Facile Modification of Flexible Electrodes via Laser Transfer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of the Donor Substrates

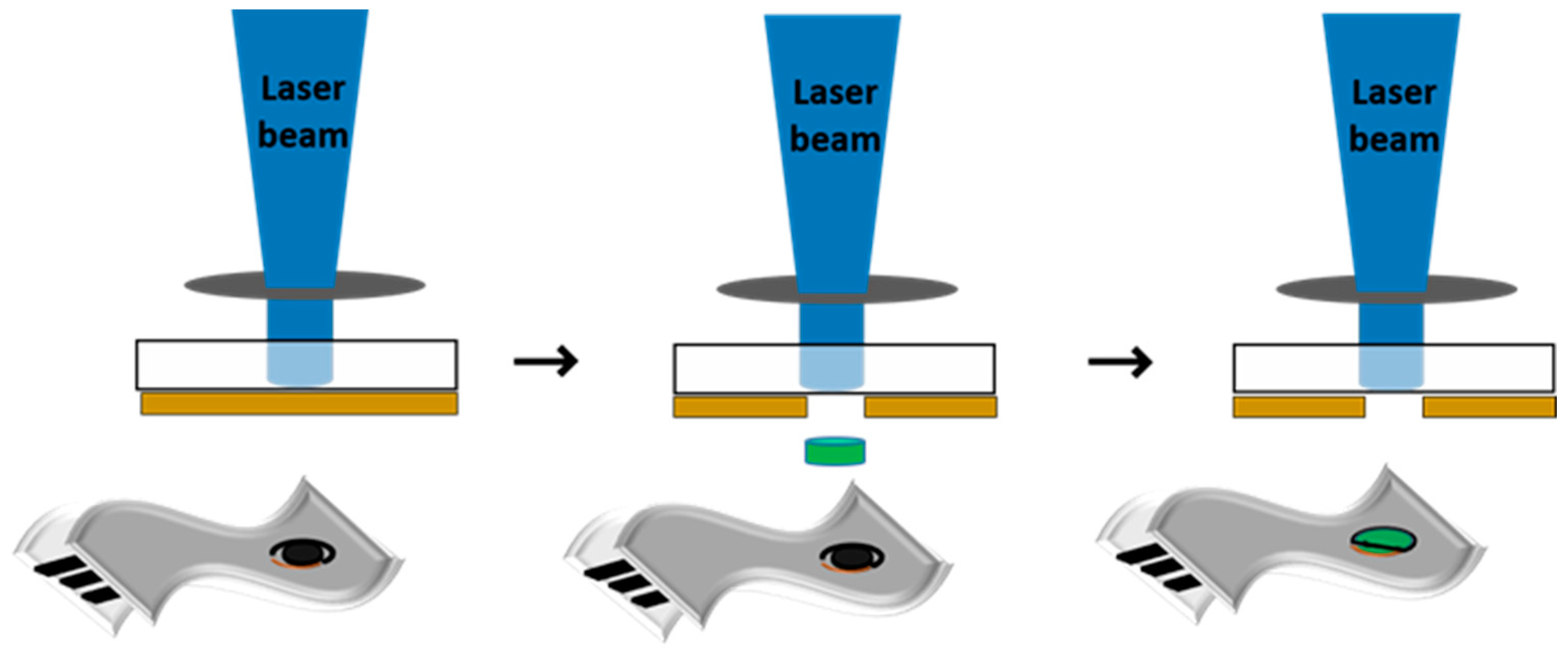

2.2. Electrode Modification via Laser-Induced Forward Transfer

2.3. Investigation of Electrode Functionality

2.4. Surface Investigation of the Transferred Material and Functionalized Electrodes

3. Results and Discussion

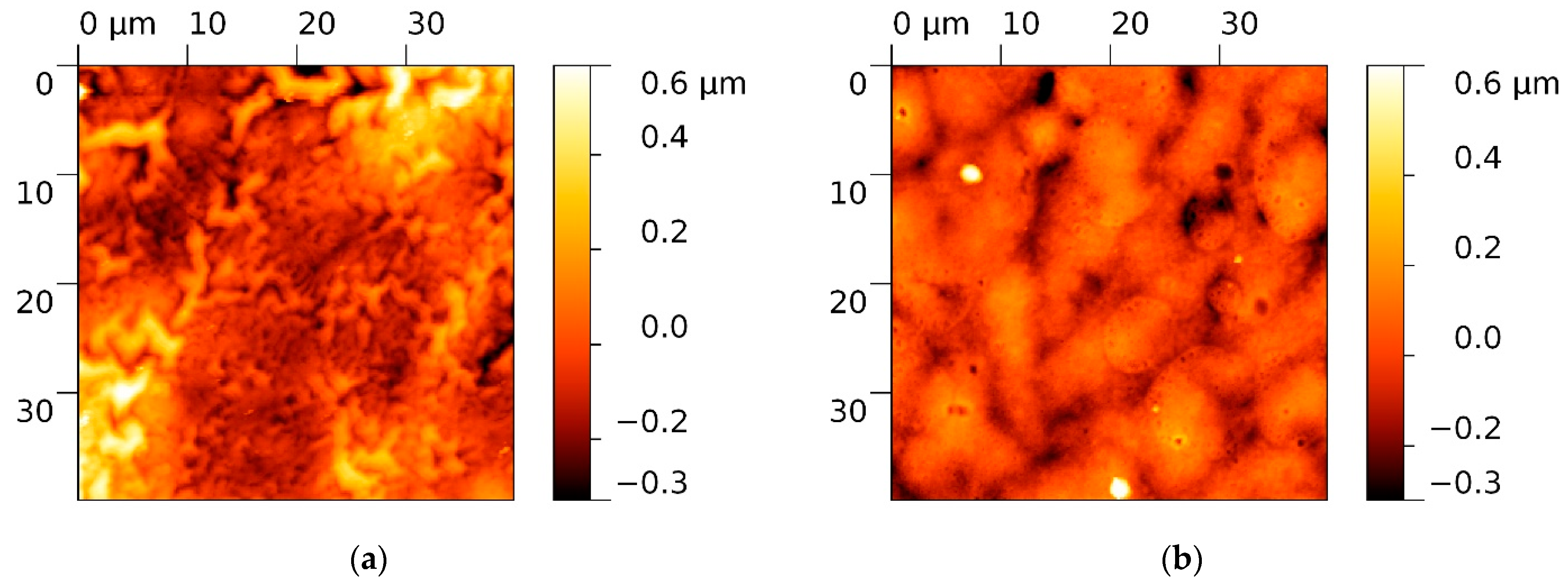

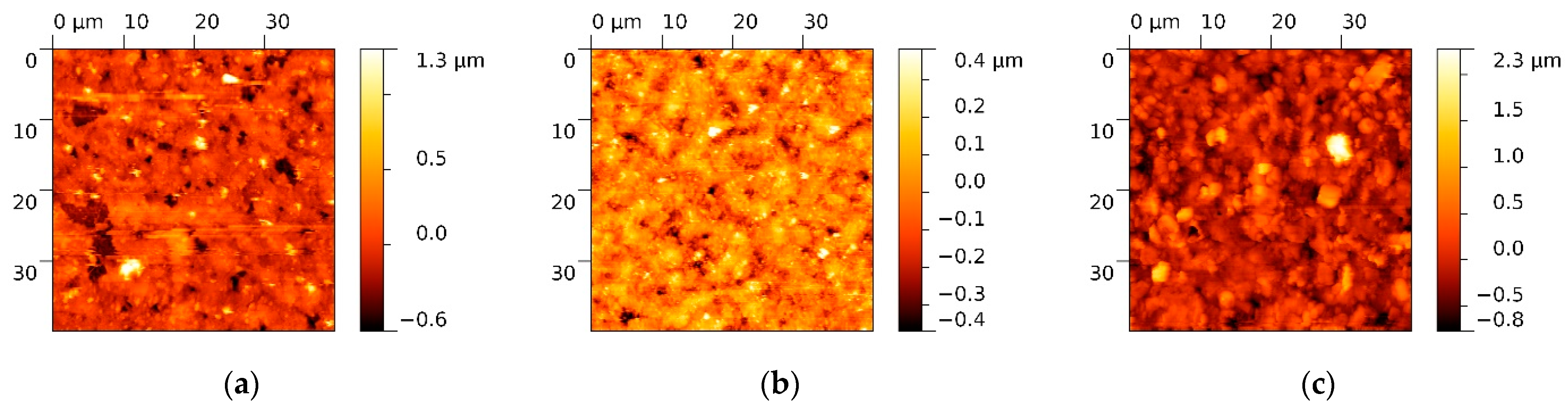

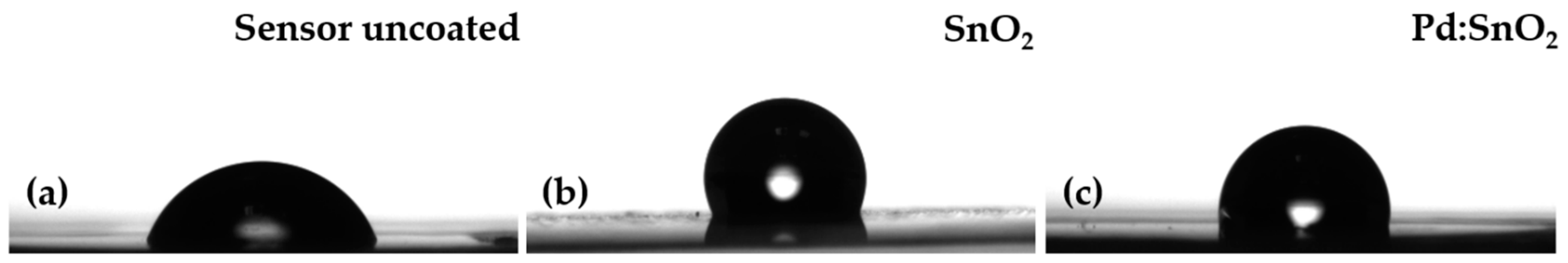

3.1. Morphological Investigation

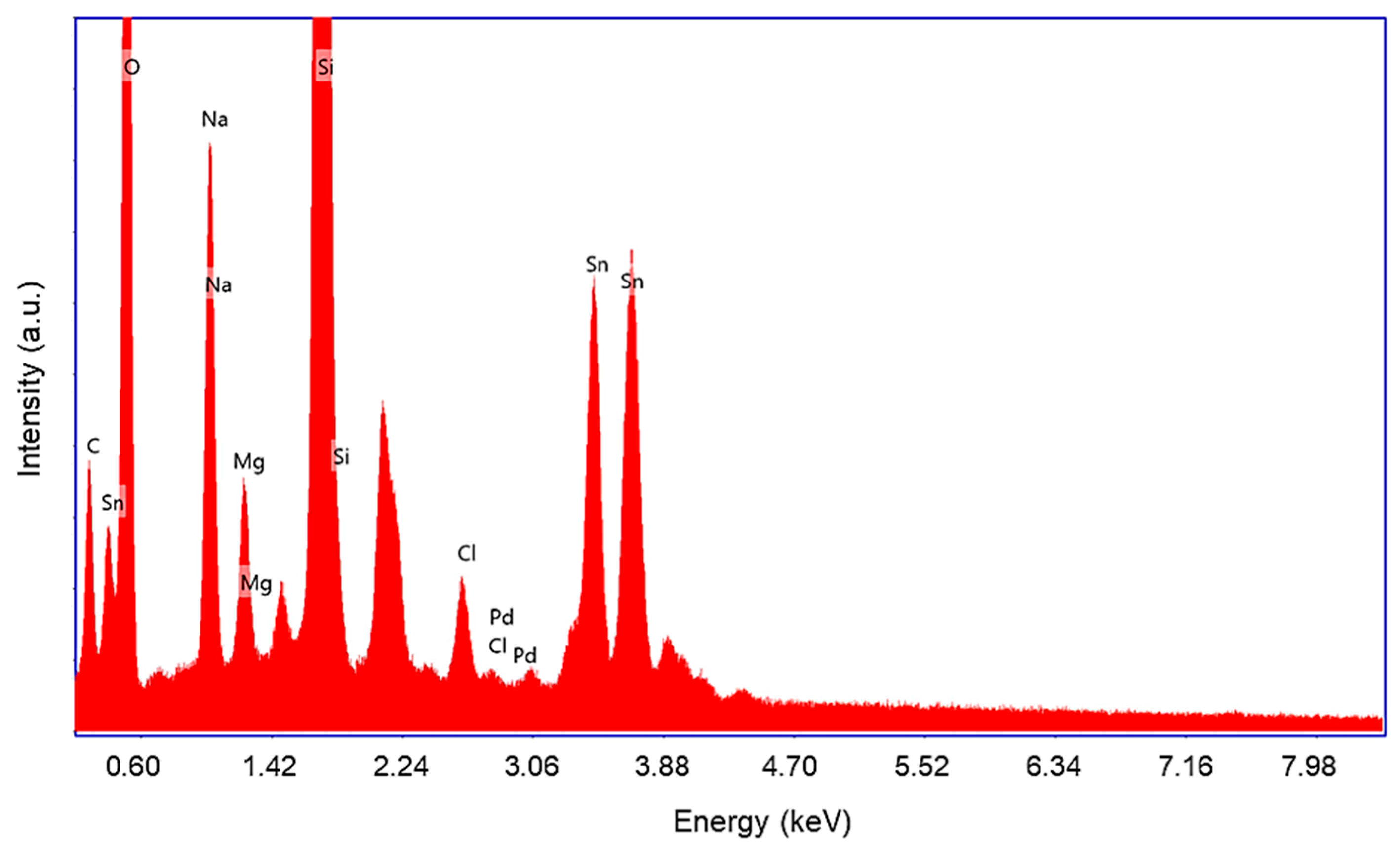

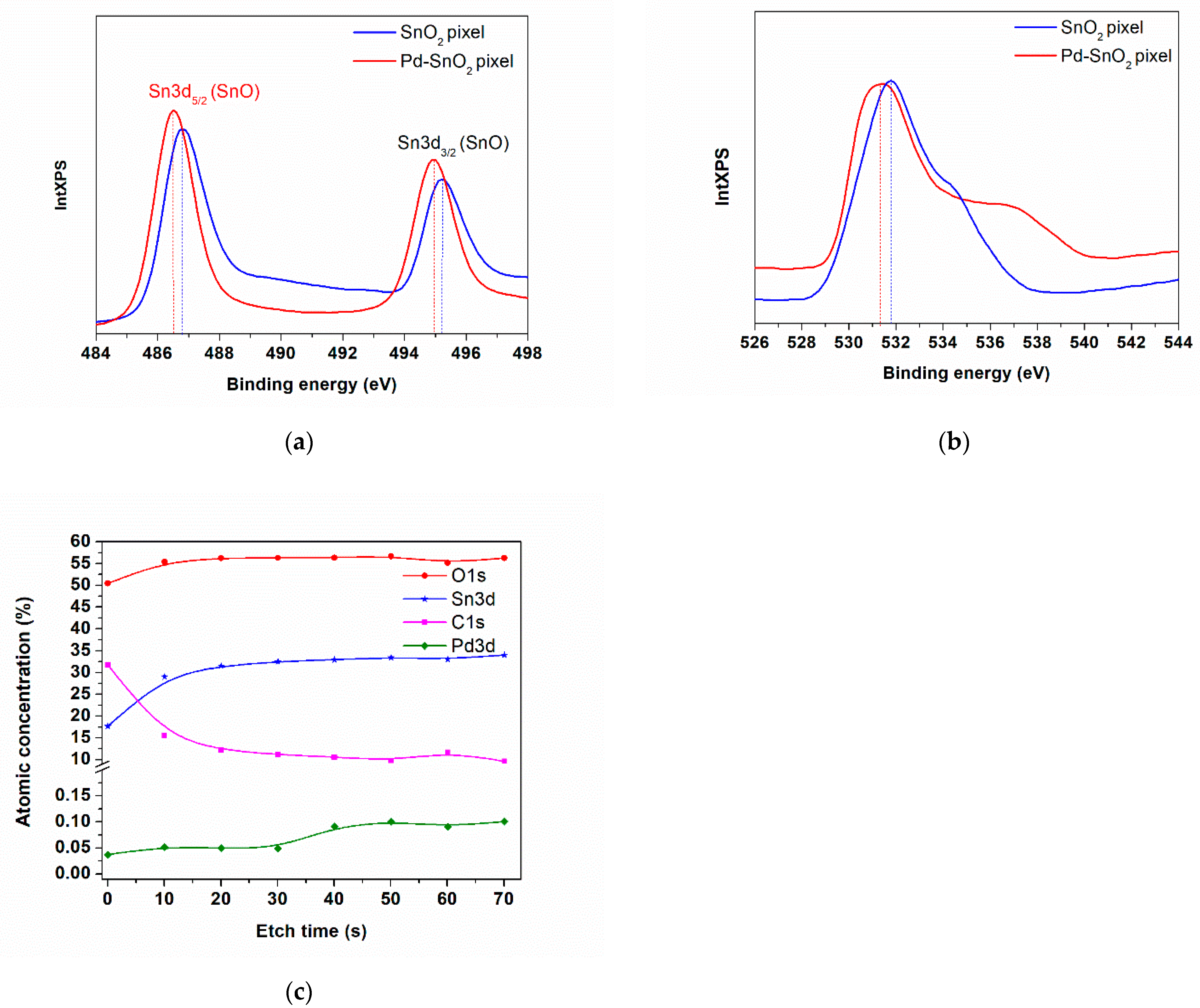

3.2. Chemical Investigation

