Workability and Mechanical Properties of Superplasticized Microfine Cement Grouts

Abstract

:1. Introduction

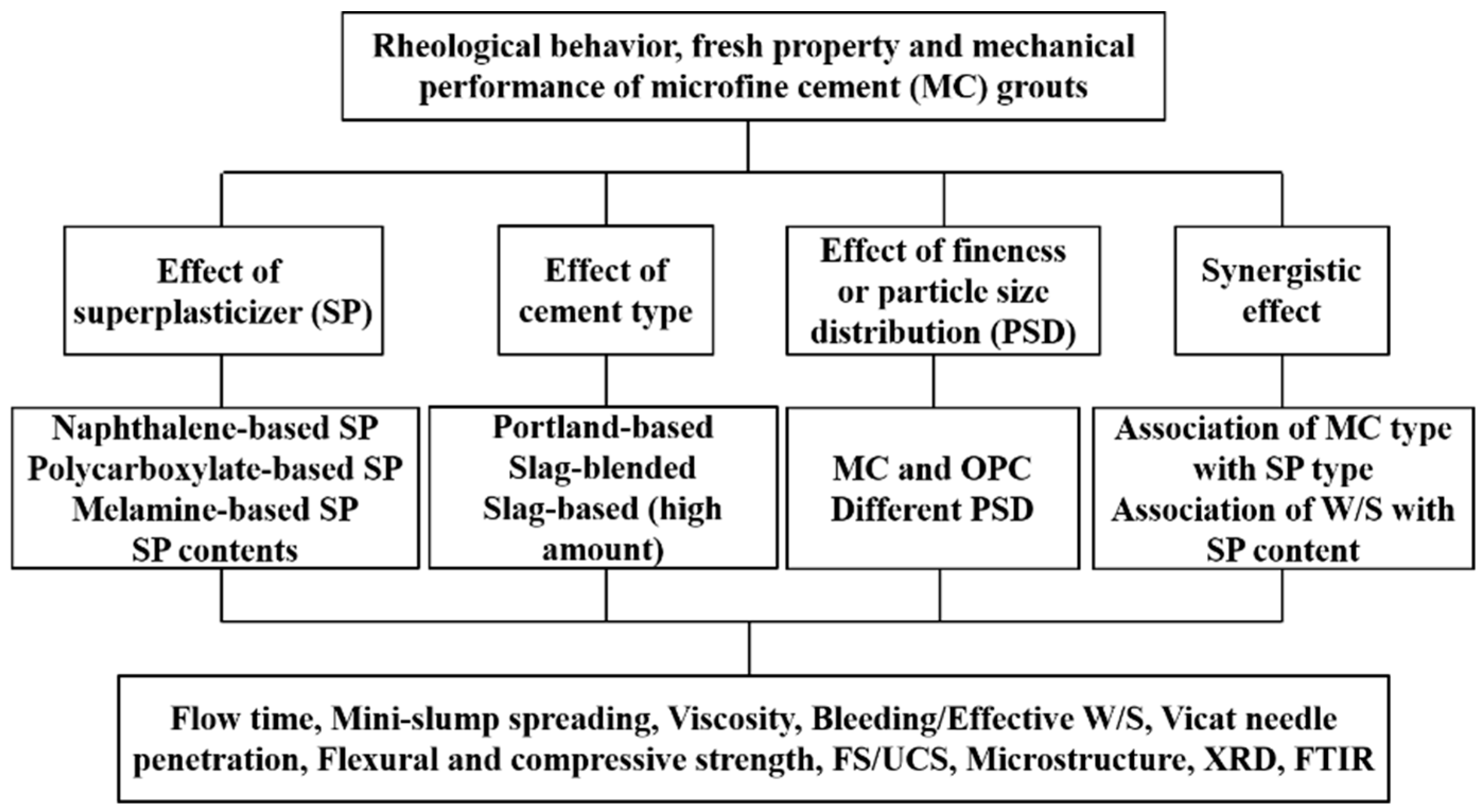

2. Significance

3. Materials and Methods

3.1. Raw Materials

3.2. Superplasticizer

