Banana Leaf Surface’s Janus Wettability Transition from the Wenzel State to Cassie–Baxter State and the Underlying Mechanism

Abstract

:1. Introduction

2. Materials and Methods

2.1. Starting Materials

2.2. Surface Characterization of Banana Leaves

2.3. Dynamic Impact Test

3. Results and Discussion

3.1. Surface Characteristics of Banana Leaves

3.2. Dynamic Wetting Behaviors on Banana Leaf Surface

3.3. Mechanism Analyses on Janus Wettability

4. Conclusions

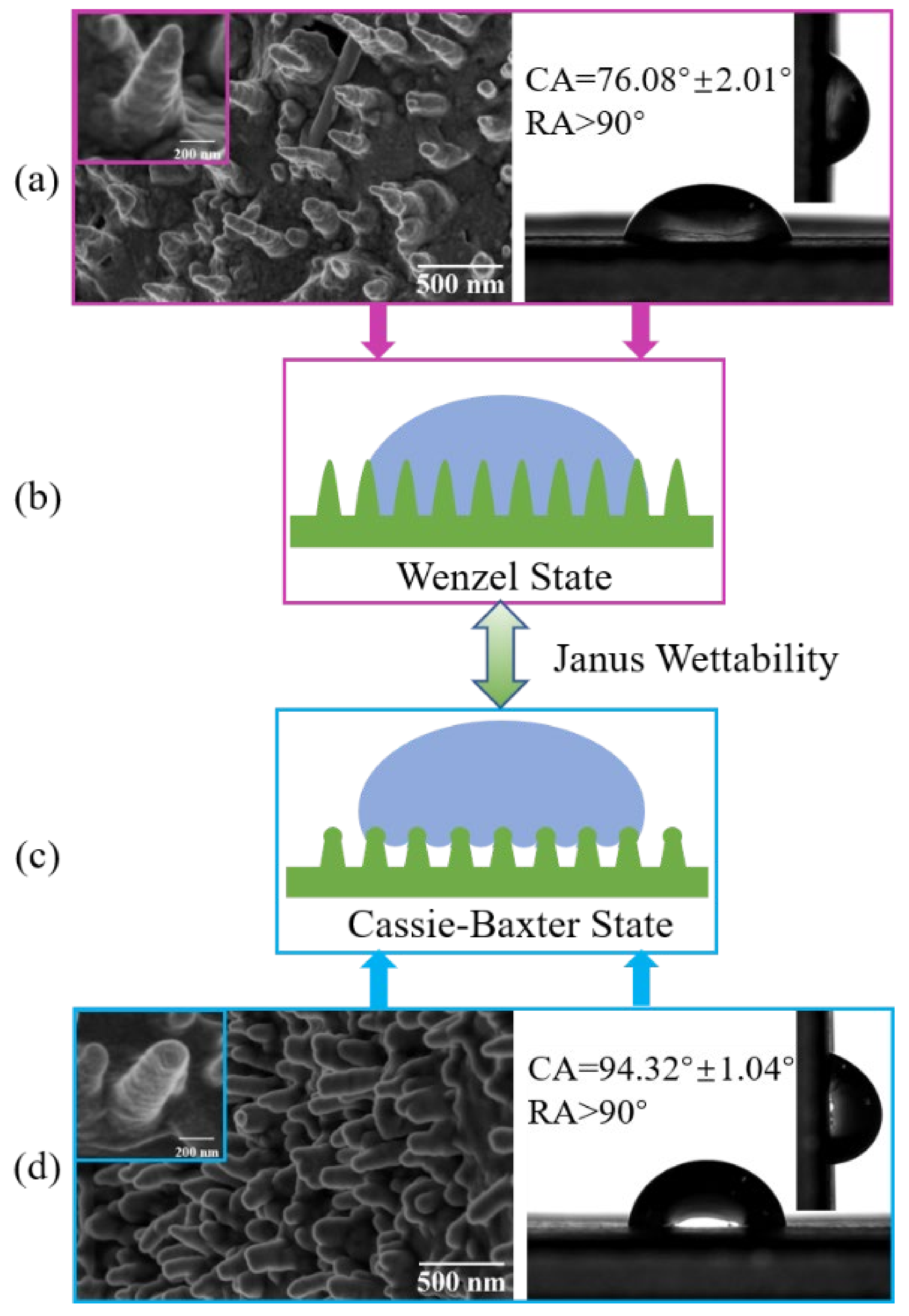

- Scanning electron microscopy studies on the banana leaf surface found that the nanopillars on the adaxial side were cone-shaped with large gaps, and the heads of the nanopillars on the abaxial side were smooth and spherical with small gaps. The contact angle test found that the banana leaf surface has high adhesion properties (RA > 90°), and the banana leaf exhibits a Janus wetting state where