Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads

Abstract

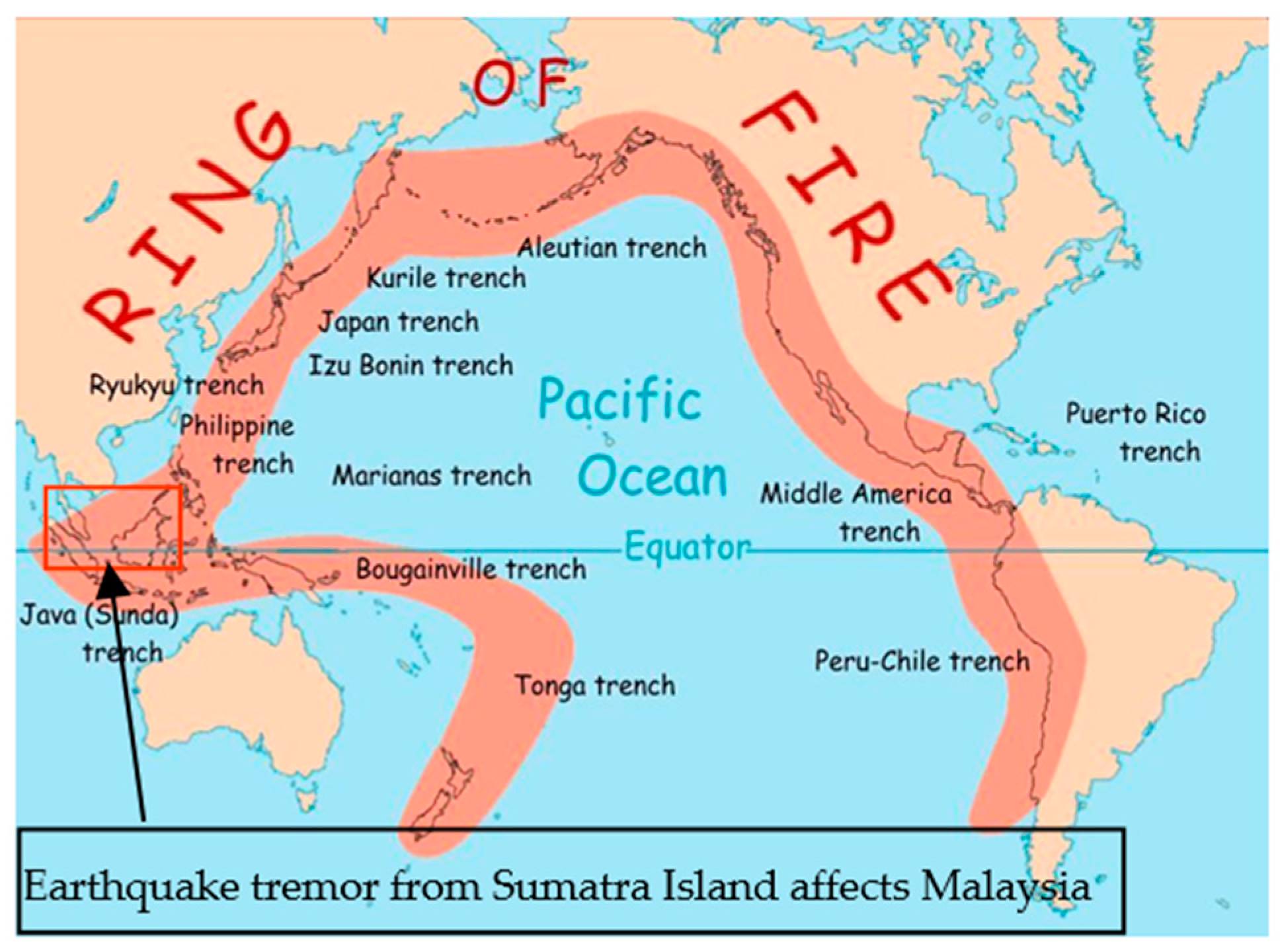

:1. Introduction

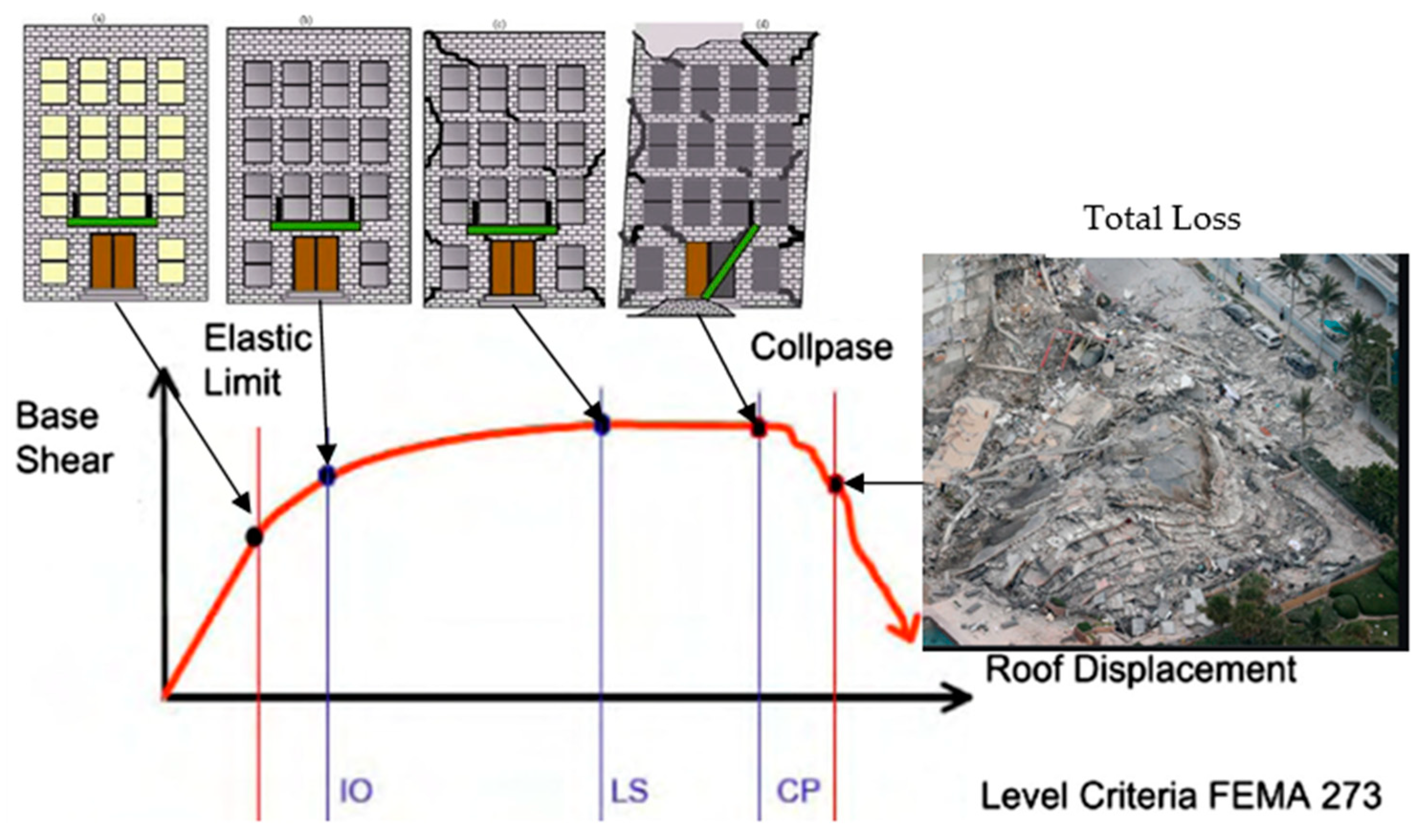

- ▪

- Operational (O).

