Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions

Abstract

:1. Introduction

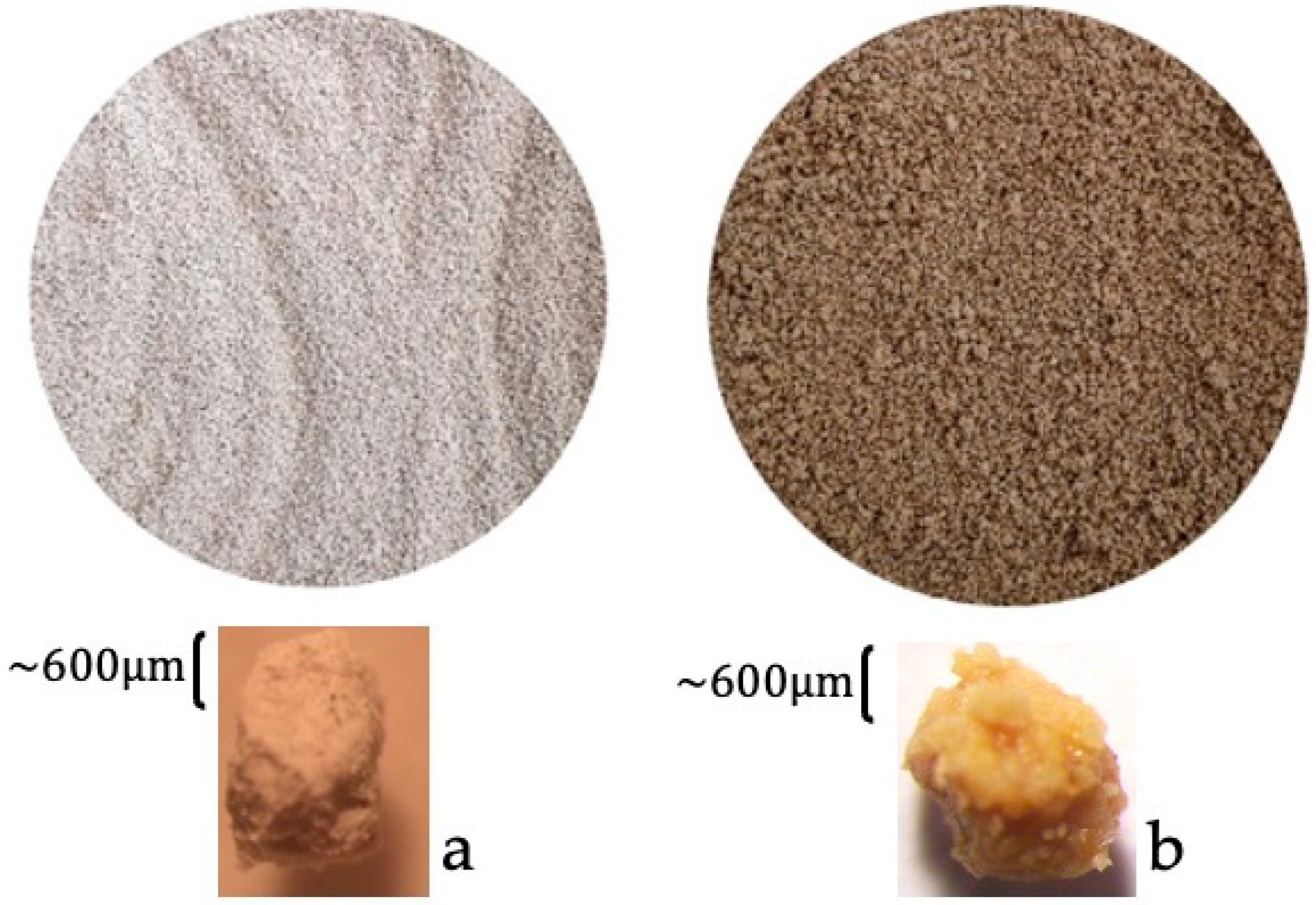

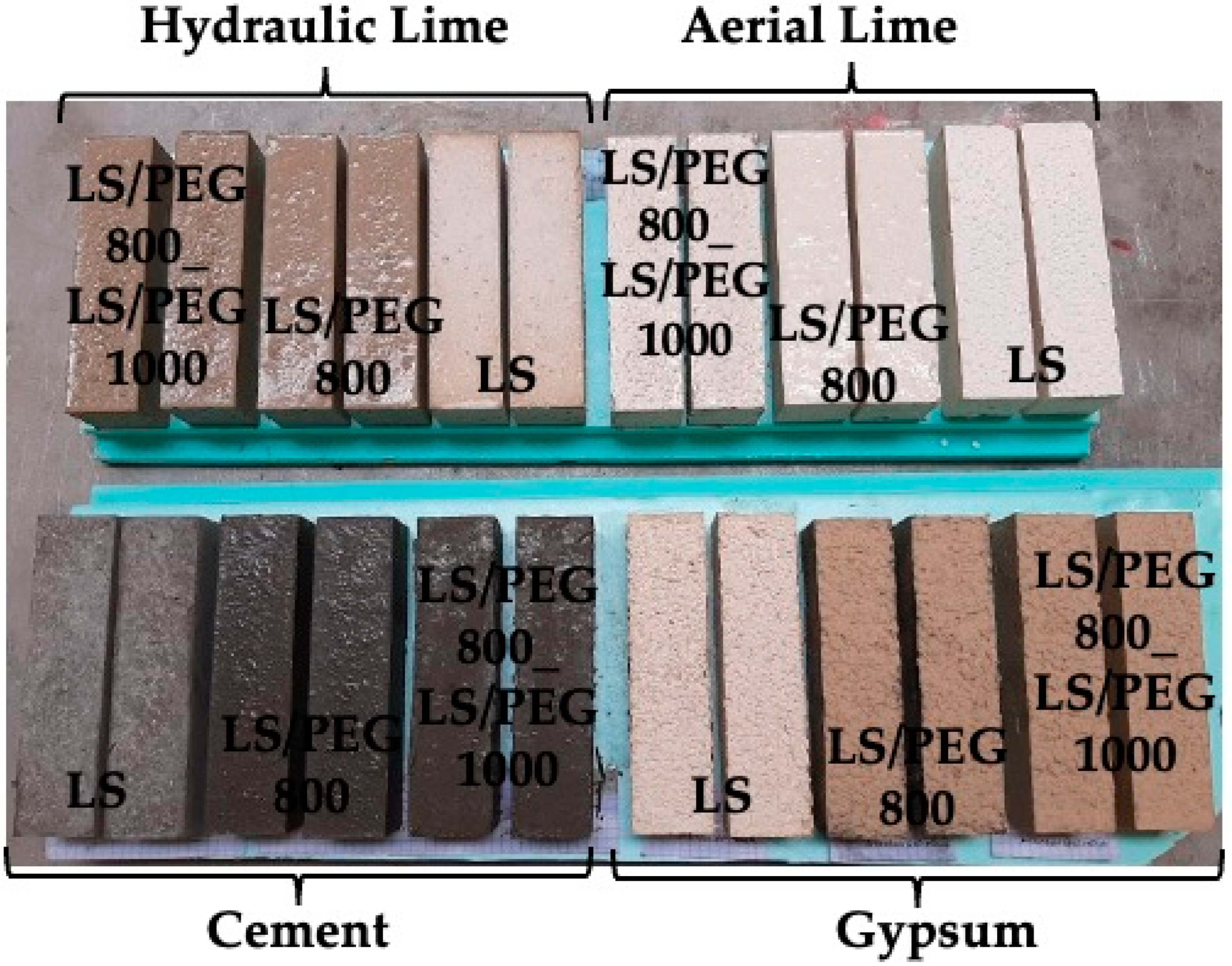

2. Materials and Methods

2.1. Materials

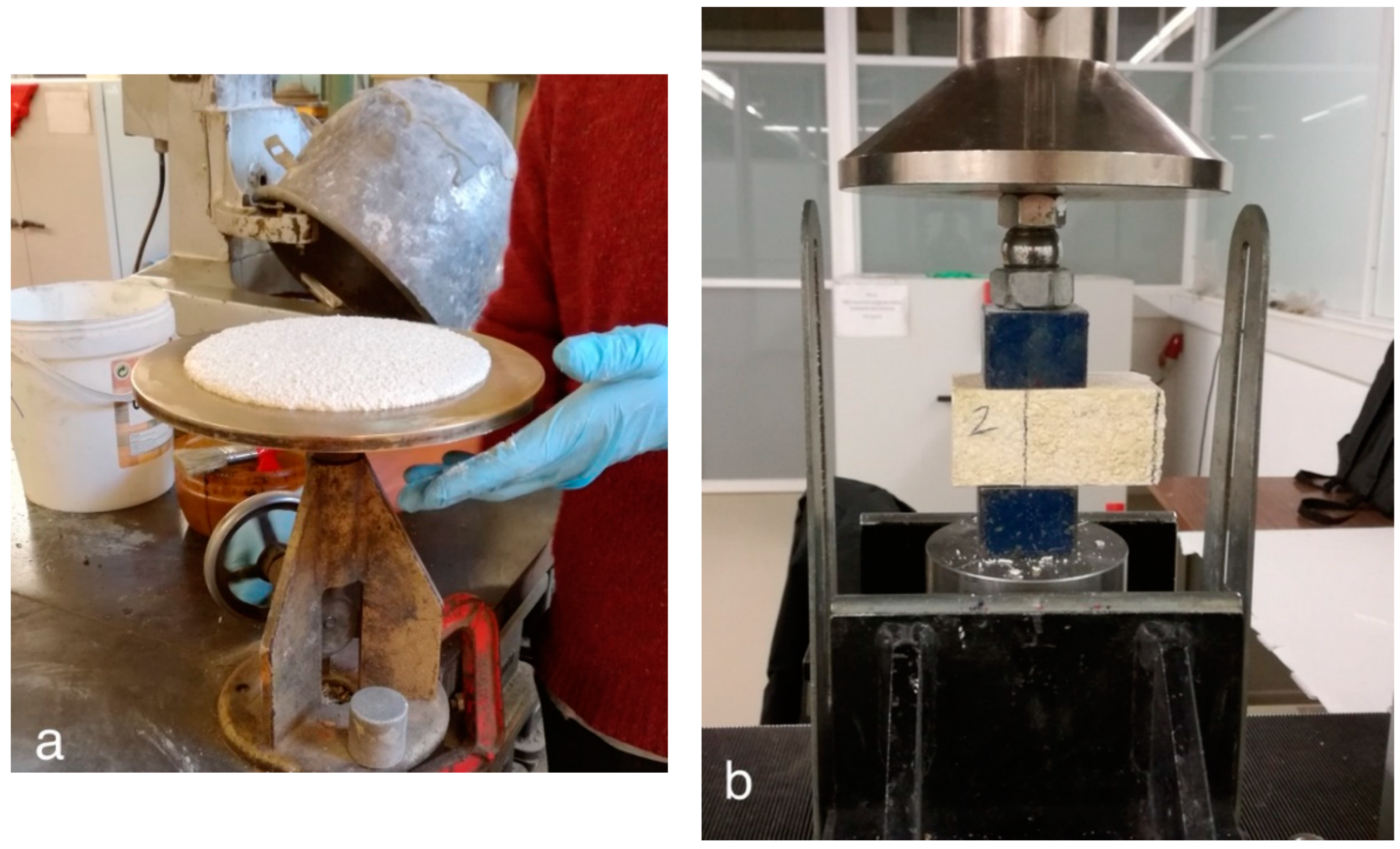

2.2. Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tyagi, V.V.; Chopra, K.; Kalidasan, B.; Chauhan, A.; Stritih, U.; Anand, S.; Pandey, A.K.; Sarı, A.; Kothari, R. Phase Change Material Based Advance Solar Thermal Energy Storage Systems for Building Heating and Cooling Applications: A Prospective Research Approach. Sustain. Energy Technol. Assess. 2021, 47, 101318. [Google Scholar] [CrossRef]

- Dulac, J.; Petrichenko, K.; Graham, P. Towards Zero-Emission Efficient and Resilient Buildings. 2016. Available online: https://backend.orbit.dtu.dk/ws/portalfiles/portal/127199228/GABC_Global_Status_Report_V09_november.pdf (accessed on 23 February 2022).

- Delmastro, C. Thibaut Abergel IEA (2020). In Building Envelopes; IEA: Paris, France, 2020. [Google Scholar]

- REN21. Renewables 2021 Global Status Report; REN21 Secretariat: Paris, France, 2021; ISBN 978-3-948393-03-8. [Google Scholar]

- Chinnasamy, V.; Palaniappan, S.K.; Raj, M.K.A.; Rajendran, M.; Cho, H. Thermal Energy Storage and Its Applications. Mater. Sol. Energy Conserv. Mater. Methods Appl. 2021, 353. