Perspective of Using Magnesium Oxychloride Cement (MOC) and Wood as a Composite Building Material: A Bibliometric Literature Review

Abstract

:1. Introduction

Research Purpose

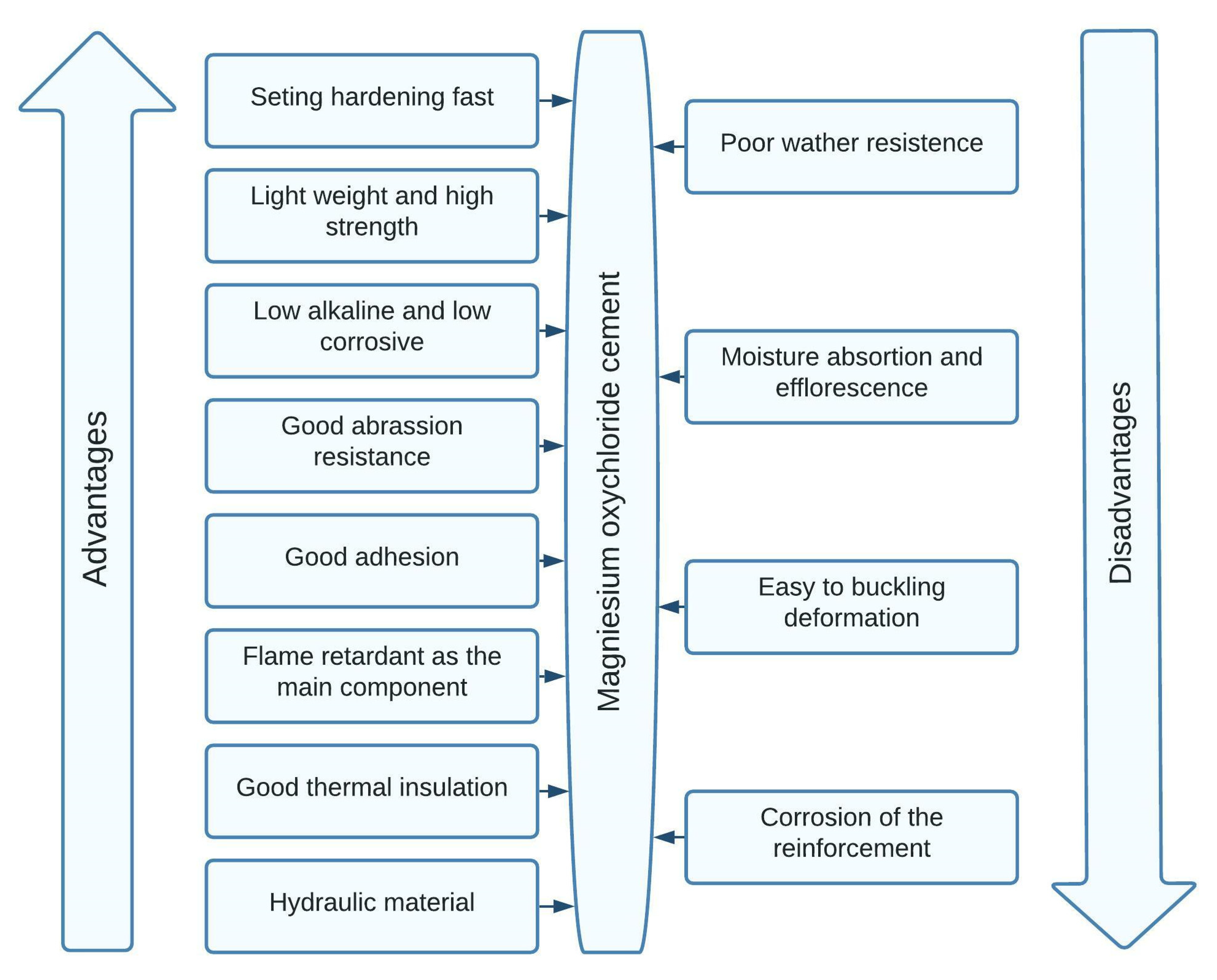

2. Background of Magnesium Oxychloride Cement (MOC)

3. Materials and Methods

3.1. The Process of Collecting Data

3.2. The Extraction and Analysis of the Research Data

4. Results and Interpretation

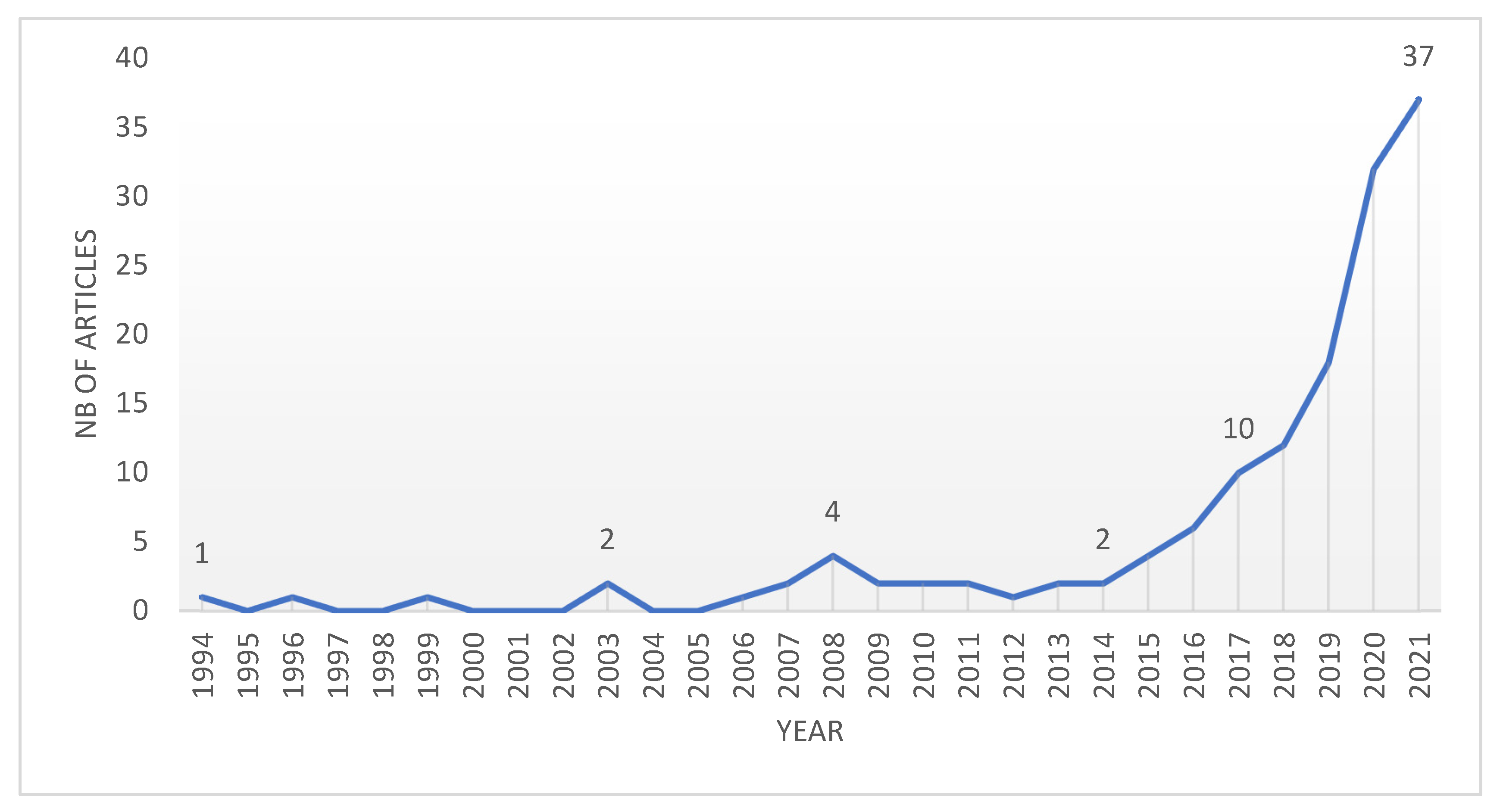

4.1. Number of Publications

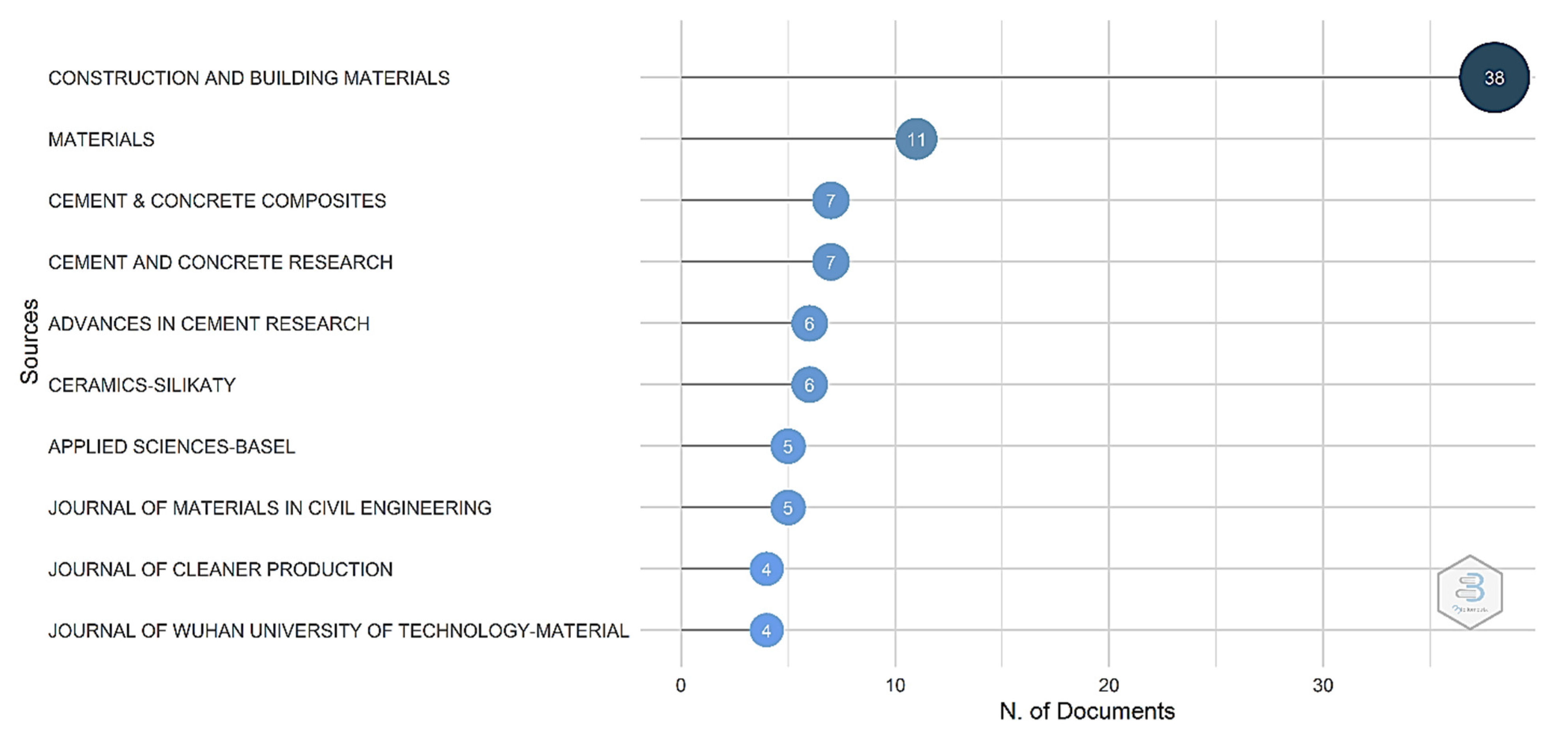

4.2. Journal Analysis

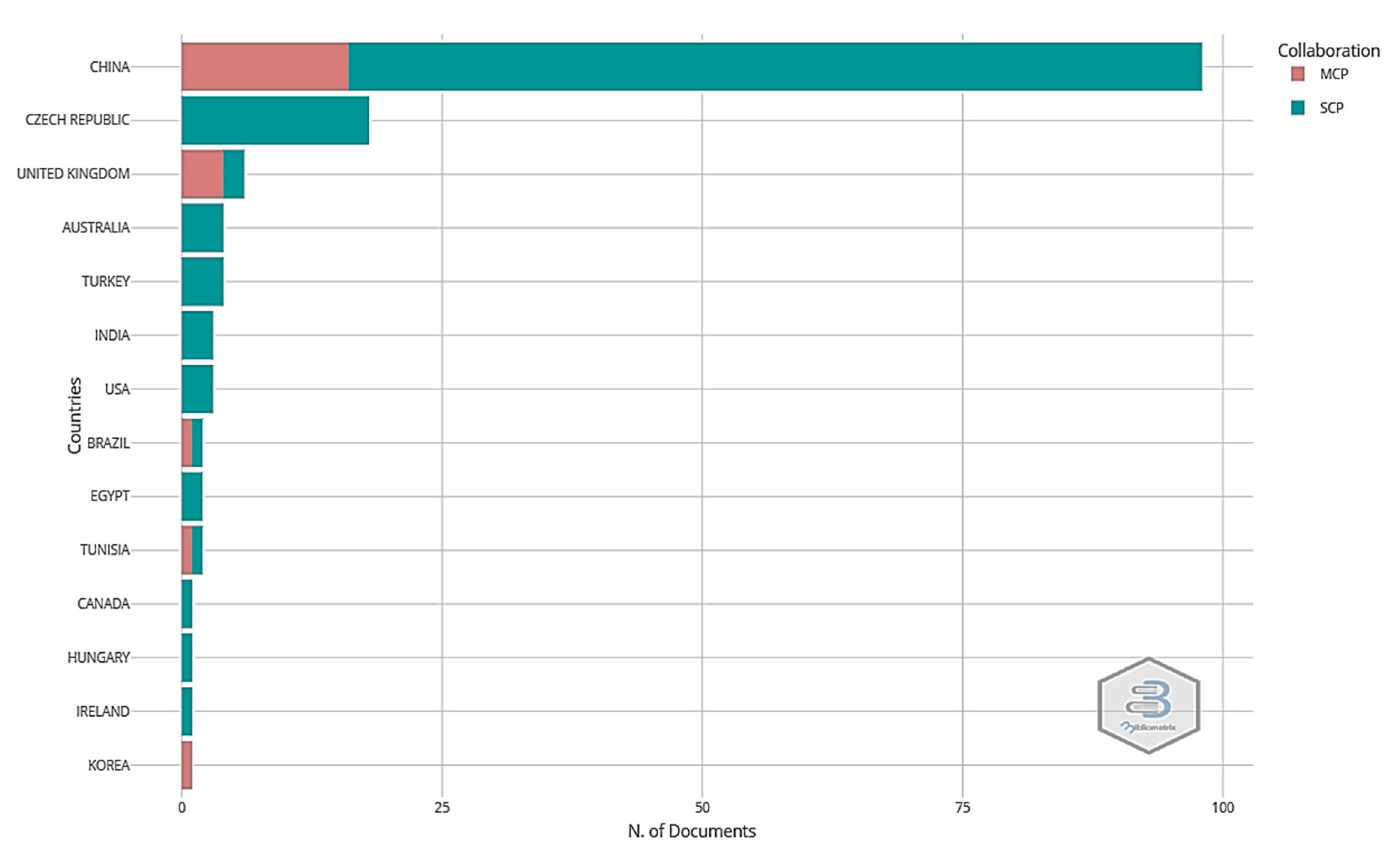

4.3. The Countries Scientific Productions

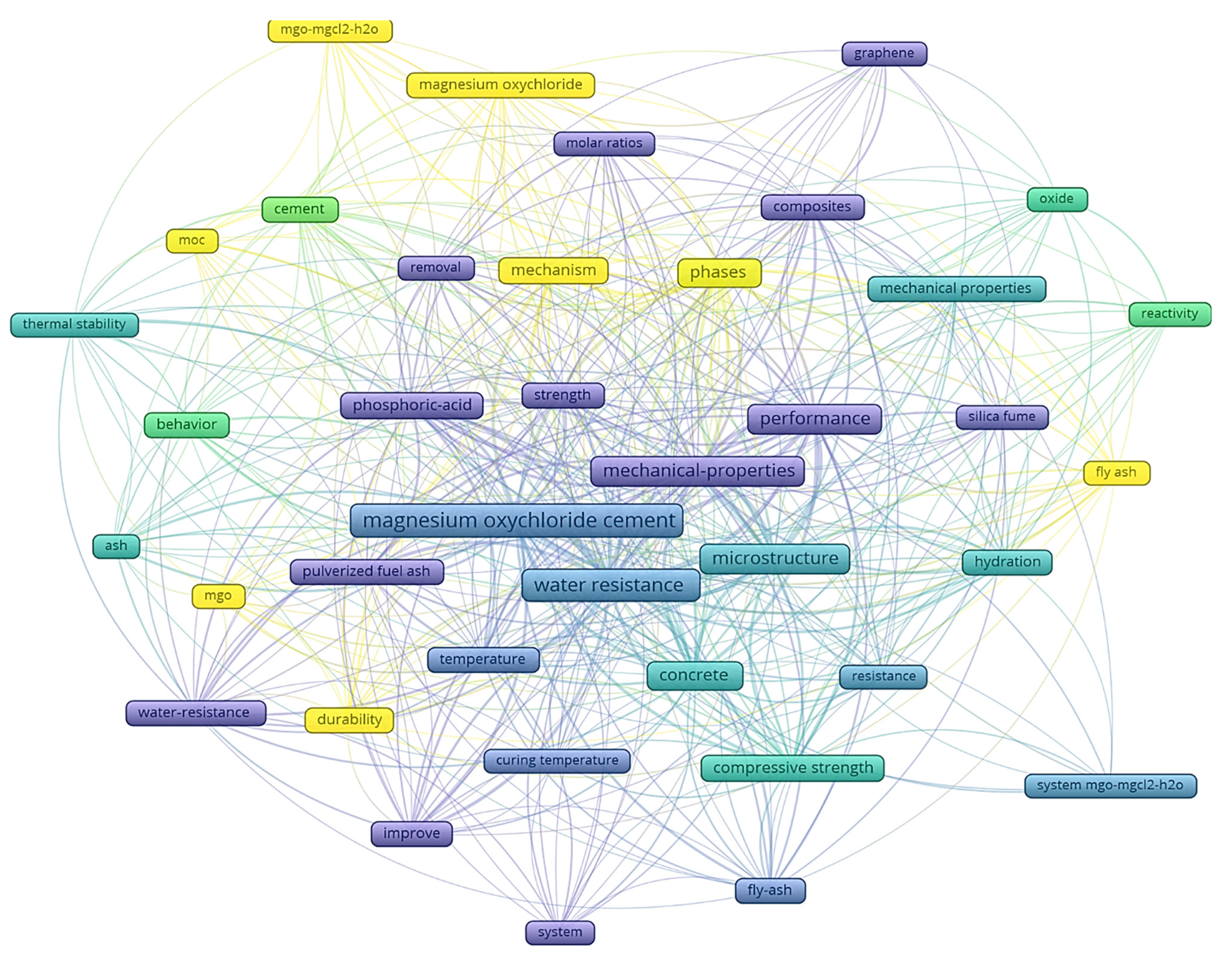

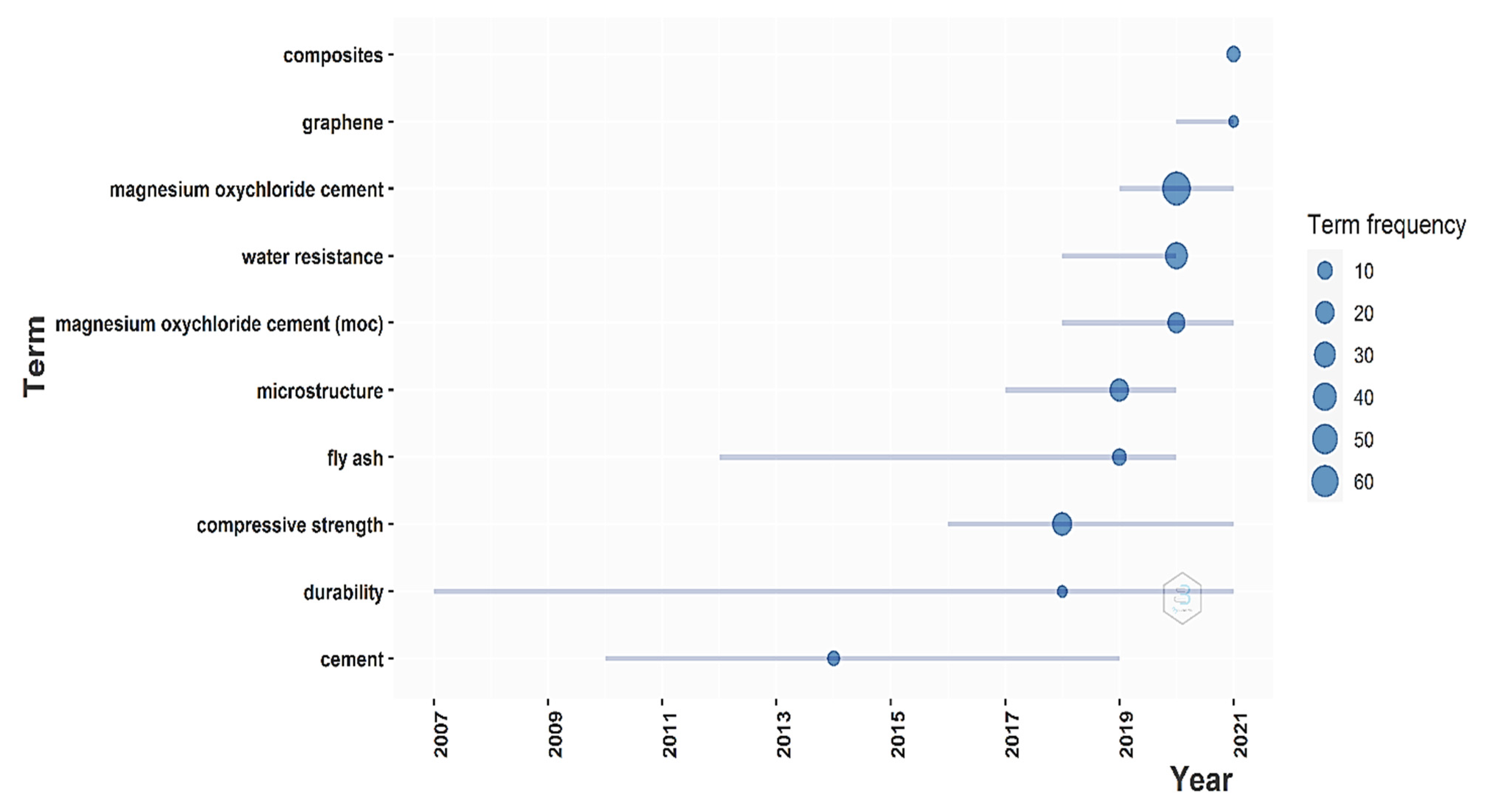

4.4. The Topical Focus in the MOC Cement Field of Research

Trend Topic Analysis

5. Discussions

6. Conclusions

- o

- In the last five years, from 2017 up to 2021, the interest for MOC cement increased substantially; in this time, more than three times more papers were published than all of the papers cumulated before 2017;

- o

