Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes

Abstract

:1. Introduction

2. Materials and Methods

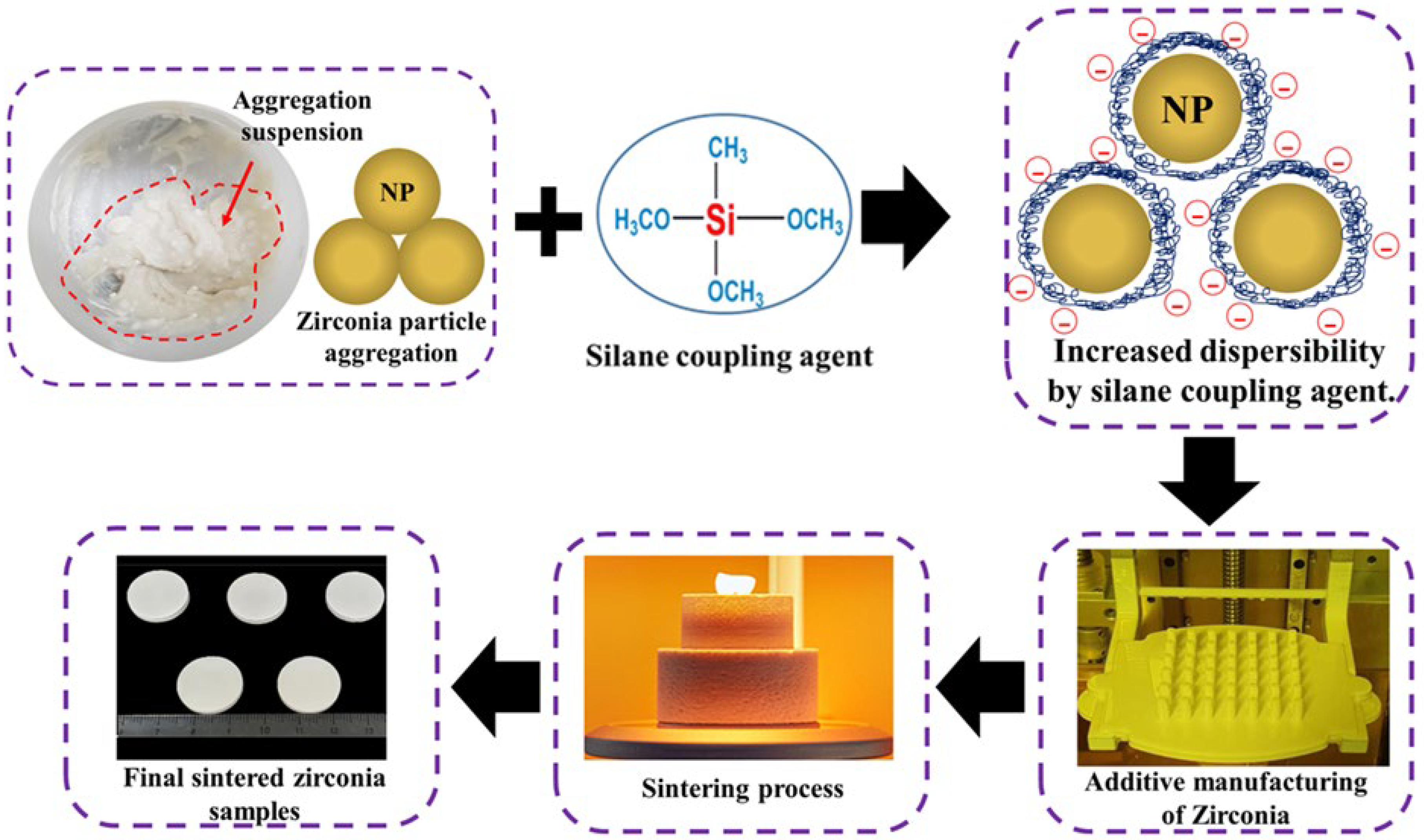

2.1. Preparation of Zirconia Photocurable Suspension

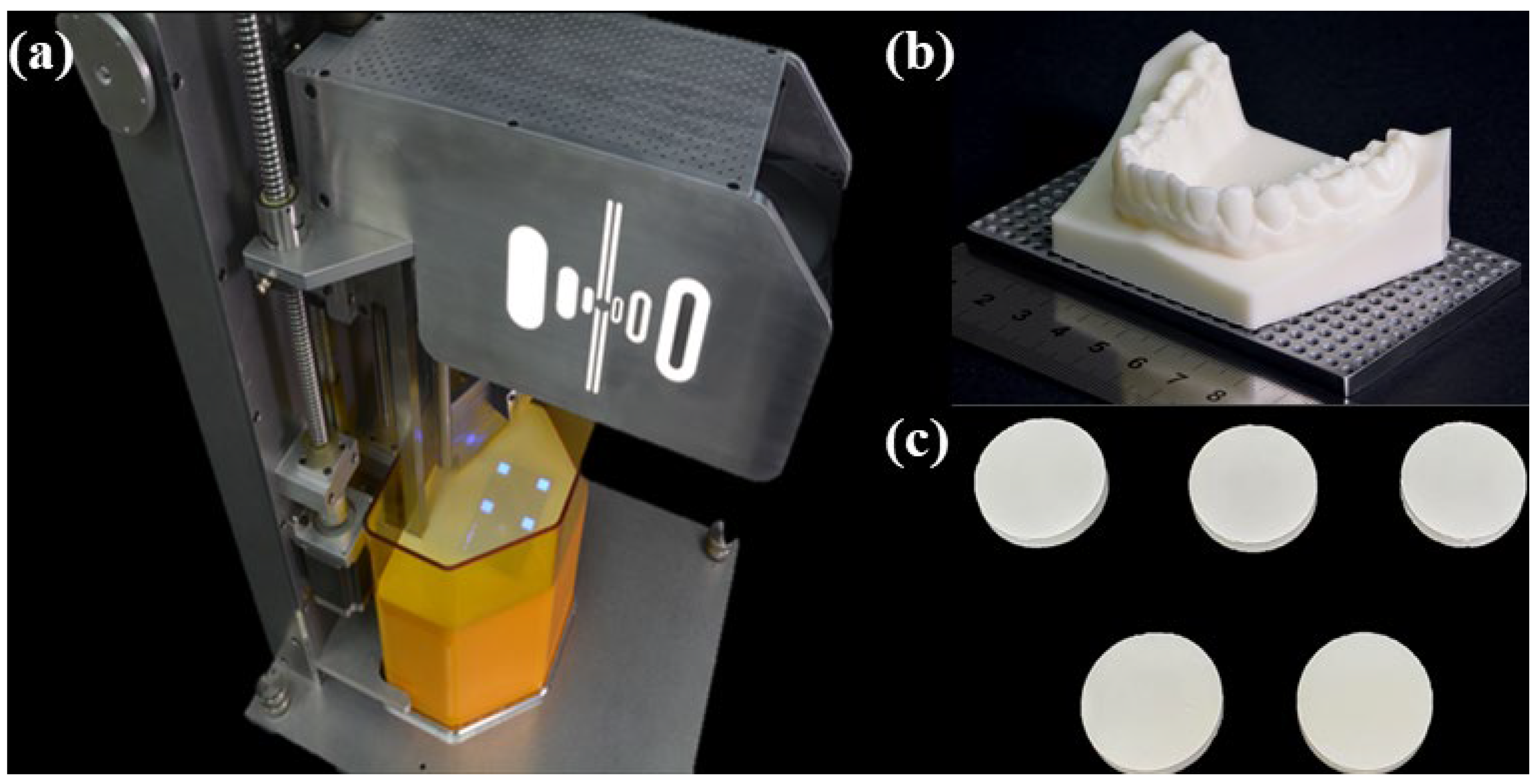

2.2. Zirconia Samples Fabrication Using Additive Manufacturing

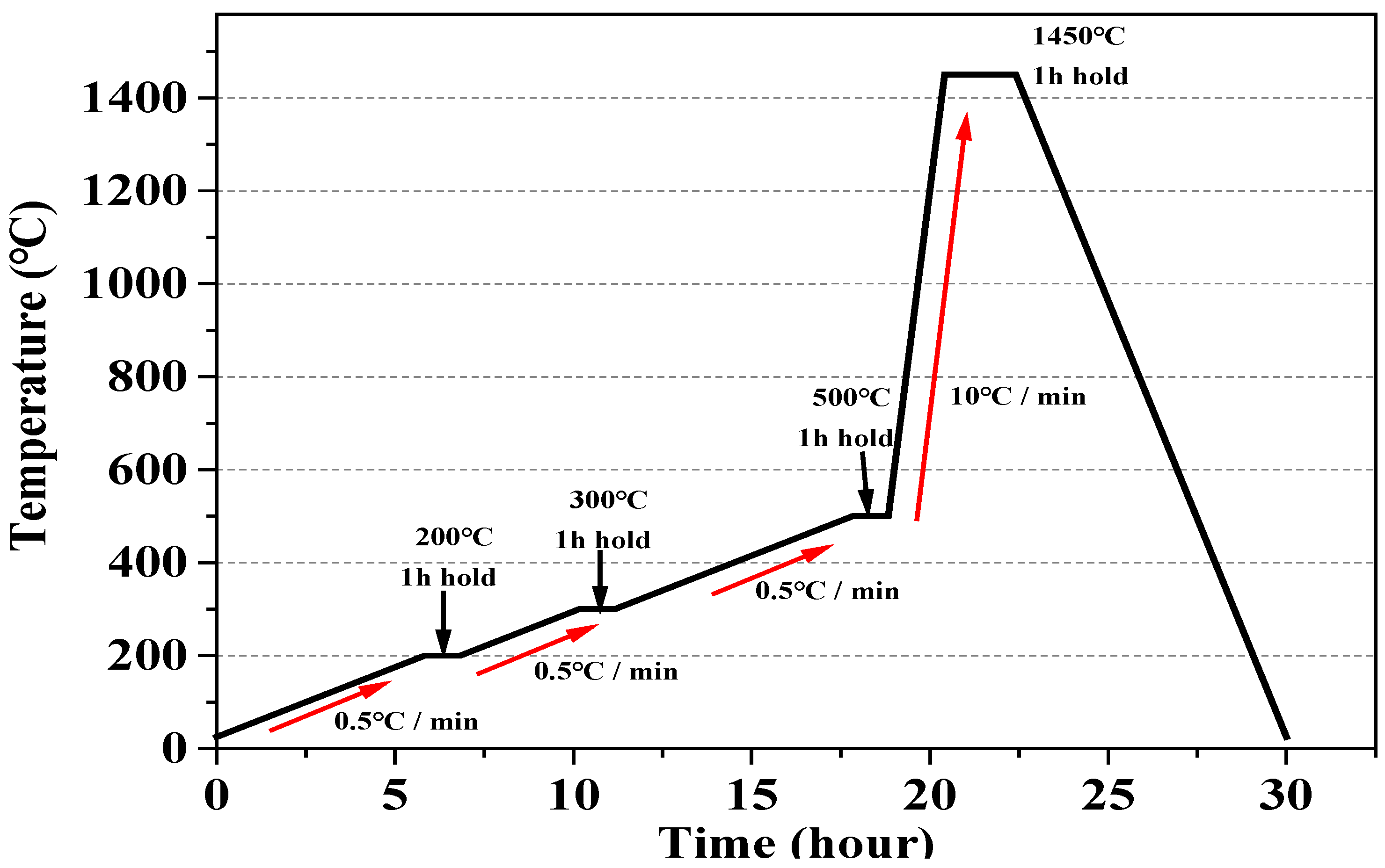

2.3. Degreasing and Sintering of Zirconia Samples

2.4. Linear Shrinkage

2.5. Relative Density Measurement

2.6. Hardness

2.7. Biaxial Flexural Strength

