Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample

2.2. Water Content Test

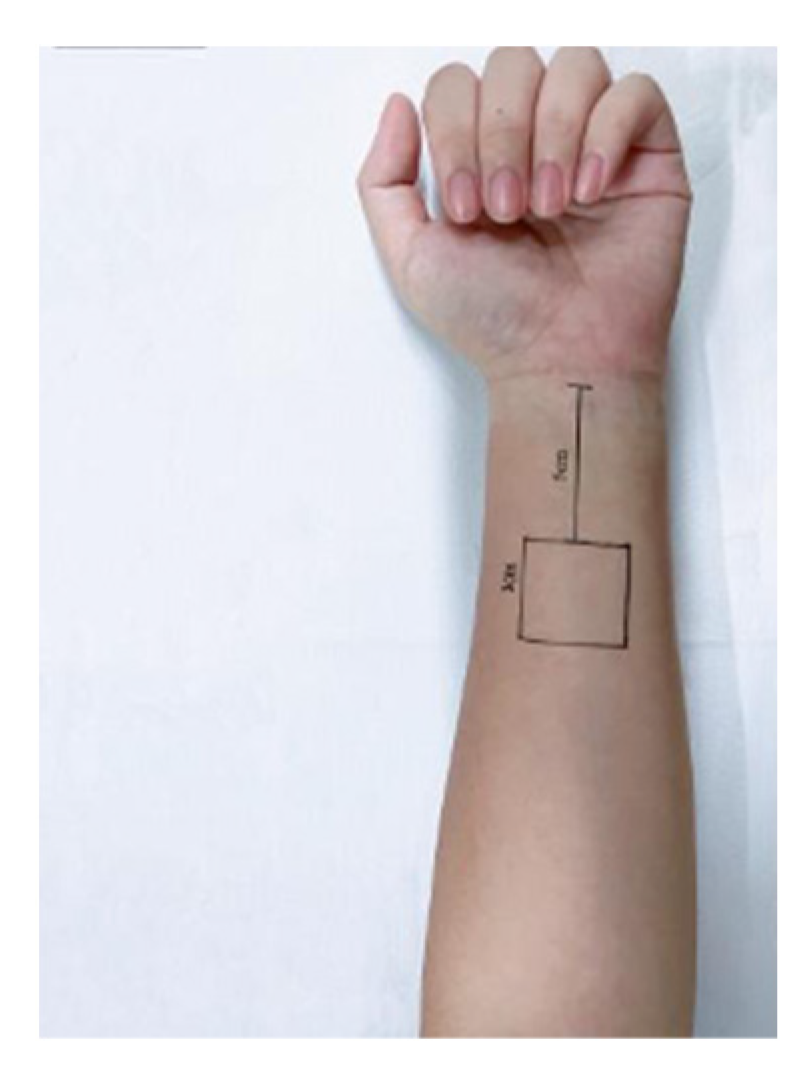

Skin Moisture Content Test Method

2.3. Measurement of Skin Trans-Epidermal Water Loss

Test Method for Trans-Epidermal Water Loss

3. Results and Discussion

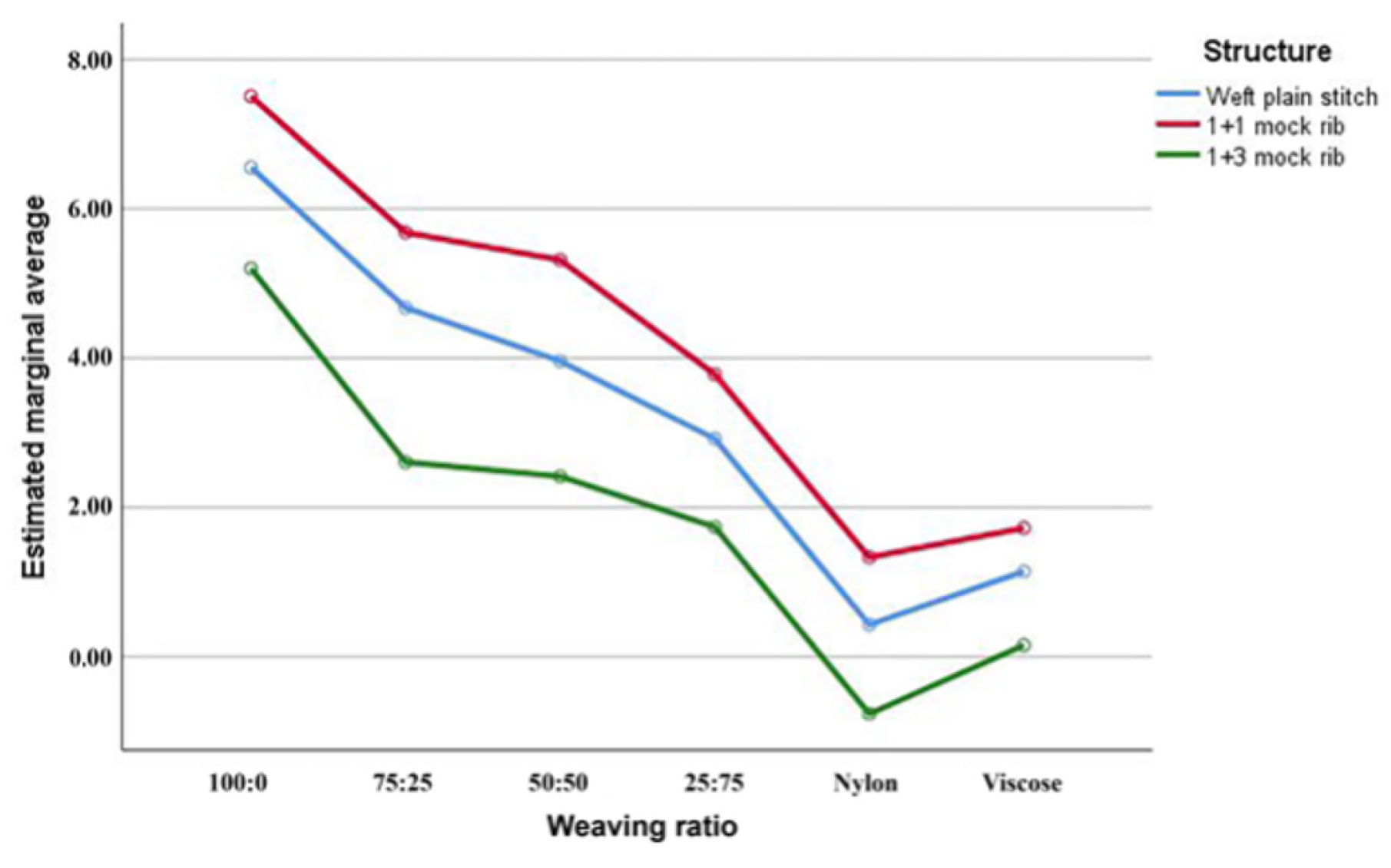

3.1. Test Results and Analysis of Skin Moisture Content

3.2. Test Results and Analysis of Trans-Epidermal Water Loss

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.E.; Ling, P.X. Hyaluronic acid and cosmetics. Food Med. 2010, 12, 278–280. [Google Scholar]

- Suchý, P.; Paprskářová, A.; Chalupová, M.; Marholdová, L.; Nešporová, K.; Klusáková, J.; Kuzmínová, G.; Hendrych, M.; Velebný, V. Composite Hemostatic Nonwoven Textiles Based on Hyaluronic Acid, Cellulose, and Etamsylate. Materials 2020, 13, 1627. [Google Scholar] [CrossRef] [Green Version]

- Uppal, R.; Ramaswamy, G.N.; Arnold, C.; Goodband, R.; Wang, Y. Hyaluronic acid nanofiber wound dressing--production, characterization, and in vivo behavior. J. Biomed. Mater. Res. Part B Appl. Biomater. 2011, 97, 20–29. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.Y.; Jin, Y.; Ling, P.X. Lubricating function of sodium hyaluronate. Food Med. 2018, 20, 303–306. [Google Scholar]

