Enhanced X-ray Emissions Arising from High Pulse Repetition Frequency Ultrashort Pulse Laser Materials Processing

Abstract

:1. Introduction

2. Experimental Section

3. Results

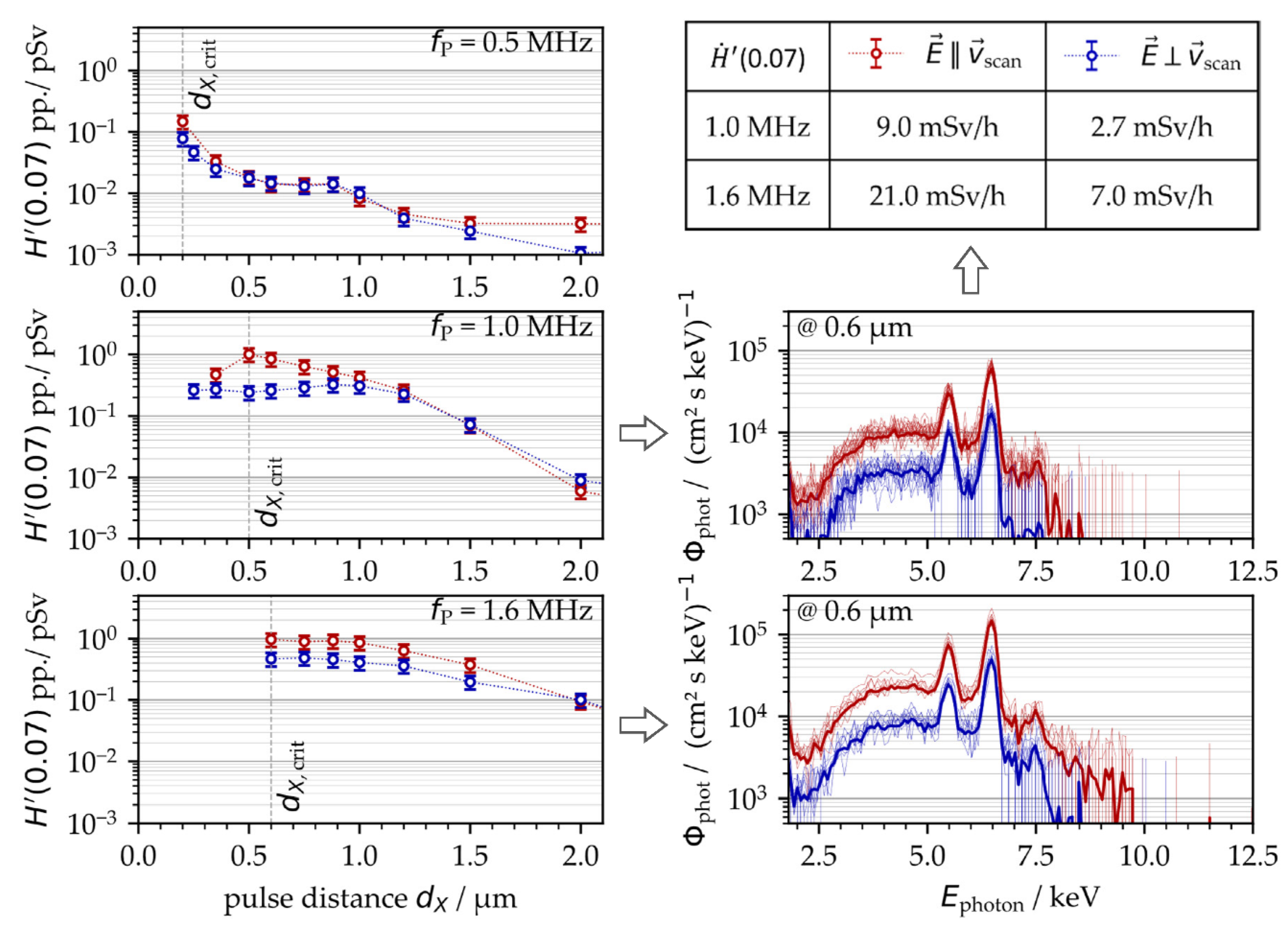

3.1. X-ray Emission as a Function of Intra-Line Pulse Distance

