Performance of Sustainable Mortars Made with Filler from Different Construction By-Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characterisation of the Fillers Used

2.2. Heavy Metal Leaching Evaluation of the Fillers Used

2.3. Experimental Programme and Methods

3. Results and Discussion

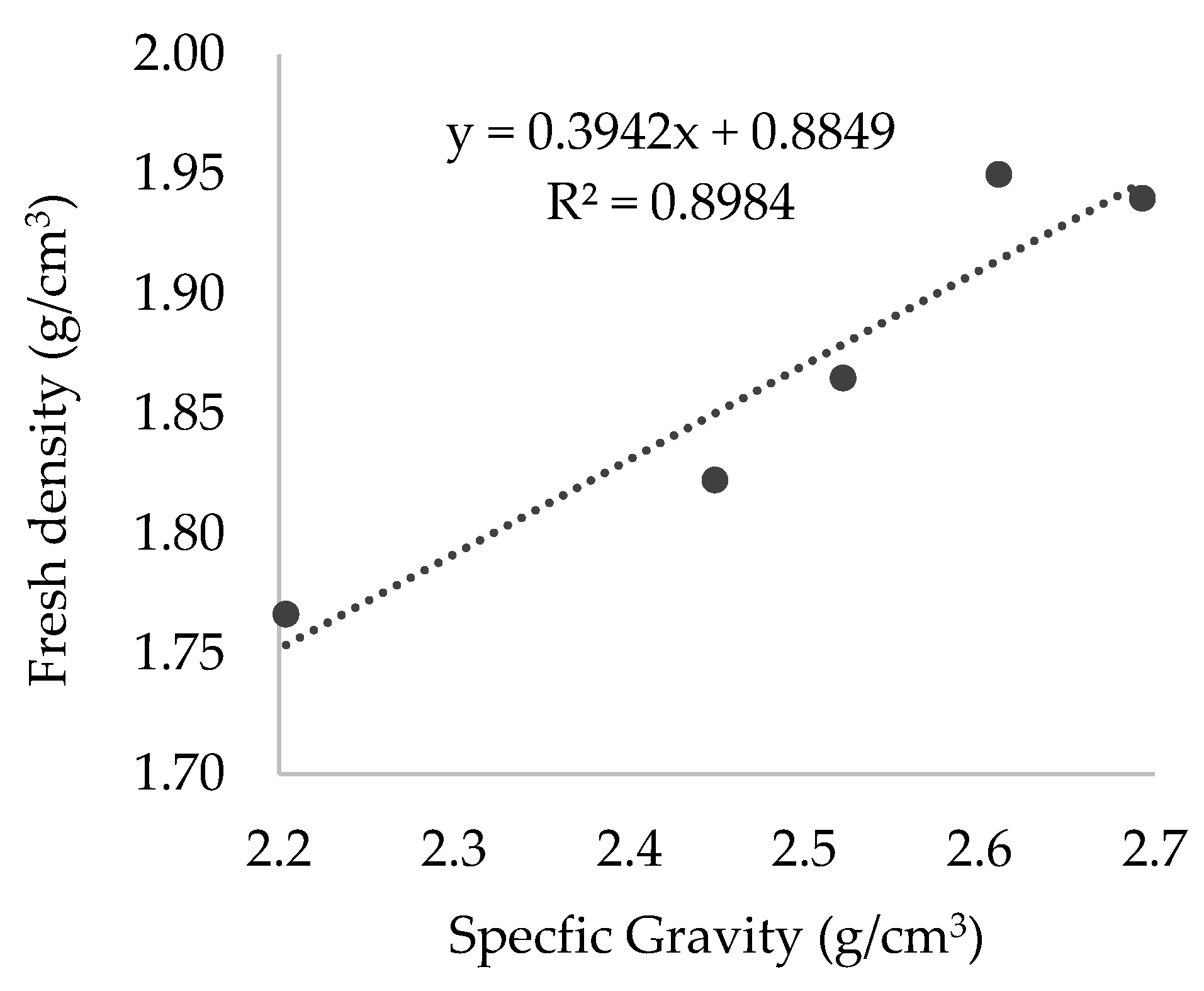

3.1. Properties in Fresh State