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of Passive PCM Latent Heat Thermal Energy Storage Systems towards Buildings’ Energy Efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Janarthanan, B.; Sagadevan, S. Thermal Energy Storage Using Phase Change Materials and Their Applications: A Review. Int. J. ChemTech Res. 2015, 7, 250–256. [Google Scholar]

- Lin, Y.; Jia, Y.; Alva, G.; Fang, G. Review on Thermal Conductivity Enhancement, Thermal Properties and Applications of Phase Change Materials in Thermal Energy Storage. Renew. Sustain. Energy Rev. 2018, 82, 2730–2742. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A. Phase Change Materials for Energy Efficiency in Buildings and Their Use in Mortars. Materials 2019, 12, 1260. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rao, V.V.; Parameshwaran, R.; Ram, V.V. PCM-Mortar Based Construction Materials for Energy Efficient Buildings: A Review on Research Trends. Energy Build. 2018, 158, 95–122. [Google Scholar] [CrossRef]

- Al-Yasiri, Q.; Szabó, M. Incorporation of Phase Change Materials into Building Envelope for Thermal Comfort and Energy Saving: A Comprehensive Analysis. J. Build. Eng. 2021, 36, 102122. [Google Scholar] [CrossRef]

- Li, M.; Wu, Z.; Tan, J. Heat Storage Properties of the Cement Mortar Incorporated with Composite Phase Change Material. Appl. Energy 2013, 103, 393–399. [Google Scholar] [CrossRef]

