The Influence of Clay Structures to the Hygrothermal Component of the Indoor Environment

Abstract

:1. Introduction

1.1. Indoor Air Quality

1.1.1. Indoor Microclimate

1.1.2. Relative Humidity in Buildings

1.1.3. Summary

1.2. Sorption Properties of Clay Materials and Structures

1.2.1. Sorption Properties in Steady State

1.2.2. Sorption Properties in Dynamic State

1.2.3. Summary

2. Materials and Methods

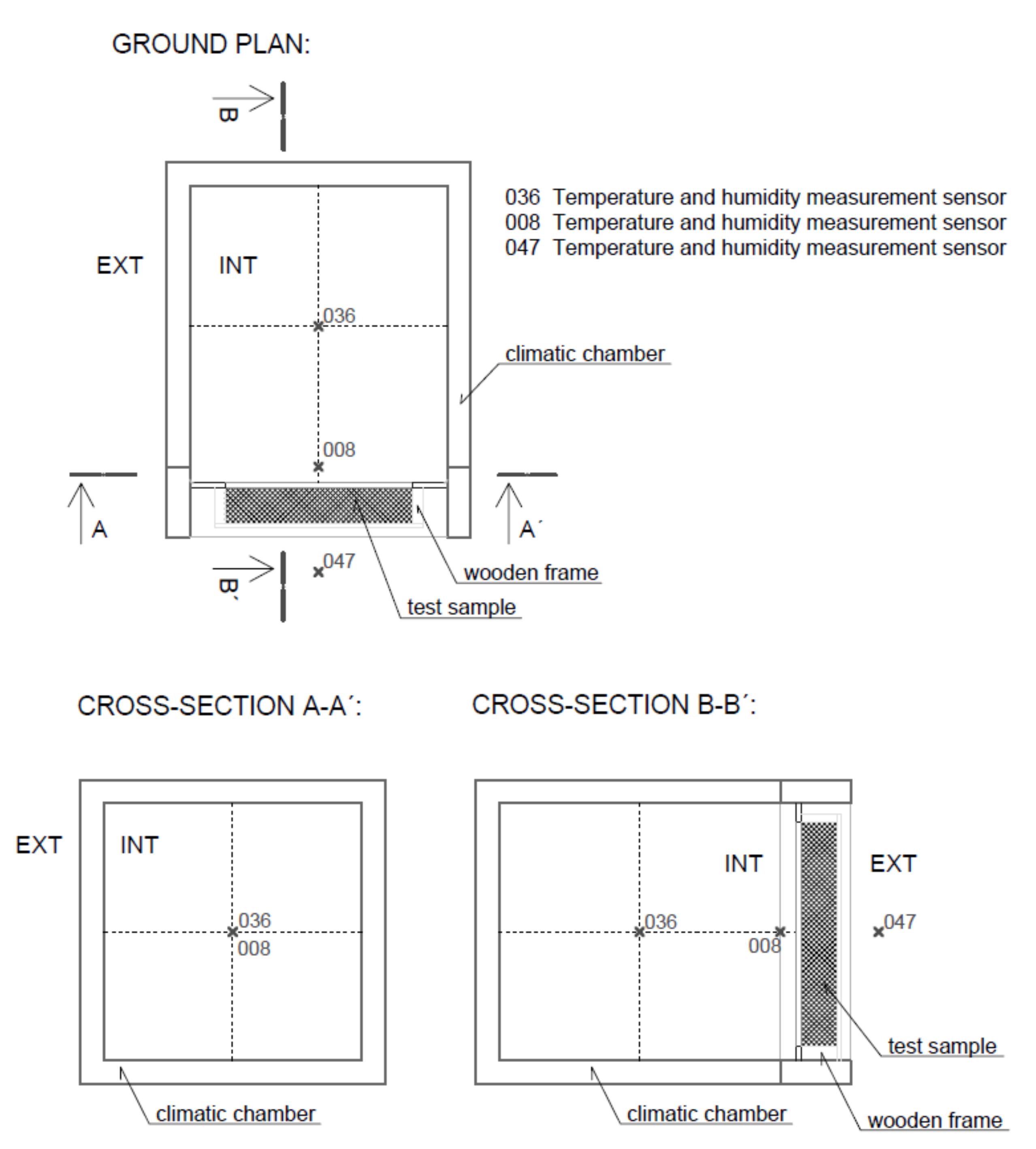

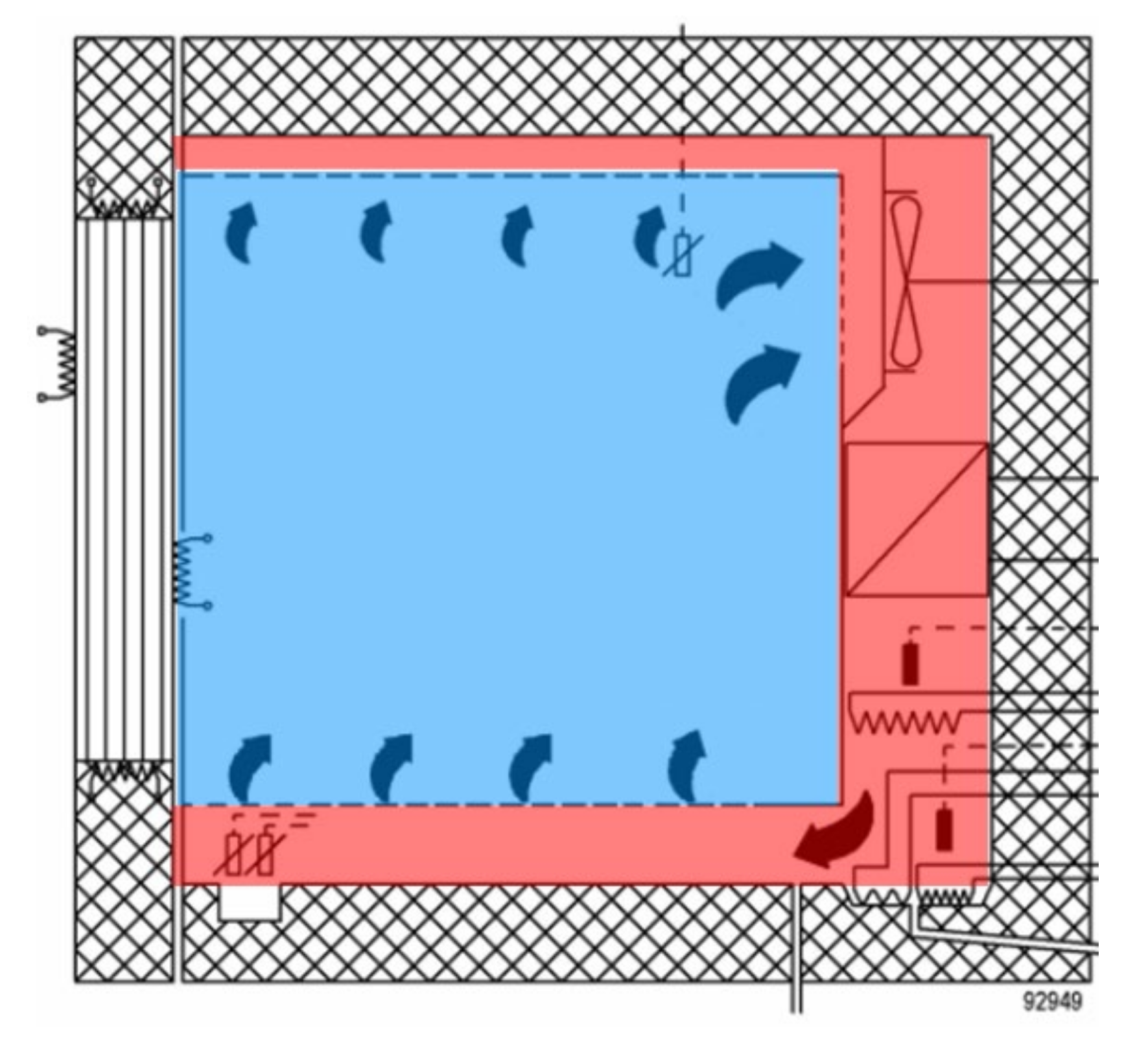

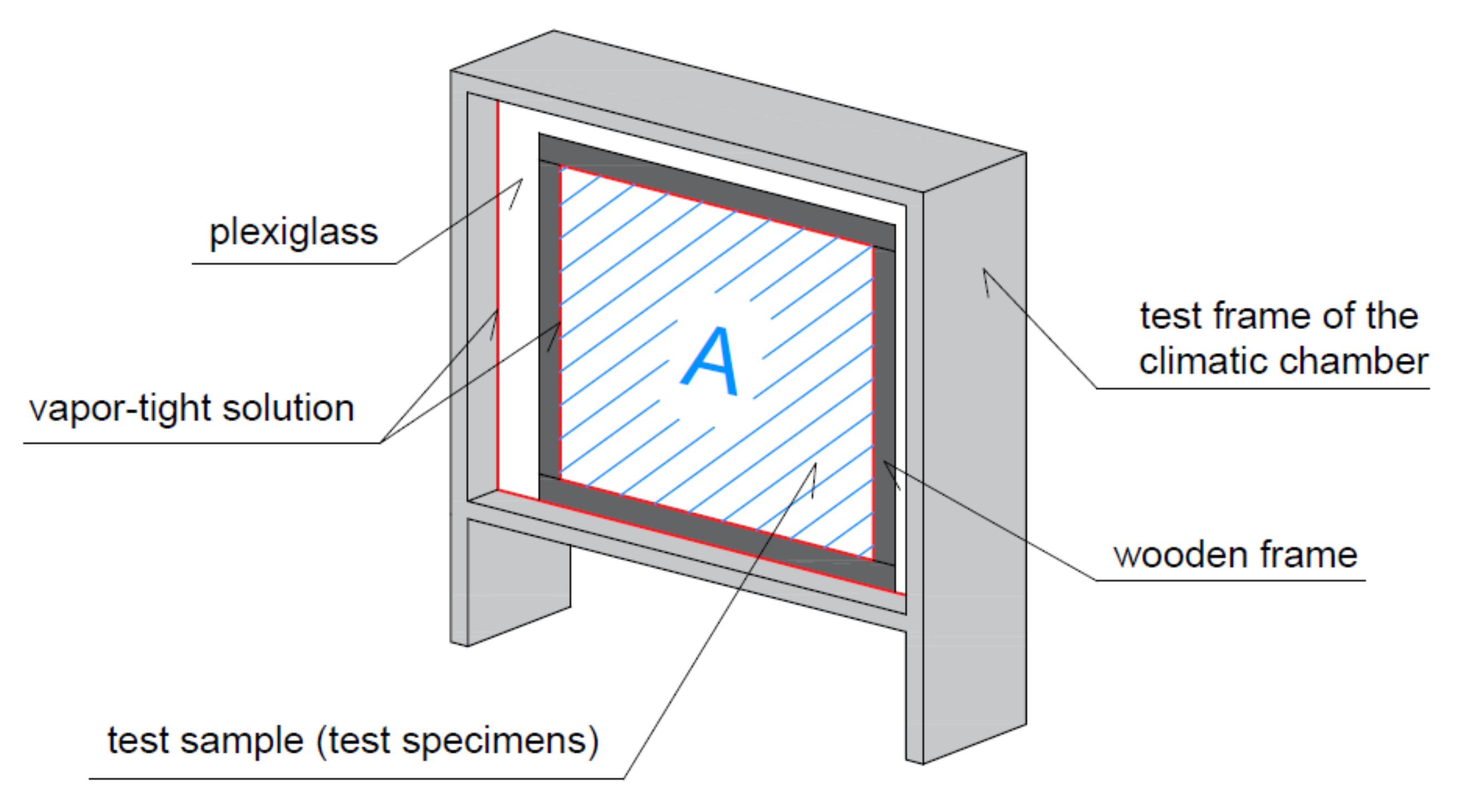

2.1. Proposed Methodology for Medium-Scale Experimental Test

- climate test chamber WEISS WK3-1000/0-S;

- laboratory balance AND GX-4000 for measuring water consumption;

- datataker DT85 Series 3 for data recording;

- temperature and humidity measurement sensors Rotronic HC2-S+E2-05XX.