3.2. Properties in Hardened State

3.2.1. Physical Properties and Their Effects on Durability

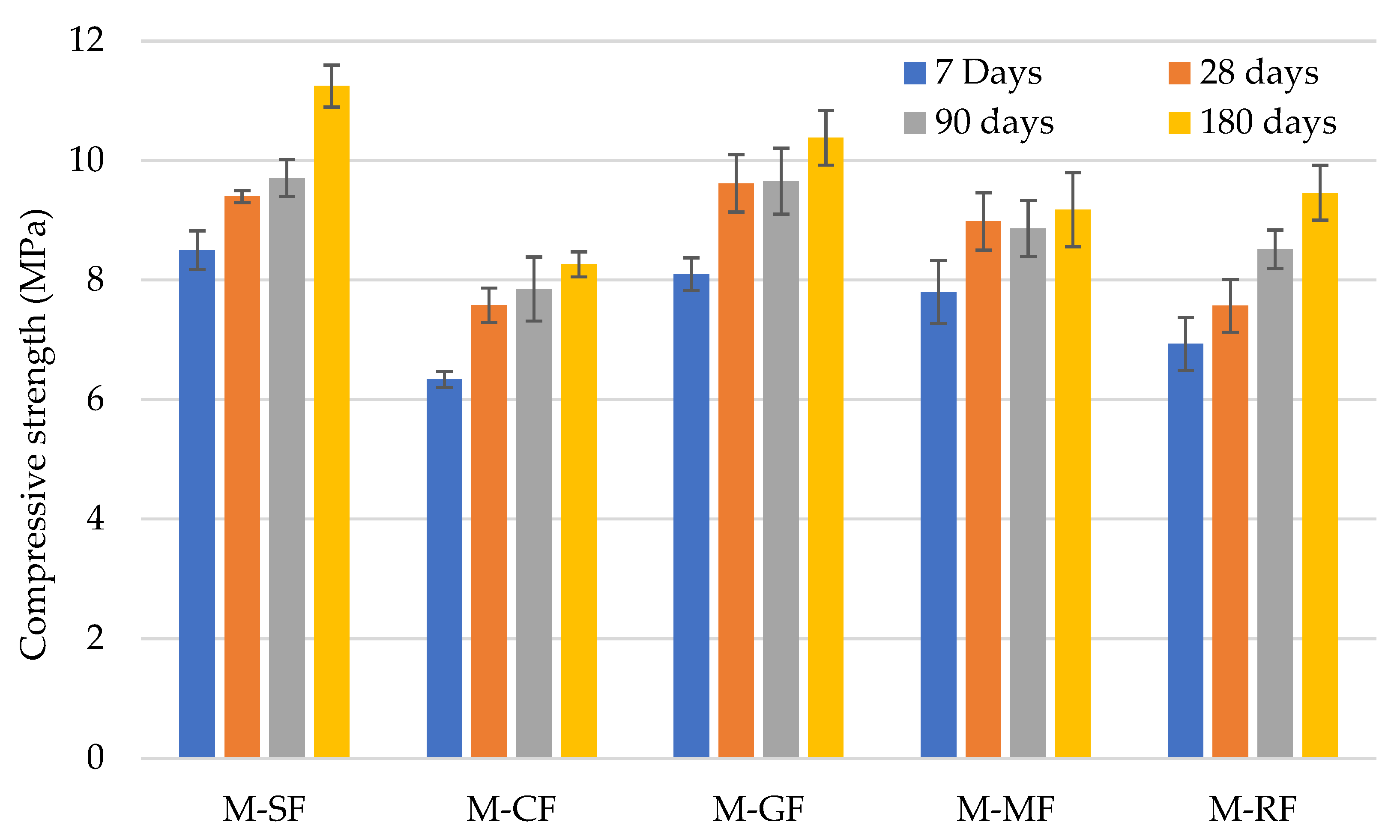

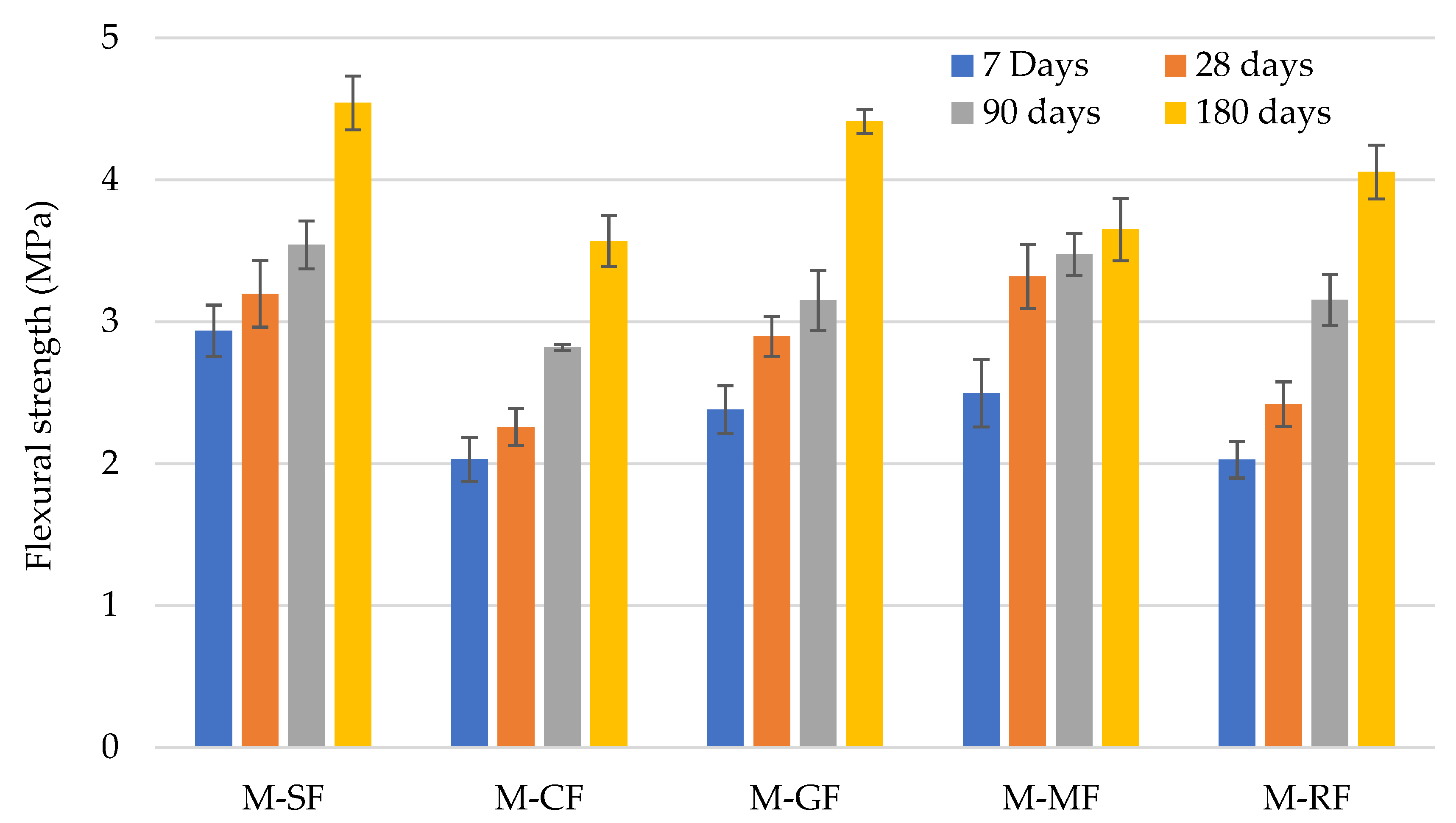

3.2.2. Mechanical Properties

4. Conclusions

- The fresh properties presented by the mortars produced were not substantially affected by the incorporation of the different construction by-products used as fillers compared to the reference, except the mortar with GF, which exhibited a relevant lower workable life and air entrained content. Despite the fact that the EN 998-1 and EN 998-2 specifications do not set any limit for these test methods, the addition of an additive agent in mortar mixes with ornamental rock sludge (M-MF), in order to enhance performance, could be interesting;