2.8. Evaluation of Microstructure of Final Sintered Zirconia Samples

2.9. Statistical Analysis

3. Results

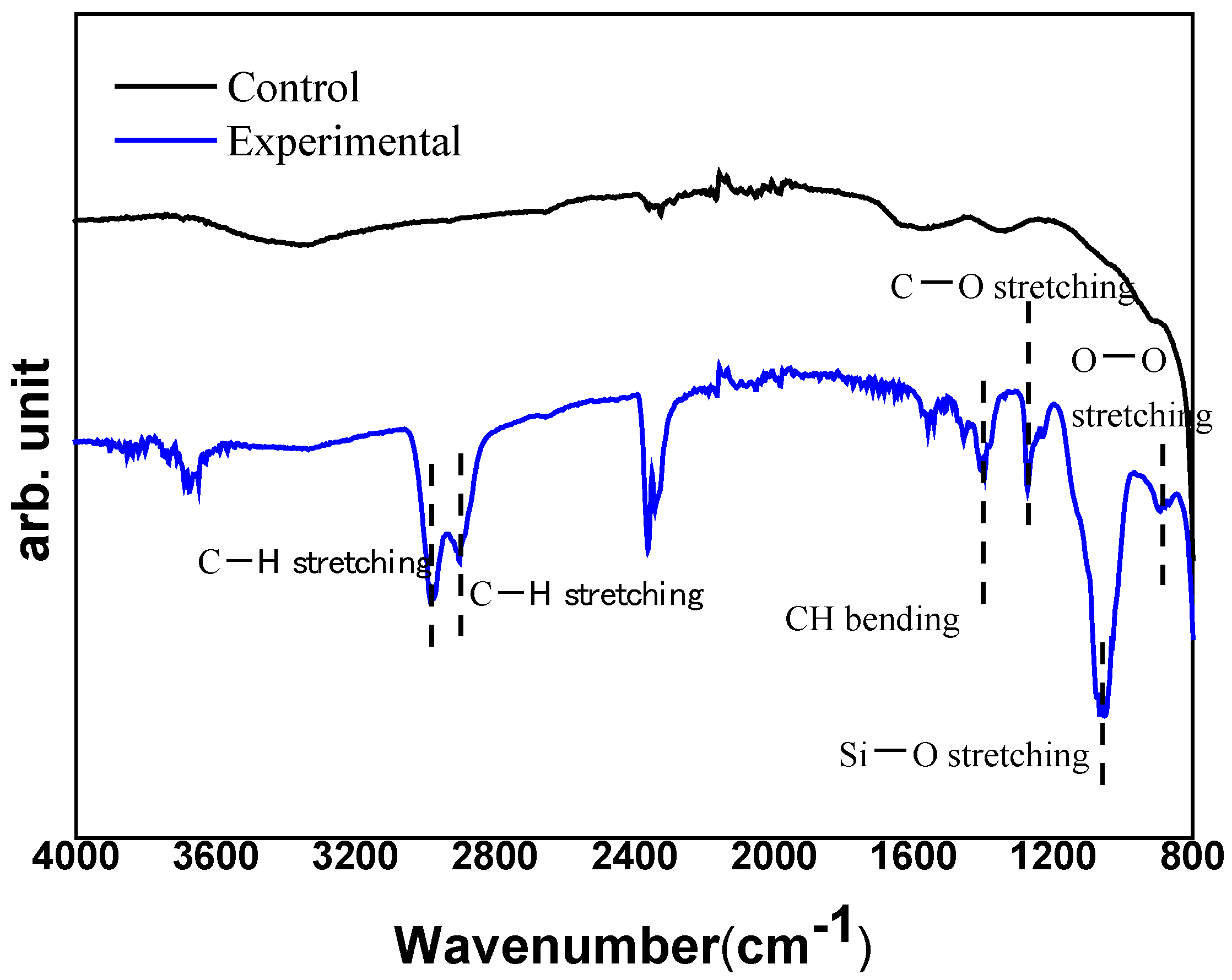

3.1. FT-IR Analysis

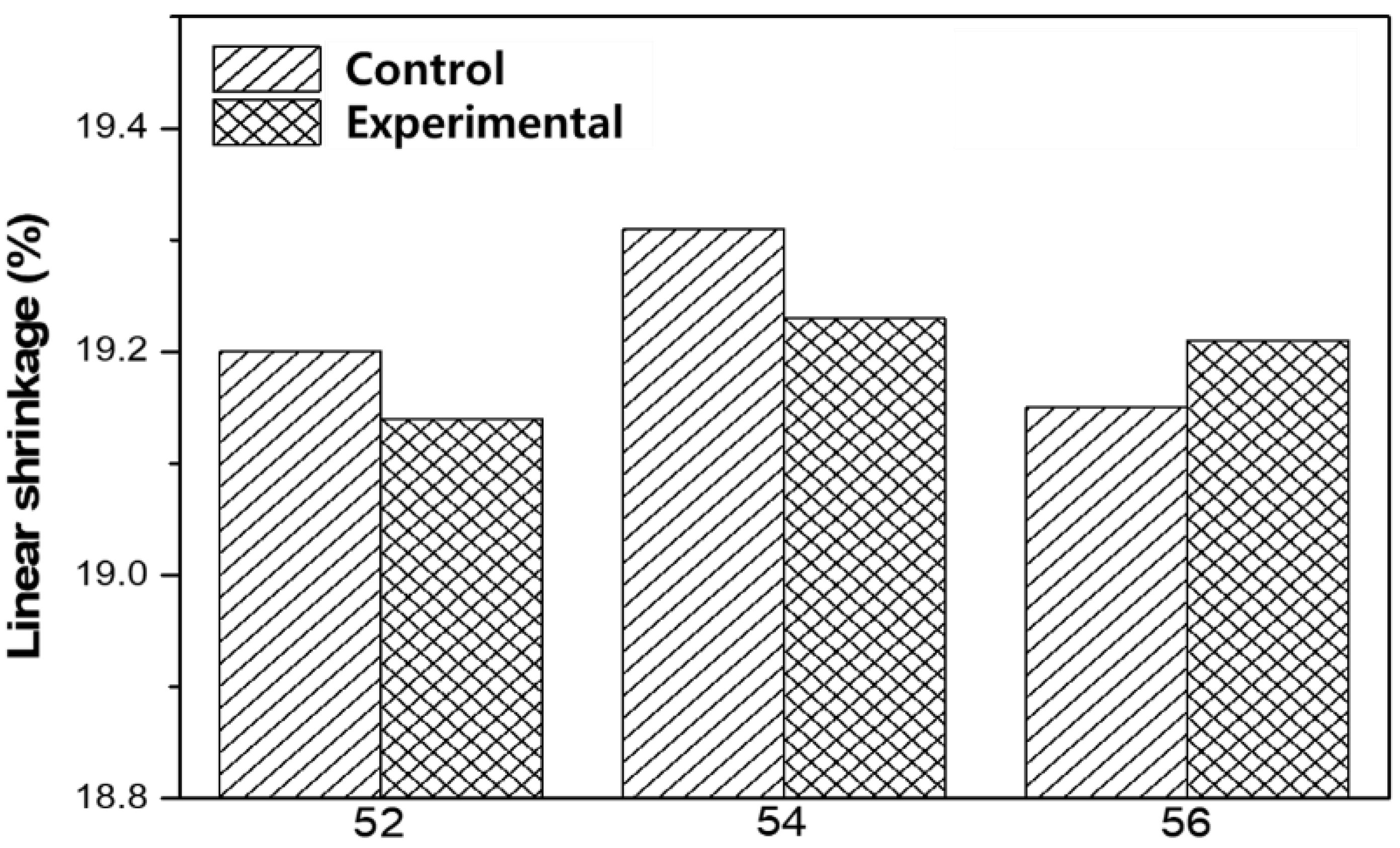

3.2. Linear Shrinkage

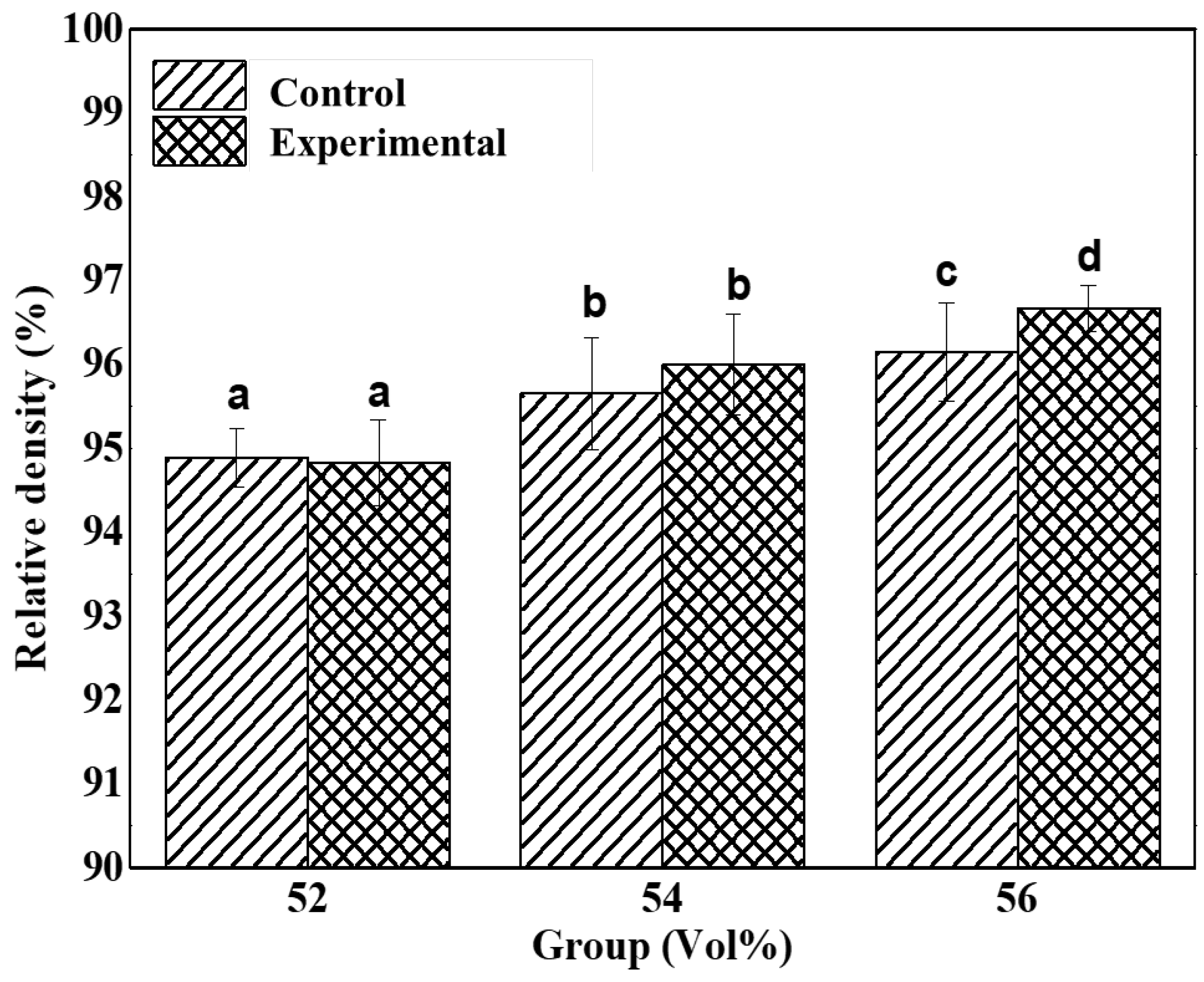

3.3. Relative Density

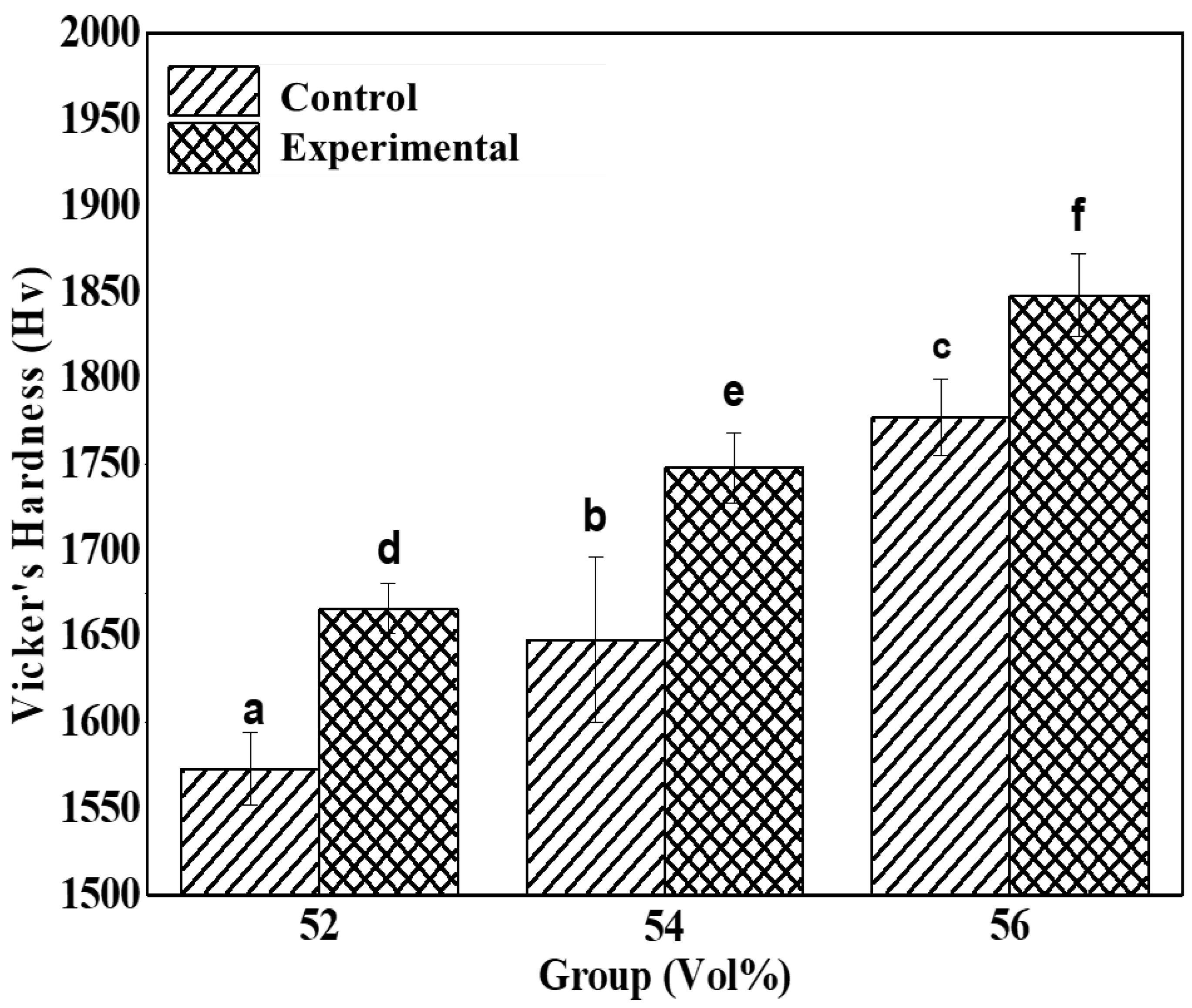

3.4. Hardness Measurement

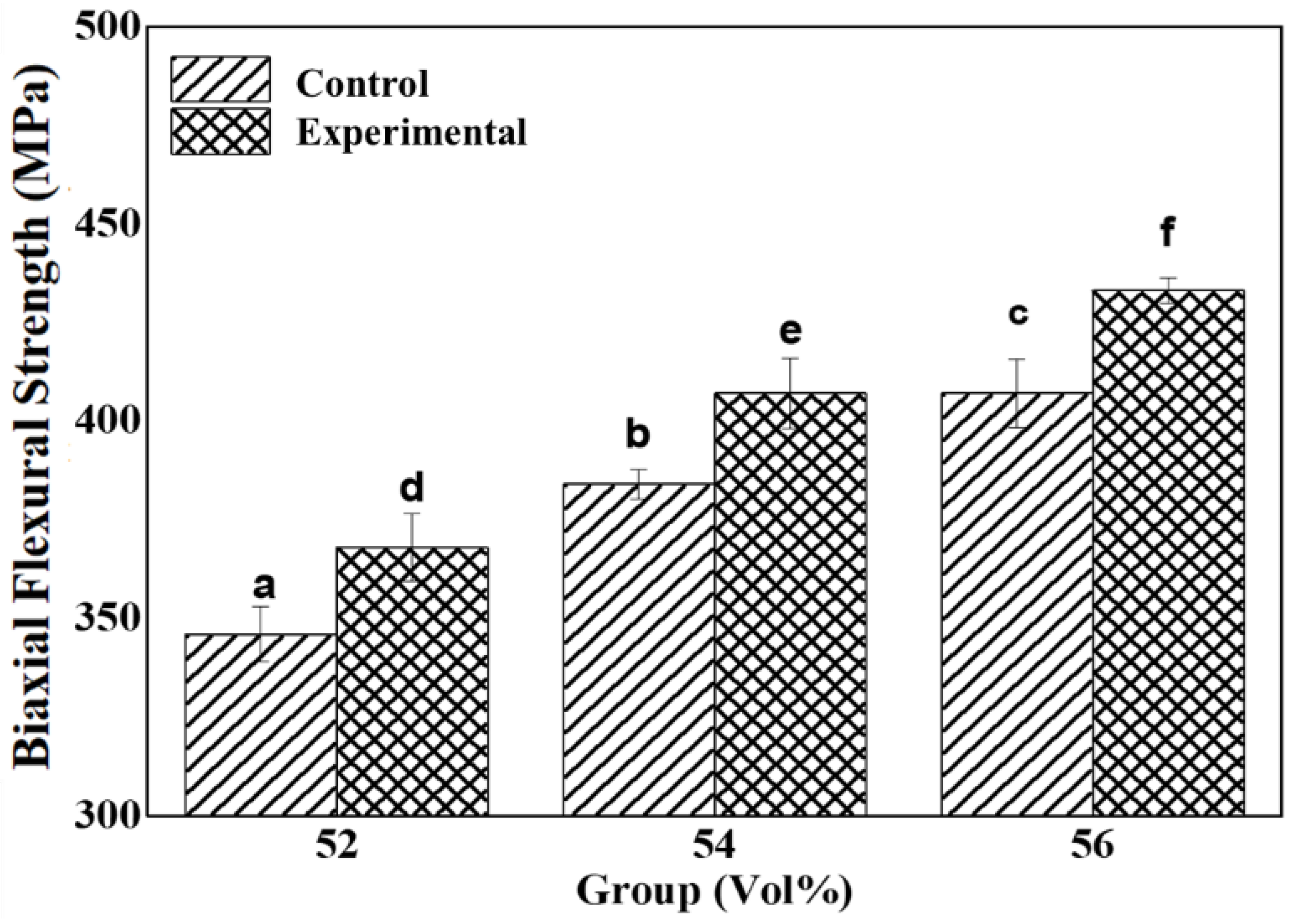

3.5. Biaxial Flexural Strength

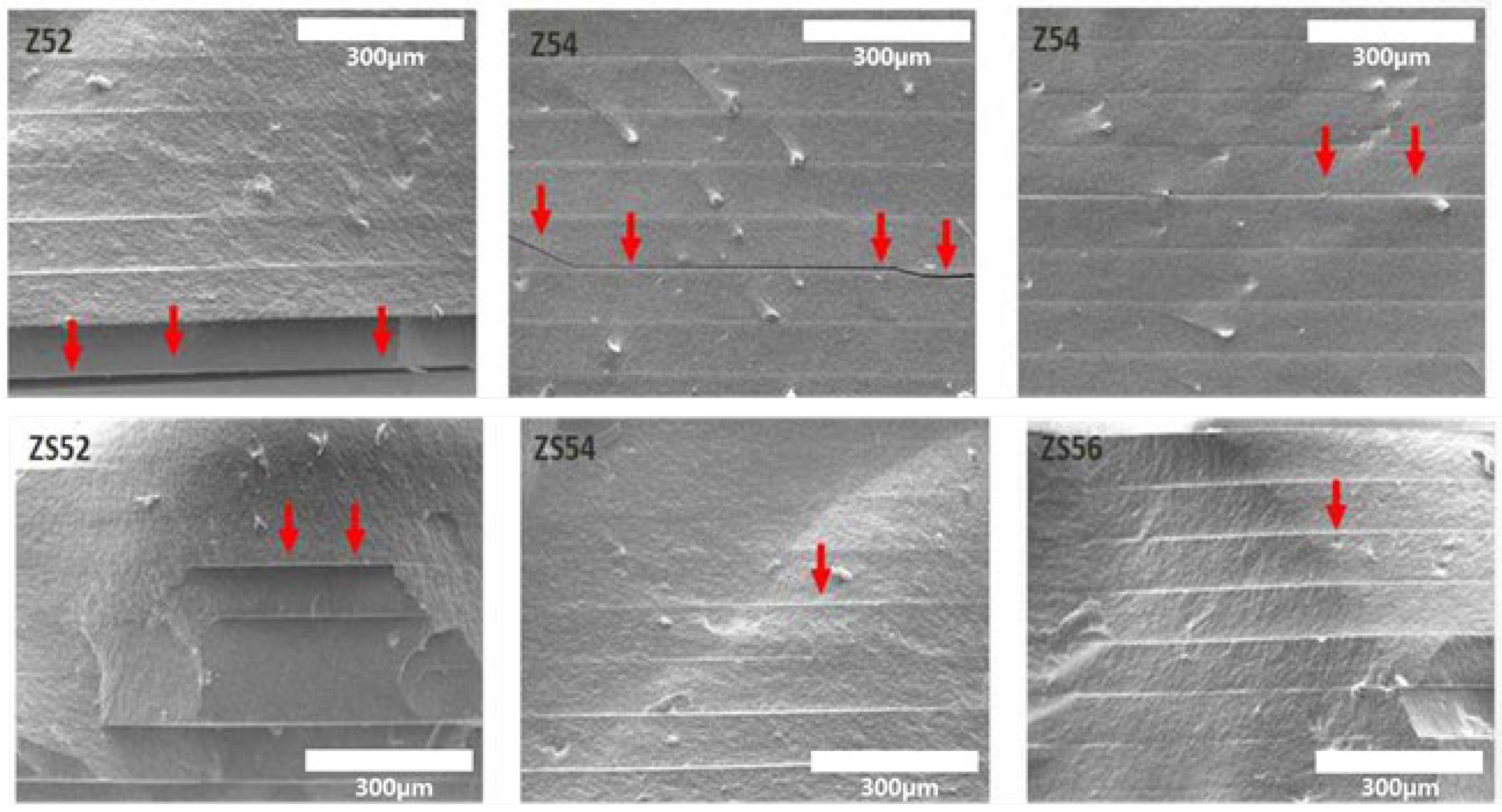

