The Influence of Reactive PS-PVD Process Parameters on the Microstructure and Thermal Properties of Yb2Zr2O7 Thermal Barrier Coating

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

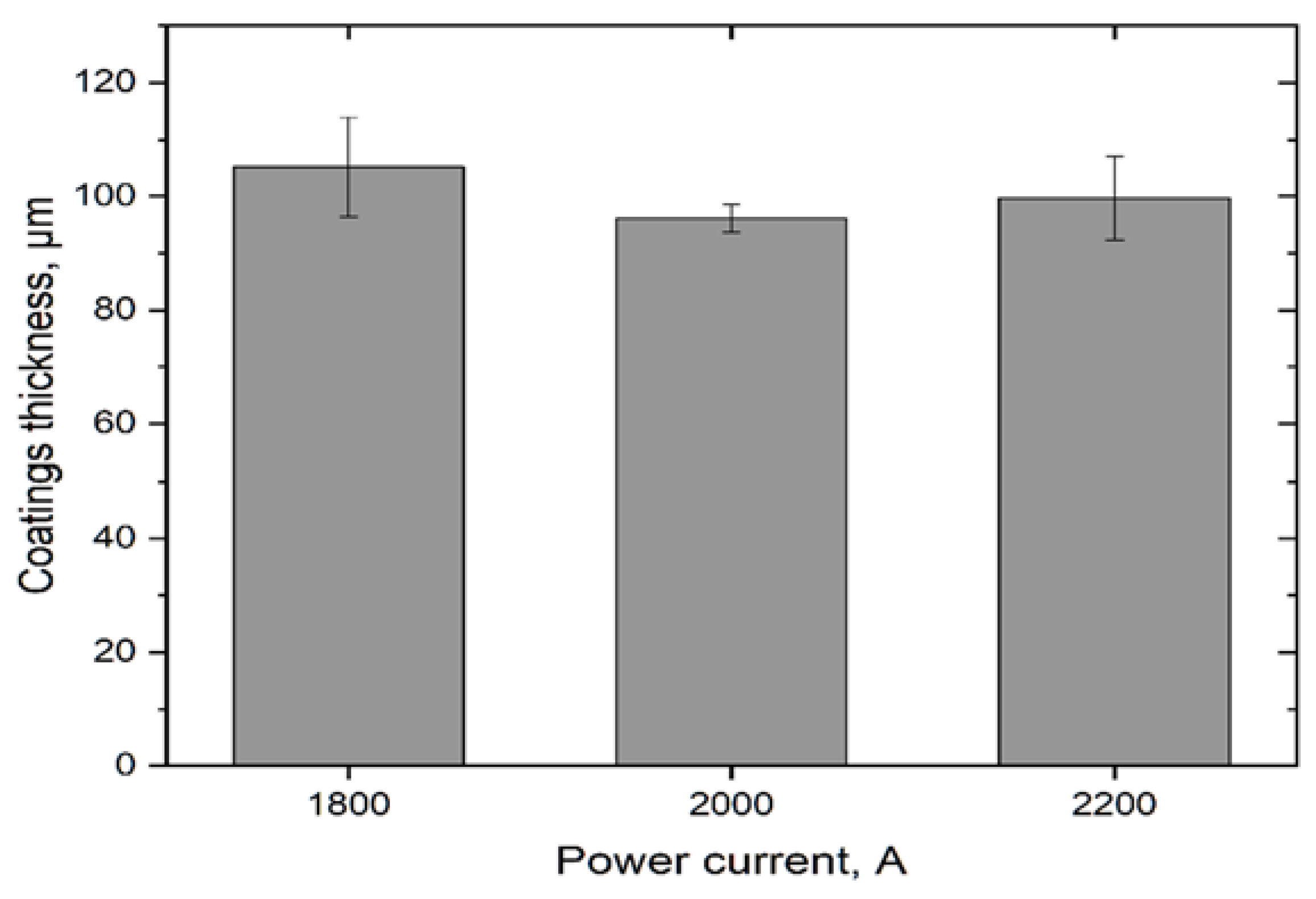

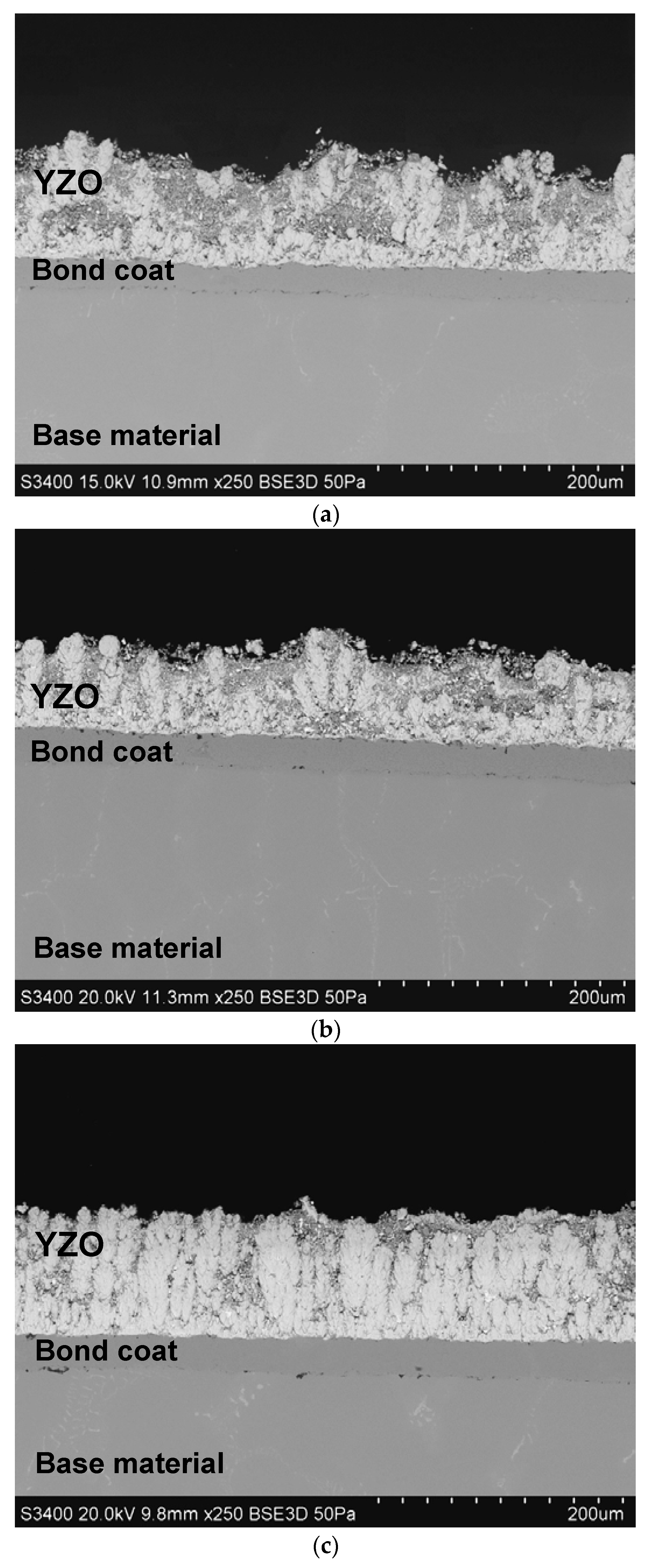

3.1. The Microstructure

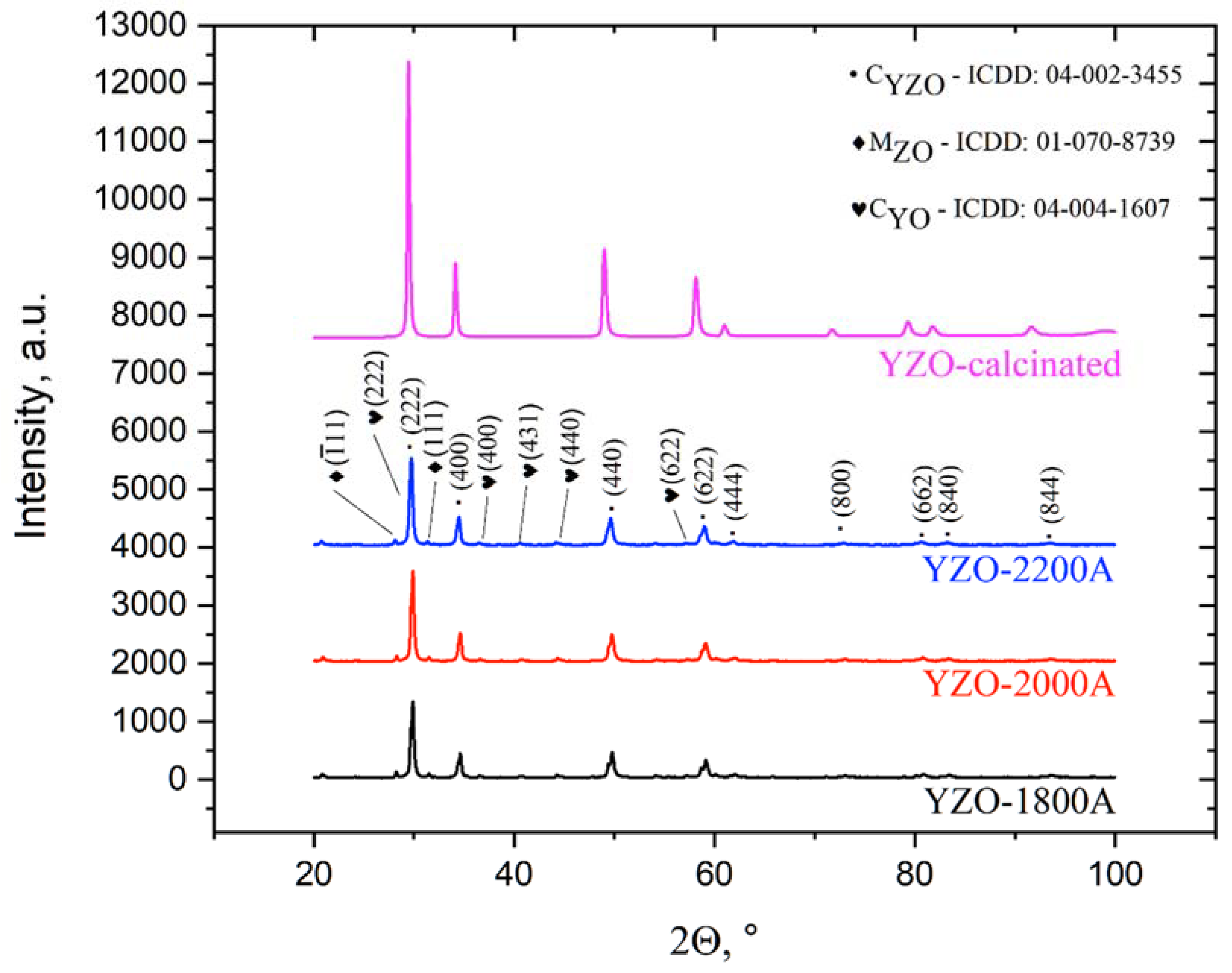

3.2. Phase Composition