- The MOC cement presents a lot of advantages, in many ways it exhibits properties superior to standard Portland cement. The biggest disadvantage that acts as the major limitation for its widespread use is its poor water resistance;

- o

- The MOC cement presents very good compatibility with wood, and by using wood waste in the mixture, the positive effect on the environment can be increased;

- o

- A big advantage of using MOC cement in combination with wood is given due to the natural color of the MOC cement, which is yellowish, so it is closer to the color of many natural wood species;

- o

- The main journals publishing papers about this subject are Construction and Building Materials, the journal Materials, the journal Cement&Concrete Composite and the journal Cement and Concrete Research;

- o

- An interesting aspect related to MOC cement is that more than 65% of the studies in the field are conducted by Chinese researchers. They are followed, at a big distance, by researchers from the Czech Republic, where published papers are written only by Czech researchers;

- o

- The MOC cement is only the most frequently used keyword from 2020, indicating that it is a new material with a big potential to be further discovered and used to obtain various composite building materials.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- United Nations. COP 26 Glasgow Climate Pact; United Nations: Glasgow, UK, 2021. [Google Scholar]

- UNFCCC. What Is Action for Climate Empowerment?|UNFCCC. United Nations Framework Convention on Climate Change. 2021. Available online: https://unfccc.int/topics/education-youth/the-big-picture/what-is-action-for-climate-empowerment. (accessed on 16 January 2022).

- Pacheco-Torgal, F.; Jalali, S. Toxicity of building materials: A key issue in sustainable construction. Int. J. Sustain. Eng. 2011, 4, 281–287. [Google Scholar] [CrossRef] [Green Version]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- Maier, D. Building Materials Made of Wood Waste a Solution to Achieve the Sustainable Development Goals. Materials 2021, 14, 7638. [Google Scholar] [CrossRef] [PubMed]

- Quiroga, A.; Marzocchi, V.; Rintoul, I. Influence of wood treatments on mechanical properties of wood–cement composites and of Populus Euroamericana wood fibers. Compos. Part B Eng. 2016, 84, 25–32. [Google Scholar] [CrossRef]

