Bond–Slip Relationship between Sand-Coated Polypropylene Coarse Aggregate Concrete and Plain Rebar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cement and Superplasticizer

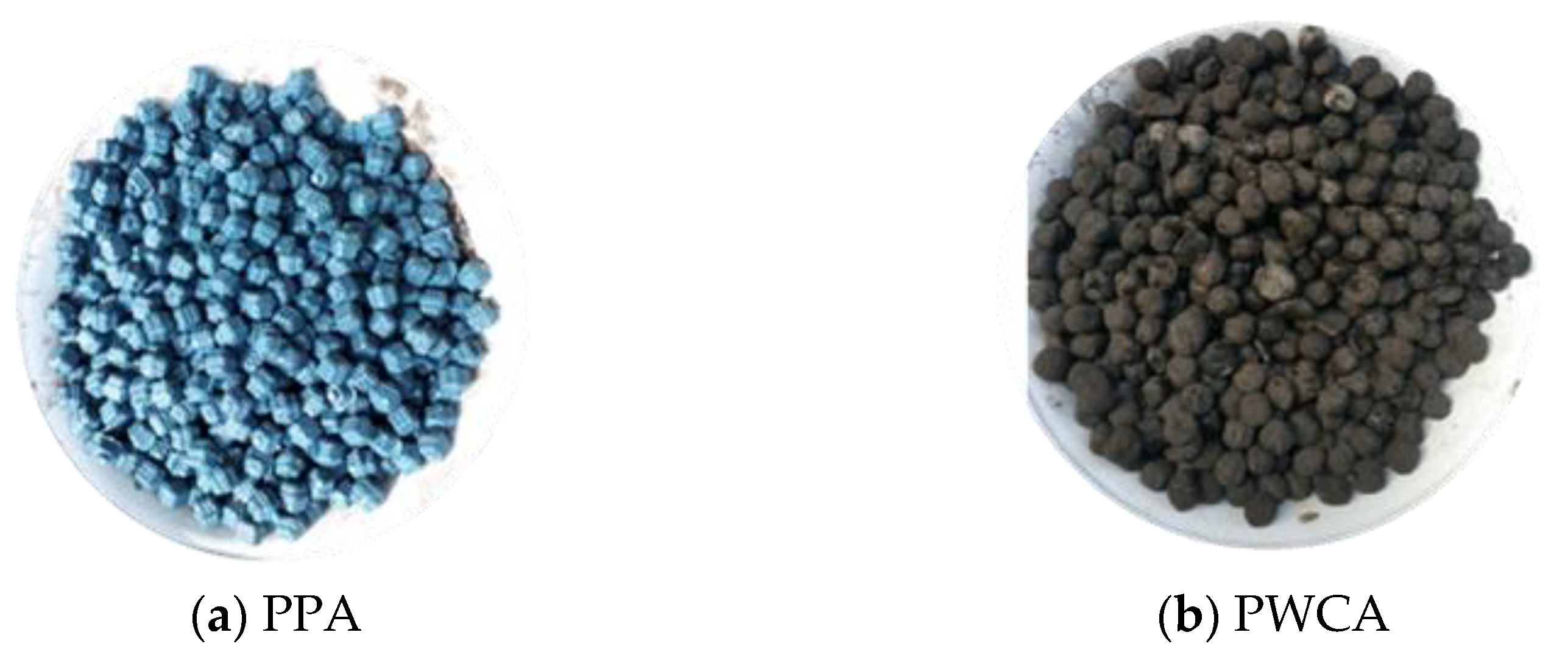

2.1.2. Fine Aggregate and PP Waste Coarse Aggregate

2.1.3. Reinforcement Steel

2.2. Mix Proportions

2.3. Designation of Specimens

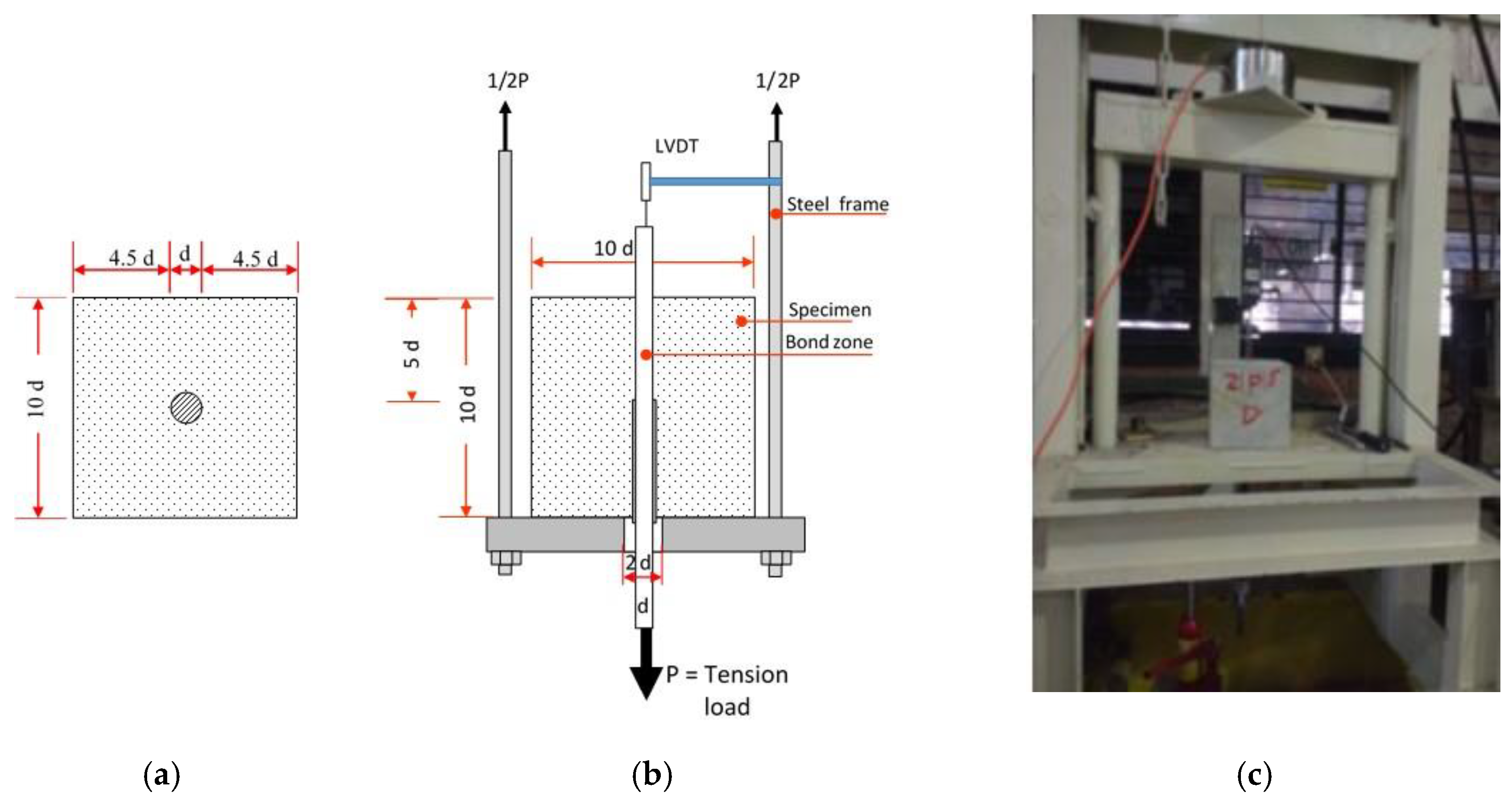

2.4. Test Method

3. Results and Discussion

3.1. Physical and Mechanical Properties of Concrete

3.2. Bond Stress–Slip Behavior

3.3. Failure Mode

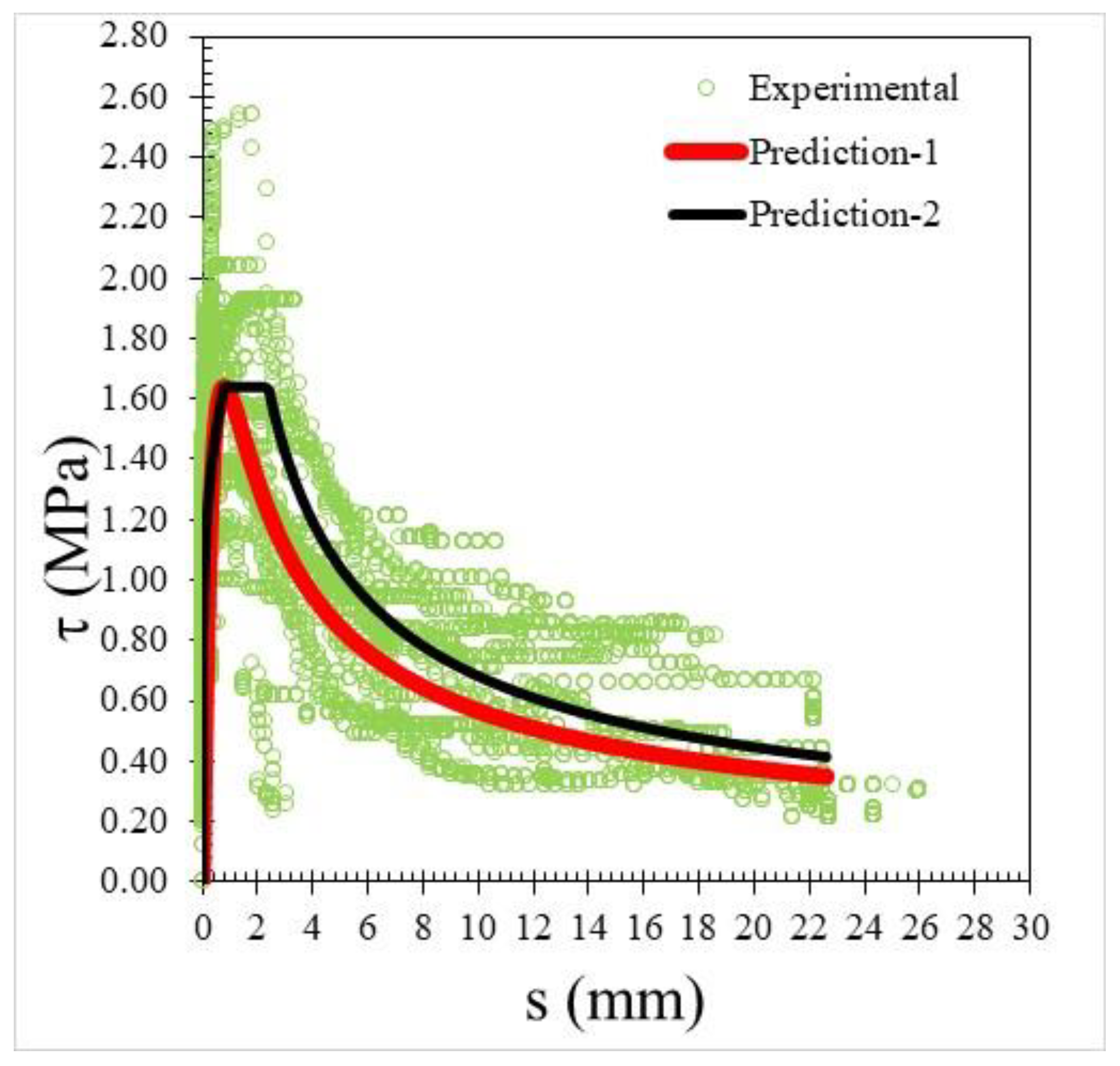

3.4. Bond–Slip Model

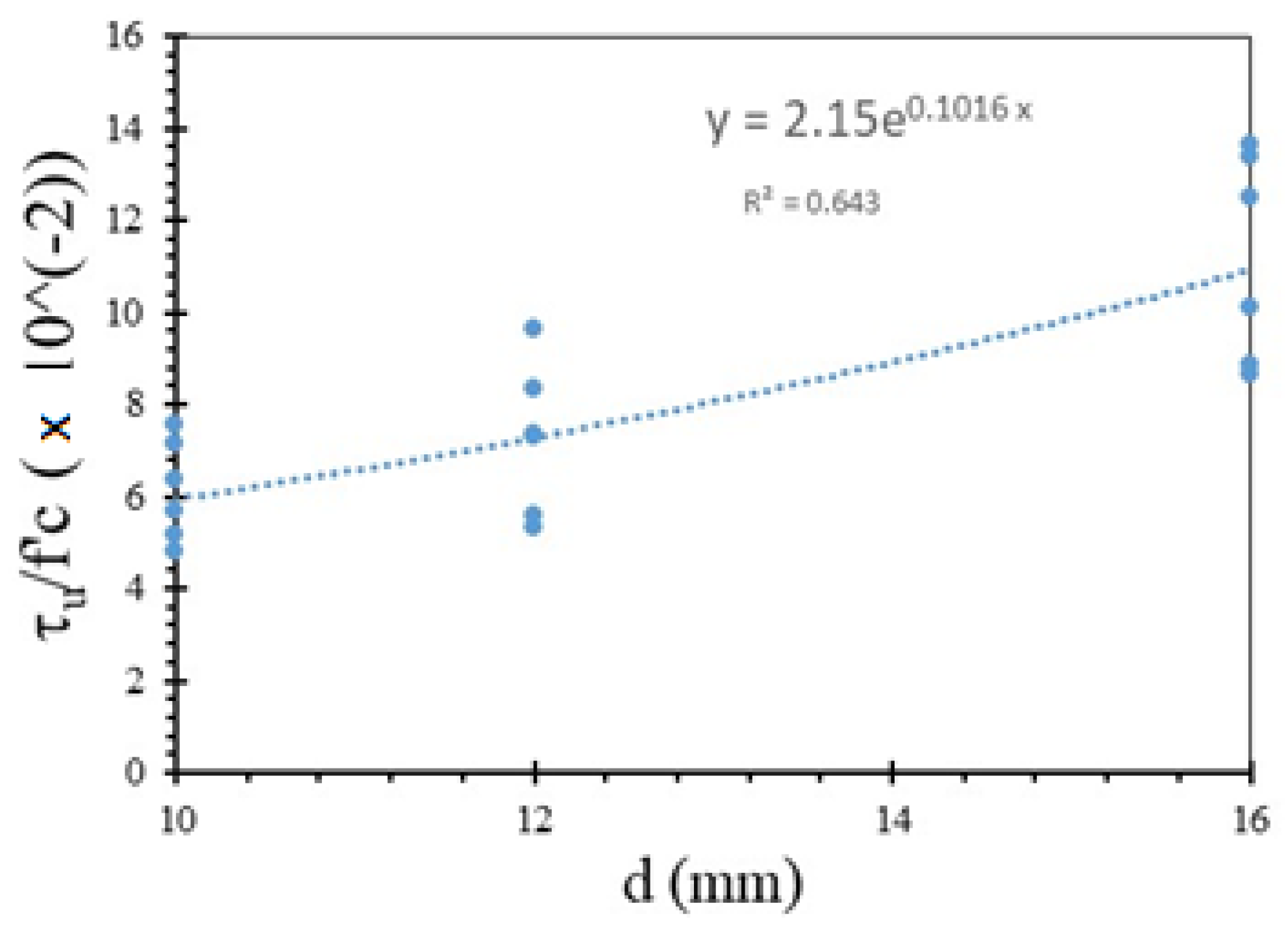