3.6. Microstructure Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mclean, J.W. The reinforcement of dental porcelain with ceramic oxides. Br. Dent. J. 1965, 119, 251–267. [Google Scholar] [PubMed]

- Shareef, M.; Van Noort, R.; Messer, P.; Piddock, V. The effect of microstructural features on the biaxial flexural strength of leucite reinforced glass-ceramics. J. Mater. Sci. Mater. Med. 1994, 5, 113–118. [Google Scholar] [CrossRef]

- Jones, D.W. Development of dental ceramics. An historical perspective. Dent. Clin. North Am. 1985, 29, 621–644. [Google Scholar] [PubMed]

- Ammarullah, M.I.; Afif, I.Y.; Maula, M.I.; Winarni, T.I.; Tauviqirrahman, M.; Akbar, I.; Basri, H.; van der Heide, E.; Jamari, J. Tresca Stress Simulation of Metal-on-Metal Total Hip Arthroplasty during Normal Walking Activity. Materials 2021, 14, 7554. [Google Scholar] [CrossRef] [PubMed]

- Ramaraj, S.; Kim, M.-A.; Rosa, V.; Prasanna, N.; Shon, W.-J.; Min, K.-S. Combined Effect of Melittin and DNase on Enterococcus faecalis Biofilms and Its Susceptibility to Sodium Hypochlorite. Materials 2020, 13, 3740. [Google Scholar] [CrossRef] [PubMed]

- Sakthiabirami, K.; Kang, J.H.; Jang, J.G.; Lim, H.P.; Yun, K.D.; Park, C.; Yim, E.K.; Park, S.W.; Ko, K.T.; Oh, G.J. Effect of Argon Plasma Treatment on Surface-Treated Titanium. Adv. Dent. Oral Health 2019, 11, 158–164. [Google Scholar]

- Kumaresan, S.; Vaiyapuri, S.; Kang, J.-H.; Dubey, N.; Manivasagam, G.; Yun, K.-D.; Park, S.-W. Additive Manufactured Zirconia-Based Bio-Ceramics for Biomedical Applications [Online First], IntechOpen. 19 January 2022. Available online: https://www.intechopen.com/online-first/80125 (accessed on 10 February 2022). [CrossRef]

- Sakthiabirami, K.; Kim, J.W.; Kang, J.H.; Jang, K.J.; Oh, G.J.; Fisher, J.G.; Yun, K.D.; Lim, H.P.; Park, S.W. Tailoring interfacial interaction through glass fusion in glass/zinc-hydroxyapatite composite coatings on glass-infiltrated zirconia. Ceram. Int. 2018, 44, 16181–16190. [Google Scholar] [CrossRef]