- He, P.; Hossain, U.; Poon, C.S.; Tsang, D. Mechanical, durability and environmental aspects of magnesium oxychloride cement boards incorporating waste wood. J. Clean. Prod. 2019, 207, 391–399. [Google Scholar] [CrossRef]

- Zhou, X.; Li, Z. Light-weight wood–magnesium oxychloride cement composite building products made by extrusion. Constr. Build. Mater. 2012, 27, 382–389. [Google Scholar] [CrossRef] [Green Version]

- Wei, L.; Wang, Y.; Yu, J.; Xiao, J.; Xu, S. Feasibility study of strain hardening magnesium oxychloride cement-based composites. Constr. Build. Mater. 2018, 165, 750–760. [Google Scholar] [CrossRef]

- Jankovský, O.; Lojka, M.; Lauermannová, A.-M.; Antončík, F.; Pavlíková, M.; Pavlík, Z.; Sedmidubský, D. Carbon Dioxide Uptake by MOC-Based Materials. Appl. Sci. 2020, 10, 2254. [Google Scholar] [CrossRef] [Green Version]

- Sorel, S. Sur un nouveau ciment magnésien. In Comptes Rendus Hebdomadaires des Séances de l’Académie des Sciences; Académie des Sciences: Paris, France, 1867; pp. 102–104. [Google Scholar]