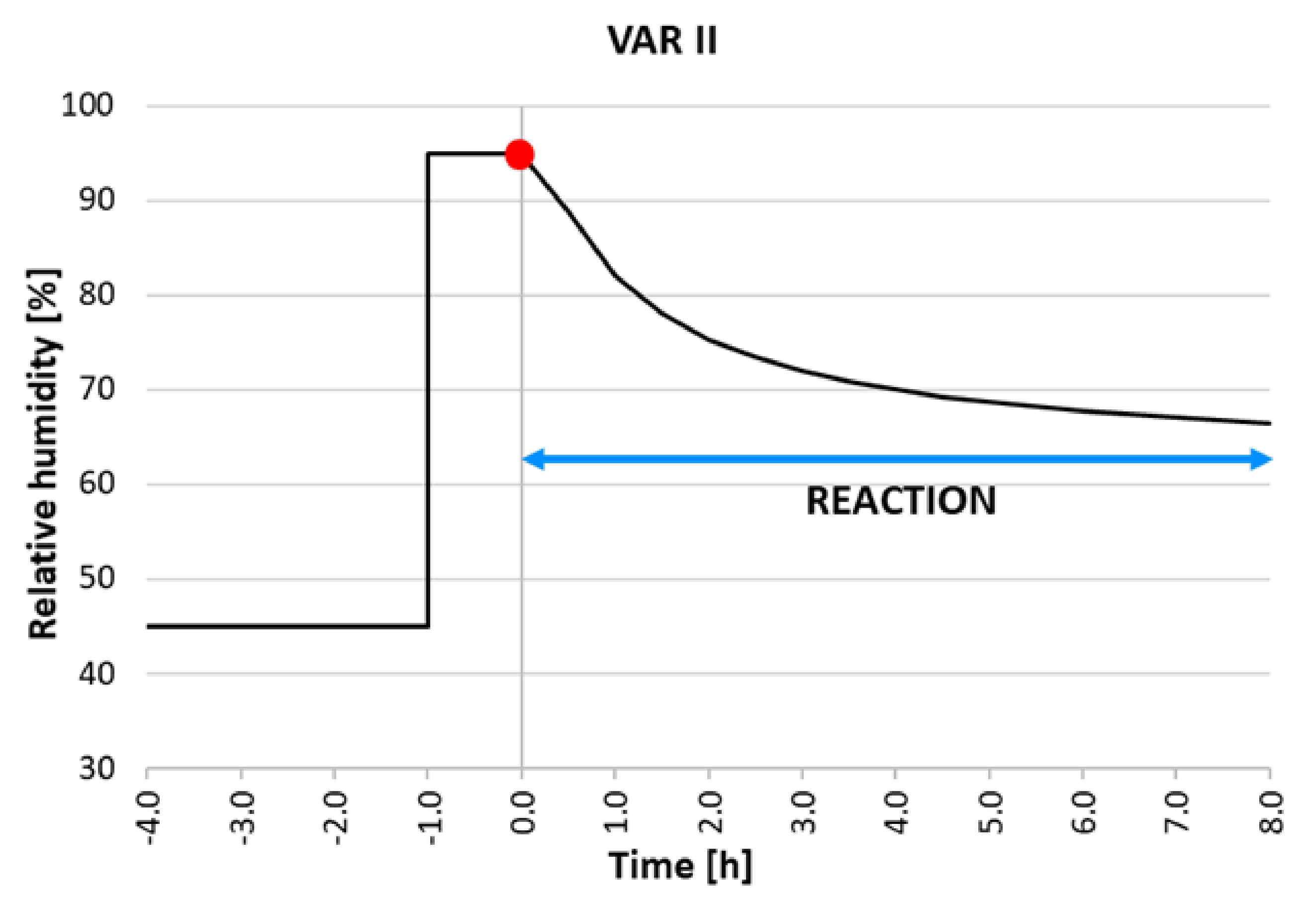

- Conditioning of the test sample and the internal environment to an equilibrium state at T = 23 °C and RH = 45% for 48 h;

- Fast increasing of relative humidity at 95% RH for 60 min;

- Monitoring of RH changes in the climatic chamber for 8 h.