3.2. Influencing Effect of Dust and Fume Extraction on X-ray Emission

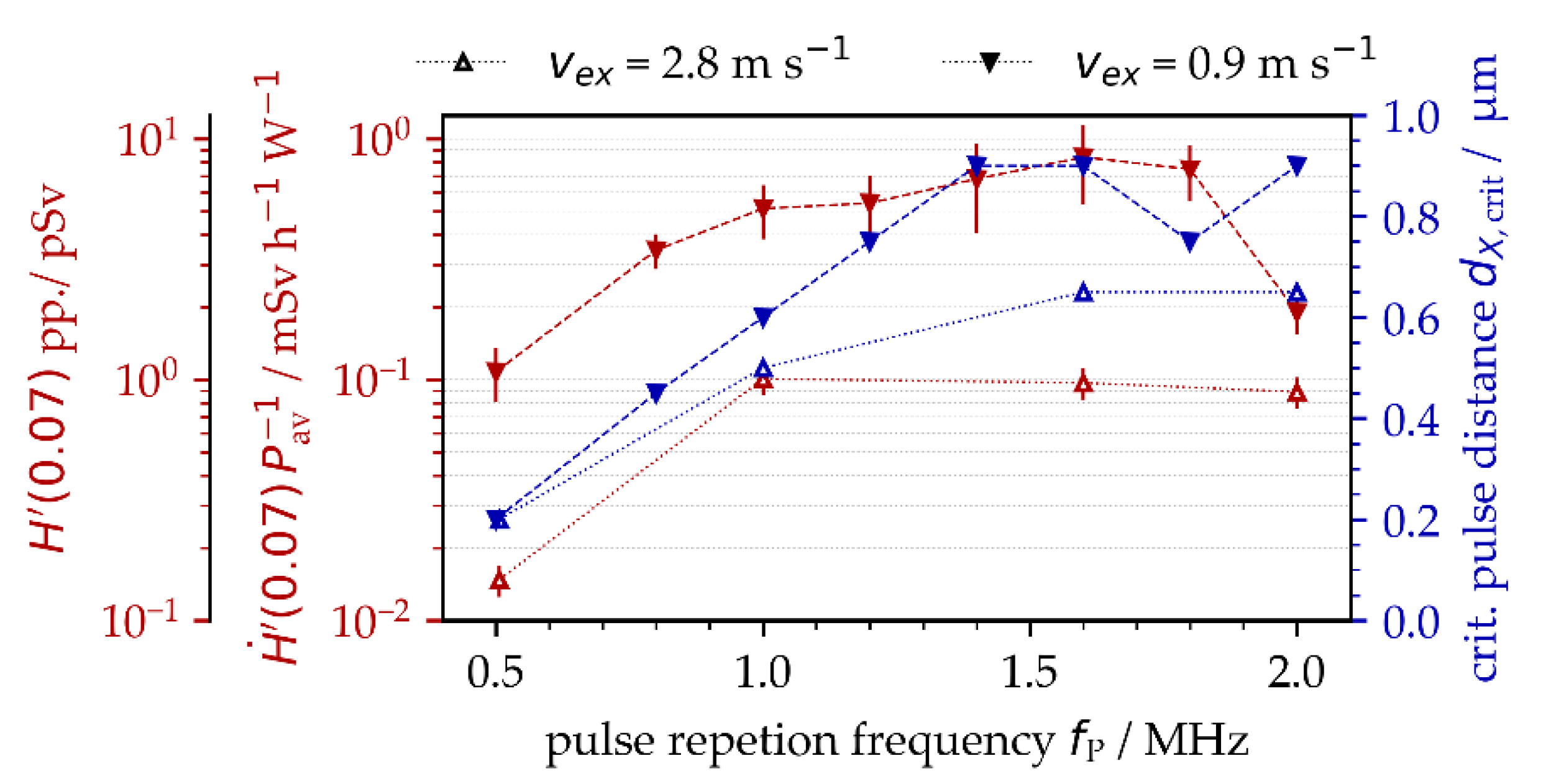

3.3. X-ray Emission as a Function of PRF and Polarization State

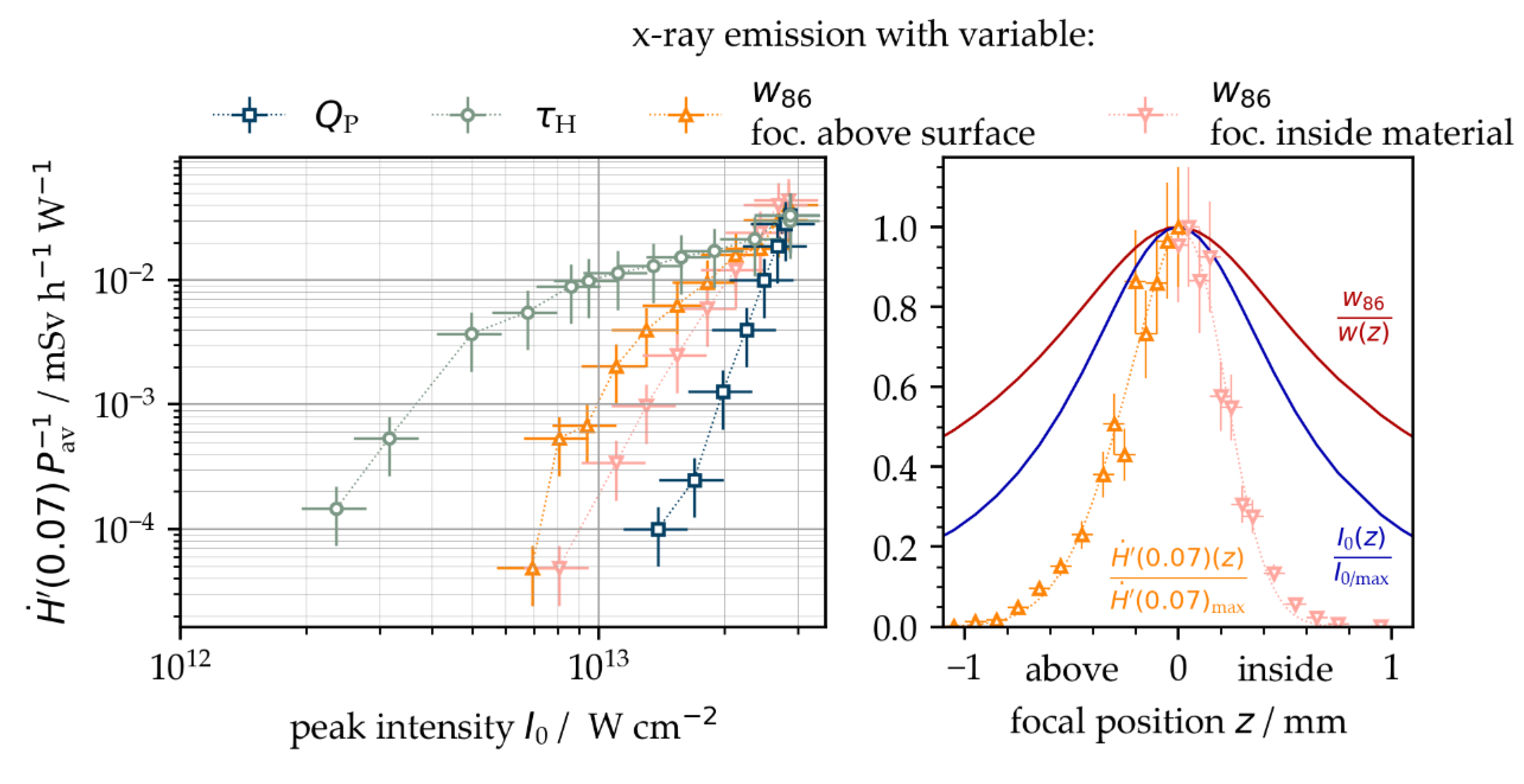

3.4. Influence of the Peak Intensity on X-ray Emission

4. Summary and Main Conclusions

- X-ray emission dose levels could increase up to ten-fold when ultrashort laser pulses irradiate at MHz PRF and submicrometer intra-line pulse distances;

- A critical intra-line distance depending on PRF existed for maximum X-ray emissions;

