Large Deflections of Thin-Walled Plates under Transverse Loading—Investigation of the Generated In-Plane Stresses

Abstract

:1. Introduction

2. State of the Art

3. Materials and Methods

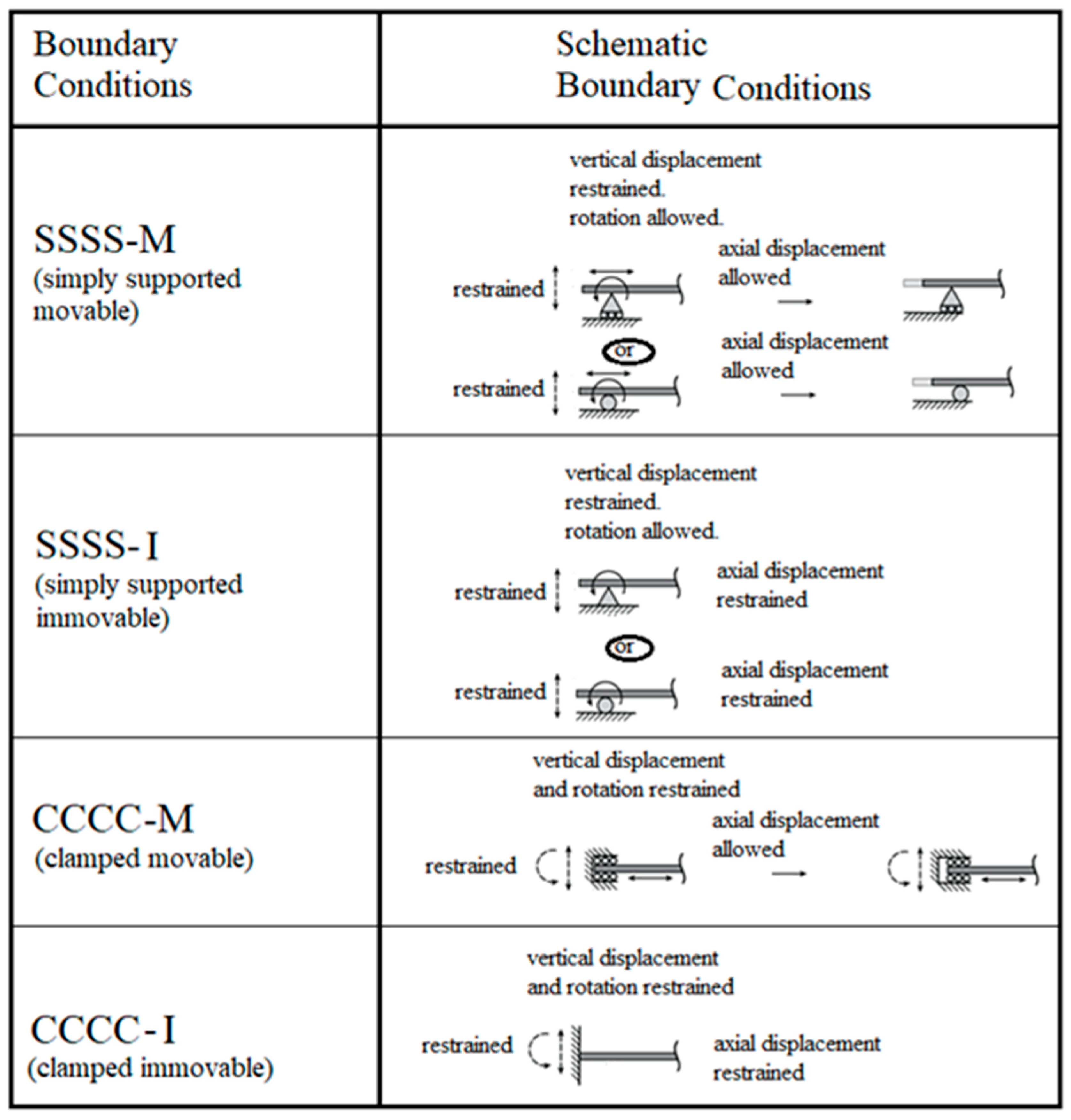

- SSSS–M: TZ, designated 3;

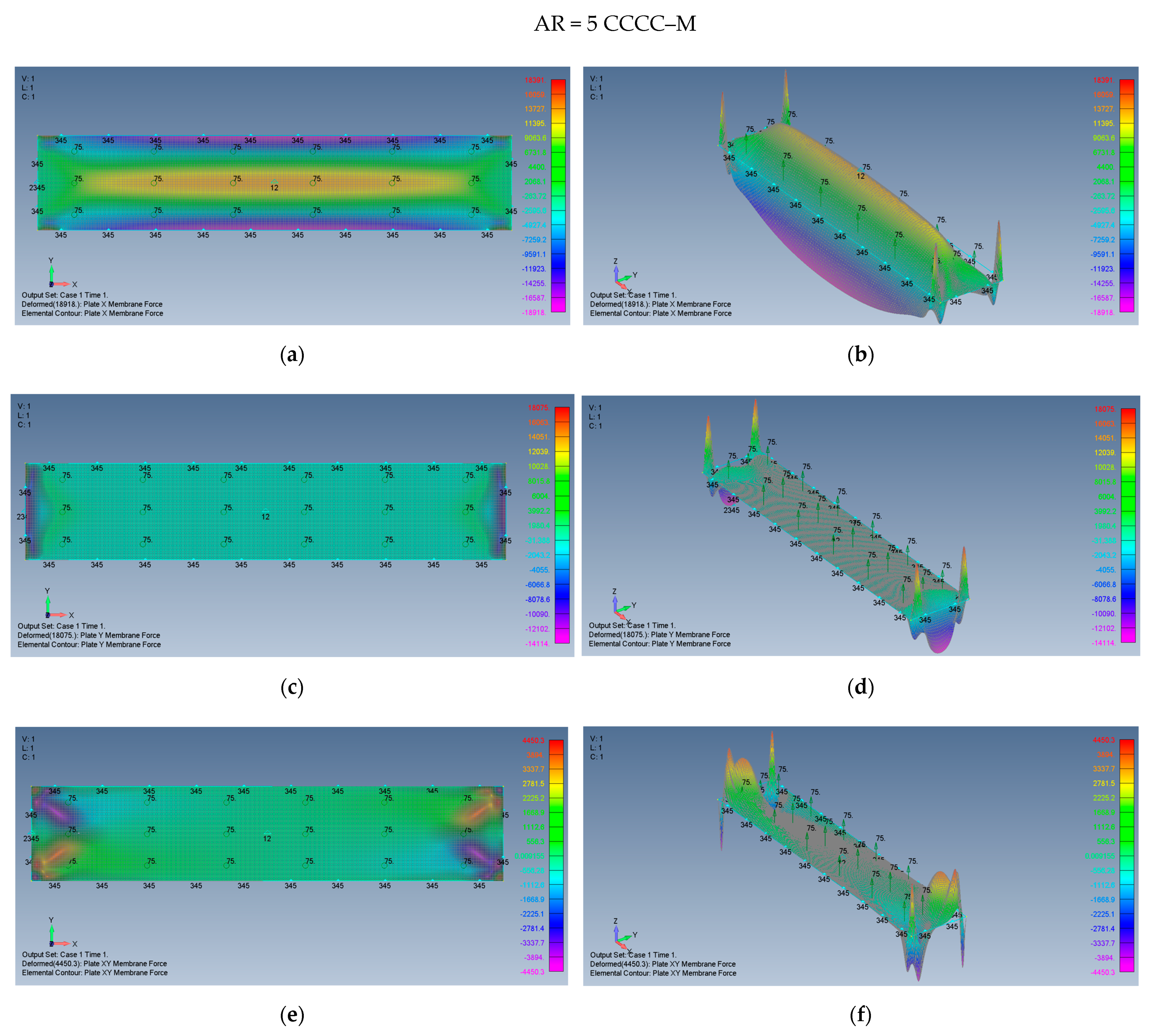

- CCCC–M: TZ,RX,RY, designated 3,4,5;

- SSSS–I: TX,TY,TZ, designated T;