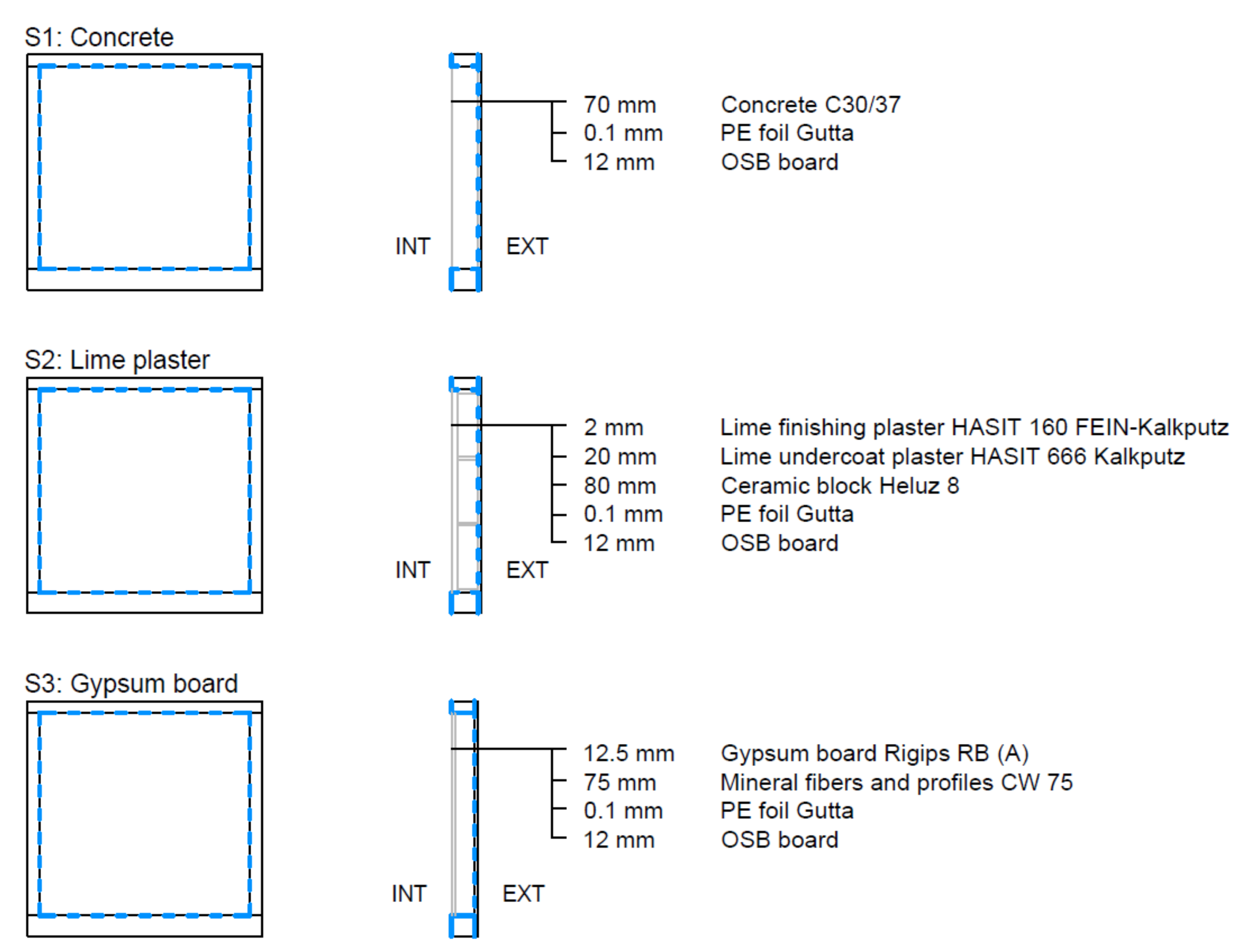

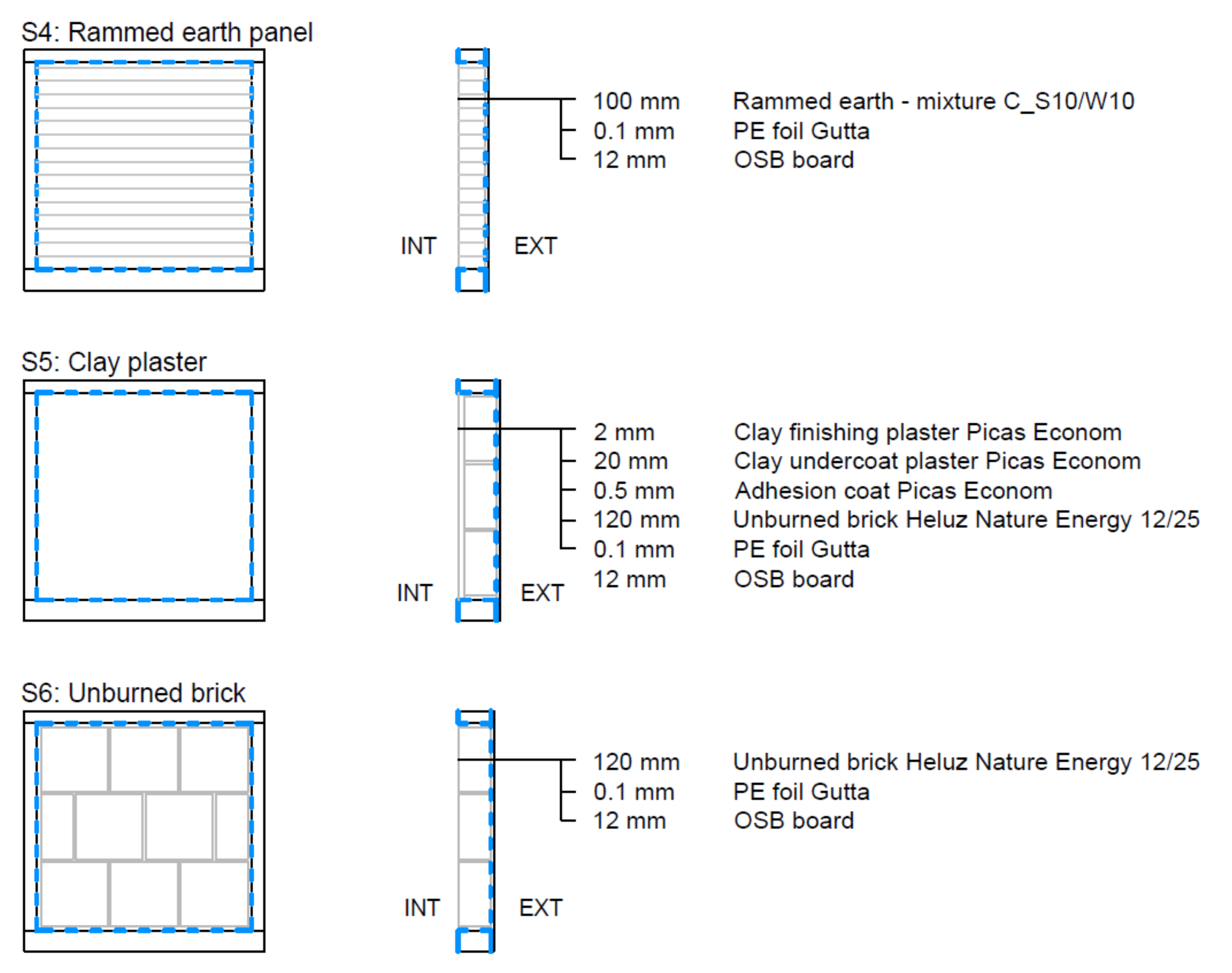

2.2. Materials and Building Structures

2.3. Methodology for Evaluation of Measured Data of Dynamic Sorption Properties of Building Structures

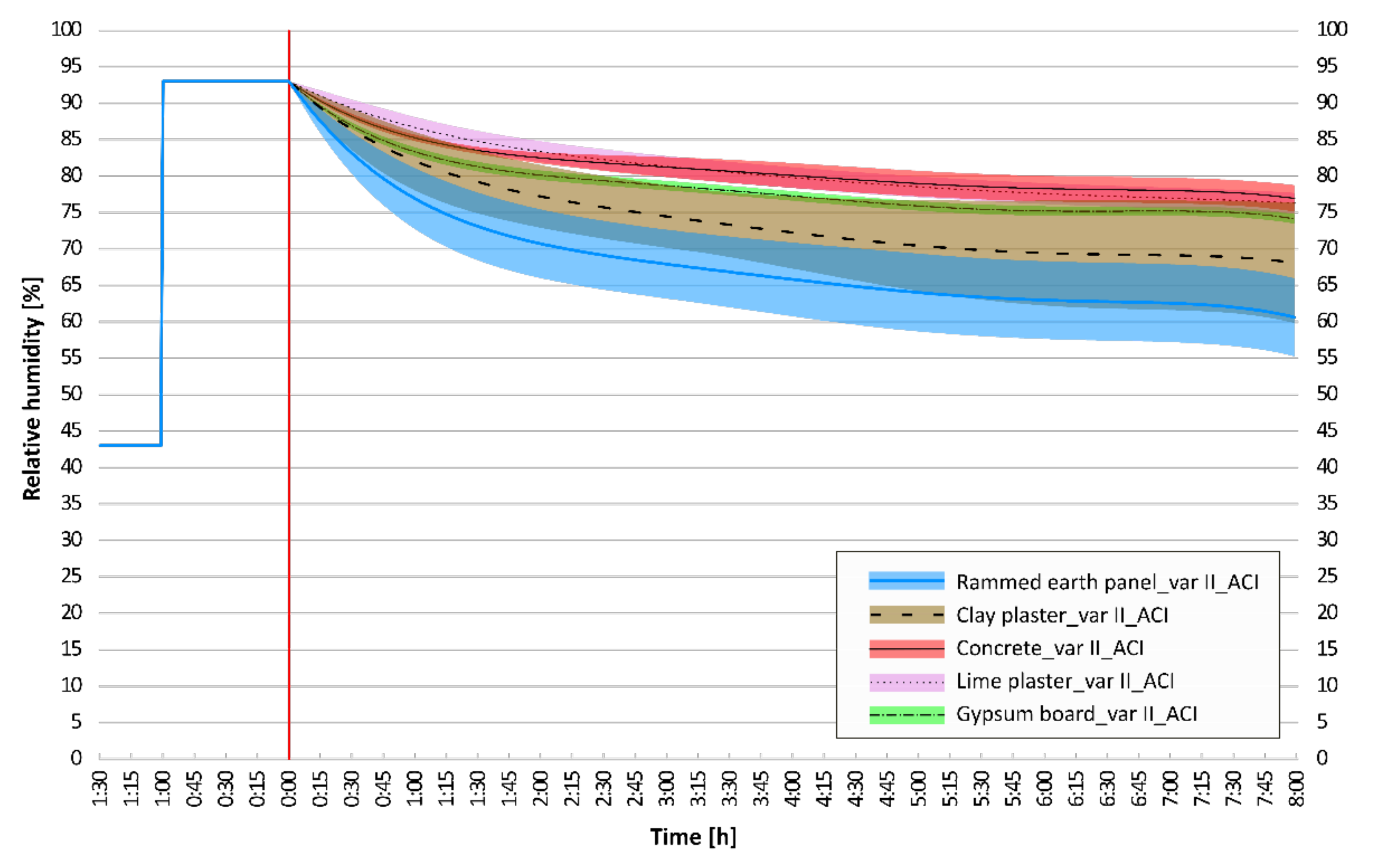

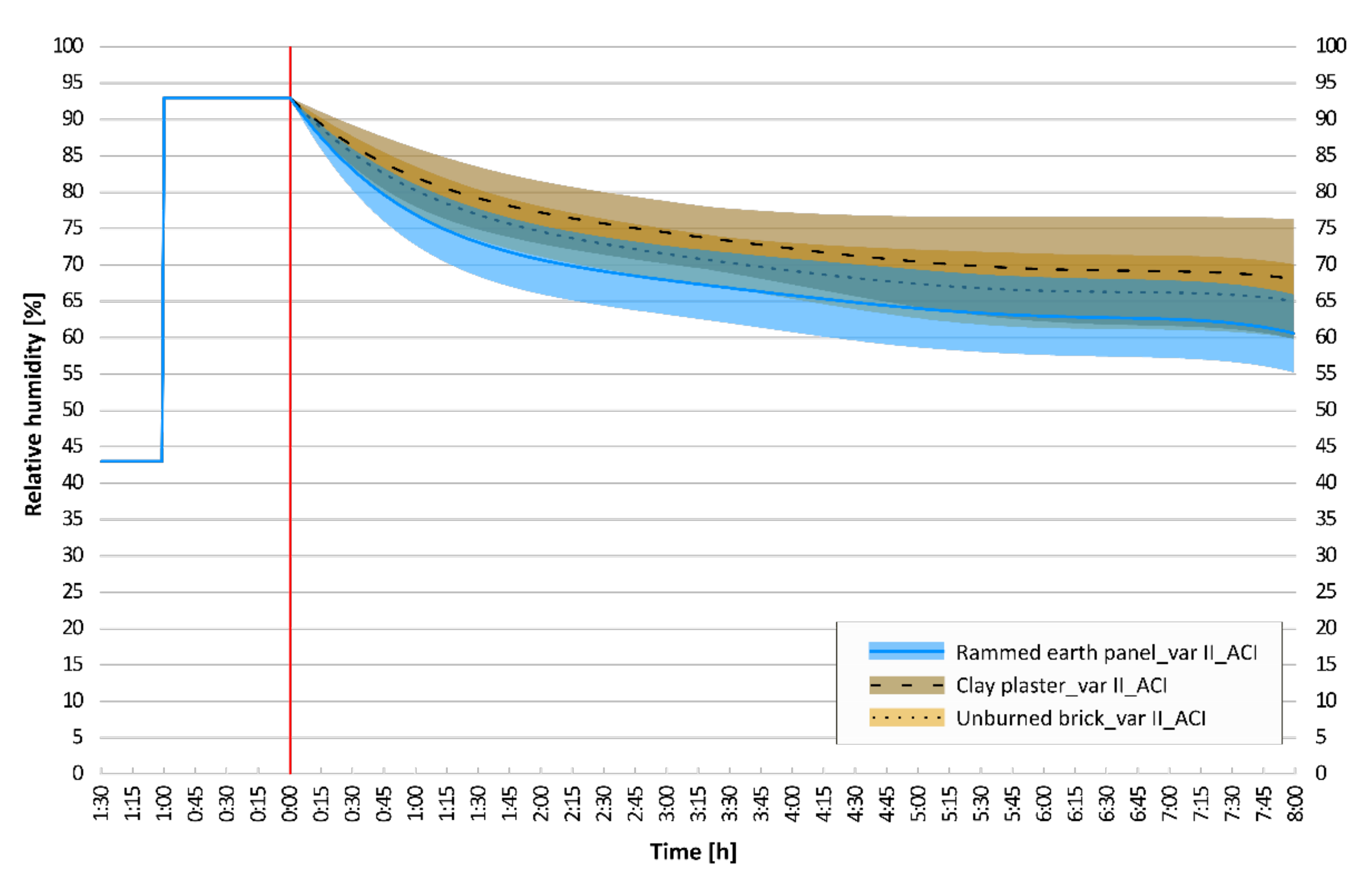

- In the first step, it was necessary to smooth individual observations using regression analysis. The suitable regression curves were determined using the least squares method. Regression parameters were determined for polynomial functions of degree m = 5.

- The adjusted confidence interval (ACI) was then determined. It was established by using the Student’s distribution.