- Vieira, J.; Senff, L.; Gonçalves, H.; Silva, L.; Ferreira, V.M.; Labrincha, J.A. Functionalization of Mortars for Controlling the Indoor Ambient of Buildings. Energy Build. 2014, 70, 224–236. [Google Scholar] [CrossRef]

- Šavija, B.; Zhang, H.; Schlangen, E. Influence of Microencapsulated Phase Change Material (PCM) Addition on (Micro) Mechanical Properties of Cement Paste. Materials 2017, 10, 863. [Google Scholar] [CrossRef] [Green Version]

- Zhou, S.; Zhu, H.; Yan, Z.; Ju, J.W.; Zhang, L. A Micromechanical Study of the Breakage Mechanism of Microcapsules in Concrete Using PFC2D. Constr. Build. Mater. 2016, 115, 452–463. [Google Scholar] [CrossRef]

- Zhou, S.; Zhu, H.; Ju, J.W.; Yan, Z.; Chen, Q. Modeling Microcapsule-Enabled Self-Healing Cementitious Composite Materials Using Discrete Element Method. Int. J. Damage Mech. 2017, 26, 340–357. [Google Scholar] [CrossRef]

- Lv, P.; Liu, C.; Rao, Z. Review on Clay Mineral-Based Form-Stable Phase Change Materials: Preparation, Characterization and Applications. Renew. Sustain. Energy Rev. 2017, 68, 707–726. [Google Scholar] [CrossRef]

- Sundararajan, S.; Samui, A.B.; Kulkarni, P.S. Versatility of Polyethylene Glycol (PEG) in Designing Solid–Solid Phase Change Materials (PCMs) for Thermal Management and Their Application to Innovative Technologies. J. Mater. Chem. A 2017, 5, 18379–18396. [Google Scholar] [CrossRef]