- Witting, M.; Boreham, A.; Brodwolf, R.; Vavrova, K.; Alexiev, U.; Friess, W.; Hedtrich, S. Interactions of Hyaluronic Acid with the Skin and Implications for the Dermal Delivery of Biomacromolecules. Mol. Pharm. 2015, 12, 1391–1401. [Google Scholar] [CrossRef] [PubMed]

- Cheng, S.Y.; Yuen, C.W.M.; Kan, C.W.; Cheuk, K.K.L.; Tang, J.C.O.; Li, S.Y. A comprehensive study of silicone-based cosmetic textile agent. Fibers Polym. 2009, 10, 132–140. [Google Scholar] [CrossRef]

- Alonso, C.; Martí, M.; Martínez, V.; Rubio, L.; Parra, J.L.; Coderch, L. Antioxidant cosmeto-textiles: Skin assessment. Eur. J. Pharm. Biopharm. 2013, 84, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Krysiak, Z.J.; Knapczyk-Korczak, J.; Maniak, G.; Stachewicz, U. Moisturizing effect of skin patches with hydrophobic and hydrophilic electrospun fibers for atopic dermatitis. Colloids Surf. B Biointerfaces 2020, 199, 111554. [Google Scholar] [CrossRef] [PubMed]

- Ghaheh, F.S.; Khoddami, A.; Alihosseini, F.; Jing, S.; Ribeiro, A.; Cavaco-Paulo, A.; Silva, C. Antioxidant cosmetotextiles: Cotton coating with nanoparticles containing vitamin E. Process Biochem. 2017, 59, 46–51. [Google Scholar] [CrossRef] [Green Version]