3.3. Preparation of SMCG Suspensions

3.4. Experimental Approach

4. Results and Discussions

4.1. Spreading Ability and Flowability

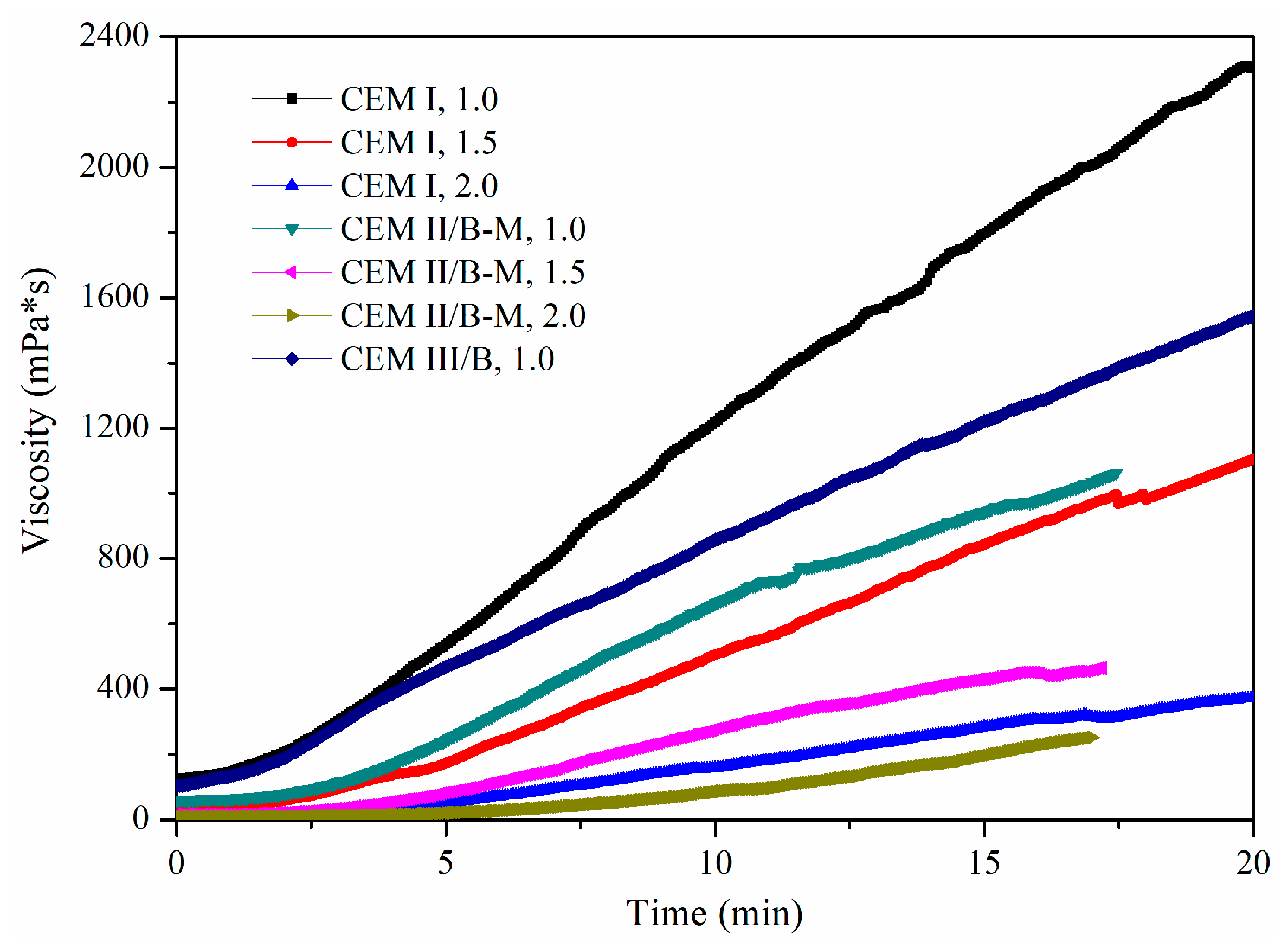

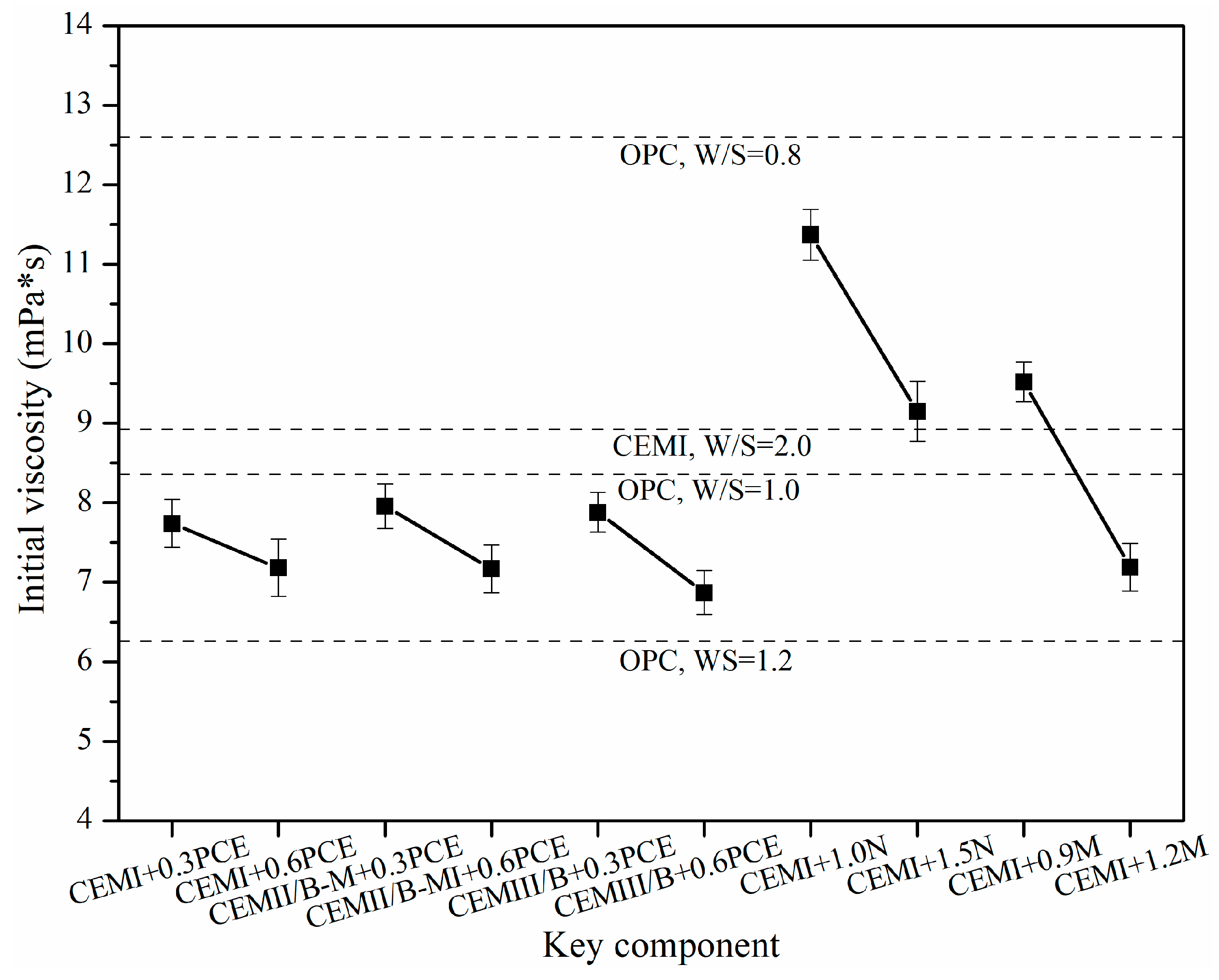

4.2. Viscosity Variation and Initial Viscosity

