The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica

Abstract

:1. Introduction

- To improve the technological properties of concrete mixtures by reducing their water content, improving their workability, and increasing their homogeneity and resistance to stratification, by using a complex modifier consisting of a hyperplasticizer based on polycarboxylate ester and ultradispersed active silica;

- To reduce the shrinkage deformations of concrete in the early stage of curing and increase the flexural strength of cement concrete through the use of volumetric fiber reinforcement with low-modulus polypropylene fiber, in order to improve the crack resistance and quality of products.

2. Materials and Methods

- Selection of compositions of modified heavy concrete of popular grades, as described in [26];

- Determination of the basic strength characteristics (compressive and flexural strength) at the design age of 28 days;

- Determination of basic performance characteristics (i.e., frost resistance, volumetric water absorption, average density);

- Comparison and analysis of test results of modified heavy concrete of mainstream grades.

2.1. Calculation of the Concrete Composition of Popular Grades

- Formulation of technical specifications which, in addition to the conventional requirements for concrete strength and workability of the concrete mix, must contain the minimum allowable value of its ultimate extensibility, based on the conditions of formation and, therefore, the expected or measured value of the possible deformations;

- Selection of raw materials and obtaining the necessary data characterizing their properties, including the water consumption of aggregates;

- Calculation of the concrete mix composition to determine the consumption of key components in kg per 1 m3;

- Experimental verification of the obtained composition and its adjustment (if necessary).

2.2. Determination of Compressive and Flexural Strengths

2.3. Determination of the Frost Resistance

2.4. Determination of Water Absorption

2.5. Determination of the Average Density

3. Results and Discussion

4. Conclusions

5. Recommendations and Applications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sha, Z.; Long, X.; Feng, J.; Jiang, H.; Wang, T. Development of a fast-hardening retarding high-early-strength concrete with low-alkalinity sulphoaluminate cement and practical application. Adv. Bridg. Eng. 2020, 1, 1–22. [Google Scholar] [CrossRef]

- Mailyan, L.R.; Beskopylny, A.N.; Meskhi, B.; Shilov, A.V.; Stel’makh, S.A.; Shcherban, E.M.; Smolyanichenko, A.S.; El’shaeva, D. Improving the Structural Characteristics of Heavy Concrete by Combined Disperse Reinforcement. Appl. Sci. 2021, 11, 6031. [Google Scholar] [CrossRef]

- Qasim, O.A. Comparative study between the Cost of Normal Concrete and Reactive Powder Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2019, 518, 022082. [Google Scholar] [CrossRef]

- Makul, N. Cost-benefit analysis of the production of ready-mixed high-performance concrete made with recycled concrete aggregate: A case study in Thailand. Heliyon 2020, 6, e04135. [Google Scholar] [CrossRef] [PubMed]

- Bondar, V.; Shulgin, V.; Demchenko, O.; Bondar, L. Experimental study of properties of heavy concrete with bottom ash from power stations. MATEC Web Conf. 2017, 116, 02007. [Google Scholar] [CrossRef] [Green Version]

- Andreikiv, O.E.; Dolins’ka, I.Y.; Raiter, O.K. Evaluation of the Durability of the Fiber-Reinforced Concrete Beam under Long-Term Pure Bending and Local Creep. Strength Mater. 2021, 53, 227–233. [Google Scholar] [CrossRef]

- Liu, X.; Li, T.; Tian, W.; Wang, Y.; Chen, Y. Study on the durability of concrete with FNS fine aggregate. J. Hazard. Mater. 2020, 381, 120936. [Google Scholar] [CrossRef]

- Interstate Standard GOST 10060-2012; Concretes. Methods for Determination of Frost-Resistance. Stroyizdat: Moscow, Russia, 2018. Available online: https://docs.cntd.ru/document/1200100906 (accessed on 2 March 2022).

- Kuzmin, S.A.; Argunova, A.A.; Krasilnikov, D.A.; Emelianova, Z.V. Research of Durability and Structure of the Heavy Concrete Modified by Polymeric Impregnation in the Frigid Climate. Mater. Sci. Forum 2019, 945, 250–256. [Google Scholar] [CrossRef]

- Mao, M.; Zhang, D.; Yang, Q.; Zhang, W. Study of Durability of Concrete with Fly Ash as Fine Aggregate under Alternative Interactions of Freeze-Thaw and Carbonation. Adv. Civ. Eng. 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Nizina, T.A.; Balykov, A.S. Experimental-statistical models of properties of modified fiber-reinforced fine-grained concretes. Mag. Civ. Eng. 2016, 62, 13–25. [Google Scholar] [CrossRef]

- Ashola, M. Cost Effectiveness of Replacing Sand with Crushed Granite Fine (CGF) in the Mixed Design of Concrete. IOSR J. Mech. Civ. Eng. 2013, 10, 1–6. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; de Brito, J.; Fiol, F. Micro- and macro-porosity of dry- and saturated-state recycled aggregate concrete. J. Clean. Prod. 2019, 211, 932–940. [Google Scholar] [CrossRef]

- Kalashnikov, V.I. Effective High-Strength and Conventional Concretes, 1st ed.; Volga House of Knowledge: Penza, Russia, 2015; ISBN 978-5-8356-1540-7. [Google Scholar]