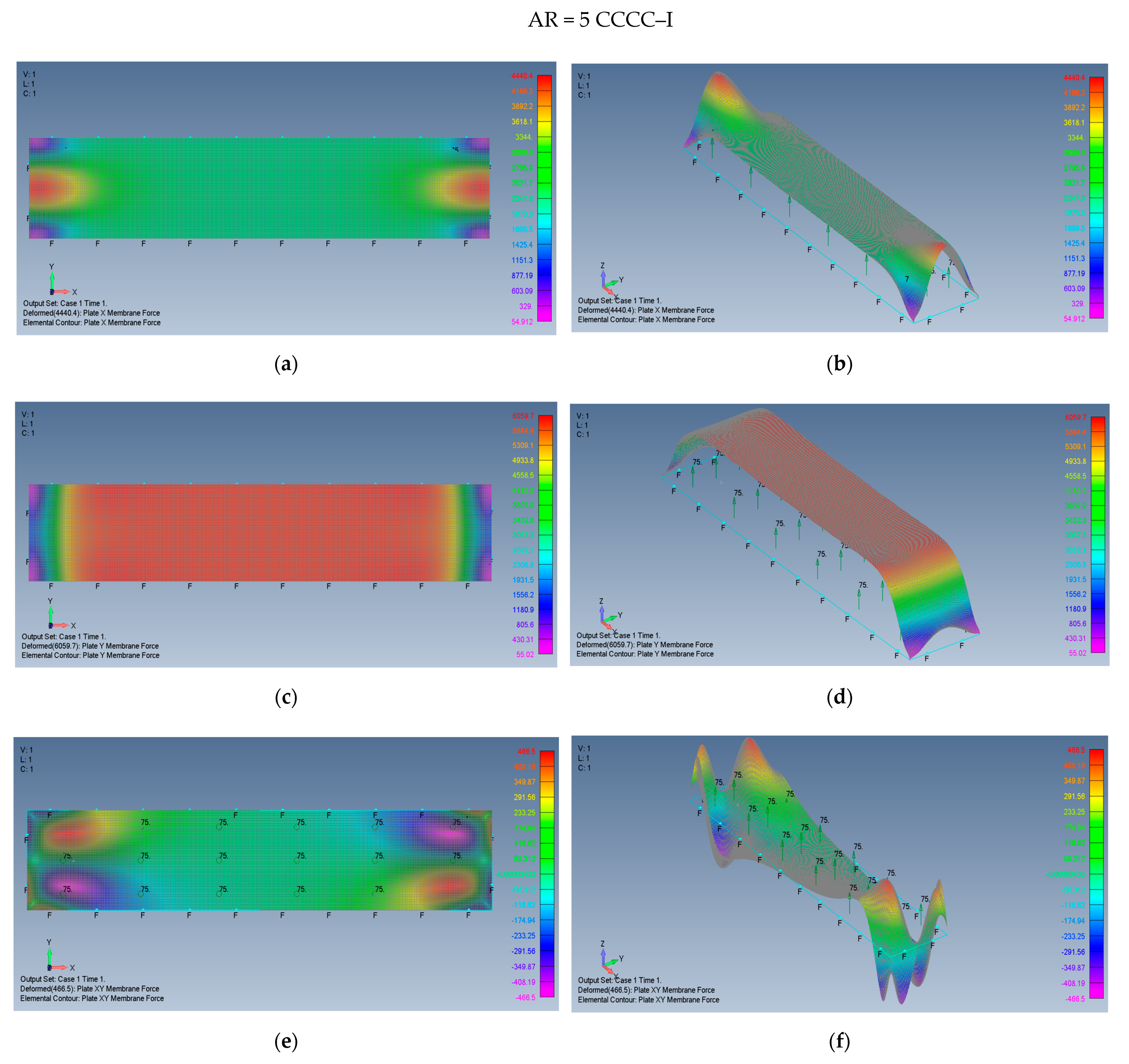

- CCCC–I: TX,TY,TZ,RX,RY,RZ, designated F.

- Large deflection with small strains;

- Nonlinear stress–strain material response;

- Material plastic yield;

- Geometric nonlinearities;

- Creep behavior;

- Snap-in mechanism;

- Physical contact between objects;

- Thin-shell buckling.