4.3. Bleeding Capacity and Effective W/S

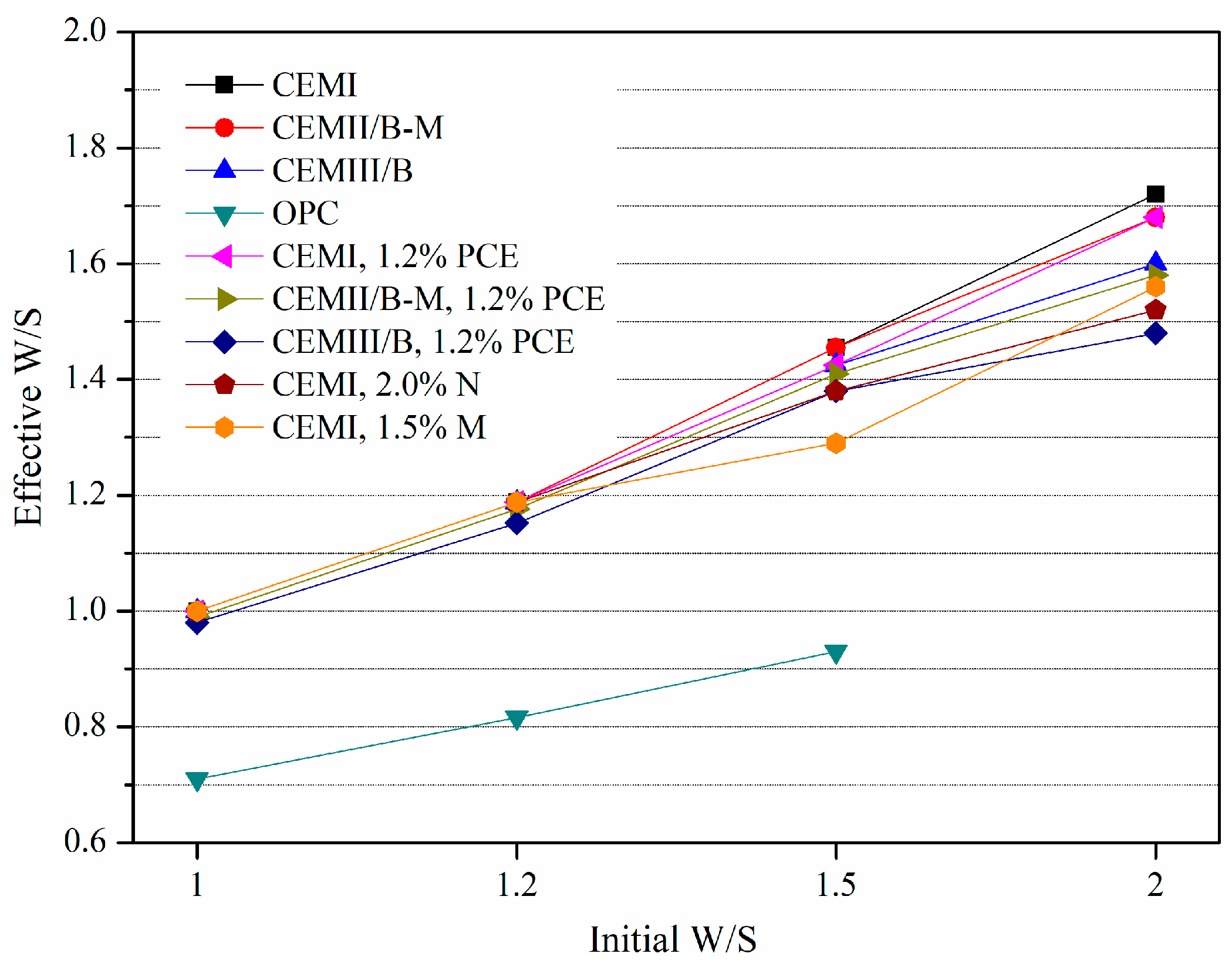

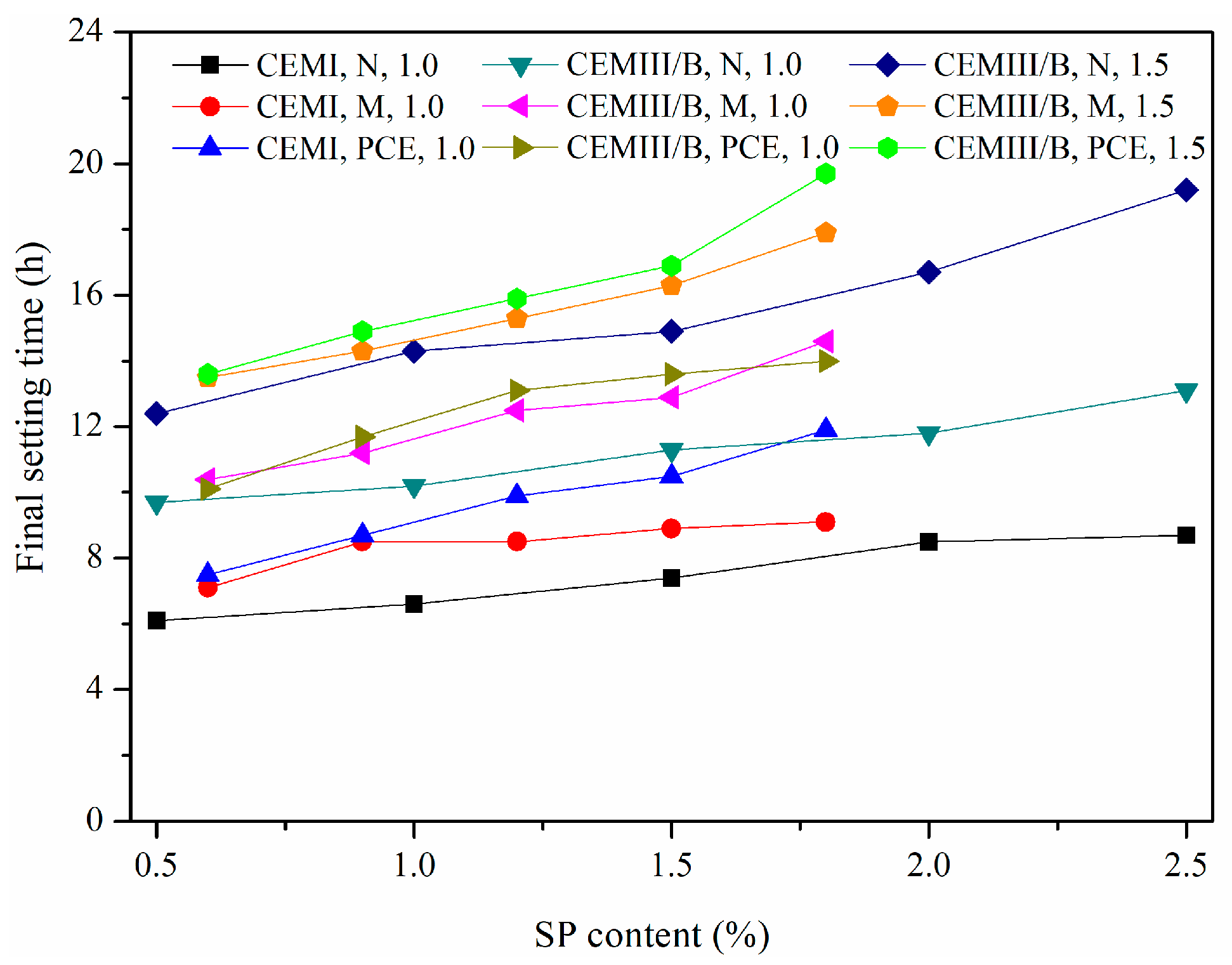

4.4. Final Setting Time

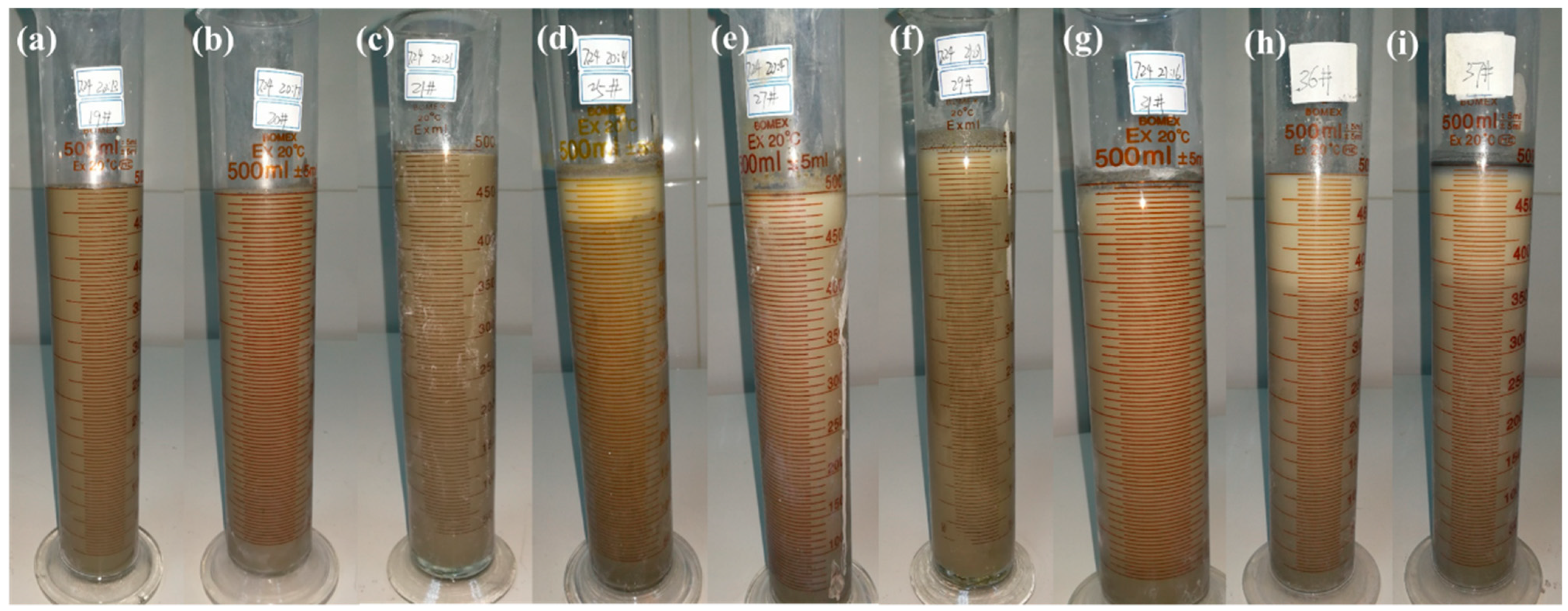

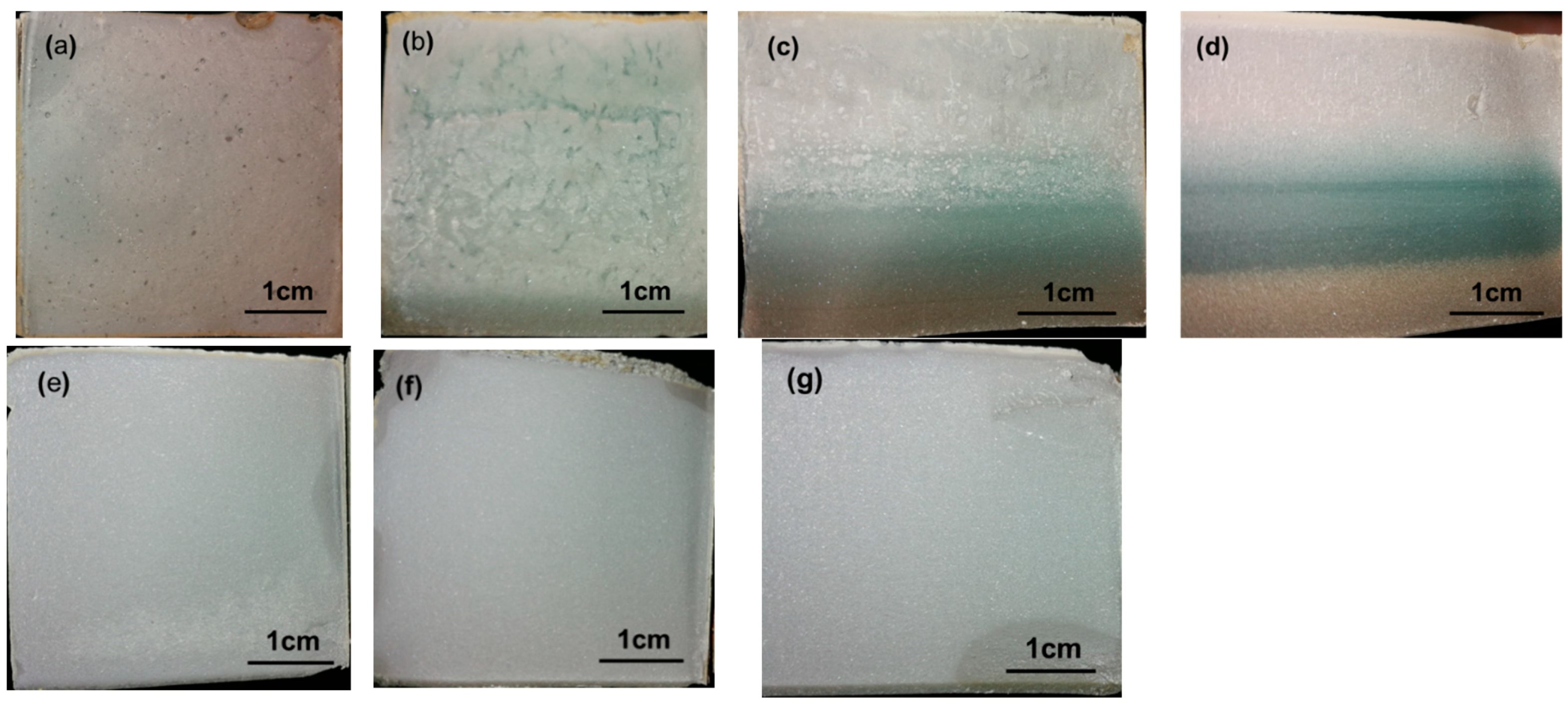

4.5. Stability of Stone Body