- Karaman, S.; Karaipekli, A.; Sarı, A.; Biçer, A. Polyethylene Glycol (PEG)/Diatomite Composite as a Novel Form-Stable Phase Change Material for Thermal Energy Storage. Sol. Energy Mater. Sol. Cells 2011, 95, 1647–1653. [Google Scholar] [CrossRef]

- Sarı, A.; Bicer, A.; Al-Sulaiman, F.A.; Karaipekli, A.; Tyagi, V.V. Diatomite/CNTs/PEG Composite PCMs with Shape-Stabilized and Improved Thermal Conductivity: Preparation and Thermal Energy Storage Properties. Energy Build. 2018, 164, 166–175. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, M.; Liu, Q.; Wan, J.; Hu, J. Preparation and Thermal Properties of Molecular-Bridged Expanded Graphite/Polyethylene Glycol Composite Phase Change Materials for Building Energy Conservation. Materials 2018, 11, 818. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Li, H.; Tu, J.; Shi, R.; Luo, Z.; Xiong, C.; Jiang, M. Shape Stability of Polyethylene Glycol/Acetylene Black Phase Change Composites for Latent Heat Storage. Adv. Mater. Sci. Eng. 2018, 2018, 3954163. [Google Scholar] [CrossRef] [Green Version]

- Abbasi Hattan, H.; Madhkhan, M.; Marani, A. Thermal and Mechanical Properties of Building External Walls Plastered with Cement Mortar Incorporating Shape-Stabilized Phase Change Materials (SSPCMs). Constr. Build. Mater. 2021, 270, 121385. [Google Scholar] [CrossRef]

- Sarcinella, A.; De Aguiar, J.L.B.; Lettieri, M.; Cunha, S.; Frigione, M. Thermal Performance of Mortars Based on Different Binders and Containing a Novel Sustainable Phase Change Material (PCM). Materials 2020, 13, 2055. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J. Sustainable Polymer-Based Phase Change Materials for Energy Efficiency in Buildings and Their Application in Aerial Lime Mortars. Constr. Build. Mater. 2020, 231, 117149. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; Barroso de Aguiar, J.L. Applications of Sustainable Polymer-Based Phase Change Materials in Mortars Composed by Different Binders. Materials 2019, 12, 3502. [Google Scholar] [CrossRef] [Green Version]

- Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of an Eco-Sustainable, Form-Stable Phase Change Material Included in Aerial-Lime-Based Mortar Intended for Different Climates. Materials 2022, 15, 1192. [Google Scholar] [CrossRef]

- Kou, Y.; Wang, S.; Luo, J.; Sun, K.; Zhang, J.; Tan, Z.; Shi, Q. Thermal Analysis and Heat Capacity Study of Polyethylene Glycol (PEG) Phase Change Materials for Thermal Energy Storage Applications. J. Chem. Thermodyn. 2019, 128, 259–274. [Google Scholar] [CrossRef]

- Frigione, M.; Lettieri, M.; Sarcinella, A.; de Aguiar, J.B. Mortars with Phase Change Materials (PCM) and Stone Waste to Improve Energy Efficiency in Buildings. In International Congress on Polymers in Concrete (ICPIC 2018); Taha, M.M.R., Ed.; Springer International Publishing: Cham, Switzerland, 2018; pp. 195–201. ISBN 978-3-319-78174-7. [Google Scholar]

- Cui, Y.; Xie, J.; Liu, J.; Wang, J.; Chen, S. A Review on Phase Change Material Application in Building. Adv. Mech. Eng. 2017, 9, 168781401770082. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Su, H.; Zhao, S.; Zhao, N. Influence of Phase Change Material on Mechanical and Thermal Properties of Clay Geopolymer Mortar. Constr. Build. Mater. 2016, 120, 329–334. [Google Scholar] [CrossRef]

- European Committee for Standardization (CEN). EN 998-1: Specification for Mortar for Masonry—Part 1: Rendering and Plastering Mortar; CEN: Brussels, Belgium, 2010. [Google Scholar]

- European Committee for Standardization (CEN). EN 1015-3: Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); CEN: Brussels, Belgium, 2004. [Google Scholar]

- European Committee for Standardization (CEN). EN 1015-11: Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar; CEN: Brussels, Belgium, 1999. [Google Scholar]

- Cunha, S.; Aguiar, J.; Ferreira, V.; Tadeu, A. Mortars Based in Different Binders with Incorporation of Phase-Change Materials: Physical and Mechanical Properties. Null 2015, 19, 1216–1233. [Google Scholar] [CrossRef] [Green Version]

- Cunha, S.; Lima, M.; Aguiar, J.B. Influence of Adding Phase Change Materials on the Physical and Mechanical Properties of Cement Mortars. Constr. Build. Mater. 2016, 127, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Cunha, S.; Aguiar, J.; Ferreira, V.; Tadeu, A.; Garbacz, A. Mortars with Phase Change Materials—Part I: Physical and Mechanical Characterization. Key Eng. Mater. 2014, 634, 22–32. [Google Scholar] [CrossRef] [Green Version]

- Kontoleon, K.J.; Stefanidou, M.; Saboor, S.; Mazzeo, D.; Karaoulis, A.; Zegginis, D.; Kraniotis, D. Defensive Behaviour of Building Envelopes in Terms of Mechanical and Thermal Responsiveness by Incorporating PCMs in Cement Mortar Layers. Sustain. Energy Technol. Assess. 2021, 47, 101349. [Google Scholar] [CrossRef]