- ▪

- Immediate Occupancy (IO).

- ▪

- Life Safety (LS).

- ▪

- Collapse Prevention (CP).

- -

- Simple translation at the x-axis.

- -

- Simple translation at the y-axis.

- -

- Rotation about the z-axis.

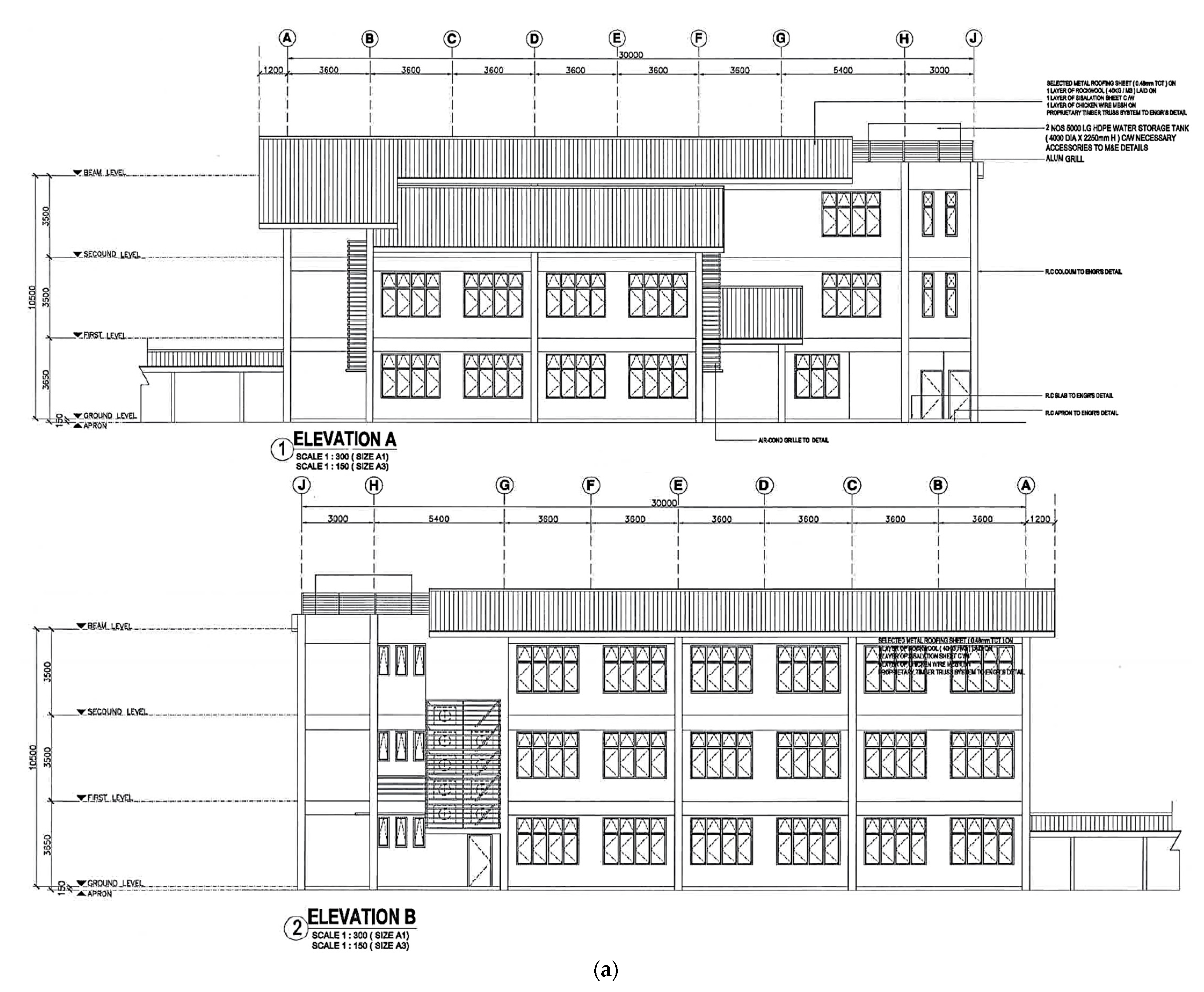

2. Design and Methods

2.1. Materials Preparation

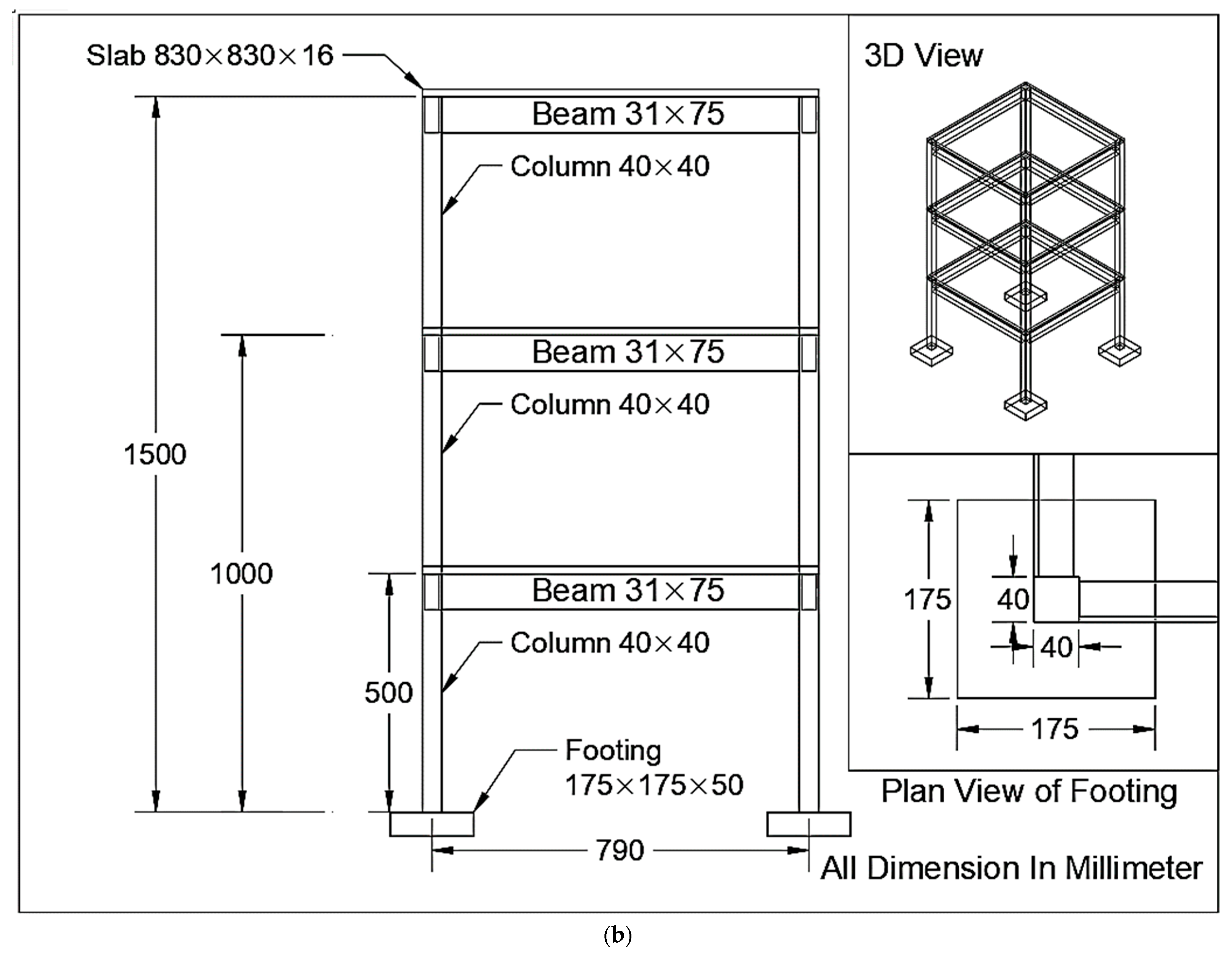

2.2. Model Construction

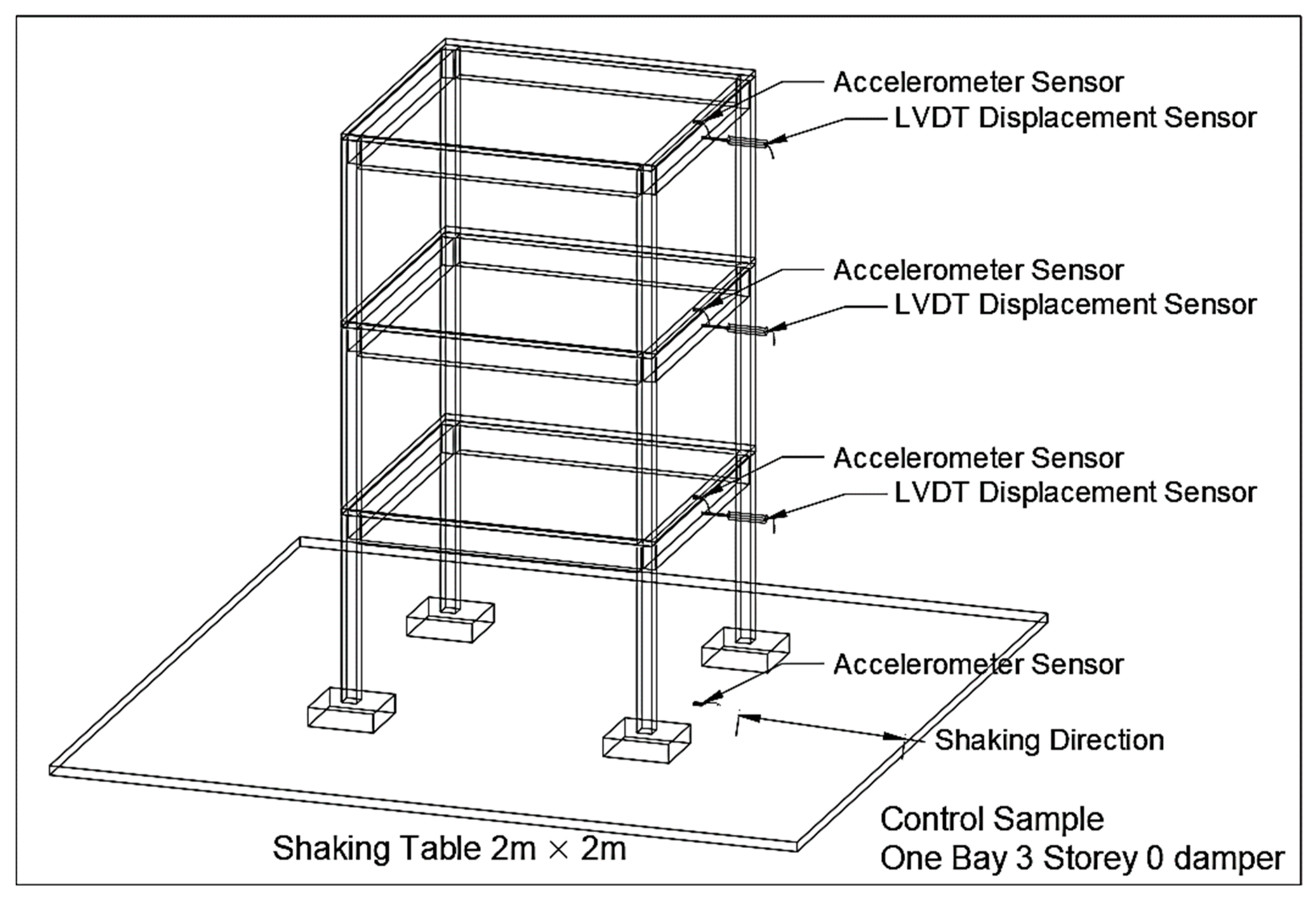

2.3. Experimental Setup

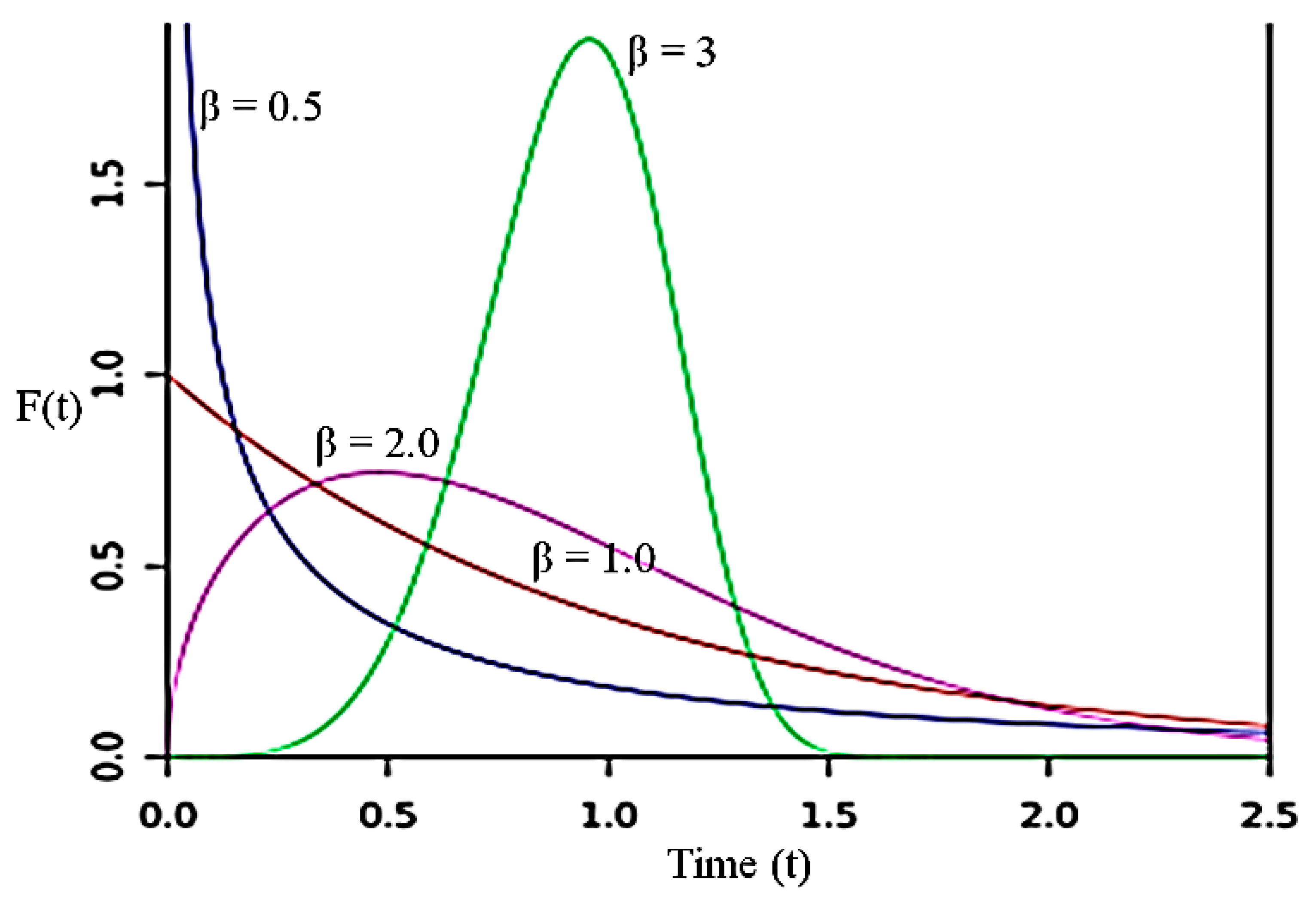

2.4. Reliability Analysis