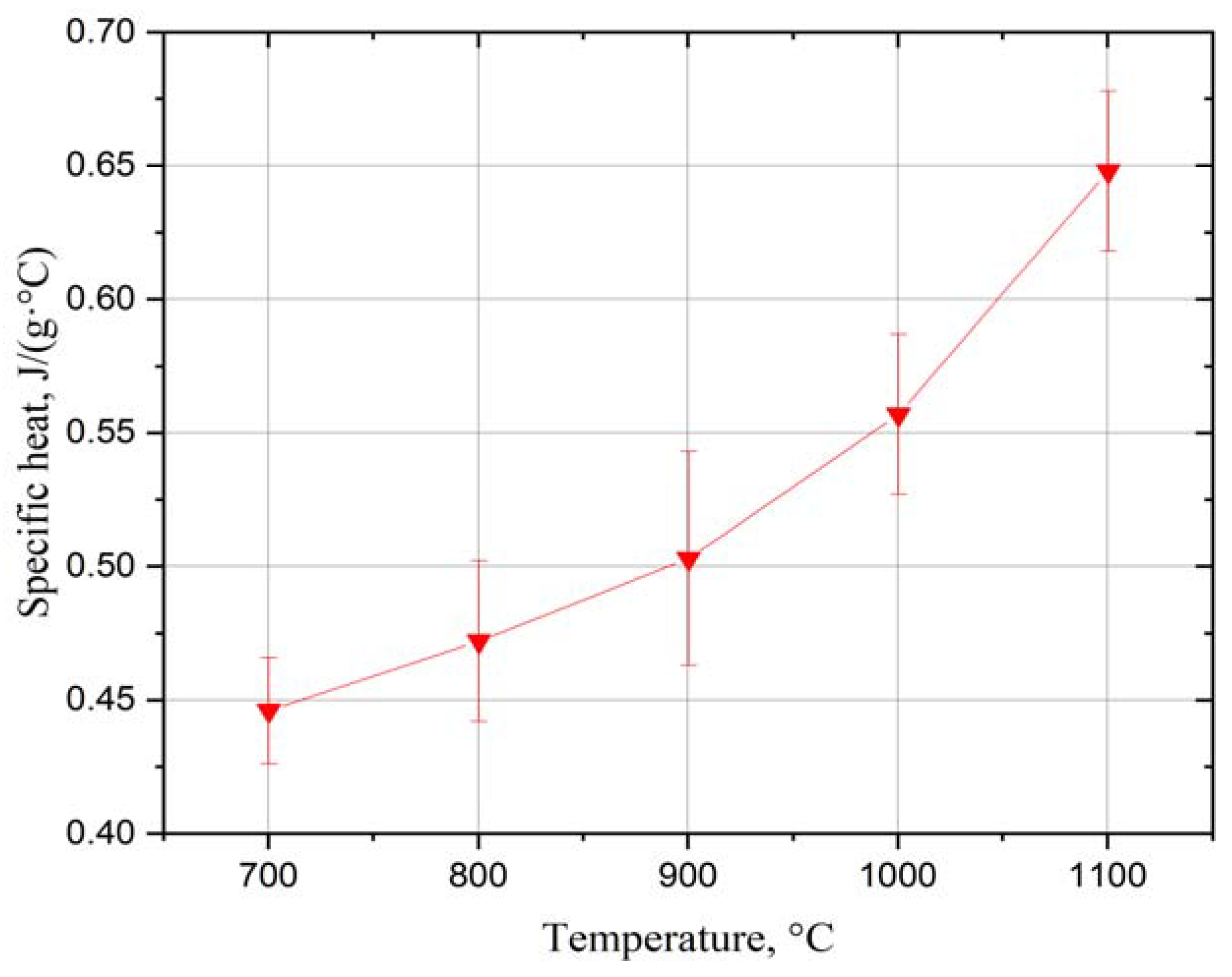

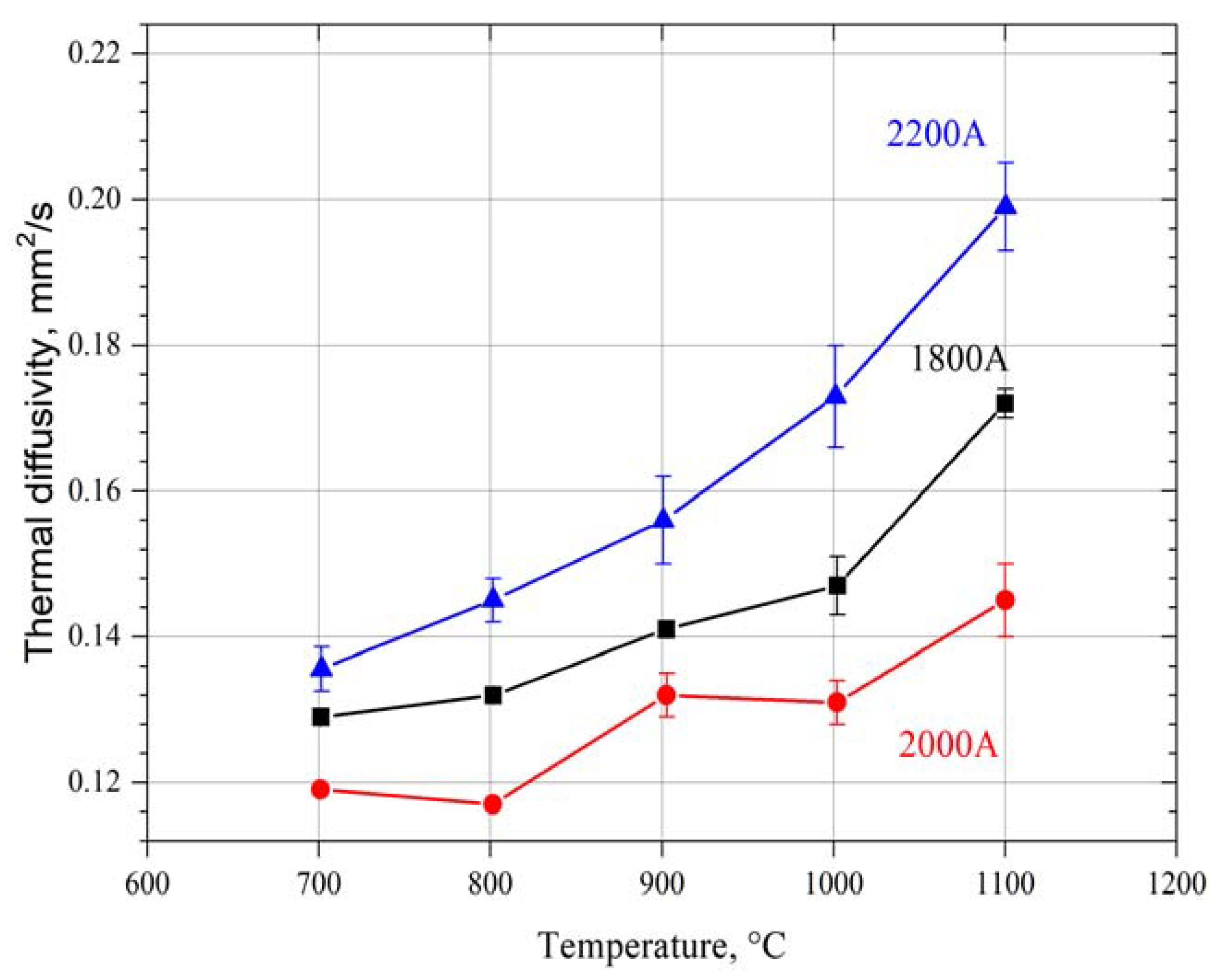

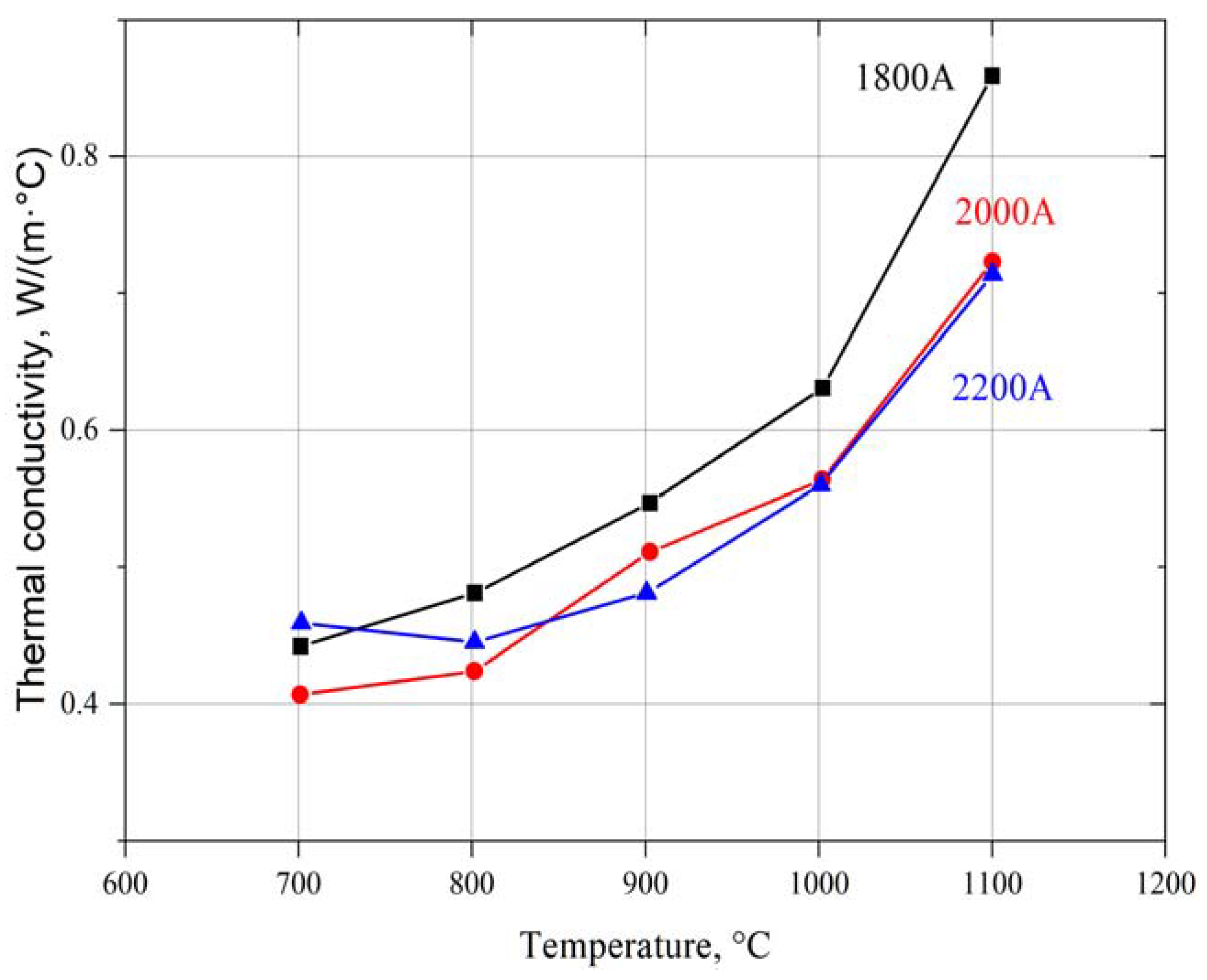

3.3. Thermal Properties

4. Conclusions

- Ytterbium zirconate (Yb2Zr2O7) was successfully formed during a reactive PS-PVD process using only a mixture of pure Yb2O3 and ZrO2 powder.

- When the lower power current was used (1800 and 2000 A) a hybrid structure for the coating was obtained. The increase in power current to 2200 A caused the quasi-columnar structure to form during the reactive PS-PVD process.