- Kim, H.G.; Qudoos, A.; Jeon, I.K.; Ryou, J.S. Assessment of PCM/SiC-Based Composite Aggregate in Concrete: Mechanical, Physical and Microstructural Properties. Constr. Build. Mater. 2020, 262, 120088. [Google Scholar] [CrossRef]

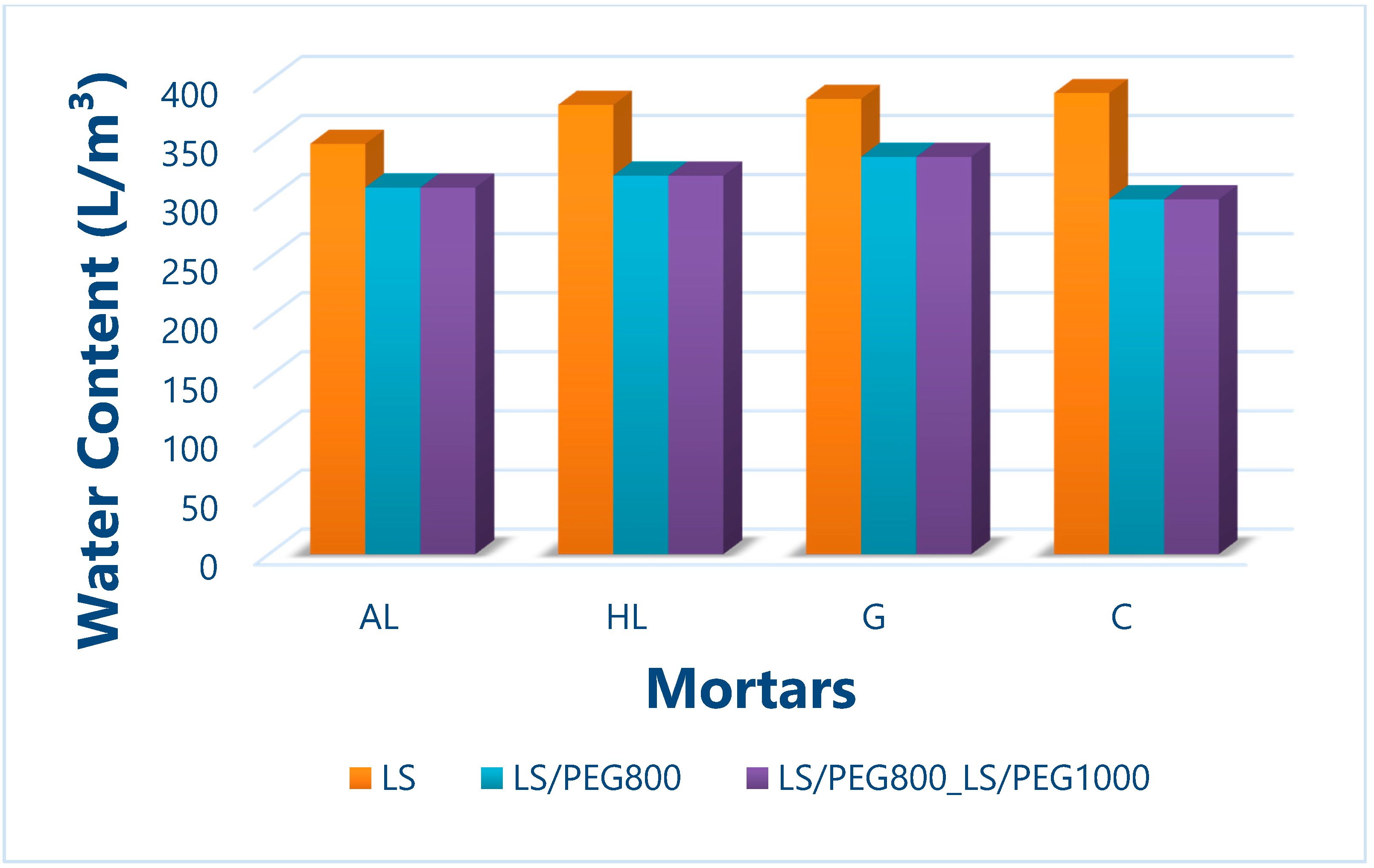

| Mortars | Binder a/ Content | Aggregates | SP | Water Saturation b | Water | Water/ Binder | ||