- Strzałkowski, J.; Garbalińska, H. The Influence of Silica Fume on the Mechanical and Thermal Parameters of Portland Cement Concretes. J. Ecol. Eng. 2019, 20, 95–102. [Google Scholar] [CrossRef]

- Ahmad, S.; Mohaisen, K.O.; Adekunle, S.K.; Al-Dulaijan, S.U.; Maslehuddin, M. Influence of admixing natural pozzolan as partial replacement of cement and microsilica in UHPC mixtures. Constr. Build. Mater. 2019, 198, 437–444. [Google Scholar] [CrossRef]

- Mai, N.L.; Hoang, N.-H.; Do, H.T.; Pilz, M.; Trinh, T.T. Elastic and thermodynamic properties of the major clinker phases of Portland cement: Insights from first principles calculations. Constr. Build. Mater. 2021, 287, 122873. [Google Scholar] [CrossRef]

- Utepov, Y.; Akhmetov, D.; Akhmatshaeva, I. Effect of fine fillers from industrial waste and various chemical additives on the placeability of self-compacting concrete. Comput. Concr. 2020, 25, 59–65. [Google Scholar] [CrossRef]

- Kiyanets, A.V. Concrete with recycled polyethylene terephthalate fiber. Mag. Civ. Eng. 2018, 84, 109–118. [Google Scholar] [CrossRef]

- Begich, Y.E.; Klyuev, S.V.; Jos, V.A.; Cherkashin, A.V. Fine-grained concrete with various types of fibers. Mag. Civ. Eng. 2020, 97, 9702. [Google Scholar] [CrossRef]

- Hasani, M.; Moghadas Nejad, F.; Sobhani, J.; Chini, M. Mechanical and durability properties of fiber reinforced concrete overlay: Experimental results and numerical simulation. Constr. Build. Mater. 2021, 268, 121083. [Google Scholar] [CrossRef]

- Murali, G.; Prasad, N.; Klyuev, S.; Fediuk, R.; Abid, S.R.; Amran, M.; Vatin, N. Impact Resistance of Functionally Layered Two-Stage Fibrous Concrete. Fibers 2021, 9, 88. [Google Scholar] [CrossRef]

- Paul, S.; van Zijl, G.; Šavija, B. Effect of Fibers on Durability of Concrete: A Practical Review. Materials 2020, 13, 4562. [Google Scholar] [CrossRef] [PubMed]

- Akhmetov, D.A.; Aniskin, A.; Utepov, Y.B.; Root, Y.N.; Kozina, G. Determination of Optimal Fibre Reinforcement Parameters for Self-Compacting Concretes. Teh. Vjesn.Tech. Gaz. 2020, 27, 1982–1989. [Google Scholar] [CrossRef]

- Li, S.; Yang, J.; Zhang, P. Water-Cement-Density Ratio Law for the 28-Day Compressive Strength Prediction of Cement-Based Materials. Adv. Mater. Sci. Eng. 2020, 2020, 1–8. [Google Scholar] [CrossRef]

- Interstate Standard GOST 30459-2008; Admixtures for Concretes and Mortars. Determination and Estimate of the efficiency. Stroyizdat: Moscow, Russia, 2008. Available online: https://docs.cntd.ru/document/1200078684 (accessed on 2 March 2022).

- Interstate Standard GOST 31108-2016; Common Cements. Specifications. Stroyizdat: Moscow, Russia, 2016. Available online: https://docs.cntd.ru/document/1200140199 (accessed on 2 March 2022).

- Interstate Standard GOST 8736-2014; Sand for Construction Works. Stroyizdat: Moscow, Russia, 2014. Available online: https://docs.cntd.ru/document/1200114239 (accessed on 2 March 2022).

- Interstate Standard GOST 8267-93; Crushed Stone and Gravel of Solid Rocks for Construction Works. Stroyizdat: Moscow, Russia, 1995; Specifications. Available online: https://docs.cntd.ru/document/1200000314 (accessed on 2 March 2022).

- Interstate Standard GOST 58894-2020; Silica Fume for Concretes and Mortars. Specifications. Stroyizdat: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200173805 (accessed on 2 March 2022).

- Technical Specification 2272-001-90345062-2012; Polypropelene Fiber. Fibralux: St. Petersburg, Russia, 2020. Available online: https://cdn.vseinstrumenti.ru/img/certificate_compliance/2070823/1124.pdf (accessed on 2 March 2022).

- Interstate Standard GOST 27006-2019; Concretes. Rules for Mix Proposing. Stroyizdat: Moscow, Russia, 2019. Available online: https://docs.cntd.ru/document/1200165762 (accessed on 2 March 2022).

- Interstate Standard GOST 22685-89; Moulds for Making Control Specimens of Concrete. Specifications. Stroyizdat: Moscow, Russia, 1989. Available online: https://docs.cntd.ru/document/901705762 (accessed on 2 March 2022).

- Interstate Standard GOST 10180-2012; Concretes. Methods for Strength Determination Using Reference Specimens. Stroyizdat: Moscow, Russia, 2012. Available online: https://docs.cntd.ru/document/1200100908 (accessed on 2 March 2022).

- Interstate Standard GOST 12730.3-2020; Concretes. Method of determination of water absorption. Stroyizdat: Moscow, Russia, 2020. Available online: https://docs.cntd.ru/document/1200177301/titles (accessed on 2 March 2022).