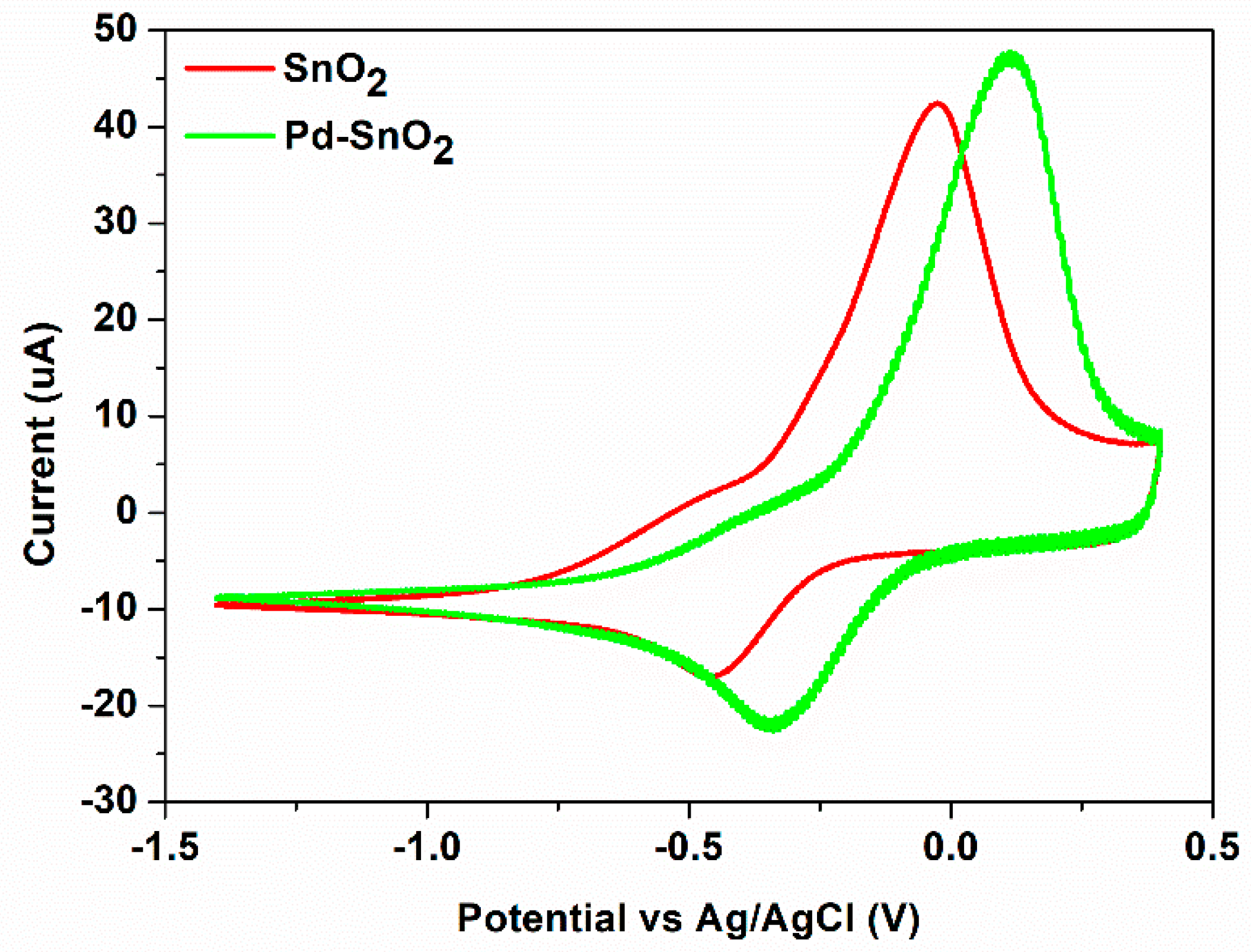

3.3. Assessment of the LIFT Modified Electrodes Functionality

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sodhi, R.K.; Paul, S. An Overview of Metal Acetylacetonates: Developing Areas/Routes to New Materials and Applications in Organic Syntheses. Catal. Surv. Asia 2018, 22, 31–62. [Google Scholar] [CrossRef]

- Caille, J.-R.; Debuigne, A.; Jérôme, R. Quinone Transfer Radical Polymerization (QTRP) of Styrene: Catalysis by Different Metal Complexes. J. Polym. Sci. Part A Polym. Chem. 2005, 43, 2723–2733. [Google Scholar] [CrossRef]

- Chua, M.L.; Xiao, Y.; Chung, T.S. Using Iron (III) Acetylacetonate as Both a Cross-Linker and Micropore Former to Develop Polyimide Membranes with Enhanced Gas Separation Performance. Sep. Purif. Technol. 