|---|---|---|---|---|---|---|---|---|

| LS | PEG800 Content | PEG1000 Content | ||||||

| AL_LS | AL/1000 | 668 | 0 | 0 | 20 | 168 | 347 | 0.35 |

| AL_LS/PEG800 | 979 | 225 | 0 | 20 | 0 | 310 | 0.31 | |

| AL_LS/PEG800_LS/PEG1000 | 979 | 113 | 113 | 20 | 0 | 310 | 0.31 | |

| HL_LS | HL/1000 | 682 | 0 | 0 | 20 | 171 | 380 | 0.38 |

| HL_LS/PEG800 | 1082 | 249 | 0 | 20 | 0 | 320 | 0.32 | |

| HL_LS/PEG800_LS/PEG1000 | 1082 | 124 | 124 | 20 | 0 | 320 | 0.32 | |

| G_LS | G/1000 | 763 | 0 | 0 | 20 | 192 | 385 | 0.39 |

| G_LS/PEG800 | 1129 | 260 | 0 | 20 | 0 | 336 | 0.34 | |

| G_LS/PEG800_LS/PEG1000 | 1129 | 130 | 130 | 20 | 0 | 340 | 0.34 | |

| C_LS | C/1000 | 772 | 0 | 0 | 20 | 194 | 390 | 0.39 |

| C_LS/PEG800 | 1307 | 301 | 0 | 20 | 0 | 300 | 0.30 | |

| C_LS/PEG800_LS/PEG1000 | 1307 | 150 | 150 | 20 | 0 | 300 | 0.30 | |

| Mortars | Workability (mm) |

|---|---|

| AL_LS | 178 ± 2.0 |

| AL_LS/PEG800 | 160 ± 3.0 |

| AL_LS/PEG800_LS/PEG1000 | 175 ± 2.0 |

| HL_LS | 175 ± 1.0 |

| HL_LS/PEG800 | 170 ± 3.0 |

| HL_LS/PEG800_LS/PEG1000 | 163 ± 2.0 |

| G_LS | 170 ± 4.0 |