3. Results and Discussion

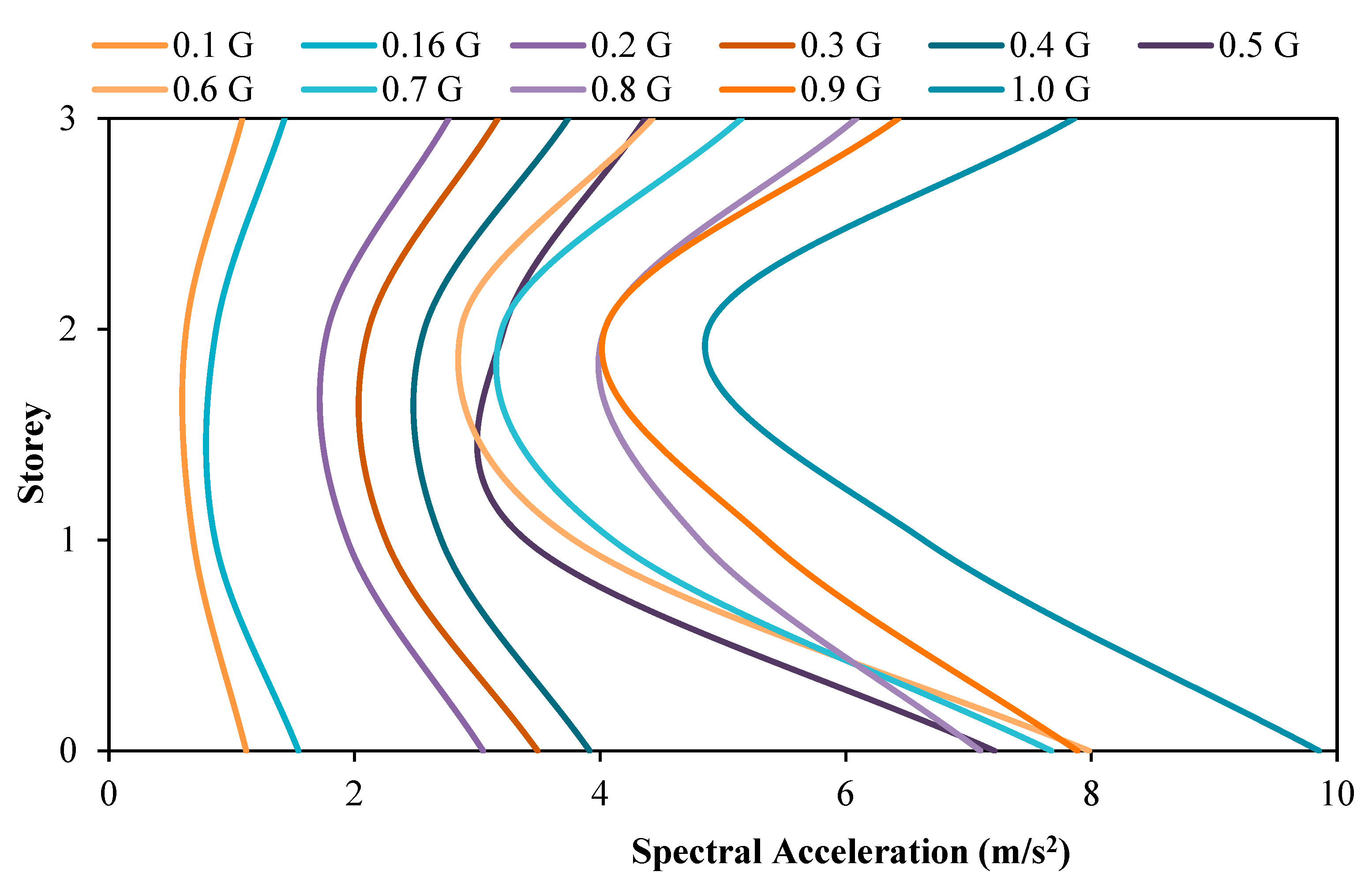

3.1. Comparison of Acceleration between the Model with and without Attached Viscous Dampers

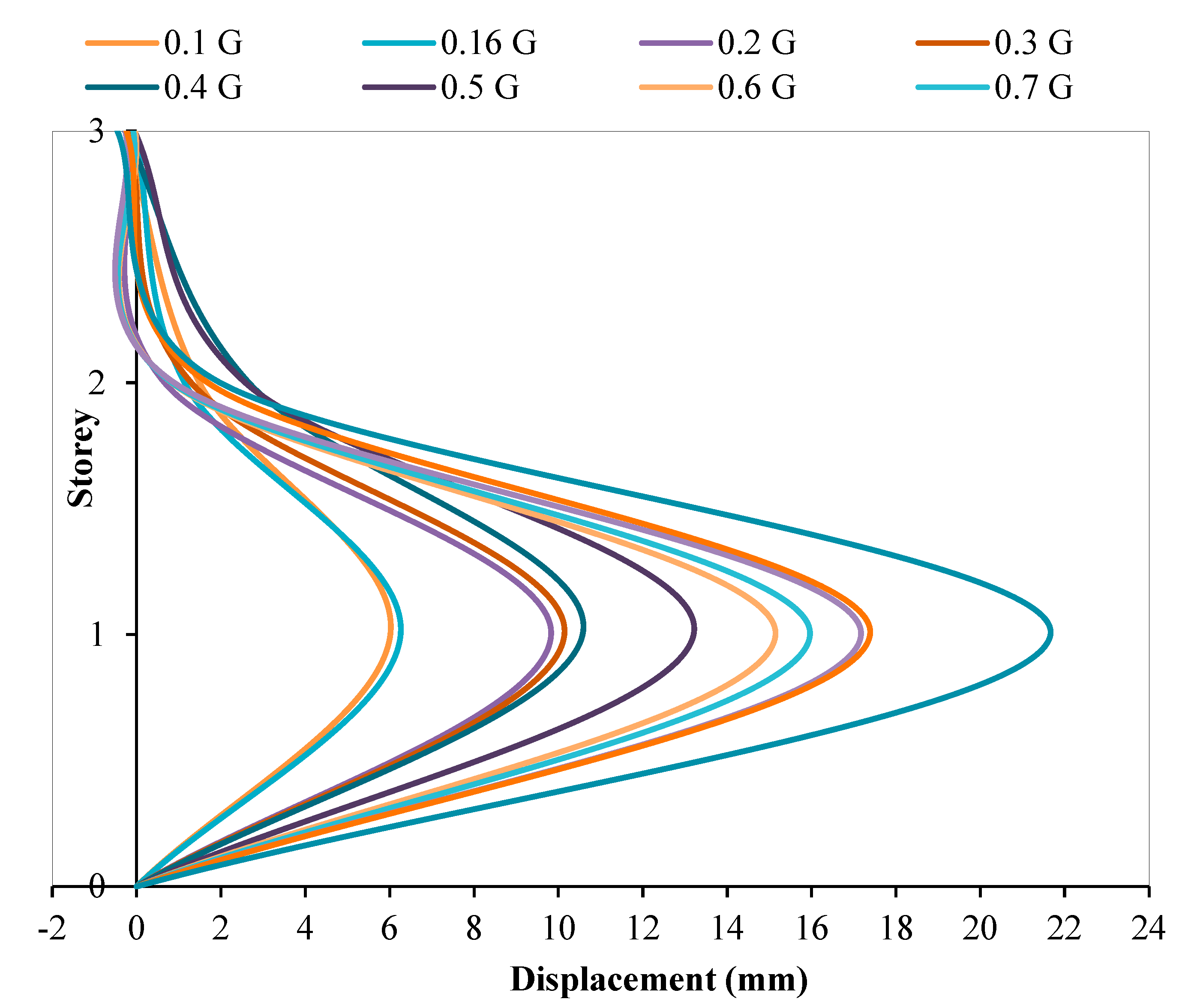

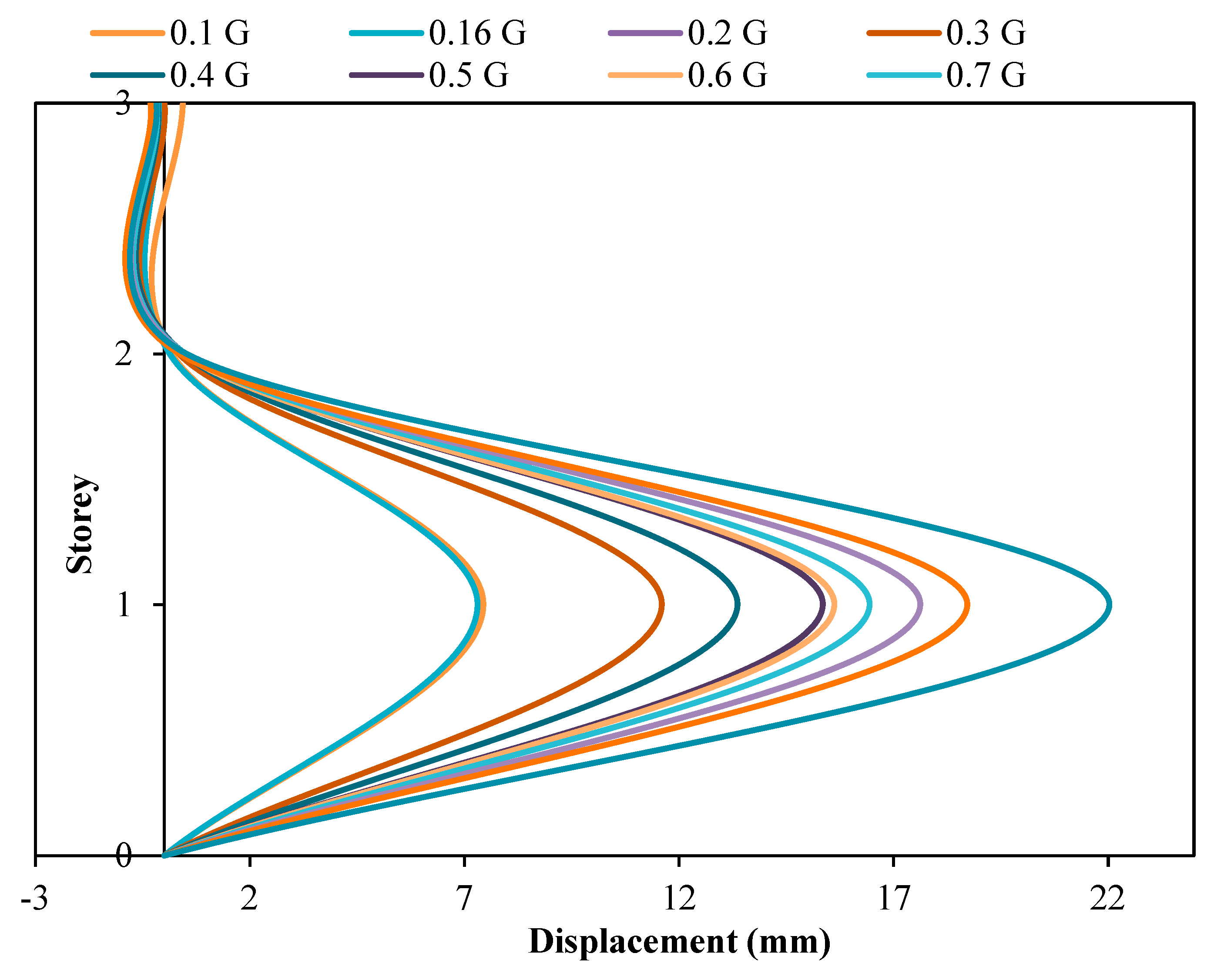

3.2. Comparison of Displacement between the Model with and without Attached Viscous Dampers

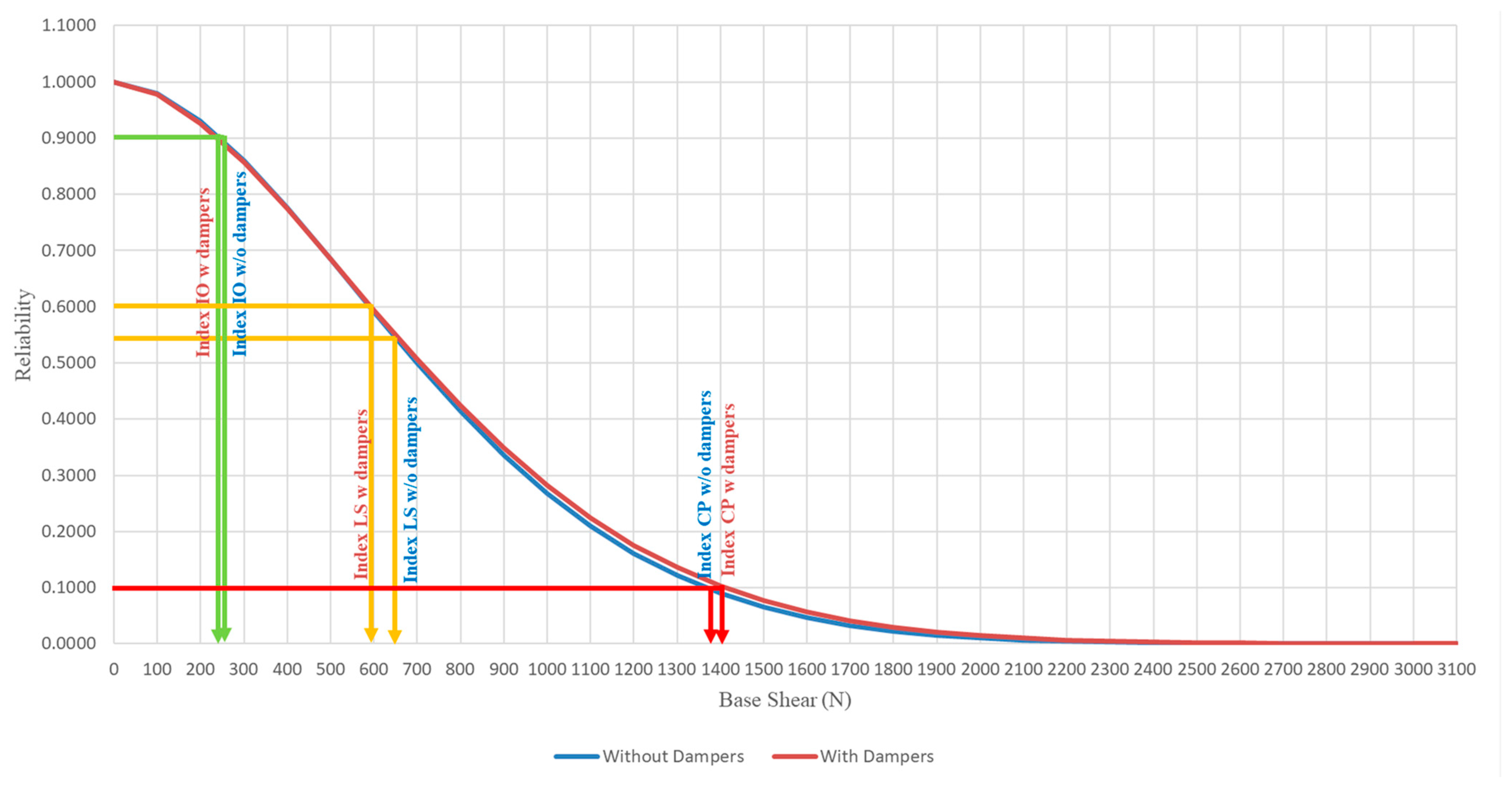

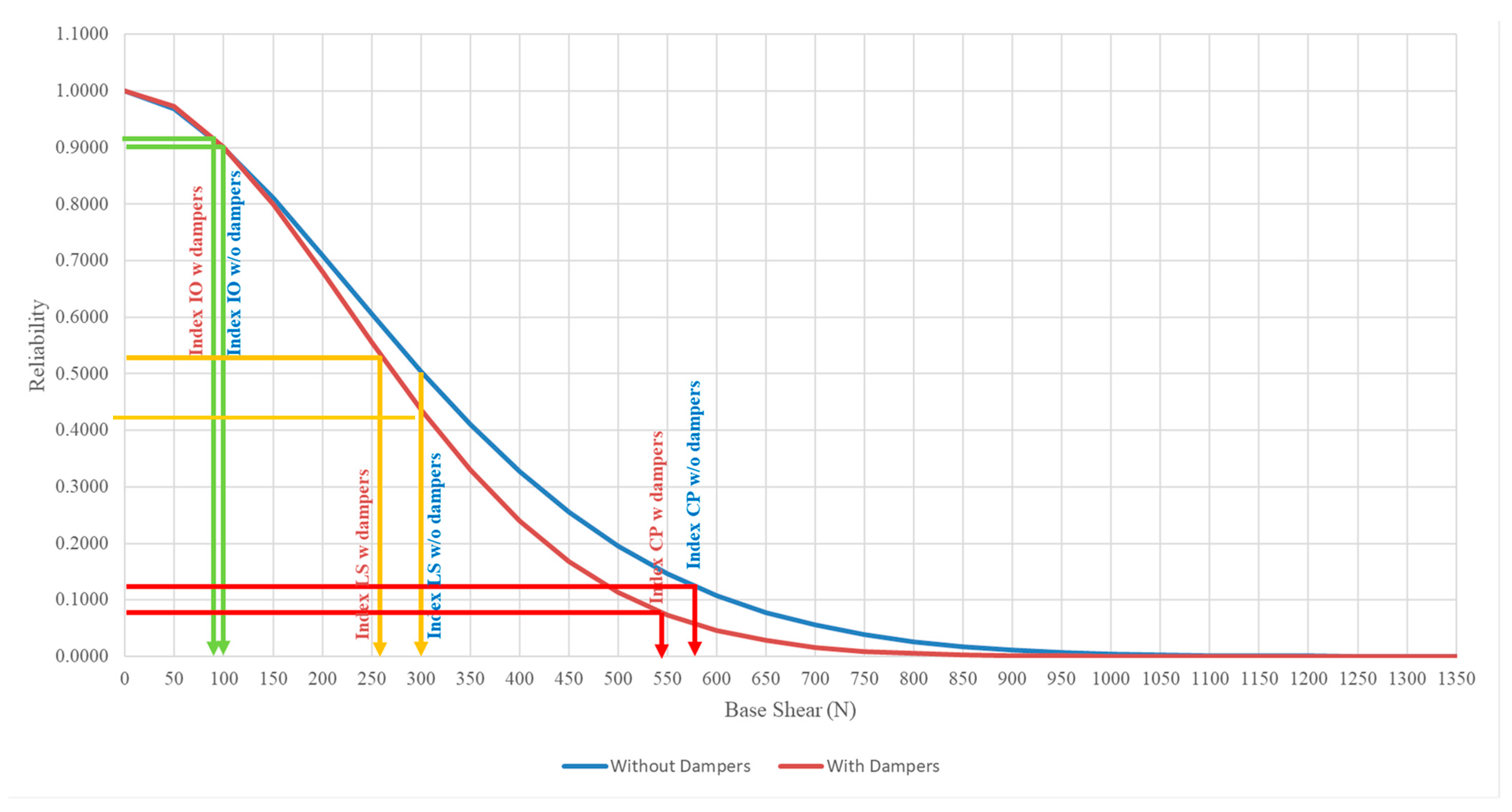

3.3. Comparison of Structural Reliability between Model with and without Attached Viscous