Microstructure and Mechanical Properties of AlN/Al Joints Brazing by a Sputtering Al/Cu Bilayer Film Solder

Abstract

:1. Introduction

2. Materials and Methods

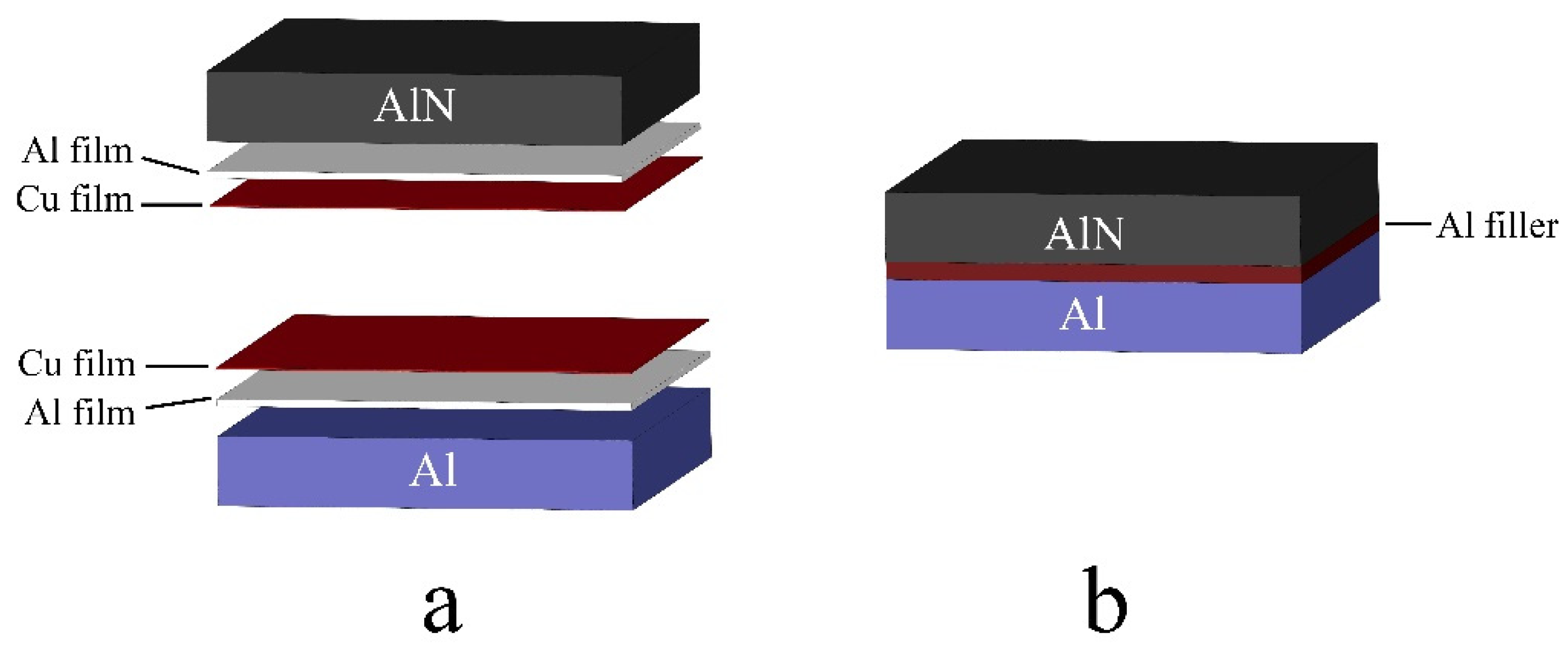

2.1. Experimental Design

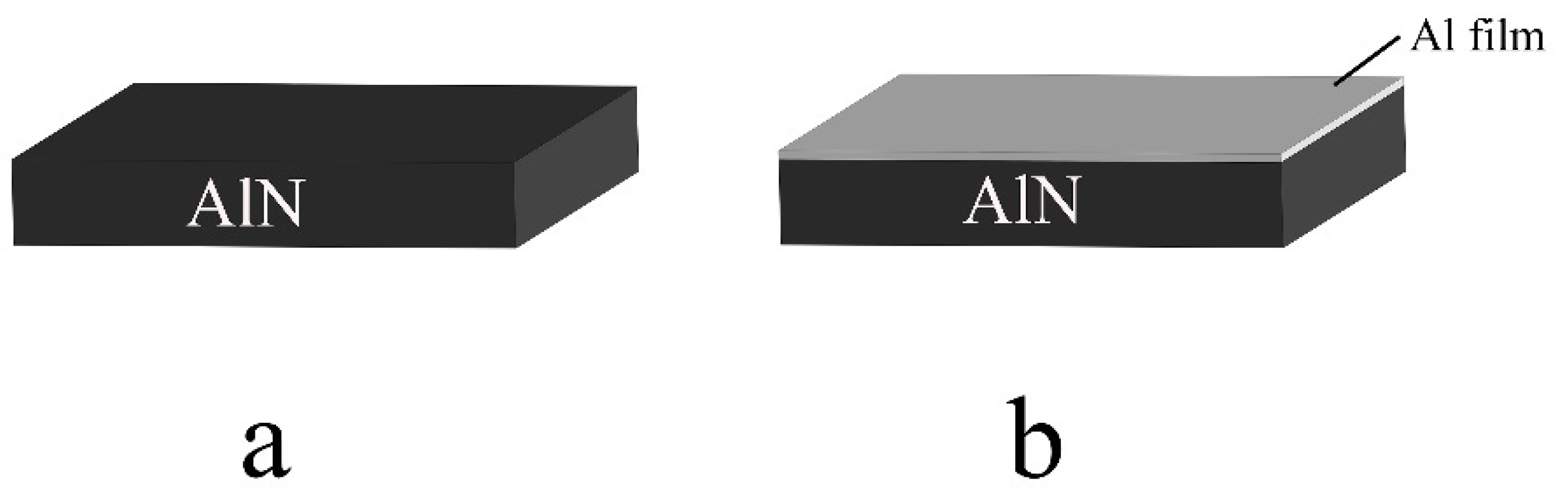

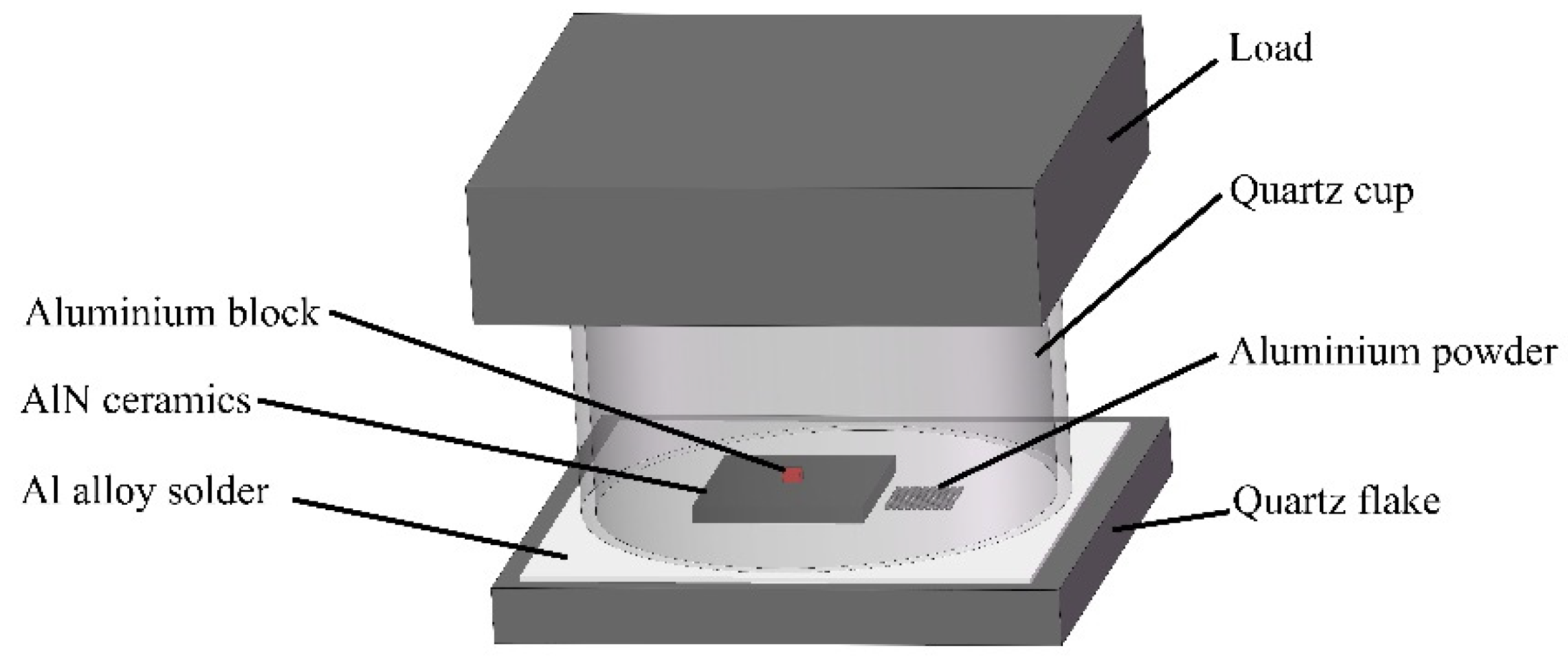

2.2. Wetting Experiment

2.3. Brazing Experiment

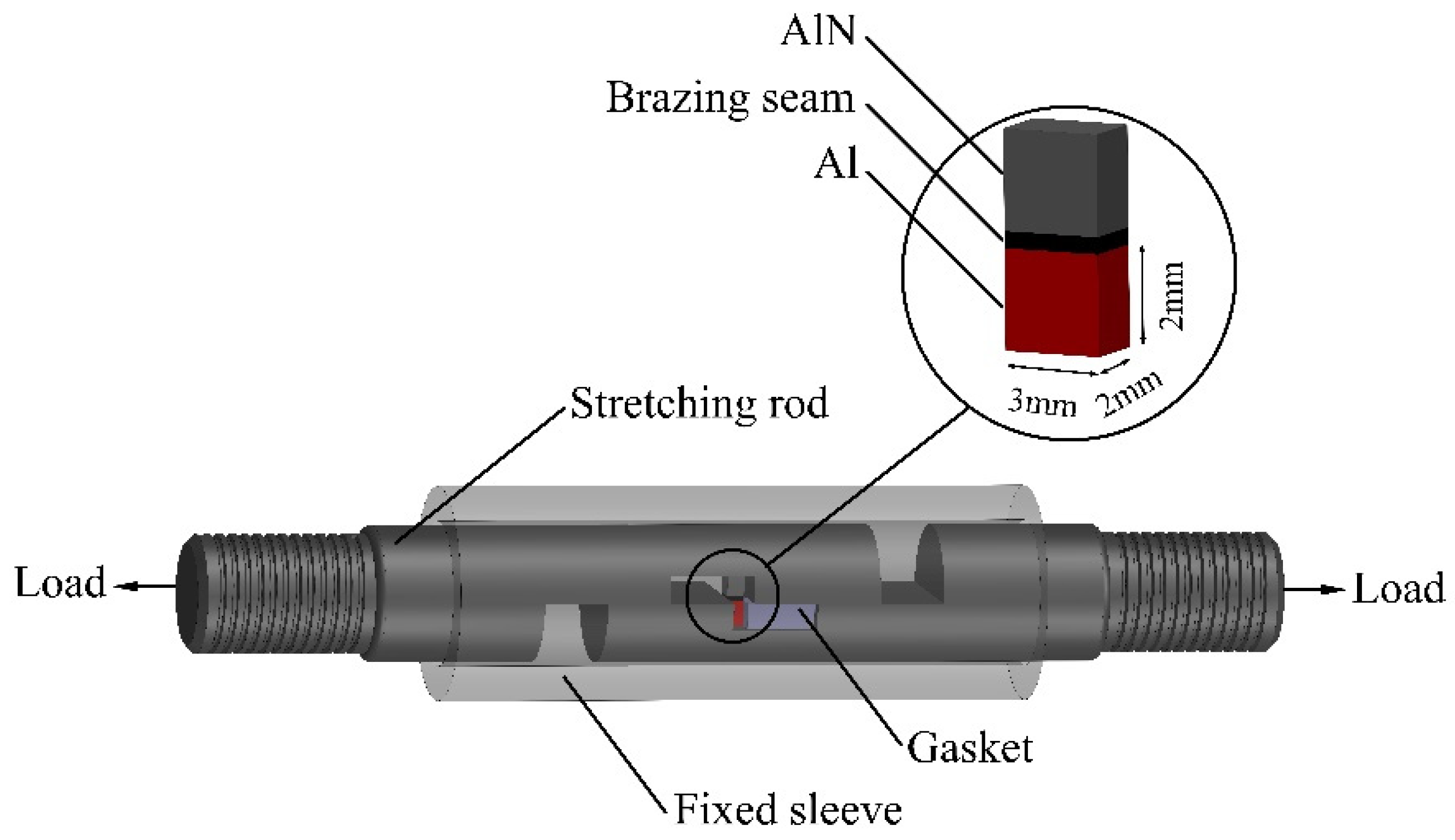

2.4. Characterization

3. Results

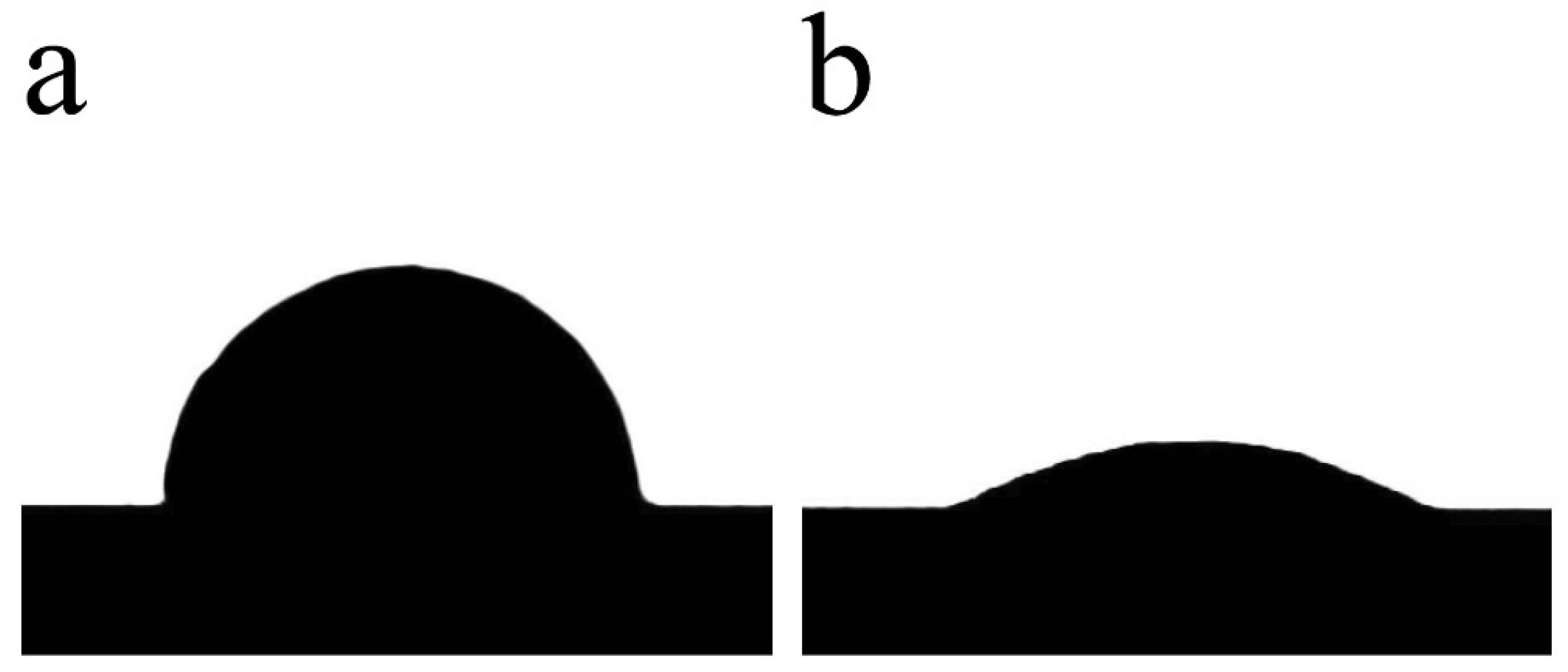

3.1. Wetting Behavior of Sputtering Al Particles on AlN