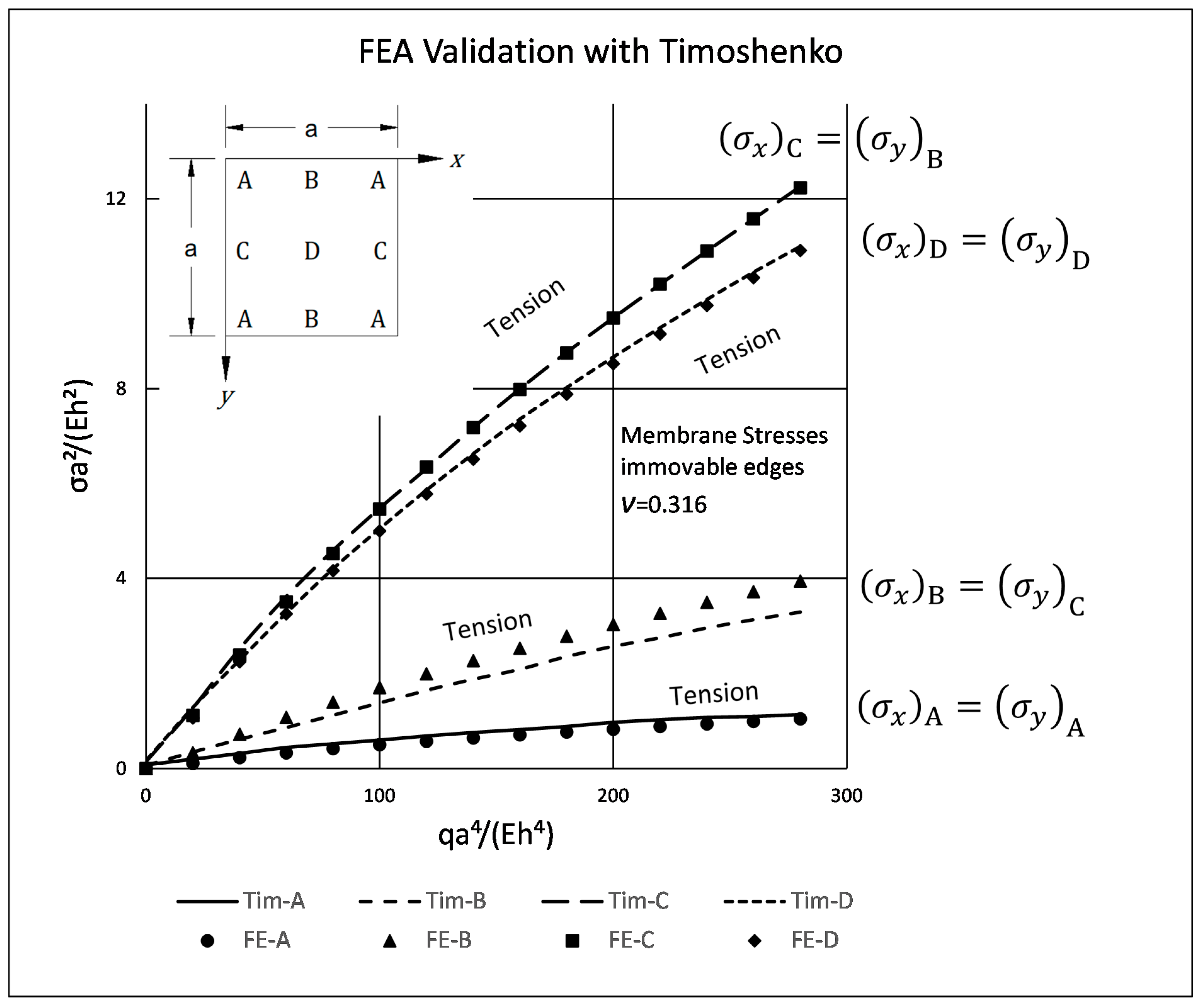

4. Validation

| Size: | Length × Width a × a [m] = 1 × 1 |

| Thickness | h [m] = 0.006 |

| Young’s Modulus | E [GPa] = 2.4 (Isotropic material) |

| Poisson’s Ratio | ν = 0.316 |

| Distributed load (uniform) | q [Pa] = 871 |

| BCs | SSSS–I (4 edged Simply Supported, In-plane Immovable) |

| Mesh | 100 × 100 Plate, Cquad4 elements (Plane stress) |

| Analysis | Nonlinear Static, 15 Steps |

| Model run time | t [sec] = 35 |

| Points A,B,C—are located 5 elements away from the plate edge | |

5. Results

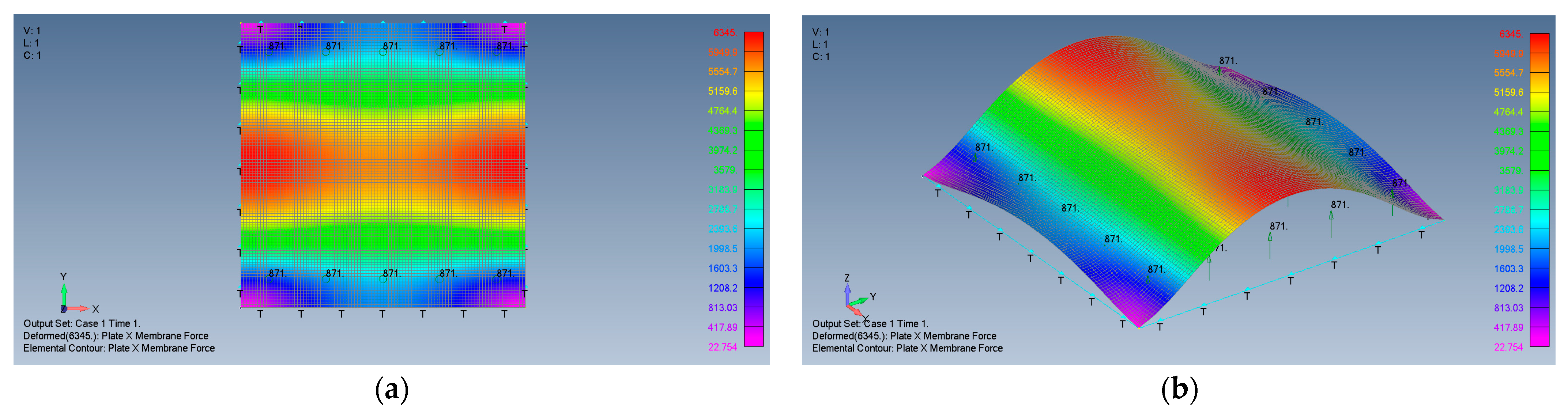

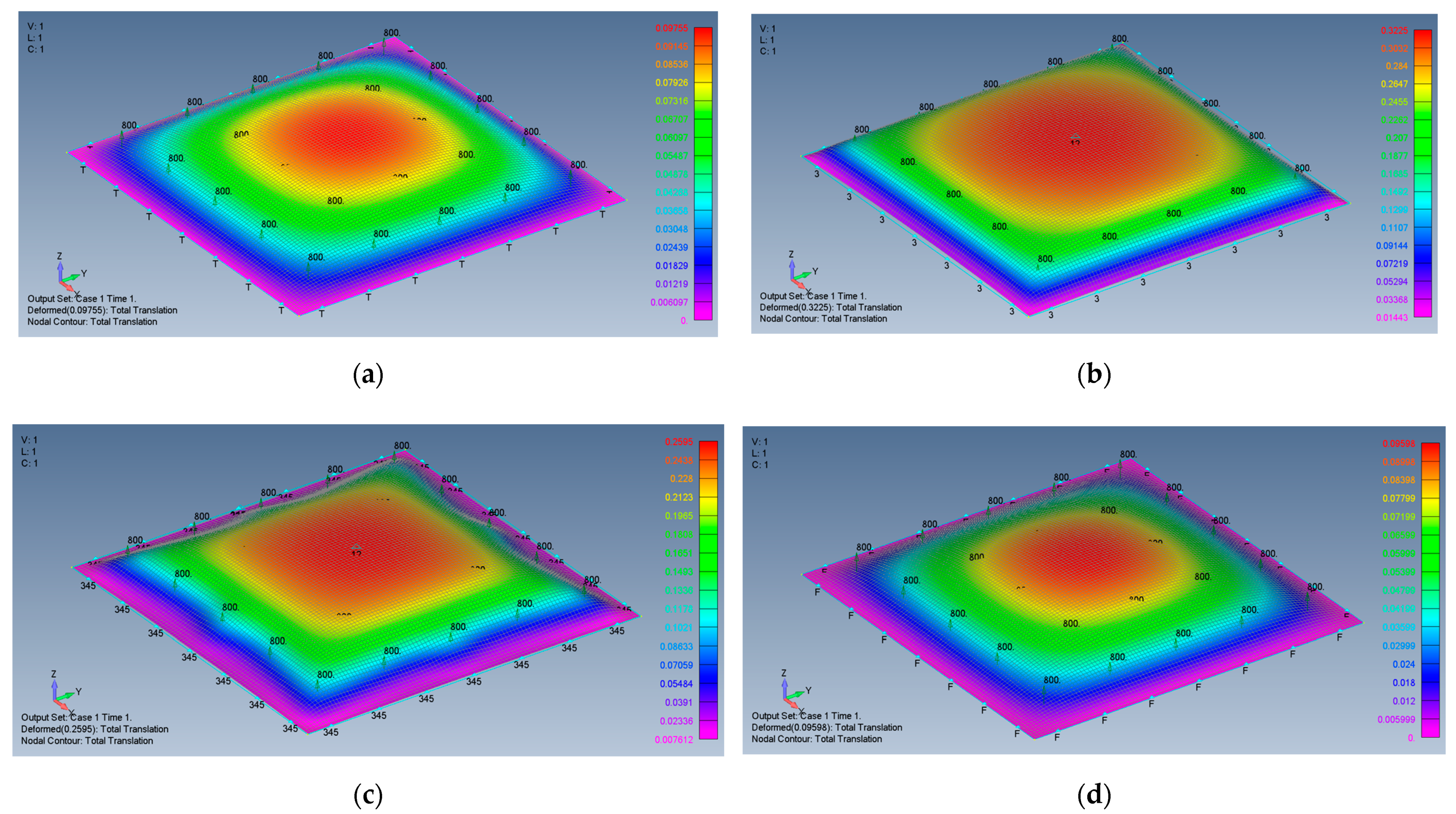

5.1. Square Plate (AR = 1)

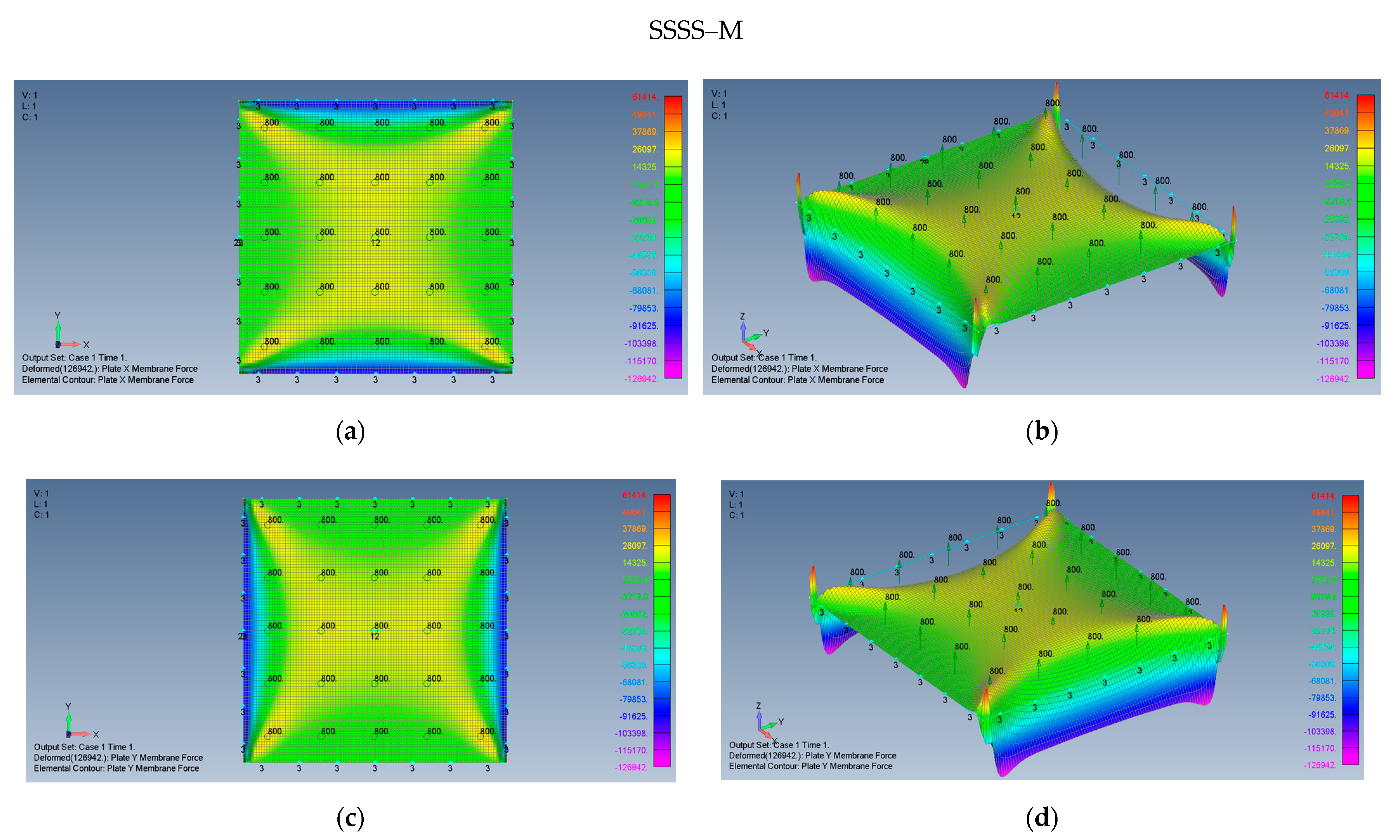

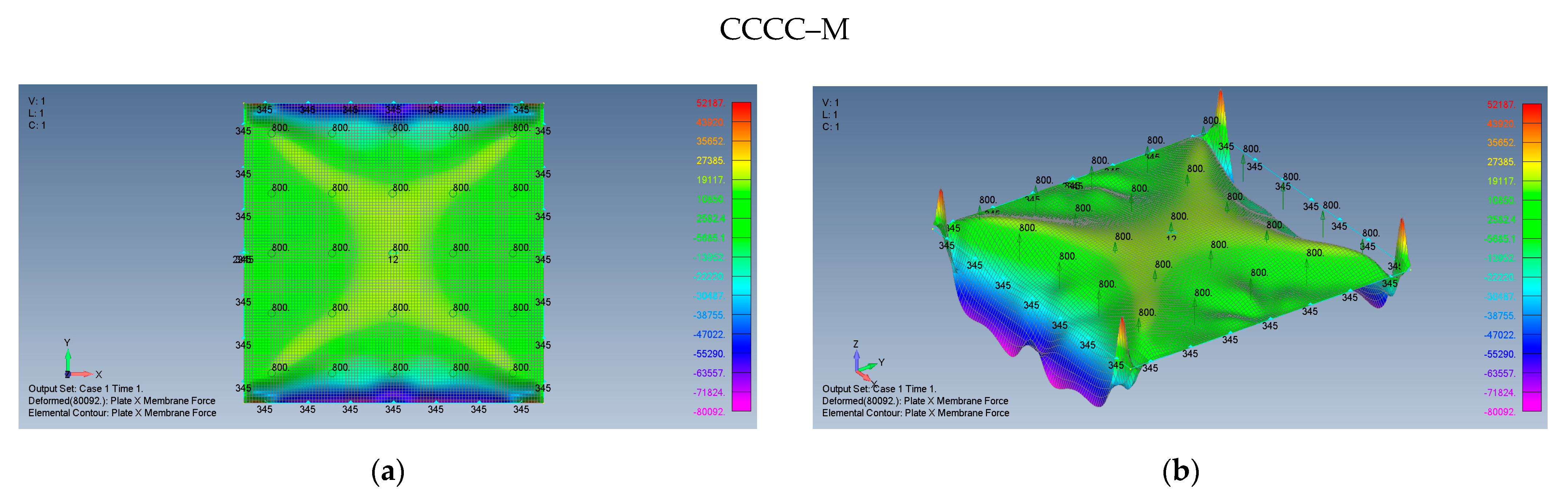

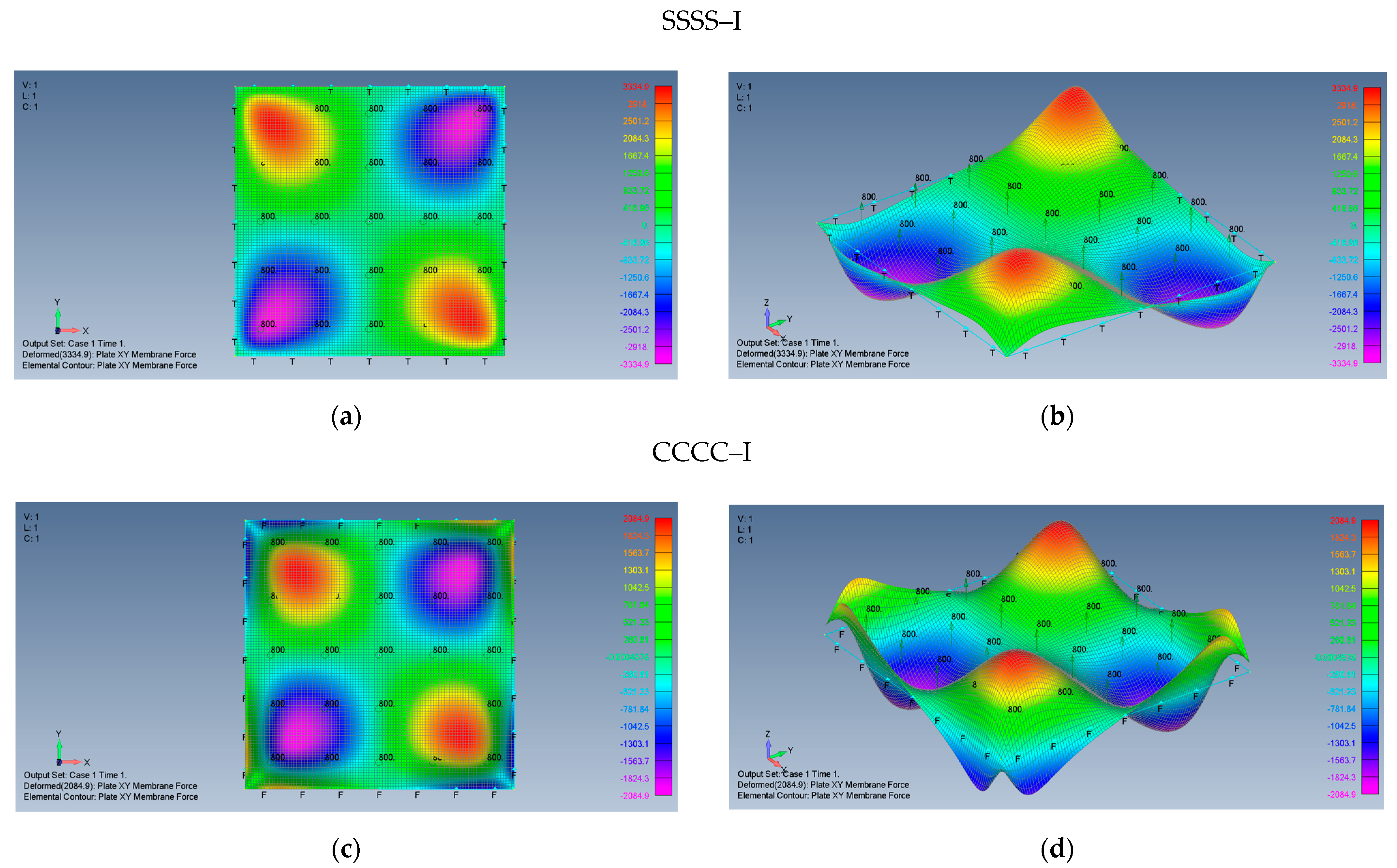

- The maps for the distributions of and membrane stresses are symmetrical relative to both x and y-axes.

- The middle plate area encounters tension stresses in both x and y directions, with moderate changes of the amplitude.

- At the plate edges, namely at high compression stress is visible, with a similar behavior at - high compression stress. The presence of compressive stresses on the plate’s edges might lead to local buckling at those areas.

- At the plate’s corners, very sharp changes in the stress amplitudes are encountered possibly due to the relatively coarse mesh at those locations, as the mesh distribution was kept constant across the plate.

- The maximal midpoint tensile stress (in both x and y directions) for the SSSS–M case is 1.684 MPa, while the maximal compression stress on the plate’s edges reaches the value of −10.767 MPa. For the CCCC–M case, those stresses reach the values of 1.518 MPa and −6.674 MPa, accordingly.