3. Results

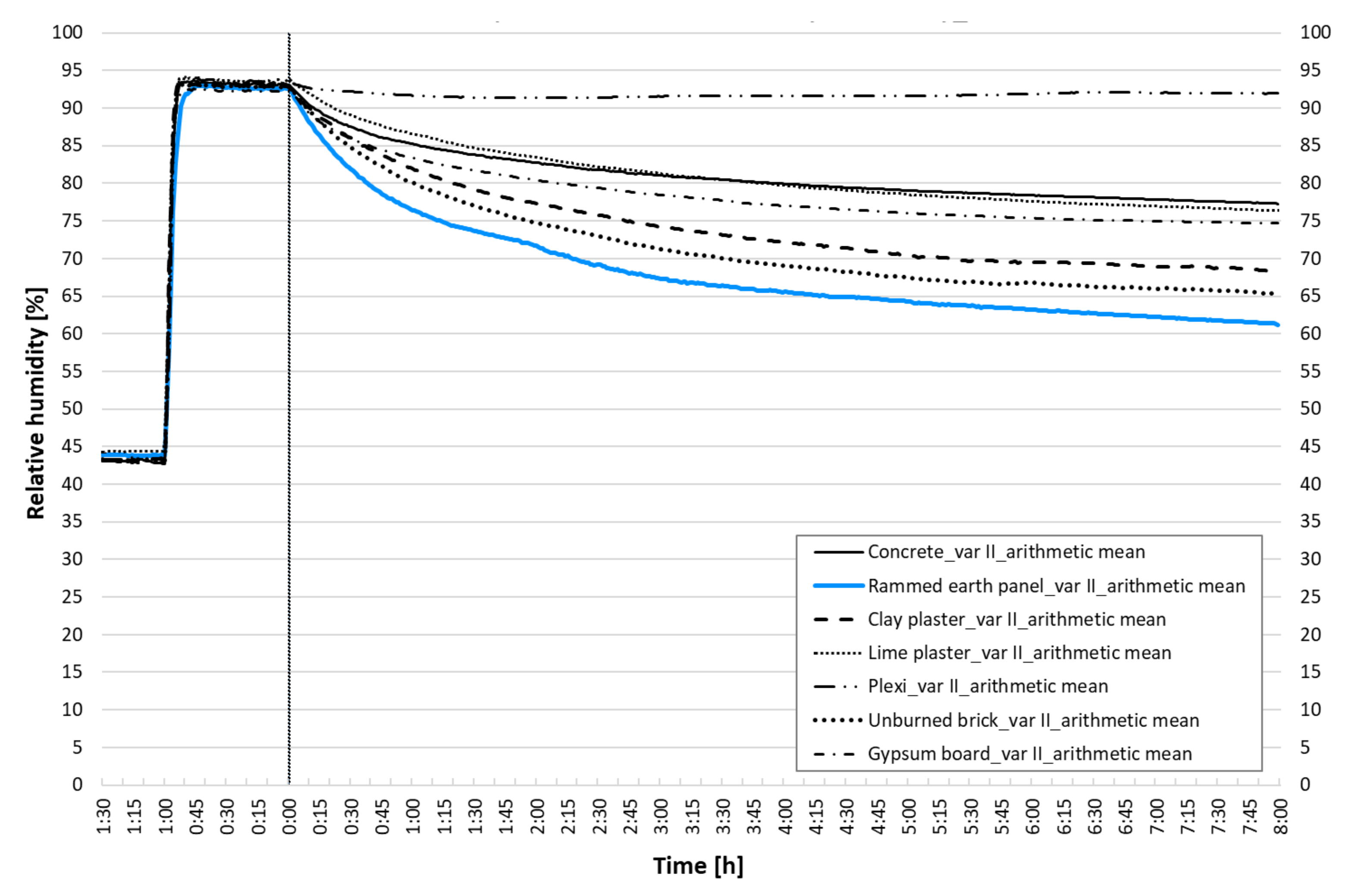

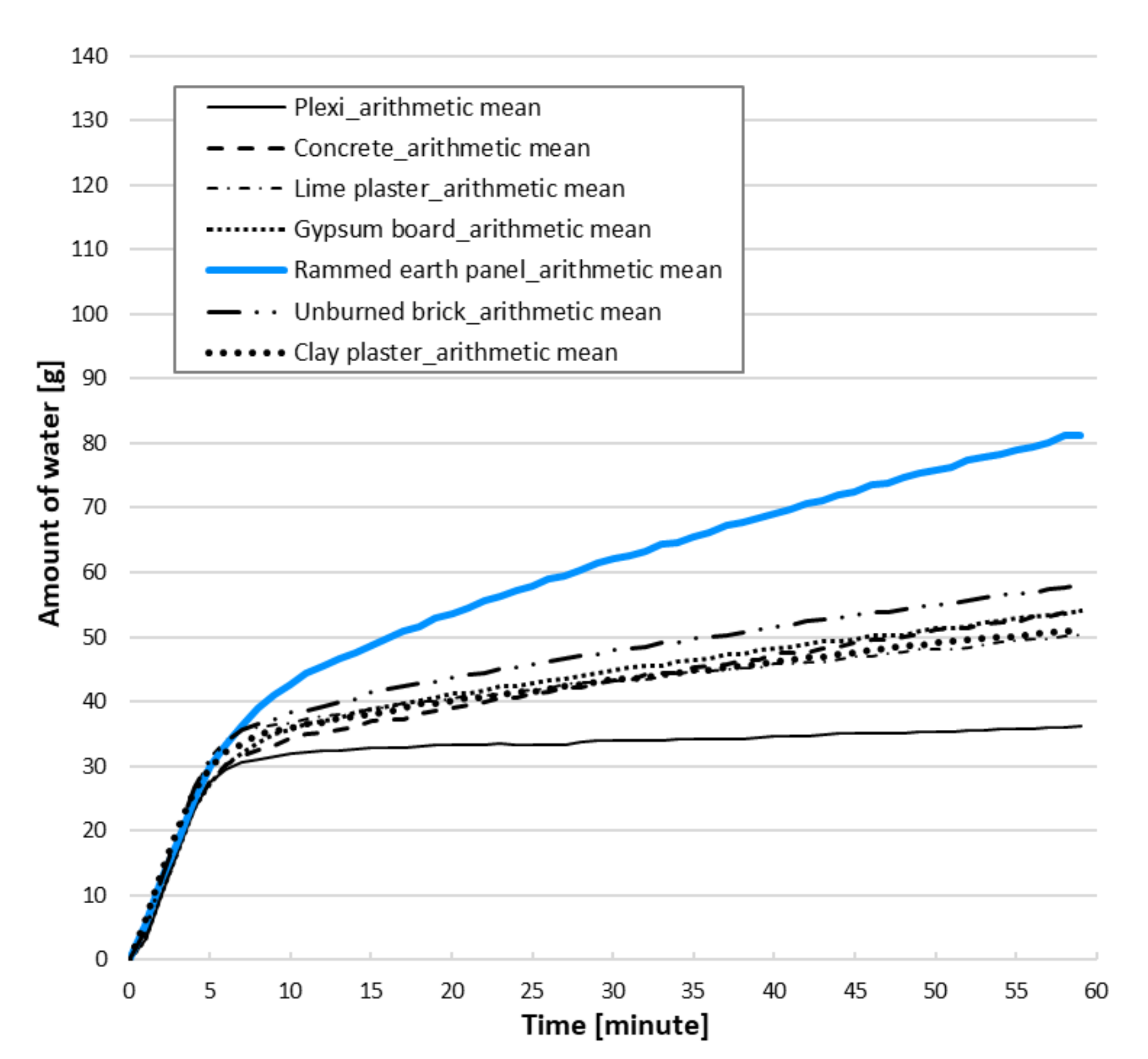

3.1. Averages of Three Measurements

3.2. Analysis of Dynamic Behaviour

- 0–60 min: The first interval was the most dynamic. Sixty minutes after the start of the observation, the dynamic potential had a half value;