- Yao, G.P. Preparation of Vitamin E Microcapsules and Its Application to Silk Fabrics; Zhejiang Sci-Tech University: Hangzhou, China, 2012. [Google Scholar]

- Karel, S.; Starigazdová, J.; Vágnerová, H.; Kulhánek, J.; Horáčková, L.; Flegel, M.; Drašar, P.; Brožek, J.; Velebný, V. Hyaluronic Acid Fibres in Solid Phase Peptide Synthesis—Their Properties, Morphology and Stability. Fibers Polym. 2020, 21, 2707–2717. [Google Scholar] [CrossRef]

- Dai, F.M.; Wang, L.J.; Behm, C.; Chen, R.Y.; Zhang, N.; Shi, Z.Y. Research Progress on Evaluation and intervention of skin dryness in the elderly abroad. Chin. J. Nurs. 2017, 52, 53–58. [Google Scholar]

- Pinnagoda, J.; Tupkek, R.A.; Agner, T.; Serup, J. Guidelines for trans epidermal water loss (TEWL) measurement. A report from the Standardization Group of the European Society of Contact Dermatitis. Contact Dermat. 1990, 22, 164–178. [Google Scholar] [CrossRef] [PubMed]

- Proksch, E.; Lachapella, J.M. The management of dry skin with topical emollients-recent perspectives. JDDG J. Der Dtsch. Dermatol. Ges. 2005, 3, 768–774. [Google Scholar] [CrossRef] [PubMed]

- Hayama, K.; Takano, Y.; Tamura, J.; Tagami, H.; Terui, T. Effectiveness of a heparinoid-containing moisturiser to treat senile xerosis. Australas. J. Dermatol. 2015, 56, 36–39. [Google Scholar] [CrossRef] [PubMed]

- Danby, S.G.; Brown, K.; Higgs-Bayliss, T.; Chittock, J.; Albenali, L.; Cork, M.J. The Effect of an Emollient Containing Urea, Ceramide NP, and Lactate on Skin Barrier Structure and Function in Older People with Dry Skin. Ski. Pharmacol. Physiol. 2016, 29, 135–147. [Google Scholar] [CrossRef] [PubMed]

- Su, N.; Wang, C.T. Guidelines for Evaluation of Moisturizing Efficacy of Cosmetics; Chinese Academy of Inspection and Quarantine: Beijing, China, 2011. [Google Scholar]

- Danby, S.G. Biological Variation in Skin Barrier Function: From A (Atopic Dermatitis) to X (Xerosis). Curr. Probl. Dermatol. 2016, 49, 47–60. [Google Scholar] [PubMed]

| Yarn Type | Fineness | Filaments |

|---|---|---|

| Hyaluronic acid viscose fiber | 105D | 36F |

| Graphene viscose fiber | 105D | 36F |

| Nylon | 100D | 48F |

| Viscose | 105D | 48F |

| Nylon/spandex-coated yarn | 20D/70D | 6F/1F |

| Fabric Structure | PA/(Wale/5 cm) | PB/(Wale/5 cm) |

|---|---|---|

| Weft plain stitch | 55 | 150 |

| 1 + 1 mock rib | 55 | 180 |

| 1 + 3 mock rib | 55 | 200 |

| Sample Numbers | Veil Raw Materials | Weaving Ratio | Fabric Structure |

|---|---|---|---|

| 1 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | Weft plain stitch |

| 2 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | Weft plain stitch |

| 3 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | Weft plain stitch |

| 4 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | Weft plain stitch |

| 5 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 1 + 1 mock rib |

| 6 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 1 + 1 mock rib |

| 7 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 1 + 1 mock rib |

| 8 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 1 + 1 mock rib |

| 9 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 1 + 3 mock rib |

| 10 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 1 + 3 mock rib |

| 11 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 1 + 3 mock rib |

| 12 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 1 + 3 mock rib |

| 13 | Nylon | Weft plain stitch | |

| 14 | Nylon | 1 + 1 mock rib | |

| 15 | Nylon | 1 + 3 mock rib | |

| 16 | Viscose | Weft plain stitch | |

| 17 | Viscose | 1 + 1 mock rib | |

| 18 | Viscose | 1 + 3 mock rib |

| Sample Numbers | GSM/(g/m2) | Sample Numbers | GSM/(g/m2) |

|---|---|---|---|

| 1 | 300.93 | 10 | 467.70 |

| 2 | 311.57 | 11 | 457.86 |

| 3 | 305.91 | 12 | 465.29 |

| 4 | 306.21 | 13 | 252.25 |

| 5 | 368.20 | 14 | 297.44 |

| 6 | 367.82 | 15 | 369.11 |

| 7 | 367.83 | 16 | 293.18 |

| 8 | 370.01 | 17 | 370.68 |

| 9 | 460.85 | 18 | 465.20 |

| Sample Numbers | Veil Raw Materials | Weaving Ratio | Skin Moisture Content Change Rate (%) |