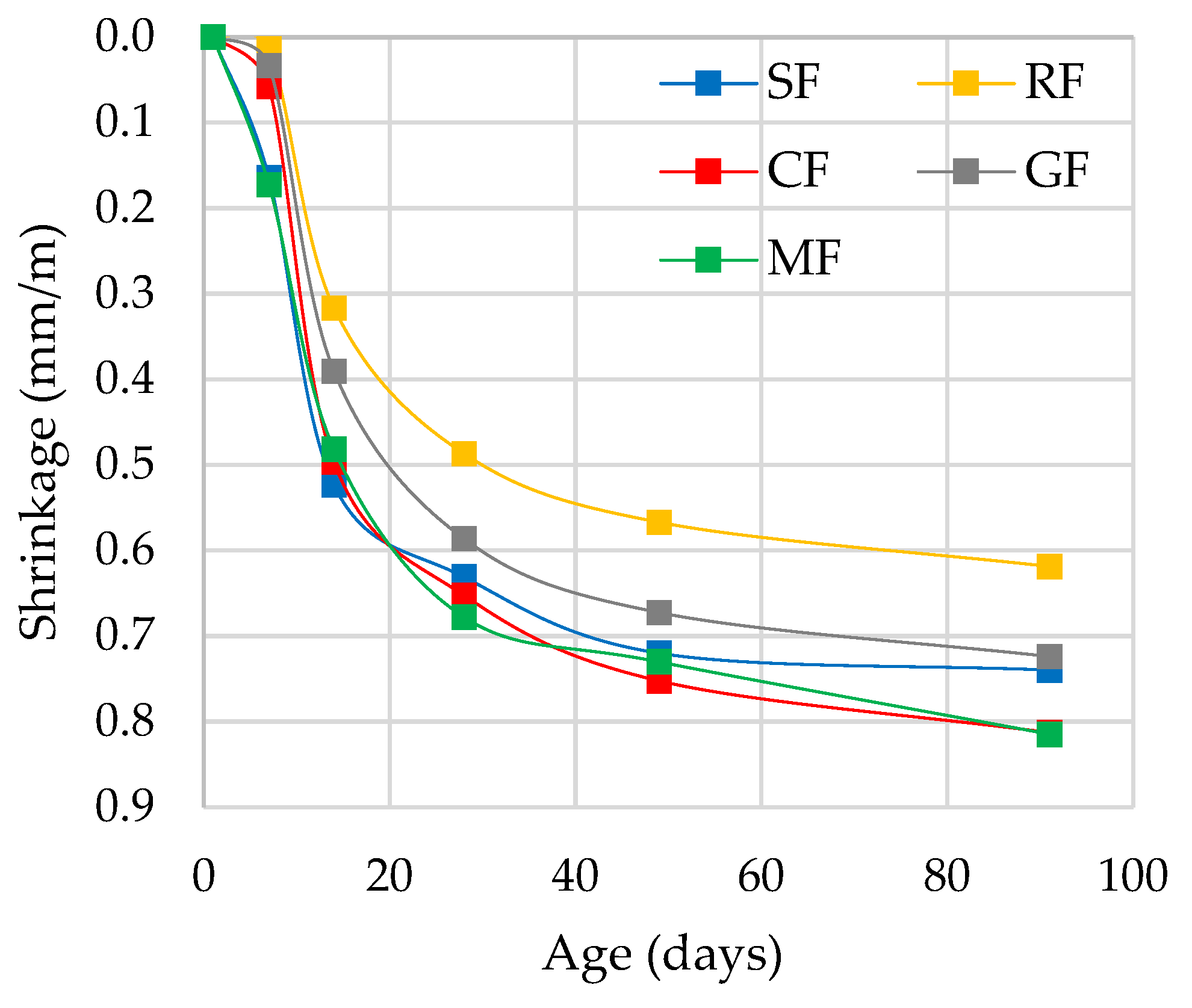

- In terms of the physical properties studied and their effects on durability, no relevant differences were found compared to the reference mortar. Capillarity water absorption differences in the mortars with respect to reference mix were ±23%, whereas in water vapour permeability, reference mix presented the highest value and M-MF a reduction of 35% with respect to it. The shrinkage of all the mortars studied was lower than 1 mm/m, which is the value usually presented by OPC mortars, and slight differences were found among them. Regarding the specifications EN 998-1 and EN 998-2, the use of the mortars produced would be restricted to regular, light, or coloured rendering and plastering mortar or bonding bricks and discarded as coating, repair, or thermal isolation mortars;

- With respect to the mechanical behaviour of the mortars produced, adhesive strength exhibited by the mortars with the different construction by-products as fillers was higher than the reference one, its use being valid as rendering plastering, according to EN 998-2, while the reference one was not. The incorporation of the construction by-products negatively affected the compressive and flexural strength. Despite this, all mortars would be commercially classified as M7.5, and, with respect to EN 998-1, Class CS IV would be proposed for regular, coloured, and coating rendering and plastering mortar. Over time, a similar performance was exhibited by all the mortars, achieving greater values of 8 MPa after 180 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Innovation Union. Communication from the Commission to the European Parliament, the COuncil, the European Economic and Social Committee and the Committee of the Regions; European Commission: Luxembourg, 2014; pp. 1–43. [Google Scholar]

- European Environment Agency (EEA). Circular Economy in Europe-Developing the Knowledge Base; EEA: Luxembourg, 2016; ISBN 9789292137199. [Google Scholar]

- Bouasker, M.; Mounanga, P. Chemical shrinkage of cement pastes and mortars at very early age: Effect of limestone filler and granular inclusions. Cem. Concr. Compos. 2008, 30, 13–22. [Google Scholar] [CrossRef] [Green Version]

- Srivastava, A.; Singh, S.K. Utilization of alternative sand for preparation of sustainable mortar: A review. J. Clean. Prod. 2020, 253, 119706. [Google Scholar] [CrossRef]

- Jackiewicz-Rek, W.; Załęgowski, K.; Garbacz, A.; Bissonnette, B. Properties of cement mortars modified with ceramic waste fillers. Procedia Eng. 2015, 108, 681–687. [Google Scholar] [CrossRef] [Green Version]