- Schriwer, C.; Skjold, A.; Gjerdet, N.R.; Øilo, M. Monolithic zirconia dental crowns. Internal fit, margin quality, fracture mode and load at fracture. Dent. Mater. 2017, 33, 1012–1020. [Google Scholar] [CrossRef]

- D’Addazio, G.; Santilli, M.; Rollo, M.L.; Cardelli, P.; Rexhepi, I.; Murmura, G.; Al-Haj Husain, N.; Sinjari, B.; Traini, T.; Özcan, M. Fracture resistance of zirconia-reinforced lithium silicate ceramic crowns cemented with conventional or adhe-sive systems: An in vitro study. Materials 2020, 13, 2012. [Google Scholar] [CrossRef]

- Denry, I.; Kelly, J.R. State of the art of zirconia for dental applications. Dent. Mater. 2008, 24, 299–307. [Google Scholar] [CrossRef]

- Preis, V.; Behr, M.; Hahnel, S.; Handel, G.; Rosentritt, M. In vitro failure and fracture resistance of veneered and full-contour zirconia restorations. J. Dent. 2012, 40, 921–928. [Google Scholar] [CrossRef] [PubMed]

- Preis, V.; Behr, M.; Handel, G.; Schneider-Feyrer, S.; Hahnel, S.; Rosentritt, M. Wear performance of dental ceramics after grinding and polishing treatments. J. Mech. Behav. Biomed. Mater. 2012, 10, 13–22. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Zhang, L.; Zhu, J.; Zhao, Y.; Zhang, X. Clinical marginal and internal fit of crowns fabricated using different CAD/CAM technologies. J. Prosthodont. 2015, 24, 291–295. [Google Scholar] [CrossRef] [PubMed]

- Dawood, A.; Marti, B.M.; Sauret-Jackson, V.; Darwood, A. 3D printing in dentistry. Br. Dent. J. 2015, 219, 521–529. [Google Scholar] [CrossRef]

- Park, J.-M.; Ahn, J.-S.; Cha, H.-S.; Lee, J.-H. Wear resistance of 3D printing resin material opposing zirconia and metal antagonists. Materials 2018, 11, 1043. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zeltser, C.; Lewinstein, I.; Grajower, R. Fit of crown wax patterns after removal from the die. J. Prosthet. Dent. 1985, 53, 344–346. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Swain, M. Fit of zirconia fixed partial denture: A systematic review. J. Oral Rehabil. 2010, 37, 866–876. [Google Scholar] [CrossRef]

- Harish, V.; Mohamed Ali, S.; Jagadesan, N.; Mohamed Ifthikar, S.S.; Debasish Basak, F.H. Evaluation of internal and marginal fit of two metal ceramic system—In vitro study. J. Clin. Diagn. Res. JCDR 2014, 8, ZC53. [Google Scholar]

- He, R.; Liu, W.; Wu, Z.; An, D.; Huang, M.; Wu, H.; Jiang, Q.; Ji, X.; Wu, S.; Xie, Z. Fabrication of complex-shaped zirconia ceramic parts via a DLP-stereolithography-based 3D printing method. Ceram. Int. 2018, 44, 3412–3416. [Google Scholar] [CrossRef]

- Kang, J.-H.; Jang, K.-J.; Sakthiabirami, K.; Oh, G.-J.; Jang, J.-G.; Park, C.; Lim, H.-P.; Yun, K.-D.; Park, S.-W. Mechanical properties and optical evaluation of scaffolds produced from 45S5 bioactive glass suspensions via stereolithography. Ceram. Int. 2020, 46, 2481–2488. [Google Scholar] [CrossRef]

- Sakthiabirami, K.; Soundharrajan, V.; Kang, J.-H.; Yang, Y.P.; Park, S.-W. Three-Dimensional Zirconia-Based Scaffolds for Load-Bearing Bone-Regeneration Applications: Prospects and Challenges. Materials 2021, 14, 3207. [Google Scholar] [CrossRef] [PubMed]

- Moreno, M.B.P.; Murillo-Gómez, F.; de Goes, M.F. Physicochemical and morphological characterization of a glass ceramic treated with different ceramic primers and post-silanization protocols. Dent. Mater. 2019, 35, 1073–1081. [Google Scholar] [CrossRef] [PubMed]

- Moreno, M.B.P.; Murillo-Gómez, F.; De Goes, M. Effect of different ceramic-primers and silanization-protocols on glass-ceramic bond strength. Dent. Mater. 2018, 34, e80–e81. [Google Scholar] [CrossRef]

- Villa, S.; Riani, P.; Locardi, F.; Canepa, F. Functionalization of Fe3O4 NPs by silanization: Use of amine (APTES) and thiol (MPTMS) silanes and their physical characterization. Materials 2016, 9, 826. [Google Scholar] [CrossRef] [Green Version]

- Jang, K.-J.; Kang, J.-H.; Fisher, J.G.; Park, S.-W. Effect of the volume fraction of zirconia suspensions on the microstructure and physical properties of products produced by additive manufacturing. Dent. Mater. 2019, 35, e97–e106. [Google Scholar] [CrossRef]

- Lopez de Armentia, S.; Pantoja, M.; Abenojar, J.; Martinez, M.A. Development of silane-based coatings with zirconia nanoparticles combining wetting, tribological, and aesthetical properties. Coatings 2018, 8, 368. [Google Scholar] [CrossRef] [Green Version]

- Barczewski, M.; Matykiewicz, D.; Szostak, M. The effect of two-step surface treatment by hydrogen peroxide and silani-zation of flax/cotton fabrics on epoxy-based laminates thermomechanical properties and structure. J. Mater. Res. Technol. 2020, 9, 13813–13824. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Antonowicz, M.; Paszenda, Z. Surface modification methods of ceramic filler in ceramic-carbon fibre composites for bioengineering applications—A systematic review. Rev. Adv. Mater. Sci. 2020, 59, 586–605. [Google Scholar] [CrossRef]

- Nakonieczny, D.S.; Kern, F.; Dufner, L.; Dubiel, A.; Antonowicz, M.; Matus, K. Effect of Calcination Temperature on the Phase Composition, Morphology, and Thermal Properties of ZrO2 and Al2O3 Modified with APTES (3-aminopropyltriethoxysilane). Materials 2021, 14, 6651. [Google Scholar] [CrossRef]