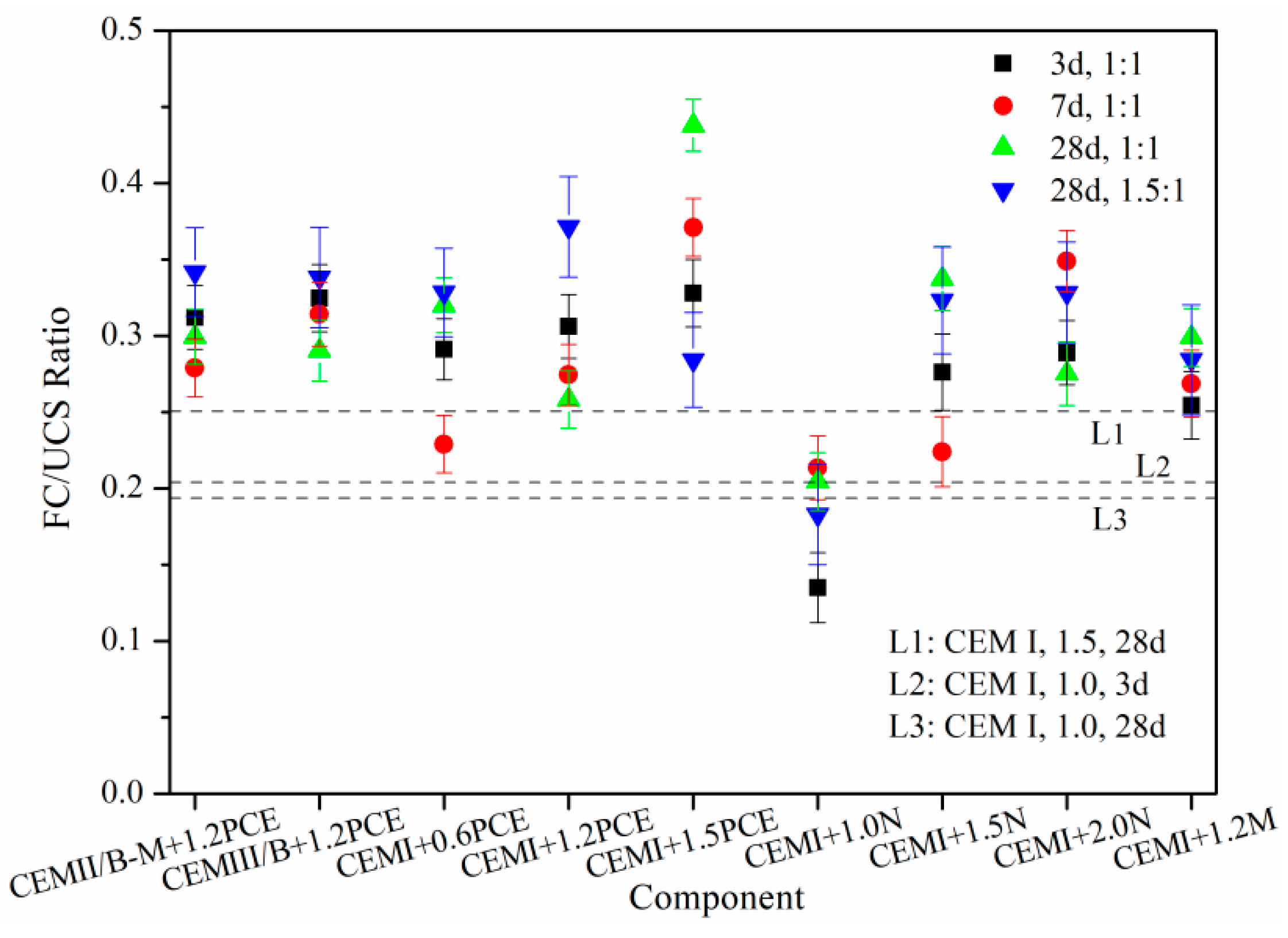

4.6. Flexural and Unconfined Compressive Strength

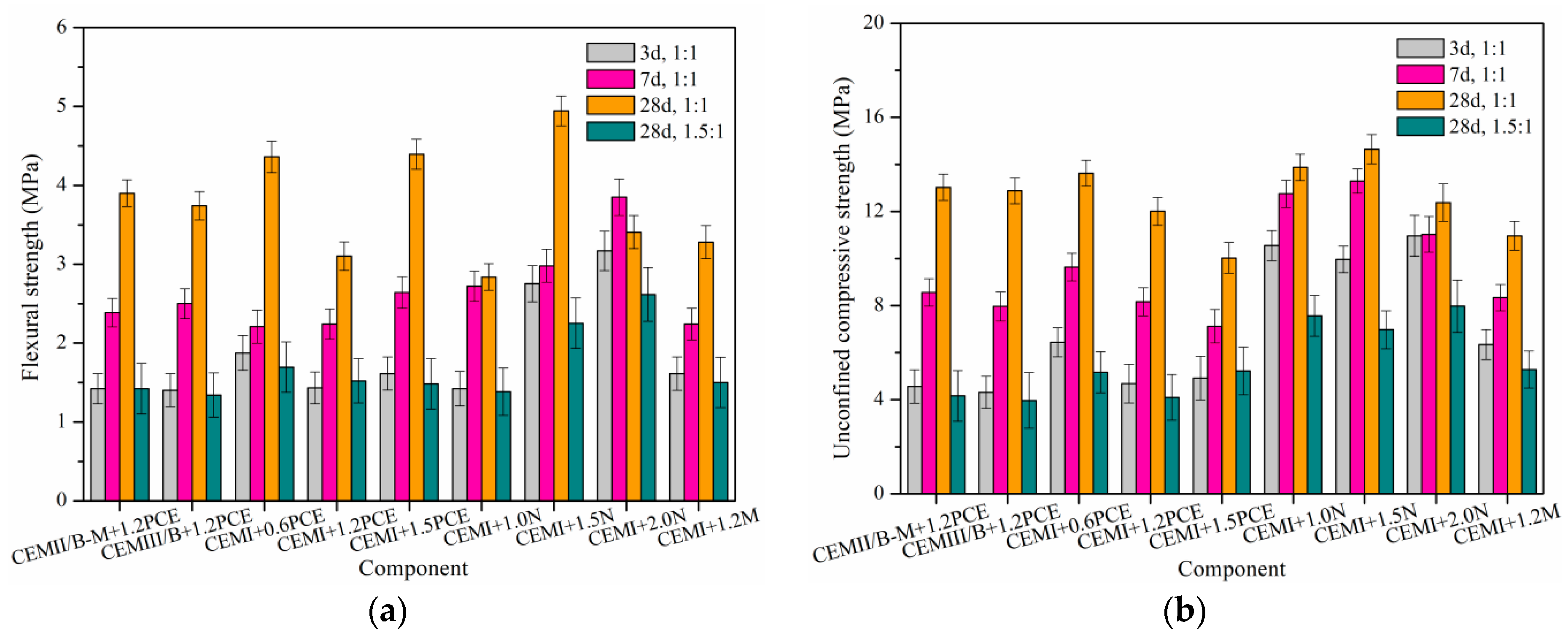

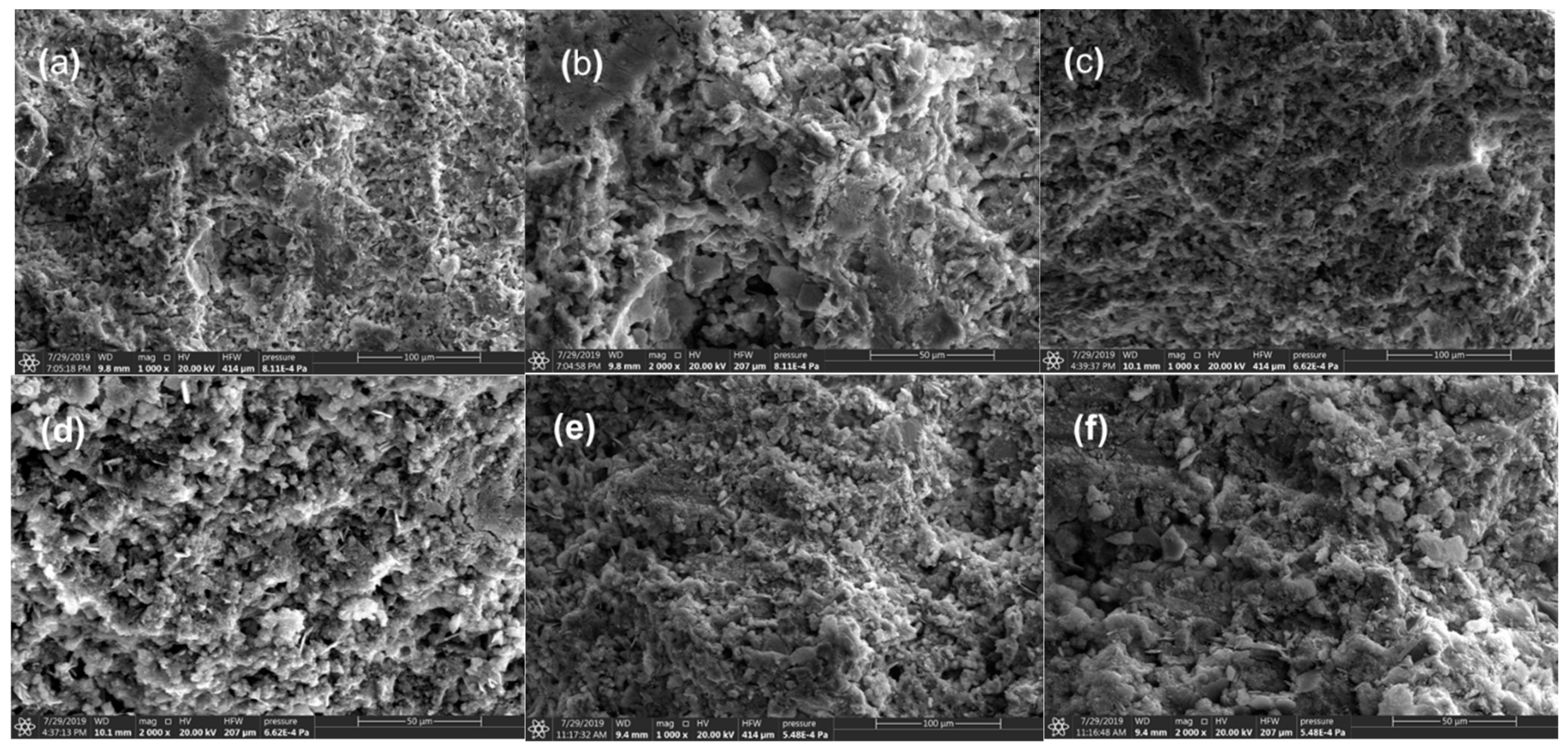

4.7. Microstructures

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sha, F.; Li, S.C.; Liu, R.T.; Li, Z.F.; Zhang, Q.S. Experimental study on performance of cement-based grouts admixed with fly ash, bentonite, superplasticizer and water glass. Constr. Build. Mater. 2018, 161, 282–291. [Google Scholar] [CrossRef]