- Farinha, C.; de Brito, J.; Veiga, R. Incorporation of fine sanitary ware aggregates in coating mortars. Constr. Build. Mater. 2015, 83, 194–206. [Google Scholar] [CrossRef]

- López Gayarre, F.; López Boadella, Í.; López-Colina Pérez, C.; Serrano López, M.; Domingo Cabo, A. Influence of the ceramic recycled agreggates in the masonry mortars properties. Constr. Build. Mater. 2017, 132, 457–461. [Google Scholar] [CrossRef]

- Esquinas, A.R.; Ramos, C.; Jiménez, J.R.; Fernández, J.M.; de Brito, J. Mechanical behaviour of self-compacting concrete made with recovery filler from hot-mix asphalt plants. Constr. Build. Mater. 2017, 131, 114–128. [Google Scholar] [CrossRef]

- Esquinas, A.R.; Álvarez, J.I.; Jiménez, J.R.; Fernández, J.M.; de Brito, J. Durability of self-compacting concrete made with recovery filler from hot-mix asphalt plants. Constr. Build. Mater. 2018, 161, 407–419. [Google Scholar] [CrossRef]

- Amaral, L.F.; Girondi Delaqua, G.C.; Nicolite, M.; Marvila, M.T.; de Azevedo, A.R.G.; Alexandre, J.; Fontes Vieira, C.M.; Monteiro, S.N. Eco-friendly mortars with addition of ornamental stone waste-A mathematical model approach for granulometric optimization. J. Clean. Prod. 2020, 248, 119283. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Alexandre, J.; Marvila, M.T.; de CastroXavier, G.; Monteiro, S.N.; Pedroti, L.G. Technological and environmental comparative of the processing of primary sludge waste from paper industry for mortar. J. Clean. Prod. 2020, 249, 119336. [Google Scholar] [CrossRef]

- Mármol, I.; Ballester, P.; Cerro, S.; Monrós, G.; Morales, J.; Sánchez, L. Use of granite sludge wastes for the production of coloured cement-based mortars. Cem. Concr. Compos. 2010, 32, 617–622. [Google Scholar] [CrossRef]

- Gupta, L.K.; Vyas, A.K. Impact on mechanical properties of cement sand mortar containing waste granite powder. Constr. Build. Mater. 2018, 191, 155–164. [Google Scholar] [CrossRef]

- Torres-Gómez, A.I.; Ledesma, E.F.; Otero, R.; Fernández, J.M.; Jiménez, J.R.; de Brito, J. Combined effects of non-conforming fly ash and recycled masonry aggregates on mortar properties. Materials 2016, 9, 729. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chouhan, H.S.; Kalla, P.; Nagar, R.; Gautam, P.K. Influence of dimensional stone waste on mechanical and durability properties of mortar: A review. Constr. Build. Mater. 2019, 227, 116662. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Performance of cementitious renderings and masonry mortars containing recycled aggregates from construction and demolition wastes. Constr. Build. Mater. 2016, 105, 400–415. [Google Scholar] [CrossRef]

- Akhtar, A.; Sarmah, A.K. Construction and demolition waste generation and properties of recycled aggregate concrete: A global perspective. J. Clean. Prod. 2018, 186, 262–281. [Google Scholar] [CrossRef]

- Eurostat. Eurostat Statistics for Waste Flow Generation 2016; Eurostat: Luxembourg, 2016. [Google Scholar]

- lam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. J. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef]

- Montani, C. XXVIII Report Marble and Stones in the World 2016; Aldus Casa di Edizioni in Carrara: Massa-Carrara, Italy, 2016. [Google Scholar]

- Marchán Sanz, C. Regueiro y González-Barros, M; Delgado Arenas, P. Natural Stone in Spain: Trends and perspectives. Boletín Geológico Y Min. 2017, 128, 395–403. [Google Scholar] [CrossRef]

- Martín, J.; Montero, J.R.; Moreno, F.; Sala, J.P.; Rubio, M.C. Feasibility analysis of the reuse of waste filler of bituminous mixtures for the production of self-compacting concrete. Mater. Des. 2013, 46, 372–380. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jiménez, J.R.; Ayuso, J.; Fernández, J.M.; De Brito, J. Maximum feasible use of recycled sand from construction and demolition waste for eco-mortar production-Part-I: Ceramic masonry waste. J. Clean. Prod. 2015, 87, 692–706. [Google Scholar] [CrossRef]

- Rodrigues, F.; Carvalho, M.T.; Evangelista, L.; De Brito, J. Physical-chemical and mineralogical characterization of fine aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2013, 52, 438–445. [Google Scholar] [CrossRef] [Green Version]