- 60–120 min: In another 60 min, the dynamic potential dropped by another 1/3; this was the last significant dynamic part;

- 120–300 min: The properties of dynamic adsorption of selected materials were grouped as follows: clay structures, concrete and gypsum board, and lime plaster;

- 300–420 min: Identical dynamic properties of all materials. The value of the slope of the tangent was less than 0.017 (conversion to degree < 1 °), i.e., it was almost constant;

- 420–480 min: The values of the slope of the tangent in this interval cannot be used for analysis because the regression curves in this interval allowed for the potential trend of other data (i.e., observations longer than 8 h). The regression curves rose significantly in this interval, even when they did not follow the laws of physics. It would be better to find a more accurate regression curve, but it is extremely time consuming and, for the purposes of this work, this curve is sufficient. Dynamic behaviour is especially important at the beginning of observation.

3.3. Confidence Interval Analysis

4. Conclusions and Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Klepeis, N.E. A Resource for Assessing Exposure to Environmental Pollutants. J. Expo. Anal. Environ. Epidemiol. 2001, 11, 231–252. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Clausen, G. (Ed.) Ventilation, Good Indoor Air Quality and Rational Use of Energy; EUR Environment and quality of life; Office for Official Publications of the European Communities: Luxembourg, 2003; ISBN 978-92-894-5664-7. [Google Scholar]

- Ing. Hana Doležílková, Ph.D. Kvalita vnějšího a vnitřního vzduchu. Available online: https://vetrani.tzb-info.cz/vnitrni-prostredi/6486-kvalita-vnejsiho-a-vnitrniho-vzduchu (accessed on 6 October 2020).

- Centrum Pasivního Domu Indoor Air Quality. Available online: https://www.pasivnidomy.cz/kvalita-vnitrniho-prostredi/t384 (accessed on 22 July 2020).

- Jokl, M.V. Thermal Comfort and Optimum Humidity Part 1. Acta Polytech. 2002, 42. [Google Scholar] [CrossRef]

- Pinterić, M. Building Physics: From Physical Principles to International Standards; Springer: Cham, Switzerland, 2017; ISBN 978-3-319-57484-4. [Google Scholar]

- Jokl, M. Teorie vnitřního Prostředí Budov (Indoor Environmental Quality), 2nd ed.; CTU in Prague: Prague, Check Republic, 1991; ISBN 978-80-01-00481-4. [Google Scholar]

- Gertis, K.; Erhorn, H. Wohnfeuchte und Wärmebrücken. Heiz. LüftungKlima Haustech. 1985, 36, 130–135. [Google Scholar]

- ANSI/ASHRAE Standard 55; Thermal Environmental Conditions for Human Occupancy. ASHRAE: Atlanta, GA, USA, 2013.

- Korjenic, A.; Teblick, H.; Bednar, T. Increasing the Indoor Humidity Levels in Buildings with Ventilation Systems: Simulation Aided Design in Case of Passive Houses. Build. Simul. 2010, 3, 295–310. [Google Scholar] [CrossRef]

- Centrum Pasivního Domu Kvalita Vnitřního Prostředí—Pasivnidomy.cz. Available online: https://www.pasivnidomy.cz/kvalita-vnitrniho-prostredi/t384?chapterId=1832 (accessed on 9 October 2020).

- Kraus, M. Hygrothermal Analysis of Indoor Environment of Residential Prefabricated Buildings. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 042071. [Google Scholar] [CrossRef]

- European Commission Green Deal. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?qid=1588580774040&uri=CELEX:52019DC0640 (accessed on 21 July 2020).

- Ben-Alon, L.; Loftness, V.; Harries, K.A.; Cochran Hameen, E. Life Cycle Assessment (LCA) of Natural vs Conventional Building Assemblies. Renew. Sustain. Energy Rev. 2021, 144, 110951. [Google Scholar] [CrossRef]

- Melià, P.; Ruggieri, G.; Sabbadini, S.; Dotelli, G. Environmental Impacts of Natural and Conventional Building Materials: A Case Study on Earth Plasters. J. Clean. Prod. 2014, 80, 179–186. [Google Scholar] [CrossRef]

- Fernandes, J.; Peixoto, M.; Mateus, R.; Gervásio, H. Life Cycle Analysis of Environmental Impacts of Earthen Materials in the Portuguese Context: Rammed Earth and Compressed Earth Blocks. J. Clean. Prod. 2019, 241, 118286. [Google Scholar] [CrossRef] [Green Version]

- Michot, L.J. Determination of Surface Areas and Textural Properties of Clay Minerals. In Developments in Clay Science; Elsevier: Amsterdam, The Netherlands, 2018; Volume 9, pp. 23–47. ISBN 978-0-08-102432-4. [Google Scholar]

- Huggett, J.M. Clay Minerals. In Encyclopedia of Geology; Elsevier: Amsterdam, The Netherlands, 2021; pp. 341–349. ISBN 978-0-08-102909-1. [Google Scholar]

- Macht, F.; Eusterhues, K.; Pronk, G.J.; Totsche, K.U. Specific Surface Area of Clay Minerals: Comparison between Atomic Force Microscopy Measurements and Bulk-Gas (N2) and -Liquid (EGME) Adsorption Methods. Appl. Clay Sci. 2011, 53, 20–26. [Google Scholar] [CrossRef]

- Keppert, M. Pore Size Distribution of Building Materials—Characterisation and Importance; Elsevier: Amsterdam, The Netherlands, 2010. [Google Scholar]

- McGregor, F.; Heath, A.; Shea, A.; Lawrence, M. The Moisture Buffering Capacity of Unfired Clay Masonry. Build. Environ. 2014, 82, 599–607. [Google Scholar] [CrossRef] [Green Version]

- Gomes, M.I.; Lima, J.; Santos, T.; Gomes, J.; Faria, P. The Benefits of Eco-Efficient Plasters for Occupant’s Health—A Case Study. In Ecological and Health Effects of Building Materials; Malik, J.A., Marathe, S., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 383–404. ISBN 978-3-030-76072-4. [Google Scholar]

- Jiang, Y.; Phelipot-Mardele, A.; Collet, F.; Lanos, C.; Lemke, M.; Ansell, M.; Hussain, A.; Lawrence, M. Moisture Buffer, Fire Resistance and Insulation Potential of Novel Bio-Clay Plaster. Constr. Build. Mater. 2020, 244, 118353. [Google Scholar] [CrossRef]