2014, 133, 120–128. [Google Scholar] [CrossRef]

- Kucharyson, J.F.; Cheng, L.; Tung, S.O.; Curtiss, L.A.; Thompson, L.T. Predicting the Potentials, Solubilities and Stabilities of Metal-Acetylacetonates for Non-Aqueous Redox Flow Batteries Using Density Functional Theory Calculations. J. Mater. Chem. A 2017, 5, 13700–13709. [Google Scholar] [CrossRef]

- Kaneko, T.; Watanuki, Y.; Toyama, T.; Kojima, Y.; Nishimiya, N. Characterization and Hydrogen Sorption Behaviors of FeNiCr-Carbon Composites Derived from Fe, Ni and Cr-Containing Polyacrylonitrile Fibers Prepared by Electrospinning Method. Int. J. Hydrogen Energy 2017, 42, 10014–10022. [Google Scholar] [CrossRef]

- Inagaki, N.; Tasaka, S.; Nozue, Y. Plasma Polymerization of Metal Acetylacetonates and Application for Gas Sensor Devices. J. Appl. Polym. Sci. 1992, 45, 1041–1048. [Google Scholar] [CrossRef]

- Goncharov, T.; Nasriddinov, A.; Zubenko, A.; Tokarev, S.; Shatalova, T.; Khmelevsky, N.; Fedorova, O.; Rumyantseva, M. Nanocrystalline SnO2 Functionalized with Ag(I) Organometallic Complexes as Materials for Low Temperature H2S Detection. Materials 2021, 14, 7778. [Google Scholar] [CrossRef]

- Kamedulski, P.; Skorupska, M.; Binkowski, P.; Arendarska, W.; Ilnicka, A.; Lukaszewicz, J.P. High surface area micro-mesoporous graphene for electrochemical applications. Sci. Rep. 2021, 11, 22054. [Google Scholar] [CrossRef]

- Vasiliev, V.P.; Manzhos, R.A.; Kochergin, V.K.; Krivenko, A.G.; Kabachkov, E.N.; Kulikov, A.V.; Shulga, Y.M.; Gutsev, G.L. A Facile Synthesis of Noble-Metal-Free Catalyst Based on Nitrogen Doped Graphene Oxide for Oxygen Reduction Reaction. Materials 2022, 15, 821. [Google Scholar] [CrossRef]

- Alwin, E.; Kočí, K.; Wojcieszak, R.; Zieliński, M.; Edelmannová, M.; Pietrowski, M. Influence of High Temperature Synthesis on the Structure of Graphitic Carbon Nitride and Its Hydrogen Generation Ability. Materials 2020, 13, 2756. [Google Scholar] [CrossRef]