Dampers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, M.; McNamara, A.K. Evolving morphology of crustal accumulations in Earth’′s lowermost mantle. Earth Planet. Sci. Lett. 2021, 577, 117265. [Google Scholar] [CrossRef]

- Ishikawa, T.; Yoshimib, M.; Shoji, K.I.; Yokohama, S. Reconnaissance report on geotechnical damage caused by 2018 Hokkaido Eastern Iburi earthquake with JMA seismic intensity 7. Soils Found. 2021, 61, 1151–1171. [Google Scholar] [CrossRef]

- Kanamori, H.; Brodsky, E. The physics of earthquakes. Rep. Prog. Phys. 2004, 67, 1429. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, S.; Kumar, A. Earthquakes associated subionospheric VLF anomalies recorded at two low latitude stations in the South Pacific region. J. Atmos. Solar-Terr. Phys. 2022, 229, 105834. [Google Scholar] [CrossRef]

- Adil, M.A.; Şentürk, E.; Shah, M.; Naqvi, N.A.; Saqib, M.; Abbasi, A.R. Atmospheric and ionospheric disturbances associated with the M > 6 earthquakes in the East Asian sector: A case study of two consecutive earthquakes in Taiwan. J. Southeast Asian Earth Sci. 2021, 220, 104918. [Google Scholar] [CrossRef]

- Sulaiman, S. Is Malaysia Located in the Pacific Ring of Fire? A Leg. Perspect. 2019, 70, 1–299. [Google Scholar] [CrossRef]

- Wim, J.F.; Simons; Marc, C.; Naeije; Barbara, E.; Brown; Niemnil, S.; Pradit, S.; Thongtham, N.; Mohamad, A.; et al. Vertical motion of Phuket Island (1994–2018) due to the Sumatra-Andaman mega-thrust earthquake cycle: Impact on sea-level and consequences for coral reefs. Mar. Geol. 2019, 414, 92–102. [Google Scholar]