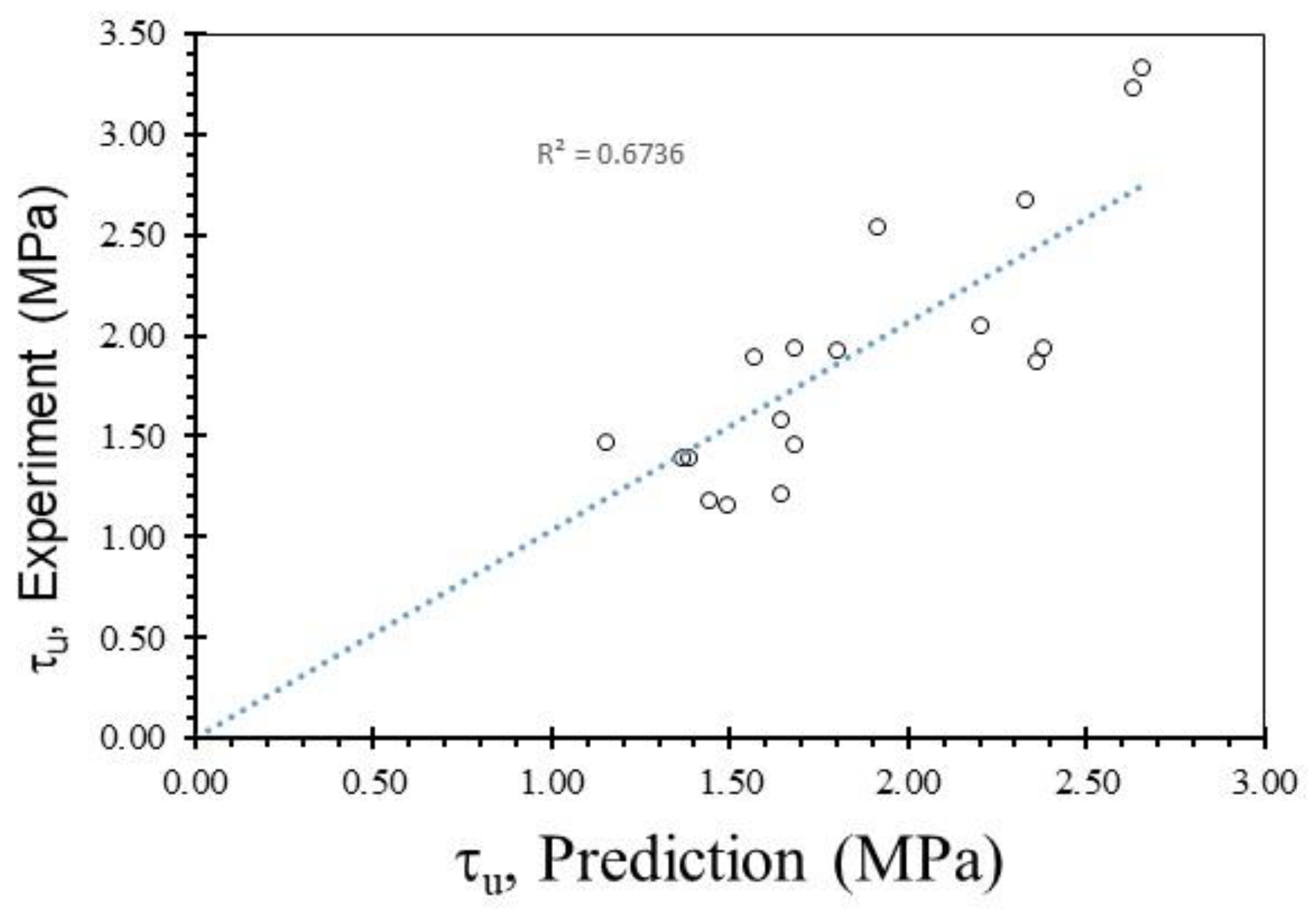

3.4.1. Proposed Bond Strength

3.4.2. Bond–Slip Relationship

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cairns, J. Local bond–slip model for plain surface reinforcement. Struct. Concr. 2020, 22, 666–675. [Google Scholar] [CrossRef]

- Tang, C.-W.; Cheng, C.-K. Modelling Local Bond Stress–Slip Relationships of Reinforcing Bars Embedded in Concrete with Different Strengths. Materials 2020, 13, 3701. [Google Scholar] [CrossRef] [PubMed]

- ACI 408R-03; Bond and Development of Straight Reinforcing Bars in Tension. American Concrete Institute: Farmington Hills, MI, USA, 2003.