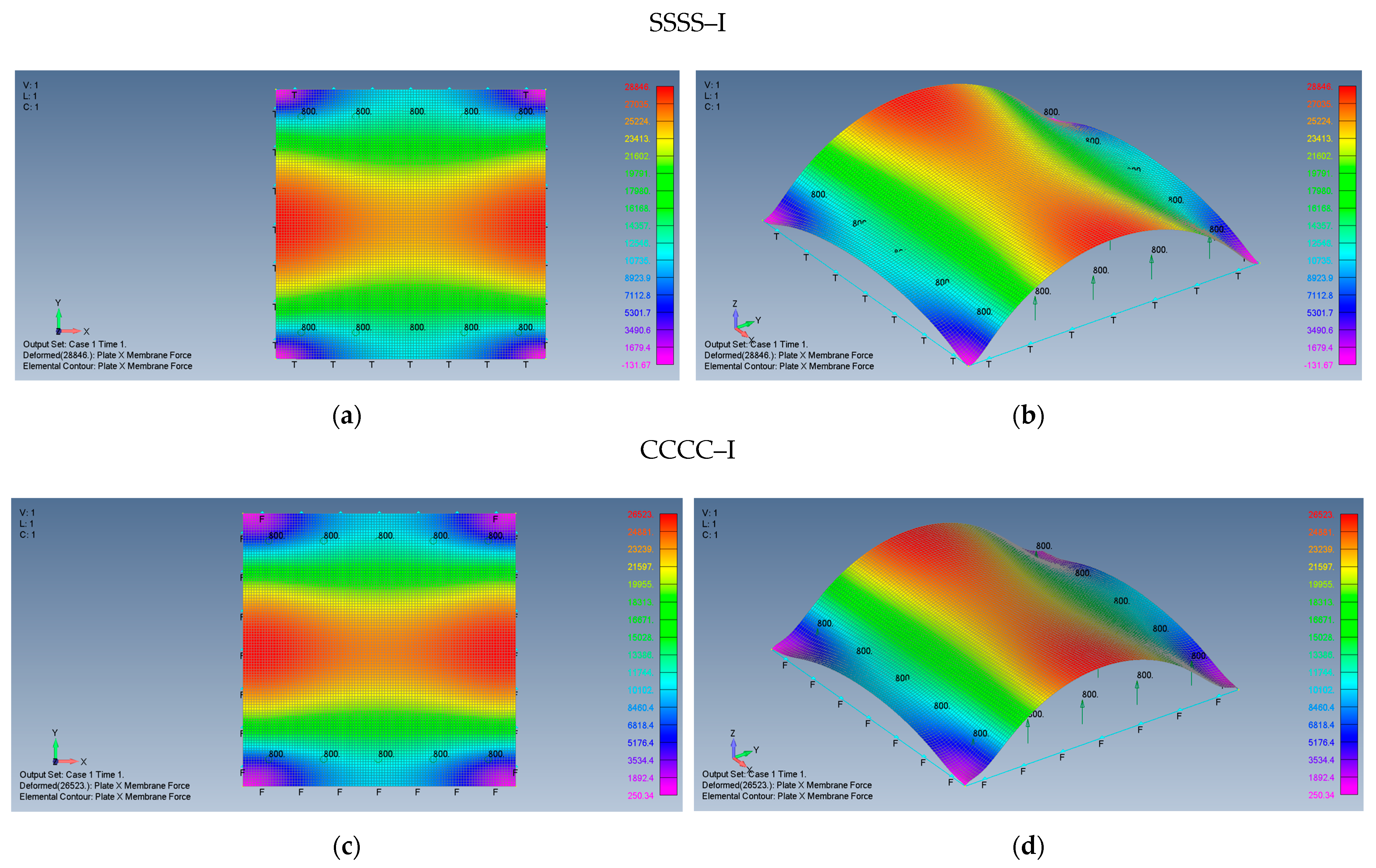

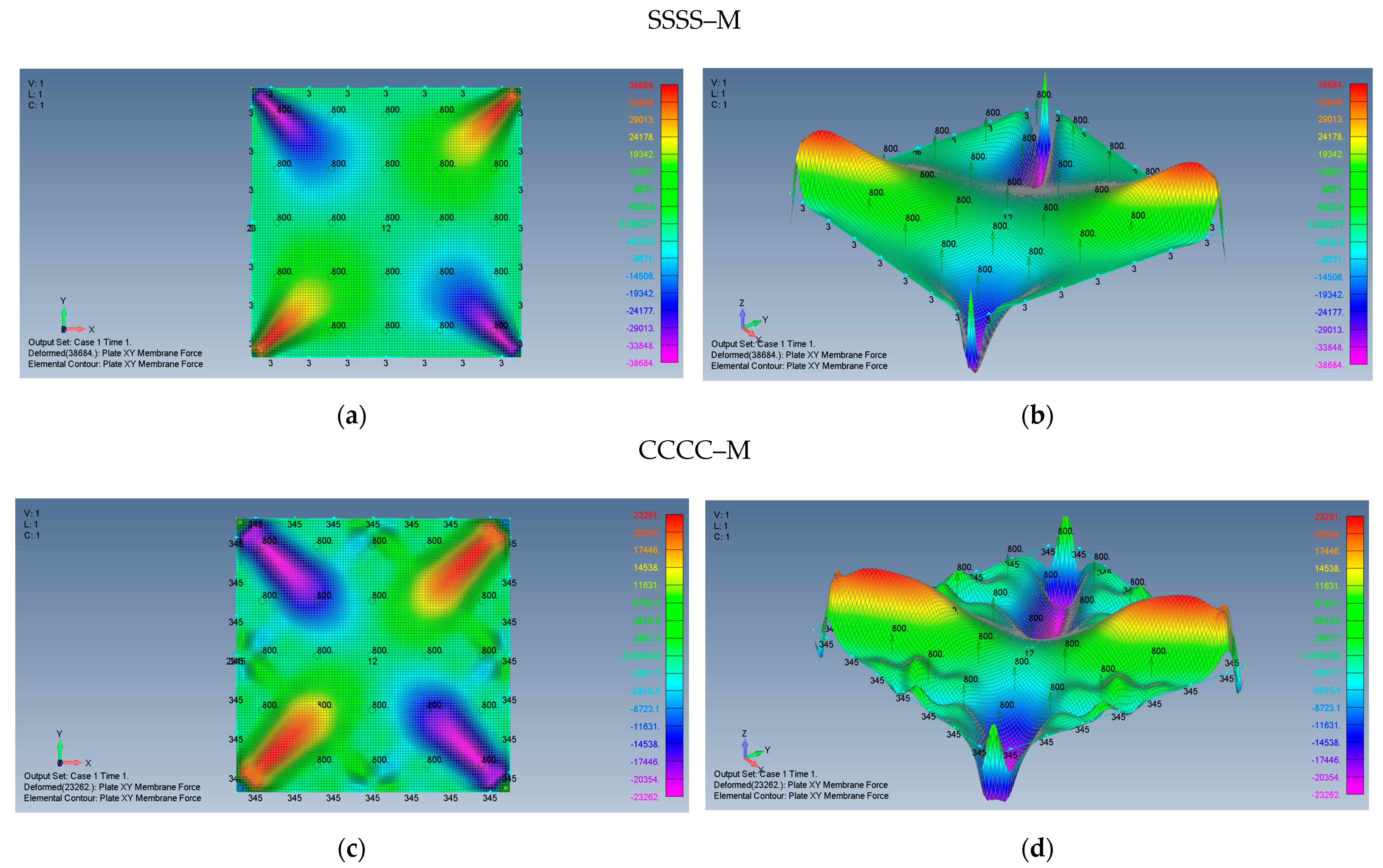

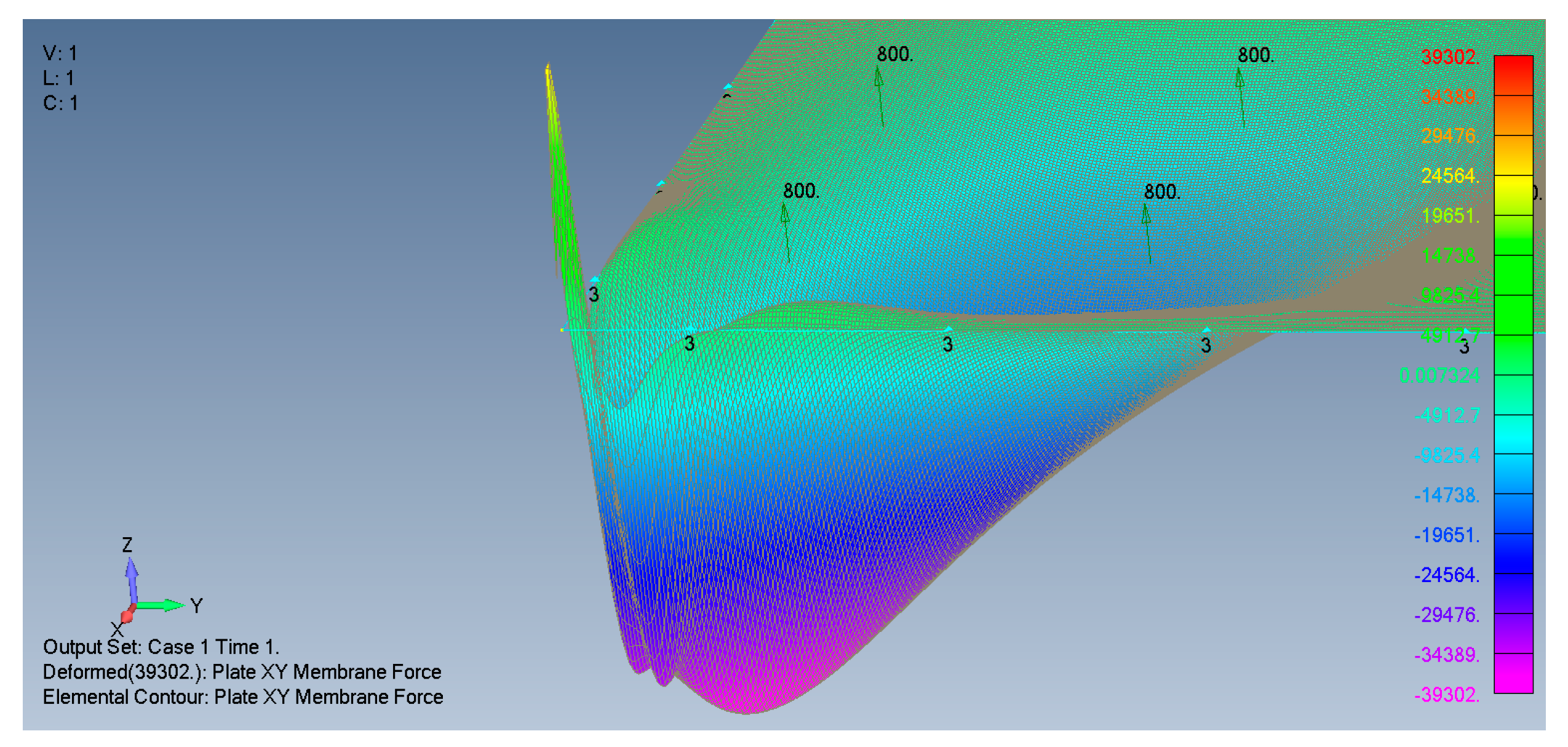

- The stress function is anti-symmetric relative to both x and y axes, namely . In addition, the function is symmetric relative to both square main diagonals, namely and its value along the x and y axes is zero.

- Although the boundary conditions for the movable cases (M) require on the plate edges, the calculated shear stresses near the edges is not zero. This discrepancy might be explained by remembering that the finite element membrane forces are calculated at the element mid-point, which is half width of the element distant from the edge.

- The maximal values of the shear stresses are located on the two main diagonals of the plate. For the SSSS–M case we get , while for CCCC–M boundary conditions we get . Changing the boundary conditions from movable (M) to immovable (I) drastically reduces the shear stresses, to yield for the SSSS–I a value of , while for the CCCC–I case a value of was calculated.