- Misra, A.K.; Mathur, R. Magnesium oxychloride cement concrete. Bull. Mater. Sci. 2007, 30, 239–246. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Wang, Y.; Zhang, X.; Wang, X.; Zhang, A. Raw material ratio optimisation of magnesium oxychloride cement using response surface method. Constr. Build. Mater. 2021, 272, 121648. [Google Scholar] [CrossRef]

- Kanesaka, I.; Aoyama, S. Vibrational spectra of magnesia cement, phase. J. Raman Spectrosc. 2001, 32, 361–367. [Google Scholar] [CrossRef]

- Chau, C.K.; Li, Z. Microstructures of magnesium oxychloride Sorel cement. Adv. Cem. Res. 2008, 20, 85–92. [Google Scholar] [CrossRef]

- Ye, Q.; Han, Y.; Zhang, S.; Gao, Q.; Zhang, W.; Chen, H.; Gong, S.; Shi, S.Q.; Xia, C.; Li, J. Bioinspired and biomineralized magnesium oxychloride cement with enhanced compressive strength and water resistance. J. Hazard. Mater. 2020, 383, 121099. [Google Scholar] [CrossRef] [PubMed]

- Aiken, T.A.; Russell, M.; McPolin, D.; Gavin, B.; Nugent, L.; Bagnall, L. Effect of Molar Ratios and Curing Conditions on the Moisture Resistance of Magnesium Oxychloride Cement. J. Mater. Civ. Eng. 2022, 34, 04021426. [Google Scholar] [CrossRef]