- Rangel, A.; De Azevedo, G.; Marvila, M.T.; Barroso, S.; Alexandre, J.; Xavier, G.D.C.; Monteiro, S.N. Effect of Granite Residue Incorporation on the Behavior of Mortars. Materials 2019, 12, 1449. [Google Scholar] [CrossRef] [Green Version]

- Jiménez, J.R.; Ayuso, J.; López, M.; Fernández, J.M.; De Brito, J. Use of fine recycled aggregates from ceramic waste in masonry mortar manufacturing. Constr. Build. Mater. 2013, 40, 679–690. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Fernández, D.C.; Fernández, J.M.; Jiménez, J.R. The combined effect of CO2 and calcined hydrotalcite on one-coat limestone mortar properties. Constr. Build. Mater. 2021, 280, 122532. [Google Scholar] [CrossRef]

- Zhao, Z.; Grellier, A.; El Karim Bouarroudj, M.; Michel, F.; Bulteel, D.; Courard, L. Substitution of limestone filler by waste brick powder in self-compacting mortars: Properties and durability. J. Build. Eng. 2021, 43, 102898. [Google Scholar] [CrossRef]

- Maroušek, J.; Hašková, S.; Zeman, R.; Žák, J.; Vaníčková, R.; Maroušková, A.; Váchal, J.; Myšková, K. Techno-economic assessment of processing the cellulose casings waste. Clean Technol. Environ. Policy 2015, 17, 2441–2446. [Google Scholar] [CrossRef]

- Lucas, J.; de Brito, J.; Veiga, R.; Farinha, C. The effect of using sanitary ware as aggregates on rendering mortars’ performance. Mater. Des. 2016, 91, 155–164. [Google Scholar] [CrossRef]

- Silva, J.; de Brito, J.; Veiga, R. Incorporation of fine ceramics in mortars. Constr. Build. Mater. 2009, 23, 556–564. [Google Scholar] [CrossRef]

- Jesus, S.; Maia, C.; Brazão Farinha, C.; de Brito, J.; Veiga, R. Rendering mortars with incorporation of very fine aggregates from construction and demolition waste. Constr. Build. Mater. 2019, 229, 116844. [Google Scholar] [CrossRef]

- Rissanen, J.; Giosué, C.; Ohenoja, K.; Kinnunen, P.; Marcellini, M.; Letizia Ruello, M.; Tittarelli, F.; Illikainen, M. The effect of peat and wood fly ash on the porosity of mortar. Constr. Build. Mater. 2019, 223, 421–430. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jiménez, J.R.; Fernández, J.M.; Galvín, A.P.; Agrela, F.; Barbudo, A. Properties of masonry mortars manufactured with fine recycled concrete aggregates. Comput. Chem. Eng. 2014, 71, 289–298. [Google Scholar] [CrossRef]

- Zhang, W.; Zakaria, M.; Hama, Y. Influence of aggregate materials characteristics on the drying shrinkage properties of mortar and concrete. Constr. Build. Mater. 2013, 49, 500–510. [Google Scholar] [CrossRef] [Green Version]

- Itim, A.; Ezziane, K.; Kadri, E.H. Compressive strength and shrinkage of mortar containing various amounts of mineral additions. Constr. Build. Mater. 2011, 25, 3603–3609. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The combined use of admixtures for shrinkage reduction in one-part alkali activated slag-based mortars and pastes. Constr. Build. Mater. 2020, 248, 118682. [Google Scholar] [CrossRef]

- Reddy, B.V.; Gupta, A. Influence of sand grading on the characteristics of mortars and soil–cement block masonry. Constr. Build. Mater. 2008, 22, 1614–1623. [Google Scholar] [CrossRef]

- Silva, J.; de Brito, J.; Veiga, R. Recycled Red-Clay Ceramic Construction and Demolition Waste for Mortars Production. J. Mater. Civ. Eng. 2010, 22, 236–244. [Google Scholar] [CrossRef]

- Kabeer, K.I.S.A.; Vyas, A.K. Utilization of marble powder as fine aggregate in mortar mixes. Constr. Build. Mater. 2018, 165, 321–332. [Google Scholar] [CrossRef]

- Bernat-Maso, E.; Escrig, C.; Aranha, C.A.; Gil, L. Experimental assessment of Textile Reinforced Sprayed Mortar strengthening system for brickwork wallettes. Constr. Build. Mater. 2014, 50, 226–236. [Google Scholar] [CrossRef] [Green Version]