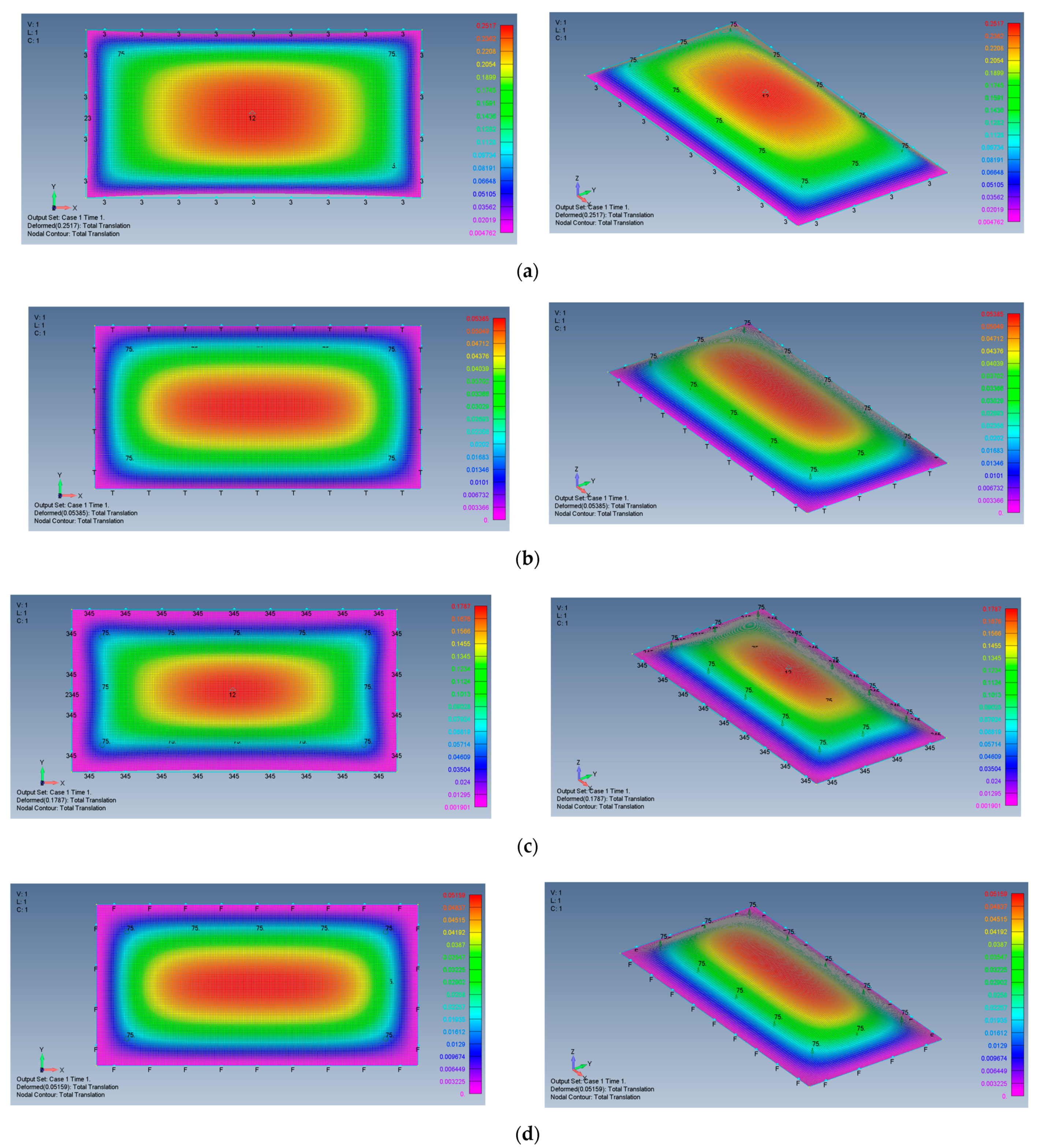

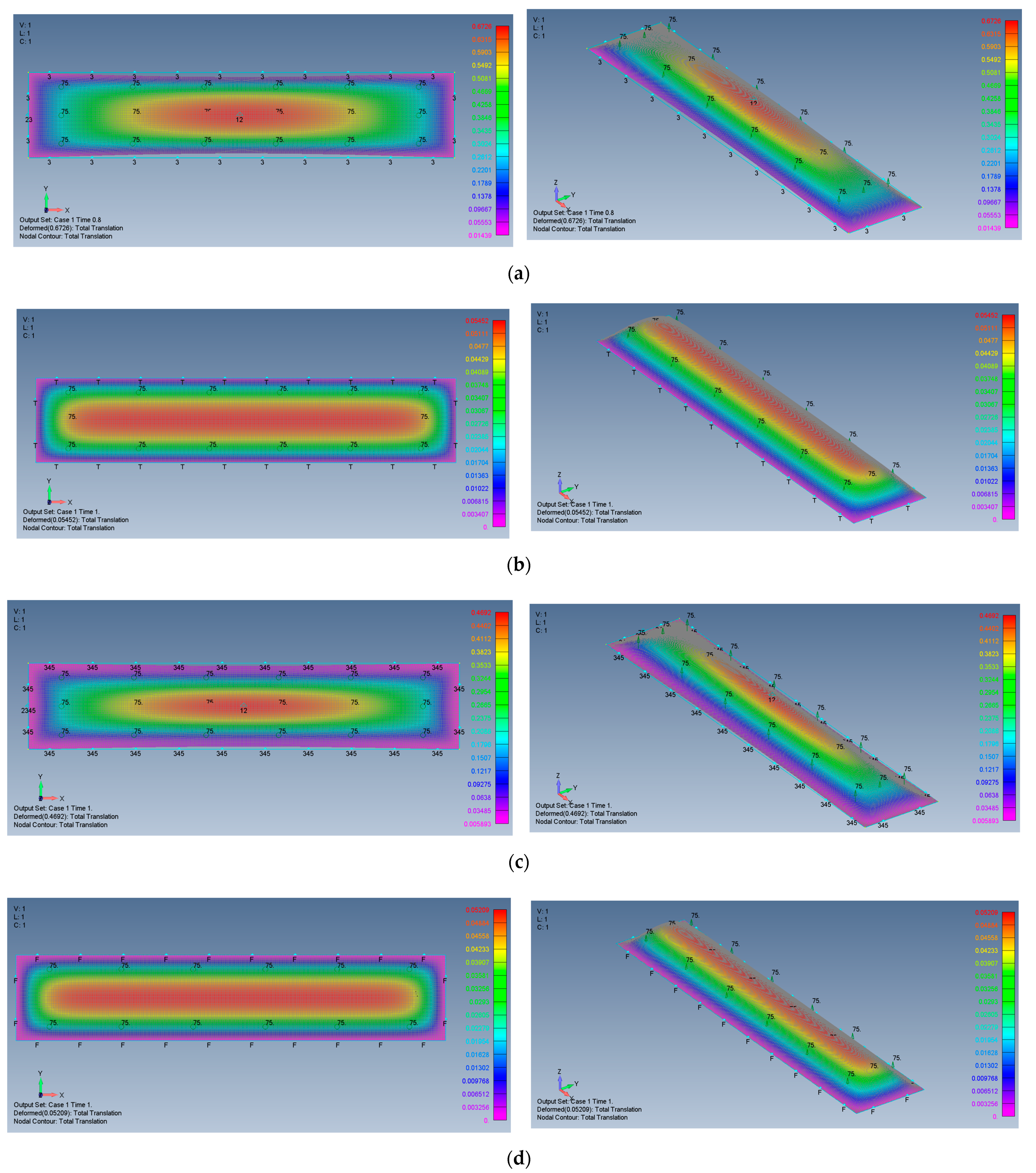

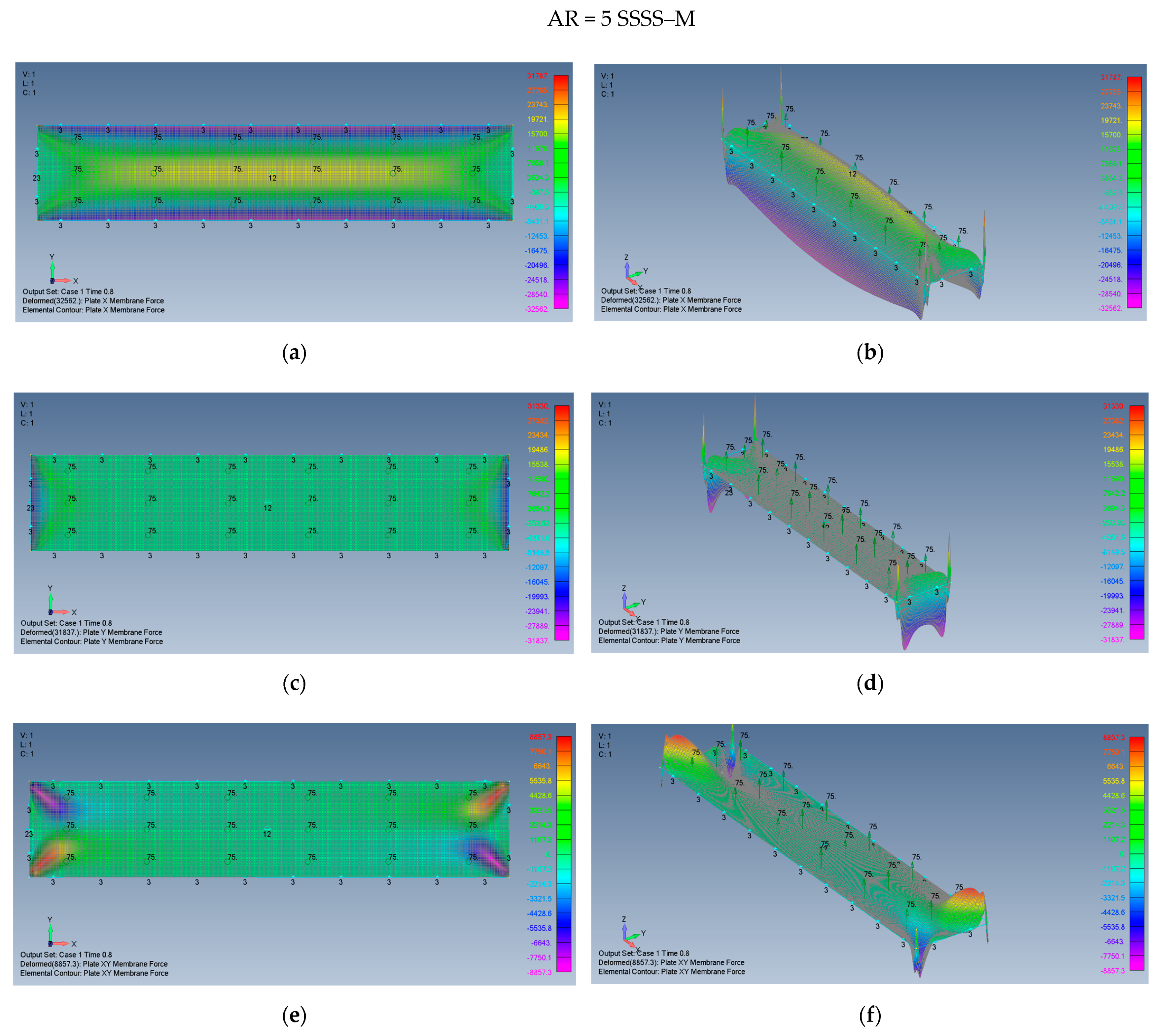

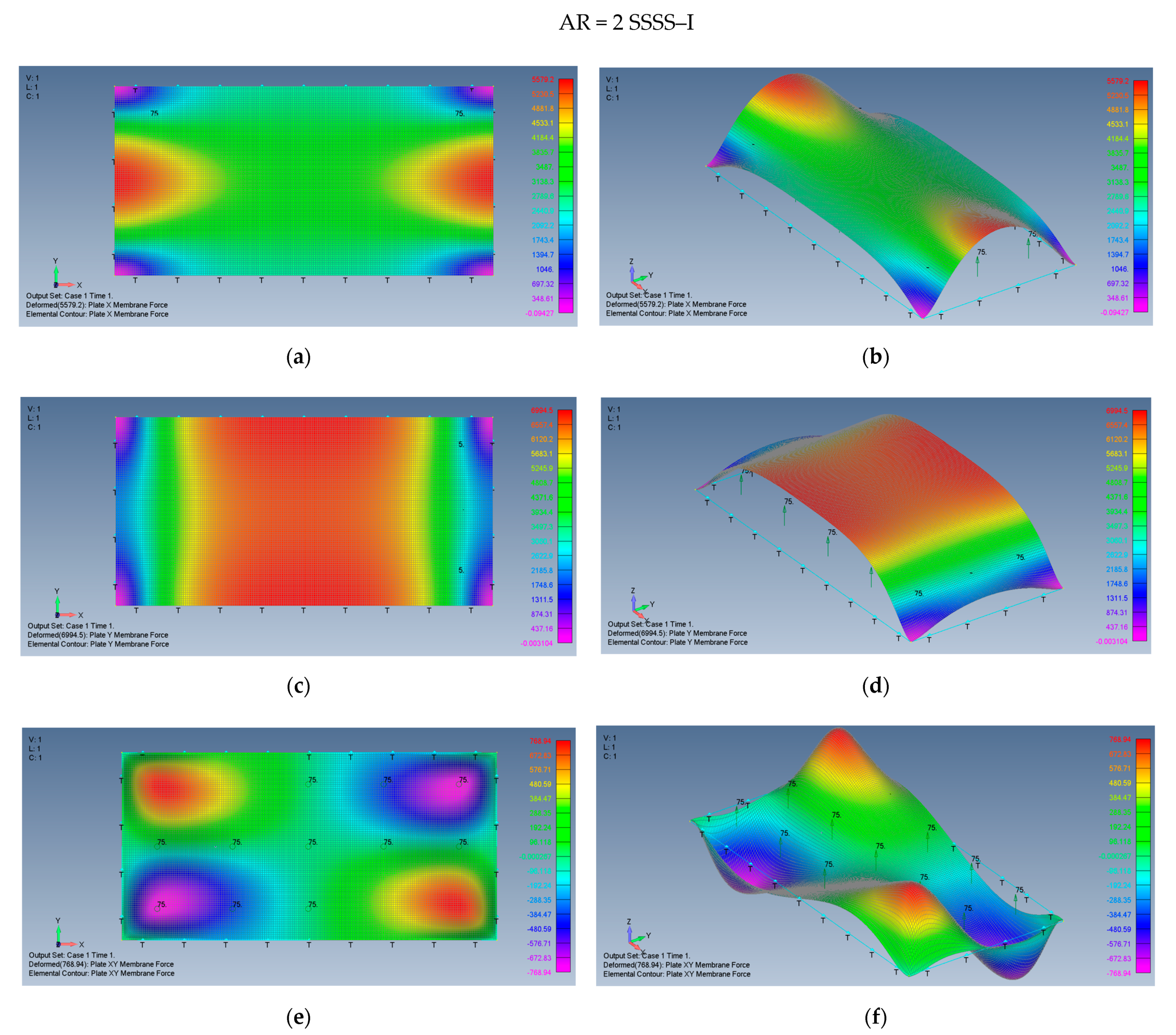

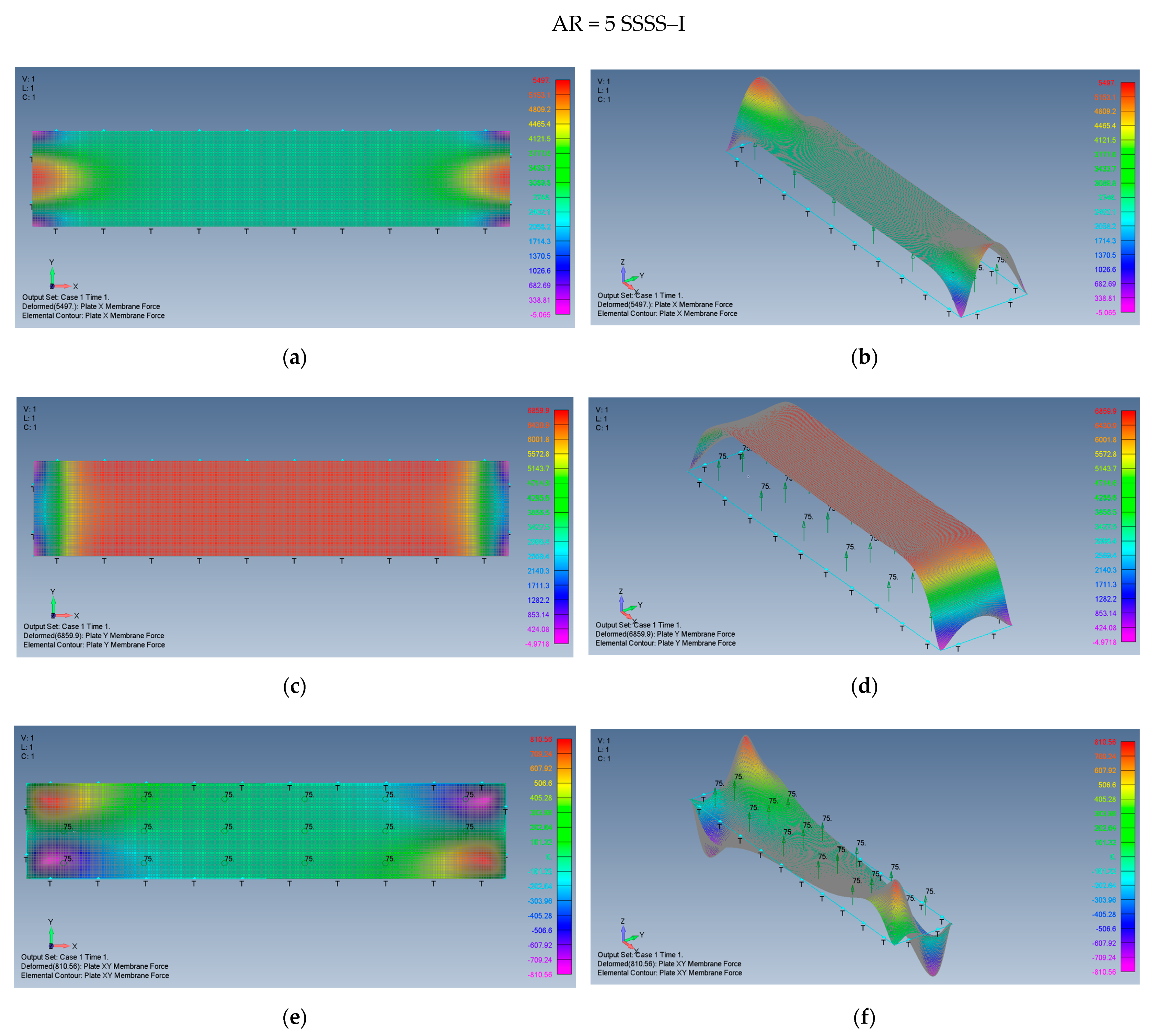

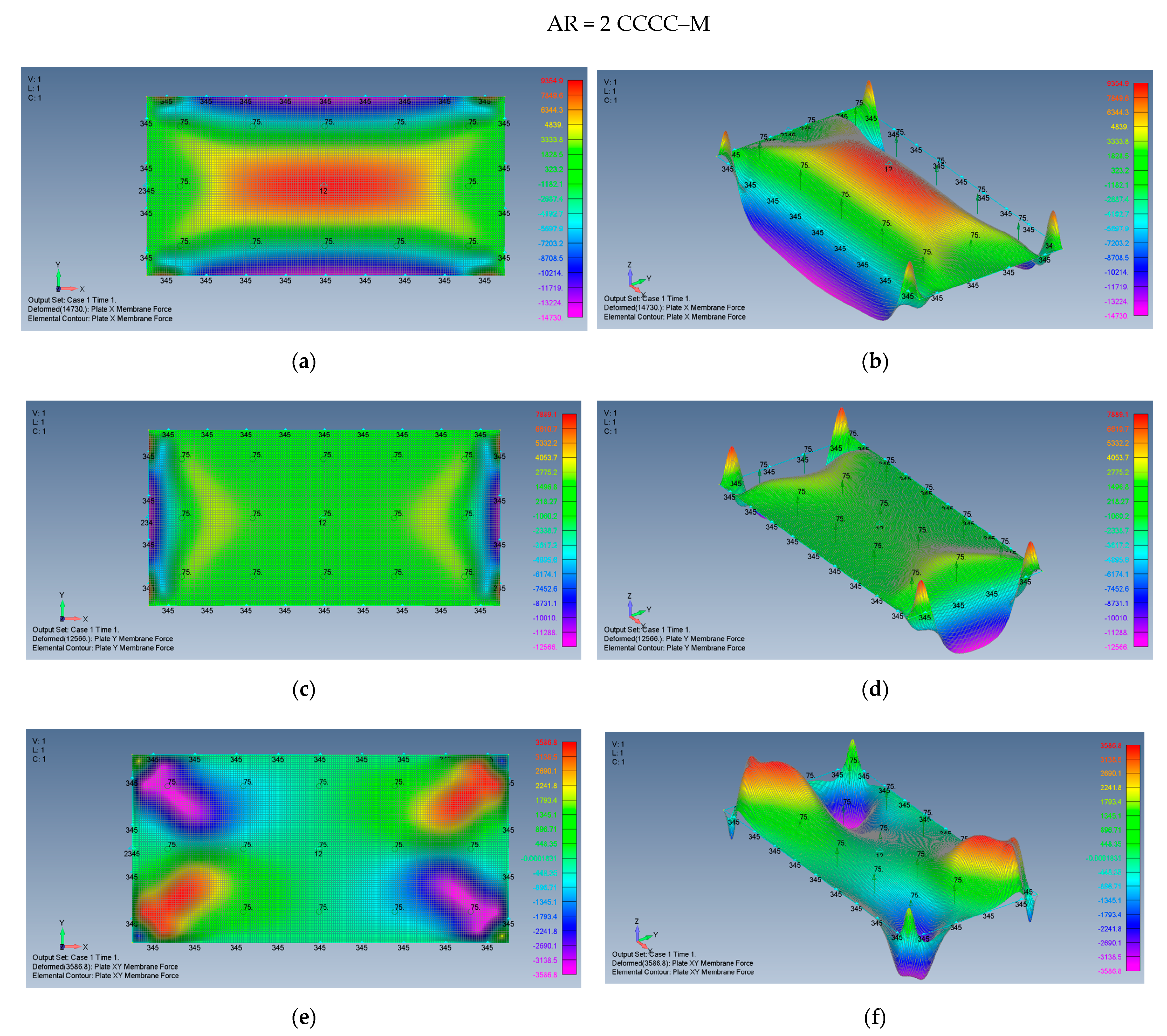

5.2. Rectangular Plates (AR = 2 and AR = 5)

6. Discussion and Conclusions

- The general shape of the plate deflection is rather similar for all the investigated cases. The various four applied boundary conditions do not significantly change the appearance of the deformed plate.

- Enabling the in-plane movement of the plate would generate higher membrane stresses for both SSSS and CCCC boundary conditions in comparison with restricting this movement yielding an immovable boundary condition.

- The stresses generated on the plate due to its large transverse deflections for the clamped cases CCCC–M and CCCC–I, are consistently lower than those on simply supported cases SSSS–M and SSSS–I (see Table 3).

- Compression stresses would appear on the plate edges for both movable SSSS and CCCC boundary conditions. This should be considered during the design of the plate, to prevent local buckling of the plate.

- To prevent local buckling of the plate, it is recommended to assure CCCC or SSSS immovable boundary conditions, leading to only tensile stresses.

- The existence of tensile stresses in the movable cases at relatively high aspect ratio AR = 5, suggests checking how these stresses asymptotically approach zero for the case of infinitely long plate, where the membrane tensile stress must be zero.

Author Contributions

Funding

Conflicts of Interest

References