- Mo, Y.L.; Chan, J. Bond and Slip of Plain Rebars in Concrete. J. Mater. Civ. Eng. 1996, 8, 208–211. [Google Scholar] [CrossRef]

- Feldman, L.; Bartlett, F.M. Bond Strength Variability in Pullout Specimens with Plain Reinforcement. ACI Struct. J. 2005, 102, 860–867. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, Z.; Zheng, J.; Dong, W.; Bouchair, A. Ultimate bond strength of plain round bars embedded in concrete subjected to uniform lateral tension. Constr. Build. Mater. 2016, 117, 163–170. [Google Scholar] [CrossRef]

- Ahmad, S.; Pilakoutas, K.; Rafi, M.M.; Khan, Q.U.Z.; Neocleous, K. Experimental Investigation of Bond Characteristics of Deformed and Plain Bars in Low Strength Concrete. Sci. Iran. 2018, 25, 2954–2966. [Google Scholar] [CrossRef] [Green Version]

- Feldman, L.; Bartlett, F.M. Bond Stresses along Plain Steel Reinforcing Bars in Pullout Specimens. ACI Struct. J. 2007, 104, 685–692. [Google Scholar] [CrossRef]

- Alkaysi, M.; El-Tawil, S. Bond between Ultra-High Performance Concrete and Steel Bars. In Proceedings of the First International Interactive Symposium on UHPC, Des Moines, IA, USA, 18–20 July 2016; pp. 1–10. [Google Scholar]

- Shang, H.-S.; Cui, F.-K.; Zhang, P.; Zhao, T.-J.; Ren, G.-S. Bond behavior of steel bar embedded in recycled coarse aggregate concrete under lateral compression load. Constr. Build. Mater. 2017, 150, 529–537. [Google Scholar] [CrossRef]

- Xiao, J.; Falkner, H. Bond behaviour between recycled aggregate concrete and steel rebars. Constr. Build. Mater. 2007, 21, 395–401. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Bond characteristics of plain and deformed bars in lightweight pumice concrete. Constr. Build. Mater. 2008, 22, 1491–1499. [Google Scholar] [CrossRef]

- Liu, X.; Liu, Y.; Wu, T.; Wei, H. Bond-slip properties between lightweight aggregate concrete and rebar. Constr. Build. Mater. 2020, 255, 119355. [Google Scholar] [CrossRef]

