, H. (2022). Evaluation of the Mechanical Properties and Drilling of Glass Bead/Fiber-Reinforced Polyamide 66 (PA66)-Based Hybrid Polymer Composites. Materials, 15(8), 2765. https://doi.org/10.3390/ma15082765