the adaxial side was hydrophilic (CA = 76.08° ± 2.01°) and the abaxial side was weakly hydrophobic (CA = 94.32° ± 1.04°). This is caused by the different morphology and distribution of the nanopillars on the adaxial and abaxial sides of the banana leaf.

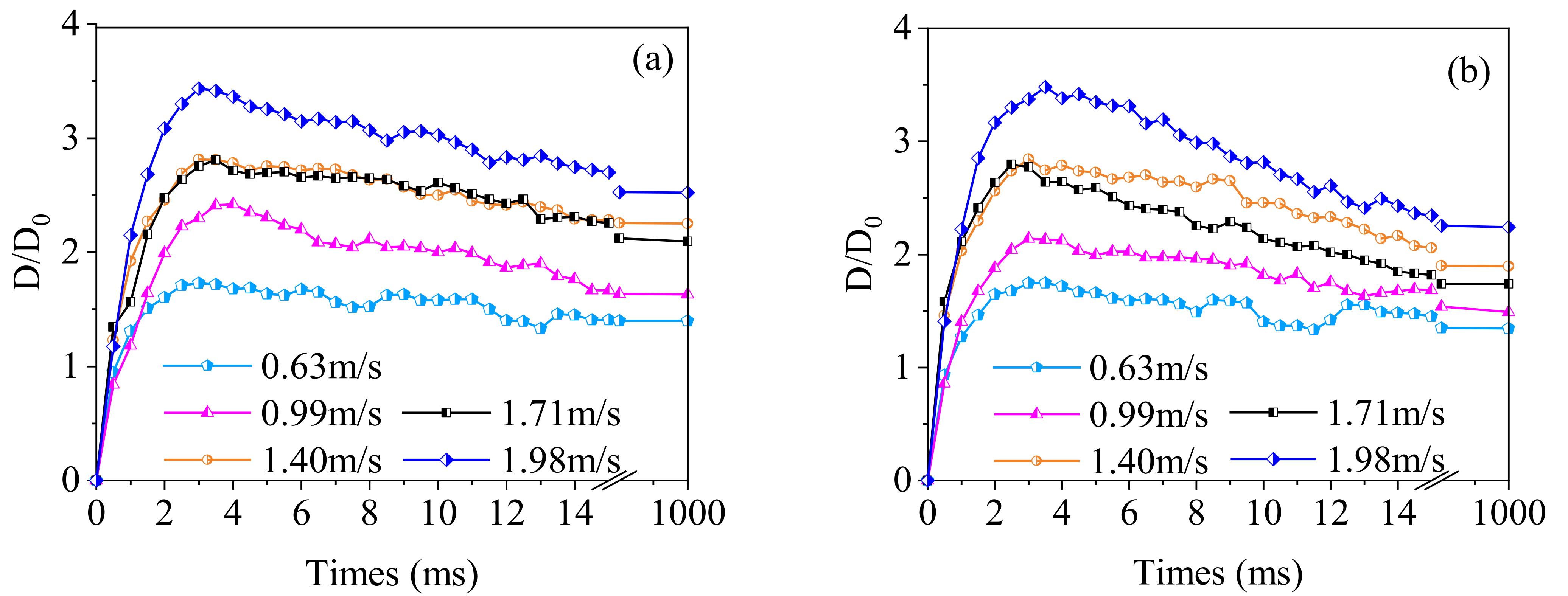

- A dynamic impact test was carried out to study the wettability of the banana leaf surface. The study found that when water droplets hit the adaxial and abaxial sides of the banana leaves, they showed different dynamic responses, and the wettability of the adaxial side was always stronger than the abaxial side. The change trend of the spreading factor under different impact velocities was the same, and with the increase in the impact velocity, when the impact velocity reached 1.4 m·s−1, the maximum spreading factor and the final steady-state spreading factor showed a small peak, achieving the best effect.