- Teo, D.C.L.; Mannan, M.A.; Kurian, V.J. Structural Bond Performance of Lightweight Concrete. Build. Environ. 2007, 42, 2614–2621. [Google Scholar] [CrossRef]

- Purnomo, H.; Pamudji, G.; Satim, M. Influence of uncoated and coated plastic waste coarse aggregates to concrete compressive strength. MATEC Web Conf. 2017, 101, 1016. [Google Scholar] [CrossRef] [Green Version]

- Pamudji, G.; Satim, M.; Chalid, M.; Purnomo, H. The Influence of River and Volcanic Sand as Coatings on Polypropylene Waste Coarse Aggregate towards Concrete Compressive Strength. J. Teknol. 2020, 82, 11–16. [Google Scholar] [CrossRef]

- Abu-Saleem, M.; Zhuge, Y.; Hassanli, R.; Ellis, M.; Rahman, M.; Levett, P. Stress-Strain Behaviour and Mechanical Strengths of Concrete Incorporating Mixed Recycled Plastics. J. Compos. Sci. 2021, 5, 146. [Google Scholar] [CrossRef]

- Al Bakri, A.M.M.; Tamizi, S.M.; Rafiza, A.R.; Zarina, Y. Investigation of HDPE plastic waste aggregate on the properties of concrete. J. Asian Sci. Res. 2011, 1, 340–345. [Google Scholar]

- Abeysinghe, S.; Gunasekara, C.; Bandara, C.; Nguyen, K.; Dissanayake, R.; Mendis, P. Engineering Performance of Concrete Incorporated with Recycled High-Density Polyethylene (HDPE)—A Systematic Review. Polymers 2021, 13, 1885. [Google Scholar] [CrossRef]

- Choi, Y.W.; Moon, D.J.; Kim, Y.J.; Lachemi, M. Characteristics of mortar and concrete containing fine aggregate manufactured from recycled waste polyethylene terephthalate bottles. Constr. Build. Mater. 2009, 23, 2829–2835. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef]

- Islam, J.; Meherier, S.; Islam, A.R. Effects of waste PET as coarse aggregate on the fresh and harden properties of concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Alqahtani, F. Sustainable Green Lightweight Concrete Containing Plastic-Based Green Lightweight Aggregate. Materials 2021, 14, 3304. [Google Scholar] [CrossRef] [PubMed]

- Lakshmi, R.; Nagan, S. Studies on Concrete containing E plastic waste. Int. J. Environ. Sci. 2010, 1, 270–281. [Google Scholar]

- Arora, A.; Dave, U.V. Utilization of e-waste and plastic bottle waste. Int. J. Stud. Res. Technol. Manag. 2013, 1, 398–406. [Google Scholar]

- Ali, K.; Qureshi, M.I.; Saleem, S.; Khan, S.U. Effect of waste electronic plastic and silica fume on mechanical properties and thermal performance of concrete. Constr. Build. Mater. 2021, 285, 122952. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2022, 15, 175. [Google Scholar] [CrossRef]

- Ullah, S.; Qureshi, M.I.; Joyklad, P.; Suparp, S.; Hussain, Q.; Chaiyasarn, K.; Yooprasertchai, E. Effect of partial replacement of E-waste as a fine aggregate on compressive behavior of concrete specimens having different geometry with and without CFRP confinement. J. Build. Eng. 2022, 50, 104151. [Google Scholar] [CrossRef]

- Ekolu, S.O. Service Life Design for Inland Concrete Structures in Africa: Kampala Case Study. In RILEM Bookseries; Springer Science and Business Media LLC: Singapore, 2020; Volume 26, pp. 132–136. [Google Scholar]

- Pamudji, G.; Heribowo, B.; Adam, Y.; Purnomo, H. Bond-Slip Behavior of Steel Bar Embedded in Lightweight Concrete Using Sand Coated Polypropylene Coarse Aggregate. Mater. Sci. Forum 2018, 929, 103–108. [Google Scholar] [CrossRef]

- RC 6 Bond Test for Reinforcement Steel. Pull-Out Test. In RILEM Technical Recommendations for the Testing and Use of Construction Materials; CRC Press: Boca Raton, FL, USA, 1994.

- Pamudji, G.; Purnomo, H.; Katili, I.; Imran, I. The use of plastics waste as coarse aggregates. In Proceeding of the 6th Civil Engineering Conference in Asia Region: Embracing the Future through Sustainability, Jakarta, Indonesia, 20–22 August 2013. [Google Scholar]

- ASTM C330; Standard Specification for Lightweight Aggregates for Structural Concrete. ASTM: West Conshohocken, PA, USA, 2000.