- Ahmadun, F.-R.; Wong, M.M.R.; Said, A.M. Consequences of the 2004 Indian Ocean Tsunami in Malaysia. Saf. Sci. 2019, 121, 619–631. [Google Scholar] [CrossRef]

- Thermou, A.D.S. Micromechanical homogenization of steel bars in reinforced concrete for damage analysis. Mater. Today Commun. 2022, 31, 103235. [Google Scholar]

- Zhou, S.; Xie, L.; Jia, Y.; Wang, C. Review of Cementitious Composites Containing Polyethylene Fibers as Repairing Materials. Polymers 2020, 12, 2624. [Google Scholar] [CrossRef]

- Li, L.; Wang, H.; Wu, J.; Li, S.; Wu, W. Experimental Investigation on Dynamic Tensile Behaviors of Engineered Cementitious Composites Reinforced with Steel Grid and Fibers. Materials 2021, 14, 7042. [Google Scholar] [CrossRef] [PubMed]

- Singh, A.A. Flexural behavior of Expanded Polystyrene core Reinforced Concrete Sandwich Panels with different construction methods and end conditions. Structures 2021, 34, 2900–2911. [Google Scholar]

- Yön, B. Identification of failure mechanisms in existing unreinforced masonry buildings in rural areas after April 4, 2019 earthquake in Turkey. J. Build. Eng. 2021, 43, 102586. [Google Scholar] [CrossRef]

- El-Zeadani, M.R.; Raizal Saifulnaz, M.R.; Mugahed Amran, Y.H.; Hejazi, F.; Jaafar, M.S.; Alyousef, R.; Alabduljabbar, H. Analytical mechanics solution for measuring the deflection of strengthened RC beams using FRP plates. Case Stud. Constr. Mater. 2019, 11, e00272. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Raizal Saifulnaz, M.R.; Hejazi, F.; Mugahed Amran, Y.H.; Jaafar, M.S.; Alyousef, R.; Alrshoudi, F. Mechanics-based approach for predicting the short-term deflection of CFRP plated RC beams. Compos. Struct. 2019, 225, 111169. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Raizal Saifulnaz, M.R.; Amran, M. Full-range bondstress-slip model for externally bonded FRP plates including a frictional component. Compos. Struct. 2021, 262, 113372. [Google Scholar] [CrossRef]

- Guevara-Perez, L. Soft Story and Weak Story in Earthquake Resistant Design: A Multidisciplinary Approach; 15WCEE: Lisboa, Portugal, 2012. [Google Scholar]

- El-Zeadani, M.; Rashid, R.S.M.; Amran, M.Y.H.; Swi, M.I. Effect of the plate bondstress-slip property on the flexural strength of FRP Plated RC beams using a displacement-based approach. SN Appl. Sci. 2020, 2, 1–23. [Google Scholar] [CrossRef]

- Yip, C.C.; Marsono, A.K.; Wong, J.Y.; Amran, M.Y.H. Flexural strength of special reinforced lightweight concrete beam for Industrialized Building System (IBS). J. Teknol. 2015, 77, 187–196. [Google Scholar] [CrossRef] [Green Version]

- Mugahed Amran, Y.H.; El-Zeadani, M.; Huei Lee, Y.; Yong Lee, Y.; Murali, G.; Feduik, R. Design innovation, efficiency and applications of structural insulated panels: A review. Structures 2020, 27, 1358–1379. [Google Scholar] [CrossRef]

- Seker, O. Seismic response of dual concentrically braced steel frames with various bracing configurations. J. Constr. Steel Res. 2022, 188, 107057. [Google Scholar] [CrossRef]

- Zhu, Y.-J.Z.-M. Distortion of steel tub-girder with top flange bracing considering warping restraint effect. J. Constr. Steel Res. 2021, 187, 106954. [Google Scholar] [CrossRef]

- Imanpour, A. Seismic design of columns in two-story steel concentrically braced frames with bracing members intersecting columns between floors. Structures 2021, 33, 3885–3896. [Google Scholar] [CrossRef]

- El-Zeadani, M.; Saifulnaz, M.R.R.; Mugahed Amran, Y.H.; Hejazi, F.; Jaafar, M.S.; Alyousef, R.; Alabduljabbar, H. Flexural strength of FRP plated RC beams using a partial-interaction displacement-based approach. Structures 2019, 22, 405–420. [Google Scholar] [CrossRef]

- Tafheem, Z.; Khusru, S. Structural behavior of steel building with concentric and eccentric bracing: A comparative study. Int. J. Civ. Struct. Eng. 2013, 4, 12. [Google Scholar]

- Ou, G.X. Seismic performance of combined rotational friction and flexural yielding metallic dampers. J. Build. Eng. 2022, 49, 104059. [Google Scholar]

- Pawade, S.S. Performance evaluation of friction dampers for building with soil-structure interaction. Mater. Today Proc. 2022, 67. [Google Scholar] [CrossRef]

- Yang, C.; Chen, Z.; Wang, W.; Hua, X.; Wang, Y. Optimal design of two viscous dampers for multi-mode control of a cable covering broad frequency range. Eng. Struct. 2021, 245, 112830. [Google Scholar] [CrossRef]

- Pall, A.; Pall, R. Performance-based design using pall friction dampers-an economical design solution. In Proceedings of the 13th Word Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004; pp. 571–576. [Google Scholar]

- Ray, A.G.; Baidya, D. Reliability based pseudo-dynamic analysis of gravity retaining walls. Indian Geotech. J. 2018, 48, 575–584. [Google Scholar]

- Zhang, Z.P.; Cheng, S.G.; He, J. Dynamic analysis and calculation of the large scale six degree of freedom shaking table foundation. Build. Sci. 2004, 20, 37–41. [Google Scholar]

- Owens, B.C.; Tipton, D.G.; McDowell, M. 6 Degree of Freedom Shock and Vibration: Testing and Analysis. In Proceedings of the proposed for presentation at the Shock and Vibration Exchange, Orlando, FL, USA, 5–8 October 2015; pp. 1–11. [Google Scholar]

- FEMA. Seismic performance assessment of buildings; Federal Emergency Management Agency: Washington, DC, USA, 2012.

- FEMA. Design Guide for Improving Critical Facility Safety from Flooding and High Winds; Federal Emergency Management Agency: Washington, DC, USA, 2007.

- Tagliafierro, B.; Nastri, E. Seismic design lateral force distributions based on elastic analysis of structures. AIP Conf. Proc. 2019, 2116, 260022. [Google Scholar]

- Zhou, S.; Zhuang, X. Characterization of Loading Rate Effects on the Interactions between Crack Growth and Inclusions in Cementitious Material. Comput. Mater. Contin. 2018, 57, 417–466. [Google Scholar] [CrossRef]

- Jabboor, W. Dynamic Structural Analysis of Beams. Ph.D. Thesis, Herriot-Watt University, Edinburgh, UK, October 2011. [Google Scholar]

- Arvindreddy, R.J.; Fernandes, M. Seismic analysis of RC regular and irregular frame structures. Int. Res. J. Eng. Technol. 2015, 2, 44–47. [Google Scholar]

- Kolekar, A.N.; Pawar, Y.P.; Pise, C.P.; Mohite, D.D.; Kadam, S.S.; Deshmukh, C. Comparative study of Performance of RCC Multi-Storey Building for Koyna and Bhuj Earthquakes. J. Eng. Res. Appl. 2017, 7, 45–52. [Google Scholar] [CrossRef]