- Sha, F.; Liu, R.T.; Li, S.C.; Lin, C.J.; Li, Z.F.; Liu, B.; Bai, J.W. Application on different types of cementitious grouts for water-leakage operational tunnels. J. Cent. South. Univ. 2016, 47, 4163–4172. (In Chinese) [Google Scholar]

- Sha, F.; Li, S.C.; Liu, R.T.; Zhang, Q.S.; Li, Z.F. Performance of typical cement suspension-sodium silicate double slurry grout. Constr. Build. Mater. 2019, 200, 408–419. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.C.; Lin, C.J.; Liu, R.T.; Zhang, Q.S.; Yang, L.; Li, Z.F. Research on penetration grouting diffusion experiment and reinforcement mechanism for sandy soil porous media. Rock. Soil. Mech. 2019, 40, 4259–4269. (In Chinese) [Google Scholar]

- Sha, F.; Lin, C.J.; Li, Z.F.; Liu, R.T. Reinforcement simulation of water-rich and broken rock with Portland cement-based grout. Constr. Build. Mater. 2019, 221, 292–300. [Google Scholar] [CrossRef]

- Li, S.C.; Sha, F.; Liu, R.T.; Li, W.; Li, Z.F.; Wang, G.C. Properties of cement-based grouts with high amounts of ground granulated blast-furnace slag and fly ash. J. Mater. Civil. Eng. 2017, 29, 04017219. [Google Scholar] [CrossRef]

- Sha, F.; Li, H.Y.; Pan, D.; Liu, H.L.; Zhang, X.F. Development of steel slag composite grouts for underground engineering. J. Mater. Res. Technol. 2020, 9, 2793–2809. [Google Scholar] [CrossRef]

- Sha, F.; Fan, G.X. Durability of a novel effective microfine cementitious grouting material in corrosion environments. Constr. Build. Mater. 2021, 306, 124842. [Google Scholar] [CrossRef]

- Sha, F.; Liu, P. Development of high-performance microfine cementitious grout with high amount of fly ash, silica fume and slag. J. Mater. Civil. Eng. 2021, 33, 04021270. [Google Scholar] [CrossRef]

- Saleh, K.; Mirza, J.; Ballivy, G. Selection Criteria for Portland and Microfine Cement-Based Injection Grouts. In Proceedings of the International Conference on Grouting in Rock and Concrete, Salzburg, Austria, 11–12 October 1993; Balkema Publ: Rotterdam, The Netherlands, 1993; pp. 97–105. [Google Scholar]

- Li, S.C.; Sha, F.; Liu, R.T.; Zhang, Q.S.; Li, Z.F. Investigation on fundamental properties of microfine cement and cement-slag grouts. Constr. Build. Mater. 2017, 153, 965–974. [Google Scholar] [CrossRef]

- Murat, M.; Yuksel, Y. Engineering Properties of Medium-to-fine Sands Injected with Microfine Cement Grout. Mar. Georesour. Geotec. 2011, 29, 95–109. [Google Scholar]

- AFTES (Association Française des Travaux En Souterrain). Recommendations Concerning Grouting for Underground Structures Rehabilitation. Tunnels et Ouvrages Souterrains 1998, 146, 103–134. (In French) [Google Scholar]

- Perret, S.; Palardy, D.; Ballivy, G. Rheological behavior and setting time of microfine cement-based grouts. ACI Mater. J. 2000, 97, 472–478. [Google Scholar]

- Sha, F.; Jin, Q.; Liu, P. Development of effective microfine cement-based grouts (EMCG) for porous and fissured strata. Constr. Build. Mater. 2020, 262, 120775. [Google Scholar] [CrossRef]

- BSI (British Standards Institution). Bleeding Rates, Sedimentation-(R6): The Bleeding (Sedimentation) Rate Shall be Determined in a Cylinder of 1000 ml Volume with an Inner Diameter of 60 mm. EN 12715; BSI: London, UK, 2000; pp. 35–36. [Google Scholar]

- Yuan, R.Z. Cementitious Materials; Wuhan University of Technology Press: Wuhan, China, 1996. [Google Scholar]

- Pantazopoulos, I.A.; Markou, I.N.; Christodoulou, D.N. Development of microfine cement grouts by pulverizing ordinary cements. Cem. Concr. Compos. 2012, 34, 593–603. [Google Scholar] [CrossRef]

- Li, S.C.; Sha, F.; Liu, R.T.; Li, Z.F.; Zhang, Q.S. Investigation on Viscous Behavior and Strength of Microfine Cement-based Grout Mixed with Microfine Fly Ash (MFA) and Superplasticizer (SP). Adv. Cem. Res. 2017, 29, 206–215. [Google Scholar] [CrossRef]

- Sha, F.; Li, S.C.; Liu, R.T.; Li, Z.F.; Zhang, Q.S. Effects of fineness on viscoelasticity of microfine cement-based grouts with fly ash, silica fume and superplasticizer. Adv. Cem. Res. 2018, 30, 469–481. [Google Scholar] [CrossRef]

- Cunningham, J.C.; Dury, B.L.; Gregory, T. Absorption Characteristics of Sulfonated Melamine Formaldehyde Condensates by High Performance Size Exclusion Chromatography. Cem. Concr. Res. 1989, 19, 919–928. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of Zeta Potential of Early Cement Hydration Phases on Superplasticizer Adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Yamada, K.; Hanehara, S.; Honma, K. Effects of the Chemical Structure on the Properties of Polycarboxylate-type Superplasticizer. Cem. Concr. Res. 2000, 30, 197–207. [Google Scholar] [CrossRef]

- Li, C.Z.; Feng, N.Q.; Li, Y.D.; Chen, R.J. Effect of Polyethylene Oxide Chains on the Performance of Polycarboxylate-type Water-reducers. Cem. Concr. Res. 2004, 35, 867–873. [Google Scholar] [CrossRef]

- Felekoğlu, B.; Sarıkahya, H. Effect of Chemical Structure of Polycarboxylate-based Superplasticizers on Workability Retention of Self-compacting Concrete. Constr. Build. Mater. 2008, 22, 1972–1980. [Google Scholar] [CrossRef]

- Uchikawa, H.; Hanebar, S.; Sawaki, S. The Role of Steric Repulsive Force in the Dispersion of Ccement Particles in Fresh Paste Prepared with Organic Admixtures. Cem. Concr. Res. 1997, 27, 37–50. [Google Scholar] [CrossRef]

- Langevin, M.A. Rheological and Mechanical Behaviour of Microfine Cement-based Grouts. Master of Engineering; McGill University: Montreal, QC, Canada, 1993; 158p. [Google Scholar]

- ASTM C143/C143M-15a; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2015.