- Li, Z.; Chau, C. Influence of molar ratios on properties of magnesium oxychloride cement. Cem. Concr. Res. 2007, 37, 866–870. [Google Scholar] [CrossRef]

- Gao, Y.; Liu, P.; Wang, F.; Yang, L.; Zhang, W.; Yang, J.; Liu, Y. Air purification behavior of magnesium oxychloride cement combined with Ag/AgBr particle under visible light. Constr. Build. Mater. 2019, 211, 1034–1041. [Google Scholar] [CrossRef]

- Singh, A.; Kumar, R.; Goel, P. Factors influencing strength of magnesium oxychloride cement. Constr. Build. Mater. 2021, 303, 124571. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, Y.; Grover, L. Effect of phosphoric acid on the properties of magnesium oxychloride cement as a biomaterial. Cem. Concr. Res. 2014, 56, 69–74. [Google Scholar] [CrossRef]

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Lauermannová, A.-M.; Faltysová, I.; Jankovský, O.; Pavlík, Z. Foam Glass Lightened Sorel’s Cement Composites Doped with Coal Fly Ash. Materials 2021, 14, 1103. [Google Scholar] [CrossRef]

- Lauermannová, A.-M.; Lojka, M.; Antončík, F.; Sedmidubský, D.; Pavlíková, M.; Pavlík, Z.; Jankovský, O. Magnesium Oxybromides MOB-318 and MOB-518: Brominated Analogues of Magnesium Oxychlorides. Appl. Sci. 2020, 10, 4032. [Google Scholar] [CrossRef]

- Zhou, W.; Ye, Q.; Shi, S.Q.; Fang, Z.; Gao, Q.; Li, J. A strong magnesium oxychloride cement wood adhesive via organic–inorganic hybrid. Constr. Build. Mater. 2021, 297, 123776. [Google Scholar] [CrossRef]

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Lauermannová, A.-M.; Jankovský, O.; Pavlík, Z. Low-Carbon Composite Based on MOC, Silica Sand and Ground Porcelain Insulator Waste. Processes 2020, 8, 829. [Google Scholar] [CrossRef]

- Power, I.M.; Dipple, G.M.; Francis, P.S. Assessing the carbon sequestration potential of magnesium oxychloride cement building materials. Cem. Concr. Compos. 2017, 78, 97–107. [Google Scholar] [CrossRef]

- Li, K.; Wang, Y.; Zhang, X.; Wu, J.; Wang, X.; Zhang, A. Intrinsically hydrophobic magnesium oxychloride cement foam for thermal insulation material. Constr. Build. Mater. 2021, 288, 123129. [Google Scholar] [CrossRef]

- Li, J.; Li, G.; Yu, Y. The influence of compound additive on magnesium oxychloride cement/urban refuse floor tile. Constr. Build. Mater. 2008, 22, 521–525. [Google Scholar] [CrossRef]

- Mathur, R.; Chandrawat, M.P.S.; Sharma, S.K. Effects on Setting, Strength, Moisture Resistance and Linear Changes of Sorel’s Cement on Mixing Portland Cement as an Additive. E-J. Chem. 2009, 6, 412–418. [Google Scholar] [CrossRef]

- Qiao, H.; Cheng, Q.; Jinlei, W.; Yingying, S. The application review of magnesium oxychloride cement. J. Chem. Pharm. Res. 2014, 6, 180–185. [Google Scholar]

- Pavlíková, M.; Pivák, A.; Záleská, M.; Jankovský, O.; Reiterman, P.; Pavlík, Z. Magnesium Oxychloride Cement Composites Lightened with Granulated Scrap Tires and Expanded Glass. Materials 2020, 13, 4828. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Wei, L.; Yu, J.; Yu, K. Mechanical properties of high ductile magnesium oxychloride cement-based composites after water soaking. Cem. Concr. Compos. 2019, 97, 248–258. [Google Scholar] [CrossRef]

- Ozer, M.S.; Ozturk, A.; Timucin, M. Production and characterization of magnesium oxychloride cement bricks for fine polishing of porcelain stoneware tiles. Ind. Ceram. 2011, 31, 89–98. [Google Scholar]

- Sun, X.; Ye, Q.; Shi, S.Q.; Gong, S.; Gao, Q.; Li, J.; Fang, Z. A nacre-inspired strong and flame retardant laminated veneer lumber bonded with magnesium oxychloride cement. Wood Mater. Sci. Eng. 2021, 16, 1–8. [Google Scholar] [CrossRef]

- Lowther, M.; Robinson, T.E.; Villapun, V.M.; Stark, C.P.; Grover, L.M.; Cox, S.C. Formulation of inherently antimicrobial magnesium oxychloride cement and the effect of supplementation with silver phosphate. Mater. Sci. Eng. C 2021, 126, 112158. [Google Scholar] [CrossRef] [PubMed]

- Lauermannová, A.-M.; Faltysová, I.; Lojka, M.; Antončík, F.; Sedmidubský, D.; Pavlík, Z.; Pavlíková, M.; Záleská, M.; Pivák, A.; Jankovský, O. Regolith-based magnesium oxychloride composites doped by graphene: Novel high-performance building materials for lunar constructions. FlatChem 2021, 26, 100234. [Google Scholar] [CrossRef]

- Jankovský, O.; Lojka, M.; Lauermannová, A.-M.; Antončík, F.; Pavlíková, M.; Záleská, M.; Pavlík, Z.; Pivák, A.; Sedmidubský, D. Towards novel building materials: High-strength nanocomposites based on graphene, graphite oxide and magnesium oxychloride. Appl. Mater. Today 2020, 20, 100766. [Google Scholar] [CrossRef]