- According to the information of the parameters and structure of the nanopillars on the banana leaf surface, an idealized geometric model of both the adaxial and abaxial sides of the banana leaf was established, and the classical wetting theory model was introduced to reveal the Janus wettability transition from the Wenzel state to Cassie–Baxter states of the banana leaf surface and the underlying mechanism.The study of Janus wettability on banana leaf surface can provide an important reference for the design and manufacture of bionic nanostructured surfaces with Janus wettability and the exploration of efficient and high-quality production management of banana orchards. In the future, on the basis of current research, we will use banana leaves as a biological template to prepare a series of surface materials with Janus wettability and conduct practical production and application research in the fields of droplet condensation and fog harvest.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Guo, Z.; Liu, W. Biomimic from the Superhydrophobic Plant Leaves in Nature: Binary Structure and Unitary Structure. Plant Sci. 2007, 172, 1103–1112. [Google Scholar] [CrossRef]

- Jiang, L.; Feng, L. Bioinspired Intelligent Nanostructured Interface Materials; Chemical Industry Press: Beijing, China, 2016; p. 338. [Google Scholar]

- Rykaczewski, K.; Jordan, J.S.; Linder, R.; Woods, E.T.; Sun, X.; Kemme, N.; Manning, K.C.; Cherry, B.R.; Yarger, J.L.; Majure, L.C. Microscale Mechanism of Age Dependent Wetting Properties of Prickly Pear Cacti (Opuntia). Langmuir 2016, 32, 9335–9341. [Google Scholar] [CrossRef]

- Nishimoto, S.; Bhushan, B. Bioinspired Self-Cleaning Surfaces with Superhydrophobicity, Superoleophobicity, and Superhydrophilicity. RSC Adv. 2013, 3, 671–690. [Google Scholar] [CrossRef]

- Xie, H.; Huang, H. Gradient Wetting Transition From the Wenzel to Robust Cassie-Baxter States Along Nanopillared Cicada Wing and Underlying Mechanism. J. Bionic Eng. 2020, 17, 1009–1018. [Google Scholar] [CrossRef]

- Xie, H.; Huang, H.; Mi, H. Gradient Wetting State for Droplet Transportation and Efficient Fog Harvest on Nanopillared Cicada Wing Surface. Mater. Lett. 2018, 221, 123–127. [Google Scholar] [CrossRef]

- Kim, K.W. Morphology and Surface Characteristics of the Anamorphic Stage of Powdery Mildew Erysiphe Australiana on Crape Myrtle Leaves. Micron 2021, 143, 103013. [Google Scholar] [CrossRef]

- Park, J.; Kim, H.; Huh, Y.H.; Kim, K.W. Ultrastructure of Phytoplasma-Infected Jujube Leaves with Witches’ Broom Disease. Micron 2021, 148, 103108. [Google Scholar] [CrossRef]

- Yudha, S.S.; Falahudin, A.; Triawan, D.A.; Adfa, M. A SEM Study of Unexplored Wax Microtubes Produced by Caterpillar Living on Common Banana Leaves. Micron 2019, 125, 102729. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, H.; Zhou, H.; Lin, T. Directional Fluid Transport in Thin Porous Materials and its Functional Applications. Small 2016, 13, 1601070. [Google Scholar] [CrossRef]

- He, X.; Fan, C.; Xu, T.; Zhang, X. Biospired Janus Silk E-Textiles with Wet–Thermal Comfort for Highly Efficient Biofluid Monitoring. Nano Lett. 2021, 21, 8880–8887. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, X.; Chen, Q.; Pan, Y.; Liu, C.; Shen, C. A Simple Superhydrophobic/Superhydrophilic Janus-paper with Enhanced Biocompatibility by PDMS and Candle Soot Coating for Actuator. Chem. Eng. J. 2021, 406, 126532. [Google Scholar] [CrossRef]

- Wu, J.; Wang, N.; Wang, L.; Dong, H.; Zhao, Y.; Jiang, L. Unidirectional Water-Penetration Composite Fibrous Film Via Electrospinning. Soft Matter 2012, 8, 5996–5999. [Google Scholar] [CrossRef]