- Holder, E.; Langeveld, B.M.W.; Schubert, U.S. New Trends in the Use of Transition Metal-Ligand Complexes for Applications in Electroluminescent Devices. Adv. Mater. 2005, 17, 1109–1121. [Google Scholar] [CrossRef]

- El-Mahalawy, A.M. Structural and Optical Characteristics of Nickel Bis(Acetylacetonate) Thin Films as a Buffer Layer for Optoelectronic Applications. Mater. Sci. Semicond. Process. 2019, 100, 145–158. [Google Scholar] [CrossRef]

- Taheri, M.; Naderi, R.; Saremi, M.; Mahdavian, M. Development of an Ecofriendly Silane Sol-Gel Coating with Zinc Acetylacetonate Corrosion Inhibitor for Active Protection of Mild Steel in Sodium Chloride Solution. J. Sol.-Gel. Sci. Technol. 2017, 81, 154–166. [Google Scholar] [CrossRef]

- Ortiz, A.; Alonso, J.C.; Haro-Poniatowski, E. Spray Deposition and Characterization of Zirconium-Oxide Thin Films. J. Electron. Mater. 2005, 34, 150–155. [Google Scholar] [CrossRef]

- Chang, Q.; Zhang, N.; Liu, W.; Ye, Q.; Yu, Y.; Chen, X.; Li, C. Thermal Properties and Gas Decomposition Products of Hafnium(IV) Acetylacetonate. Asian J. Chem. 2010, 22, 1935–1938. [Google Scholar]

- Singhal, A.; Sanyal, B.; Tyagi, A.K. Tin Oxide Nanocrystals: Controllable Synthesis, Characterization, Optical Properties and Mechanistic Insights into the Formation Process. RSC Adv. 2011, 1, 903–910. [Google Scholar] [CrossRef]

- Adedeji, A.V.; Egharevba, G.O.; Jeynes, C.; Ajayi, E.O.B. Preparation and Characterization of Pyrolytically Deposited (Co-V-O and Cr-V-O) Thin Films. Thin Solid Films 2002, 402, 49–54. [Google Scholar] [CrossRef]

- Tsuchiya, T.; Watanabe, A.; Imai, Y.; Niino, H.; Yabe, A.; Yamaguchi, I.; Manabe, T.; Kumagai, T.; Mizuta, S. Preparation of Metal Oxide Thin Films Using Coating Photolysis Process with ArF Excimer Laser. In Proceedings of the 1st International Symposium on Laser Precision Microfabrication; Miyamoto, I., Sugioka, K., Sigmon, T.W., Eds.; Spie-Int Soc Optical Engineering: Bellingham, WA, USA, 2000; Volume 4088, pp. 311–314. [Google Scholar]

- Gil-Rostra, J.; Yubero, F.; Ferrer, F.J.; González-Elipe, A.R. Combined Reactive Magnetron Sputtering and Plasma Decomposition of Non-Volatile Precursors to Grow Luminescent Thin Films. Surf. Coat. Technol. 2013, 222, 144–150. [Google Scholar] [CrossRef]

- Arnold, C.B.; Serra, P.; Pique, A. Laser Direct-Write Techniques for Printing of Complex Materials. MRS Bull. 2007, 32, 23–31. [Google Scholar] [CrossRef] [Green Version]

- Springer, M.; Dusing, J.; Koch, J.; Jaschke, P.; Kaierle, S.; Overmayer, L. Laser-Induced Forward Transfer as a Potential Alternative to Pick-and-Place technology when Assembling Semiconductor Components. J. Laser Appl. 2021, 33, 042030. [Google Scholar] [CrossRef]

- Sammartino, C.; Sedghani Cohen, S.; Kotler, Z.; Eliaz, N. Direct Writing of High-Resolution, High-Quality Pure Metal Patterns on Smooth Transparent Substrates by Laser-induced Forward Transfer Followed by a Novel Laser Treatment. Adv. Eng. Mater. 2021, 23, 2100245. [Google Scholar] [CrossRef]

- Wang, X.; Zheng, J.; Mei, X.; Xu, B.; Miao, J. Laser Fabrication of fully Printed Graphene Oxide Microsensor. Opt. Lasers Eng. 2021, 140, 106520. [Google Scholar] [CrossRef]

- Delaporte, P.; Alloncle, A.-P. Laser-induced forward transfer: A high resolution additive manufacturing technology. Opt. Laser Technol. 2016, 78, 33–41. [Google Scholar] [CrossRef]

- Serra, P.; Duocastella, M.; Fernández-Pradas, J.M.; Morenza, J.L. Liquids microprinting through laser-induced forward transfer. Appl. Surf. Sci. 2009, 255, 5342–5345. [Google Scholar] [CrossRef]