- ASTM C939/C939M-16a; Standard Test Method for Flow of Grout for Preplaced-Aggregate Concrete (Flow Vone Method). ASTM International: West Conshohocken, PA, USA, 2016.

- Izumo, N.; Koiwai, A. Static Viscosity [SV] and Vibration Type Viscometer. In Proceedings of the 23rd Sensing Forum, Sendai, Japan, 21–23 November 2007; pp. 141–146. [Google Scholar]

- Izumo, N.; Koiwai, A. Technological Background and Latest Market Requirements Concerning ‘Static Viscosity’ Measurement with A Tuning-Fork Vibration Viscometer. In Proceedings of the Asia-Pacific Symposium on Measurement of Mass, Force and Torque, Tokyo, Japan, 1–4 June 2009; Kazunaga, U., Ed.; The Society of Instrument and Control Engineers (SICE): Tokyo, Japan, 2009; pp. 51–57. [Google Scholar]

- Banfill, P.F.G.; Carter, R.E.; Weaver, P.J. Simultaneous Rheological and Kinetic Measurements on Cement Pastes. Cem. Concr. Res. 1991, 21, 1148–1154. [Google Scholar] [CrossRef]

- Celik, F.; Canakci, H. An Investigation of Rheological Properties of Cement-based Grout Mixed with Rice Husk Ash (RHA). Constr. Build. Mater. 2015, 91, 187–194. [Google Scholar] [CrossRef]

- Izumo, N.; Oda, H. Observation of Hardening Process by Static Viscosity Measurement of Cement Materials—Characterization of Phase Change from Paste to Solid Using the Tuning fork Vibration Type Viscosity Meter. Ceram. Jpn. Bull. Ceram. Soc. Jpn. 2008, 43, 200–204. (In Japanese) [Google Scholar]

- Jefferis, S.A.; Lam, C. Hydraulic characteristics of bentonite cake fabricated on cutoff walls. Clay. Clay. Miner. 2012, 60, 557–560. [Google Scholar] [CrossRef] [Green Version]

- ASTM. ASTM C531-00; Standard Test Method for Linear Shrinkage and Coefficient of Thermal Expansion of Chemical-Resistant Mortars, Grouts, Monolithic Surfacings, and Polymer Concretes. ASTM International: West Conshohocken, PA, USA, 2021.

- GB/T 17671-1999 1999; Method of Testing Cements-Determination of Strength. Chinese National Quality and Technical Supervision & Chinese Ministry of Construction: Beijing, China, 1999.

- Li, Y.W.; Yang, C.L.; Zhang, Y.F.; Zheng, J.; Guo, H.L.; Lu, M.G. Study on Dispersion, Adsorption and Flow Retaining Behaviors of Cement Mortars with TPEG-type Polyether kind Polycarboxylate Superplasticizers. Constr. Build. Mater. 2014, 64, 324–332. [Google Scholar] [CrossRef]

- Pourchet, S.; Liautaud, S.; Rinaldi, D.; Pochard, I. Effect of the Repartition of the PEG Side Chains on the Adsorption and Dispersion Behaviors of PCEP in Presence of Sulfate. Cem. Concr. Res. 2012, 42, 431–439. [Google Scholar] [CrossRef]

- Flatt, R.J.; Houst, Y.F. A Simplified View on Chemical Effects Perturbing the Action of Superplasticizers. Cem. Concr. Res. 2001, 31, 1169–1176. [Google Scholar] [CrossRef]

- Yoshioka, K.; Tazawa, E.; Kawai, K.; Enohata, T. Adsorption Characteristics of Superplasticizers on Cement Component Minerals. Cem. Concr. Res. 2002, 32, 1507–1513. [Google Scholar] [CrossRef]

- Zingg, A.; Winnefeld, F.; Holzer, L.; Pakusch, J.; Becker, S.; Figi, R.; Gauckler, L. Interaction of Polycarboxylate-based Superplasticizers with Cements Containing Different C3A Amounts. Cem. Concr. Compos. 2009, 31, 153–162. [Google Scholar] [CrossRef]

- Alrshoudi, F.; Mohammadhosseini, H.; Md Tahir, M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.; Alsaif, A. Drying shrinkage and creep properties of prepacked aggregate concrete reinforced with waste polypropylene fibers. J. Build. Eng. 2020, 32, 101522. [Google Scholar] [CrossRef]

- Castaldo, P.; Palazzo, B.; Mariniello, A. Effects of the axial force eccentricity on the time-variant structural reliability of aging r.c. cross-sections subjected to chloride-induced corrosion. Eng. Struct. 2017, 130, 261–274. [Google Scholar] [CrossRef]

- Mehta, P.K. Concrete: Structure, Properties and Materials; Prentice-Hall Inc: Hoboken, NJ, USA, 1986; 450p. [Google Scholar]

- Nath, S.K.; Kumar, S. Influence of Granulated Silico-Manganese Slag on Compressive Strength and Microstructure of Ambient Cured Alkali-Activated Fly Ash Binder. Waste. Biomass. Valori. 2019, 10, 2045–2055. [Google Scholar] [CrossRef]

- Aydın, S.; Baradan, B. Engineering Properties of Reactive Powder Concrete without Portland Cement. ACI Mater. J. 2013, 110, 619–627. [Google Scholar]

- Puertas, F.; Fernández-Jiménez, A. Mineralogical and Microstructural Characterisation of Alkali-activated Fly Ash/slag Pastes. Cem. Concr. Compos 2003, 25, 287–292. [Google Scholar] [CrossRef]

- Puertas, F.; Palacios, M.; Vázquez, T. Carbonation Process of Alkali-activated Slag Mortars. J. Mater. Sci. 2006, 41, 3071–3082. [Google Scholar] [CrossRef]