- Nasr, M.S.; Shubbar, A.A.; Abed, Z.A.A.R.; Ibrahim, M.S. Properties of eco-friendly cement mortar contained recycled materials from different sources. J. Build. Eng. 2020, 31, 101444. [Google Scholar] [CrossRef]

- Ramos, T.; Matos, A.M.; Schmidt, B.; Rio, J.; Sousa-Coutinho, J. Granitic quarry sludge waste in mortar: Effect on strength and durability. Constr. Build. Mater. 2013, 47, 1001–1009. [Google Scholar] [CrossRef]

- Zafar, M.S.; Javed, U.; Khushnood, R.A.; Nawaz, A.; Zafar, T. Sustainable incorporation of waste granite dust as partial replacement of sand in autoclave aerated concrete. Constr. Build. Mater. 2020, 250, 118878. [Google Scholar] [CrossRef]

- Medina, G.; Del Bosque, I.S.; Frías, M.; De Rojas, M.S.; Medina, C. Granite quarry waste as a future eco-efficient supplementary cementitious material (SCM): Scientific and technical considerations. J. Clean. Prod. 2017, 148, 467–476. [Google Scholar] [CrossRef]

- Bacarji, E.; Toledo Filho, R.D.; Koenders, E.A.B.; Figueiredo, E.P.; Lopes, J.L.M.P. Sustainability perspective of marble and granite residues as concrete fillers. Constr. Build. Mater. 2013, 45, 1–10. [Google Scholar] [CrossRef]

- Li, L.; Liu, W.; You, Q.; Chen, M.; Zeng, Q. Waste ceramic powder as a pozzolanic supplementary filler of cement for developing sustainable building materials. J. Clean. Prod. 2020, 259, 120853. [Google Scholar] [CrossRef]

- Segura, J.; Aponte, D.; Pelà, L.; Roca, P. Influence of recycled limestone filler additions on the mechanical behaviour of commercial premixed hydraulic lime based mortars. Constr. Build. Mater. 2020, 238, 117722. [Google Scholar] [CrossRef]

| Characterization Test Methods | Siliceous SF | Ceramic CF | Granite GF | Mixed MF | Recovery RF |

|---|---|---|---|---|---|

| Specific gravity (UNE 80103:2013) (Mg/m3) | 2.61 | 2.52 | 2.45 | 2.20 | 2.69 |

| Bulk density (1097-3:1999) (Mg/m3) | 0.74 | 0.95 | 0.50 | 0.52 | 1.33 |

| Chloride (UNE-EN 1744-1:2010) (%) | 0.01 | 0.02 | 0.03 | 0.01 | 0.01 |

| Acid Soluble sulphates (UNE-EN 1744-1:2010) (SO3%) | <0.01 | 0.98 | <0.01 | <0.01 | <0.01 |

| Total sulphurs (UNE-EN1744-1:2010) (SO3%) | <0.01 | 0.98 | <0.01 | <0.01 | <0.01 |

| Sieve size (mm) | |||||

| 0.25 (% passing) | 100 | 100 | 100 | 100 | 100 |

| 0.125 (% passing) | 100 | 100 | 97.35 | 99.49 | 75.91 |

| 0.063 (% passing) | 87.33 | 73.81 | 27.58 | 81.36 | 44.94 |

| Mortar mixture names | M-SF (ref) | M-CF | M-GF | M-MF | M-RF |

| Mineral Relative Abundance (*) | |||||

|---|---|---|---|---|---|

| Mineral Phases | SF | CF | GF | MF | RF |

| Albite Na(Si3Al)O8 | - | ** | *** | - | - |

| Calcite CaCO3 | - | ** | - | * | - |

| Dolomite CaMg(CO3)2 | - | - | - | - | ****** |

| Illite KAl2Si3AlO20(OH)2 | - | - | - | - | - |

| Quartz (SiO2) | ****** | **** | ***** | ***** | - |

| Sanidine (Na,K)(Si3Al)O8 | - | *** | - | - | - |

| Gypsum CaSO4·2H2O | - | * | - | - | - |

| Biotite K(Mg,Fe)3 AlSi3O10(OH,F)2 | - | - | **** | * | - |

| Microcline KAlSi3O8 | - | - | ** | - | - |

| Cristobalite SiO2 | - | - | - | ** | - |

| Criteria EU LD 2003/33/EC (L/S = 10) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Elements | SF | CF | GF | MF | RF | Inert | Non-Hazardous | Hazardous |