- Palla-Papavlu, A.; Patrascioiu, A.; Di Pietrantonio, F.; Fernández-Pradas, J.-M.; Cannatà, D.; Benetti, M.; D’Auria, S.; Verona, E.; Serra, P. Preparation of surface acoustic wave odor sensors by laser-induced forward transfer. Sens. Actuators B Chem. 2014, 192, 369–377. [Google Scholar] [CrossRef]

- Gorodesky, N.; Sedghani-Cohen, S.; Fogel, O.; Silber, A.; Tkachev, M.; Kotler, Z.; Zalevsky, Z. Improving Compactness of 3D Metallic Microstructures Printed by Laser-Induced Forward Transfer. Crystals 2021, 11, 291. [Google Scholar] [CrossRef]

- Visser, C.W.; Pohl, R.; Sun, C.; Roemer, G.-W.; in ’t Veld, B.H.; Lohse, D. Toward 3D Printing of Pure Metals by Laser-Induced Forward Transfer. Adv. Mater. 2015, 27, 4087–4092. [Google Scholar] [CrossRef] [Green Version]

- Mills, B.; Heath, D.J.; Feinaeugle, M.; Eason, R.W. LIFT of Solid Films (Ceramics and Polymers). In Laser Printing of Functional Materials; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2018; pp. 175–198. ISBN 978-3-527-80510-5. [Google Scholar]

- Makrygianni, M.; Zacharatos, F.; Andritsos, K.; Theodorakos, I.; Reppas, D.; Oikonomidis, N.; Spandonidis, C.; Zergioti, I. Eco-Friendly Lead-Free Solder Paste Printing via Laser-Induced Forward Transfer for the Assembly of Ultra-Fine Pitch Electronic Components. Materials 2021, 14, 3353. [Google Scholar] [CrossRef]

- Papazoglou, S.; Zergioti, I. Laser Induced Forward Transfer (LIFT) of Nano-Micro Patterns for Sensor Applications. Microelectron. Eng. 2017, 182, 25–34. [Google Scholar] [CrossRef]

- Shaw Stewart, J.; Lippert, T.; Nagel, M.; Nüesch, F.; Wokaun, A. Red-Green-Blue Polymer Light-Emitting Diode Pixels Printed by Optimized Laser-Induced Forward Transfer. Appl. Phys. Lett. 2012, 100, 203303. [Google Scholar] [CrossRef] [Green Version]

- Charipar, K.M.; Charipar, N.A.; Prestigiacomo, J.C.; Bingham, N.S.; Pique, A. Laser Printing of Flip-Chip Interconnects for High Frequency Applications. J. Manuf. Process. 2018, 32, 110–115. [Google Scholar] [CrossRef]

- Nastulyavichus, A.; Tolordava, E.; Rudenko, A.; Zazymkina, D.; Shakhov, P.; Busleev, N.; Romanova, Y.; Ionin, A.; Kudryashov, S. In Vitro Destruction of Pathogenic Bacterial Biofilms by Bactericidal Metallic Nanoparticles via Laser-Induced Forward Transfer. Nanomaterials 2020, 10, 2259. [Google Scholar] [CrossRef] [PubMed]

- Soulis, D.; Trigazi, M.; Tsekensis, G.; Chandrinou, C.; Klinakis, A.; Zergioti, I. Facile and Low-Cost SPE Modification Towards Ultra-Sensitive Organophosphorous and Carbamate Pesticide Detection in Olive Oil. Molecules 2020, 25, 4988. [Google Scholar] [CrossRef] [PubMed]

- Mattle, T.; Shaw-Stewart, J.; Hintennach, A.; Schneider, C.W.; Lippert, T.; Wokaun, A. Shadowgraphic Investigations into the Laser-Induced Forward Transfer of Different SnO2 Precursor Films. Appl. Surf. Sci. 2013, 278, 77–81. [Google Scholar] [CrossRef]

- Mattle, T.; Hintennach, A.; Lippert, T.; Wokaun, A. Laser induced forward transfer of SnO2 for sensing applications using different precursors systems. Appl. Phys. A 2013, 110, 309–316. [Google Scholar] [CrossRef]

- Palla Papavlu, A.; Mattle, T.; Temmel, S.; Lehmann, U.; Hintennach, A.; Grisel, A.; Wokaun, A.; Lippert, T. Highly Sensitive SnO2 Sensor via Reactive Laser-Induced Transfer. Sci. Rep. 2016, 6, 25144. [Google Scholar] [CrossRef] [Green Version]

- Gschwend, P.M.; Schenk, F.M.; Gogos, A.; Pratsinis, S.E. Acetone Sensing and Catalytic Conversion by Pd-Loaded SnO2. Materials 2021, 14, 5921. [Google Scholar] [CrossRef]

- Labar, J.L. Standardless Quantitative Analysis by X-Ray Spectrometry. Scanning Microsc. 1993, 1993, 10. [Google Scholar]

- Ansell, R.O.; Dickinson, T.; Povey, A.F.; Sherwood, P.M.A. Quantitative use of the angular variation technique in studies of tin by X-ray photoelectron spectroscopy. J. Electron. Spectros. Relat. Phenom. 1977, 11, 301–313. [Google Scholar] [CrossRef]