- The XRD phase analysis showed non-significant differences in the coating using different power current values. The Yb2Zr2O7 was the main component of the obtained coating. On the other hand, the presence of ytterbium and zirconium oxides indicates incomplete transformation of the entire mixture of oxides. The complete reaction was only observed in the mixture of powders calcined at 1500 °C.

- Higher thermal conductivity was calculated for the Yb2Zr2O7 coating formed using a higher power current (2200 A). It was a result the of quasi-columnar structure of coating characterized by higher thermal conductivity in comparison with the hybrid structure formed using the 1800 A power current.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mondal, K.; Nuñez, L.; Downey, C.M.; Van Rooyen, I.J. Thermal barrier coatings overview: Design, manufacturing, and applications in high-temperature industries. Ind. Eng. Chem. Res. 2021, 60, 6061–6077. [Google Scholar] [CrossRef]

- Cao, X.Q.; Vassen, R.; Stoever, D. Ceramic materials for thermal barrier coatings. J. Eur. Ceram. Soc. 2004, 24, 1–10. [Google Scholar] [CrossRef]

- Vaßen, R.; Sebold, D.; Stöver, D. Corrosion behavior of new thermal barrier coatings. Ceram. Eng. Sci. Proc. 2008, 28, 27–38. [Google Scholar] [CrossRef]

- Vassen, R.; Stuke, A.; Stöver, D. Recent developments in the field of thermal barrier coatings. J. Therm. Spray Technol. 2009, 18, 181–186. [Google Scholar] [CrossRef]

- Saruhan, B.; Schulz, U.; Bartsch, M. Developments in processing of ceramic top coats of EB-PVD thermal barrier coatings. Key Eng. Mater. 2007, 333, 137–146. [Google Scholar] [CrossRef]

- Moskal, G.; Witala, B.; Rozmyslowska, A. Thermal diffusivity of RE2Zr2O7—Type ceramic powders intended for TBCs deposited by APS. Arch. Mater. Sci. Eng. 2009, 36, 76–81. [Google Scholar]

- Moskal, G.; Rozmysłowska, A. Microstructure and thermal diffusivity of Gd2Zr2O7 powders. Adv. Mater. Res. 2010, 89–91, 739–744. [Google Scholar] [CrossRef]

- Sun, X.; Wang, Q.; Liu, Y.; Ning, X.; Wang, C. Preparation and properties of Sm2Zr2O7 ceramics for thermal barrier coatings by APS. Adv. Mater. Res. 2012, 354–355, 478–482. [Google Scholar] [CrossRef]

- Moskal, G.; Swadźba, L.; Hetmańczyk, M.; Mendala, J.; Sosnowy, P. Characterisation of the microstructure and thermal properties of Nd2Zr2O7 and Nd2Zr2O7/YSZ thermal barrier coatings. J. Eur. Ceram. Soc. 2012, 32, 2035–2042. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markocsan, N.; Nylén, P. Failure analysis of Gd2Zr2O7/YSZ multi-layered thermal barrier coatings subjected to thermal cyclic fatigue. J. Alloy. Compd. 2016, 689, 1011–1019. [Google Scholar] [CrossRef]

- Wang, C.; Wang, Y.; Wang, L.; Hao, G.; Sun, X.; Shan, F.; Zou, Z. Nanocomposite Lanthanum Zirconate Thermal Barrier Coating Deposited by Suspension Plasma Spray Process. J. Therm. Spray Technol. 2014, 23, 1030–1036. [Google Scholar] [CrossRef]

- Mahade, S.; Curry, N.; Björklund, S.; Markoscan, N.; Nylén, P.; Vaßen, R. Functional performance of Gd2Zr2O7/YSZ multi-layered thermal barrier coatings deposited by suspension plasma spray. Surf. Coat. Technol. 2017, 318, 208–216. [Google Scholar] [CrossRef]

- Xu, Z.H.; Shen, Z.Y.; Mu, R.D.; He, L.M. Phase structure, thermophysical properties and thermal cycling behavior of novel (Sm0.2La0.8)2(Zr0.7Ce0.3)2O7 thermal barrier coatings. Vacuum 2018, 157, 105–110. [Google Scholar] [CrossRef]

- Yang, P.; An, Y.; Zhao, D.; Li, Y.; Zhou, H.; Chen, J. Structure evolution, thermal properties and sintering resistance of promising thermal barrier coating material La2(Zr0.75Ce0.25)2O7. Ceram. Int. 2020, 46, 20652–20663. [Google Scholar] [CrossRef]