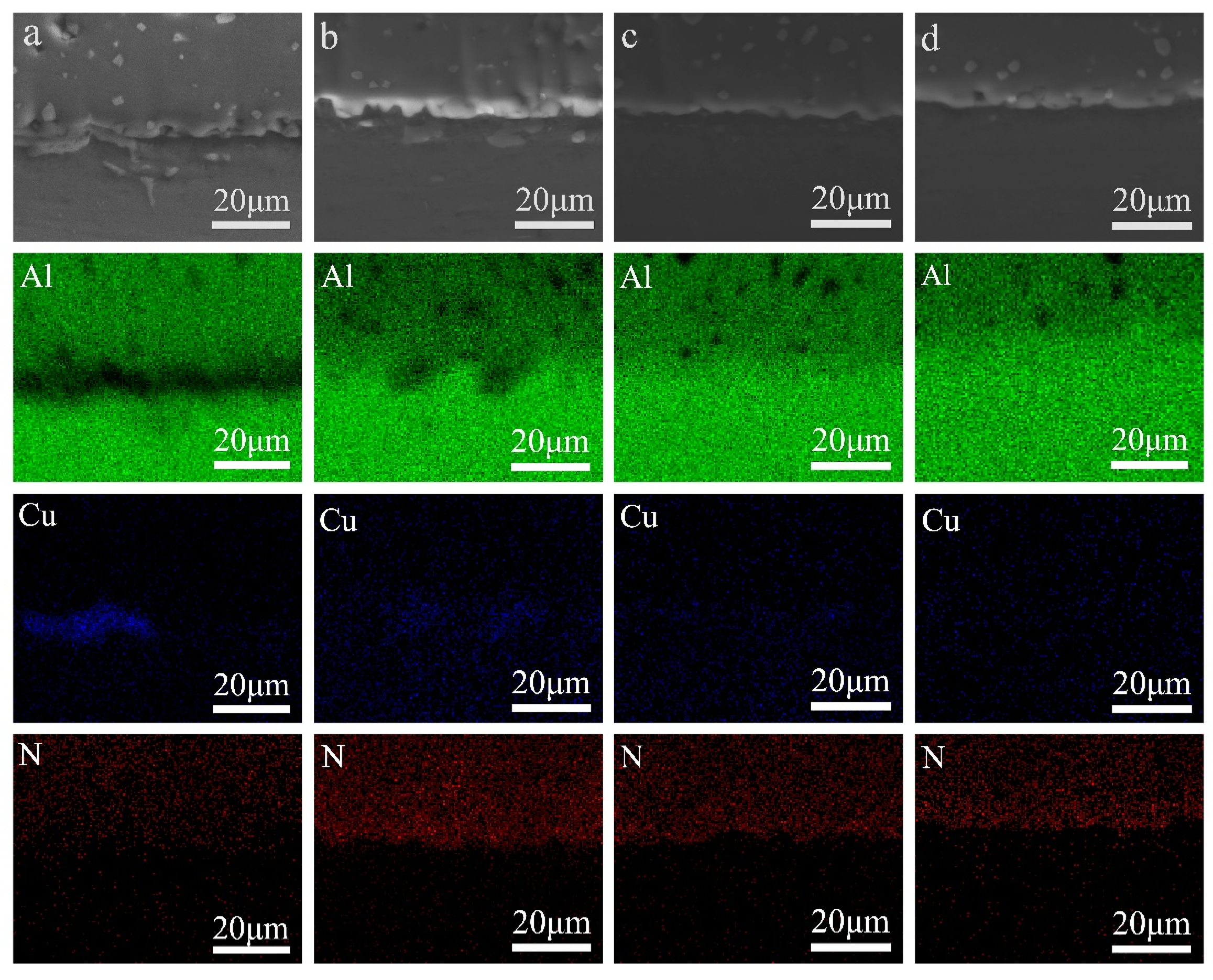

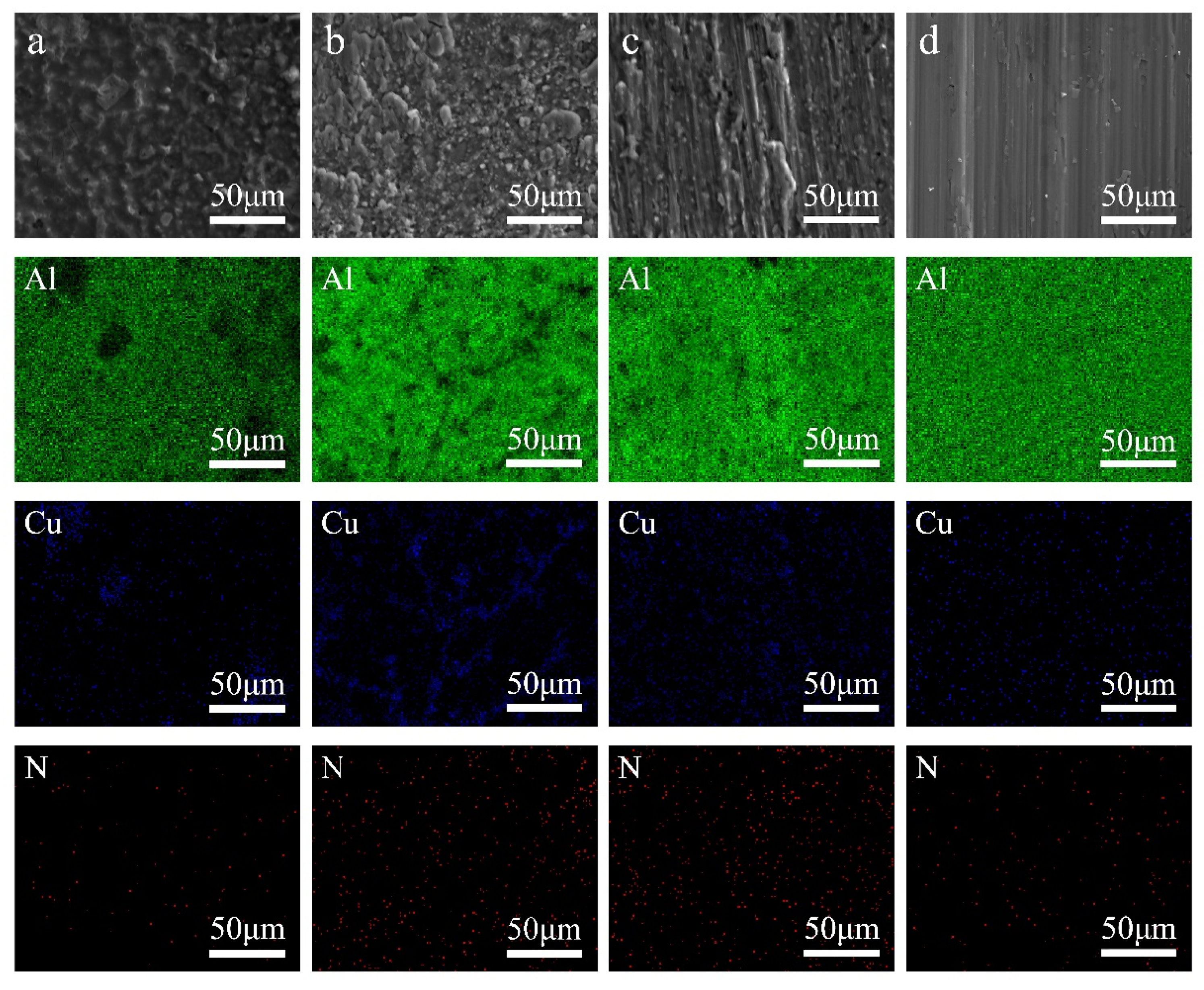

3.2. Microstructure Characteristics of AlN/Al Joint

3.3. Mechanical Properties of AlN/Al Joint

4. Discussion

4.1. Sputtering Wetting Effect

4.2. Removal of Oxide Film and Local Melting Brazing

5. Conclusions

- (1)

- Sputtered Al particles have a sputtering wetting effect on AlN ceramic. The contact angle of molten Al on AlN ceramic with Al film deposited at 700 °C can be as low as about 30°. While