- Szuber, J.; Czempik, G.; Larciprete, R.; Koziej, D.; Adamowicz, B. XPS study of the L-CVD deposited SnO2 thin films exposed to oxygen and hydrogen. Thin Solid Films 2001, 391, 198–203. [Google Scholar] [CrossRef]

- Cao, X.; Cao, L.; Yao, W.; Ye, X. Structural Characterization of Pd-doped SnO2 Thin Films Using XPS. Surf. Interface Anal. 1996, 24, 662–666. [Google Scholar] [CrossRef]

- Shaikh, A.A.; Firdaws, J.; Badrunnessa; Serajee, S.; Rahman, M.S.; Bakshi, P.K. Electrochemical Studies of the PH Dependence of Cu(II) Reduction in Aqueous Britton-Robinson Buffer Solution. Int. J. Electrochem. Sci. 2011, 6, 2333–2343. [Google Scholar]

- Haque, F.; Rahman, M.S.; Ahmed, E.; Bakshi, P.; Shaikh, A. A Cyclic Voltammetric Study of the Redox Reaction of Cu(II) in Presence of Ascorbic Acid in Different PH Media. Dhaka Univ. J. Sci. 2013, 61, 161–166. [Google Scholar] [CrossRef] [Green Version]

- Mei, C.J.; Yusof, N.A.; Ahmad, S.A.A. Electrochemical Determination of Lead & Copper Ions Using Thiolated Calix[4]Arene-Modified Screen-Printed Carbon Electrode. Chemosensors 2021, 9, 157. [Google Scholar] [CrossRef]

| Donor | Min (nm) | Max (nm) | Rq (nm) | Rsk | Thickness (nm) |

|---|---|---|---|---|---|

| SnCl2(acac)2 | −457.323 | 781.542 | 156.176 | −1.105 | 1085 |

| Pd-SnCl2(acac)2 | −519.386 | 781.174 | 97.251 | −0.379 | 895 |

| Pixel 1 | Pixel 2 | Pixel 3 | Pixel 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Element | wt % | Atomic % | Error % | wt % | Atomic % | Error % | wt % | Atomic % | Error % | wt % | Atomic % | Error % |

| OK | 51.34 | 88.67 | 4.29 | 46.92 | 88.77 | 4.52 | 40.09 | 83.23 | 4.82 | 41.88 | 84.23 | 4.89 |

| PdL | 0.04 | 0.01 | 17.45 | 0.07 | 0.02 | 15.91 | 0.26 | 0.08 | 10.00 | 0.39 | 0.12 | 11.87 |

| SnL | 48.62 | 11.32 | 3.04 | 53.02 | 13.22 | 2.89 | 59.65 | 16.69 | 2.67 | 57.73 | 15.65 | 2.68 |

| Sn 3d5 | O1s | C1s |

|---|---|---|

| 20.65 ± 2.5 | 66.3 ± 3.5 | 13.05 ± 4 |

| Sensor | Cu2+ Concentration | pH | Peak Current (μA) | Peak Potential (mV) | ∆Ep = Epa − Epc | |ipa/ipc| | Ref. | ||

|---|---|---|---|---|---|---|---|---|---|

| (−) ipc | ipa | (−) Epc | Epa | ||||||

| Commercial SPE-PEDOT | 100 ppm | 5 | 11.41 | 42.9 | 430 | 26 | 450 | 3.76 | - |

| GCE | ca. 188 ppm | 1.03 | 50.99 | 140.24 | 82 | 53 | 135 | 2.75 | [44] |

| GCE | ca. 135 ppm | 5.3 | 125 | 148.2 | 301.4 | 291.52 | 592.92 | 1.19 | [45] |

| Modified-SPCE | 1 ppm | 8 | - | <2 | - | - | - | - | [46] |

| SnO2 | 100 ppm | 5 | 10.01 | 38.03 | 460 | −31 | 429 | 2.90 | This work |

| Pd-SnO2 | 100 ppm | 5 | 15.18 | 44.06 | 340 | 110 | 450 | 3.79 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Andrei, F.; Boerasu, I.; Filipescu, M.; Palla-Papavlu, A. Facile Modification of Flexible Electrodes via Laser Transfer. Materials 2022, 15, 2488. https://doi.org/10.3390/ma15072488

Andrei F, Boerasu I, Filipescu M, Palla-Papavlu A. Facile Modification of Flexible Electrodes via Laser Transfer. Materials. 2022; 15(7):2488. https://doi.org/10.3390/ma15072488

Chicago/Turabian StyleAndrei, Florin, Iulian Boerasu, Mihaela Filipescu, and Alexandra Palla-Papavlu. 2022. "Facile Modification of Flexible Electrodes via Laser Transfer" Materials 15, no. 7: 2488. https://doi.org/10.3390/ma15072488

APA StyleAndrei, F., Boerasu, I., Filipescu, M., & Palla-Papavlu, A. (2022). Facile Modification of Flexible Electrodes via Laser Transfer. Materials, 15(7), 2488. https://doi.org/10.3390/ma15072488