- Interstate Standard GOST 12730.1-78; Concretes. Methods of Determination of Density. Stroyizdat: Moscow, Russia, 1978. Available online: https://docs.cntd.ru/document/901703627 (accessed on 2 March 2022).

- Interstate Standard GOST 33320-2015; Ferroconcrete cross Ties for Railways. Stroyizdat: Moscow, Russia, 2015. Available online: https://docs.cntd.ru/document/1200124225 (accessed on 2 March 2022).

- Heidari, F.; Keivan, T.; Sheybani, M.; Janghorban, M.; Tounsi, A. On the mechanics of nanocomposites reinforced by wavy/defected/aggregated nanotubes. Steel Compos. Struct. 2021, 38, 533–545. [Google Scholar] [CrossRef]

- Zerrouki, R.; Karas, A.; Zidour, M.; Bousahla, A.A.; Tounsi, A.; Bourada, F.; Tounsi, A.; Benrahou, K.H.; Mahmoud, S.R. Effect of nonlinear FG-CNT distribution on mechanical properties of functionally graded nano-composite beam. Struct. Eng. Mech. 2021, 78, 117–124. [Google Scholar] [CrossRef]

- Huang, Y.; Karami, B.; Shahsavari, D.; Tounsi, A. Static stability analysis of carbon nanotube reinforced polymeric composite doubly curved micro-shell panels. Arch. Civ. Mech. Eng. 2021, 21, 1–15. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Appearance | Homogeneous liquid of light-yellow color |

| Density at 25 °C (kg/m3) | 1030–1070 |

| Hydrogen index (pH) | 4 |

| Maximum content of Cl ions | 0.1 |

| Parameter | Normative Value | Actual Value |

|---|---|---|

| Chemical consistency | Polypropylene | Polypropylene |

| Type | Monofiber | Monofiber |

| Fiber length | 6–15 mm | Compliant |

| Fiber diameter | 18–21 microns | 20 microns |

| Shape | Round | Round |

| Surface | Finished with a special compound that facilitates dispersion and adhesion to cement mortar | Finished with Silastol CUT 70 |