the contact angle of molten Al on AlN ceramic without Al film deposited is only 89° at a high temperature of 1000 °C.

- (2)

- The direct brazing of AlN/Al is realized using sputtered Al/Cu bilayer film solder. The influence of Al surface oxide film on brazing is effectively eliminated. The joints brazed at different temperature are all dense and full, and there is no reaction transition layer at the interface.

- (3)

- The shear strength of the joint brazed at 600 °C is 70.6 MPa, the weld structure is a mixture of Al solid solution and AlCu compound, and the joint fracture has a brittle fracture morphology. With the increase of brazing temperature, the shear strength of the brazed joint continues to increase. The weld structure gradually transforms into a solid solution of Cu in Al. The joint fracture morphology gradually changes from brittle fracture to furrow-like plastic fracture morphology. When the brazing temperature is increased to 660 °C, the distribution of Cu in the joint is evenly dispersed, and the shear strength of the brazed joint reaches the highest value of 107.8 MPa. The joint fracture is completely furrow-like plastic fracture morphological composition.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lv, J.; Huang, Y.; Fu, R.; Ji, Y.; Wu, B.; Liu, X. AlN/Cu composite ceramic substrate fabricated using a novel TiN/AgCuTi composite brazing alloy. J. Eur. Ceram. Soc. 2020, 40, 5332–5338. [Google Scholar] [CrossRef]

- Naidich, Y.V.; Zhuravlev, V.S.; Gab, I.I.; Kostyuk, B.D.; Krasovskyy, V.P.; Adamovskyy, A.A.; Taranets, N.Y. Liquid