- Fardis, M. Designers’ Guide to EN 1998-1 and EN 1998-5 Eurocode 8: Design of Structures for Earthquake Resistance: General Rules, Seismic Actions, Design Rules for Buildings, Foundations and Retaining Structures; Thomas Telford Publ: London, UK, 2005. [Google Scholar]

- Krawinkler, H.; Seneviratna, G.D.P. Pros and cons of a pushover analysis of seismic performance evaluation. Eng. Struct. 1998, 20, 452–464. [Google Scholar] [CrossRef]

- Lagaros, N.D.; Mitropoulou, C.C.; Papadrakakis, M. Time History Seismic Analysis. In Encyclopedia of Earthquake Engineering; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Abang Ali, A.A.; Rashid, R.S.M.; Hejazi, F.; Safiee, N.A. Structural behavior of axially loaded precast foamed concrete sandwich panels. Constr. Build. Mater. 2016, 107, 307–320. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Rashid, R.S.M.; Hejazi, F.; Abang Ali, A.A.; Safiee, N.A.; Bida, S.M. Structural Performance of Precast Foamed Concrete Sandwich Panel Subjected to Axial Load. KSCE J. Civ. Eng. 2018, 22, 1179–1192. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H. Determination of Structural Behavior of Precast Foamed Concrete Sandwich Panel. Ph.D. Thesis, Universiti Putra Malaysia (UPM), Serdang, Malaysia, 2016. [Google Scholar]

- Elashai, A.S.; Di Sarno, L. Fundamentals of Earthquake Engineering; Wiley: New York, NY, USA, 2008. [Google Scholar]

- Wijesundara, K.K.; Negulescu, C.; Monfort, D.; Foerster, E. Identification of modal parameters of ambient excitation structures using continuous wavelet transform. In Proceedings of the 15th World Conference on Earthquake Engineering: 15th WCEE, Lisbon, Portugal, 24–28 September 2012. [Google Scholar]

- Datta, T. Seismic Analysis of Structures; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Dolas, D.R.; Jaybhaye, M.D.; Deshmukh, S. Estimation the system reliability using Weibull distribution. Int. Proc. Econ. Dev. Res. 2014, 75, 144. [Google Scholar]

- Vassiliou, P.; Young, N.; Guo, H.; Racaza, K.; Kahn, C.; House, R.; Hacker, L.; Smith, C. The Weibull Distribution-ReliaWiki. Available online: https://www.reliawiki.org/index.php/The_Weibull_Distribution (accessed on 21 February 2022).

- Lei, Y. Evaluation of three methods for estimating the Weibull distribution parameters of Chinese pine. J. For. Sci. 2008, 54, 566–571. [Google Scholar] [CrossRef] [Green Version]

- Mahzabin, M.S.; Hock, L.J.; Hossain, M.S.; Kang, L.S. The influence of addition of treated kenaf fibre in the production and properties of fibre reinforced foamed composite. Constr. Build. Mater. 2018, 178, 518–528. [Google Scholar] [CrossRef]

- Yip, C.-C.; Wong, J.-Y.; Ling, L.; Goh, Y.L.; Ong, H.-E. Dynamic response of scaled structure with one liquid tuned mass damper. Case Stud. Constr. Mater. 2021, 14, e00512. [Google Scholar] [CrossRef]

- Lim, S.; Wong, J.; Yip, C.; Pang, J. Case Studies in Construction Materials Flexural strength test on new profiled composite slab system. Case Stud. Constr. Mater. 2021, 15, e00638. [Google Scholar] [CrossRef]

- Yip, C.-C.; Wong, J.-Y.; Lim, X.-P. Flexural strength test of precast industrialized building system beam-corbel connection. J. Teknol. 2019, 81, 69–79. [Google Scholar] [CrossRef] [Green Version]

- Yip, C.-C.; Marsono, A.K.; Wong, J.-Y.; Lee, S.-C. Seismic performance of scaled IBS block column for static nonlinear monotonic pushover experimental analysis. J. Teknol. 2017, 80, 89–106. [Google Scholar] [CrossRef] [Green Version]

| Performance Level | Damage Level | Qualitative Performance Description | Quantitative Performance Description |

| Operational (O) | No Damage/Negligible Damage |

| Depends on construction materials, structure types and analysis models |

| Immediate Occupancy (IO) | Minor Damage |

| Depends on construction materials, structure types and analysis models |

| Life Safety (LS) | Partial Damage |

| Depends on construction materials, structure types and analysis models |

| Collapse Prevention (CP) | Extensive Damage |

| Depends on construction materials, structure types and analysis models |

| Physical Content | Chemical Content % per Unit Weight |

|---|---|

| Lime (CaO) | 64.64 |

| Silica (SiO2) | 21.28 |

| Alumina (Al2O3) | 5.60 |

| Iron Oxide (Fe2O3) | 3.36 |

| Sulphur Trioxide (SO3) | 2.14 |

| Magnesia (MgO) | 2.06 |

| Nitrogen (N2O) | 0.05 |

| Loss of Ignition | 0.64 |

| Lime Saturation Factor | 0.92 |

| Chemical C3S | 52.82 |

| Chemical C2S | 21.45 |

| Chemical C3A | 9.16 |

| Chemical C4AF | 10.2 |

| w/c = 0.42 | Water (mL) | Cement (g) | F.A (g) | C.A (g) | Plasticiser |

|---|---|---|---|---|---|

| Total | 233 | 550 | 511 | 1086 | 5.50 |

| 1 cylinder | 0.37 | 0.86 | 0.80 | 1.71 | 0.01 |

| 9 cylinders | 3.29 | 7.77 | 7.22 | 15.35 | 0.08 |

| +20% wastage | 3.95 | 9.33 | 8.66 | 18.41 | 0.09 |

| Concrete Weight (kg) | Ultimate Compressive Strength (N/mm2) | Targeted Compressive Strength at 7-day (N/mm2) | Status |

|---|---|---|---|

| 3.74 | 33.45 | 20 | Satisfactory |

| 3.45 | 31.14 | Satisfactory | |

| 3.48 | 32.59 | Satisfactory |

| Reliability Level | Base Storey | 2nd Storey | Roof Storey | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Shear Capacity (N) | |||||||||

| WO | W | +% | WO | W | +% | WO | W | +% | |

| 0.9 (IO) | 250 | 234 | - | 102 | 101 | - | 50 | 58 | 16.00 |

| 0.5 (LS) | 699 | 708 | 1.29 | 300 | 273 | - | 178 | 196 | 10.11 |

| 0.0 (CP) | 2900 | 3100 | 6.90 | 1350 | 1050 | - | 950 | 1000 | 5.26 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yip, C.-C.; Wong, J.-Y.; Amran, M.; Fediuk, R.; Vatin, N.I. Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads. Materials 2022, 15, 2688. https://doi.org/10.3390/ma15072688

Yip C-C, Wong J-Y, Amran M, Fediuk R, Vatin NI. Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads. Materials. 2022; 15(7):2688. https://doi.org/10.3390/ma15072688

Chicago/Turabian StyleYip, Chun-Chieh, Jing-Ying Wong, Mugahed Amran, Roman Fediuk, and Nikolai Ivanovich Vatin. 2022. "Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads" Materials 15, no. 7: 2688. https://doi.org/10.3390/ma15072688

APA StyleYip, C.-C., Wong, J.-Y., Amran, M., Fediuk, R., & Vatin, N. I. (2022). Reliability Analysis of Reinforced Concrete Structure with Shock Absorber Damper under Pseudo-Dynamic Loads. Materials, 15(7), 2688. https://doi.org/10.3390/ma15072688