| Cement Type | CEM I | CEM II/B-M | CEM III/B | |

|---|---|---|---|---|

| Oxide (%) | SiO2 | 19.97 | 21.65 | 30.40 |

| Al2O3 | 4.02 | 9.15 | 9.80 | |

| Fe2O3 | 3.38 | 2.85 | 1.50 | |

| CaO | 64.01 | 54.06 | 45.2 | |

| MgO | 2.36 | 3.90 | 5.90 | |

| Na2O | 0.21 | 0.24 | 0.46 | |

| K2O | 0.58 | 0.66 | 0.30 | |

| SO3 | 2.09 | 3.62 | 2.80 | |

| TiO2 | 0.28 | 0.49 | 0.50 | |

| P2O5 | 0.21 | 0.23 | 0.18 | |

| LOI | 2.69 | 2.87 | 2.80 | |

| Components (%) | Clinker | 90 | 63 | 25 |

| Limestone | 5 | 5 | 3 | |

| Slag | 0 | 22 | 70 | |

| Fly ash | 0 | 5 | 0 | |

| Gypsum | 5 | 5 | 2 | |

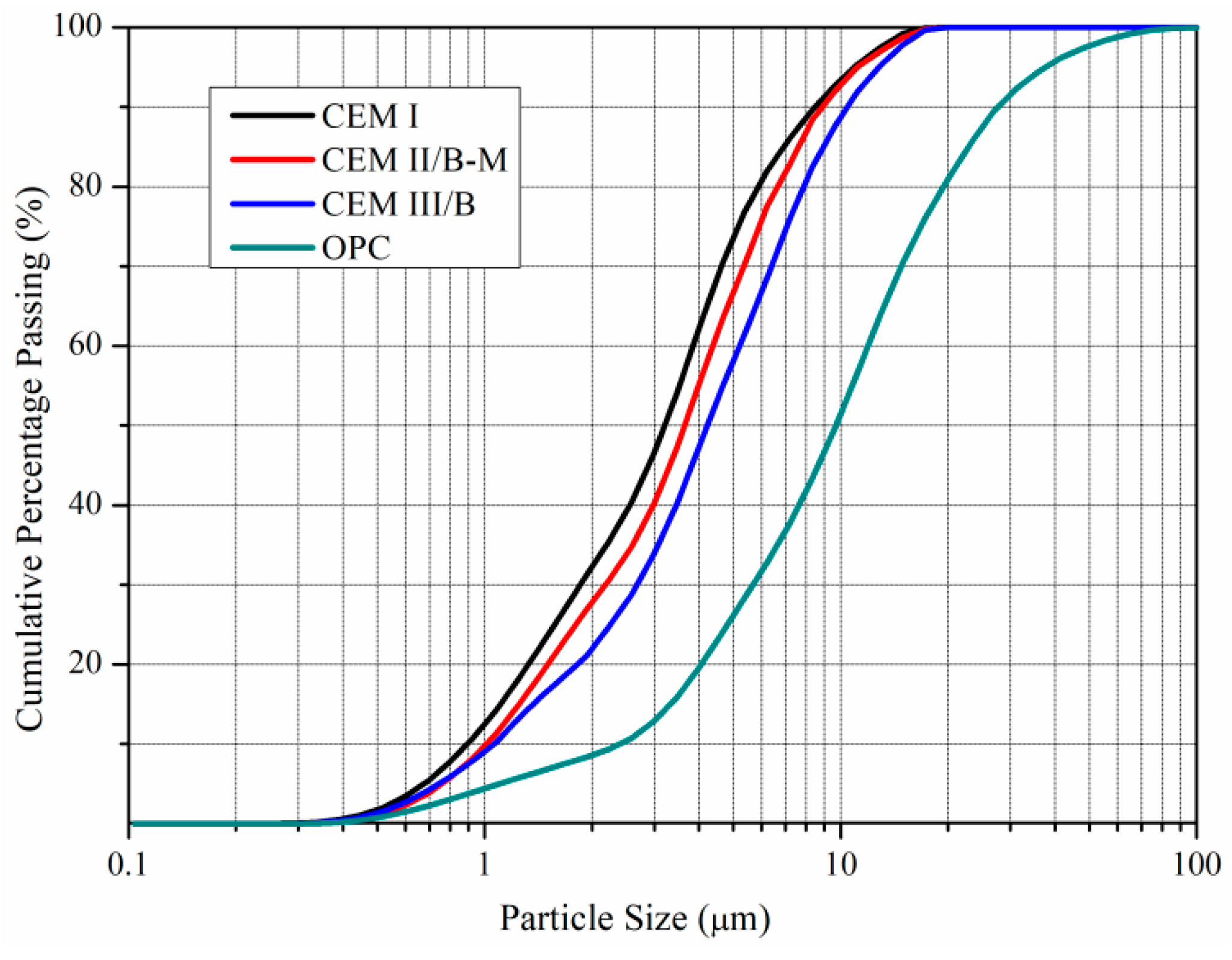

| Cement Type | CEM I | CEM II/B-M | CEM III/B | OPC |

|---|---|---|---|---|

| d10 (µm) | 0.89 | 1.01 | 1.06 | 2.39 |

| d50 (µm) | 3.21 | 3.64 | 4.22 | 9.70 |

| d95 (µm) | 10.92 | 11.15 | 12.81 | 37.62 |

| d100 (µm) | 20.02 | 20.02 | 20.50 | 110.00 |

| Specific gravity | 3.1 | 3.1 | 2.9 | 3.1 |

| Fineness, m2/kg | 870 | 850 | 825 | 430 |

| Symbol | Type | Aspect | Bulk Density (kg/m3) | Solid Content (%) | pH | Recommended Dosage (%) | Repulsion Mechanism | |

|---|---|---|---|---|---|---|---|---|

| Electrostatic | Steric Hindrance | |||||||

| N | FDN-C | Dark brown | 1.2 × 103 | ≥92 | 7–9 | 0.5–2.0 | * | - |

| M | F10 | White | 0.5–0.8 × 103 | ≥96 | 9–11.4 | 0.2–2.0 | * | - |

| PCE | 530P | White | 0.5 ± 0.1 × 103 | ≥95 | 7.0 ± 0.5 | 0.3–1.5 | * | * |

| W/S | Mini-Slump (mm), without SP | Flow Time (s), without SP | ||||||

|---|---|---|---|---|---|---|---|---|

| CEMI | CEMII/B-M | CEMIII/B | OPC | CEMI | CEMII/B-M | CEMIII/B | OPC | |

| 1:1 | 90 | 106 | 115 | 328 | - | 48.32 | 46.84 | 30.19 |

| 1.2:1 | 130 | 152 | 164 | 367 | 50.16 | 42.28 | 39.32 | 28.28 |

| 1.5:1 | 216 | 221 | 228 | - | 47.43 | 36.87 | 32.66 | - |

| 2:1 | 295 | 296 | 299 | - | 29.19 | 28.97 | 28.22 | - |

| 2.5:1 | 342 | 348 | 352 | - | 27.47 | 26.89 | 26.34 | - |

| W/S | Bleeding Capacity (%), without SP | Bleeding Capacity (%), with SP | |||||||

|---|---|---|---|---|---|---|---|---|---|

| CEMI | CEMII/B-M | CEMIII/B | OPC | CEMI, 1.2%PCE | CEMI, 2.0%N | CEMI, 1.5%M | CEMII/B-M, 1.2%PCE | CEMIII/B, 1.2%PCE | |

| 1:1 | 0 | 0 | 0 | 29 | 0 | 0 | 0 | 1 | 2 |

| 1.2:1 | 1 | 1 | 1 | 32 | 1 | 1 | 1 | 2 | 4 |

| 1.5:1 | 3 | 3 | 5 | 38 | 5 | 8 | 17 | 6 | 10 |

| 2:1 | 14 | 16 | 20 | - | 16 | 24 | 23 | 21 | 24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sha, F.; Gu, S.; Diao, Y.; Liu, P.; Lou, D.; Hu, Y. Workability and Mechanical Properties of Superplasticized Microfine Cement Grouts. Materials 2022, 15, 1747. https://doi.org/10.3390/ma15051747

Sha F, Gu S, Diao Y, Liu P, Lou D, Hu Y. Workability and Mechanical Properties of Superplasticized Microfine Cement Grouts. Materials. 2022; 15(5):1747. https://doi.org/10.3390/ma15051747

Chicago/Turabian StyleSha, Fei, Shijiu Gu, Yuhong Diao, Peng Liu, Deli Lou, and Yan Hu. 2022. "Workability and Mechanical Properties of Superplasticized Microfine Cement Grouts" Materials 15, no. 5: 1747. https://doi.org/10.3390/ma15051747

APA StyleSha, F., Gu, S., Diao, Y., Liu, P., Lou, D., & Hu, Y. (2022). Workability and Mechanical Properties of Superplasticized Microfine Cement Grouts. Materials, 15(5), 1747. https://doi.org/10.3390/ma15051747