- Kirchhoff, G. Vorlesungen über Mathematische Physik; Druck und Verlag von B.G. Teubner: Leipzig, Germany, 1876; 481p. [Google Scholar]

- Love, A.E.H. A Treatise on the Mathematical Theory of Elasticity; Dover Publications: Nassau County, NY, USA, 1944; 571p. [Google Scholar]

- Timoshenko, S.; Woinowsky-Krieger, S. Theory of Plates and Shells, 2nd ed.; McGraw-Hill Book Company: NewYork, NY, USA, 1987; 611p. [Google Scholar]

- Von Kármán, T. Festigkeitsprobleme im Maschinenbau (Strength Problems in Mechanical Engineering); Encyclopädie der Mathematischen Wissenschaften, B.G. Teubner Verlag: Leipzig, Germany, 1910; pp. 311–385. [Google Scholar]

- Föppl, A. Vorlesungen über technische Mechanik (Lectures on Technical Mechanics); Bd. 5, B.G. Teubner.: Leipzig, Germany, 1907; p. 132. [Google Scholar]

- Bakker, M.; Rosmanit, M.; Hofmeyer, H. Approximate large-deflection analysis of simply supported rectangular plates under transverse loading using plate post-buckling solutions. Thin-Walled Struct. 2008, 46, 1224–1235. [Google Scholar] [CrossRef]

- Marguerre, K. Zur theorie der gekrümmter platte grosser formänderung (On the theory of curved plate with large displacements). In Proceedings of the 5th International Congress for Applied Mechanics, Cambridge, MA, USA, 12–26 September 1938; pp. 93–101. [Google Scholar]

- Ramberg, W.; McPherson, E.A.; Levy, S. Normal-Pressure Tests of Rectangular Plates; NACA Report 748; National Bureau of Standards: Washington, DC, USA, 1941; 24p.

- Levy, S. Bending of Rectangular Plates with Large Deflections; NACA Report 737; NACA, National Bureau of Standards: Washington, DC, USA, 1942; 19p.