- Cao, M.; Xiao, J.; Yu, C.; Li, K.; Jiang, L. Hydrophobic/Hydrophilic Cooperative Janus System for Enhancement of Fog Collection. Small 2015, 11, 4379–4384. [Google Scholar] [CrossRef] [PubMed]

- Zeng, C.; Wang, H.; Zhou, H.; Lin, T. Directional Water Transport Fabrics with Durable Ultra-High One-Way Transport Capacity. Adv. Mater. Interfaces 2016, 3, 1600036. [Google Scholar] [CrossRef]

- Lau, K.H.A.; Sileika, T.S.; Park, S.H.; Sousa, A.M.L.; Burch, P.; Szleifer, I.; Messersmith, P.B. Molecular Design of Antifouling Polymer Brushes Using Sequence-Specific Peptoids. Adv. Mater. Interfaces 2015, 2, 1400225. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hassan, H.A.; Ghazali, M.J.; Azhari, C.H.; Meric, C. Microstructural Effects of Banana Leaf on Adhesion and Self-Cleaning Behaviour. MATEC Web Conf. 2017, 87, 02026. [Google Scholar] [CrossRef] [Green Version]

- Ghosh, A.; Beaini, S.; Zhang, B.J.; Ganguly, R.; Megaridis, C.M. Enhancing Dropwise Condensation through Bioinspired Wettability Patterning. Langmuir 2014, 30, 13103–13115. [Google Scholar] [CrossRef] [PubMed]

- Nie, P.; Wang, R.; Xu, X.; Cheng, Y.; Wang, X.; Shi, L.; Sun, J. High-Performance Piezoresistive Electronic Skin with Bionic Hierarchical Microstructure and Microcracks. ACS Appl. Mater. Inter. 2017, 9, 14911–14919. [Google Scholar] [CrossRef]

- Jiang, Y.; Duan, J.; Jiang, T.; Yang, Z. Microscale Mechanism of Microstructure, Micromorphology and Janus Wettability of the Banana Leaf Surface. Micron 2021, 146, 103073. [Google Scholar] [CrossRef]

- Sun, J.; Wang, W.; Liu, Z.; Li, B.; Xing, K.; Yang, Z. Study On Selective Laser Melting 316L Stainless Steel Parts with Superhydrophobic Surface. Appl. Surf. Sci. 2020, 533, 147445. [Google Scholar] [CrossRef]

- Wenzel, R.N. Resistance of Solid Surface to Wetting by Water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of Porous Surfaces. Trans. Faraday Soc. 1994, 40, 546–554. [Google Scholar] [CrossRef]

| Parameters | Adaxial Side | Abaxial Side |

|---|---|---|

| R (nm) | 66.75 ± 0.82 | 70.22 ± 1.80 |

| H (nm) | 364.19 ± 00.69 | 260.89 ± 1.00 |

| S (nm) | 201.83 ± 4.06 | 173.97 ± 0.58 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Y.; Yang, Z.; Jiang, T.; Shen, D.; Duan, J. Banana Leaf Surface’s Janus Wettability Transition from the Wenzel State to Cassie–Baxter State and the Underlying Mechanism. Materials 2022, 15, 917. https://doi.org/10.3390/ma15030917

Jiang Y, Yang Z, Jiang T, Shen D, Duan J. Banana Leaf Surface’s Janus Wettability Transition from the Wenzel State to Cassie–Baxter State and the Underlying Mechanism. Materials. 2022; 15(3):917. https://doi.org/10.3390/ma15030917

Chicago/Turabian StyleJiang, Yinlong, Zhou Yang, Tingting Jiang, Dongying Shen, and Jieli Duan. 2022. "Banana Leaf Surface’s Janus Wettability Transition from the Wenzel State to Cassie–Baxter State and the Underlying Mechanism" Materials 15, no. 3: 917. https://doi.org/10.3390/ma15030917

APA StyleJiang, Y., Yang, Z., Jiang, T., Shen, D., & Duan, J. (2022). Banana Leaf Surface’s Janus Wettability Transition from the Wenzel State to Cassie–Baxter State and the Underlying Mechanism. Materials, 15(3), 917. https://doi.org/10.3390/ma15030917