| Density | 0.91 g/cm³ | 0.91 g/cm³ |

| Fiber frequency | 19.8 mln/kg | Compliant |

| Tensile strength | 320–600 MPa | Compliant |

| Young’s modulus | 3500–3900 MPa | Compliant |

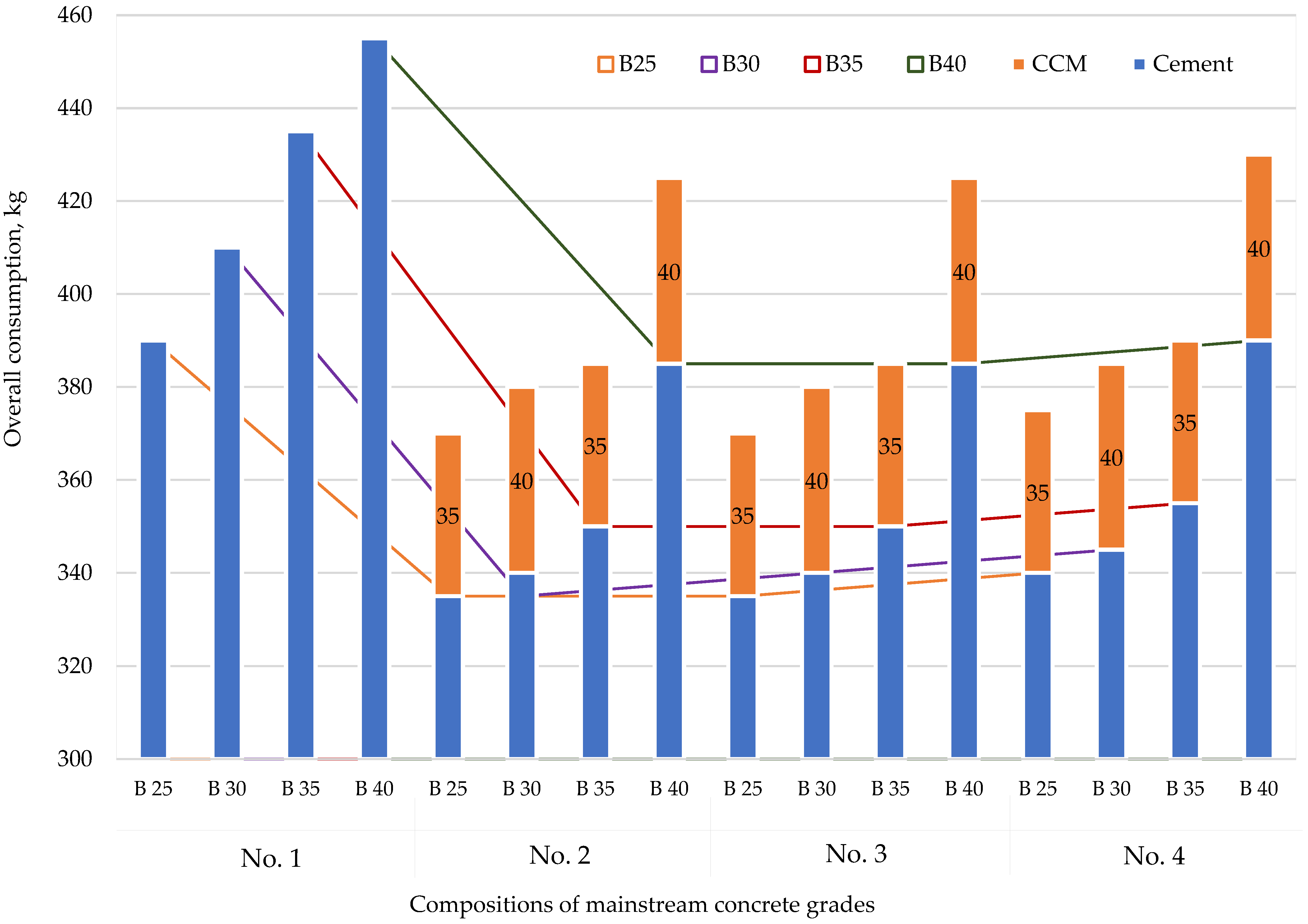

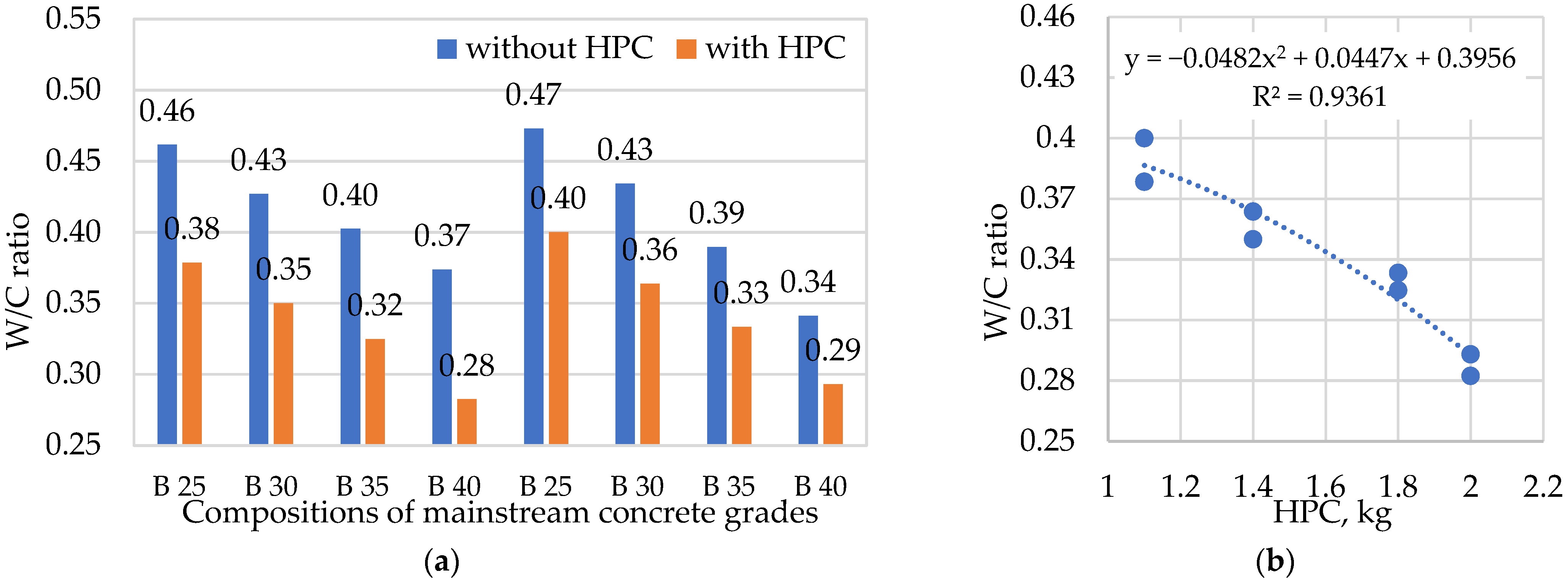

| Composition No. | Design Grade | Cement CEM I 52.5 N (kg) | Fiber (kg) | Microsilica (kg) | Hyperplasticizer (kg) | Crushed Stone (kg) | Sand (kg) | Water (L) | Total Consumption (kg) |

|---|---|---|---|---|---|---|---|---|---|

| 1 | B 25 | 390 | - | - | - | 1000 | 850 | 180 | 2420 |

| B 30 | 410 | - | - | - | 1030 | 810 | 175 | 2425 | |

| B 35 | 435 | - | - | - | 1100 | 780 | 175 | 2490 | |

| B 40 | 455 | - | - | - | 1150 | 700 | 170 | 2475 | |

| 2 | B 25 | 335 | - | 35 | - | 1100 | 770 | 175 | 2415 |

| B 30 | 340 | - | 40 | - | 1140 | 740 | 165 | 2425 | |

| B 35 | 350 | - | 35 | - | 1180 | 710 | 150 | 2425 | |

| B 40 | 385 | - | 40 | - | 1200 | 685 | 145 | 2455 | |

| 3 | B 25 | 335 | - | 35 | 1.1 | 1100 | 770 | 140 | 2380 |

| B 30 | 340 | - | 40 | 1.4 | 1140 | 740 | 133 | 2393 | |

| B 35 | 350 | - | 35 | 1.8 | 1180 | 710 | 125 | 2400 | |

| B 40 | 385 | - | 40 | 2.0 | 1200 | 685 | 120 | 2430 | |

| 4 | B 25 | 340 | 3 | 35 | 1.1 | 1095 | 770 | 150 | 2393 |

| B 30 | 345 | 3 | 40 | 1.4 | 1135 | 740 | 140 | 2403 | |

| B 35 | 355 | 3 | 35 | 1.8 | 1175 | 751 | 130 | 2449 | |

| B 40 | 390 | 3 | 40 | 2.0 | 1195 | 685 | 126 | 2439 |

| Method, Grade of Frost Resistance | Test Conditions | Concrete Type | ||

|---|---|---|---|---|

| Saturation Environment | Environment and Freezing Temperature | Environment and Thawing Temperature | ||