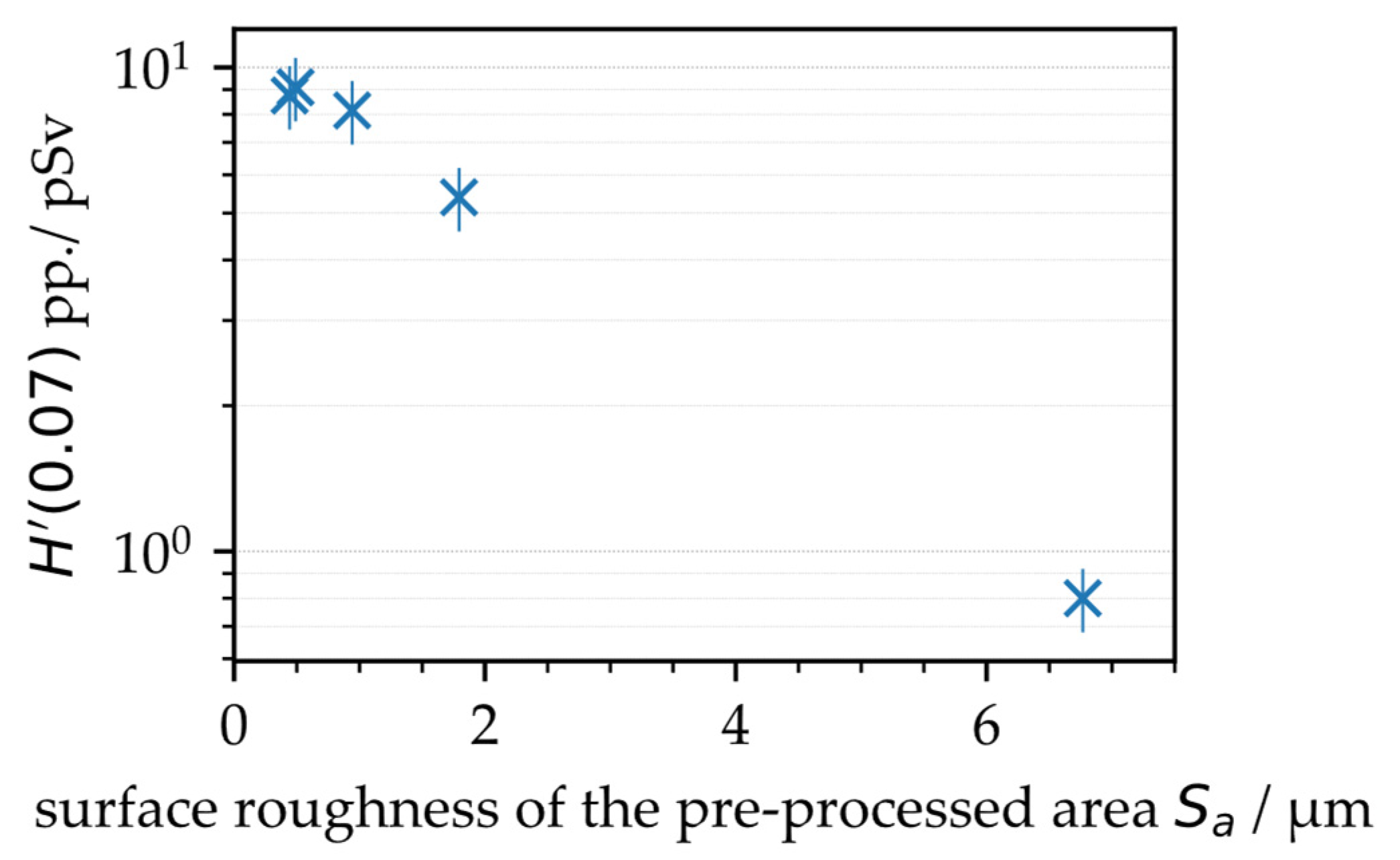

- Higher X-ray emissions could be released from smoother surfaces;

- The suction flow conditions in the laser processing area affected X-ray photon emissions, where higher suction flow speeds induced lower X-ray dose levels;

- A laser beam parallel-polarized to the beam moving direction induced higher X-ray emissions, which further confirmed plasma resonance absorption as an efficient laser beam absorption mechanism in a low-intense ultrashort pulse laser regime;

- Harmful X-ray emission dose rates exceeding the legal limit of 1 µSv/h could be generated with peak intensities below 1 × 1013 W/cm, and, finally;

- The peak intensity threshold value for X-ray emissions decreased with larger laser spot sizes and longer pulse durations.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Schille, J.; Löschner, U. Ultrashort pulse lasers in high-rate laser micro processing—Quo vadis? Adv. Opt. Technol. 2021, 10, 233–237. [Google Scholar] [CrossRef]