metal wettability and advanced ceramic brazing. J. Eur. Ceram. Soc. 2008, 28, 717–728. [Google Scholar] [CrossRef]

- Kusunose, T.; Sekino, T. Improvement in fracture strength in electrically conductive AlN ceramics with high thermal conductivity. Ceram. Int. 2016, 28, 13183–13189. [Google Scholar] [CrossRef]

- Ohashi, T.; Nagatomo, Y.; Nagase, T.; Kuromitsu, Y. A new method for liquid-phase bonding of copper plates to aluminum nitride (AlN) substrates used in high-power modules. J. Mater. Sci. Mater. Electron. 2019, 30, 6552–6555. [Google Scholar]

- Hisanori, O.; Hideki, S.; Takao, F.; Tomohiko, S. Bonding Mechanism and Microstructure of Bonded Zone of AlN Ceramics with Ti-AgCu Brazing Metal. Q. J. Jpn. Weld. Soc. 1991, 9, 494–501. [Google Scholar]

- Sivaprahasam, D.; Sujitha, T.; Gowtham, U.; Jayachandran, B.; Gopalan, R. Microstructure and heat transfer characteristics of active brazed Ceramic–Metal joints. Ceram. Int. 2021, 47, 16133–16140. [Google Scholar] [CrossRef]