| Basic methods | ||||

| First, F1 | Water | Air, −18 °C | Water, (20 ± 2) °C | All types, except for road and airfield concretes and structures operating under the influence of saline water. |

| Second, F2 | 5% aqueous NaCl mixture | Air, −18 °C | 5% aqueous NaCl mixture, (20 ± 2) °C | Concretes of road and airfield pavements and concretes of structures operating under the influence of saline water |

| Accelerated methods | ||||

| Second | 5% aqueous NaCl mixture | Air, −18 °C | 5% aqueous NaCl mixture, (20 ± 2) °C | All types, except for road and airfield pavement concretes and structures operating under the influence of saline water, as well as lightweight concretes with an average density of less than D1500. |

| Third | 5% aqueous NaCl mixture | 5% aqueous NaCl mixture, minus (50 ± 2) °C | 5% aqueous NaCl mixture, (20 ± 2) °C | All types of concrete, except for lightweight concretes with an average density of less than D1500. |

| Sample Size (mm) | Freezing | Thawing | ||

|---|---|---|---|---|

| Minimum Time (h) | Temperature (°C) | Minimum Time (h) | Temperature (°C) | |

| 100 × 100 × 100 | 2.5 | −18 | 2 ± 0.5 | 20 ± 2 |

| 150 × 150 × 150 | 3.5 | 3 ± 0.5 | ||

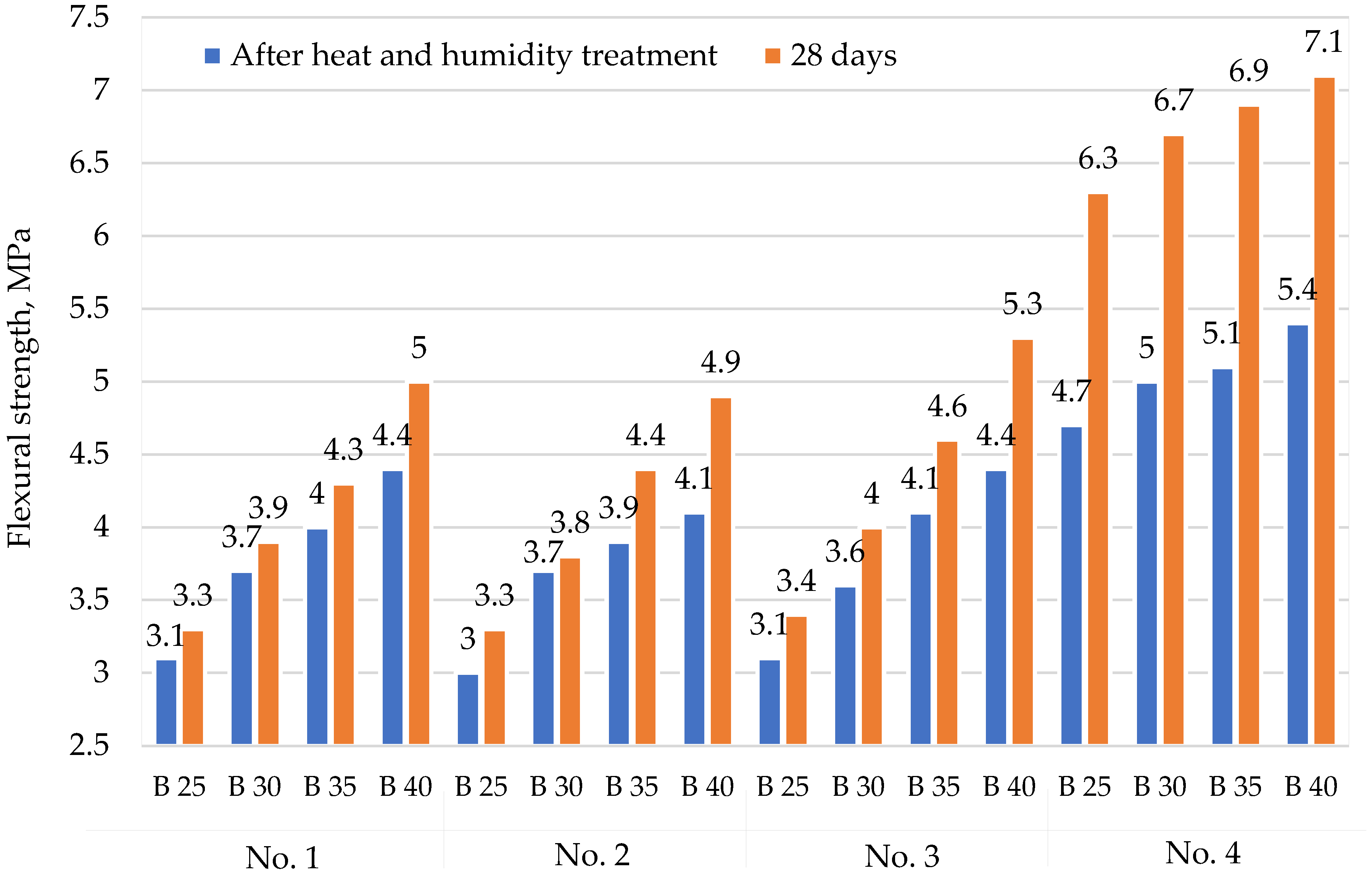

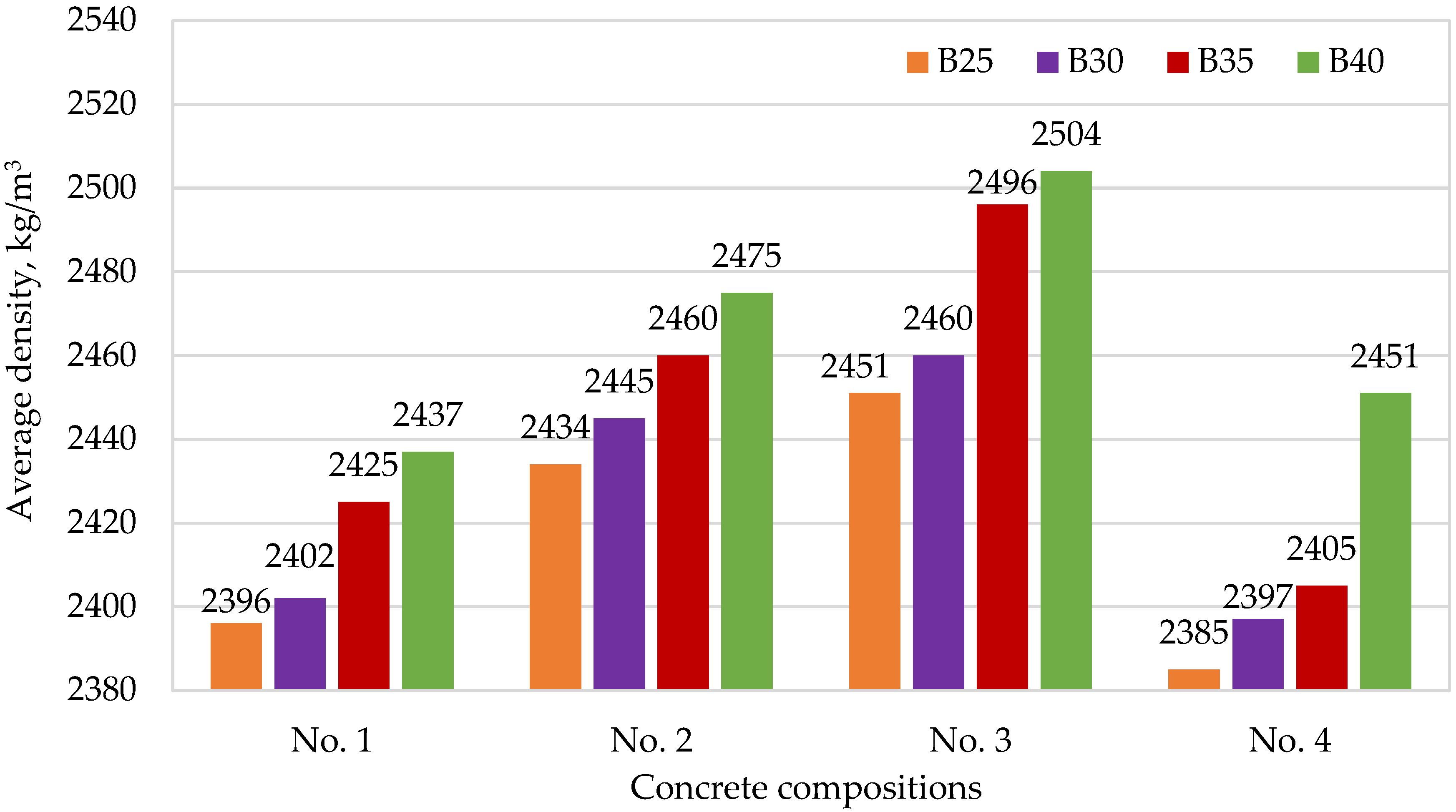

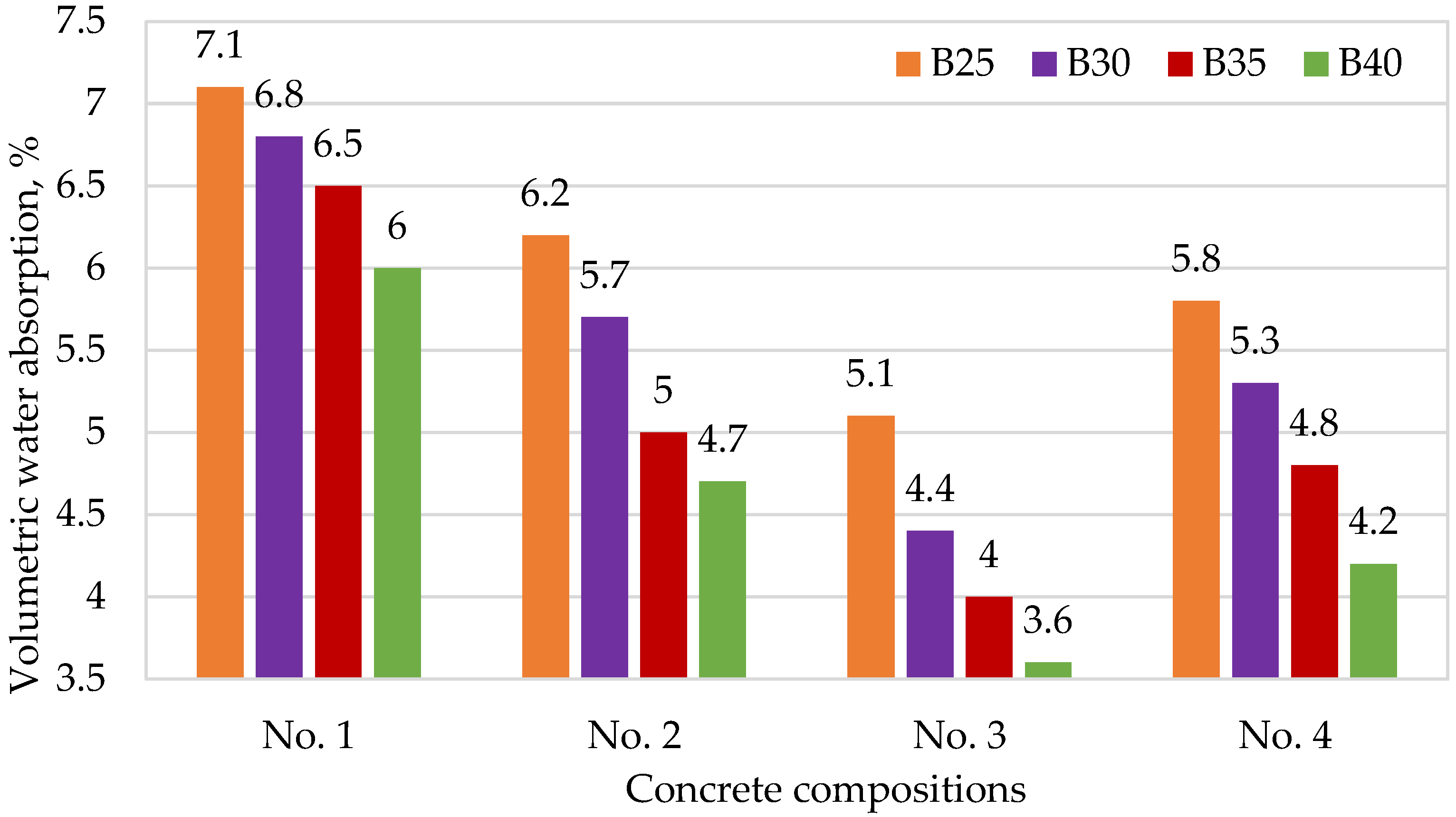

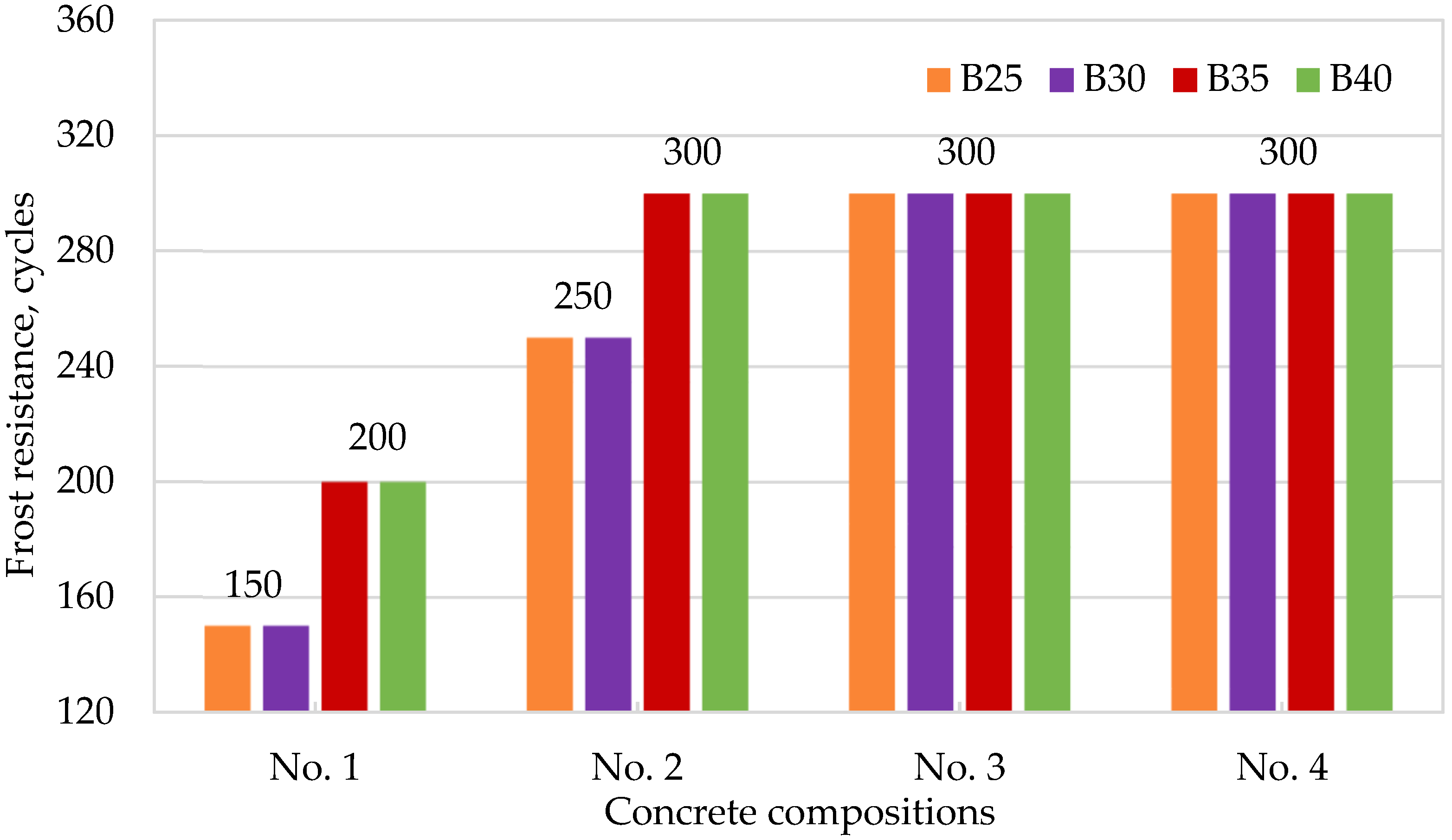

| Composition No. | Design Grade | Compressive Strength (MPa) (Rb) | Flexural Strength (MPa) (Rbt) | Frost Resistance, Cycles (F) | Volumetric Water Absorption (%) | Average Density (kg/m3) | ||

|---|---|---|---|---|---|---|---|---|

| After Heating | 28 Days | After Heating | 28 Days | |||||

| 1 | B 25 | 24.9 | 32.4 | 3.1 | 3.3 | 150 | 7.1 | 2396 |

| B 30 | 29.7 | 38.7 | 3.7 | 3.9 | 150 | 6.8 | 2402 | |

| B 35 | 31.4 | 45.3 | 4.0 | 4.3 | 200 | 6.5 | 2425 | |

| B 40 | 37.2 | 52.7 | 4.4 | 5.0 | 200 | 6.0 | 2437 | |