- SNI 2461; Standard Specification for Lightweight Aggregates for Structural Concrete. National Standardization Agency of Indonesia: Jakarta, Indonesia, 2014.

- ASTM C567; Committee Test Method for Determining Density of Structural Lightweight Concrete. ASTM: West Conshohocken, PA, USA, 2004.

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM: West Conshohocken, PA, USA, 2004.

- Xing, G.; Zhou, C.; Wu, T.; Liu, B. Experimental Study on Bond Behavior between Plain Reinforcing Bars and Concrete. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Song, Z.; Yi, J.; Li, J.; Fu, F.; Qian, K. Experimental Studies on Bond Performance of BFRP Bars Reinforced Coral Aggregate Concrete. Int. J. Concr. Struct. Mater. 2019, 13, 1–10. [Google Scholar] [CrossRef]

- Rafi, M.M. Study of Bond Properties of Steel Rebars with Recycled Aggregate Concrete. Analytical Modeling. Strength Mater. 2019, 51, 166–174. [Google Scholar] [CrossRef]

- Verderame, G.M.; DE Carlo, G.; Ricci, P.; Fabbrocino, G. Cyclic bond behaviour of plain bars. Part II: Analytical investigation. Constr. Build. Mater. 2009, 23, 3512–3522. [Google Scholar] [CrossRef]

- FIB. FIB Model Code 2010; The International Federation for Structural Concrete: Lausanne, Switzerland, 2010; Volume 1. [Google Scholar]

- Maree, A.F.; Riad, K.H. Analytical and experimental investigation for bond behaviour of newly developed polystyrene foam particles’ lightweight concrete. Eng. Struct. 2014, 58, 1–11. [Google Scholar] [CrossRef]

- Kim, D.-J.; Kim, M.S.; Yun, G.Y.; Lee, Y.H. Bond strength of steel deformed rebars embedded in artificial lightweight aggregate concrete. J. Adhes. Sci. Technol. 2013, 27, 490–507. [Google Scholar] [CrossRef]

- Ichinose, T.; Kanayama, Y.; Inoue, Y.; Bolander, J. Size effect on bond strength of deformed bars. Constr. Build. Mater. 2004, 18, 549–558. [Google Scholar] [CrossRef]

- Gambarova, P.G.; Rosati, G.P.; Zasso, B. Steel-to-concrete bond after concrete splitting: Constitutive laws and interface deterioration. Mater. Struct. 1989, 22, 347–356. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

| RS | PWCA | |

|---|---|---|

| Density (g/cm3) | 0.535 | |

| Specific gravity: | ||

| Saturated surface dry (SSD) | 2.70 | 1.092 |

| Bulk | 2.59 | 1.071 |

| Apparent | 2.90 | 1.095 |

| Absorption (%) | 4.17 | 2.040 |

| Abrasion (%) | - | 10.80 |

| Fineness modulus | 2.32 | 4.25 |

| Diameter of Rebar, d (mm) | Yield Stress, Fy (MPa) | Ultimate Stress, Fu (MPa) |

|---|---|---|

| 10 | 313 | 456 |

| 12 | 332 | 474 |

| 16 | 315 | 462 |

| Series | W/C | Cement | Sand | PWCA | Water | Superplasticizer (%) |

|---|---|---|---|---|---|---|

| LC-20 | 0.29 | 1 | 2 | 2.6 | 0.91 | 0.6 |

| LC-23 | 0.29 | 1 | 2 | 2.0 | 0.90 | 0.7 |

| LC-26 | 0.29 | 1 | 2 | 1.8 | 0.90 | 0.8 |

| NC-23 | 0.30 | 1 | 1.3 | 2.3 | 0.90 | 0.7 |

| Series | Sample Number | Density (gr/cm3) | Concrete Strength (MPa) |

|---|---|---|---|

| LC-20 | I | 1.734 | 20.72 |

| II | 1.838 | 23.93 | |

| III | 1.692 | 19.88 | |

| IV | 1.751 | 19.49 | |

| Average | 1.754 | 21.01 | |

| LC-23 | I | 1.728 | 24.13 |

| II | 1.820 | 26.52 | |

| III | 1.784 | 22.40 | |

| IV | 1.811 | 20.75 | |

| Average | 1.786 | 23.45 | |

| LC-26 | I | 1.738 | 26.55 |

| II | 1.819 | 26.32 | |

| III | 1.777 | 26.98 | |

| IV | 1.839 | 26.49 | |

| Average | 1.793 | 26.58 |

| Series | Bar Dia. | Density (gr/cm3) | Concrete Strength (MPa) | Bond Strength | Slip | |