| G_LS/PEG800 | 165 ± 3.0 |

| G_LS/PEG800_LS/PEG1000 | 163 ± 1.0 |

| C_LS | 180 ± 0.5 |

| C_LS/PEG800 | 170 ± 1.0 |

| C_LS/PEG800_LS/PEG1000 | 170 ± 4.0 |

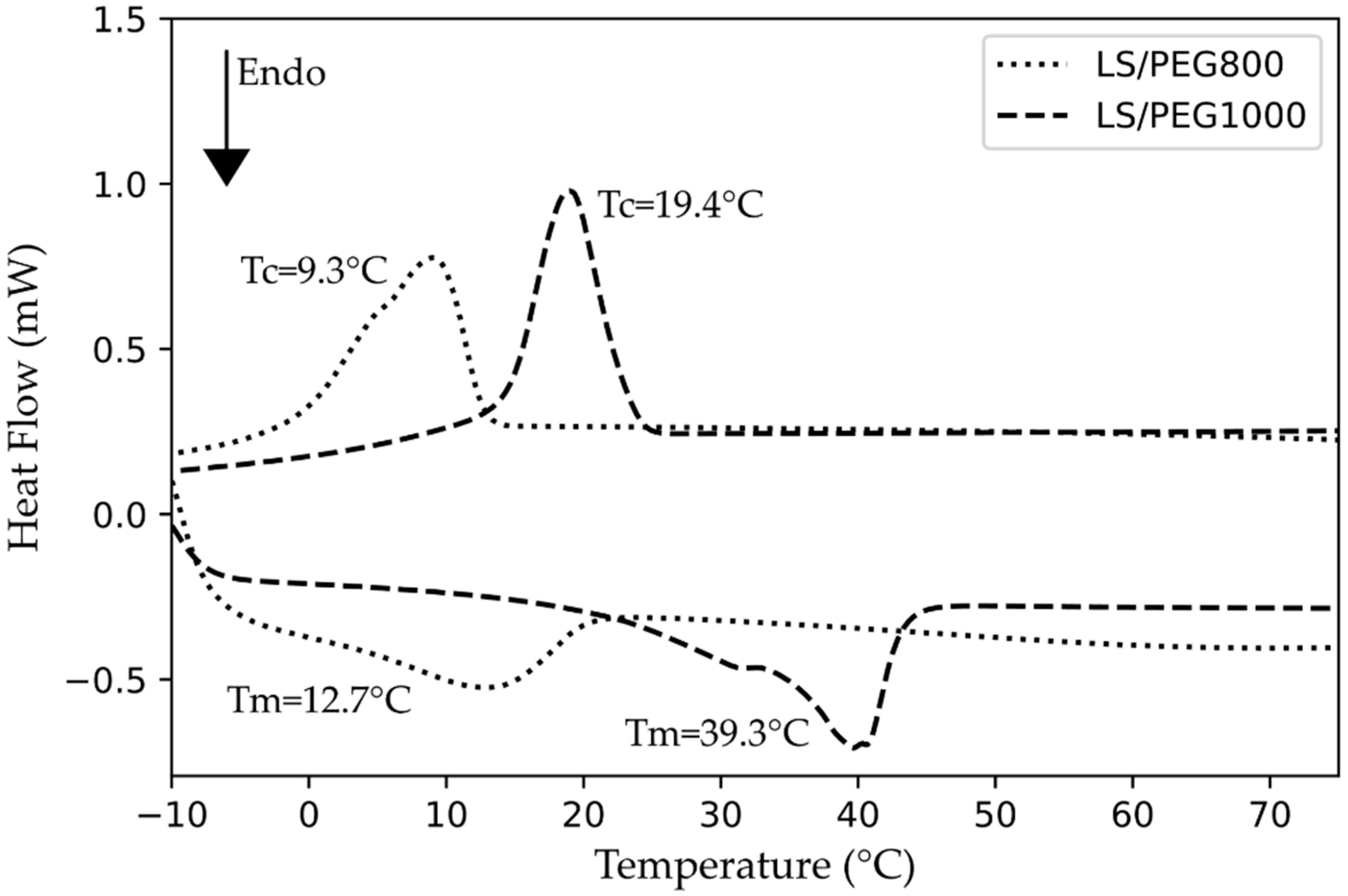

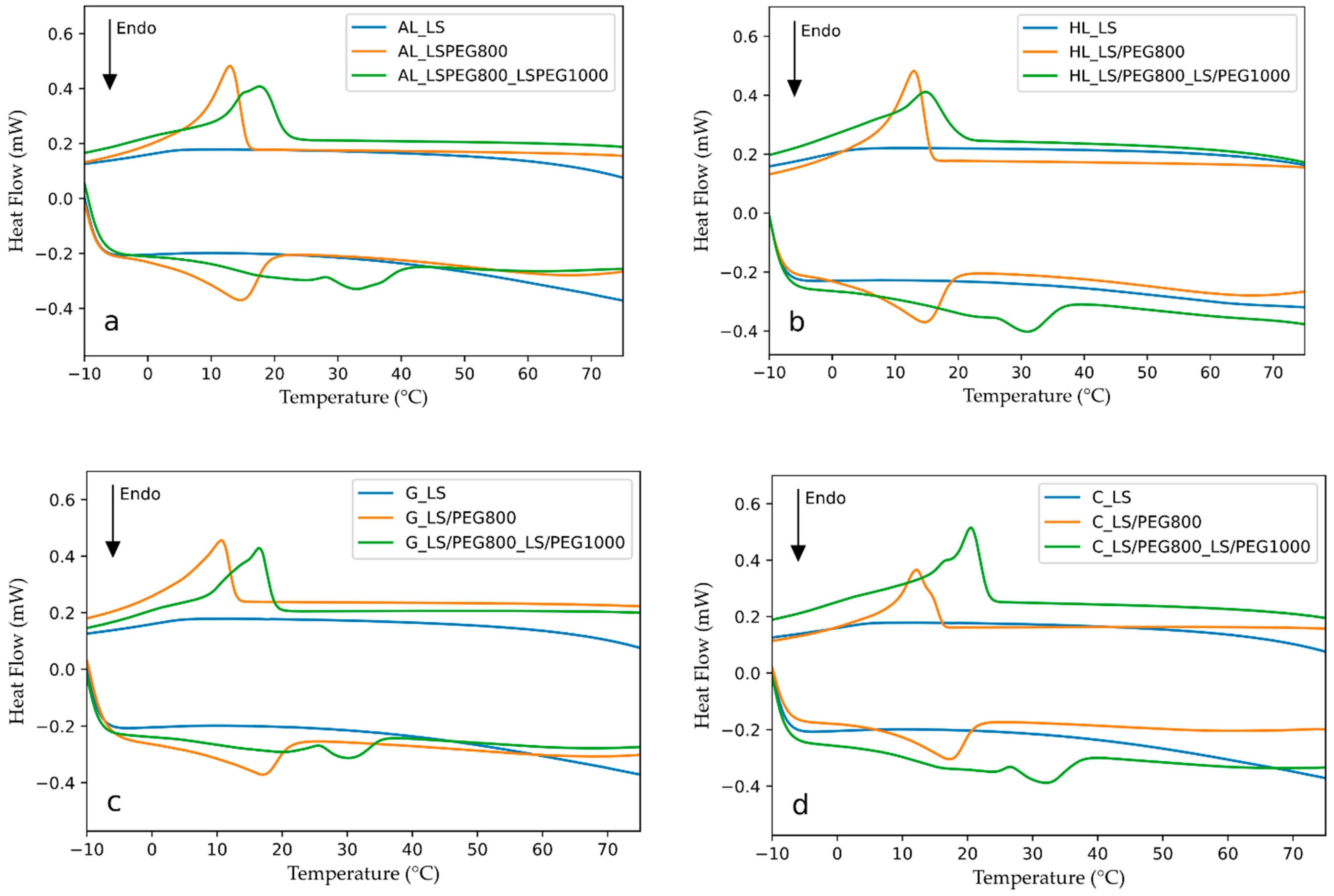

| System | Tstart (°C) | Tm (°C) | Tend (°C) | ΔHm (J/g) | |

|---|---|---|---|---|---|

| Heating Stage | AL_LS/PEG800 | 3.3 ± 1.9 | 15.0 ± 1.0 | 24.1 ± 1.2 | 11.8 ± 0.4 |

| AL_LS/PEG800_LS/PEG1000 | 4.3 ± 0.9 | 32.3 ± 0.8 | 45.2 ± 0.5 | 9.7 ± 2.1 | |

| HL_LS/PEG800 | −2.3 ± 0.8 | 14.0 ± 0.8 | 21.2 ± 0.5 | 9.1 ± 0.9 | |

| HL_LS/PEG800_LS/PEG1000 | 6.9 ± 3.1 | 32.4 ± 2.6 | 38.4 ± 0.8 | 9.1 ± 1.2 | |

| G_LS/PEG800 | 2.5 ± 1.1 | 16.4 ± 0.8 | 24.6 ± 2.0 | 7.8 ± 0.6 | |

| G_LS/PEG800_LS/PEG1000 | 3.2 ± 0.9 | 30.8 ± 1.6 | 38.9 ± 2.7 | 8.1 ± 0.4 | |

| C_LS/PEG800 | −2.0 ± 0.8 | 17.3 ± 0.2 | 25.8 ± 1.8 | 9.5 ± 0.5 | |

| C_LS/PEG800_LS/PEG1000 | 3.5 ± 1.8 | 33.5 ± 0.2 | 42.3 ± 0.4 | 9.7 ± 0.9 | |

| System | Tstart (°C) | Tc (°C) | Tend (°C) | ΔHc (J/g) | |

| Cooling Stage | AL_LS/PEG800 | 17.7 ± 1.5 | 13.1 ± 1.1 | −6.4 ± 0.9 | 12.5 ± 1.0 |