|---|---|---|---|

| 1 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 6.55 |

| 2 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 4.68 |

| 3 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 3.96 |

| 4 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 2.92 |

| 5 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 7.51 |

| 6 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 5.68 |

| 7 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 5.31 |

| 8 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 3.78 |

| 9 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 5.20 |

| 10 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 2.60 |

| 11 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 2.41 |

| 12 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 1.74 |

| 13 | Nylon | 0.43 | |

| 14 | Nylon | 1.33 | |

| 15 | Nylon | −0.77 | |

| 16 | Viscose | 1.14 | |

| 17 | Viscose | 1.72 | |

| 18 | Viscose | 0.15 |

| Inter-Subject Effect Test | |||||

|---|---|---|---|---|---|

| Dependent Variable: Skin Moisture Content Change Rate | |||||

| Source | Class III Sum of Squares | Freedom | Mean Square | F | Significance |

| Modified model | 932.093 a | 17 | 54.829 | 4.816 | 0.000 |

| Intercept | 1764.444 | 1 | 1764.444 | 154.974 | 0.000 |

| Structure | 165.204 | 2 | 82.602 | 7.255 | 0.001 |

| Materials | 758.110 | 5 | 151.622 | 13.317 | 0.000 |

| Structure* Materials | 8.779 | 10 | 0.878 | 0.077 | 1.000 |

| Error | 1844.435 | 162 | 11.385 | ||

| Total | 4540.972 | 180 | |||

| Corrected total | 2776.528 | 179 | |||

| Structure | Number of Cases | Subset | |

|---|---|---|---|

| 1 | 2 | ||

| 1 + 3 mock rib | 60 | 1.8903 | |

| Weft plain stitch | 60 | 3.2795 | |

| 1 + 1 mock rib | 60 | 4.2228 | |

| Significance | 1.000 | 0.128 | |

| The error term is the mean square (error) = 11.385. | |||

| Sample size using harmonic mean = 60.000. | |||

| Alpha = 0.05. | |||

| Materials | Number of Cases | Subset | ||

|---|---|---|---|---|

| 1 | 2 | 3 | ||

| Nylon | 30 | 0.3317 | ||

| Viscose | 30 | 1.0053 | ||

| 25:75 | 30 | 2.8127 | ||

| 50:50 | 30 | 3.8960 | ||

| 75:25 | 30 | 4.3200 | ||

| 100:0 | 30 | 6.4197 | ||

| Significance | 0.441 | 0.104 | 1.000 | |

| The error term is the mean square (error)= 11.385. | ||||

| Sample size using harmonic mean = 30.000. | ||||

| Alpha = 0.05. | ||||

| Sample Numbers | Veil Raw Materials | Weaving Ratio | Change Rate of Trans-Epidermal Water Loss (%) |

|---|---|---|---|

| 1 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 1.85 |

| 2 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 2.75 |

| 3 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 3.43 |

| 4 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 2.79 |

| 5 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 3.70 |

| 6 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 2.31 |

| 7 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 4.48 |

| 8 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 2.18 |

| 9 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 100:0 | 2.39 |

| 10 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 75:25 | 5.17 |

| 11 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 50:50 | 3.12 |

| 12 | Hyaluronic acid viscose fiber/Graphene viscose fiber | 25:75 | 2.75 |

| 13 | Nylon | −0.11 | |

| 14 | Nylon | 1.53 | |

| 15 | Nylon | 3.27 | |

| 16 | Viscose | 1.99 | |

| 17 | Viscose | 3.23 | |

| 18 | Viscose | 1.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Lu, J.; Jin, Z.; Chen, K.; Zhao, M.; Sun, Y. Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter. Materials 2022, 15, 1806. https://doi.org/10.3390/ma15051806

Wang Q, Lu J, Jin Z, Chen K, Zhao M, Sun Y. Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter. Materials. 2022; 15(5):1806. https://doi.org/10.3390/ma15051806

Chicago/Turabian StyleWang, Qiuyu, Jialiang Lu, Zimin Jin, Kun Chen, Mingtao Zhao, and Yuqiang Sun. 2022. "Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter" Materials 15, no. 5: 1806. https://doi.org/10.3390/ma15051806

APA StyleWang, Q., Lu, J., Jin, Z., Chen, K., Zhao, M., & Sun, Y. (2022). Study on the Structure and Skin Moisturizing Properties of Hyaluronic Acid Viscose Fiber Seamless Knitted Fabric for Autumn and Winter. Materials, 15(5), 1806. https://doi.org/10.3390/ma15051806