- Guo, Y.; He, W.; Guo, H. Thermo-physical and mechanical properties of Yb2O3 and Sc2O3 co-doped Gd2Zr2O7 ceramics. Ceram. Int. 2020, 46, 18888–18894. [Google Scholar] [CrossRef]

- Mikuskiewicz, M.; Moskal, G. Solid state synthesis of europium zirconate based material. Arch. Metall. Mater. 2019, 4, 1343–1352. [Google Scholar] [CrossRef]

- Mikuśkiewicz, M.; Moskal, G.; Migas, D.; Stopyra, M. Thermal diffusivity characterization of europium zirconate, cerate and hafnate. Ceram. Int. 2019, 45, 2760–2770. [Google Scholar] [CrossRef]

- Stopyra, M.; Moskal, G.; Niemiec, D. Synthesis and thermal properties of europium zirconate and hafnate via solid state reaction and polymerized complex method. Surf. Coat. Technol. 2015, 284, 38–43. [Google Scholar] [CrossRef]

- Li, F.; Zhou, L.; Liu, J.-X.; Liang, Y.; Zhang, G.-J. High-entropy pyrochlores with low thermal conductivity for thermal barrier coating materials. J. Adv. Ceram. 2019, 8, 576–582. [Google Scholar] [CrossRef] [Green Version]

- Cong, L.; Zhang, S.; Gu, S.; Li, W. Thermophysical properties of a novel high entropy hafnate ceramic. J. Mater. Sci. Technol. 2021, 85, 152–157. [Google Scholar] [CrossRef]

- Moskal, G.; Jucha, S.; Mikuśkiewicz, M.; Migas, D.; Jasik, A. Atypical decomposition processes of Sm2Zr2O7 + 8YSZ dual-phase TBCs during hot corrosion. Corros. Sci. 2020, 170, 108681. [Google Scholar] [CrossRef]

- Jasik, A.; Moskal, G.; Jucha, S.; Kuligowski, K. Surface condition of La2Zr2O7 based tbc system after hot corrosion in molten sulfate Na2SO4 salts. Ochr. Przed Koroz. 2019, 62, 82–85. [Google Scholar] [CrossRef]

- Li, S.; Liu, Z.-G.; Ouyang, J.-H. Hot corrosion behaviour of Yb2Zr2O7 ceramic coated with V2O5 at temperatures of 600–800 °C in air. Corros. Sci. 2010, 52, 3568–3572. [Google Scholar] [CrossRef]

- He, J.; Huang, Y.; Hu, M.; Jiang, M.; Qiao, Y.; Li, S.; Zeng, H. Thermal barrier materials of Yb2O3-ZrO2 system synthesized by laser excitation. Mater. Res. Express 2020, 7, 055201. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, L.; Wang, C.; Ye, F. Toughening effect of Yb2O3 stabilized ZrO2 doped in Gd2Zr2O7 ceramic for thermal barrier coatings. Mater. Sci. Eng. A 2015, 648, 385–391. [Google Scholar] [CrossRef]

- Ren, X.; Zhao, M.; Wan, C.; Zheng, Y.; Pan, W. High-Temperature Aging of Plasma Sprayed Quasi-Eutectoid LaYbZr2O7-Part I: Phase Evolution. J. Am. Ceram. Soc. 2015, 98, 2829–2835. [Google Scholar] [CrossRef]

- Ren, X.; Zhao, M.; Wan, C.; Zheng, Y.; Pan, W. High Temperature Aging of Plasma Sprayed Quasi-Eutectoid LaYbZr2O7-Part II: Microstructure & Thermal Conductivity. J. Am. Ceram. Soc. 2015, 98, 2836–2842. [Google Scholar]

- Mauer, G.; Jarligo, M.O.; Rezanka, S.; Hospach, A.; Vaßen, R. Novel opportunities for thermal spray by PS-PVD. Surf. Coat. Technol. 2015, 268, 52–57. [Google Scholar] [CrossRef]

- Góral, M.; Swadźba, R.; Kubaszek, T. TEM investigations of TGO formation during cyclic oxidation in two- and three-layered Thermal Barrier Coatings produced using LPPS, CVD and PS-PVD methods. Surf. Coat. Technol. 2020, 394, 125875. [Google Scholar] [CrossRef]

- Li, S.; He, W.; Shi, J.; Wei, L.; He, J.; Guo, H. PS-PVD gadolinium zirconate thermal barrier coatings with columnar micro-structure sprayed from sintered powder feedstocks. Surf. Coat. Technol. 2020, 383, 125243. [Google Scholar] [CrossRef]

- Zhu, R.-B.; Zou, J.-P.; Mao, J.; Deng, C.-M.; Liu, M. A comparison between novel Gd2Zr2O7 and Gd2Zr2O7/YSZ thermal barrier coatings fabricated by plasma spray-physical vapor deposition. Rare Met. 2021, 40, 2244–2253. [Google Scholar] [CrossRef]