| AL_LS/PEG800_LS/PEG1000 | 29.0 ± 0.9 | 18.6 ± 1.6 | −0.6 ± 1.2 | 10.8 ± 1.4 | |

| HL_LS/PEG800 | 14.6 ± 1.4 | 12.4 ± 3.0 | −3.3 ± 0.6 | 10.3 ± 1.2 | |

| HL_LS/PEG800_LS/PEG1000 | 25.1 ± 0.7 | 15.2 ± 0.5 | −1.4 ± 2.2 | 9.2 ± 3.5 | |

| G_LS/PEG800 | 15.8 ± 0.2 | 11.0 ± 0.3 | −1.5 ± 0.9 | 9.2 ± 1.1 | |

| G_LS/PEG800_LS/PEG1000 | 25.7 ± 1.9 | 17.5 ± 2.3 | −1.8 ± 3.1 | 9.2 ± 1.8 | |

| C_LS/PEG800 | 19.1 ± 0.6 | 13.0 ± 1.3 | −0.4 ± 0.2 | 10.5 ± 1.0 | |

| C_LS/PEG800_LS/PEG1000 | 25.9 ± 0.5 | 19.5 ± 2.4 | 0.3 ± 0.2 | 11.3 ± 3.4 |

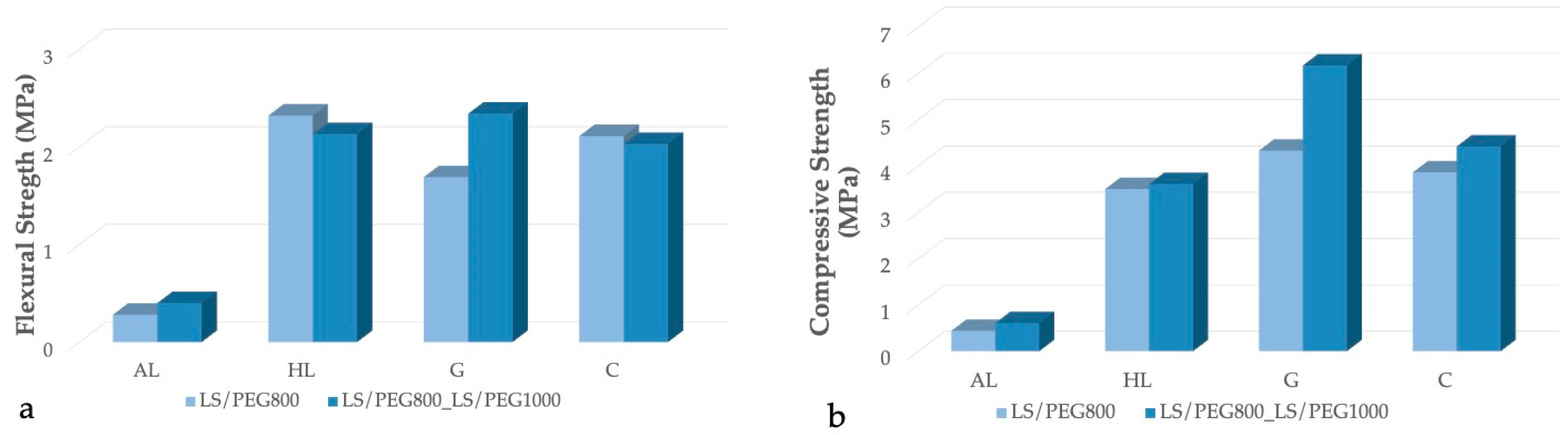

| Sample | Flexural Strength (N/mm2) | Compressive Strength (N/mm2) | Classification EN 998-1:2010 |

|---|---|---|---|

| AL_LS | 0.19 | 0.16 | CSI |

| AL_LS/PEG800 | 0.12 | 0.01 | |

| AL_LS/PEG800_LS/PEG1000 | 0.01 | 0.08 | |

| HL_LS | 1.53 | 0.47 | CSIV |

| HL_LS/PEG800 | 0.37 | 0.15 | CSII-CSIII |

| HL_LS/PEG800_LS/PEG1000 | 0.52 | 0.54 | |

| G_LS | 1.26 | 0.21 | CSIV |

| G_LS/PEG800 | 0.04 | 1.74 | CSII-CSIII |

| G_LS/PEG800_LS/PEG1000 | 0.02 | 0.51 | |

| C_LS | 1.11 | 6.09 | CSIV |

| C_LS/PEG800 | 0.11 | 1.21 | CSII-CSIII |

| C_LS/PEG800_LS/PEG1000 | 0.18 | 0.72 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarcinella, A.; de Aguiar, J.L.B.; Frigione, M. Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials 2022, 15, 2497. https://doi.org/10.3390/ma15072497

Sarcinella A, de Aguiar JLB, Frigione M. Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials. 2022; 15(7):2497. https://doi.org/10.3390/ma15072497

Chicago/Turabian StyleSarcinella, Antonella, José Luís Barroso de Aguiar, and Mariaenrica Frigione. 2022. "Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions" Materials 15, no. 7: 2497. https://doi.org/10.3390/ma15072497

APA StyleSarcinella, A., de Aguiar, J. L. B., & Frigione, M. (2022). Physical Properties of Eco-Sustainable Form-Stable Phase Change Materials Included in Mortars Suitable for Buildings Located in Different Continental Regions. Materials, 15(7), 2497. https://doi.org/10.3390/ma15072497