- Mosel, P.; Sankar, P.; Düsing, J.F.; Dittmar, G.; Püster, T.; Jäschke, P.; Vahlbruch, J.-W.; Morgner, U.; Kovacev, M. X-ray Dose Rate and Spectral Measurements during Ultrafast Laser Machining Using a Calibrated (High-Sensitivity) Novel X-ray Detector. Materials 2021, 14, 4397. [Google Scholar] [CrossRef] [PubMed]

- Weber, R.; Giedl-Wagner, R.; Förster, D.J.; Pauli, A.; Graf, T.; Balmer, J.E. Expected X-ray dose rates resulting from industrial ultrafast laser applications. Appl. Phys. A 2019, 125, 635. [Google Scholar]

- Raciukaitis, G.; Brikas, M.; Gečys, P.; Voisiat, B.; Gedvilas, M. Use of high repetition rate and high power lasers in microfabrication: How to keep the efficiency high? J. Laser Micro Nanoeng. 2008, 4, 186–191. [Google Scholar] [CrossRef]

- Neuenschwander, B.; Bucher, G.F.; Nussbaum, C.; Joss, B.; Muralt, M.; Hunziker, U.W.; Schuetz, P. Processing of metals and dielectric materials with ps laser pulses: Results, strategies, limitations and needs. In Proceedings of the Laser Applications in Microelectronic and Optoelectronic Manufacturing XV, San Francisco, CA, USA, 23–28 January 2010. [Google Scholar]

- Schille, J.; Schneider, L.; Löschner, U. Process optimization in high-average-power ultrashort pulse laser microfabrication: How laser process parameters influence efficiency, throughput and quality. Appl. Phys. A 2015, 120, 847–855. [Google Scholar] [CrossRef]

- Schille, J.; Kraft, S.; Pflug, T.; Scholz, C.; Clair, M.; Horn, A.; Löschner, U. Study on X-ray Emission Using Ultrashort Pulsed Lasers in Material Processing. Materials 2021, 14, 4537. [Google Scholar] [CrossRef] [PubMed]

- Kraft, S.; Schille, J.; Mauersberger, S.; Schneider, L.; Löschner, U. Pump-probe imaging for process control and optimization in high-speed laser micro machining. In Proceedings of the Laser-based Micro-and Nanoprocessing XIV, San Francisco, CA, USA, 1–6 February 2020. [Google Scholar]

- Ballmer, J.E.; Donaldson, T.P. Resonance Absorption of 1.06-μm Laser Radiation in Laser-Generated Plasma. Phys. Rev. Lett. 1977, 39, 17. [Google Scholar] [CrossRef]

- Teubner, U.; Bergmann, J.; van Wonterghem, B.; Schaefer, F.P.; Sauerbrey, R. Angle-dependent x-ray emission and resonance absorption in a laser-produced plasma generated by a high intensity ultrashort pulse. Phys. Rev. Lett. 1993, 70, 794. [Google Scholar] [CrossRef] [PubMed]

- Legall, H.; Schwanke, C.; Bonse, J.; Krüger, J. The influence of processing parameters on X-ray emission during ultra-short pulse laser machining. Appl. Phys. A 2019, 125, 570. [Google Scholar]

- Legall, H.; Schwanke, C.; Pentzien, S.; Dittmar, G.; Bonse, J.; Krüger, J. X-ray emission as a potential hazard during ultrashort pulse laser material processing. Appl. Phys. A 2018, 124, 407. [Google Scholar] [CrossRef] [Green Version]

- Freitag, C.; Giedl-Wagner, R. X-Ray Protection in an Industrial Production Environment. Photonics Views 2019, 17, 37. [Google Scholar] [CrossRef]

- Legall, H.; Bonse, J.; Krüger, J. Review of x-ray exposure and safety issues arising from ultra-short pulse laser material processing. J. Radiol. Prot. 2021, 41, R28. [Google Scholar] [CrossRef] [PubMed]

- Chichkov, B.N.; Momma, C.; Tünnermann, A.; Meyer, S.; Menzel, T.; Wellegehausen, B. Hard-x-ray radiation from short-pulse laser-produced plasmas. Appl. Phys. Lett. 1996, 68, 2804. [Google Scholar] [CrossRef]

- Kattan, D. Untersuchung der Röntgenemissionen durch laserinduzierte Plasmen in der Materialbear-beitung mit Ultrakurzpulslasern an Luft (written in German). Master’s Thesis, Heinrich Heine University, Düsseldorf, Germany, 18 August 2021. [Google Scholar]