| 2 | B 25 | 25.2 | 32.6 | 3.0 | 3.3 | 250 | 6.2 | 2434 |

| B 30 | 30.1 | 38.9 | 3.7 | 3.8 | 250 | 5.7 | 2445 | |

| B 35 | 35.1 | 45.5 | 3.9 | 4.4 | 300 | 5.0 | 2460 | |

| B 40 | 42.0 | 53.1 | 4.1 | 4.9 | 300 | 4.7 | 2475 | |

| 3 | B 25 | 26.0 | 32.5 | 3.1 | 3.4 | 300 | 5.1 | 2451 |

| B 30 | 29.3 | 39.0 | 3.6 | 4.0 | 300 | 4.4 | 2460 | |

| B 35 | 39.3 | 45.1 | 4.1 | 4.6 | 300 | 4.0 | 2496 | |

| B 40 | 47.2 | 53.5 | 4.4 | 5.3 | 300 | 3.6 | 2504 | |

| 4 | B 25 | 24.6 | 33.0 | 4.7 | 6.3 | 300 | 5.8 | 2385 |

| B 30 | 29.5 | 39.7 | 5.0 | 6.7 | 300 | 5.3 | 2397 | |

| B 35 | 36.2 | 50.1 | 5.1 | 6.9 | 300 | 4.8 | 2405 | |

| B 40 | 44.1 | 52.5 | 5.4 | 7.1 | 300 | 4.2 | 2451 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akhmetov, D.A.; Pukharenko, Y.V.; Vatin, N.I.; Akhazhanov, S.B.; Akhmetov, A.R.; Jetpisbayeva, A.Z.; Utepov, Y.B. The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica. Materials 2022, 15, 2648. https://doi.org/10.3390/ma15072648

Akhmetov DA, Pukharenko YV, Vatin NI, Akhazhanov SB, Akhmetov AR, Jetpisbayeva AZ, Utepov YB. The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica. Materials. 2022; 15(7):2648. https://doi.org/10.3390/ma15072648

Chicago/Turabian StyleAkhmetov, Daniyar Akbulatovich, Yuri Vladimirovich Pukharenko, Nikolai Ivanovich Vatin, Sungat Berkinovich Akhazhanov, Akbulat Raiymbekovich Akhmetov, Ainur Zhenisbekkyzy Jetpisbayeva, and Yelbek Bakhitovich Utepov. 2022. "The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica" Materials 15, no. 7: 2648. https://doi.org/10.3390/ma15072648

APA StyleAkhmetov, D. A., Pukharenko, Y. V., Vatin, N. I., Akhazhanov, S. B., Akhmetov, A. R., Jetpisbayeva, A. Z., & Utepov, Y. B. (2022). The Effect of Low-Modulus Plastic Fiber on the Physical and Technical Characteristics of Modified Heavy Concretes Based on Polycarboxylates and Microsilica. Materials, 15(7), 2648. https://doi.org/10.3390/ma15072648