- Levy, S. Bending of Rectangular Plates with Large Deflections; NACA Report 846; NACA, National Bureau of Standards: Washington, DC, USA, 1942; 47p.

- Levy, S.; Greenman, S. Bending of Large Deflection of Clamped Rectangular Plate with Length-Width Ratio of 1.5 under Normal Pressure; NACA TN-853; NACA, National Bureau of Standards: Washington, DC, USA, 1942; 47p.

- Levy, S. Large Deflection Theory of Curved Sheet; NACA TN-895; NACA, National Bureau of Standards: Washington, DC, USA, 1943; 30p.

- Wang, C.T. Nonlinear Large-Deflection Boundary-Value Problems of Rectangular Plates; NACA TN-1425; NACA, National Bureau of Standards: Washington, DC, USA, 1948; 113p.

- Wang, C.T. Bending of Rectangular Plates with Large Deflections; NACA TN-1462; NACA, National Bureau of Standards: Washington, DC, USA, 1948; 34p.

- Yen, K.T.; Gunturkum, S.; Pohle, V.F. Deflections of Simply Supported Rectangular Sandwich Plate Subjected to Transverse Loads; NACA TN-2581; NACA, National Bureau of Standards: Washington, DC, USA, 1951; 39p.

- Berger, M.H. A New Approach to the Analysis of Large Deflections of Plates. Ph.D. Thesis, California Institute of Technology, Pasadena, CA, USA, 1954; 68p. [Google Scholar]

- Scholes, A.; Bernstein, E.L. Bending of normally loaded simply supported rectangular plates in the large-deflection range. J. Strain Anal. 1969, 4, 190–198. [Google Scholar] [CrossRef]

- Scholes, A. Application of large-deflection theory to normally loaded rectangular plates with clamped edges. J. Strain Anal. 1970, 5, 140–144. [Google Scholar] [CrossRef]

- Li-Zhou, P.; Shu, W. A perturbation-variational solution of the large deflection of rectangular plates under uniform load. Appl. Math. Mech. 1986, 7, 727–740. [Google Scholar] [CrossRef]

- Bert, C.W.; Jang, S.K.; Striz, A.G. Nonlinear bending analysis of orthotropic rectangular plates by the method of differential quadrature. Comput. Mech. 1989, 5, 217–226. [Google Scholar] [CrossRef]

- Yeh, F.; Liu, W. Nonlinear analysis of rectangular orthotropic plates. Int. J. Mech. Sci. 1991, 33, 563–578. [Google Scholar] [CrossRef]

- Wang, D.; El-Sheikh, A.I. Large-Deflection Mathematical Analysis of Rectangular Plates. J. Eng. Mech. 2005, 131, 809–821. [Google Scholar] [CrossRef]

- Ugural, A.C. Plates and Shells Theory and Analysis; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Boca Raton, FL, USA, 2018. [Google Scholar]

- Razdolsky, A.G. Large Deflections of Elastic Rectangular Plates. Int. J. Comput. Methods Eng. Sci. Mech. 2015, 16, 354–361. [Google Scholar] [CrossRef]

- Turvey, G.; Osman, M. Elastic large deflection analysis of isotropic rectangular Mindlin plates. Int. J. Mech. Sci. 1990, 32, 315–328. [Google Scholar] [CrossRef]

- Paik, J.K.; Park, J.H.; Kim, B.J. Analysis of the Elastic Large Deflection Behavior for Metal Plates under Nonuniformly Distributed Lateral Pressure with In-Plane Loads. J. Appl. Math. 2012, 2012, 734521. [Google Scholar] [CrossRef]

- Nishawala, V.V. A Study of Large Deflection of Beams and Plates. Master’s Thesis, The State University of New Jersey, New Brunswick, NJ, USA, 2011. [Google Scholar]

- Ye, J. Large Deflection of Imperfect Plates by Iterative Be-Fe Method. J. Eng. Mech. 1994, 120, 431–444. [Google Scholar] [CrossRef]

- Abayakoon, S.B.S. Large Deflection Elastic-Plastic Analysis of Plate Structures by the Finite Strip Method. Ph.D. Thesis, Department of Civil Engineering, The University of British Columbia, Vancouver, BC, Canada, 1987. [Google Scholar]

- Seide, P. Large Deflections of Prestressed Simply Supported Rectangular Plates Under Uniform Pressure. Int. J. Non-Linear Mech. 1978, 13, 145–156. [Google Scholar] [CrossRef]

- Parker, H.P. A Numerical Solution to the General Large Deflection Plate Equations. SAE Trans. 1966, 74, 236–243. [Google Scholar]

- Belardi, V.G.; Fanelli, P.; Vivio, F. On the radial bending of shear-deformable composite circular plates with rectilinear orthotropy. Eur. J. Mech. Solids 2021, 86, 104157. [Google Scholar] [CrossRef]

- Plaut, R.H. Generalized Reissner analysis of large axisymmetric deflections of thin circular and annular plates. Int. J. Solids Struct. 2020, 203, 131–137. [Google Scholar] [CrossRef]

- Shufrin, I.; Rabinovitch, O.; Eisenberger, M. A semi-analytical approach for the non-linear large deflection analysis of laminated rectangular plates under general out-of-plane loading. Int. J. Non-Linear Mech. 2008, 43, 328–340. [Google Scholar] [CrossRef]

- Siemens Simcenter Femap with Nastran Ver. 2021.1, Siemens Digital Industries Software, siemens.com/software, 2021. Available online: https://www.plm.automation.siemens.com/global/en/products/simcenter/femap.html (accessed on 2 January 2022).

- Erochko, J. An Introduction to Structural Analysis, 1st ed.; Carleton University: Ottawa, ON, Canada, 2020; 384p. [Google Scholar]

- Siemens. Simcenter Nastran Basic Nonlinear Analysis User’s Guide; Siemens Industry Software: Plano, TX, USA, 2020; Available online: https://docs.plm.automation.siemens.com/data_services/resources/scnastran/2020_1/help/tdoc/en_US/pdf/basic_nonlinear.pdf (accessed on 18 January 2022).

| Mesh Size | Number of Elements in the Mesh | Calculation Duration [min] | Mid-Point Deflection % | Max X Force % | Mid-Point X Force % |

|---|---|---|---|---|---|

| 10 × 10 | 100 | 0.183 | 83.468% | 78.516% | 98.617% |

| 20 × 20 | 400 | 0.267 | 93.709% | 83.567% | 99.647% |

| 50 × 50 | 2500 | 0.533 | 99.030% | 94.438% | 99.988% |

| 100 × 100 | 10,000 | 1.97 | 99.766% | 98.249% | 99.998% |

| 200 × 200 | 40,000 | 8.92 | 99.942% | 99.568% | 99.999% |

| 500 × 500 | 250,000 | 162 | 100% | 100% | 100% |

| Boundary Conditions | SSSS—M | SSSS—I | CCCC—M | CCCC—I |

|---|---|---|---|---|

| Mid-point deflection w0, mm | 322.0 | 97.6 | 259.0 | 96.0 |

| w0/t | 26.83 | 8.13 | 21.58 | 8.0 |

| Aspect Ratio (AR) | 1 | 2 | 5 |

| Distributed Load q [Pa] | 800 | 75 | 75 |

| Boundary Conditions | SSSS–M | ||

| [MPa] tensile stress @ plate midpoint | 1.684 | 0.906 | 1.880 |

| [MPa] tensile stress @ plate midpoint | 1.684 | 0.0684 | 0.0126 |

| [MPa] compression stress @ plate edges | −10.767 | −2.077 | −2.713 |

| [MPa] compression stress @ plate edges | −10.767 | −2.087 | −2.653 |

| [MPa] shear stress @ 45° line from the corner | ±3.224 | ±0.607 | ±0.738 |

| Boundary Conditions | SSSS–I | ||

| [MPa] tensile stress @ plate midpoint | 2.095 | 0.295 | 0.217 |

| [MPa] tensile stress @ plate midpoint | 2.095 | 0.553 | 0.558 |

| [MPa] tensile stress @ plate edges | 2.404 | 0.465 | 0.458 |

| [MPa] tensile stress @ plate edges | 2.404 | 0.583 | 0.572 |

| [MPa] shear stress @ 45° line from corner | ±0.278 | ±0.064 | ±0.068 |

| Boundary Conditions | CCCC–M | ||

| [MPa] tensile stress @ plate midpoint | 1.584 | 0.780 | 1.111 |

| [MPa] tensile stress @ plate midpoint | 1.584 | 0.0629 | 0.00760 |

| [MPa] compression/tensile stress @ plate edges | −6.674 | −1.227 | −1.576/+1.533 |

| [MPa] compression/tensile stress @ plate edges | −6.674 | −1.047 | −1.176/+1.506 |

| [MPa] @ 45° line from corner into plate | ±1.938 | ±0.299 | ±0.371 |

| Boundary Conditions | CCCC–I | ||

| [MPa] tensile stress @ plate midpoint | 1.993 | 0.261 | 0.192 |

| [MPa] tensile stress @ plate midpoint | 1.993 | 0.490 | 0.494 |

| [MPa] compression stress @ plate edges | 2.037 | 0.377 | 0.370 |

| [MPa] compression stress @ plate edges | 2.037 | 0.515 | 0.505 |

| [MPa] shear stress @ 45° line from corner | ±0.174 | ±0.0352 | ±0.0388 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hakim, G.; Abramovich, H. Large Deflections of Thin-Walled Plates under Transverse Loading—Investigation of the Generated In-Plane Stresses. Materials 2022, 15, 1577. https://doi.org/10.3390/ma15041577

Hakim G, Abramovich H. Large Deflections of Thin-Walled Plates under Transverse Loading—Investigation of the Generated In-Plane Stresses. Materials. 2022; 15(4):1577. https://doi.org/10.3390/ma15041577

Chicago/Turabian StyleHakim, Gilad, and Haim Abramovich. 2022. "Large Deflections of Thin-Walled Plates under Transverse Loading—Investigation of the Generated In-Plane Stresses" Materials 15, no. 4: 1577. https://doi.org/10.3390/ma15041577

APA StyleHakim, G., & Abramovich, H. (2022). Large Deflections of Thin-Walled Plates under Transverse Loading—Investigation of the Generated In-Plane Stresses. Materials, 15(4), 1577. https://doi.org/10.3390/ma15041577