- Lauermannová, A.-M.; Antončík, F.; Lojka, M.; Jankovský, O.; Pavlíková, M.; Pivák, A.; Záleská, M.; Pavlík, Z. The Impact of Graphene and Diatomite Admixtures on the Performance and Properties of High-Performance Magnesium Oxychloride Cement Composites. Materials 2020, 13, 5708. [Google Scholar] [CrossRef]

- Lauermannová, A.-M.; Lojka, M.; Sklenka, J.; Záleská, M.; Pavlíková, M.; Pivák, A.; Pavlík, Z.; Jankovský, O. Magnesium oxychloride-graphene composites: Towards high strength and water resistant materials for construction industry. FlatChem 2021, 29, 100284. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlíková, M.; Pivák, A.; Marušiak, Š.; Jankovský, O.; Lauermannová, A.-M.; Lojka, M.; Antončík, F.; Pavlík, Z. MOC Doped with Graphene Nanoplatelets: The Influence of the Mixture Preparation Technology on Its Properties. Materials 2021, 14, 1450. [Google Scholar] [CrossRef]

- Jianli, M.; Youcai, Z.; Jinmei, W.; Li, W. Effect of magnesium oxychloride cement on stabilization/solidification of sewage sludge. Constr. Build. Mater. 2010, 24, 79–83. [Google Scholar] [CrossRef]

- Huang, Q.; Li, Y.; Zheng, W.; Wen, J.; Chang, C.; Dong, J.; Man, Y.; Danchun, A.; Xiao, X.; Zhou, Y. Investigation on the properties of magnesium oxychloride cement prepared with seawater. Adv. Cem. Res. 2020, 32, 379–388. [Google Scholar] [CrossRef]

- Liu, P.; Dong, J.; Chang, C.; Zheng, W.; Liu, X.; Xiao, X.; Wen, J. Preparation of Low-Cost Magnesium Oxychloride Cement Using Magnesium Residue Byproducts from the Production of Lithium Carbonate from Salt Lakes. Materials 2021, 14, 3899. [Google Scholar] [CrossRef]

- Huang, Q.; Li, Y.; Chang, C.; Wen, J.; Dong, J.; Zheng, W.; Danchun, A.; Liu, P.; Dong, F.; Zhou, Y.; et al. The Salt Attack Performance of Magnesium Oxychloride Cement Exposure to Three Kinds of Brines. J. Wuhan Univ. Technol. Sci. Ed. 2020, 35, 155–166. [Google Scholar] [CrossRef]

- Pivák, A.; Pavlíková, M.; Záleská, M.; Lojka, M.; Jankovský, O.; Pavlík, Z. Magnesium Oxychloride Cement Composites with Silica Filler and Coal Fly Ash Admixture. Materials 2020, 13, 2537. [Google Scholar] [CrossRef]

- Li, Y.; Yu, H.; Zheng, L.; Wen, J.; Wu, C.; Tan, Y. Compressive strength of fly ash magnesium oxychloride cement containing granite wastes. Constr. Build. Mater. 2013, 38, 1–7. [Google Scholar] [CrossRef]

- Guan, Y.; Hu, Z.; Zhang, Z.; Chang, J.; Bi, W.; Cheeseman, C.R.; Zhang, T. Effect of hydromagnesite addition on the properties and water resistance of magnesium oxysulfate (MOS) cement. Cem. Concr. Res. 2021, 143, 106387. [Google Scholar] [CrossRef]

- He, P.; Poon, C.S.; Tsang, D. Effect of pulverized fuel ash and CO 2 curing on the water resistance of magnesium oxychloride cement (MOC). Cem. Concr. Res. 2017, 97, 115–122. [Google Scholar] [CrossRef]

- Sglavo, V.M.; De Genua, F.; Conci, A.; Ceccato, R.; Cavallini, R. Influence of curing temperature on the evolution of magnesium oxychloride cement. J. Mater. Sci. 2011, 46, 6726–6733. [Google Scholar] [CrossRef]

- Xu, B.; Ma, H.; Hu, C.; Yang, S.; Li, Z. Influence of curing regimes on mechanical properties of magnesium oxychloride cement-based composites. Constr. Build. Mater. 2016, 102, 613–619. [Google Scholar] [CrossRef]

- Ye, Q.; Wang, W.; Zhang, W.; Li, J.; Chen, H. Tuning the phase structure and mechanical performance of magnesium oxychloride cements by curing temperature and H2O/MgCl2 ratio. Constr. Build. Mater. 2018, 179, 413–419. [Google Scholar] [CrossRef]

- Gong, W.; Wang, N.; Zhang, N.; Chen, G. Time-dependent model and life prediction for reinforcement corrosion in magnesium oxychloride cement concrete. Struct. Concr. 2020, 21, 1865–1879. [Google Scholar] [CrossRef]

- Gong, W.; Yu, H.; Ma, H.; Qiao, H.; Chen, G. Study on corrosion and anticorrosion of rebar in magnesium oxychloride cement concrete. Emerg. Mater. Res. 2019, 8, 94–104. [Google Scholar] [CrossRef]

- Wang, P.; Qiao, H.; Li, Y.; Feng, Q.; Chen, K. Analysis of steel corrosion-induced surface damage evolution of magnesium oxychloride cement concrete through gray-level co-occurrence matrices. Struct. Concr. 2020, 21, 1905–1918. [Google Scholar] [CrossRef]