- Minke, G. Building with Earth–Design and Technology for a Sustainable Architecture; 2.; Birkhäuser: Basel, Switzerland, 2009; Volume 2009, ISBN 978-3-936896-41-1. [Google Scholar]

- Hall, M.; Allinson, D. Analysis of the Hygrothermal Functional Properties of Stabilised Rammed Earth Materials. Build. Environ. 2009, 44, 1935–1942. [Google Scholar] [CrossRef] [Green Version]

- Liuzzi, S.; Hall, M.R.; Stefanizzi, P.; Casey, S.P. Hygrothermal Behaviour and Relative Humidity Buffering of Unfired and Hydrated Lime-Stabilised Clay Composites in a Mediterranean Climate. Build. Environ. 2013, 61, 82–92. [Google Scholar] [CrossRef]

- Saidi, M.; Cherif, A.S.; Zeghmati, B.; Sediki, E. Stabilization Effects on the Thermal Conductivity and Sorption Behavior of Earth Bricks. Constr. Build. Mater. 2018, 167, 566–577. [Google Scholar] [CrossRef]

- Cagnon, H.; Aubert, J.E.; Coutand, M.; Magniont, C. Hygrothermal Properties of Earth Bricks. Energy Build. 2014, 80, 208–217. [Google Scholar] [CrossRef]

- Randazzo, L.; Montana, G.; Hein, A.; Castiglia, A.; Rodonò, G.; Donato, D.I. Moisture Absorption, Thermal Conductivity and Noise Mitigation of Clay Based Plasters: The Influence of Mineralogical and Textural Characteristics. Appl. Clay Sci. 2016, 132–133, 498–507. [Google Scholar] [CrossRef]

- Liuzzi, S.; Rubino, C.; Stefanizzi, P.; Petrella, A.; Boghetich, A.; Casavola, C.; Pappalettera, G. Hygrothermal Properties of Clayey Plasters with Olive Fibers. Constr. Build. Mater. 2018, 158, 24–32. [Google Scholar] [CrossRef]

- Ashour, T.; Korjenic, A.; Korjenic, S. Equilibrium Moisture Content of Earth Bricks Biocomposites Stabilized with Cement and Gypsum. Cem. Concr. Compos. 2015, 59, 18–25. [Google Scholar] [CrossRef]

- El Fgaier, F.; Lafhaj, Z.; Chapiseau, C.; Antczak, E. Effect of Sorption Capacity on Thermo-Mechanical Properties of Unfired Clay Bricks. J. Build. Eng. 2016, 6, 86–92. [Google Scholar] [CrossRef]

- McGregor, F.; Heath, A.; Fodde, E.; Shea, A. Conditions Affecting the Moisture Buffering Measurement Performed on Compressed Earth Blocks. Build. Environ. 2014, 75, 11–18. [Google Scholar] [CrossRef] [Green Version]

- Rode, C.; Hansen, P.N.; Hansen, K.K. Combined Heat and Moisture Transfer in Building Constructions; Technical University of Denmark: Lyngby, Denmark, 1990. [Google Scholar]

- Rode, C. Moisture Buffer Value of Building Materials. ASTM Int. 2006, 2006. [Google Scholar] [CrossRef] [Green Version]

- Roels, S.; Janssen, H. A Comparison of the Nordtest and Japanese Test Methods for the Moisture Buffering Performance of Building Materials. J. Build. Phys. 2006, 30, 137–161. [Google Scholar] [CrossRef] [Green Version]

- Cascione, V.; Maskell, D.; Shea, A.; Walker, P.; Mani, M. Comparison of Moisture Buffering Properties of Plasters in Full Scale Simulations and Laboratory Testing. Constr. Build. Mater. 2020, 252, 119033. [Google Scholar] [CrossRef]

- Maskell, D.; Thomson, A.; Walker, P.; Lemke, M. Determination of Optimal Plaster Thickness for Moisture Buffering of Indoor Air. Build. Environ. 2018, 130, 143–150. [Google Scholar] [CrossRef]

- Růžička, J.; Diviš, J. The Influence of Building Materials on Relative Humidity of Internal Microclimate. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 012029. [Google Scholar] [CrossRef]

- Růžička, J.; Diviš, J.; Staněk, K.; Richter, J. The Influence of Natural Clays and Earthen Structures on Relative Humidity of Internal Microclimate. In Proceedings of the LEHM 2016, Weimar, Germany, 12–14 November 2016. [Google Scholar]

- Havlík, F. Development and Experimental Verification of Mechanical-Physical Properties of Pre-Formed Rammed Earth Wall Panel 2017. Acta Polytechnica 2019, 59, 372–383. [Google Scholar] [CrossRef]

- Diviš, J. Sorption Properties of Clay Materials. Doctoral Thesis, Faculty of Civil Engineering, CTU in Prague, Prague, Czech Republic, 2021. [Google Scholar]

| Tested Structure | Slope of the Curve a [g·min−1] |

|---|---|

| Ref: Plexi board | 0.07 |

| S1: Concrete | 0.39 |

| S2: Lime plaster | 0.26 |

| S3: Gypsum board | 0.34 |

| S4: Rammed earth panel | 0.71 |

| S5: Unburned brick | 0.38 |

| S6: Clay plaster | 0.28 |

| Tested Structure | Observation Time [min] | |||

|---|---|---|---|---|

| 60 | 120 | 300 | 420 | |

| Concrete | 0.9 | 1.5 | 3.5 | 3.5 |

| Lime plaster | 2.9 | 2.9 | 2.9 | 2.9 |

| Gypsum board | 1.3 | 1.3 | 1.3 | 1.3 |

| Rammed earth panel | 8.4 | 9.4 | 10.7 | 10.7 |

| Unburned brick | 8.1 | 8.6 | 12.5 | 15.0 |

| Clay plaster | 6.6 | 6.9 | 9.5 | 10.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diviš, J.; Růžička, J. The Influence of Clay Structures to the Hygrothermal Component of the Indoor Environment. Materials 2022, 15, 1744. https://doi.org/10.3390/ma15051744

Diviš J, Růžička J. The Influence of Clay Structures to the Hygrothermal Component of the Indoor Environment. Materials. 2022; 15(5):1744. https://doi.org/10.3390/ma15051744

Chicago/Turabian StyleDiviš, Jakub, and Jan Růžička. 2022. "The Influence of Clay Structures to the Hygrothermal Component of the Indoor Environment" Materials 15, no. 5: 1744. https://doi.org/10.3390/ma15051744

APA StyleDiviš, J., & Růžička, J. (2022). The Influence of Clay Structures to the Hygrothermal Component of the Indoor Environment. Materials, 15(5), 1744. https://doi.org/10.3390/ma15051744