- Lin, H.; Rosu, C.; Jiang, L.; Sundar, V.A.; Breedveld, V.; Hess, D.W. Nonfluorinated superhydrophobic chemical coatings on polyester fabric prepared with kinetically controlled hydrolyzed methyltrimethoxysilane. Ind. Eng. Chem. Res. 2019, 58, 15368–15378. [Google Scholar] [CrossRef]

- Song, S.Y.; Park, M.S.; Lee, J.W.; Yun, J.S. A study on the rheological and mechanical properties of photo-curable ceramic/polymer composites with different silane coupling agents for SLA 3D printing technology. Nanomaterials 2018, 8, 93. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jang, K.-J.; Kang, J.-H.; Sakthiabirami, K.; Lim, H.-P.; Yun, K.-D.; Yim, E.-K.; Oh, G.-J.; Yang, H.-S.; Lee, K.-K.; Park, S.-W. Evaluation of cure depth and geometrical overgrowth depending on zirconia volume fraction using digital light processing. J. Nanosci. Nanotechnol. 2019, 19, 2154–2157. [Google Scholar] [CrossRef] [PubMed]

- Shang, H.; Mohanram, A.; Olevsky, E.; Bordia, R.K. Evolution of anisotropy in hierarchical porous ceramics during sinter-forging. J. Eur. Ceram. Soc. 2016, 36, 2937–2945. [Google Scholar] [CrossRef] [Green Version]

- Lame, O.; Bouvard, D.; Wiedemann, H. Anisotropic shrinkage and gravity induced creep during sintering of steel powder compacts. Powder Metall. 2002, 45, 181–185. [Google Scholar] [CrossRef]

- Sato, K.; Yilmaz, H.; Hotta, Y.; Ijuin, A.; Watari, K. Dispersion of Ceramic Particles in Aqueous Media with Surface-Grafted Dispersant. J. Am. Ceram. Soc. 2009, 92, 256–259. [Google Scholar] [CrossRef]

- Hu, C.; Chen, Y.; Yang, T.; Liu, H.; Huang, X.; Huo, Y.; Jia, Z.; Wang, H.; Hu, L.; Sun, H. Effect of SiC powder on the properties of SiC slurry for stereolithography. Ceram. Int. 2021, 47, 12442–12449. [Google Scholar] [CrossRef]

- Manière, C.; Kerbart, G.; Harnois, C.; Marinel, S. Modeling sintering anisotropy in ceramic stereolithography of silica. Acta Mater. 2020, 182, 163–171. [Google Scholar] [CrossRef]

| Group | Zirconia Powder | Acrylic Monomers | Additive Agents | Total wt (vol)% | ||||

|---|---|---|---|---|---|---|---|---|

| IBA | HDDA | PNPGDA | Dispersant | Silane Coupling Agent | ||||

| Control | Z52 | 86.45 (52.00) | 9.23 (33.43) | 4.32(14.57) | 0 | 100 | ||

| Z54 | 87.34 (54.00) | 8.29 (30.87) | 4.37(15.13) | 0 | 100 | |||

| Z56 | 88.19 (56.00) | 7.41 (28.32) | 4.41(15.68) | 0 | 100 | |||

| Experimental | ZS52 | 86.45 (52.00) | 8.64 (30.30) | 3.27(11.65) | 1.64 (6.05) | 100 | ||

| ZS54 | 87.34 (54.00) | 7.68 (27.62) | 3.32(12.10) | 1.66 (6.28) | 100 | |||

| ZS56 | 88.19 (56.00) | 6.74 (24.94) | 3.38(12.54) | 1.69 (6.52) | 100 | |||

| Groups | Linear Shrinkage (%) | |

|---|---|---|

| Control | Experimental | |

| Z52 | 19.20 ± 0.31 | 19.14 ± 0.17 |

| Z54 | 19.31 ± 0.23 | 19.23 ± 0.20 |

| Z56 | 19.15 ± 0.29 | 19.21 ± 0.09 |

| Groups | Relative Density (%) | |

|---|---|---|

| Control | Experimental | |

| Z52 | 94.89 ± 0.35 a | 19.14 ± 0.09 a |

| Z54 | 95.65 ± 0.67 b | 19.06 ± 0.10 b |

| Z56 | 96.15 ± 0.59 c | 19.05 ± 0.03 d |

| Groups | Vickers hardness (HV) | |

|---|---|---|

| Control | Experimental | |

| Z52 | 1573 ± 21.31 a | 1666 ± 14.61 d |

| Z54 | 1648 ± 48.17 b | 1748 ± 20.33 e |

| Z56 | 1777 ± 22.19 c | 1848 ± 24.04 f |

| Group | Flexural Strength (MPa) | |

|---|---|---|

| Control | Experimental | |

| Z52 | 346 ± 6.96 a | 368 ± 8.62 d |

| Z54 | 384 ± 3.68 b | 407 ± 8.87 e |

| Z56 | 407 ± 8.73 c | 433 ± 3.27 f |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, J.-G.; Kang, J.-H.; Joe, K.-B.; Sakthiabirami, K.; Jang, K.-J.; Jun, M.-J.; Oh, G.-J.; Park, C.; Park, S.-W. Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes. Materials 2022, 15, 1337. https://doi.org/10.3390/ma15041337

Jang J-G, Kang J-H, Joe K-B, Sakthiabirami K, Jang K-J, Jun M-J, Oh G-J, Park C, Park S-W. Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes. Materials. 2022; 15(4):1337. https://doi.org/10.3390/ma15041337

Chicago/Turabian StyleJang, Jae-Gon, Jin-Ho Kang, Kwang-Bum Joe, Kumaresan Sakthiabirami, Kyoung-Jun Jang, Mee-Jin Jun, Gye-Jeong Oh, Chan Park, and Sang-Won Park. 2022. "Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes" Materials 15, no. 4: 1337. https://doi.org/10.3390/ma15041337

APA StyleJang, J.-G., Kang, J.-H., Joe, K.-B., Sakthiabirami, K., Jang, K.-J., Jun, M.-J., Oh, G.-J., Park, C., & Park, S.-W. (2022). Evaluation of Physical Properties of Zirconia Suspension with Added Silane Coupling Agent for Additive Manufacturing Processes. Materials, 15(4), 1337. https://doi.org/10.3390/ma15041337