|---|---|---|---|---|---|---|

| Non-Destructive | Average | Bond Strength (MPa), τu | Free end Slip (mm), S1 | |||

| LC26-P10B | 10 | 1.889 | 28.33 | 25.36 | 1.46 | 0.28 |

| LC26-P10C | 10 | 1.913 | 27.69 | 0.80 | 0.02 | |

| LC26-P10D | 10 | 1.871 | 30.35 | 1.93 | 1.43 | |

| LC26-P12B | 12 | 1.779 | 23.12 | 1.93 | 0.54 | |

| LC26-P12C | 12 | 1.819 | 22.63 | 1.20 | 0.90 | |

| LC26-P12D | 12 | 1.787 | 26.35 | 2.54 | 1.36 | |

| LC26-P16B | 16 | 1.782 | 24.36 | 3.68 | 2.39 | |

| LC26-P16C | 16 | 1.807 | 24.13 | 3.25 | 0.55 | |

| LC26-P16D | 16 | 1.773 | 21.31 | 3.03 | 1.90 | |

| LC23-P10A | 10 | 1.867 | 26.42 | 24.17 | 1.89 | 1.15 |

| LC23-P10B | 10 | 1.826 | 24.33 | 1.17 | 0.55 | |

| LC23-P10D | 10 | 1.780 | 27.69 | 1.57 | 0.61 | |

| LC23-P12B | 12 | 1.807 | 31.31 | 1.23 | 0.13 | |

| LC23-P12C | 12 | 1.695 | 18.85 | 1.39 | 0.81 | |

| LC23-P12D | 12 | 1.754 | 19.03 | 1.39 | 0.57 | |

| LC23-P16A | 16 | 1.877 | 25.50 | 1.40 | 1.90 | |

| LC23-P16C | 16 | 1.703 | 20.20 | 2.04 | 0.47 | |

| LC20-P10A | 10 | 1.706 | 22.23 | 20.84 | 1.62 | 0.137 |

| LC20-P10C | 10 | 1.687 | 19.42 | 1.47 | 1.52 | |

| LC20-P10D | 10 | 1.622 | 20.31 | 1.75 | 0.25 | |

| LC20-P12A | 12 | 1.723 | 21.67 | 1.04 | 0.19 | |

| LC20-P12B | 12 | 1.750 | 20.58 | 1.15 | 0.16 | |

| LC20-P16B | 16 | 1.796 | 21.81 | 1.93 | 0.14 | |

| LC20-P16C | 16 | 1.775 | 21.60 | 1.87 | 1.17 | |

| LC20-P10A | 10 | 1.706 | 22.23 | 1.62 | 0.137 | |

| Series | Bar Dia. | Density (gr/cm3) | Concrete Strength (MPa) | Bond Strength | Slip | |

|---|---|---|---|---|---|---|

| Non-Destructive | Average | Bond Strength (MPa), τu | Free and Slip (mm), S1 | |||

| NC23-P16A | 16 | 2.330 | 22.33 | 22.96 | 2.39 | 0.85 |

| NC23-P16B | 16 | 2.363 | 23.35 | 1.53 | 2.11 | |

| NC23-P16C | 16 | 2.388 | 23.21 | 2.13 | 0.36 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Purnomo, H.; Chalid, M.; Pamudji, G.; Arrifian, T.W. Bond–Slip Relationship between Sand-Coated Polypropylene Coarse Aggregate Concrete and Plain Rebar. Materials 2022, 15, 2643. https://doi.org/10.3390/ma15072643

Purnomo H, Chalid M, Pamudji G, Arrifian TW. Bond–Slip Relationship between Sand-Coated Polypropylene Coarse Aggregate Concrete and Plain Rebar. Materials. 2022; 15(7):2643. https://doi.org/10.3390/ma15072643

Chicago/Turabian StylePurnomo, Heru, Mochamad Chalid, Gandjar Pamudji, and Taufiq Wildan Arrifian. 2022. "Bond–Slip Relationship between Sand-Coated Polypropylene Coarse Aggregate Concrete and Plain Rebar" Materials 15, no. 7: 2643. https://doi.org/10.3390/ma15072643

APA StylePurnomo, H., Chalid, M., Pamudji, G., & Arrifian, T. W. (2022). Bond–Slip Relationship between Sand-Coated Polypropylene Coarse Aggregate Concrete and Plain Rebar. Materials, 15(7), 2643. https://doi.org/10.3390/ma15072643