- Taranets, N.Y.; Naidich, Y.V. Wettability of aluminum nitride by molten metals. Powder Metall. Metal Ceram. 1996, 35, 282–285. [Google Scholar] [CrossRef]

- Ho, H.-N.; Wu, S.-T. The wettability of molten aluminum on sintered aluminum nitride substrate. Mater. Sci. Eng. A 1998, 248, 120–124. [Google Scholar] [CrossRef]

- Li, Y.; Shang, H.; Ma, B.; Guo, X.; Li, R.; Li, G. The Effect of Temperature and Sputtered Particles on the Wettability of Al/Al2O3. Materials 2021, 14, 2110. [Google Scholar] [CrossRef] [PubMed]

- Toy, C.; Scott, W.D. Wetting and spreading of molten aluminium against AlN surfaces. J. Mater. Sci. 1997, 32, 3243–3248. [Google Scholar] [CrossRef]

- Prin, G.R.; Baffie, T.; Jeymond, M.; Eustathopoulos, N. Contact angles and spreading kinetics of Al and Al–Cu alloys on sintered AlN. Mater. Sci. Eng. A 2001, 298, 34–43. [Google Scholar] [CrossRef]

- Fujii, H.; Nakae, H.; Okada, K. Four wetting phases in AIN/AI and AIN Composites/AI Systems, Models of Nonreactive, Reactive, and Composite Systems. Metall. Mater. Trans. A 1993, 24, 1391–1397. [Google Scholar] [CrossRef]

- Sobczak, N.; Ksiazek, M.; Radziwill, W.; Stobierski, L.; Mikulowski, B. Wetting-Bond Strength Relationship in Al-AlN System. In Proceedings of the Third International Conference on High Temperature Capillarity, Kurashiki, Japan, 19–22 November 2000. [Google Scholar]

- Kida, M.; Bahraini, M.; Molina, J.M.; Weber, L.; Mortensen, A. High-temperature wettability of aluminum nitride during liquid metal infiltration. Mater. Sci. Eng. A 2008, 495, 197–202. [Google Scholar] [CrossRef]

- Zhao, B.; Shang, H.; Chen, F.; Shi, K.; Li, R.; Li, G. Wetting and brazing of AlN by sputtered Al. Acta Phys. Sin. 2016, 65, 086801. [Google Scholar] [CrossRef]

- Mattox, D.M. Handbook of Physical Vapor Deposition Processing; Elsevier: Amsterdam, The Netherlands, 1998; Volume 61, pp. 553–734. [Google Scholar]

- Garcia-Cordovilla, C.; Louisb, E.; Narciso, J. Pressure infiltration of packed ceramic particulates by liquid metals. Acta Mater. 1999, 47, 4461–4479. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ran, Z.; Shang, H.; Ma, B.; Li, R.; Shangguan, F.; Yu, D. Microstructure and Mechanical Properties of AlN/Al Joints Brazing by a Sputtering Al/Cu Bilayer Film Solder. Materials 2022, 15, 2674. https://doi.org/10.3390/ma15072674

Ran Z, Shang H, Ma B, Li R, Shangguan F, Yu D. Microstructure and Mechanical Properties of AlN/Al Joints Brazing by a Sputtering Al/Cu Bilayer Film Solder. Materials. 2022; 15(7):2674. https://doi.org/10.3390/ma15072674

Chicago/Turabian StyleRan, Zhun, Hailong Shang, Bingyang Ma, Rongbin Li, Fujun Shangguan, and Dayi Yu. 2022. "Microstructure and Mechanical Properties of AlN/Al Joints Brazing by a Sputtering Al/Cu Bilayer Film Solder" Materials 15, no. 7: 2674. https://doi.org/10.3390/ma15072674

APA StyleRan, Z., Shang, H., Ma, B., Li, R., Shangguan, F., & Yu, D. (2022). Microstructure and Mechanical Properties of AlN/Al Joints Brazing by a Sputtering Al/Cu Bilayer Film Solder. Materials, 15(7), 2674. https://doi.org/10.3390/ma15072674