| Cr | n.d. | 0.344 | n.d. | 0.006 | n.d. | 0.5 | 10 | 70 |

| Ni | n.d. | 0.026 | n.d. | 0.040 | 0.004 | 0.4 | 10 | 40 |

| Cu | n.d. | 0.039 | n.d. | 0.862 | n.d. | 2 | 50 | 100 |

| Zn | n.d. | 0.010 | n.d. | 0.016 | 0.011 | 4 | 50 | 200 |

| As | 0.018 | 0.030 | 0.014 | 0.043 | 0.003 | 0.5 | 2 | 25 |

| Se | 0.003 | 0.042 | n.d. | 0.034 | n.d. | 0.1 | 0.5 | 7 |

| Mo | n.d. | 0.088 | 0.565 (1) | 0.052 | 0.020 | 0.5 | 10 | 30 |

| Cd | n.d. | n.d. | n.d. | n.d. | n.d. | 0.04 | 1 | 5 |

| Sb | n.d. | 0.035 | 0.006 | 0.489 (1) | 0.024 | 0.06 | 0.7 | 5 |

| Ba | 3.746 | 0.498 | 0.010 | 0.833 | 0.272 | 20 | 100 | 300 |

| Hg | n.d. | n.d. | n.d. | 0.122 (1) | n.d. | 0.01 | 0.2 | 2 |

| Pb | n.d. | n.d. | n.d. | 0.000 | n.d. | 0.5 | 10 | 50 |

| C (µS/cm) | 28.75 | 785 | 129.8 | 118.2 | 40.4 | |||

| Ta (°C) | 25.7 | 25.9 | 28.1 | 28.3 | 28.1 | |||

| pH | 9.05 | 9.51 | 9.05 | 9.02 | 9.41 | |||

| Test Methods | Standards |

|---|---|

| Workable life | UNE-EN 1015-9:2000 |

| Entrained air content | UNE-EN 1015-7:1999 |

| Density in fresh state | UNE-EN 1015-7:1999 |

| Density in hardened mortar | UNE-EN 1015-10:2000 |

| Adhesive strength | UNE-EN 1015-12:2016 |

| Compressive strength | UNE-EN 1015-11:2000 |

| Flexural strength | UNE-EN 1015-11:2000 |

| Capillary water absorption | UNE-EN 1015-18:2003 |

| Water vapour permeability | UNE-EN 1015-19:1999 |

| Shrinkage | UNE 83831:2010 EX |

| Test Methods | M-SF | M-CF | M-GF | M-MF | M-RF |

|---|---|---|---|---|---|

| Workable life (min) | 206.5 (2.5) | 179.8 (15.6) | 152.3 (24.0) | 92.3 (6.9) | 192.5 (5.5) |

| Fresh density (g/cm3) | 1.95 (0.02) | 1.87 (0.01) | 1.82 (0.03) | 1.77 (0.02) | 1.94 (0.01) |

| Entrained air content (%) | 7.80 (0.70) | 6.80 (1.70) | 5.20 (2.10) | 2.70 (0.70) | 8.00 (3.10) |

| Test Methods | M-SF | M-CF | M-GF | M-MF | M-RF |

|---|---|---|---|---|---|

| Hardened density (g/cm3) | 1.76 (0.02) | 1.67 (0.01) | 1.80 (0.01) | 1.72 (0.01) | 1.71 (0.02) |

| Capillary water absorption (Kg/(m2·min0.5)) | 1.01 (0.04) | 1.03 (0.02) | 1.08 (0.03) | 0.79 (0.03) | 1.24 (0.06) |

| Water vapour permeability (10−11 kg/m·s·Pa) | 1.11 (0.11) | 1.01 (0.17) | 0.85 (0.04) | 0.72 (0.03) | 0.9 (0.10) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

López-Uceda, A.; Fernández-Ledesma, E.; Jiménez, J.R.; Fernández-Rodríguez, J.M. Performance of Sustainable Mortars Made with Filler from Different Construction By-Products. Materials 2022, 15, 2636. https://doi.org/10.3390/ma15072636

López-Uceda A, Fernández-Ledesma E, Jiménez JR, Fernández-Rodríguez JM. Performance of Sustainable Mortars Made with Filler from Different Construction By-Products. Materials. 2022; 15(7):2636. https://doi.org/10.3390/ma15072636

Chicago/Turabian StyleLópez-Uceda, Antonio, Enrique Fernández-Ledesma, José Ramón Jiménez, and José María Fernández-Rodríguez. 2022. "Performance of Sustainable Mortars Made with Filler from Different Construction By-Products" Materials 15, no. 7: 2636. https://doi.org/10.3390/ma15072636

APA StyleLópez-Uceda, A., Fernández-Ledesma, E., Jiménez, J. R., & Fernández-Rodríguez, J. M. (2022). Performance of Sustainable Mortars Made with Filler from Different Construction By-Products. Materials, 15(7), 2636. https://doi.org/10.3390/ma15072636