- Metzner, D.; Olbrich, M.; Lickschat, P.; Horn, A.; Weißmantel, S. X-ray generation by laser ablation using MHz to GHz pulse bursts. J. Laser Appl. 2021, 33, 032014. [Google Scholar] [CrossRef]

- Dittmar, G. Arbeitsblatt 2: Zunahme der laserinduzierten ionisierenden Strahlung (LIS) bei größer werdender Fokusfläche trotz gleicher Bestrahlungsstärke. Available online: https://www.researchgate.net/publication/339537884_Arbeitsblatt_2_Zunahme_der_laserinduzierten_ionisierenden_Strahlung_LIS_bei_grosser_werdender_Fokusflache_trotz_gleicher_Bestrahlungsstarke?channel=doi&linkId=5e57f406299bf1bdb8408aa0&showFulltext=true (accessed on 1 February 2022).

- Sauerbrey, R.; Fure, J.; Le Blanc, S.P. Reflectivity of laser-produced plasmas generated by a high intensity ultrashort pulse. Phys. Plasmas 1994, 1, 5. [Google Scholar] [CrossRef]

- Holland, J.; Weber, R.; Sailer, M.; Graf, T. Influence of Pulse Duration on X-ray Emission during Industrial Ultrafast Laser Processing. Materials 2022, 15, 2257. [Google Scholar] [CrossRef] [PubMed]

- Cerchez, M.; Jung, R.; Osterholz, J.; Toncian, T.; Willi, O.; Mulser, P.; Ruhl, H. Absorption of ultrashort laser pulses in strongly overdense targets. Phys. Rev. Lett. 2008, 100, 245001. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- German Federal Office for Radiation Protection. Limit Values in Radiation Protection. Available online: https://www.bfs.de/EN/topics/ion/radiation-protection/limit-values/limit-values_node.html (accessed on 1 February 2022).

- Schille, J.; Schneider, L.; Mauersberger, S.; Szokup, S.; Höhn, S.; Pötschke, J.; Reiss, F.; Leidich, E.; Löschner, U. High-Rate Laser Surface Texturing for Advanced Tribological Functionality. Lubricants 2020, 8, 33. [Google Scholar] [CrossRef] [Green Version]

| Parameter | Impact on X-ray Emission | References | |

|---|---|---|---|

| Laser-sided parameters | Peak intensity |

| [3,12,13,14] |

| Pulse energy |

| [15,16] | |

| Average laser power |

| [3,7,16,17] | |

| Pulse repetition frequency |

| [3,7,16] | |

| Focus spot diameter |

| [18] | |

| Wavelength |

| [14] | |

| Polarisation |

| [11,16,19] | |

| Pulse duration |

| [15,16,20] | |

| Process-sided parameters | Processing regime |

| [7,11,16] |

| Scanning direction |

| [13] | |

| Intra-line pulse distance |

| [7,11,16] | |

| Hatch distance |

| [11] | |

| Scan number |

| [7] | |

| Focus position |

| [2] | |

| Cross jet |

| [16] | |

| Fume extraction |

| [16] | |

| Angle of incidence |

| [7,16,21] | |

| Material-sided parameters | Material |

| [2,12,14] |

| Suface roughness |

| [11,16] | |

| Dimension |

| ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schille, J.; Kraft, S.; Kattan, D.; Löschner, U. Enhanced X-ray Emissions Arising from High Pulse Repetition Frequency Ultrashort Pulse Laser Materials Processing. Materials 2022, 15, 2748. https://doi.org/10.3390/ma15082748

Schille J, Kraft S, Kattan D, Löschner U. Enhanced X-ray Emissions Arising from High Pulse Repetition Frequency Ultrashort Pulse Laser Materials Processing. Materials. 2022; 15(8):2748. https://doi.org/10.3390/ma15082748

Chicago/Turabian StyleSchille, Jörg, Sebastian Kraft, Dany Kattan, and Udo Löschner. 2022. "Enhanced X-ray Emissions Arising from High Pulse Repetition Frequency Ultrashort Pulse Laser Materials Processing" Materials 15, no. 8: 2748. https://doi.org/10.3390/ma15082748

APA StyleSchille, J., Kraft, S., Kattan, D., & Löschner, U. (2022). Enhanced X-ray Emissions Arising from High Pulse Repetition Frequency Ultrashort Pulse Laser Materials Processing. Materials, 15(8), 2748. https://doi.org/10.3390/ma15082748