- Pedrak, M.; Dychton, K.; Drajewicz, M.; Goral, M. Synthesis of Gd2Zr2O7 coatings in novel Reactive PS-PVD process. Coatings 2021, 11, 1208. [Google Scholar] [CrossRef]

- Goral, M.; Kotowski, S.; Dychton, K.; Drajewicz, M.; Kubaszek, T. Influence of low pressure plasma spraying parameters on MCrAlY bond coat and its microstructure. Key Eng. Mater. 2014, 592–593, 421–424. [Google Scholar] [CrossRef]

- Goral, M.; Kotowski, S.; Nowotnik, A.; Pytel, M.; Drajewicz, M.; Sieniawski, J. PS-PVD deposition of thermal barrier coatings. Surf. Coat. Technol. 2013, 237, 51–55. [Google Scholar] [CrossRef]

- Góral, M.; Pytel, M.; Kubaszek, T.; Drajewicz, M.; Simka, W.; Nieuzyła, L. The new concept of thermal barrier coatings with Pt + Pd/Zr/Hf-modified aluminide bond coat and ceramic layer formed by PS-PVD method. High Temp. Mater. Processes 2021, 40, 281–286. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, K.; Liu, M.; Deng, C.; Deng, C. Deposition mechanism of 7YSZ thermal barrier coatings prepared by plasma spray-physical vapor deposition. Sci. Sin. Technol. 2019, 49, 1319–1330. [Google Scholar]

- Gao, L.; Wei, L.; Guo, H.; Gong, S.; Xu, H. Deposition mechanisms of yttria-stabilized zirconia coatings during plasma spray physical vapor deposition. Ceram. Int. 2016, 42, 5530–5536. [Google Scholar] [CrossRef]

- Zhang, B.; Wei, L.; Gao, L.; Guo, H.; Xhu, H. Microstructural characterization of PS-PVD ceramic thermal barrier coatings with quasi-columnar structures. Surf. Coat. Technol. 2017, 311, 199–205. [Google Scholar] [CrossRef]

- Zhang, X.F.; Zhou, K.S.; Deng, C.M.; Liu, M.; Deng, Z.Q.; Deng, C.G.; Song, J.B. Gas-deposition mechanisms of 7YSZ coating based on plasma spray-physical vapor deposition. J. Eur. Ceram. Soc. 2016, 36, 697–703. [Google Scholar] [CrossRef]

- Qiu, S.-Y.; Shi, J.; Li, S.; Ma, Y.; Guo, H.-B. Model on thermal conductivity prediction of quasi-columnar structured coating by plasma spray physical vapor deposition. Ceram. Int. 2021, 47, 27420–27429. [Google Scholar] [CrossRef]

| Process Name | Power Current, A | Argon Flow, NLPM | Helium Flow, NLPM | Powder Feed Rate, g/min |

|---|---|---|---|---|

| YZO-1800A | 1800 | 35 | 60 | 2 |

| YZO-2000A | 2000 | 35 | 60 | 2 |

| YZO-2200A | 2200 | 35 | 60 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pędrak, P.; Góral, M.; Dychton, K.; Drajewicz, M.; Wierzbinska, M.; Kubaszek, T. The Influence of Reactive PS-PVD Process Parameters on the Microstructure and Thermal Properties of Yb2Zr2O7 Thermal Barrier Coating. Materials 2022, 15, 1594. https://doi.org/10.3390/ma15041594

Pędrak P, Góral M, Dychton K, Drajewicz M, Wierzbinska M, Kubaszek T. The Influence of Reactive PS-PVD Process Parameters on the Microstructure and Thermal Properties of Yb2Zr2O7 Thermal Barrier Coating. Materials. 2022; 15(4):1594. https://doi.org/10.3390/ma15041594

Chicago/Turabian StylePędrak, Paweł, Marek Góral, Kamil Dychton, Marcin Drajewicz, Malgorzata Wierzbinska, and Tadeusz Kubaszek. 2022. "The Influence of Reactive PS-PVD Process Parameters on the Microstructure and Thermal Properties of Yb2Zr2O7 Thermal Barrier Coating" Materials 15, no. 4: 1594. https://doi.org/10.3390/ma15041594

APA StylePędrak, P., Góral, M., Dychton, K., Drajewicz, M., Wierzbinska, M., & Kubaszek, T. (2022). The Influence of Reactive PS-PVD Process Parameters on the Microstructure and Thermal Properties of Yb2Zr2O7 Thermal Barrier Coating. Materials, 15(4), 1594. https://doi.org/10.3390/ma15041594