- Chen, X.-F.; Kou, S.-C.; Xing, F. Effect of Agriculture and Construction Wastes on the Properties of Magnesium Oxychloride Cement Mortar with Tourmaline Powder. Materials 2018, 12, 115. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Záleská, M.; Pavlíková, M.; Jankovský, O.; Lojka, M.; Pivák, A.; Pavlík, Z. Experimental Analysis of MOC Composite with a Waste-Expanded Polypropylene-Based Aggregate. Materials 2018, 11, 931. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gu, K.; Chen, B.; Bi, W.; Guan, Y. Recycling of waste gypsum in preparation of magnesium oxychloride cement (MOC). J. Clean. Prod. 2021, 313, 127958. [Google Scholar] [CrossRef]

- He, P.; Poon, C.S.; Tsang, D. Water resistance of magnesium oxychloride cement wood board with the incorporation of supplementary cementitious materials. Constr. Build. Mater. 2020, 255, 119145. [Google Scholar] [CrossRef]

- Zhang, F.-J.; Sun, X.-Y.; Li, X.; Zhang, D.; Xie, W.-J.; Liu, J.; Oh, W.-C. Study on Water Resistance of Environmentally Friendly Magnesium Oxychloride Cement for Waste Wood Solidification. J. Korean Ceram. Soc. 2018, 55, 446–451. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.D.G.; Liberati, A.; Tetzla, J.; Altman, D.G. Preferred reporting items for systematic reviews and meta-analyses: The PRISMA statement. Ann. Intern. Med. 2009, 151, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Infometr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Maier, D. Researchers approaches on innovation process in the construction sector. In Proceedings of the 34th International-Business-Information-Management-Association (IBIMA) Conference, Madrid, Spain, 13–14 November 2019; pp. 6816–6824. [Google Scholar]

- Zupic, I.; Čater, T. Bibliometric methods in management and organization. Organ. Res. Methods 2015, 18, 429–472. [Google Scholar] [CrossRef]

- Callon, M.; Courtial, J.P.; Laville, F. Co-word analysis as a tool for describing the network of interactions between basic and technological research: The case of polymer chemsitry. Science 1991, 22, 155–205. [Google Scholar] [CrossRef]

- Cambrosio, A.; Courtial, J. Historical scientometrics? Mapping over 70 years of biological safety research with coword analysis. Scientometrics 1993, 27, 119–143. [Google Scholar] [CrossRef]

- Maier, D. The use of wood constructions for sustainable development of the urban areas. In Proceedings of the 37st International Business Information Management Association Conference, IBIMA 2020: Innovation Management and Education Excellence through Vision 2020, Seville, Spain, 4–7 November 2021. [Google Scholar]

- Batool, F.; Islam, K.; Cakiroglu, C.; Shahriar, A. Effectiveness of wood waste sawdust to produce medium- to low-strength concrete materials. J. Build. Eng. 2021, 44, 103237. [Google Scholar] [CrossRef]

- Chau, C.; Chan, J.; Li, Z. Influences of fly ash on magnesium oxychloride mortar. Cem. Concr. Compos. 2009, 31, 250–254. [Google Scholar] [CrossRef]

- Wu, J.; Chen, H.; Guan, B.; Xia, Y.; Sheng, Y.; Fang, J. Effect of Fly Ash on Rheological Properties of Magnesium Oxychloride Cement. J. Mater. Civ. Eng. 2019, 31, 04018405. [Google Scholar] [CrossRef]

- Guo, Y.; Zhang, Y.; Soe, K.; Hutchison, W.D.; Timmers, H.; Poblete, M.R. Effect of fly ash on mechanical properties of magnesium oxychloride cement under water attack. Struct. Concr. 2020, 21, 1181–1199. [Google Scholar] [CrossRef]

- Chengdong, L.; Hongfa, Y. Influence of Fly Ash and Silica Fume on Water-resistant Property of Magnesium Oxychloride Cement. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2010, 25, 721–724. [Google Scholar]

- Gong, W.; Wang, N.; Zhang, N.; Chen, G. Experiment and time-varying characteristics of steel corrosion in magnesium oxychloride cement. Struct. Concr. 2020, 21, 1880–1893. [Google Scholar] [CrossRef]

- Aigbomian, E.P.; Fan, M. Development of Wood-Crete building materials from sawdust and waste paper. Constr. Build. Mater. 2013, 40, 361–366. [Google Scholar] [CrossRef]

- Quiroga, A.G.; Rintoul, I. Mechanical properties of hierarchically structured wood–cement composites. Constr. Build. Mater. 2015, 84, 253–260. [Google Scholar] [CrossRef]

- Jin, S.; Li, K.; Li, J.; Chen, H. A Low-Cost, Formaldehyde-Free and High Flame Retardancy Wood Adhesive from Inorganic Adhesives: Properties and Performance. Polymers 2017, 9, 513. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Na, B.; Wang, H.; Ding, T.; Lu, X. Study on factors affecting the sound absorption property of magnesia—bonded wood-wool panel. Wood Res. 2018, 63, 617–624. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maier, A.; Manea, D.L. Perspective of Using Magnesium Oxychloride Cement (MOC) and Wood as a Composite Building Material: A Bibliometric Literature Review. Materials 2022, 15, 1772. https://doi.org/10.3390/ma15051772

Maier A, Manea DL. Perspective of Using Magnesium Oxychloride Cement (MOC) and Wood as a Composite Building Material: A Bibliometric Literature Review. Materials. 2022; 15(5):1772. https://doi.org/10.3390/ma15051772

Chicago/Turabian StyleMaier, Andreea, and Daniela Lucia Manea. 2022. "Perspective of Using Magnesium Oxychloride Cement (MOC) and Wood as a Composite Building Material: A Bibliometric Literature Review" Materials 15, no. 5: 1772. https://doi.org/10.3390/ma15051772

APA StyleMaier, A., & Manea, D. L. (2022). Perspective of Using Magnesium Oxychloride Cement (MOC) and Wood as a Composite Building Material: A Bibliometric Literature Review. Materials, 15(5), 1772. https://doi.org/10.3390/ma15051772